Phase proportion control method for surfacing welding of two-phase corrosion resistant layer on surface of carbon steel

A surface surfacing and corrosion-resistant layer technology, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems that the dynamics of tissue transformation deviates from the equilibrium state and is difficult to obtain, so as to improve the efficiency of surfacing welding, good forming, and The effect of low welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

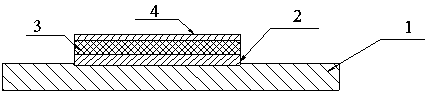

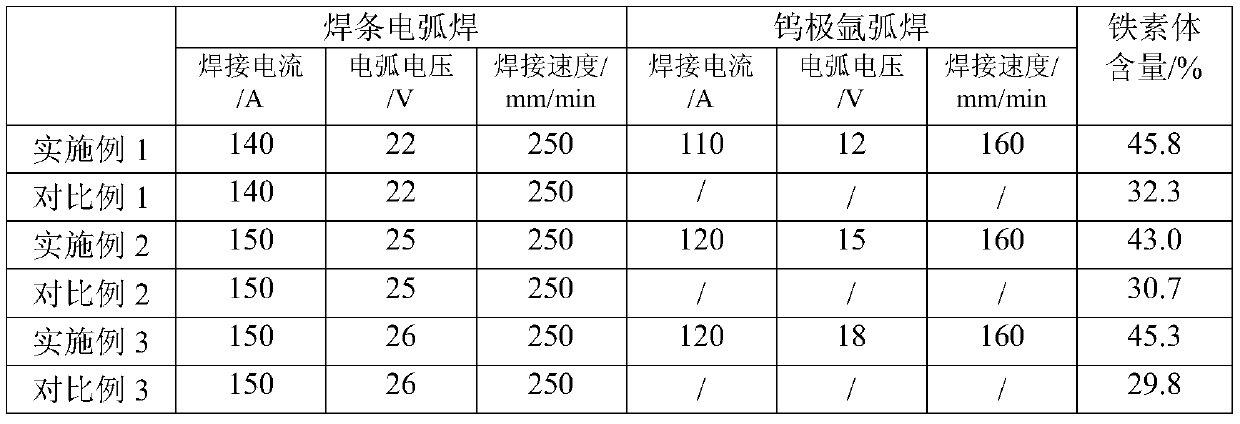

[0034]Before surfacing operation, degrease and derust the base metal, and preheat the base metal to 100°C; then surfacing the transition isolation layer, filling layer and cover layer on the base metal in sequence. Electrode arc welding with a diameter of 4.0mm and a model of E309LMo is used to form a transition isolation layer; a diameter of 4.0mm and a model of E2594 is used for arc welding to form a filling layer; before welding, the electrode is heat-preserved and dried at 200°C 2 hours. For SMAW (stick arc welding), the welding current is 140A, the arc voltage is 22V, and the welding speed is 250mm / min. Finally, argon tungsten arc welding with a diameter of 2.4mm and a model of ER2594 is used to form a cover layer; GTAW (argon tungsten arc welding) selects a welding current of 110A, an arc voltage of 12V, and a welding speed of 160mm / min.

[0035] During the surfacing welding process, the interlayer temperature is controlled to 120°C after one surfacing welding is comple...

Embodiment 2

[0037] Before surfacing operation, degrease and derust the base metal, and preheat the base metal to 100°C; then surfacing the transition isolation layer, filling layer and cover layer on the base metal in sequence. Electrode arc welding with a diameter of 4.0mm and a model of E309LMo is used to form a transition isolation layer; a diameter of 4.0mm and a model of E2594 is used for arc welding to form a filling layer; before welding, the electrode is heat-preserved and dried at 200°C 2 hours. For SMAW (stick arc welding), the welding current is 150A, the arc voltage is 25V, and the surfacing welding speed is 250mm / min. Finally, argon tungsten arc welding with a diameter of 2.4mm and a model of ER2594 is used to form a cover layer; GTAW (argon tungsten arc welding) selects a welding current of 120A, an arc voltage of 15V, and a welding speed of 160mm / min.

[0038] During the surfacing welding process, the interlayer temperature is controlled to 120°C after one surfacing weldin...

Embodiment 3

[0040] Before surfacing operation, degrease and derust the base metal, and preheat the base metal to 100°C; then surfacing the transition isolation layer, filling layer and cover layer on the base metal in sequence. Electrode arc welding with a diameter of 4.0mm and a model of E309LMo is used to form a transitional isolation layer; a diameter of 4.0mm and a model of E2594 is used for arc welding to form a filling layer; before welding, the electrode is heat-preserved and dried at 200°C 2 hours. For SMAW (stick arc welding), the selected welding current is 150A, the arc voltage is 26V, and the surfacing welding speed is 250mm / min. Finally, argon tungsten arc welding with a diameter of 2.4mm and a model of ER2594 is used to form a cover layer; GTAW (argon tungsten arc welding) selects a welding current of 120A, an arc voltage of 16V, and a welding speed of 160mm / min.

[0041] During the surfacing welding process, the interlayer temperature is controlled to 120°C after one surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com