Patents

Literature

331results about "Metal recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

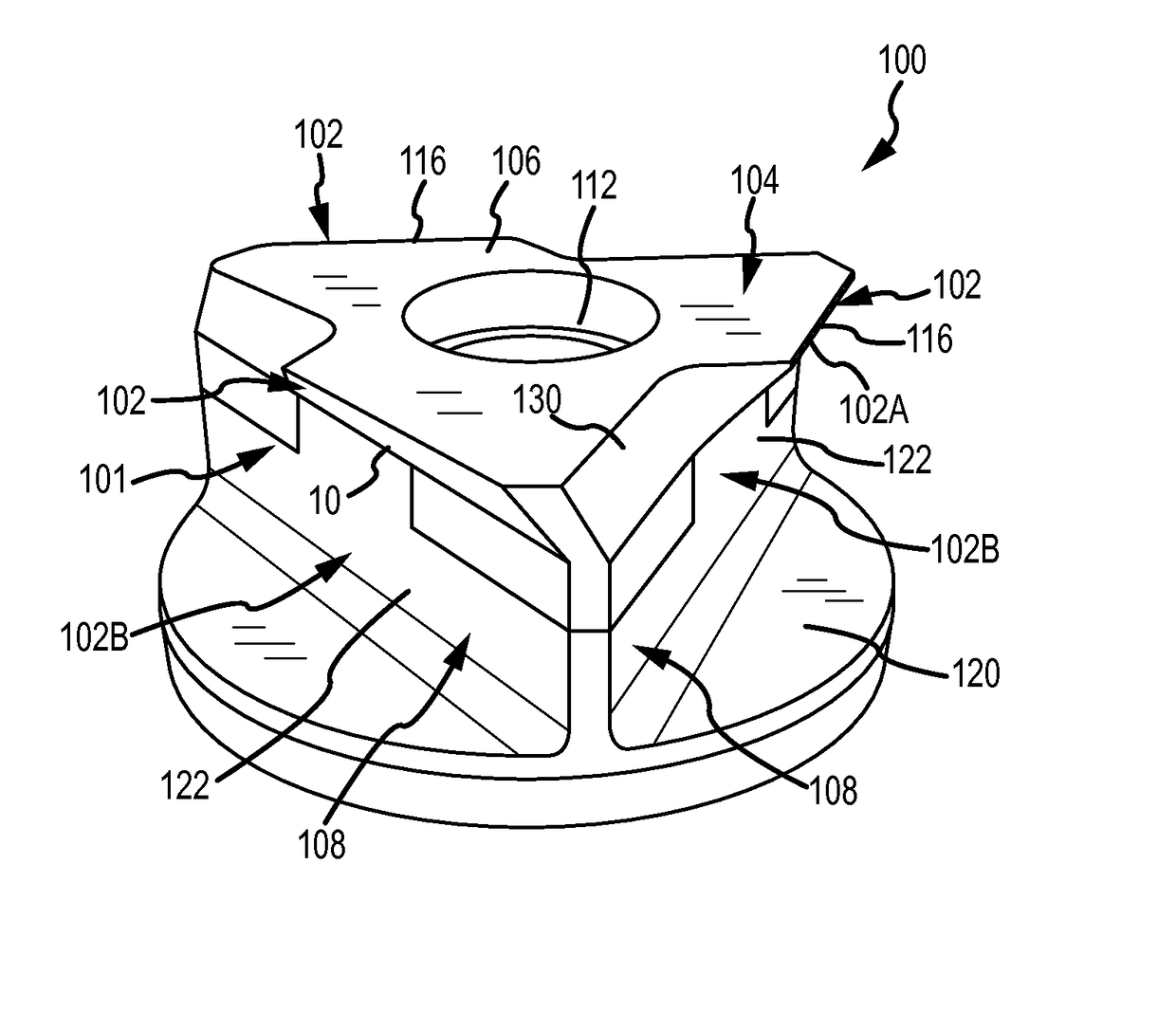

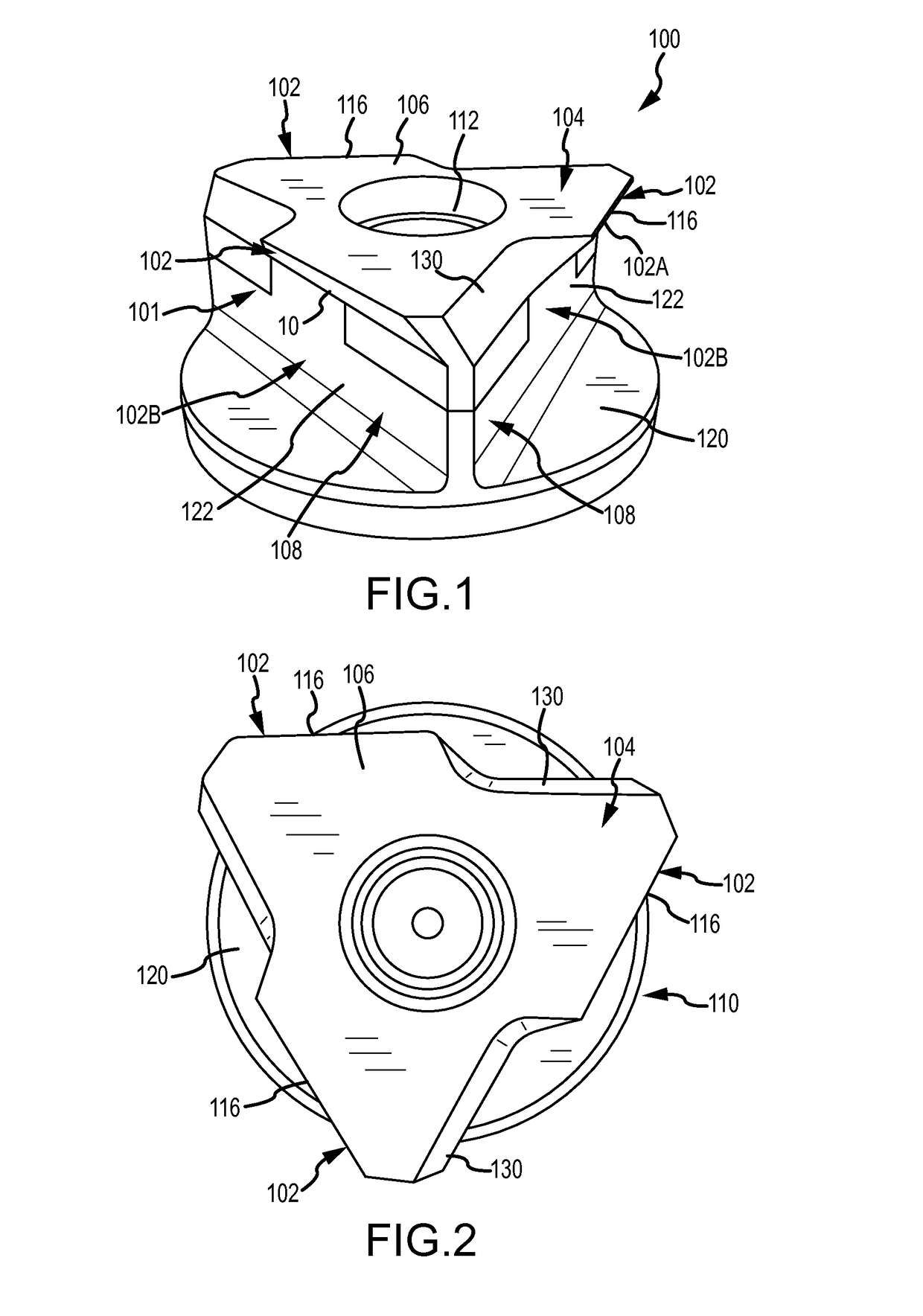

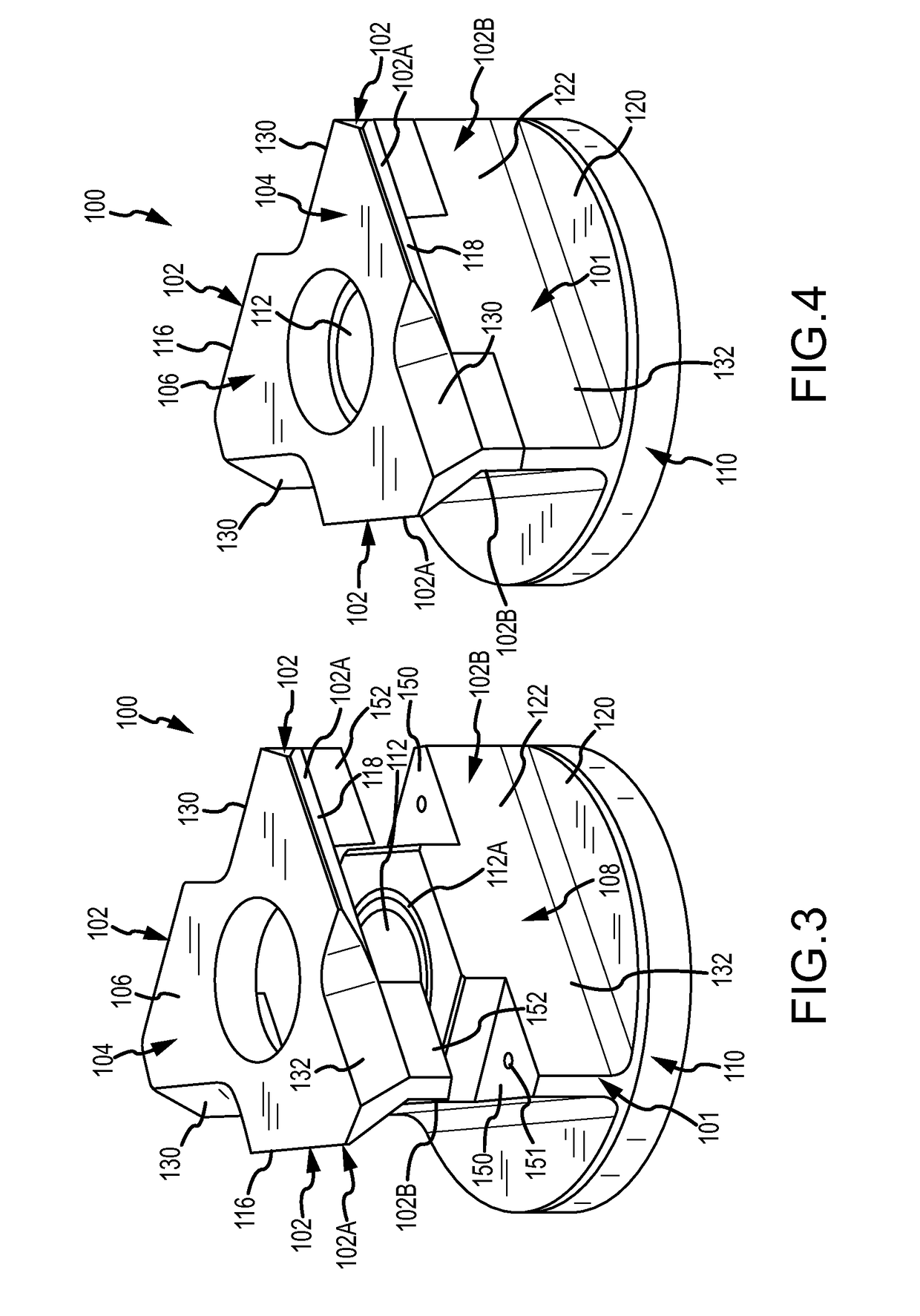

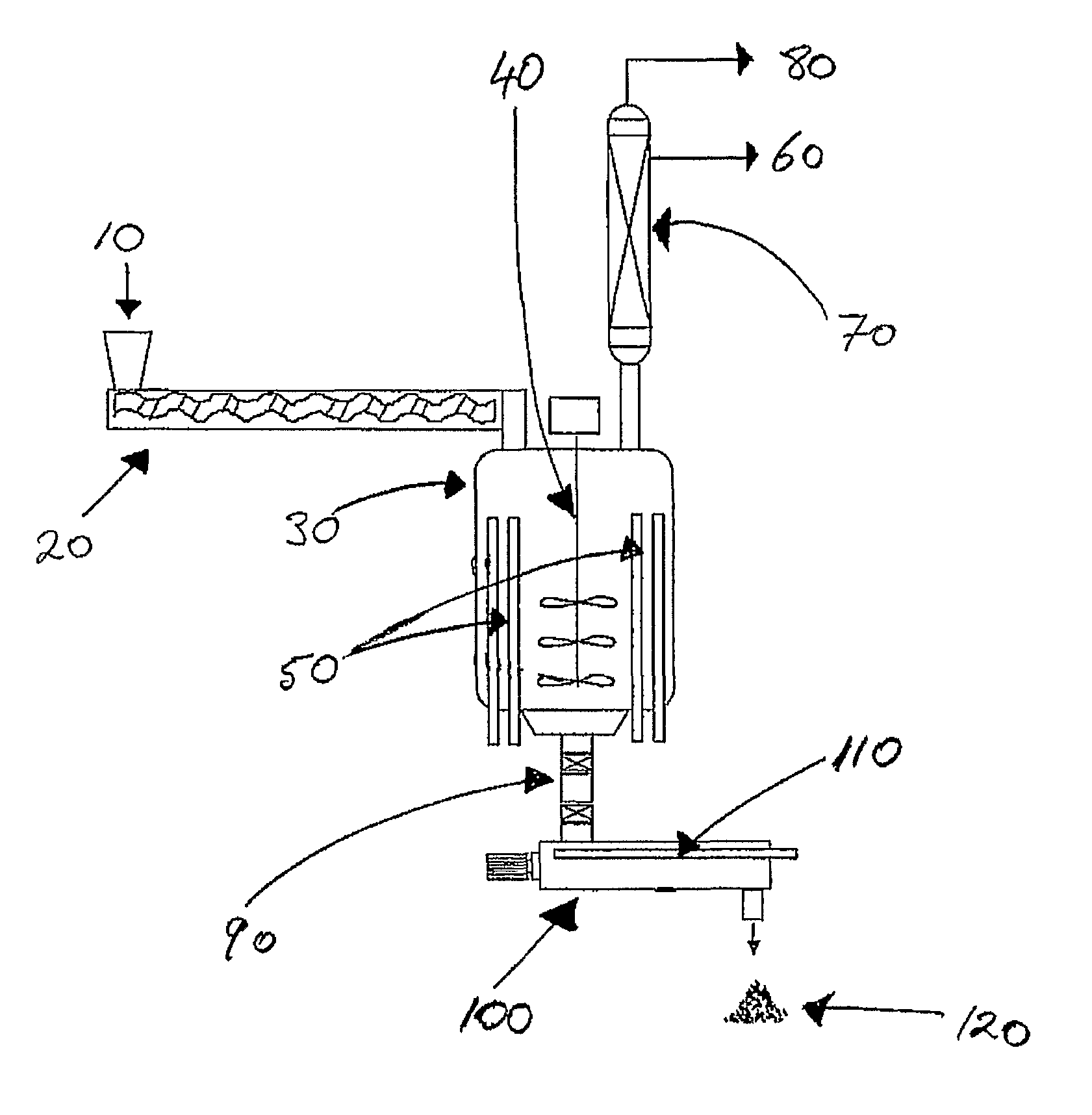

Molten metal rotor with hardened top

Embodiments of the invention are directed to a rotor for a molten metal pump and a molten metal pump including the rotor. The rotor has a main body and a top comprised of a material that is at least twice as hard as the main body. The top, among other things, may form a first portion of each rotor blade wherein the first portion directs molten metal into a pump chamber or other structure in which the rotor is mounted.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

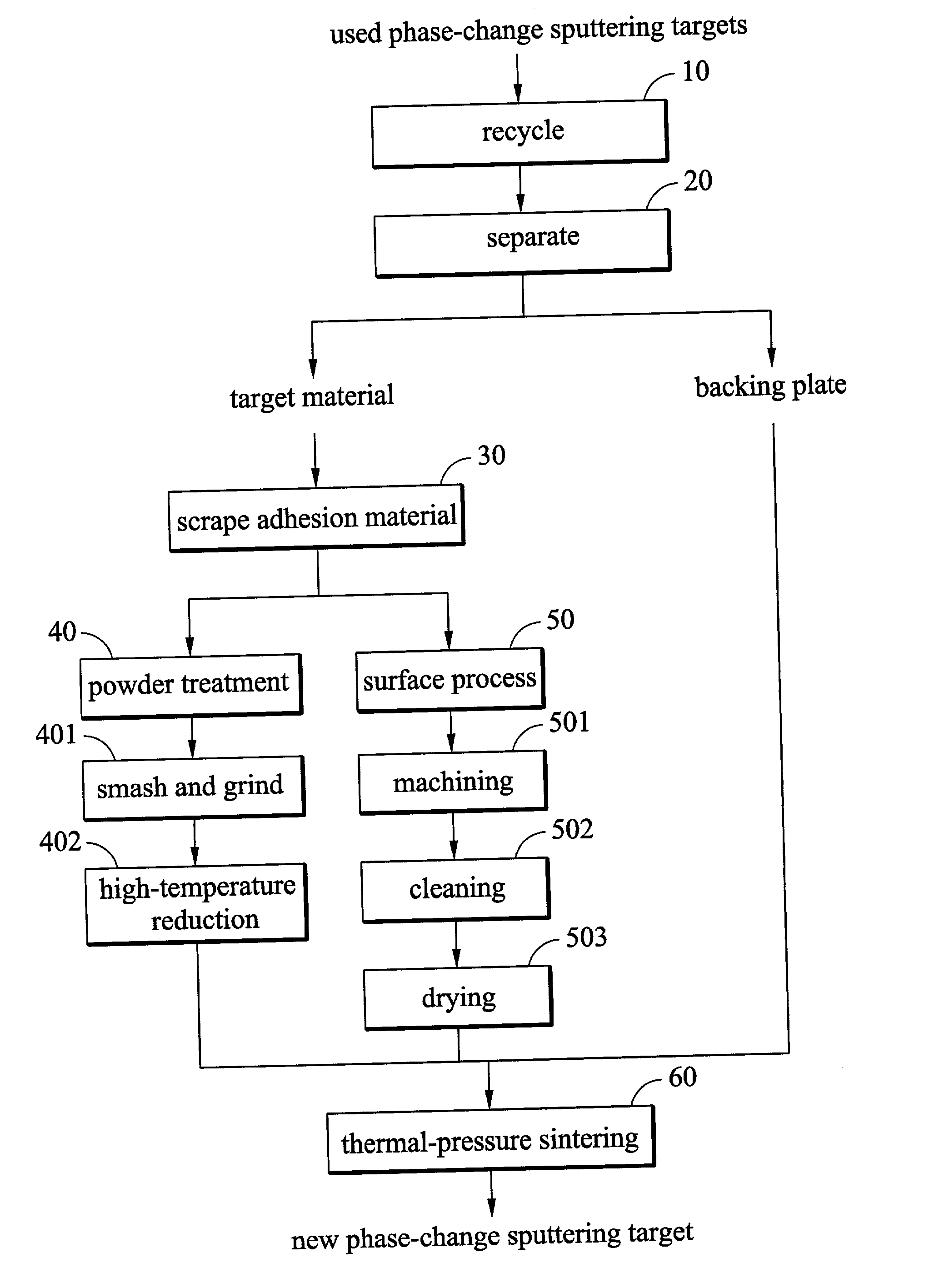

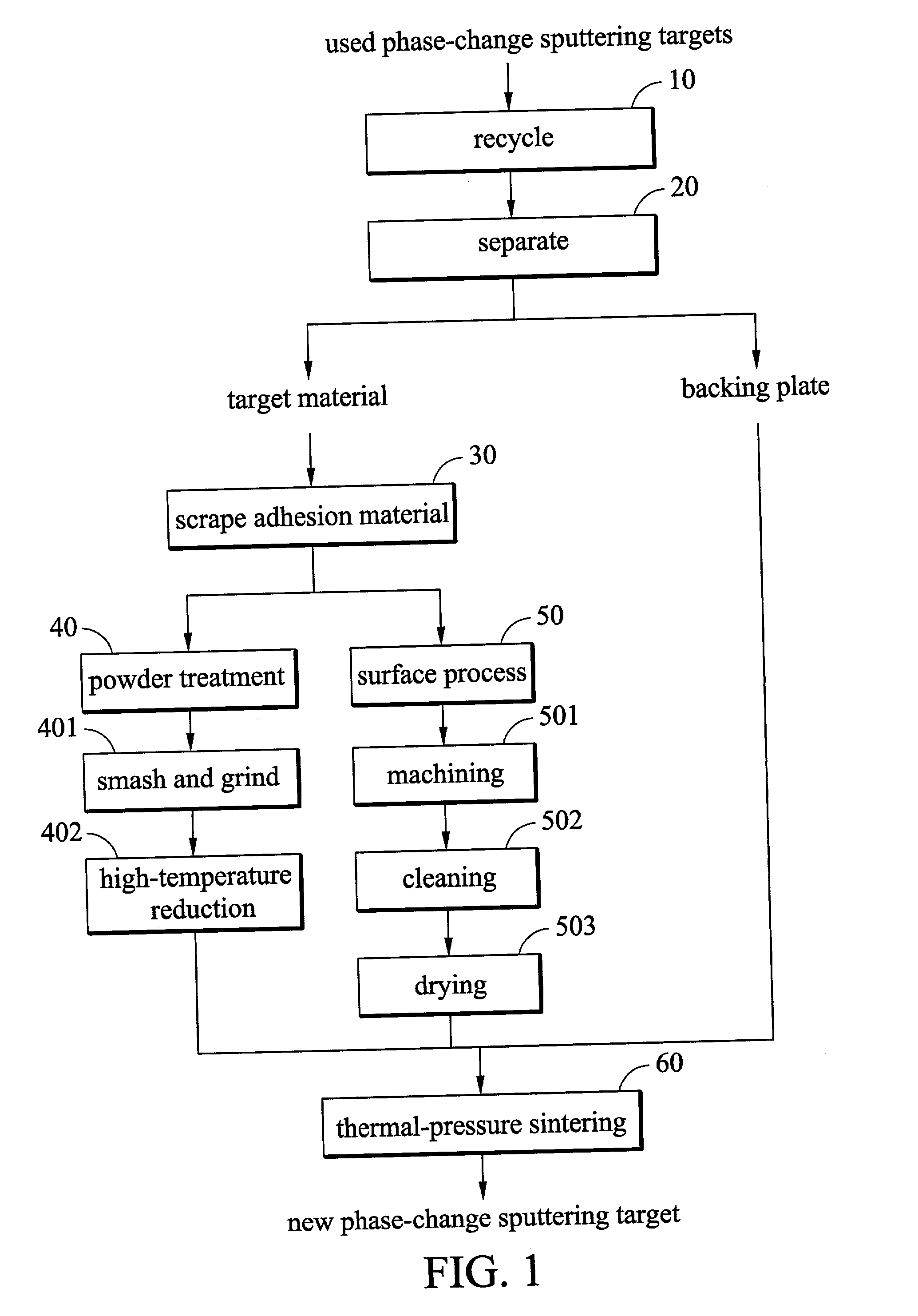

Method of regenerating a phase-change sputtering target for optical storage media

InactiveUS20020130041A1Increase profitReduce material costsMetal recyclingCellsSputteringOptical storage

A method of regenerating a phase-change sputtering target for optical storage media. First, a used powder-metallurgy sputtering target composed of a target material, an adhesion material, and a backing plate is recycled. Then, the target material is separated from the backing plate. Then, the target adhesion material is scraped from the recycled target material Thereafter, the surface of the recycled target material is processed. Finally, the backing plate, a new adhesion material, the recycled target material, and new powders are placed in a vacuum thermal-pressure furnace in sequence to perform a thermal-pressure sintering process. This completes a new phase-change sputtering target

Owner:IND TECH RES INST

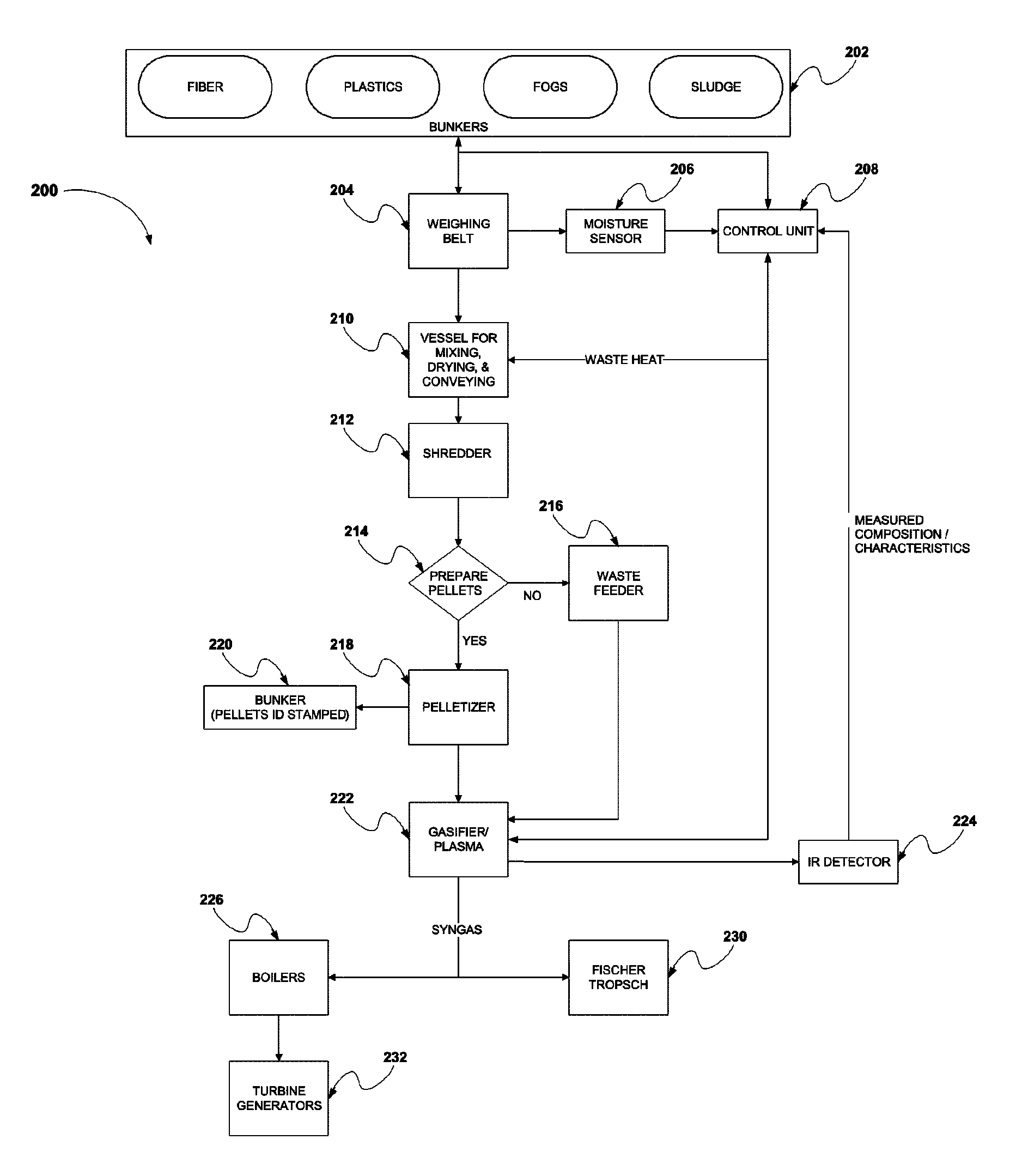

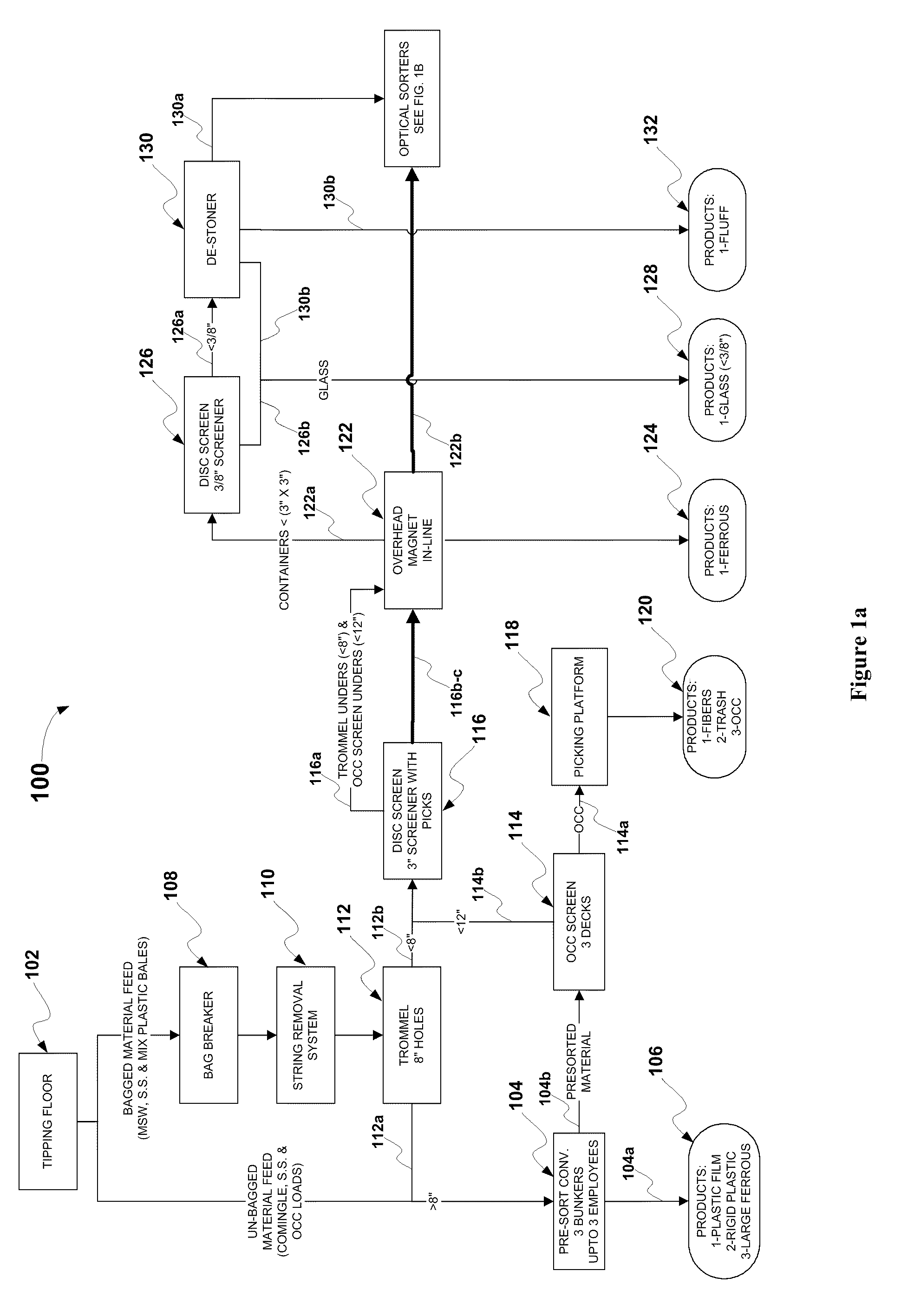

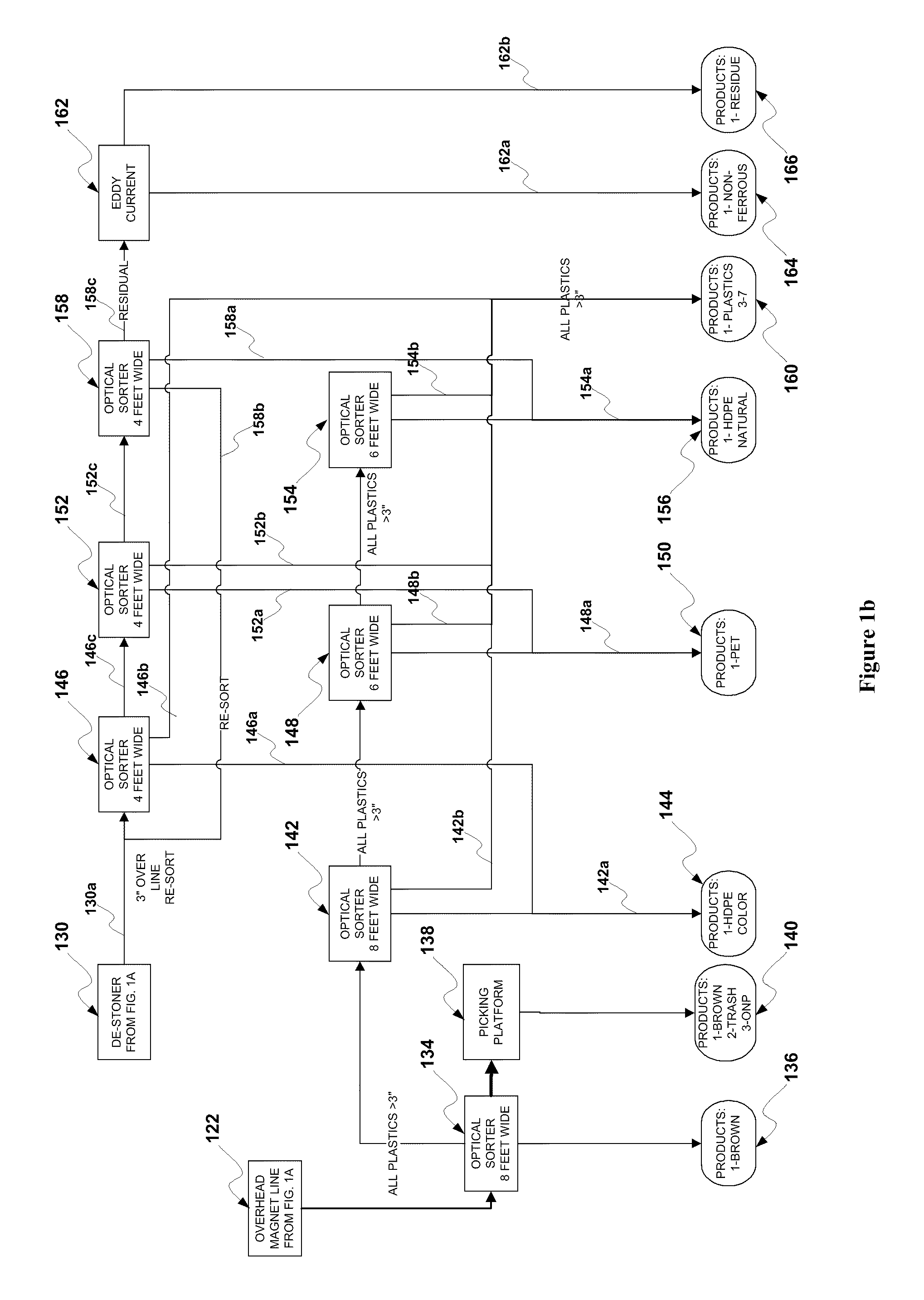

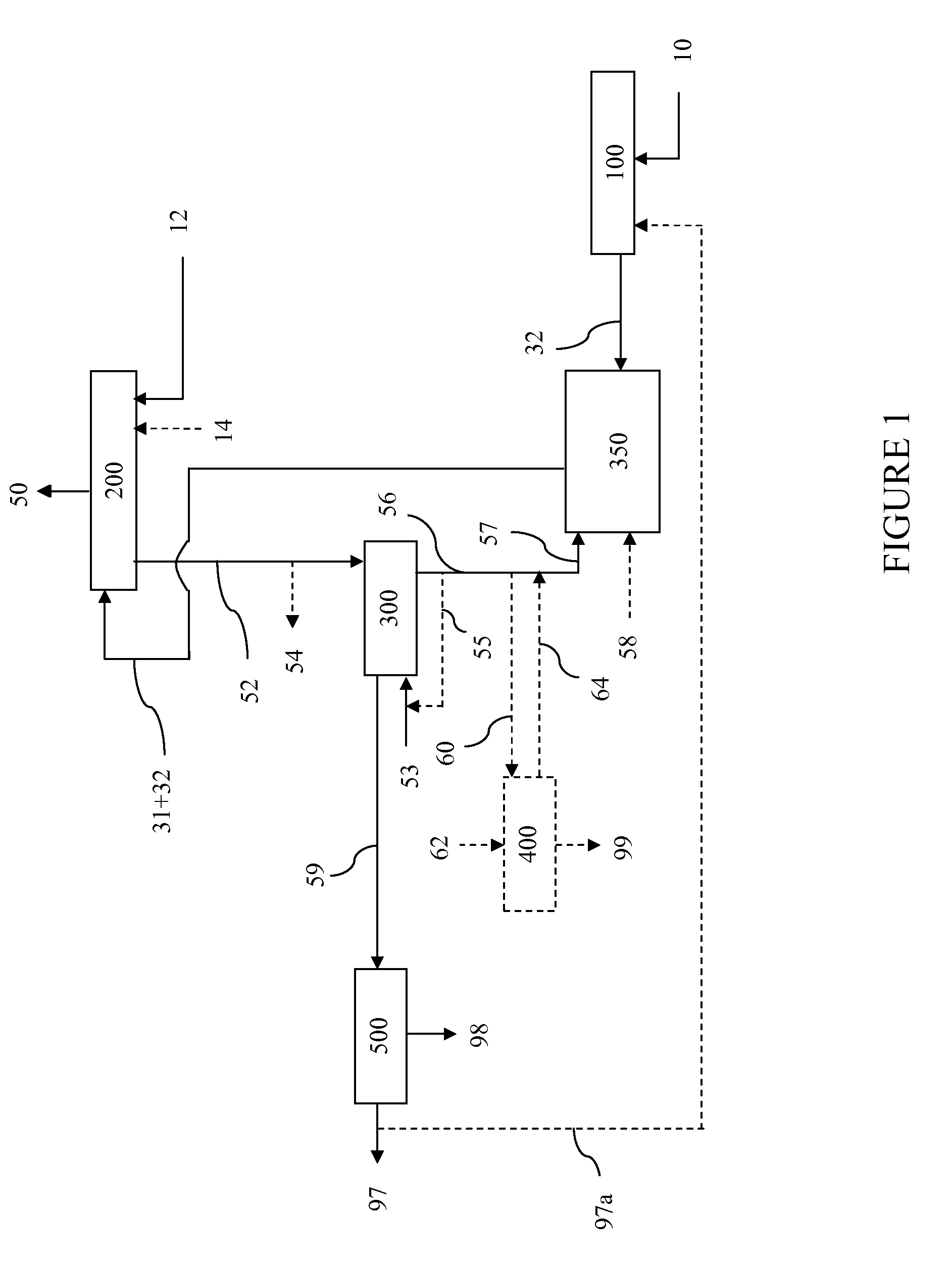

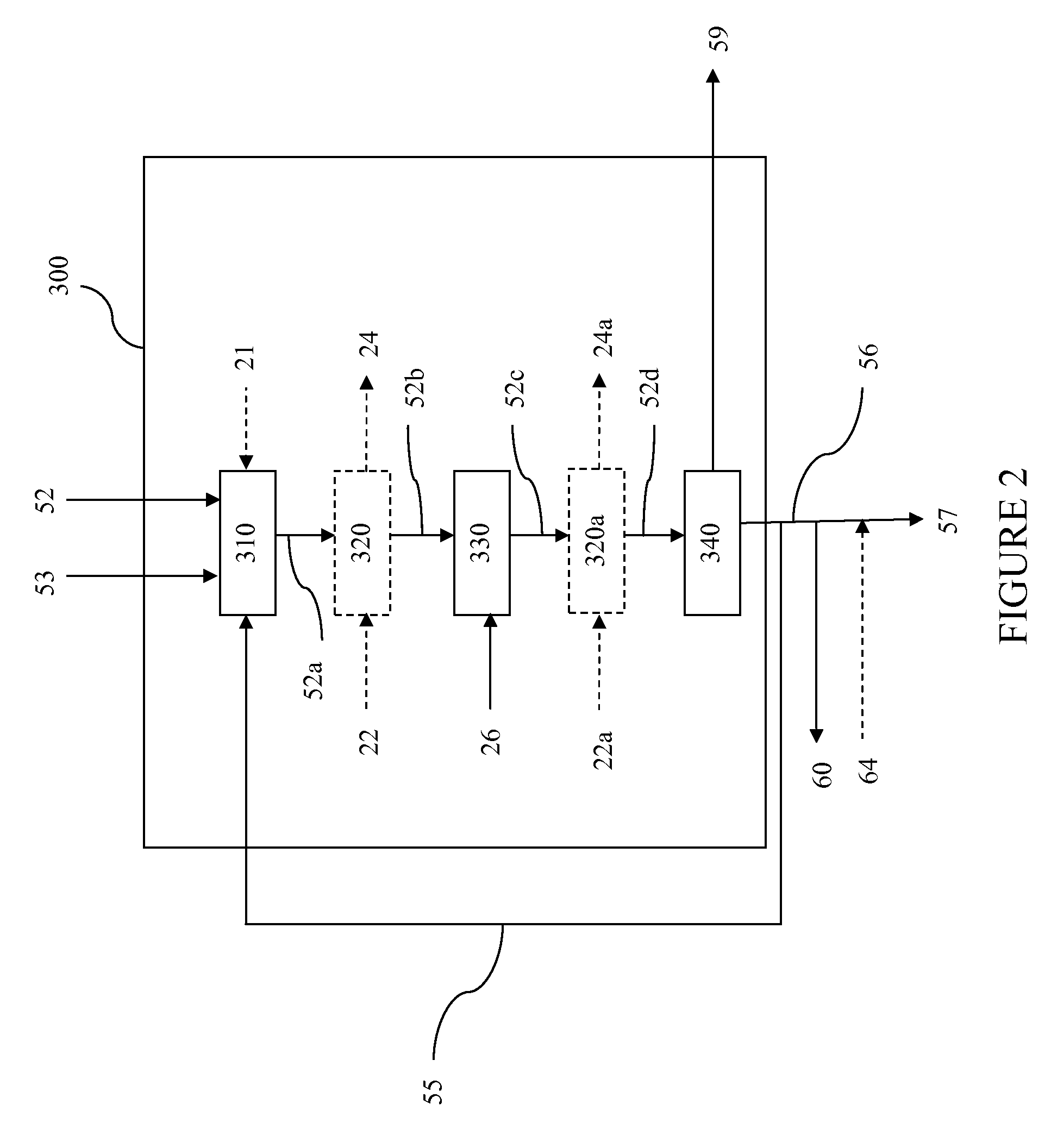

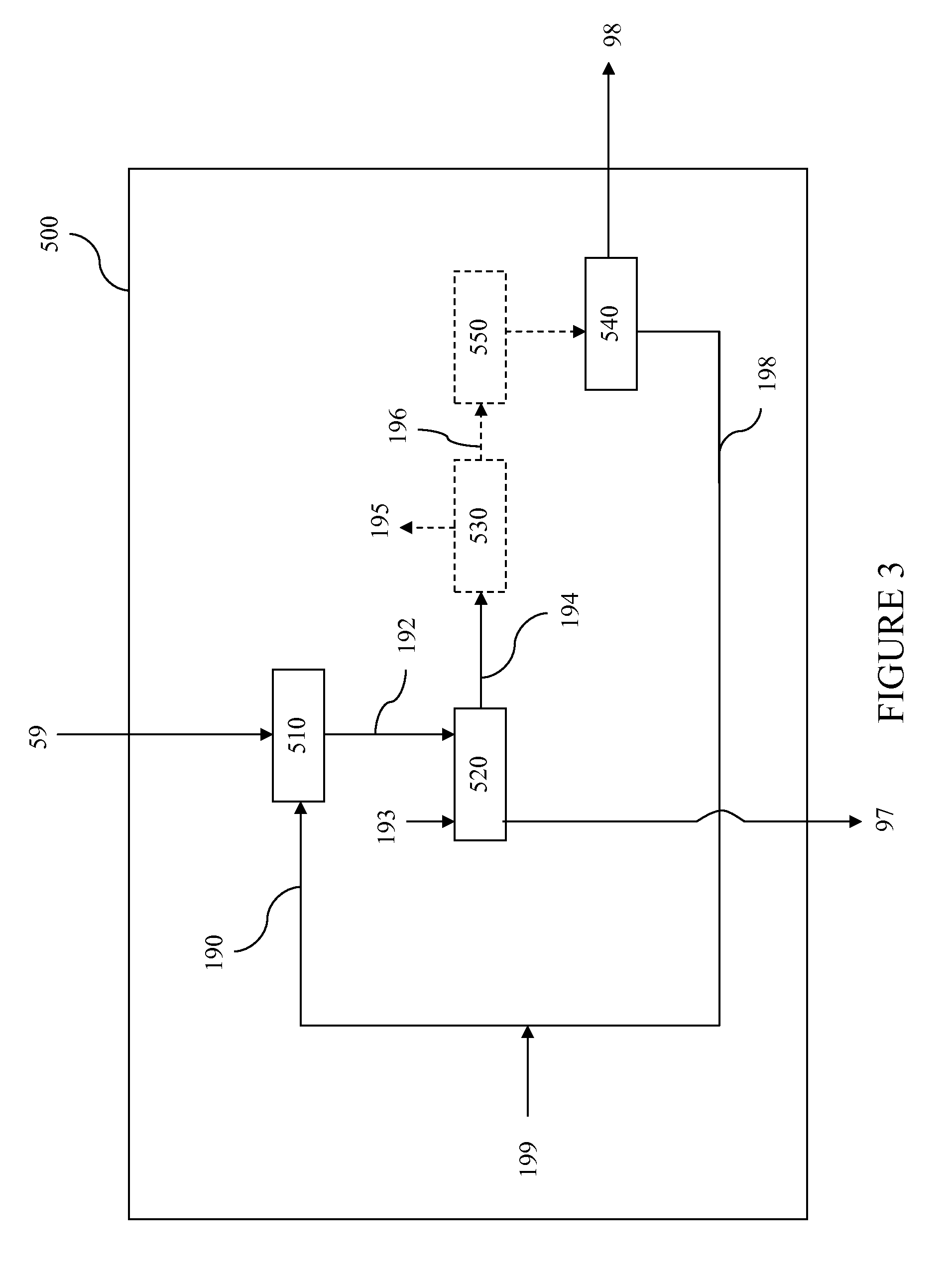

System and method for integrated waste storage

ActiveUS9217188B2Pressurized chemical processChemical/physical/physico-chemical processesThird partyWaste stream

The present invention provides integrated bunker storage systems for waste streams based on the composition and characteristics of waste streams. In particular, the present invention provides a process for generating individual waste streams based on a set of material characteristics. According to the system and method of the present invention, individual waste streams from wastes stored in bunkers are mixed in a given feed ratio to generate a feed stock that will produce a desired output from a chemical conversion process, e.g., gasification. Optionally, composition data regarding the feed stock can be certified to a third party.

Owner:REPOWER IP LLC

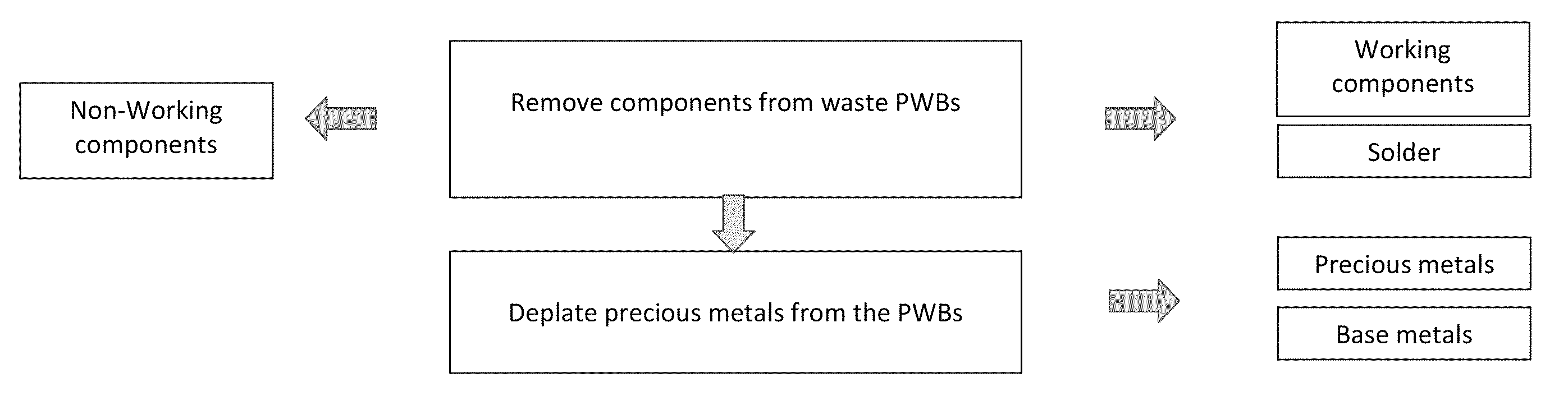

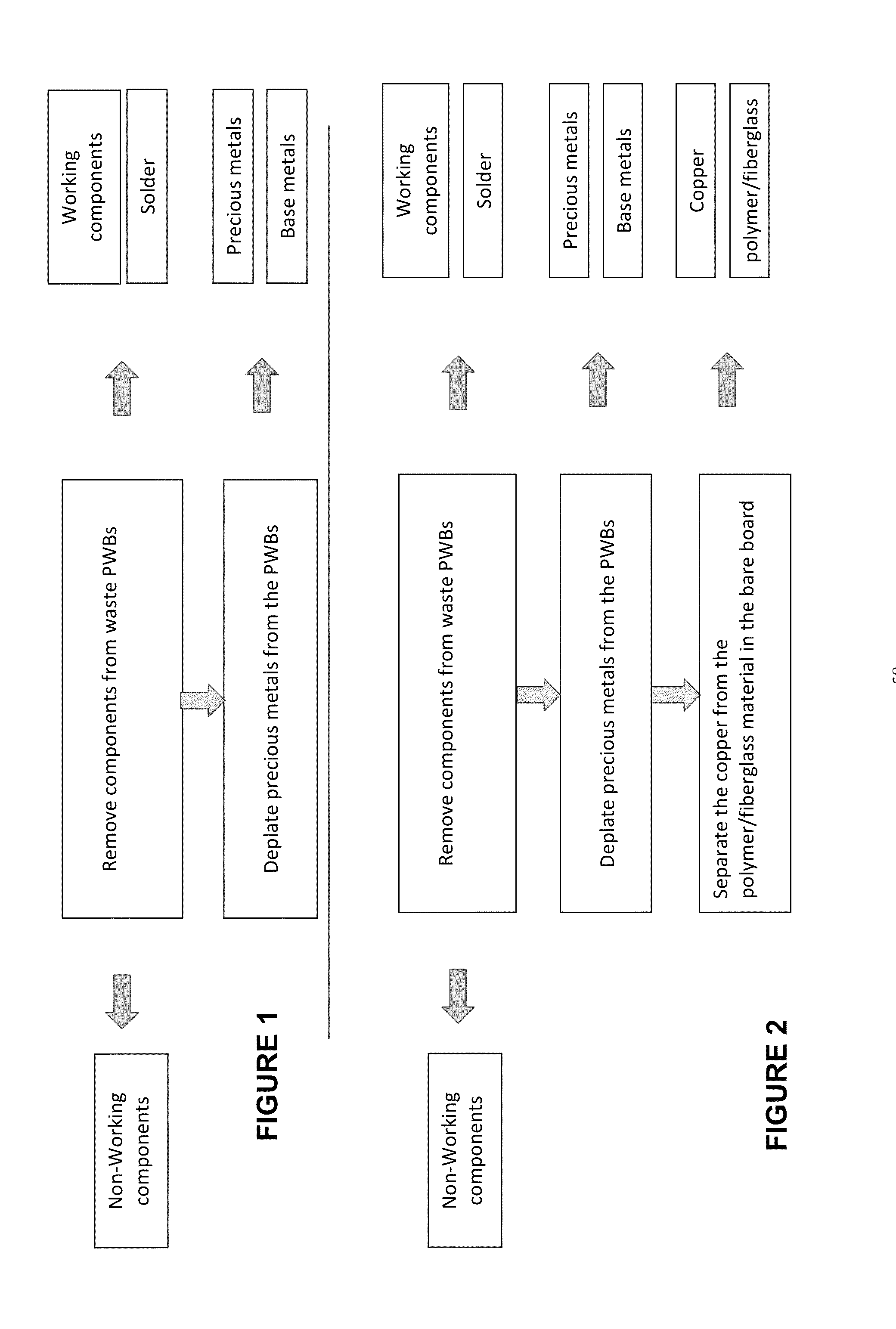

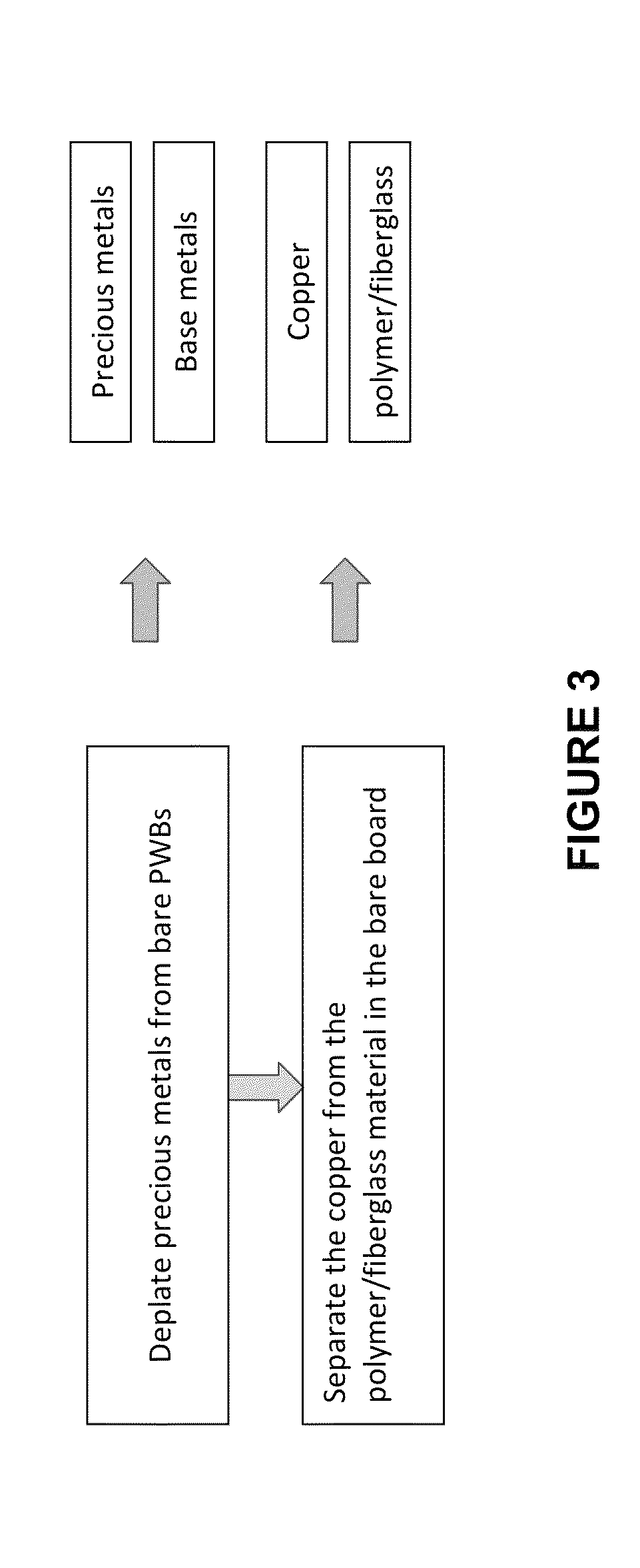

Method for recycling of obsolete printed circuit boards

Owner:ENTEGRIS INC

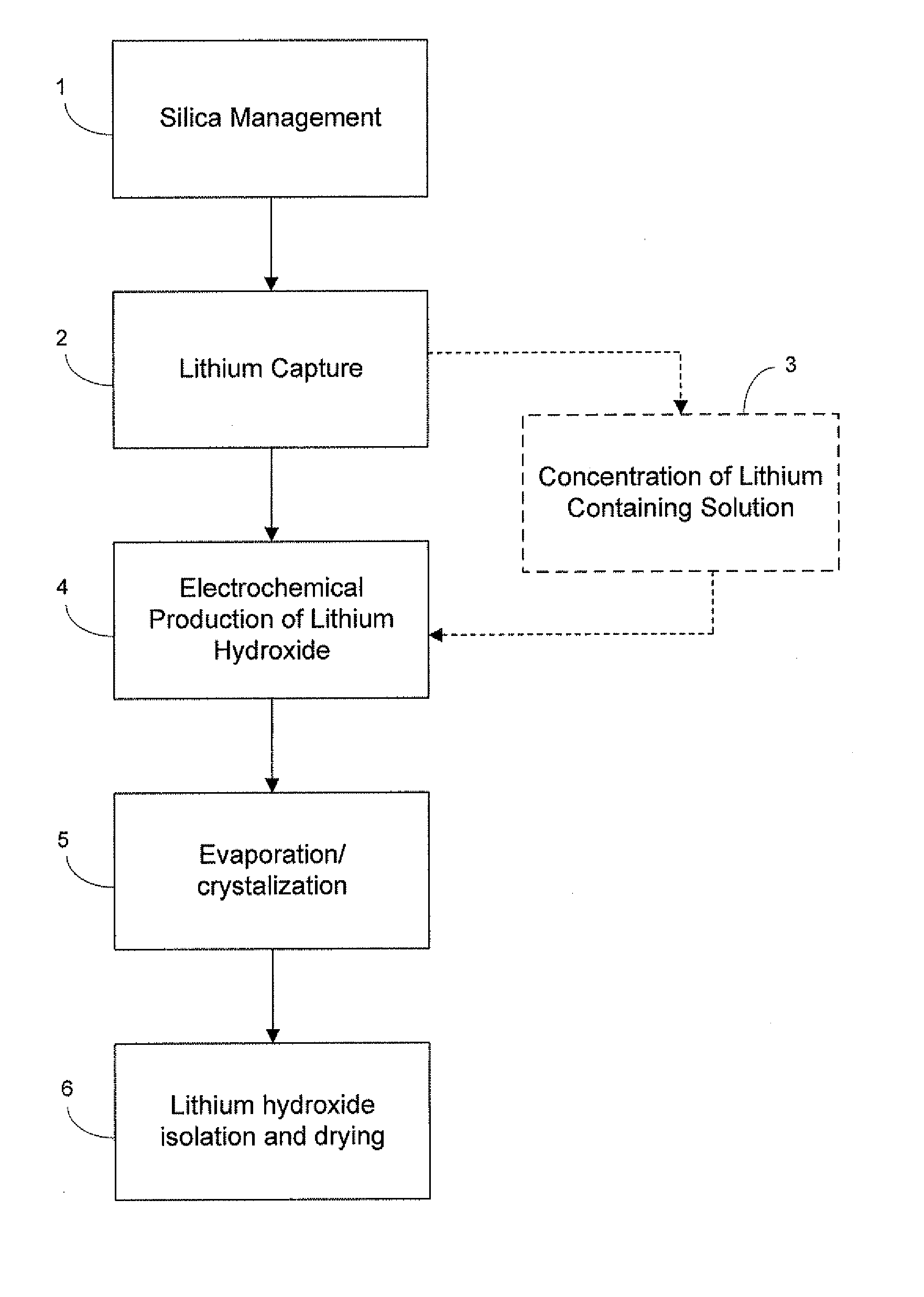

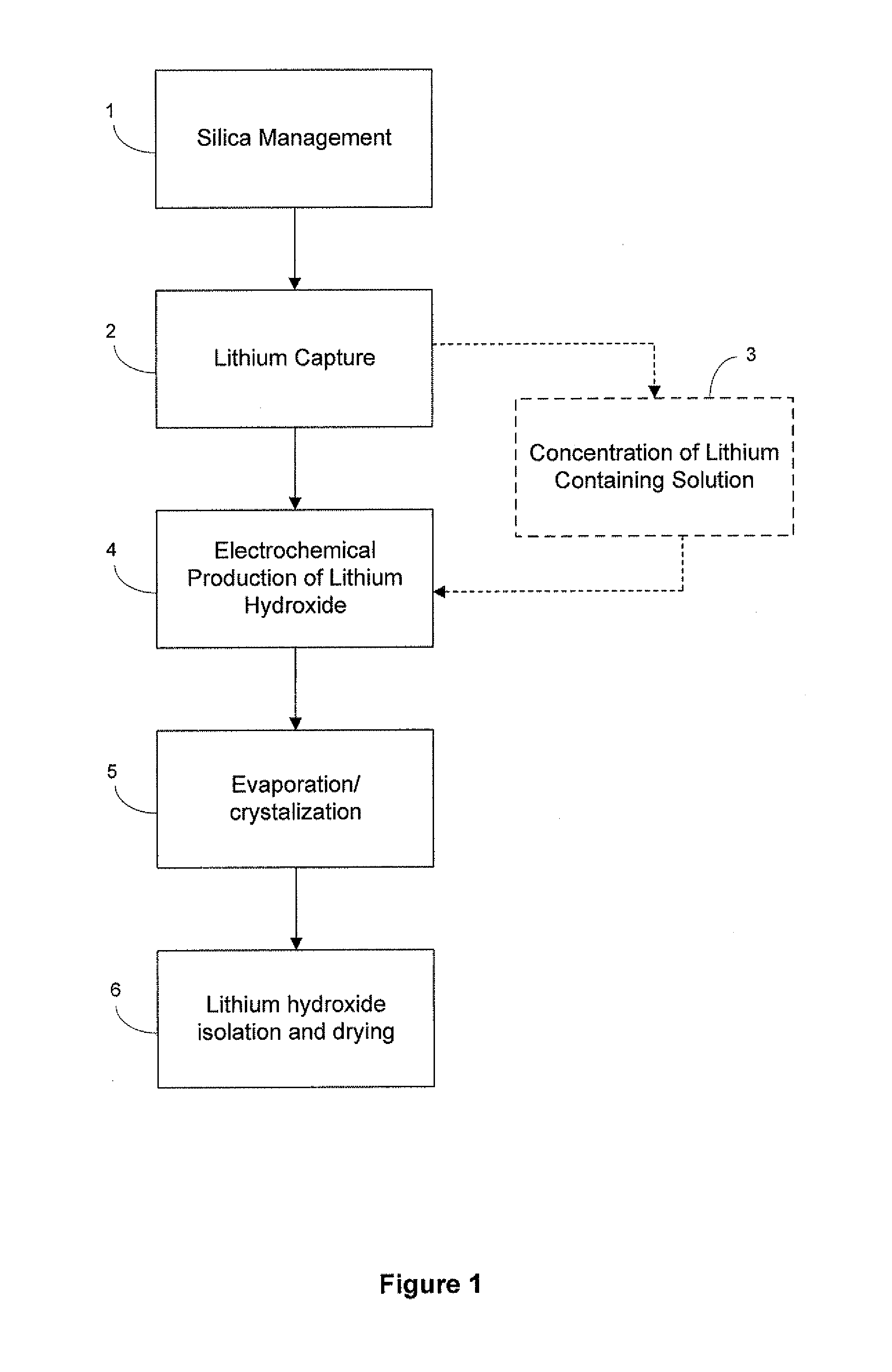

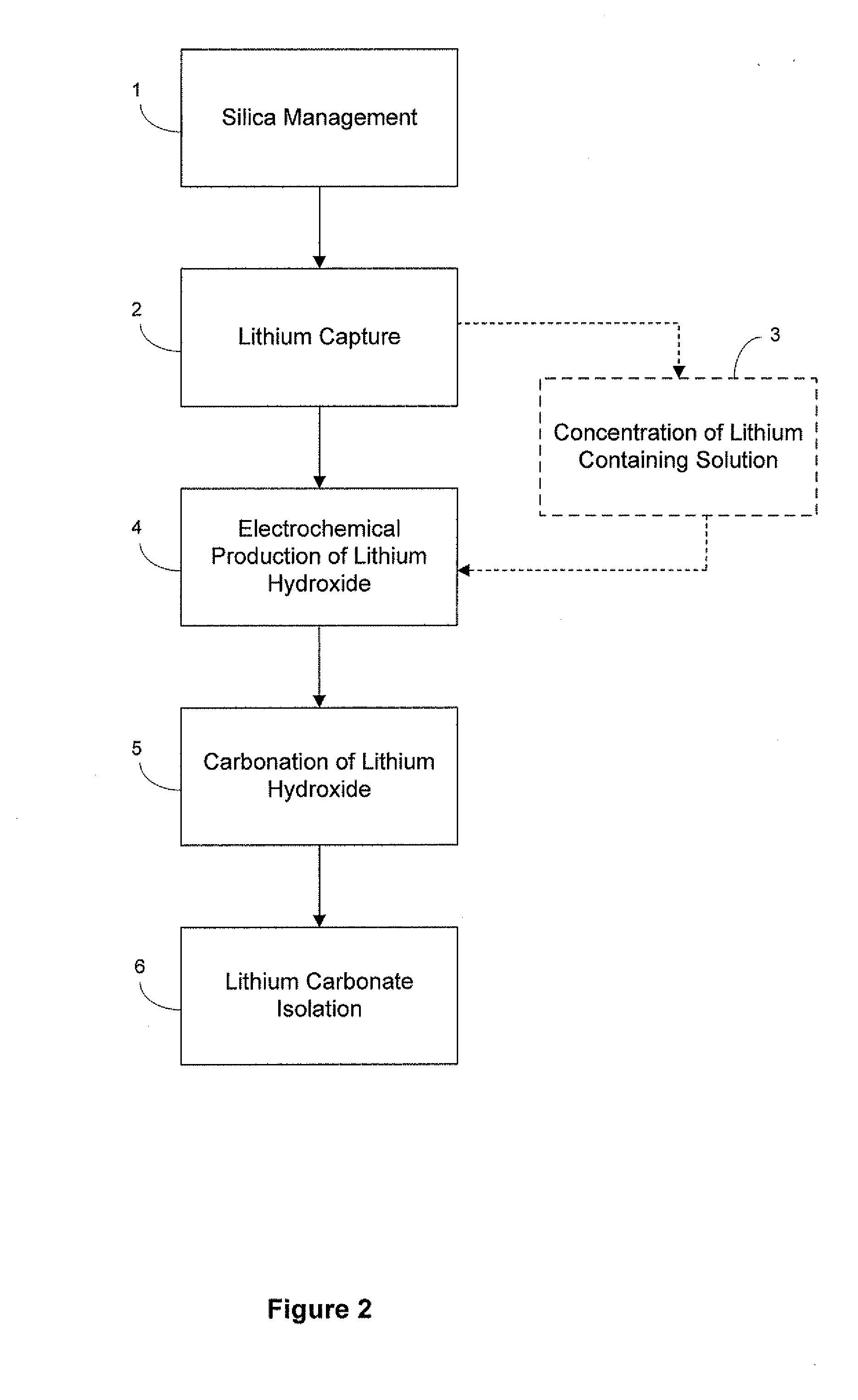

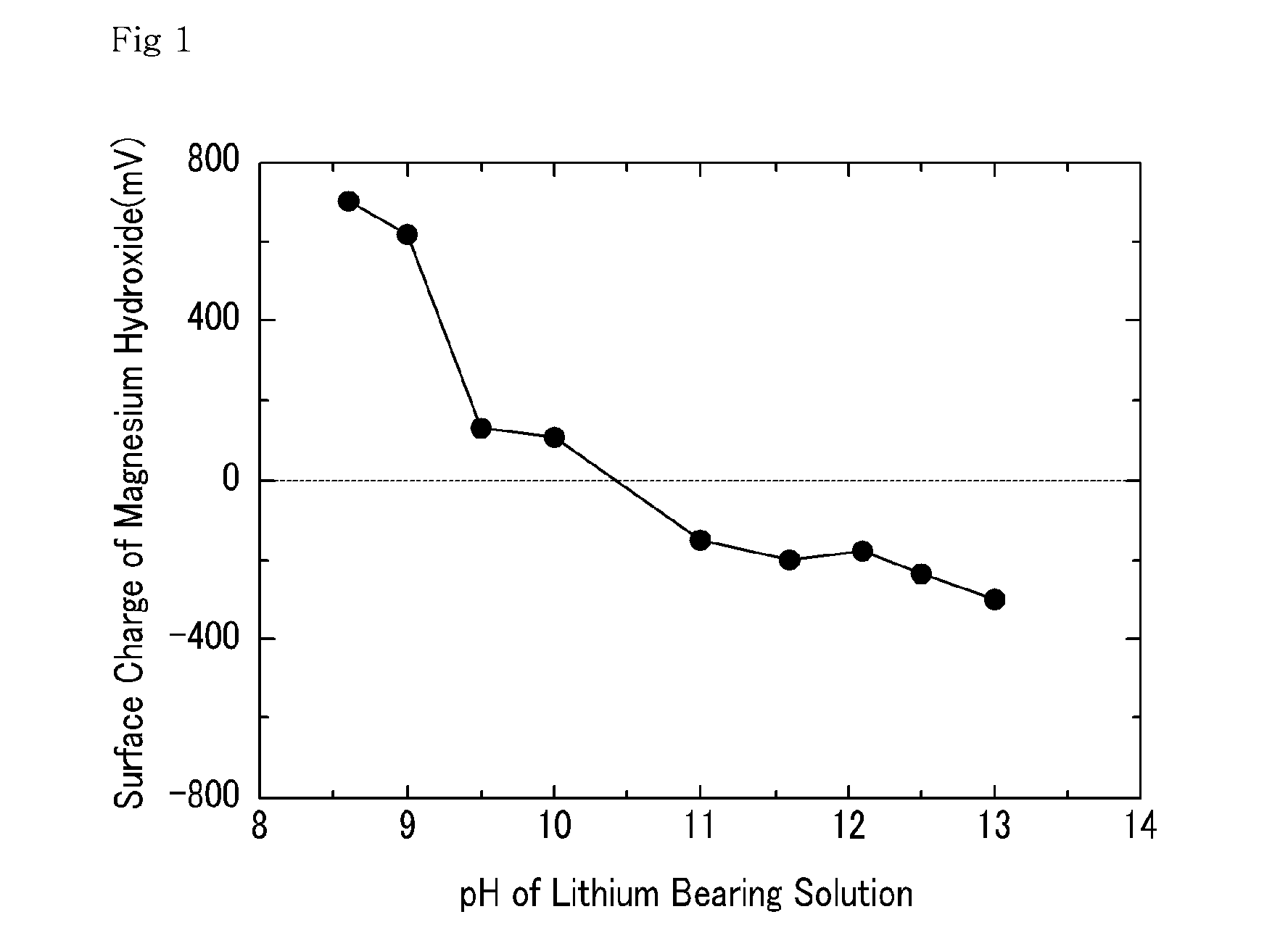

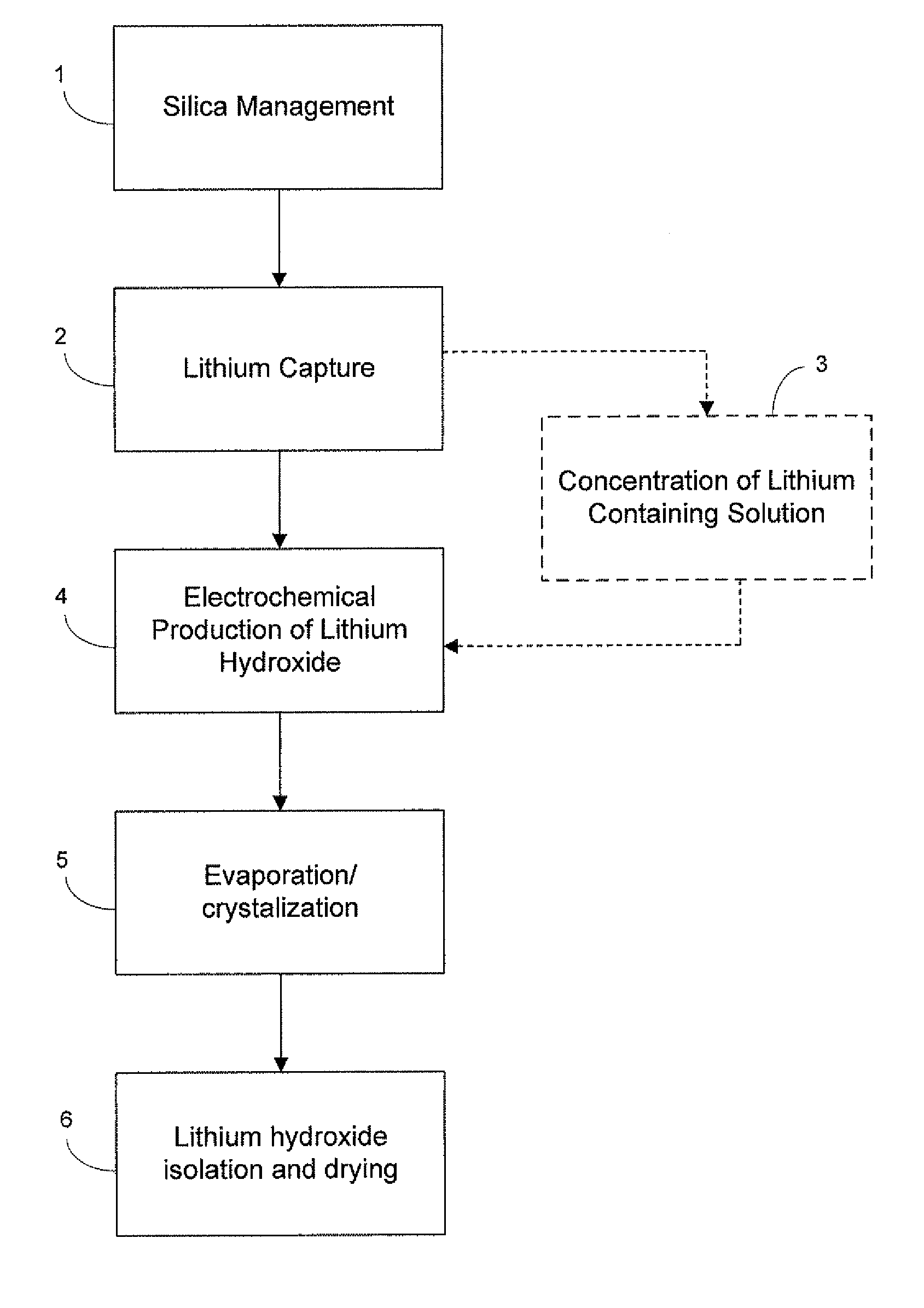

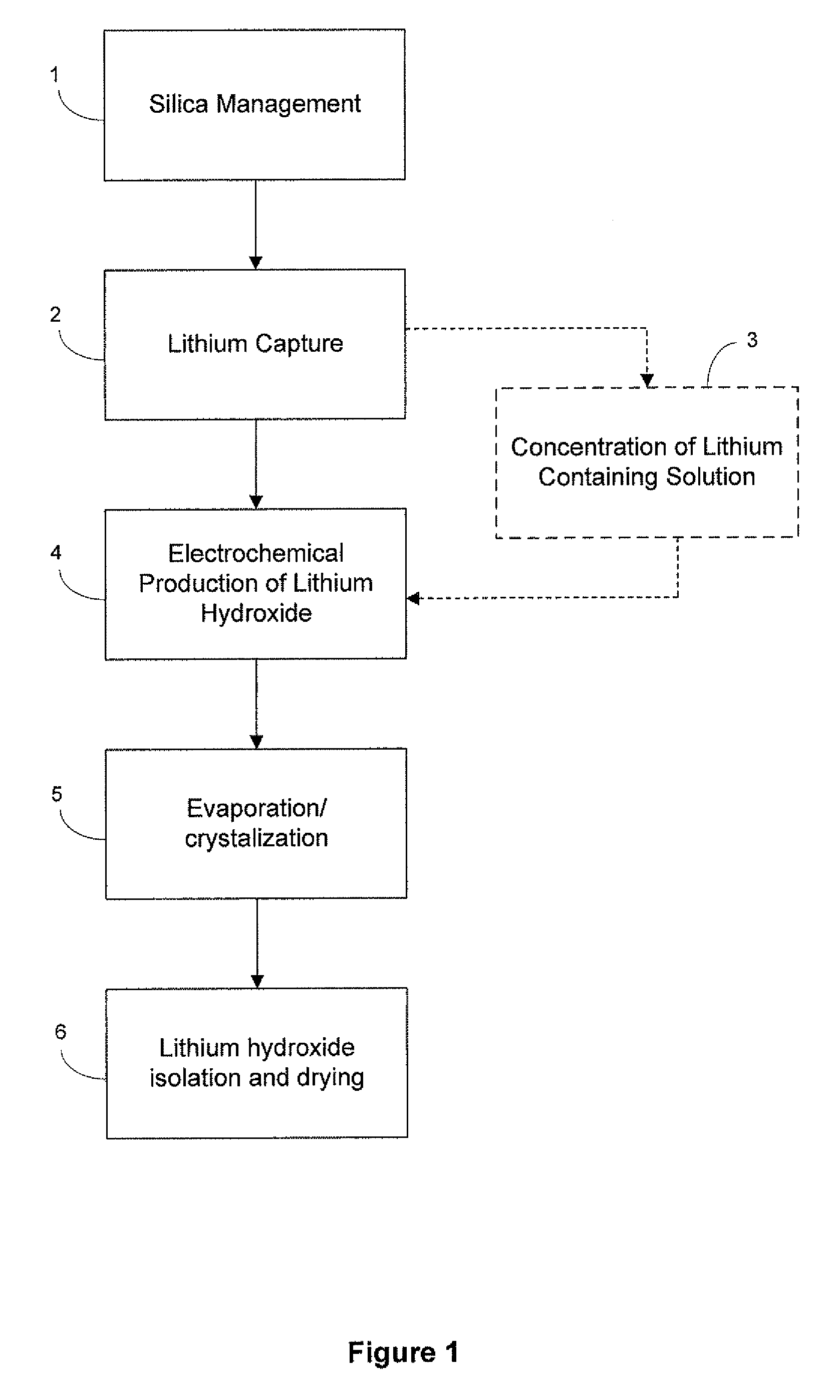

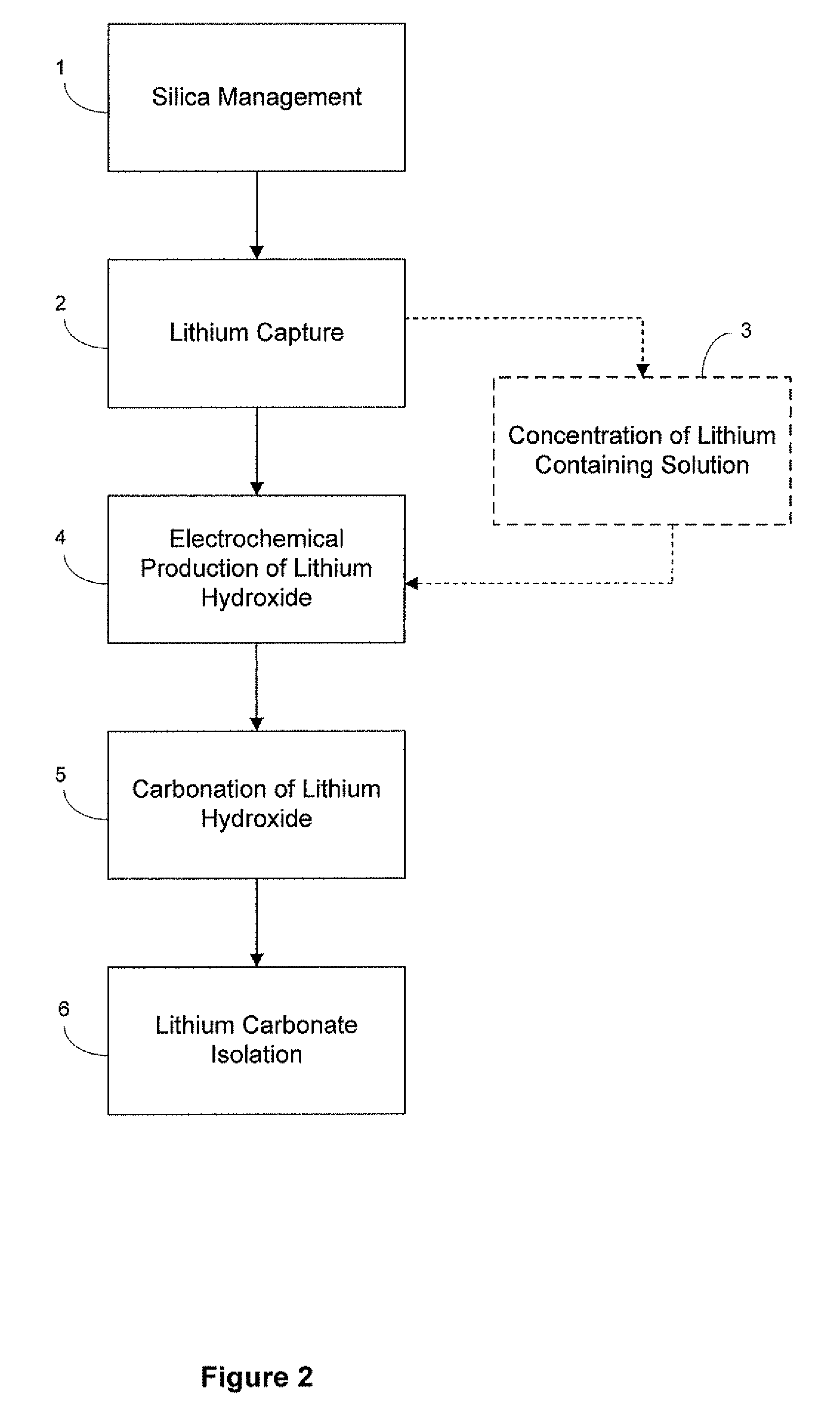

Preparation of Lithium Carbonate From Lithium Chloride Containing Brines

ActiveUS20140227154A1Metal recyclingLithium carbonates/bicarbonatesLithium chlorideLithium hydroxide

This invention relates to a method for the preparation of lithium carbonate from lithium chloride containing brines. The method can include a silica removal step, capturing lithium chloride, recovering lithium chloride, supplying lithium chloride to an electrochemical cell and producing lithium hydroxide, contacting the lithium hydroxide with carbon dioxide to produce lithium carbonate.

Owner:TERRALITHIUM LLC

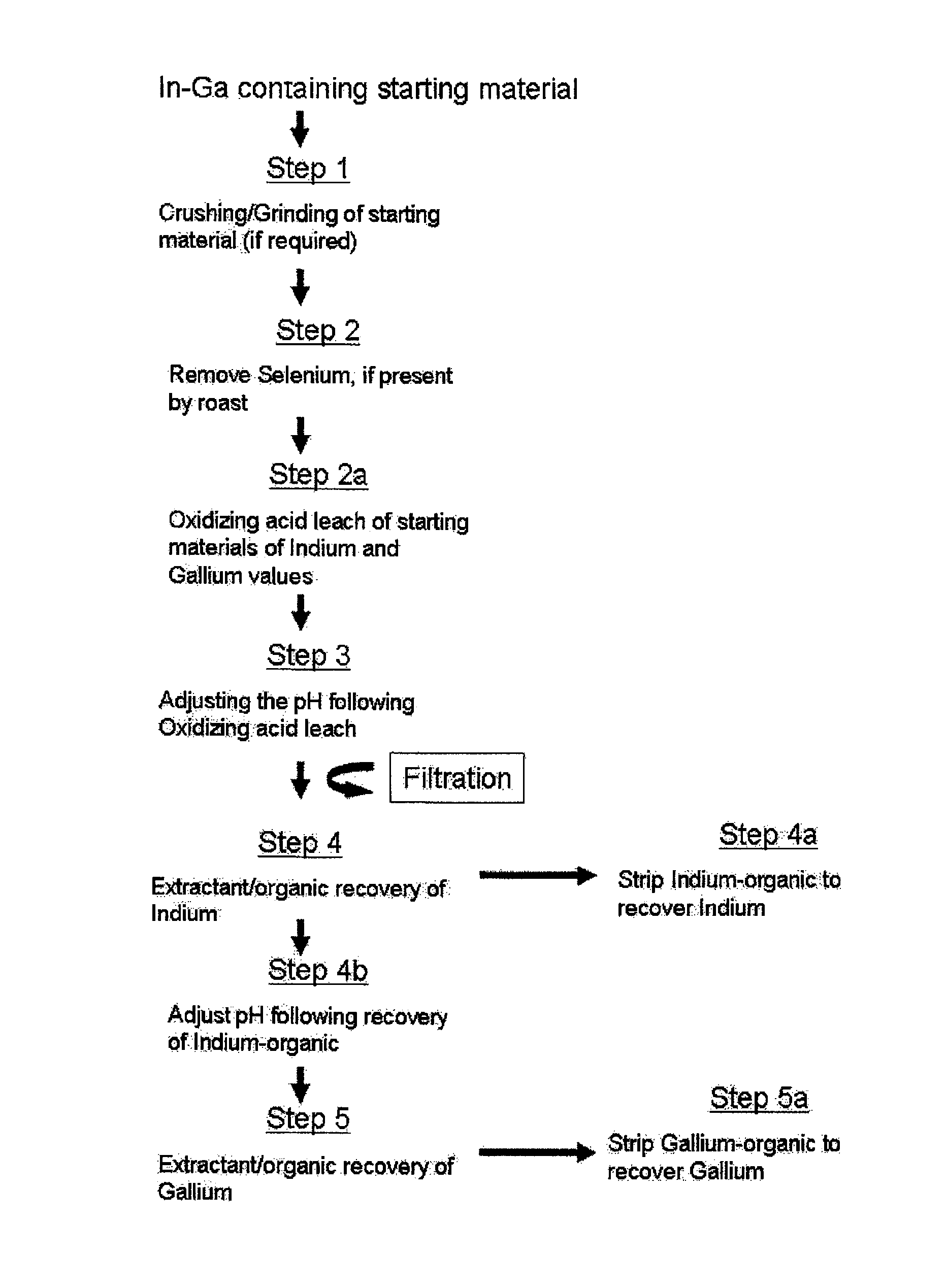

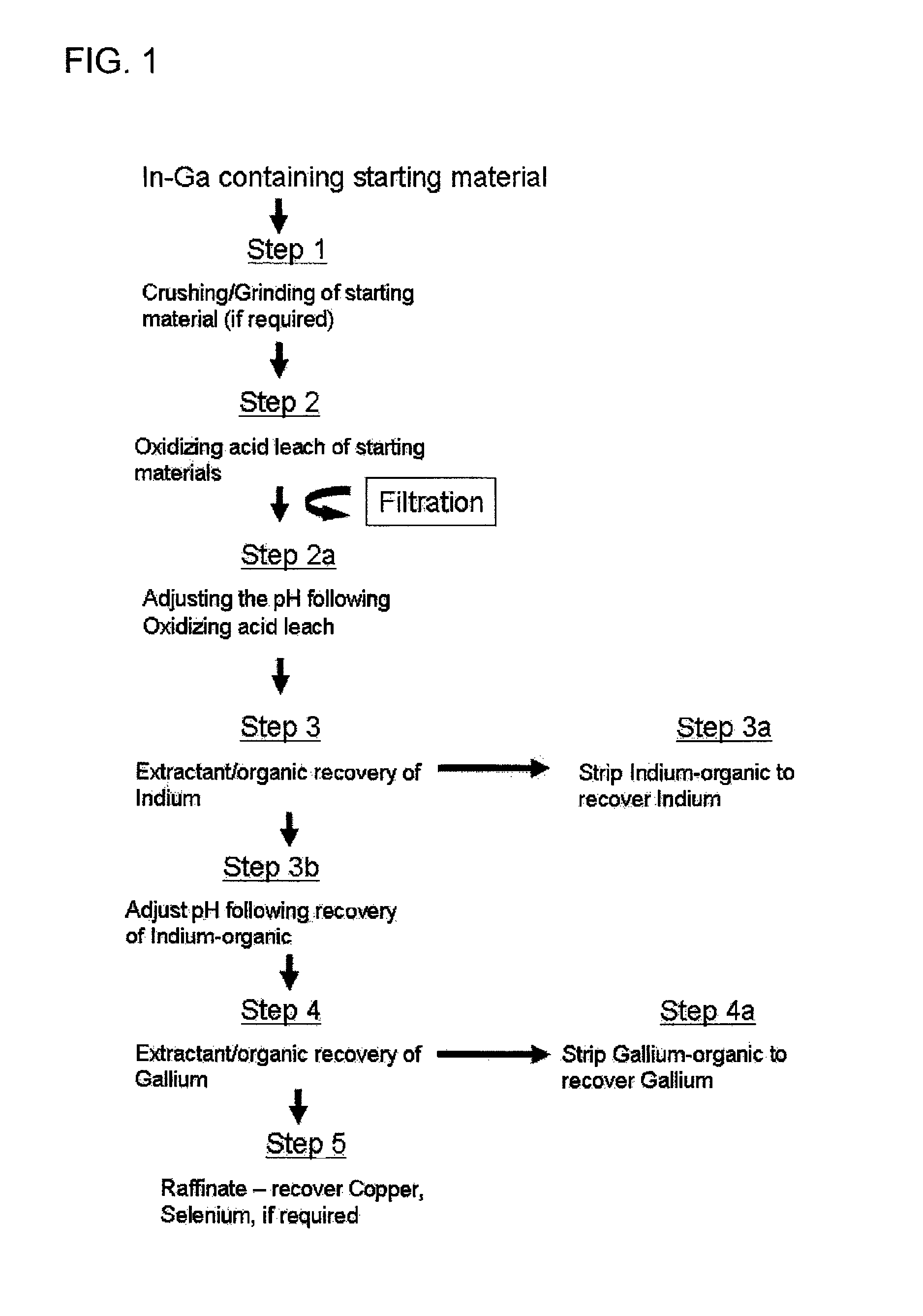

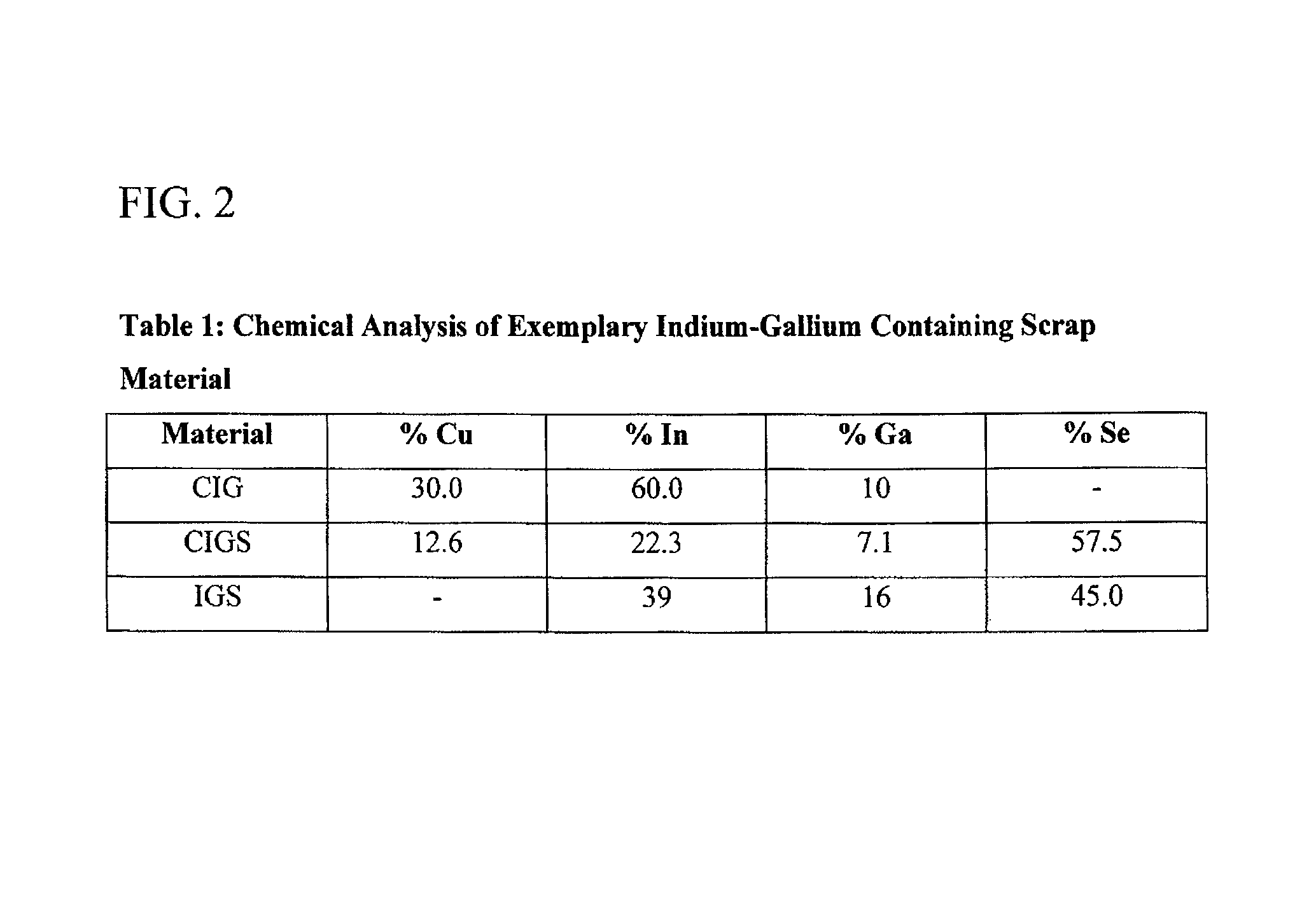

Treatment of indium gallium alloys and recovery of indium and gallium

There is provided a hydrometallurgical process of recovering indium and gallium values from mixtures thereof with other metal values for example recycled and scrap solar panel cells which comprises subjecting the mixture to strongly oxidizing acid conditions, preferably via the simultaneous addition of sulfuric acid and hydrogen peroxide to the leach vessel, so as to form indium and gallium salt species of at least the major proportion of the indium and gallium values in the mixture, extracting the indium and gallium values with an organic extractant by adjusting the pH so as to extract individually the indium and gallium values with the organic extractant, stripping indium and gallium values from the extractant using an acid and an alkaline solution respectively and recovering the indium and gallium values.

Owner:MOLYCORP MINERALS CANADA ULC

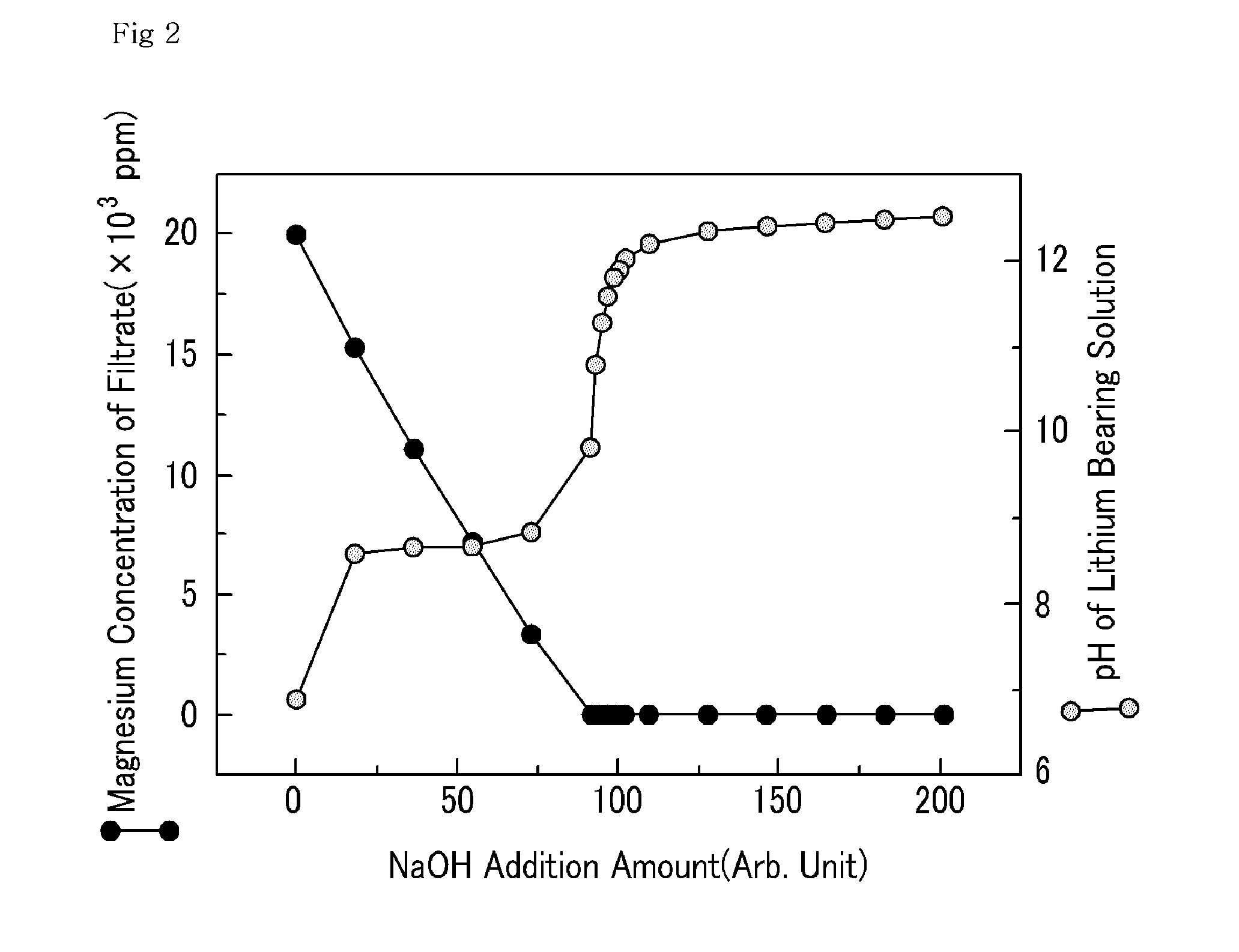

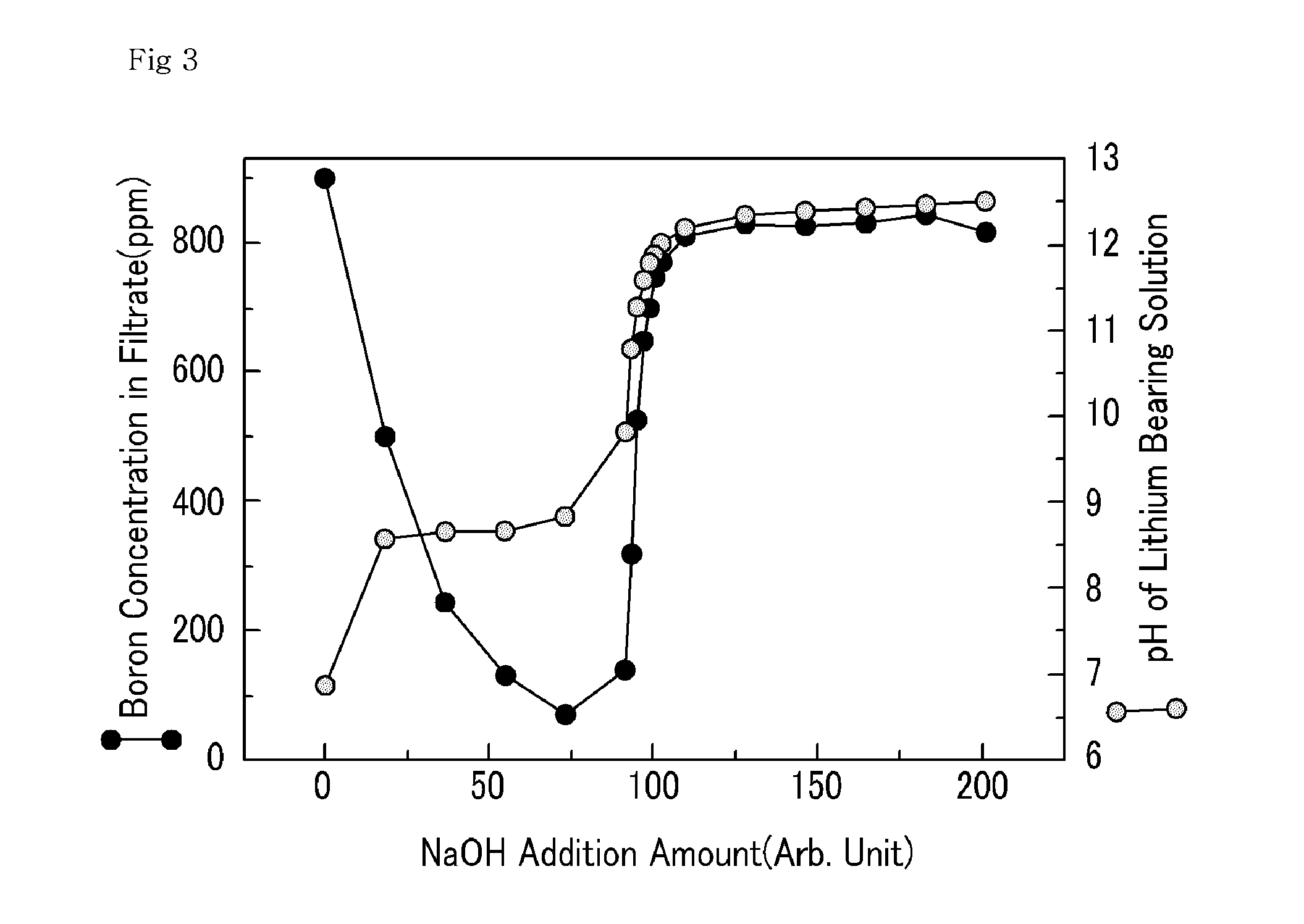

Method for economical extraction of lithium from solution including lithium

ActiveUS8778289B2High extraction rateReduce solubilityCalcium/strontium/barium carbonatesMetal recyclingLITHIUM PHOSPHATEPhosphorus

The present invention relates to a method of extracting lithium from a lithium bearing solution. More specifically, the present invention provides a method of economical extraction of lithium from a lithium bearing solution by adding a phosphorous supplying material to the solution to precipitate lithium phosphate from the dissolved lithium.

Owner:RES INST OF IND SCI & TECH

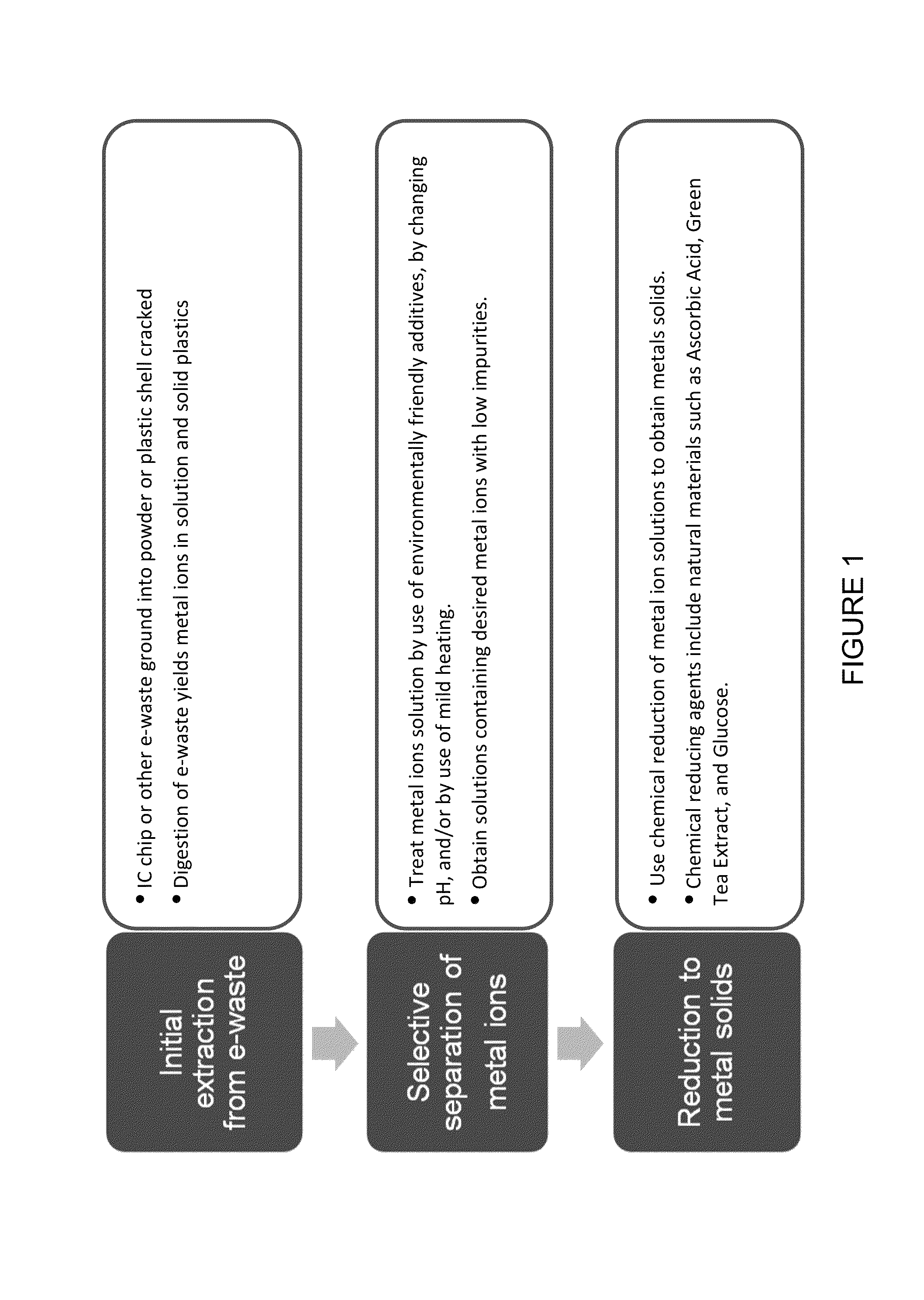

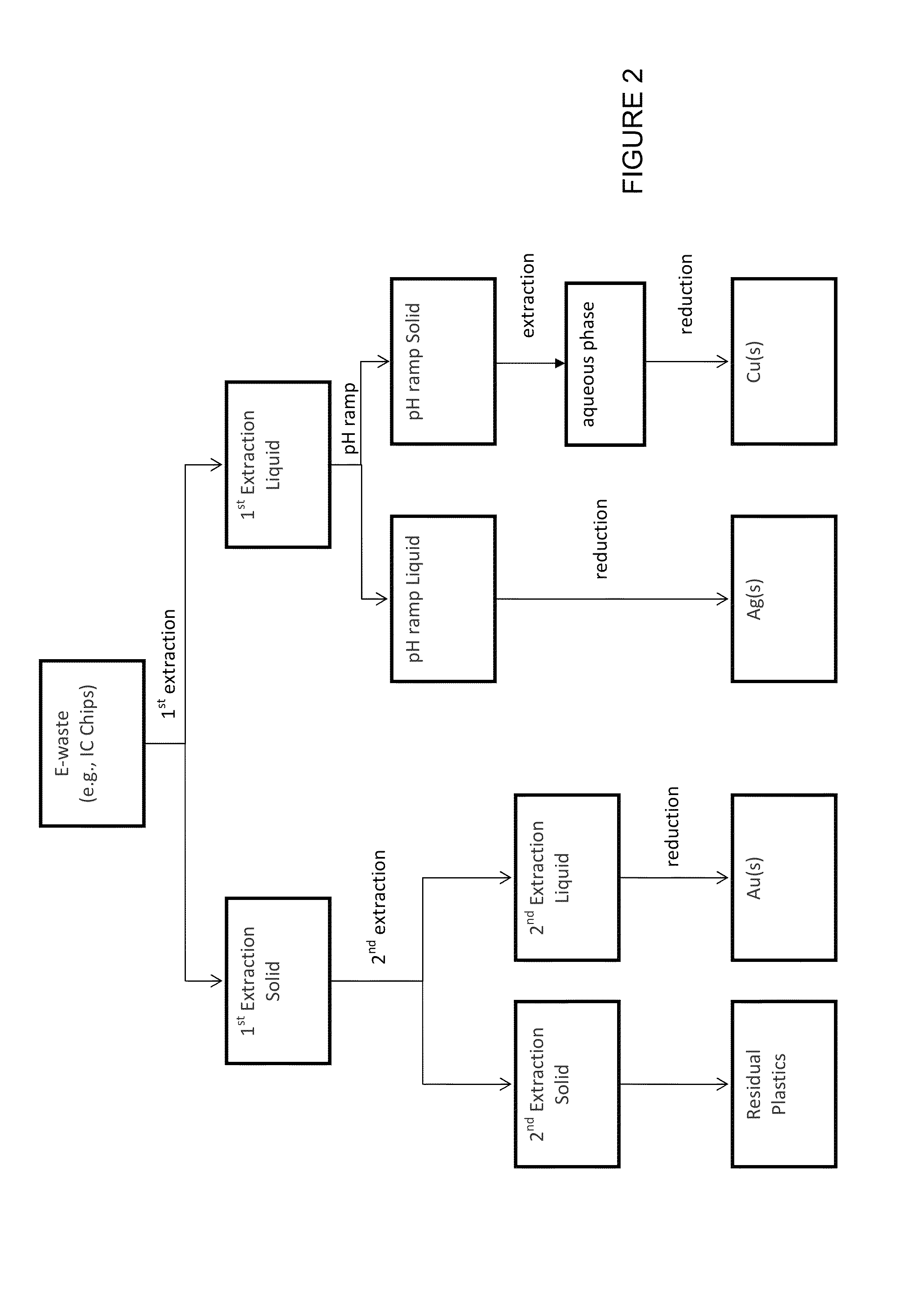

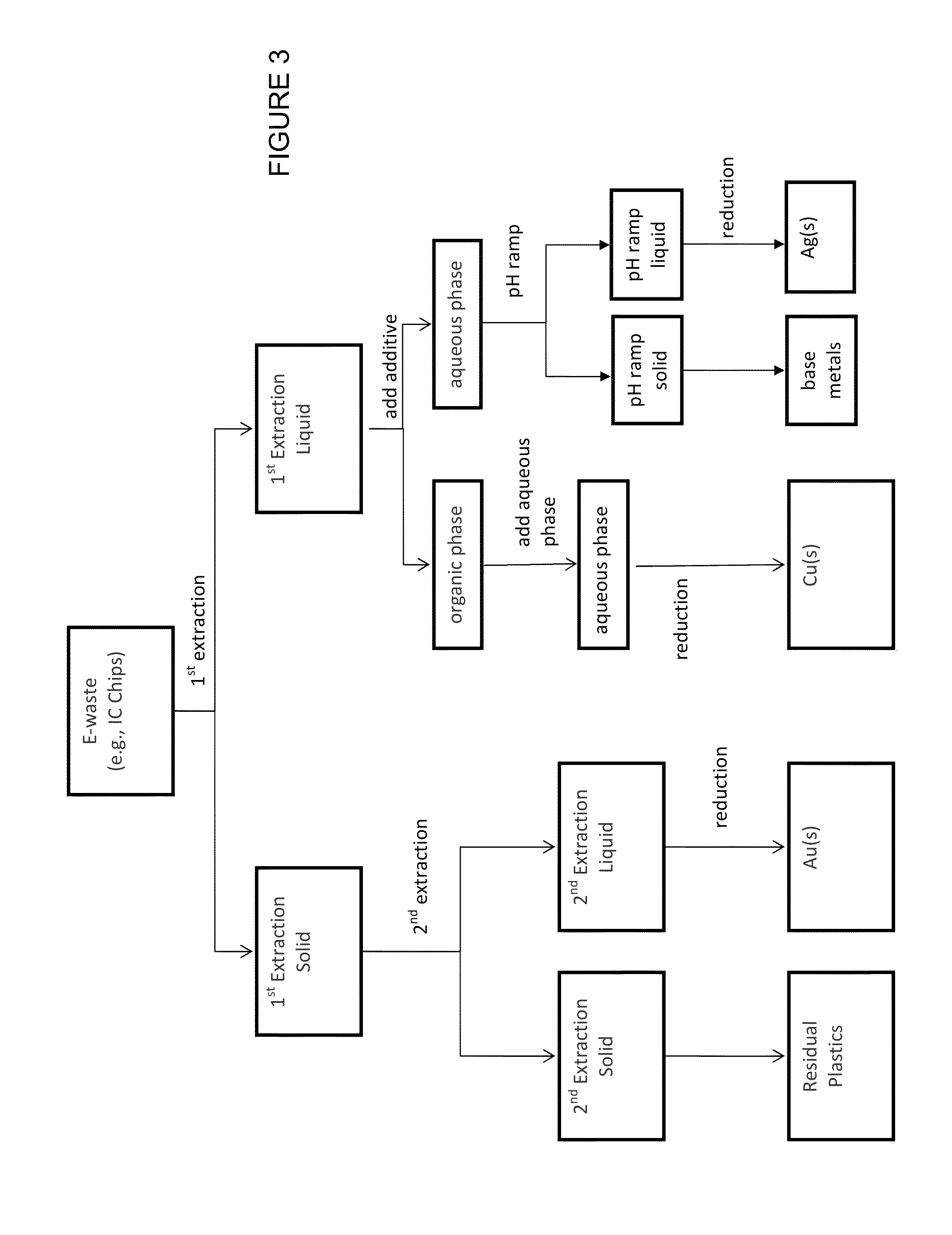

Sustainable process for reclaiming precious metals and base metals from e-waste

Processes for recycling electronic components removed from printed wire boards, whereby precious metals and base metals are extracted from the electronic components using environmentally friendly compositions. At least gold, silver and copper ions can be extracted from the electronic components and reduced to their respective metals using the processes and compositions described herein.

Owner:ENTEGRIS INC

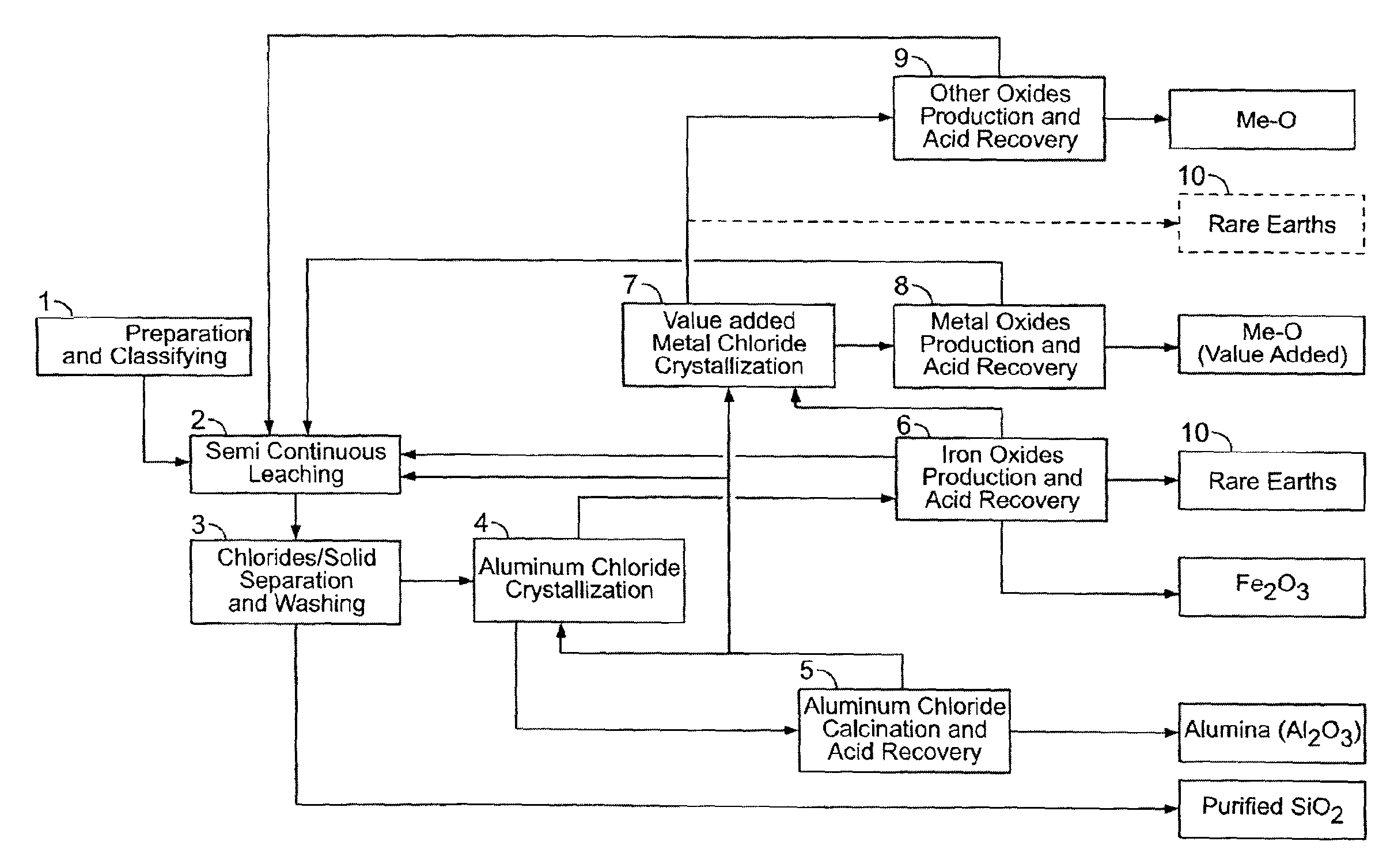

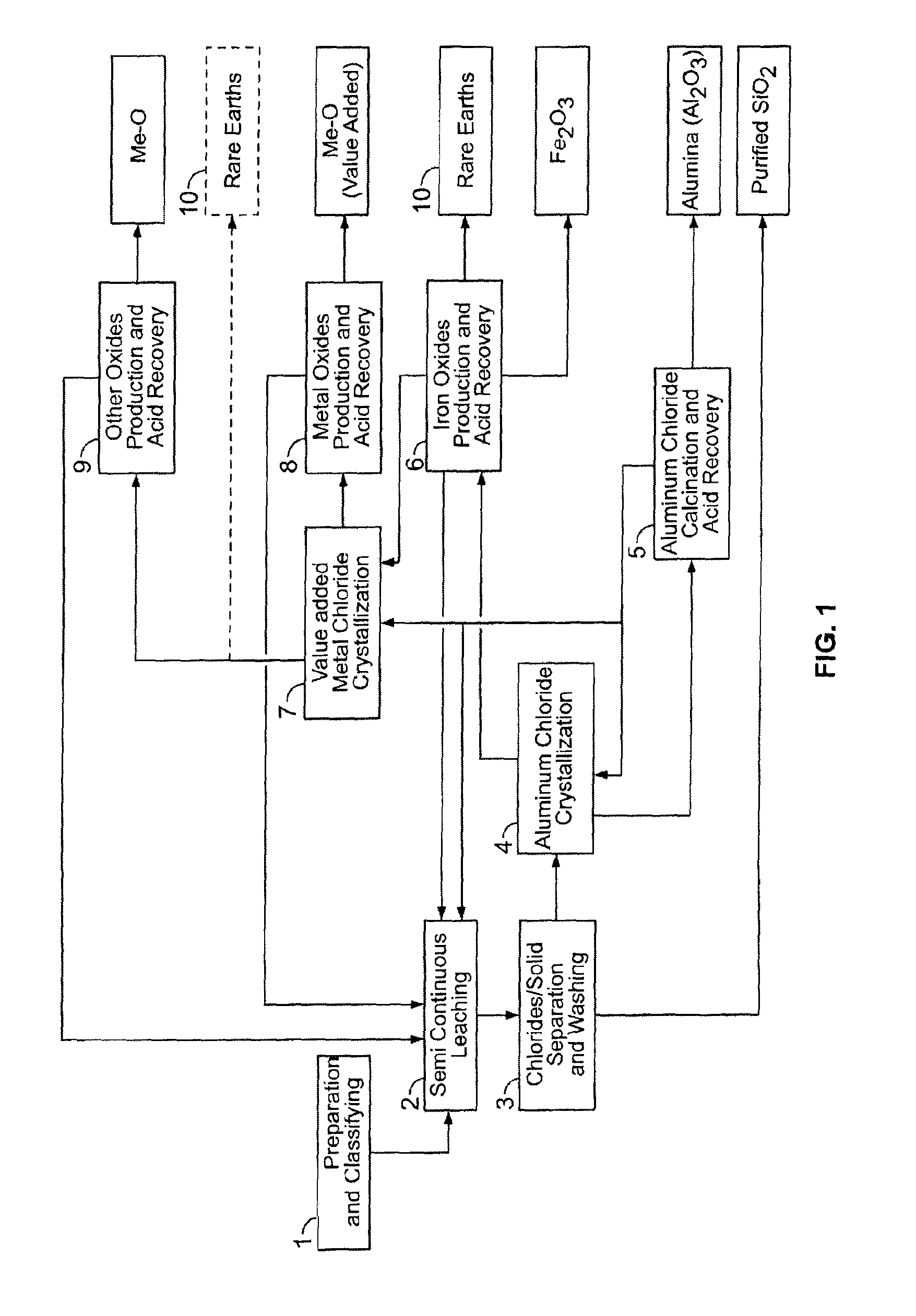

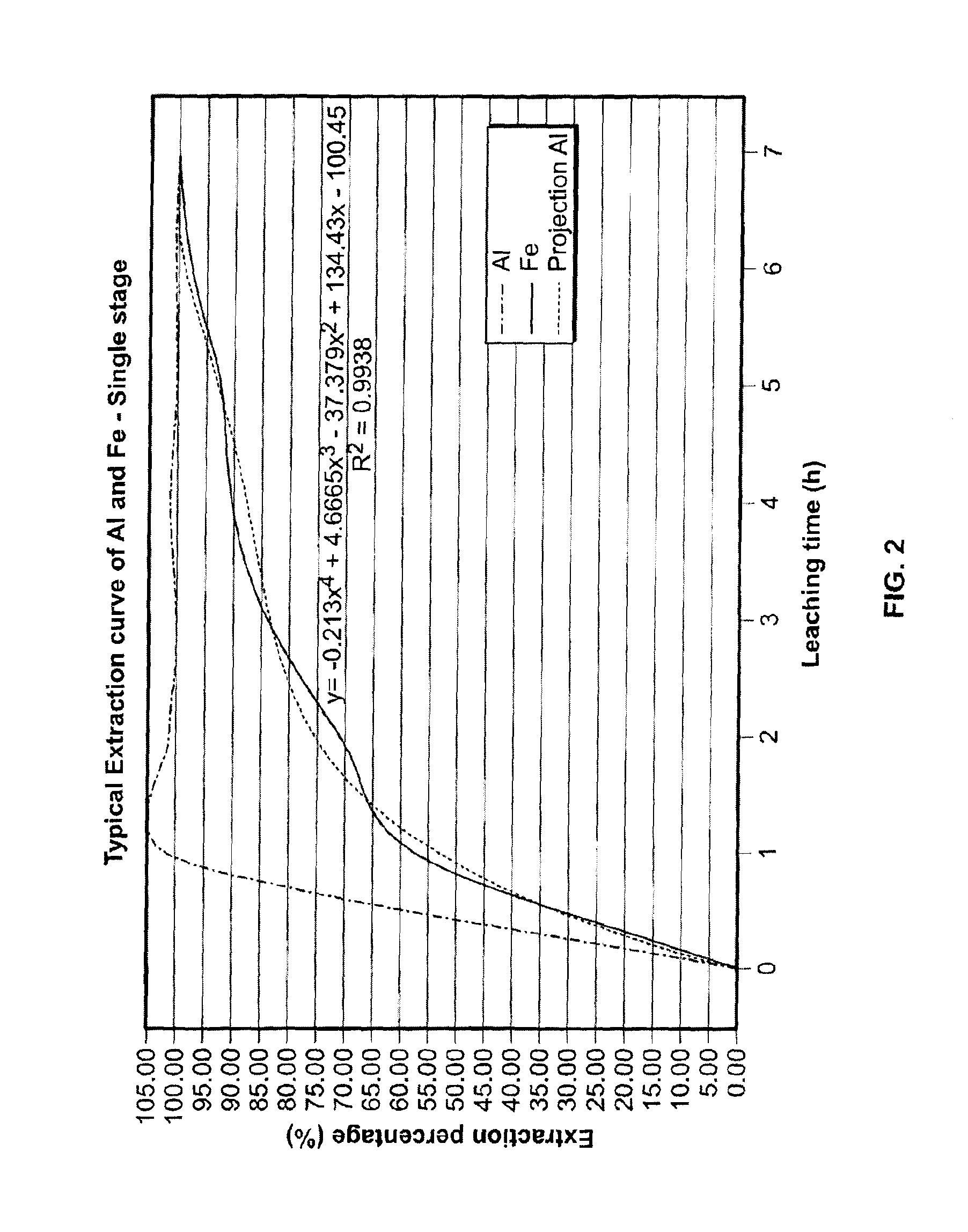

Processes for treating fly ashes

There are provided processes for treating fly ash. For example, the processes can comprise leaching fly ash with HCl so as to obtain a leachate comprising aluminum ions and a solid, and separating the solid from the leachate; reacting the leachate with HCl so as to obtain a liquid and a precipitate comprising the aluminum ions in the form of AlCl3, and separating the precipitate from the liquid; and heating the precipitate under conditions effective for converting AlCl3 into Al2O3 and optionally recovering gaseous HCl so-produced.

Owner:ORBITE ALUMINAE INC

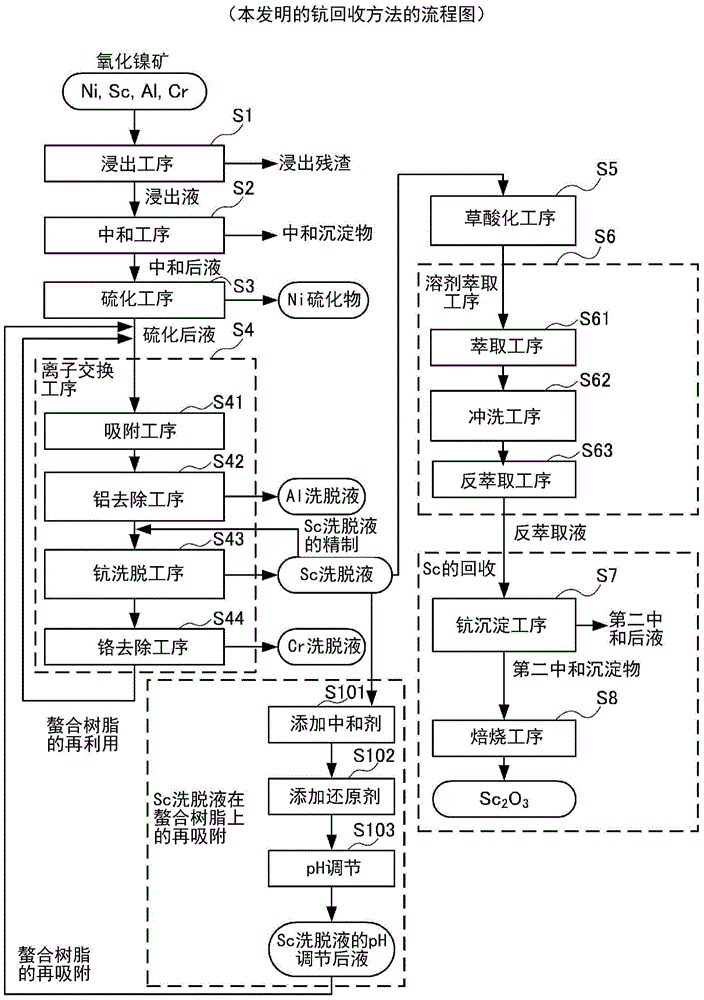

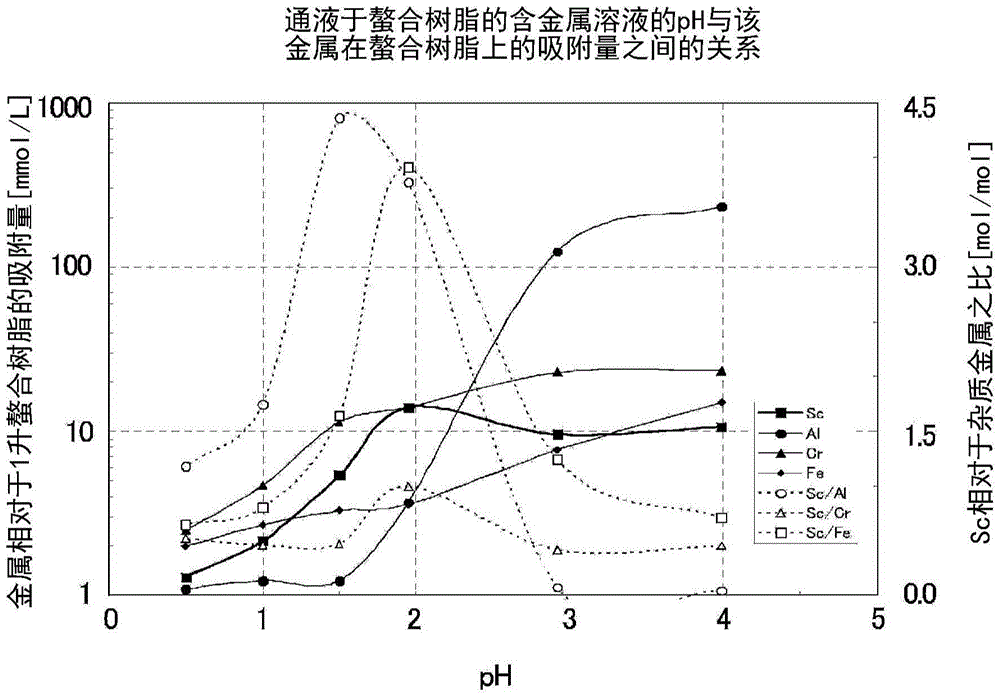

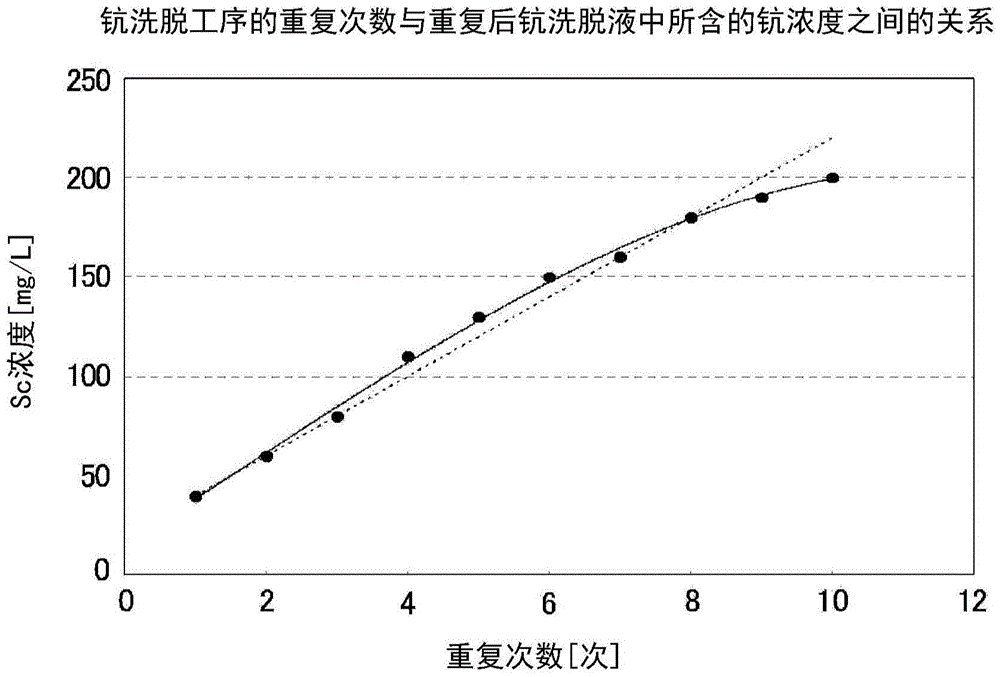

Method for recovering scandium

InactiveCN104995321AEfficient recyclingMetal recyclingProcess efficiency improvementIon exchangeNickel sulfide

The present invention effectively recover high-grade scandium from nickel oxide ores. The present invention includes a leaching step (S1) for charging nickel oxide ores and sulfuric acid into a pressurized vessel to cause solid-liquid separation of a leachate and a leaching residue under high temperature and high pressure, a neutralizing step (S2) for adding a neutralizing agent to the leachate to obtain a neutralized precipitate and a neutralized liquid, a sulfidizing step (S3) for adding a sulfidizing agent to the neutralized liquid to separate a nickel sulfide and a sulfidized liquid, an ion exchange step (S4) for bringing the sulfidized solution into contact with a chelate resin to adsorb Sc onto the chelate resin to obtain a Sc eluent, a solvent extraction step (S6) for bringing the Sc eluent into contact with an extracting agent to obtain a stripping solution, a Sc precipitation step (S7) for adding a neutralizing agent or oxalic acid to the stripping solution to obtain a precipitate, and a calcination step (S8) for drying and calcining the precipitate to obtain scandium oxide.

Owner:SUMITOMO METAL MINING CO LTD

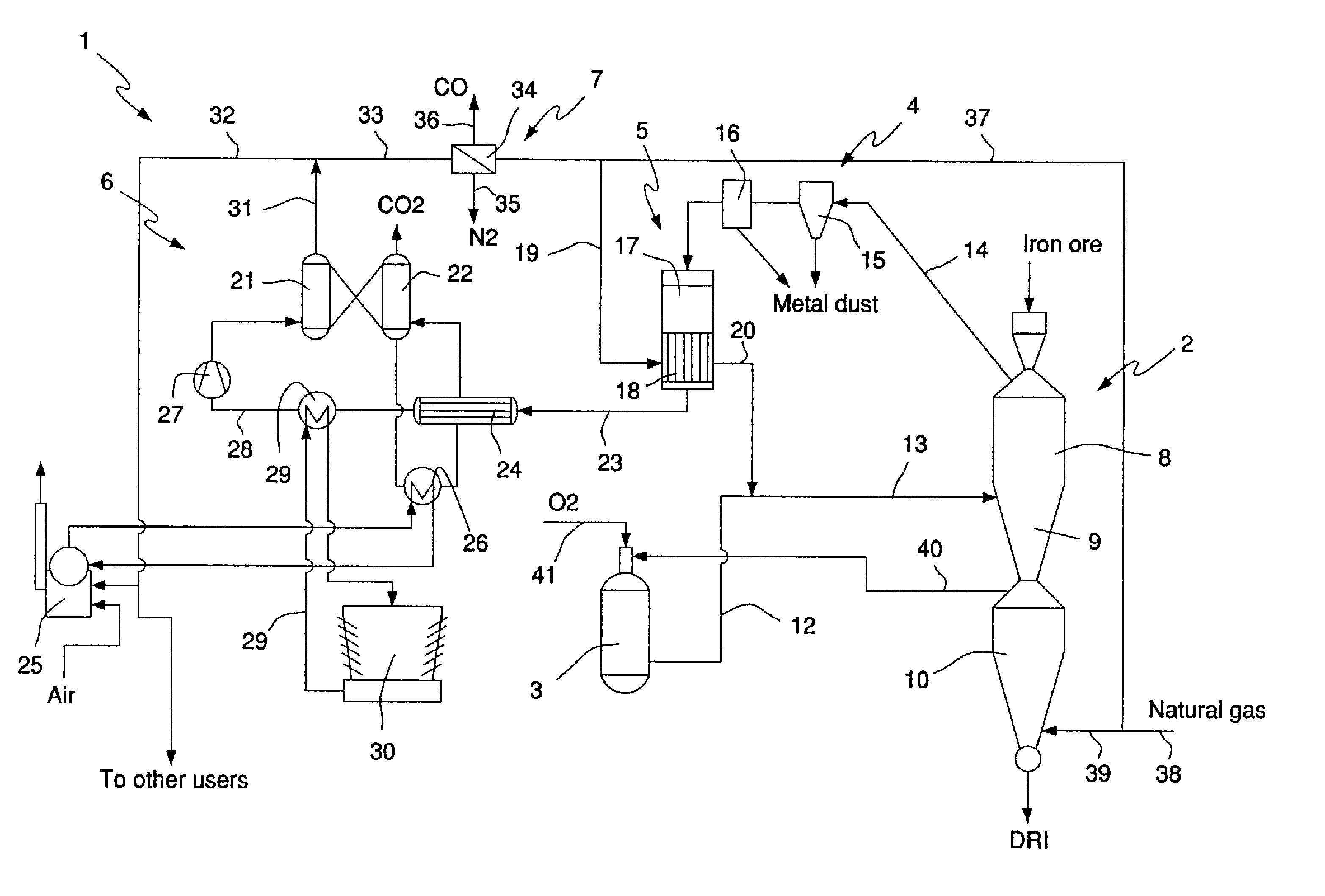

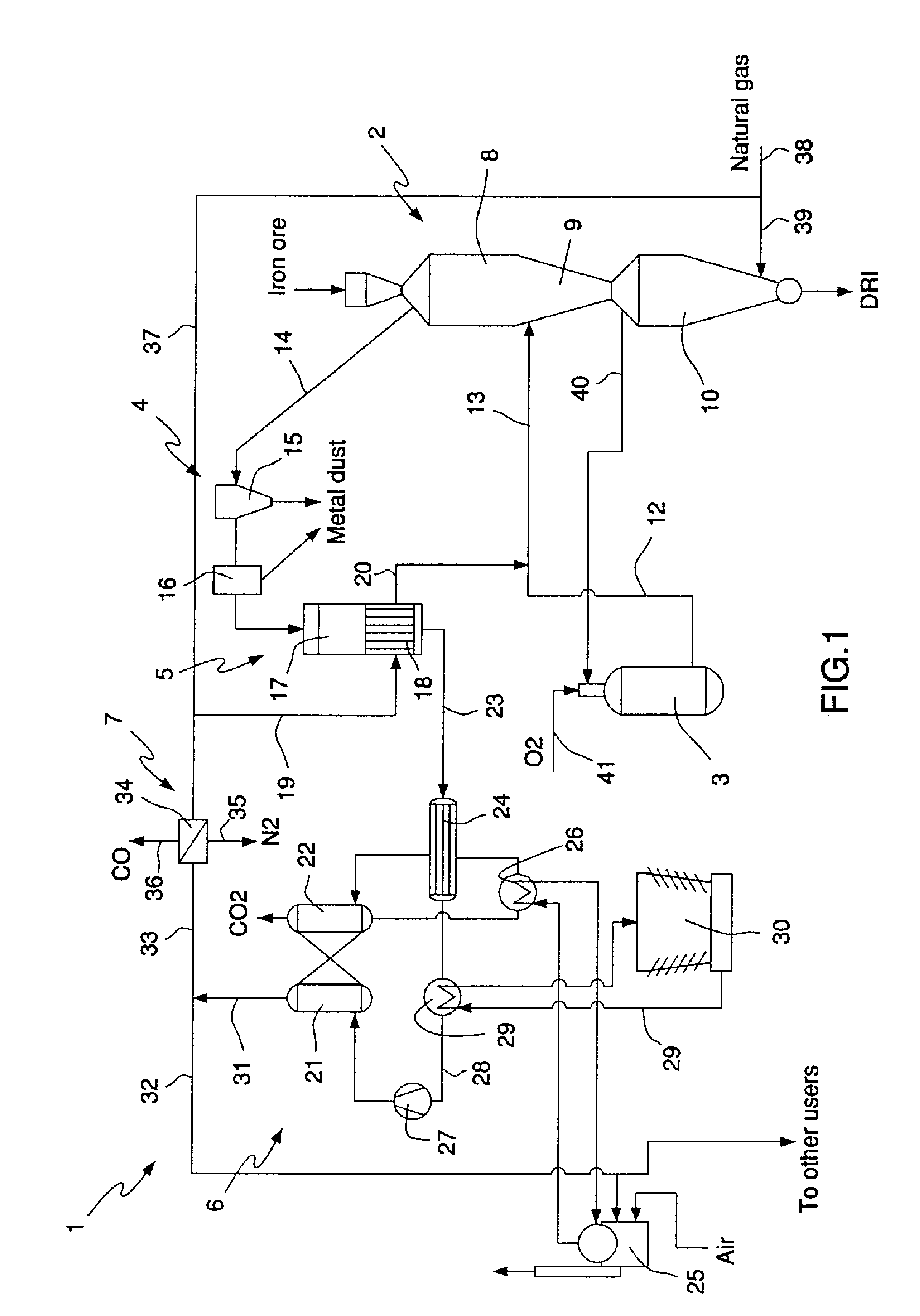

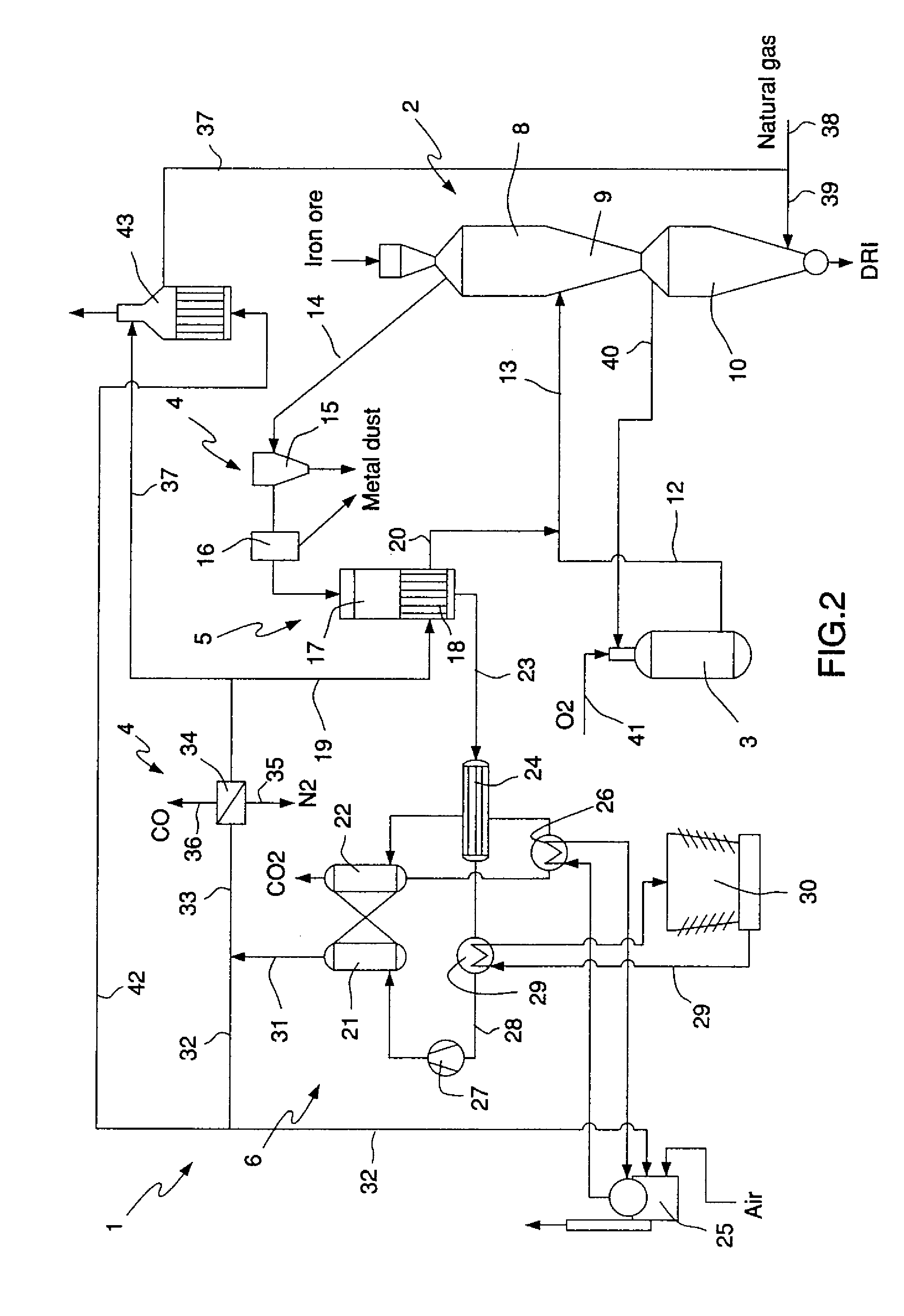

Process for production of direct reduced iron

The present invention relates to a process for the direct reduction of iron ore performed by means of a plant comprising a gravitational furnace (2) having at least one iron ore reduction zone (8) in the upper part thereof, and at least one carbon deposition zone (9) and one reduced metal product cooling zone (10) in the lower part thereof, and means for feeding a reducing gas mixture into the reactor in correspondence to the with the reduction zone, means for recycle exhaust or reactor off gas from the reactor to syngas and mixing the recycled gas with natural gas to form a reducing gas mixture. According to the invention a in first reformation step (5) unreacted carbon monoxide CO and steam present in the reactor off gas is reformed to carbon dioxide and hydrogen following the water gas shift reaction CO+H2O=CO2+H2, in a secondary reformation step the de-watered reactor off gas comprising mainly of carbon dioxide and hydrogen is processed to remove carbon dioxide, and in a third reformation step physical separation of both nitrogen and carbon oxide CO from the reducing syngas is carried out to bring down the levels of CO and any existing other gases in the recycled gas to as low level as possible such that recycled reducing gas is as close to pure hydrogen H2 as possible.

Owner:LOUSSAVAARA KIIRUNAVAORA AB

Preparation of lithium carbonate from lithium chloride containing brines

ActiveUS8741256B1Reduce concentrationMetal recyclingVarying alkali metal carbonate water contentLithium chlorideLithium hydroxide

This invention relates to a method for the preparation of lithium carbonate from lithium chloride containing brines. The method can include a silica removal step, capturing lithium chloride, recovering lithium chloride, supplying lithium chloride to an electrochemical cell and producing lithium hydroxide, contacting the lithium hydroxide with carbon dioxide to produce lithium carbonate.

Owner:TERRALITHIUM LLC

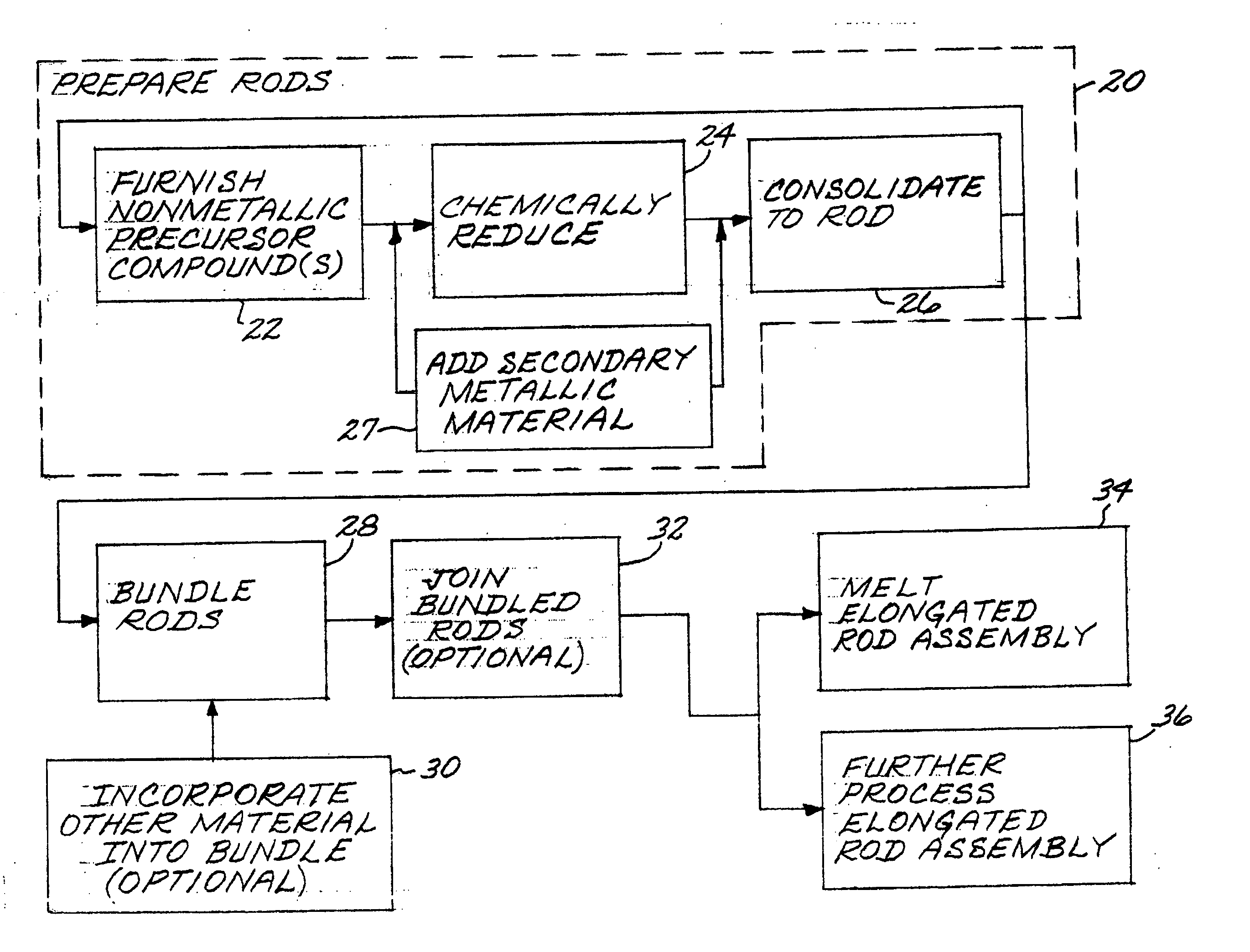

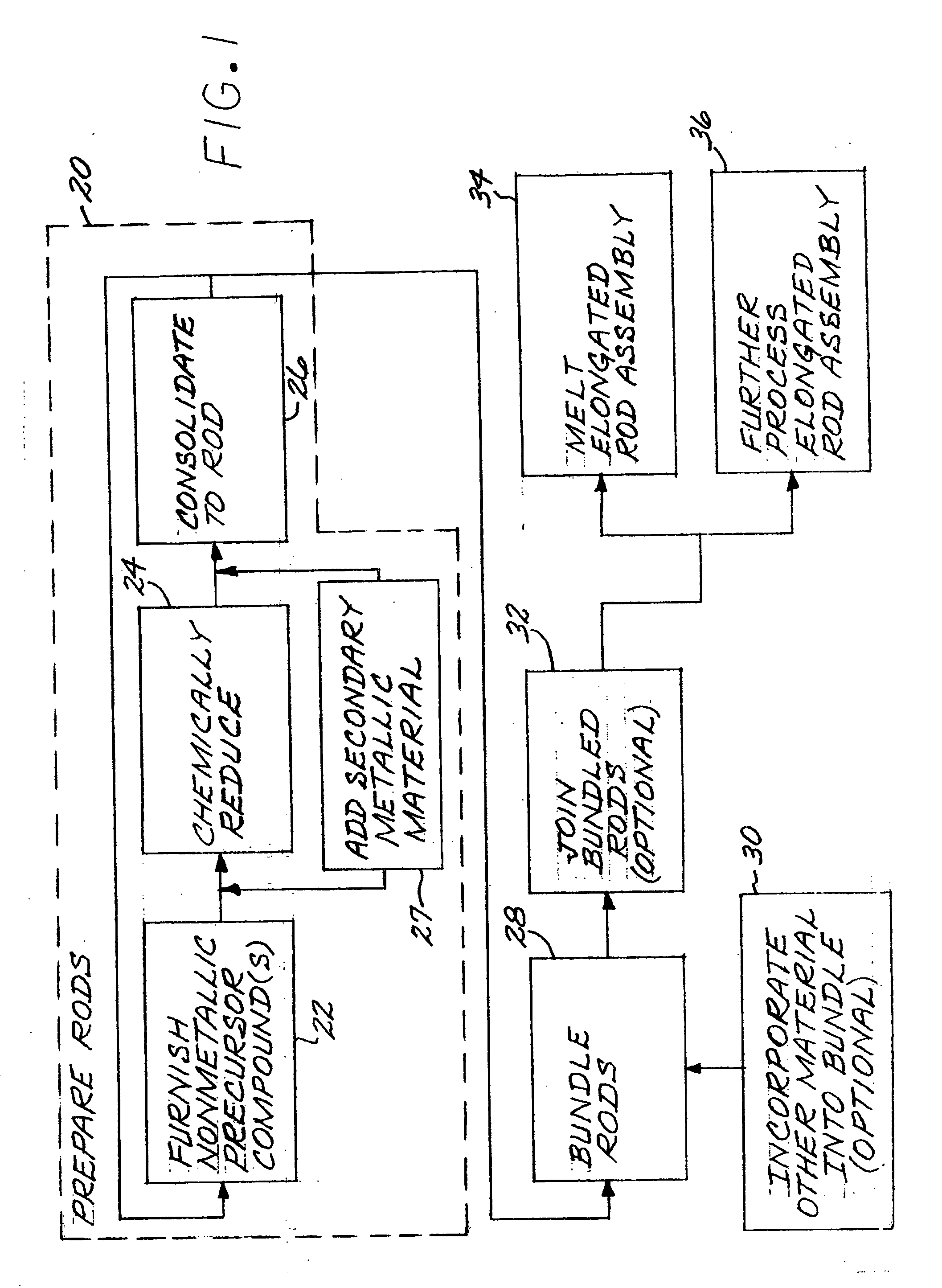

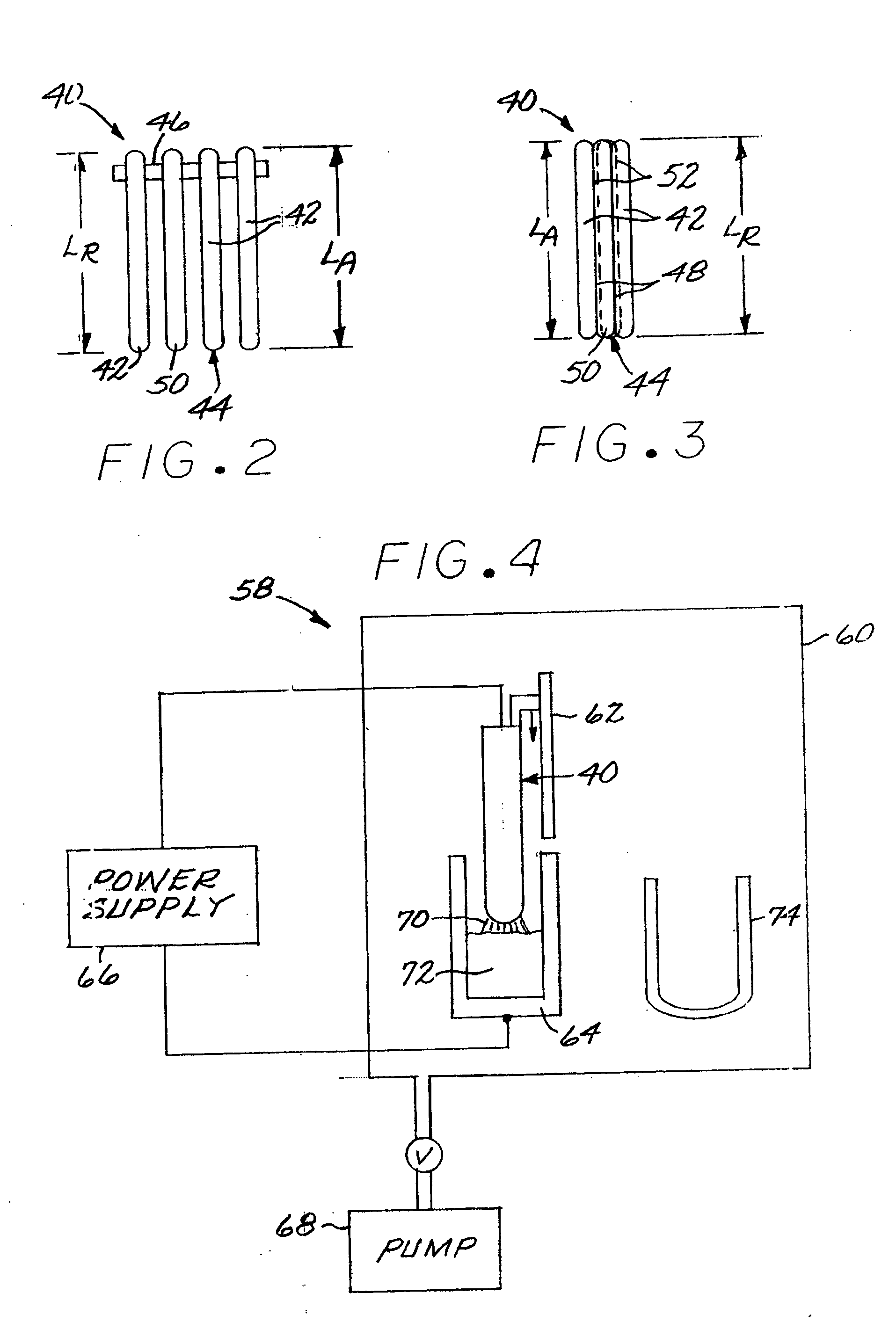

Method for making and using a rod assembly

InactiveUS20050223849A1Reduce the possibilityMetal recyclingRecovering materialsMetallic materialsCompound (substance)

An elongated rod assembly is made by preparing a plurality of rods. Each rod is prepared by the steps of furnishing at least one nonmetallic precursor compound, thereafter chemically reducing the precursor compounds to produce the metallic material, and thereafter consolidating the metallic material to form the rod, wherein the rod has a rod length equal to the assembly length. The rods are bundled together to form a bundled rod assembly. The rod assembly may be used as a consumable feedstock in a melting-and-casting operation.

Owner:GENERAL ELECTRIC CO

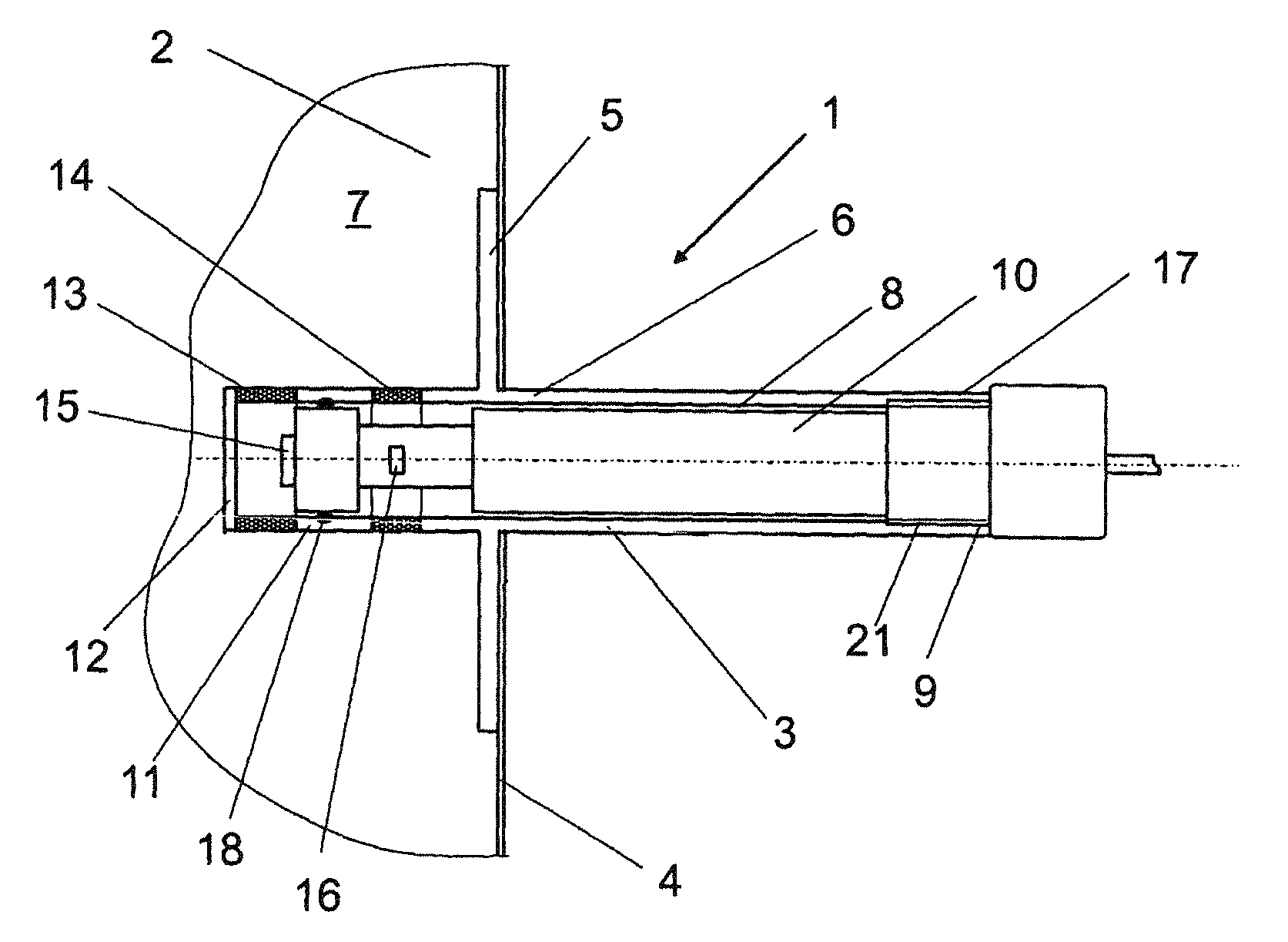

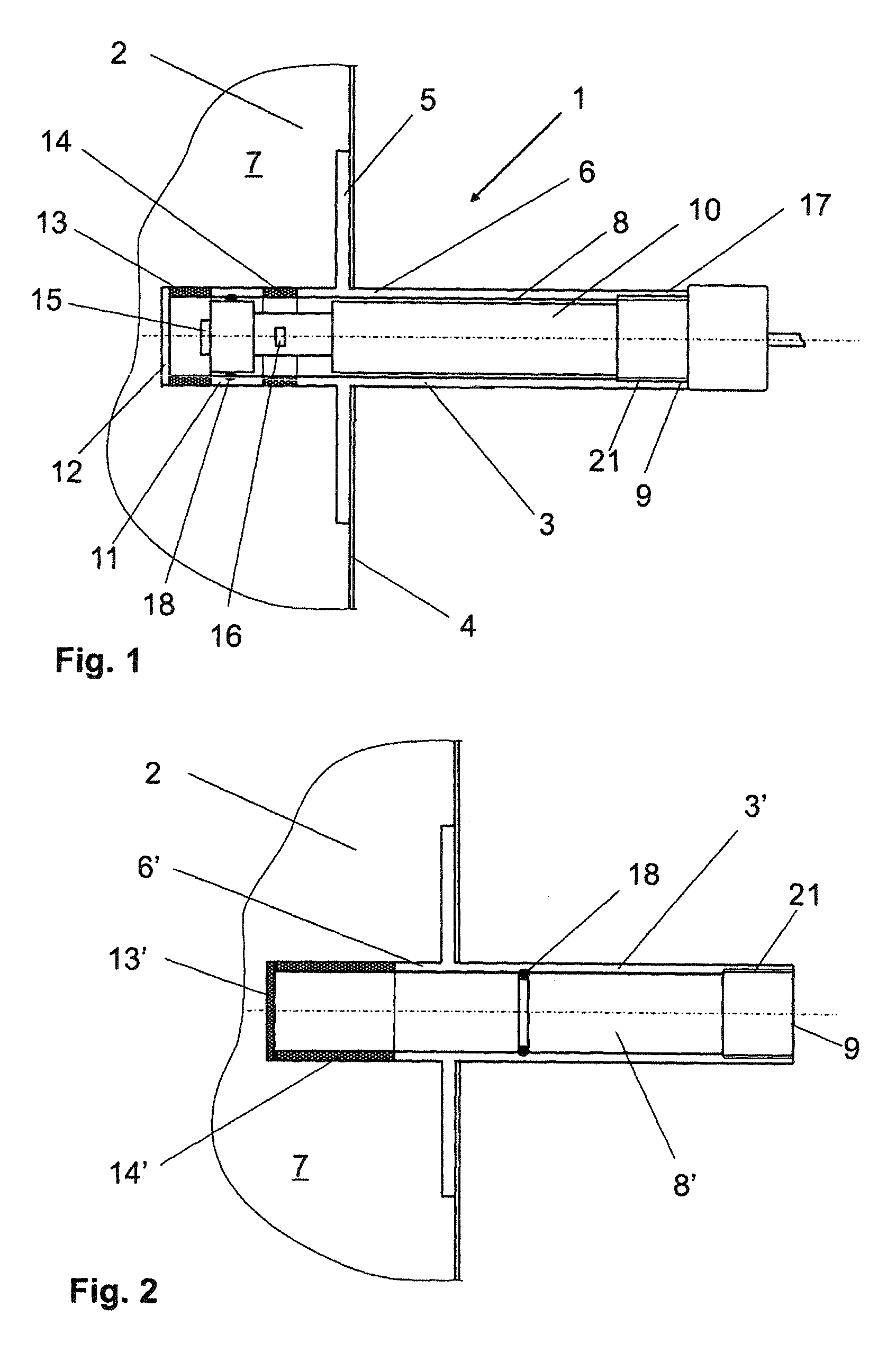

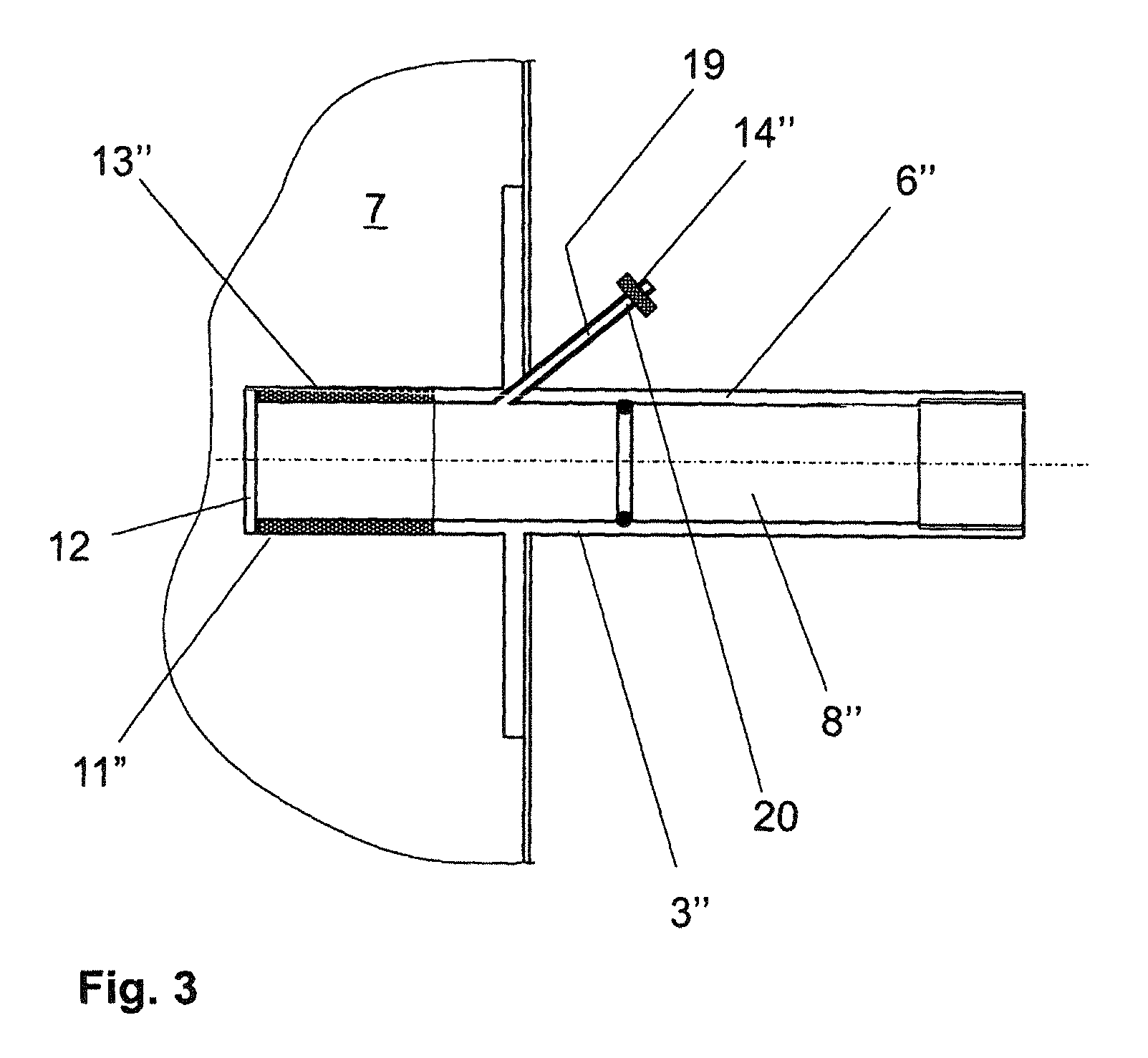

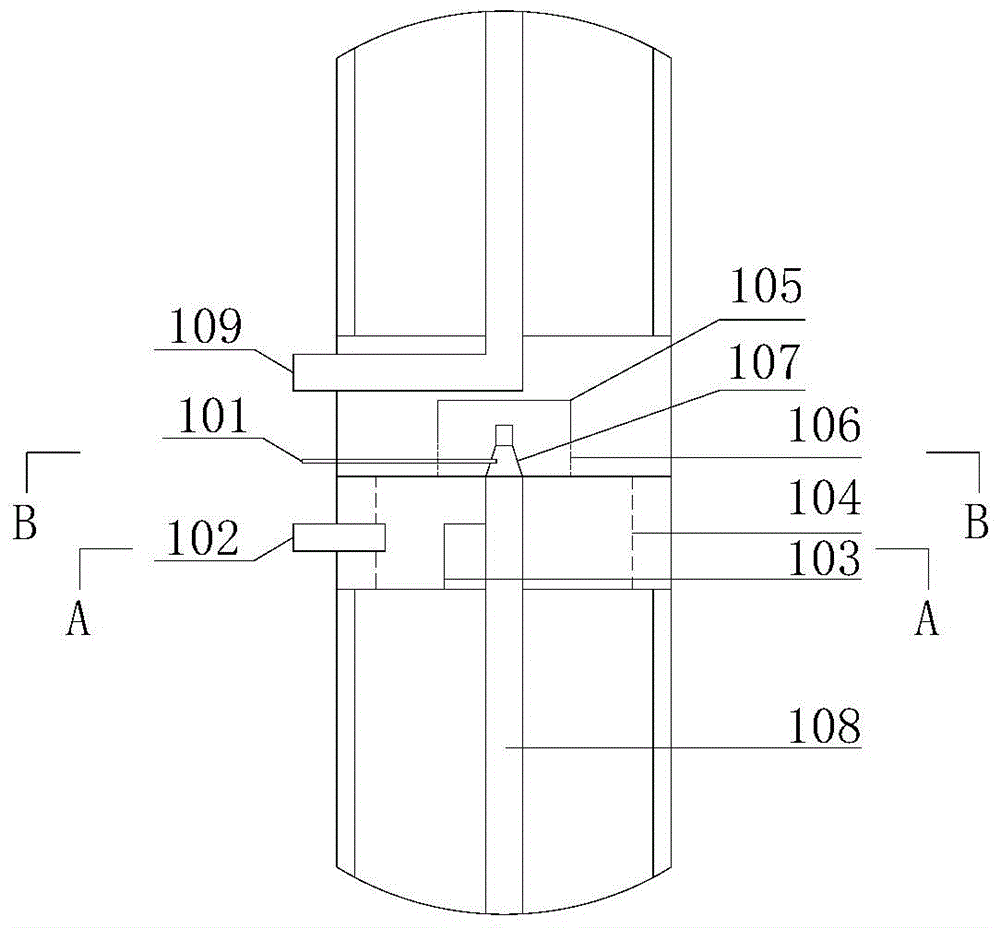

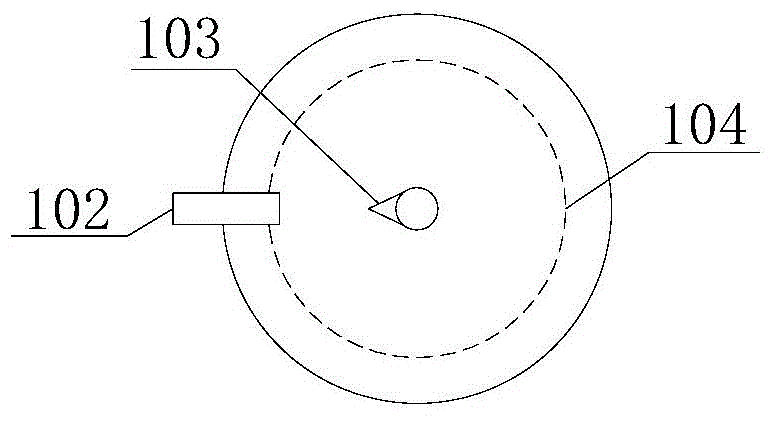

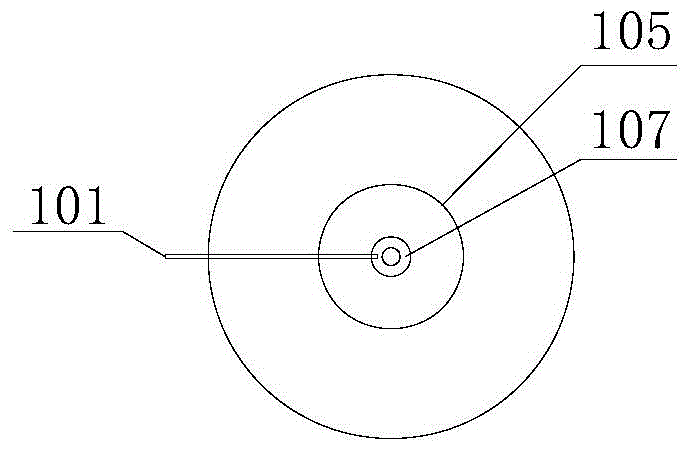

Container having a sensor adapter

ActiveUS9103703B2Avoid pollutionMetal recyclingMeasurement apparatus componentsElectrical and Electronics engineering

Owner:SARTORIUS STEDIM BIOTECH GMBH

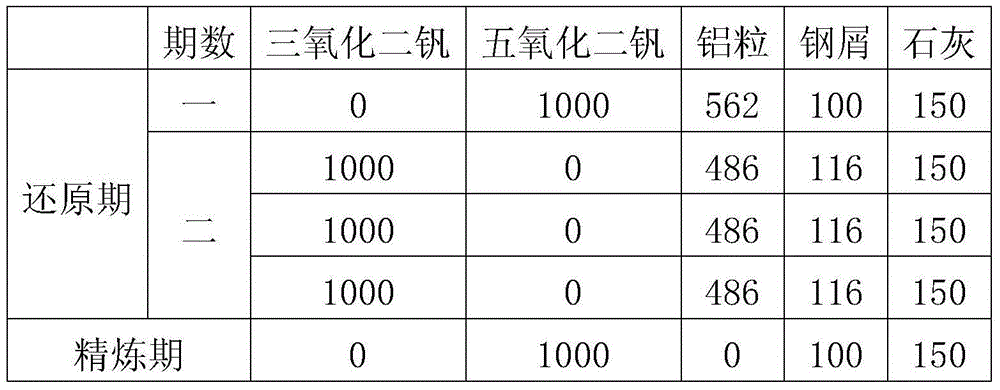

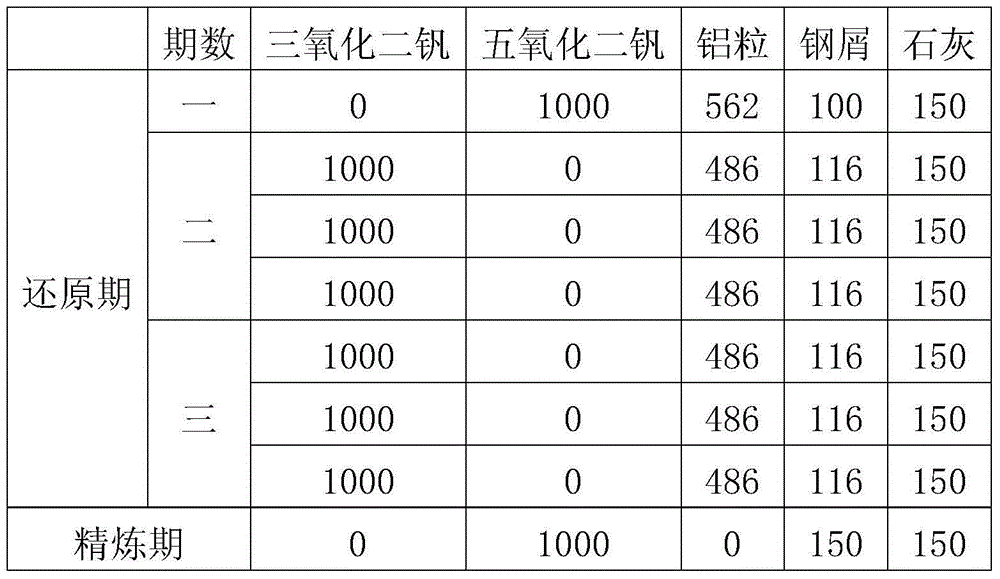

High vanadium ferroalloy smelting method

ActiveCN103757171BReduce coolingOvercoming difficult follow-up problemsMetal recyclingProcess efficiency improvementReduction treatmentElectric arc furnace

The invention discloses a high vanadium ferroalloy smelting method. The method comprises the steps of adding cold-state vanadium-rich slag and limestone to the bottom of an electric arc furnace, adding a phase-I mixture consisting of vanadium pentoxide, aluminum particles, limestone and steel cuttings and smelting; returning heat-state vanadium-enriched slag of last batch into the electric arc furnace and discharging slag when vanadium content in smelting slag is less than 0.5%; adding a phase-II mixture consisting of vanadium trioxide, aluminum particles, limestone and steel cuttings, smelting, discharging slag when vanadium content in smelting slag is less than 0.5%, and before discharging the slag, adding aluminum or aluminum-magnesium alloy for reduction treatment; adding a refining mixture consisting of vanadium pentoxide and limestone or iron scale and limestone, smelting, controlling temperature of vanadium-iron alloy liquid in the furnace to be above 1900 DEG C, discharging the vanadium-iron alloy liquid and the vanadium-enriched slag when vanadium content is 78-82% and aluminum content is less than 1.5% in the vanadium-iron alloy liquid, pouring the vanadium-iron alloy liquid into an ingot mould which is preheated to be above 500 DEG C, and cooling, demoulding and breaking to obtain high vanadium ferroalloy which contains more than 80% of vanadium.

Owner:攀钢集团西昌钒制品科技有限公司

Method of recovering rare-earth elements

ActiveUS9228248B2Improve leaching rateRaise the ratioMetal recyclingLanthanide oxides/hydroxidesRare-earth elementSlurry

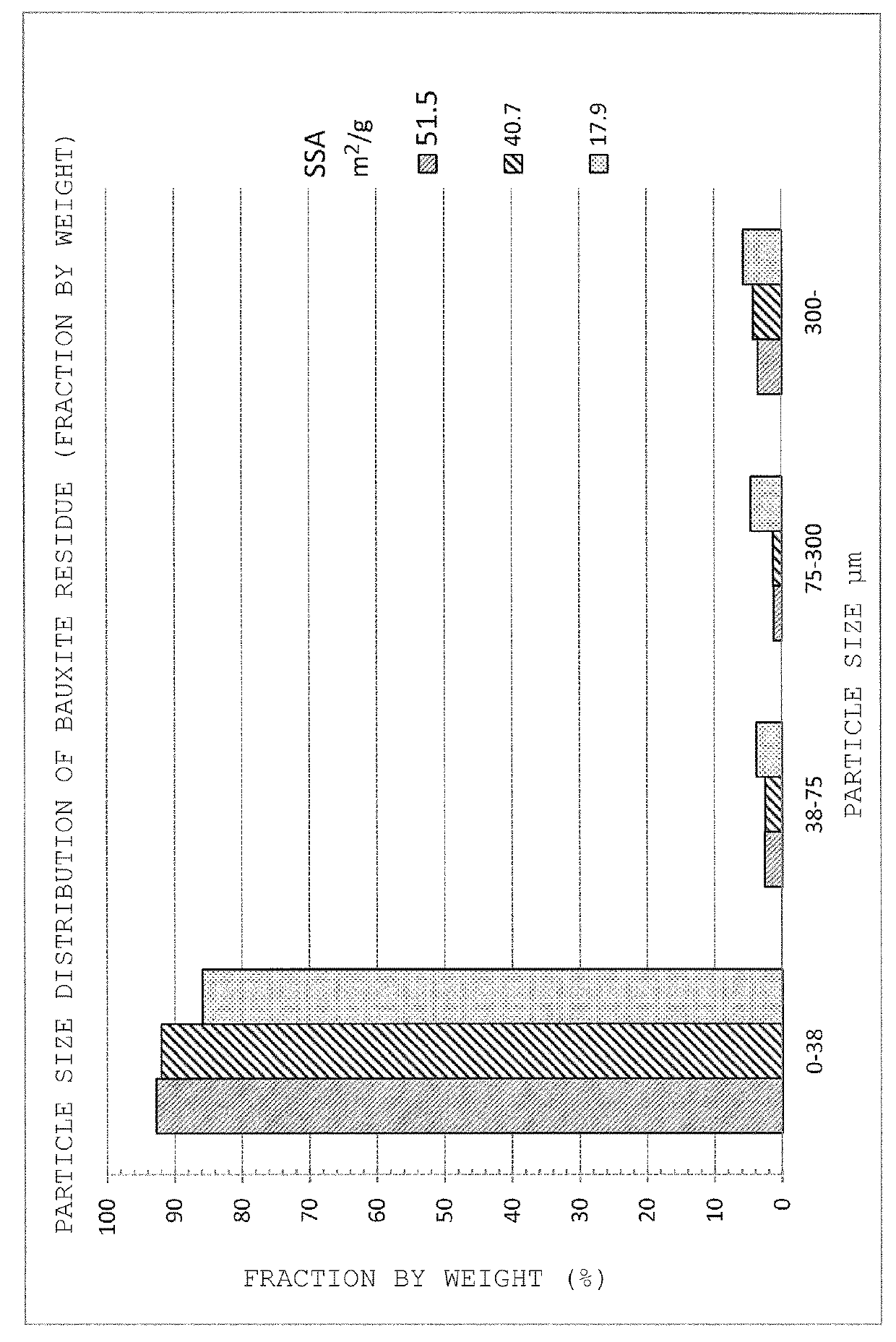

Provided is a method of recovering rare-earth elements by which rare-earth elements can be recovered efficiently from a bauxite residue serving as a raw material and containing the rare-earth elements. Specifically provided is a method of recovering rare-earth elements from a raw material, the raw material being a bauxite residue produced as a by-product in a Bayer process, the method including: using a bauxite residue having a specific surface area of 35 m2 / g or more; adding, to the raw material bauxite residue, a liquid leaching agent formed of an aqueous solution of at least one kind of mineral acid selected from sulfuric acid, hydrochloric acid, nitric acid, and sulfurous acid, thereby preparing a slurry having a liquid-solid ratio of 2 to 30 and a pH of 0.5 to 2.2; subjecting the slurry to leaching treatment of the rare-earth elements under a temperature condition of room temperature to 160° C.; subjecting the slurry after the leaching treatment to solid-liquid separation, yielding a leachate; and separating and recovering the rare-earth elements from the leachate.

Owner:NIPPON LIGHT METAL CO LTD

Method and device for treating steel slag

ActiveCN103757152BRealize comprehensive utilizationImprove recycling ratesMetal recyclingCement productionSlagClinker (waste)

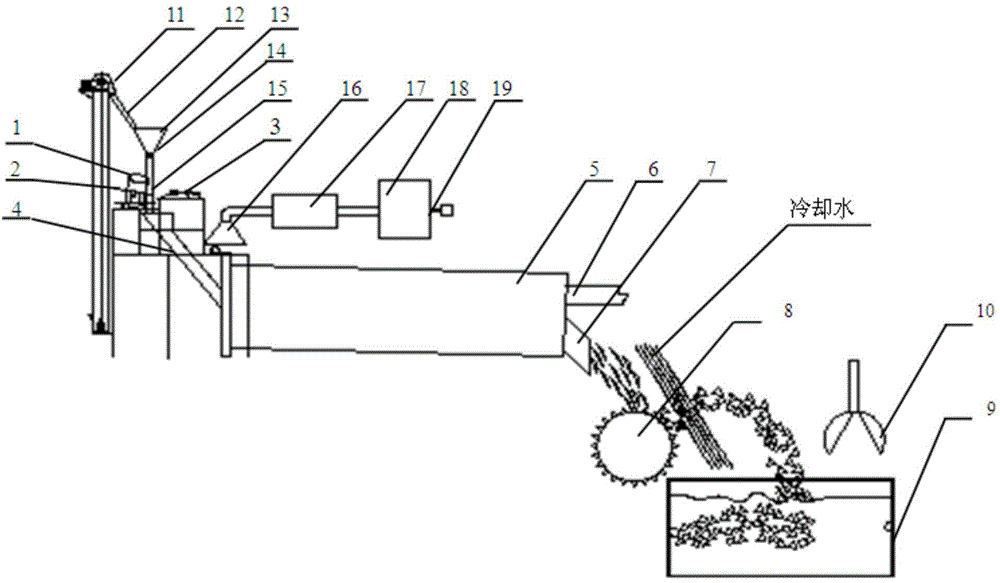

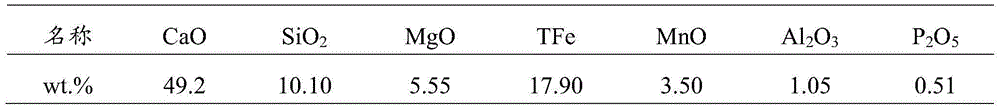

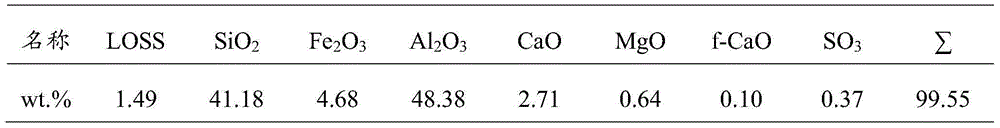

The invention provides a method for treating steel slag. The method comprises the steps of feeding silicon-aluminum acidic oxide and steel slag, wherein the total mole ratio of the silicon-aluminum acidic oxide to basic oxide in the mixture is 1:(2.5-2.9); heating and mixing the mixture in a rotary kiln in the presence of a reducing agent, wherein the temperature of the rotary kiln is 1350-1450 DEG C; granulating the product into particles, performing water quenching and cooling, then falling the particles into water, and performing dehydration; and performing magnetic separation on the dehydrated particles to ensure that steel particles are separated from series silicate particles. The invention also provides a device for treating the steel slag, and the device comprises a rotary kiln (5), a coal spraying device (6) which is arranged at the upper end of the tail of the rotary kiln (5), and a granulation wheel (8) which is arranged below a discharge chute (7) in the lower end of the tail of the rotary kiln (5). The series silicates obtained after the treatment of the steel slag by adopting the method disclosed by the invention can replace a silicate cement clinker to produce cement. The method disclosed by the invention realizes comprehensive utilization of industrial wastes.

Owner:BERIS ENG & RES CORP

An integrated desulfurization, denitrification and demercuration flue gas purification system and purification process

ActiveCN104014231BLow investment costSmall footprintMetal recyclingDispersed particle separationFlue gasSulfur

The invention relates to a smoke gas purification system with an integrated function of desulfuration, denitration and demercuration and a purification process, which are used for treating SOX, NOX and Hg in smoke gas and recycling sulphur and Hg in smoke gas. A uniform gas distribution plate and a flow guide plate are arranged at a smoke gas inlet in the middle of an adsorption tower, a contracting nozzle structure of a central flow collection pipe outlet in the lower section of the adsorption tower is connected with an NH3 inlet, and by the structure improvement, the adsorption tower has the advantages of uniform distribution and mixing of gas, and the smoke gas purification efficiency and the utilization rate of active coke are also improved. Due to a ring-shaped partition plate gas extracting structure of an active coke regeneration tower, no residue is formed in the tower when the regeneration tower desorbs gas; meanwhile, a mercury capturing device is arranged outside the active coke regeneration tower. The characteristic of low content of mercury in smoke gas is taken into account in the smoke gas purification process, active coke is designed for gathering Hg till Hg is saturated and then is regenerated by an acid washing method, and Hg is recycled or subjected to refilling. The smoke gas purification system has the advantages of simultaneous removal of various pollutants, good effect of uniformly distributing smoke gas and high utilization rates of heat energy and by-products, and complete gas exhaust of the regeneration tower is guaranteed.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

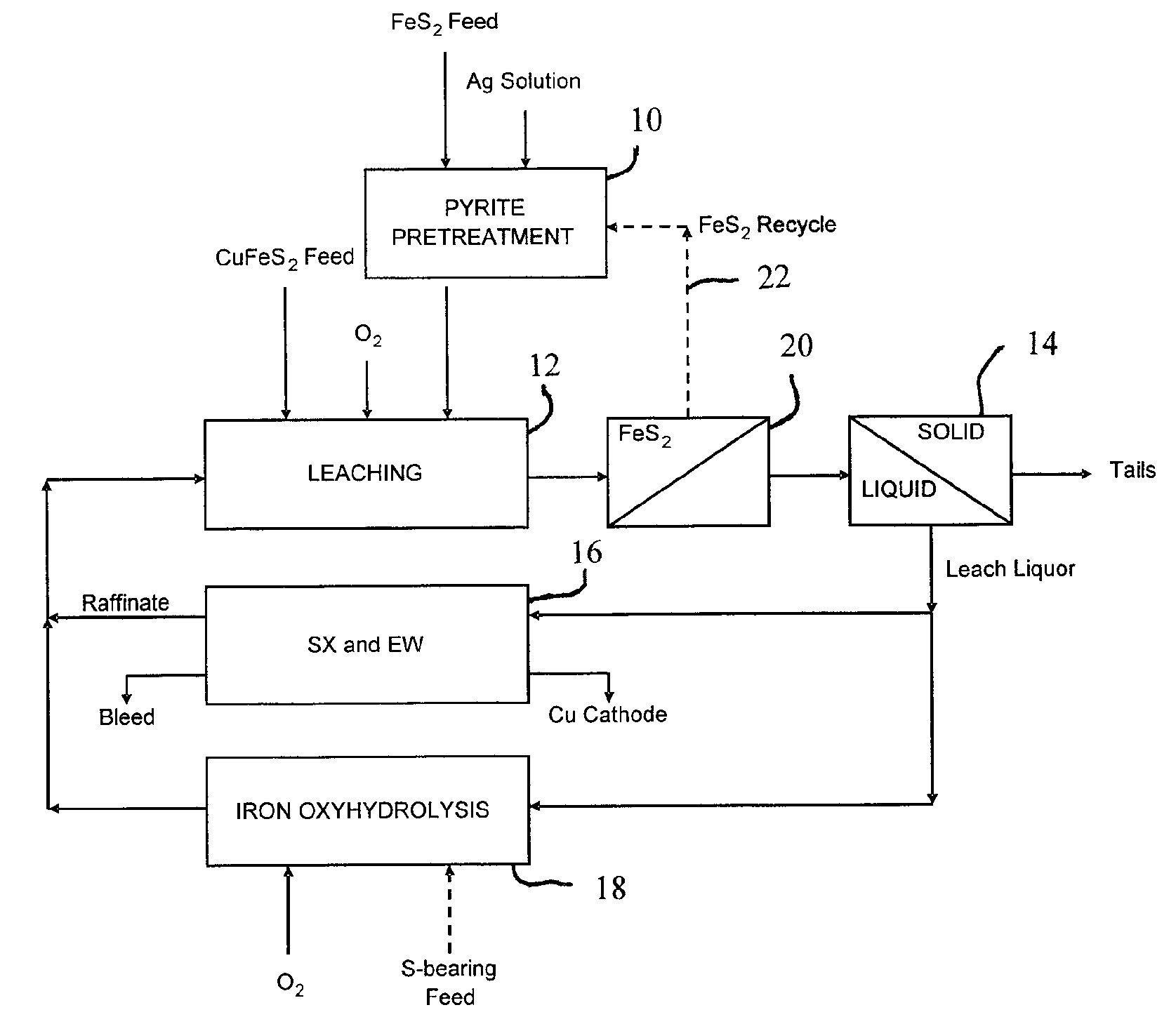

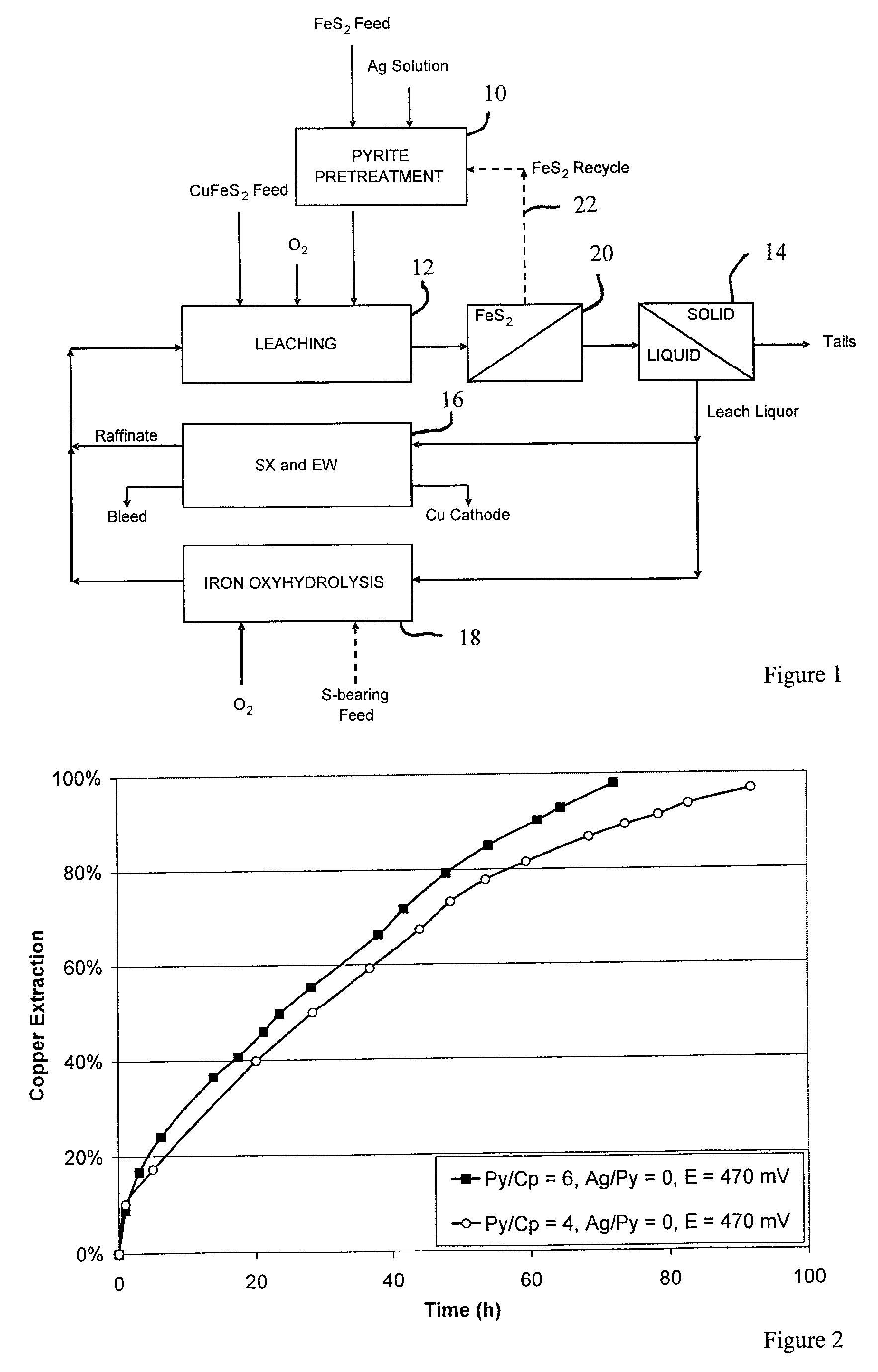

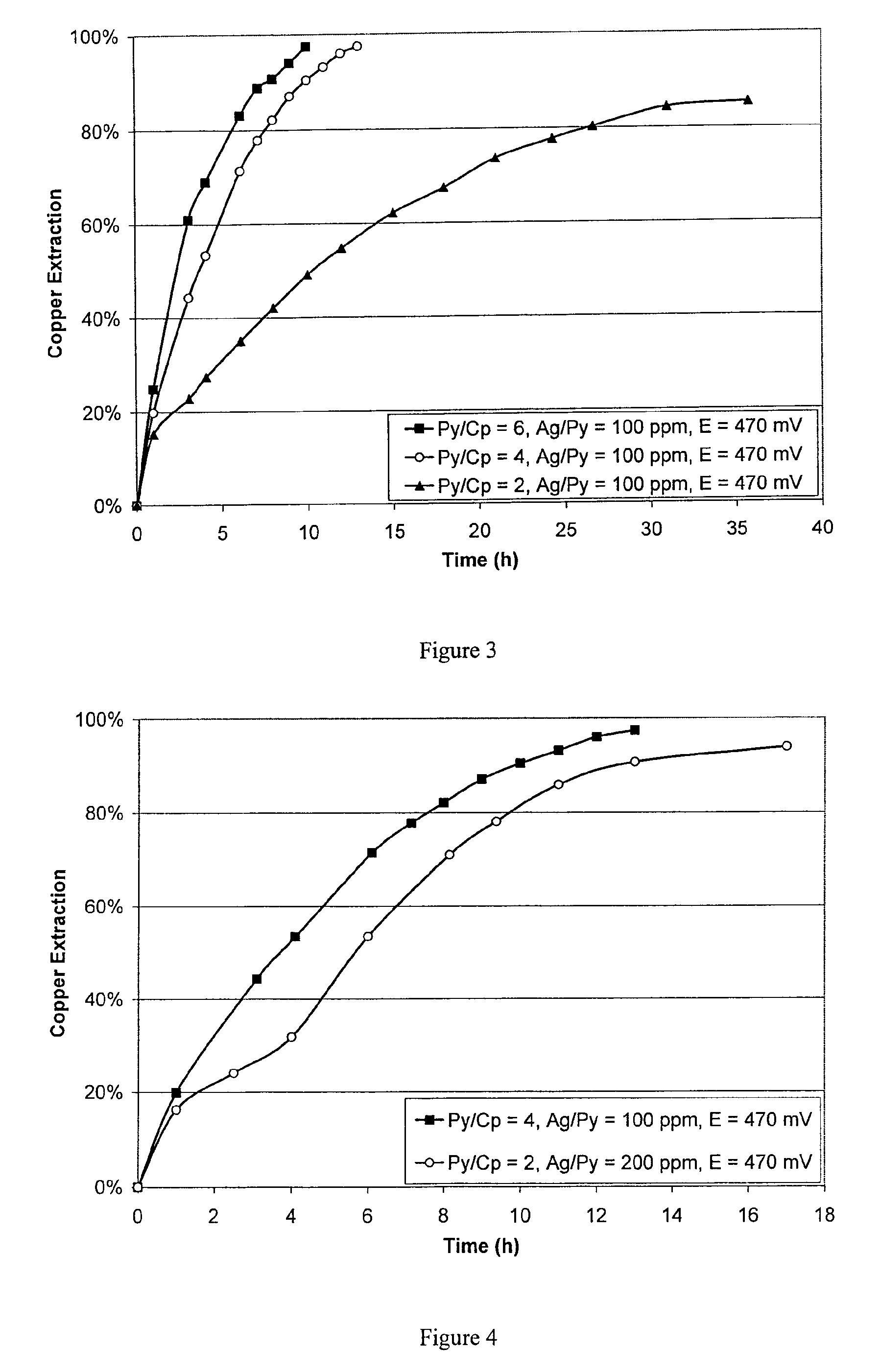

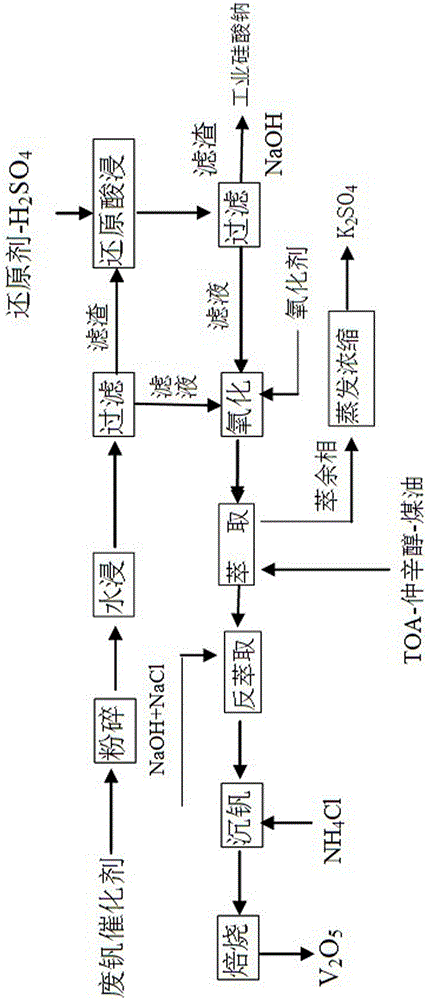

Leaching process for copper concentrates containing chalcopyrite

ActiveUS8795612B2Improve catalytic performanceMetal recyclingPhotography auxillary processesParticulatesChalcopyrite

A method of recovering copper from chalcopyrite concentrate by chemical leaching, using pyrite and silver. The catalytic properties of pyrite in the chalcopyrite leaching process are significantly enhanced by pretreating the pyrite with silver ions. Particulate pyrite is exposed to a solution containing silver ions to form silver-treated pyrite. Particulate chalcopyrite and the silver-treated pyrite are mixed in an acidic sulfate leach solution. The copper is leached from the concentrate in the leach solution in the presence of an oxygen-containing gas, under conditions whereby the pyrite is substantially unoxidized. The leached copper is recovered from the solution by conventional methods. The used silver-treated pyrite is recycled to the leaching process.

Owner:THE UNIV OF BRITISH COLUMBIA

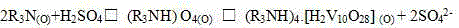

Recovery method of vanadium potassium silicon in waste vanadium catalyst

InactiveCN103789550BGood choiceLarge distribution ratioMetal recyclingAlkali metal silicatesSlagMetal impurities

The invention discloses a method for recovering vanadium, potassium and silicon from a waste vanadium catalyst. The method comprises the following steps: firstly, leaching the waste vanadium catalyst in water, and leaching in a reductic acid, wherein the total leaching rate of vanadium is greater than or equal to 95.0%, separating the silicon from vanadium and potassium transferred to a leaching solution in a form of a leaching slag; preparing liquid sodium silicate to recover silicon from the leaching slag by alkali dissolution; separating the vanadium from potassium in the leaching solution in an extraction manner; preparing potassium sulphate to recover potassium from a raffinate phase in an evaporative crystallization manner; and preparing vanadium pentoxide from an extract phase by the procedures of re-extraction, molybdenum precipitation, calcination and the like. Meanwhile, the vanadium in the extract phase and the raffinate phase is larger in distribution ratio, and does not react with other metal impurities such as iron and the like due to excellent selectivity of an extraction agent TOA on vanadium, other metal impurity ions such as iron and the like do not need to be removed in advance, and the vanadium can be directly extracted. Thus, a part of edulcoration procedures are reduced, the raw material consumption is saved, and a high-purity product of vanadium can be directly prepared. By adopting the method disclosed by the invention, not only can the vanadium, potassium and silicon in the waste vanadium catalyst be comprehensively recovered, but also the targets of turning the waste into treasure and protecting the environment are achieved.

Owner:KAIFENG UNIV

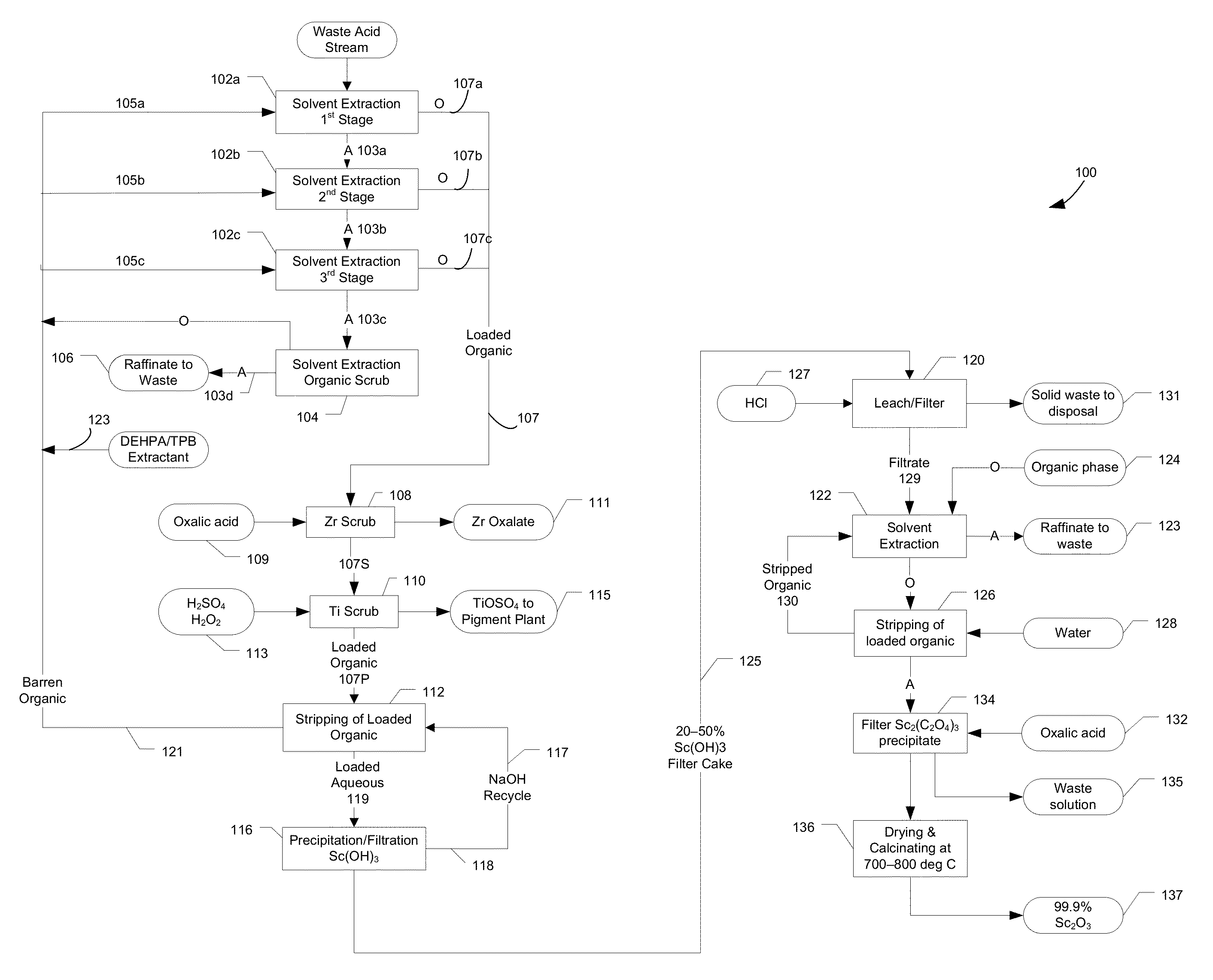

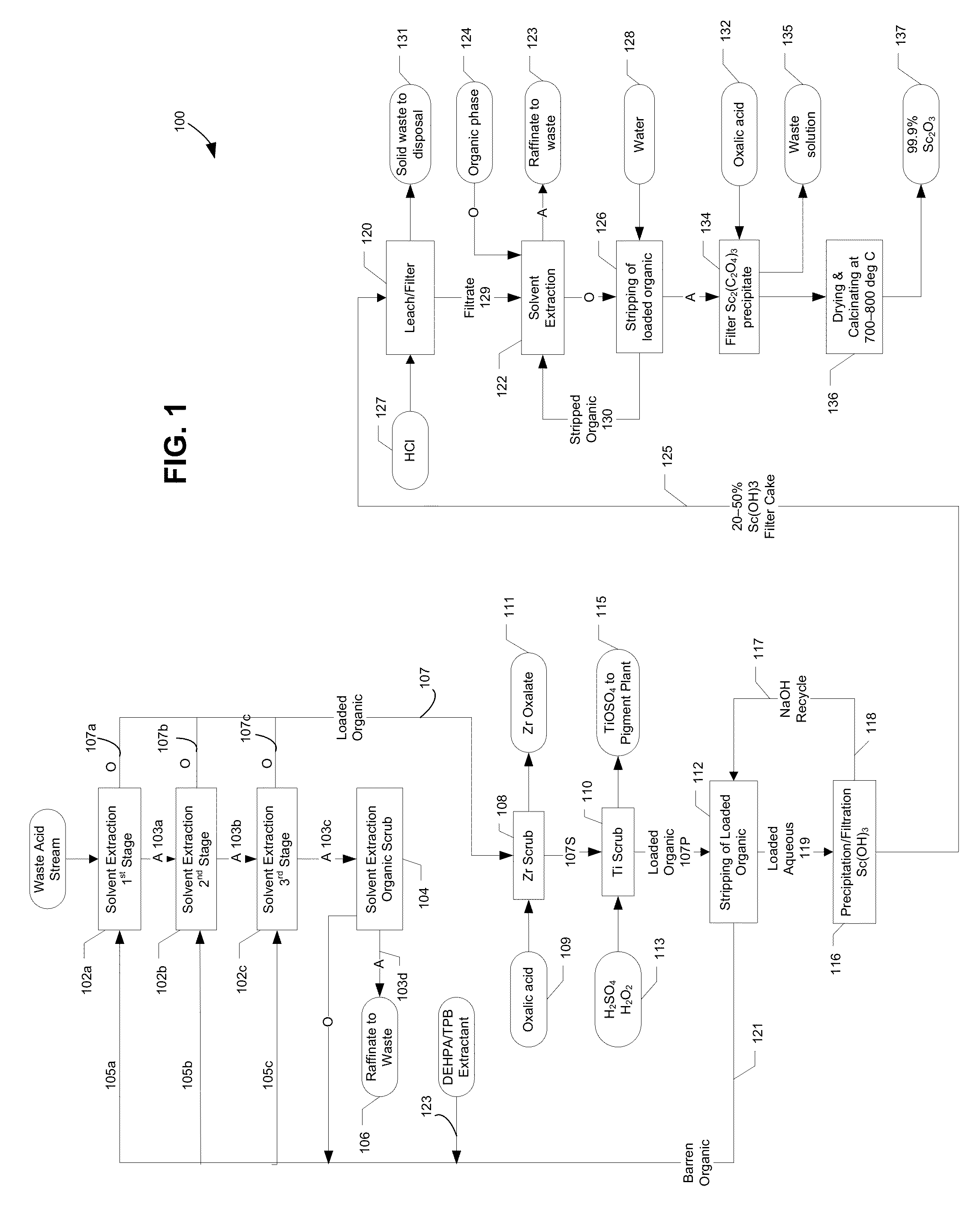

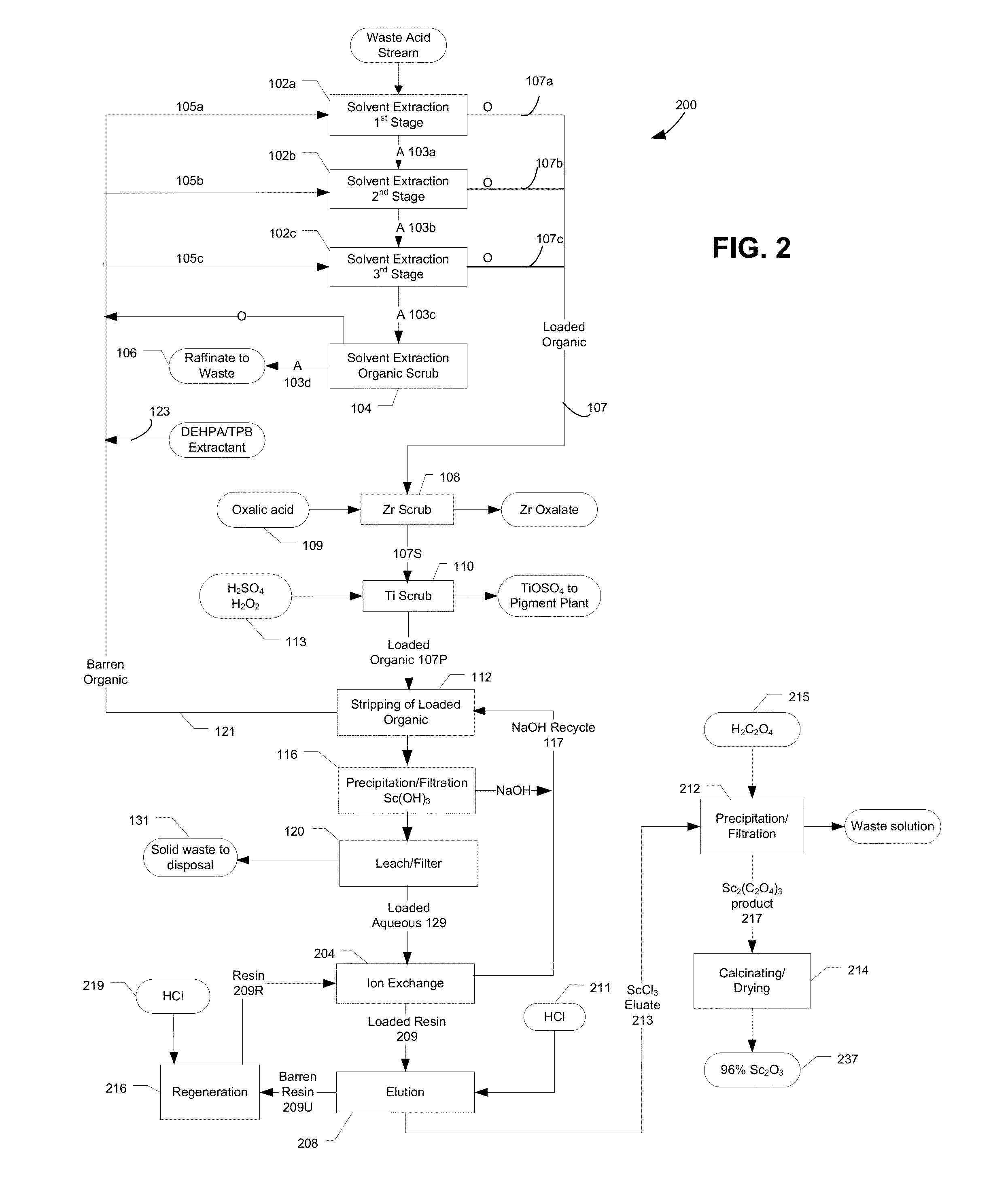

Methods of recovering scandium from titanium residue streams

A method for selectively removing scandium from a scandium-containing feed solution includes contacting the scandium-containing feed solution with a solvent stream in plural stages using cross current extraction, in which the solvent is loaded with at least a portion of the scandium from the feed solution, and / or ion exchange, and separating the loaded solvent from remaining scandium-containing feed solution.

Owner:BLOOM ENERGY CORP

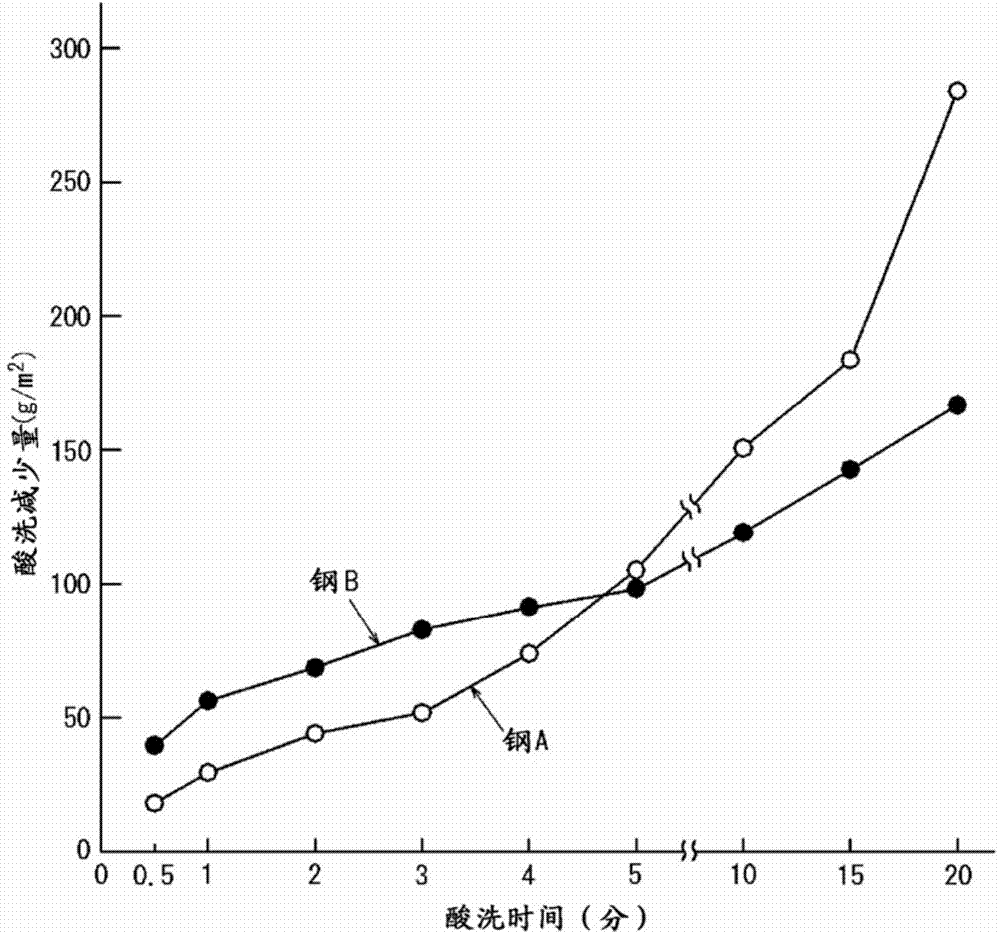

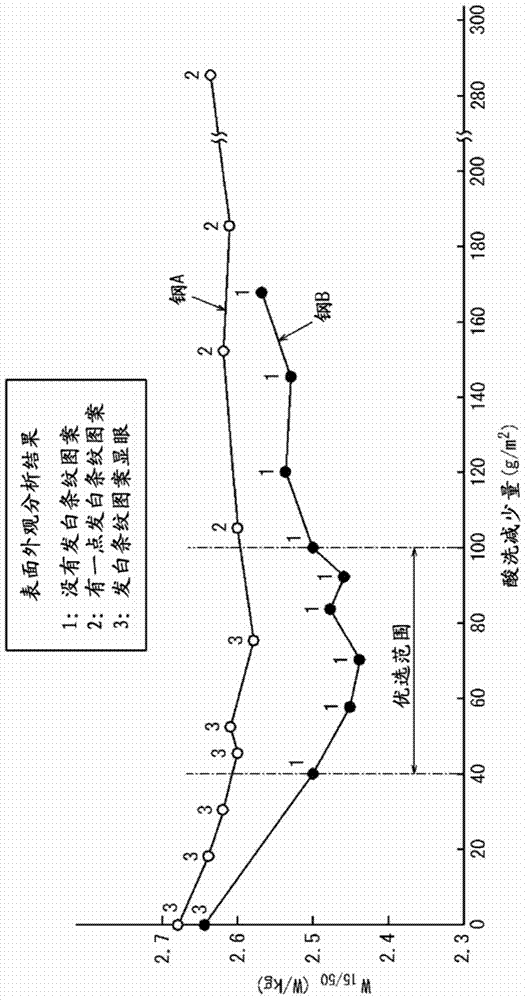

Hot-rolled steel sheet for production of non-oriented magnetic steel sheet and process for manufacturing same

ActiveCN104781435ABeautiful appearanceHigh magnetic flux density aesthetics with beautiful surface appearanceMetal recyclingInorganic material magnetismSheet steelNitrogen atmosphere

According to the present invention, the pickling weight loss of a hot-rolled steel sheet having a prescribed composition is adjusted to 40 to 100g / m2 as determined after subjecting the hot-rolled steel sheet to annealing at 1000ºC for 30sec in a nitrogen atmosphere and then immersion in a 7% HCl solution at 80ºC for 60sec. Thus, a hot-rolled steel sheet which is for use in producing a nonoriented magnetic steel sheet and which exhibits not only excellent magnetic characteristics such as iron loss and magnetic flux density but also excellent recyclability and sheet surface appearance can be obtained.

Owner:JFE STEEL CORP

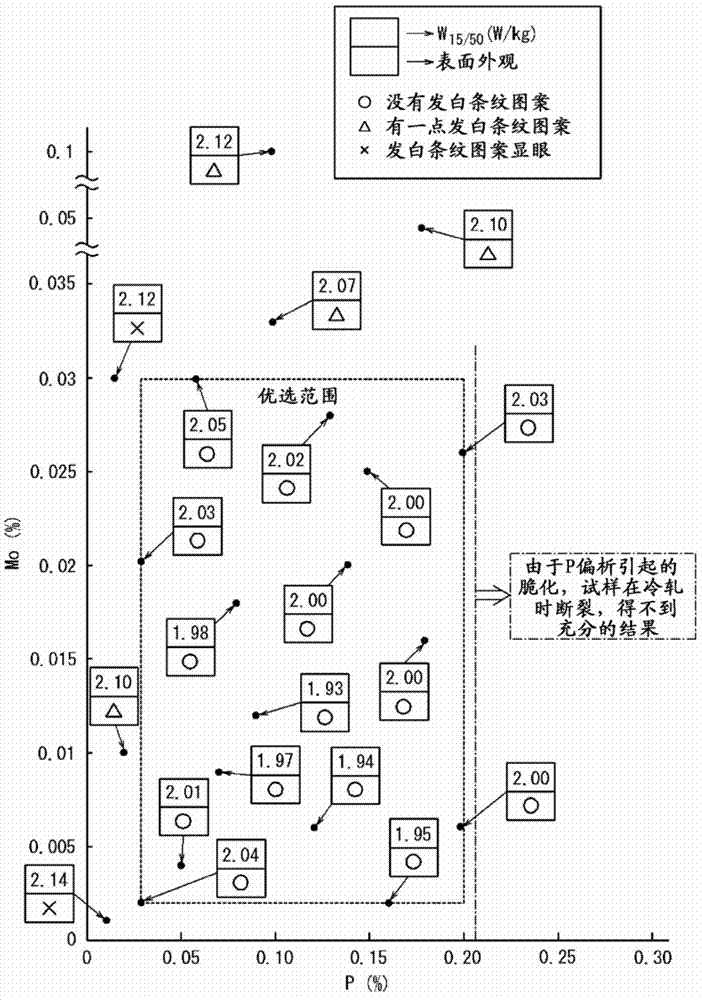

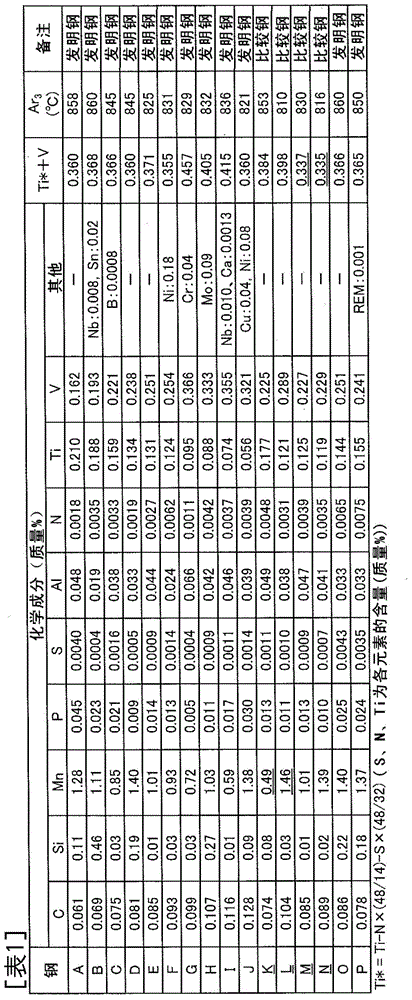

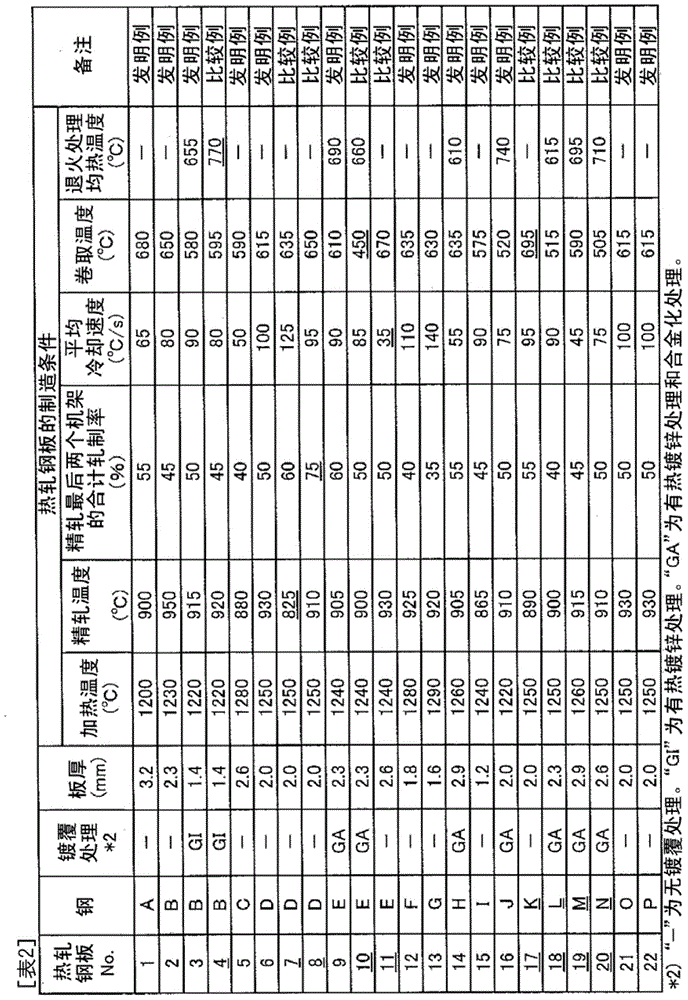

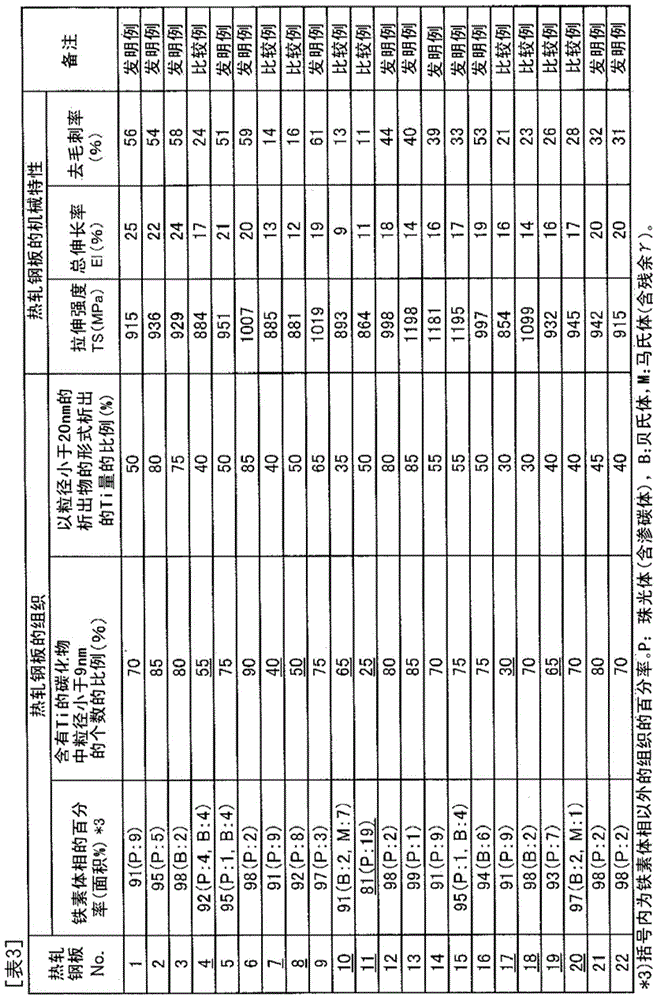

High-strength hot-rolled steel sheet and production method thereof

ActiveCN104968819AHelps to reduce weightExcellent deburring processabilityMetal recyclingHot-dipping/immersion processesCarbidePhase fraction

A high-strength hot-rolled steel sheet with excellent burring workability, and a production method thereof are provided. This high-strength hot-rolled steel sheet with excellent burring workability has a composition which includes, in mass%, C: 0.06%-0.13%, Si: less than 0.5%, Mn: greater than 0.5% and less than or equal to 1.4%, P: 0.05% or less, S: 0.005% or less, N: 0.01% or less, Al: 0.1% or less, Ti: 0.05%-0.25% and V: greater than 0.15% and less than or equal to 0.4%, such that S, N, Ti and V satisfy Ti* + V ≧ 0.35 (here, Ti*=Ti-N×(48 / 14)-S×(48 / 32), and S, N, Ti and V represent the content (in mass%) of each element), with the remainder consisting of Fe and unavoidable impurities, and is of a material in which the ferrite phase fraction exceeds 90%, carbides containing Ti are precipitated, and 70% or more of said carbides have a particle diameter of less than 9nm.

Owner:JFE STEEL CORP

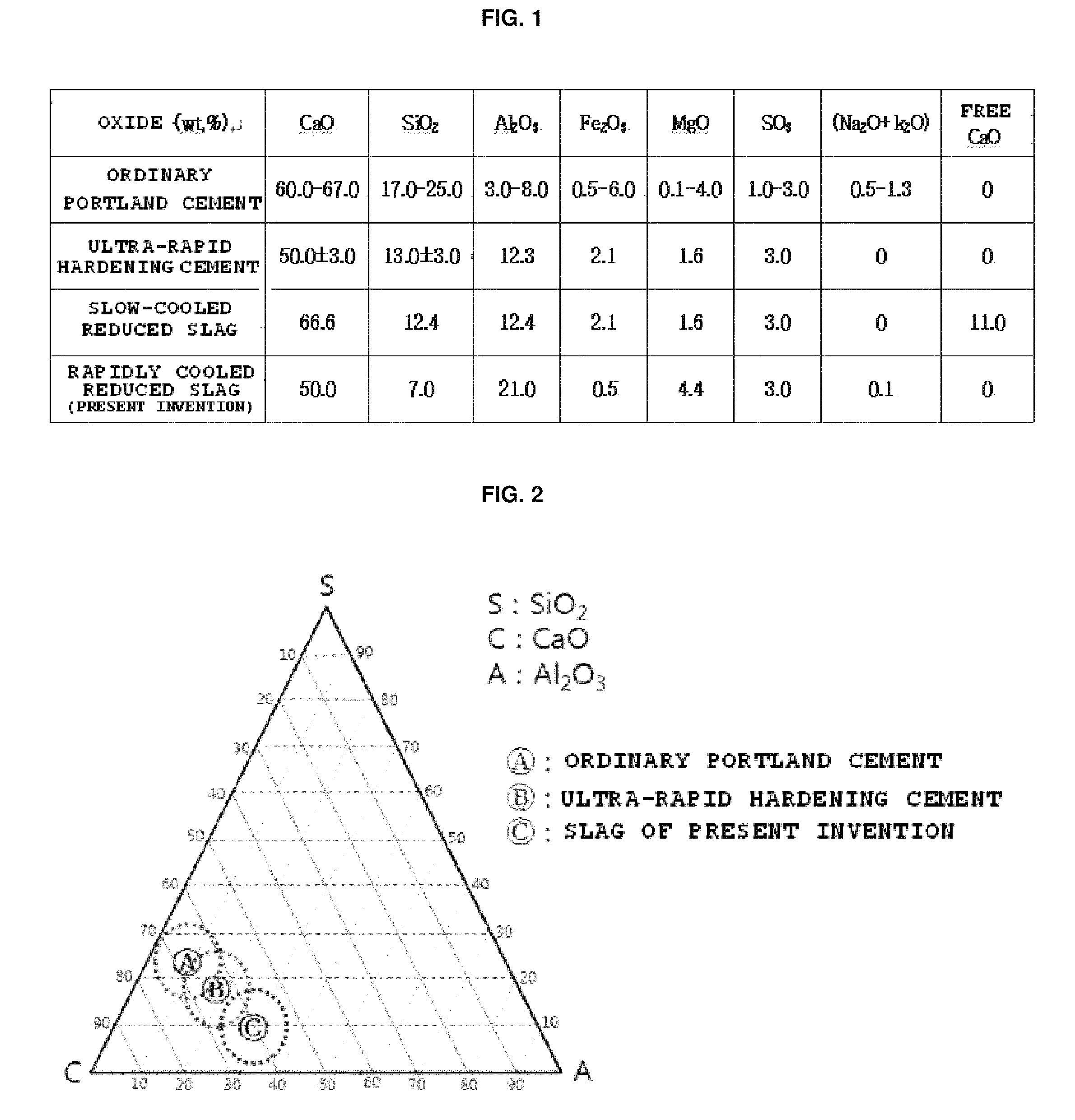

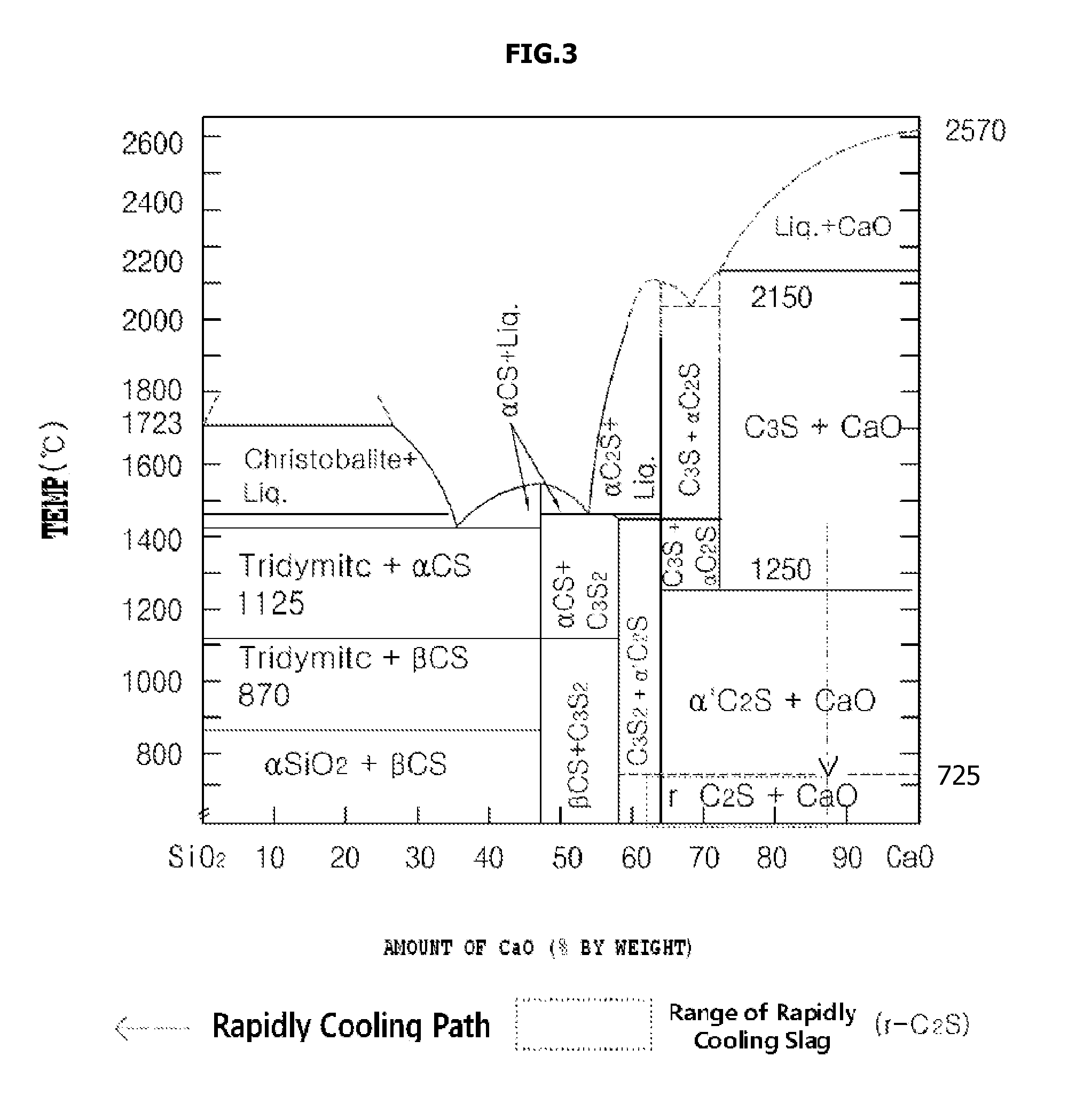

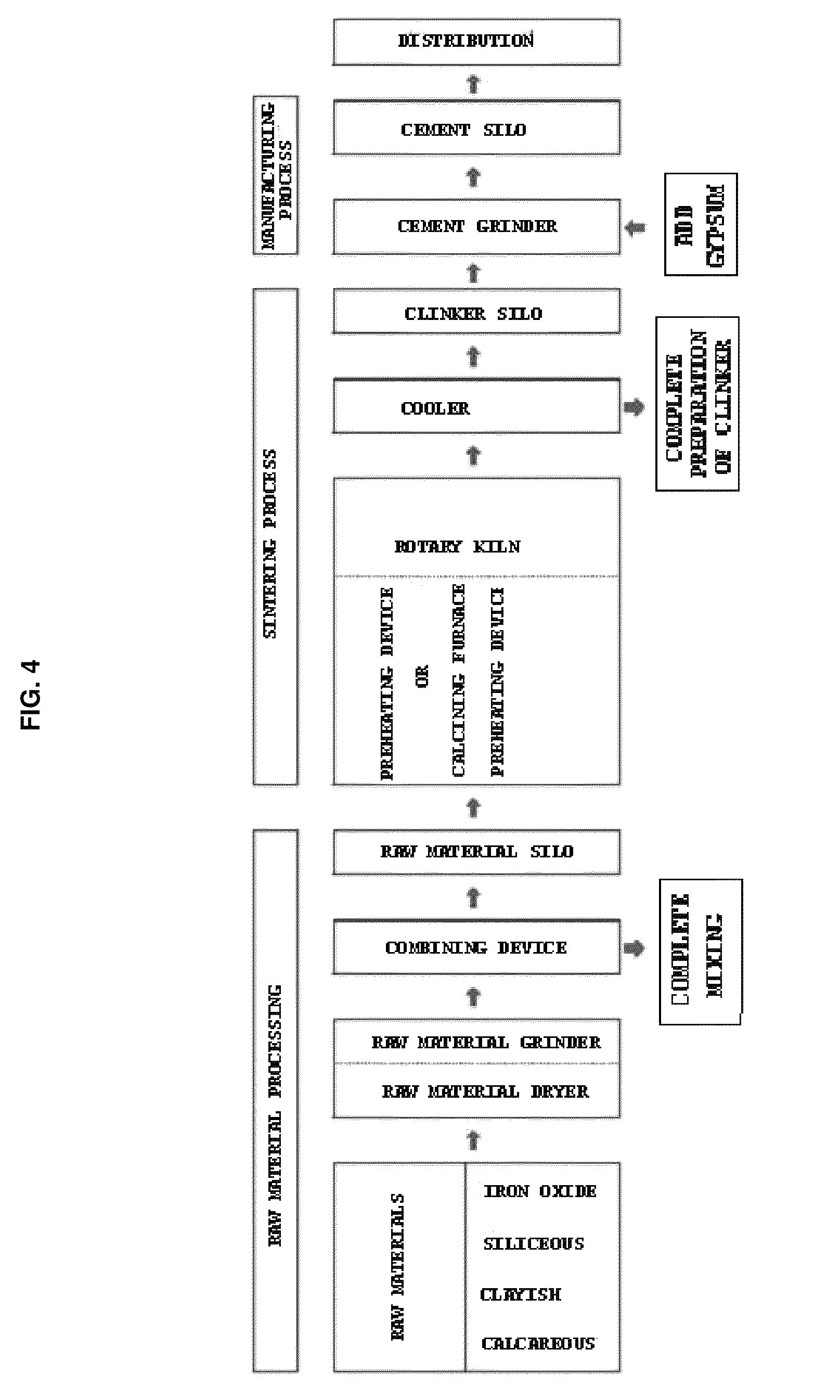

Ultra-rapid hardening hydraulic binder using reduced slag powder, and method of preparing the same

InactiveUS8834625B2Reduce slaggingUltra-rapid hardening propertyMetal recyclingCement productionElectric arc furnaceSlag

Provided are an ultra-rapid hardening hydraulic binder including reduced slag powder and a method of preparing the same. The reduced slag powder is prepared by rapidly cooling molten electric arc furnace reduced slag, among by-products generated during an iron refinement process in a steel mill, to room temperature not to have free-calcium oxide by scattering the molten electric arc furnace reduced slag into the air using high-pressure gas by dropping the molten electric arc furnace reduced slag through a tundish.

Owner:UNECO CO LTD

Disposal of electrical and electronic equipment

ActiveUS8864946B2Simple process equipmentSimple and efficientElectrical coke oven heatingSolid waste disposalMetalHydrocarbon

A method for disposing electrical and electronic equipment comprising plastic and metal components, the method comprising: melt processing the equipment and / or comminuted parts thereof to form a melt processed product; transferring the melt processed product into a vessel and heating the product using far infrared radiation such that it liberates volatile hydrocarbons and leaves behind non-volatile residue comprising metal; and collecting one or both of the volatile hydrocarbons and the non-volatile residue for subsequent use.

Owner:P FUEL

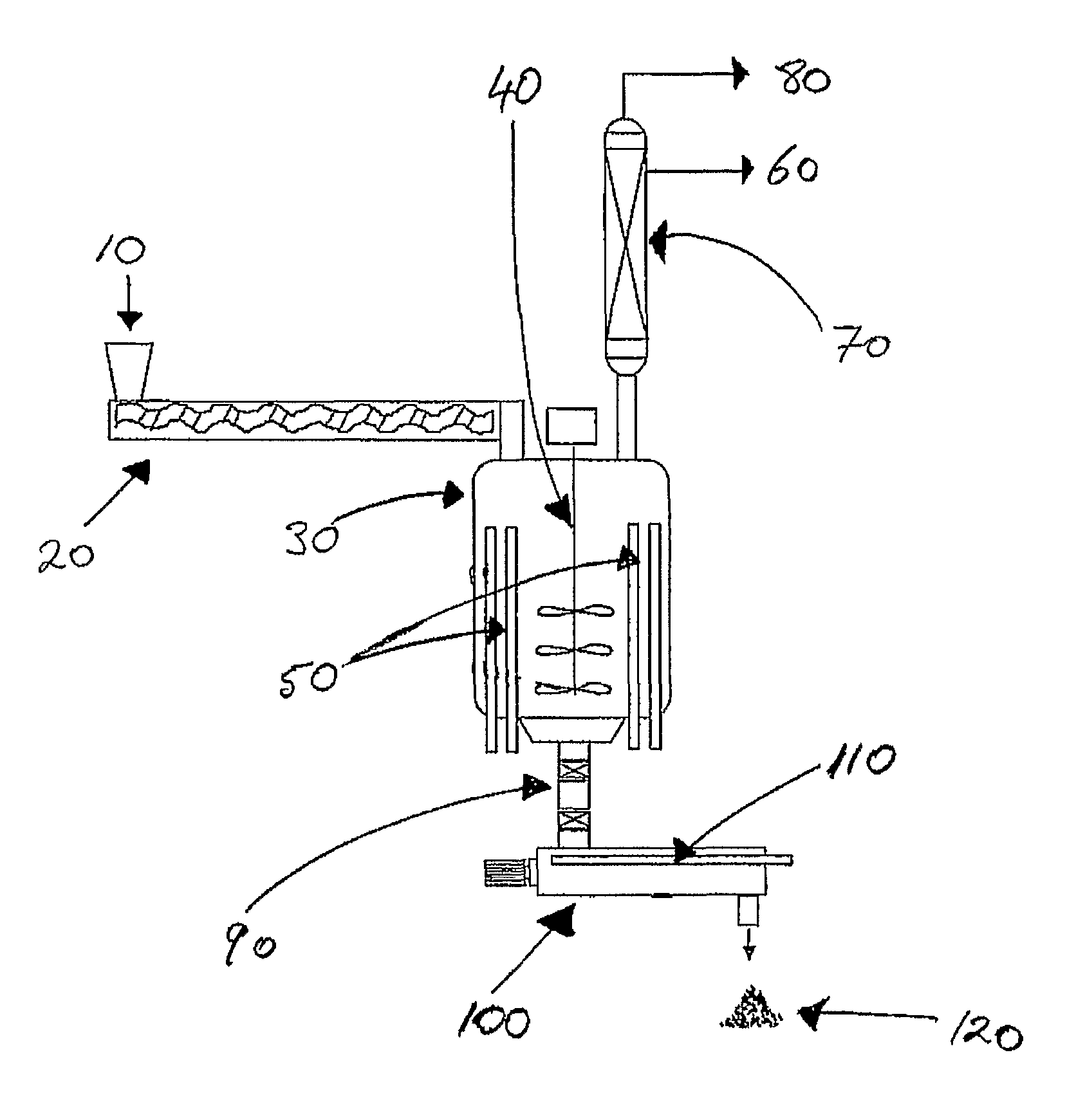

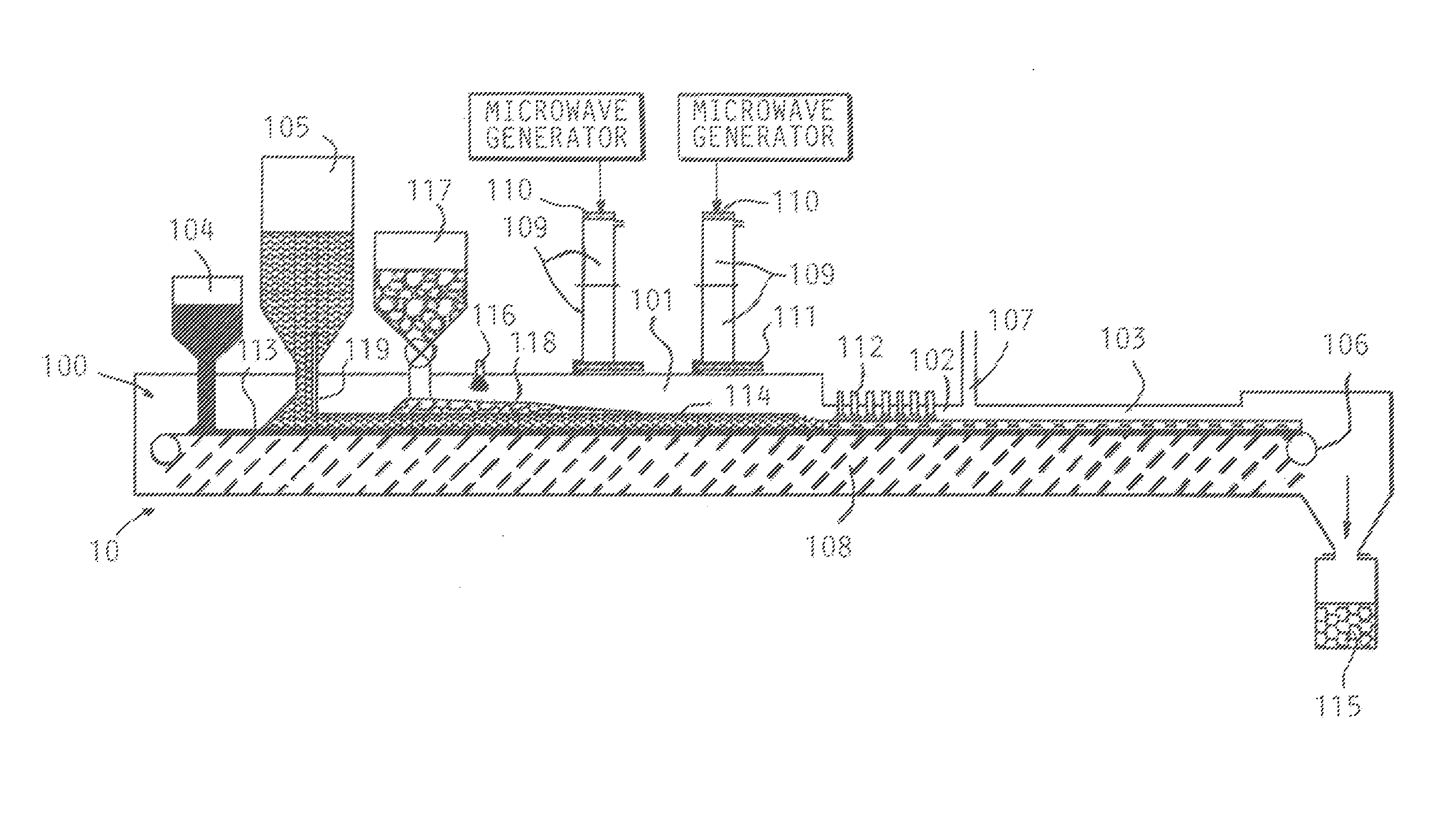

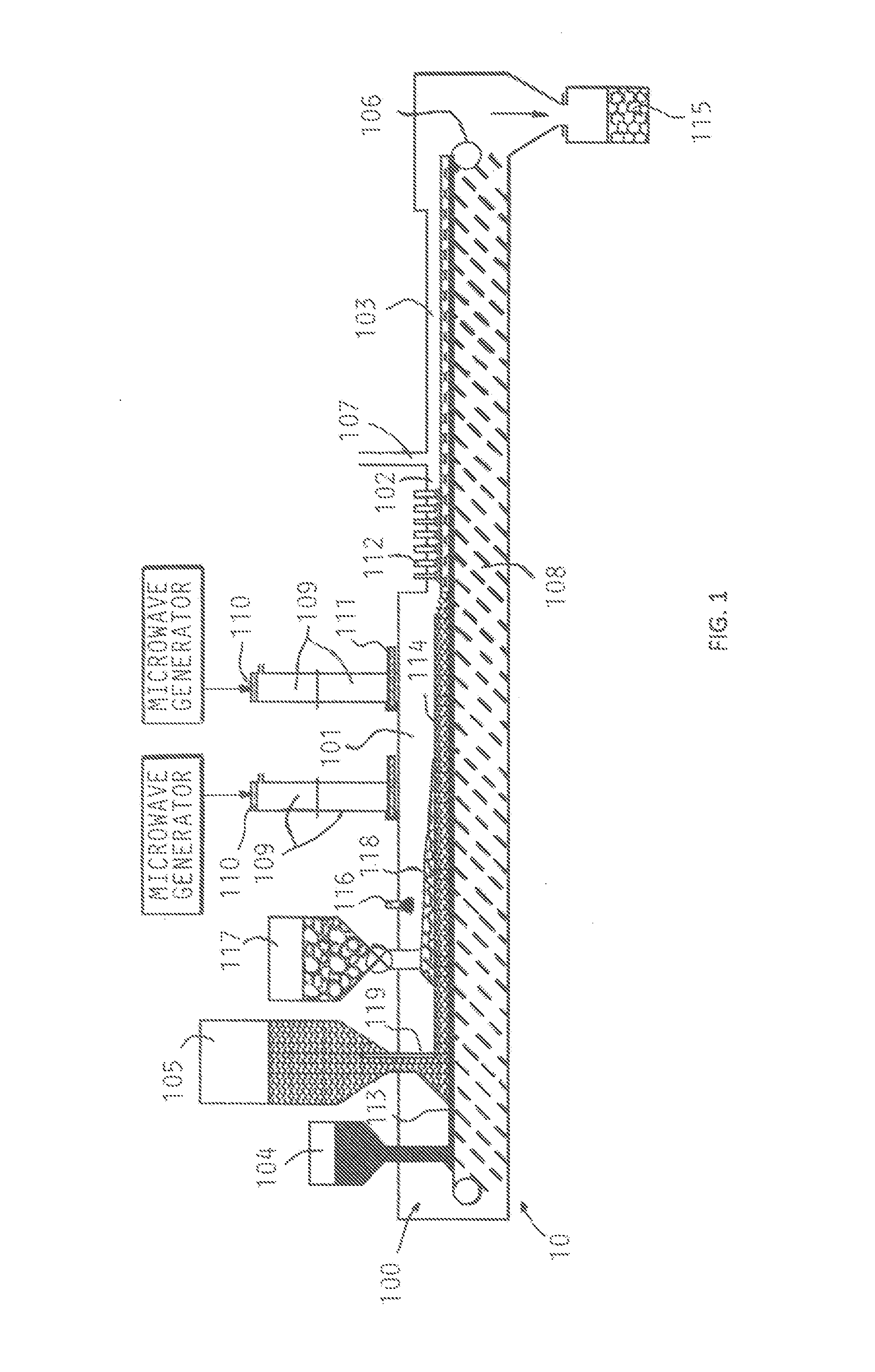

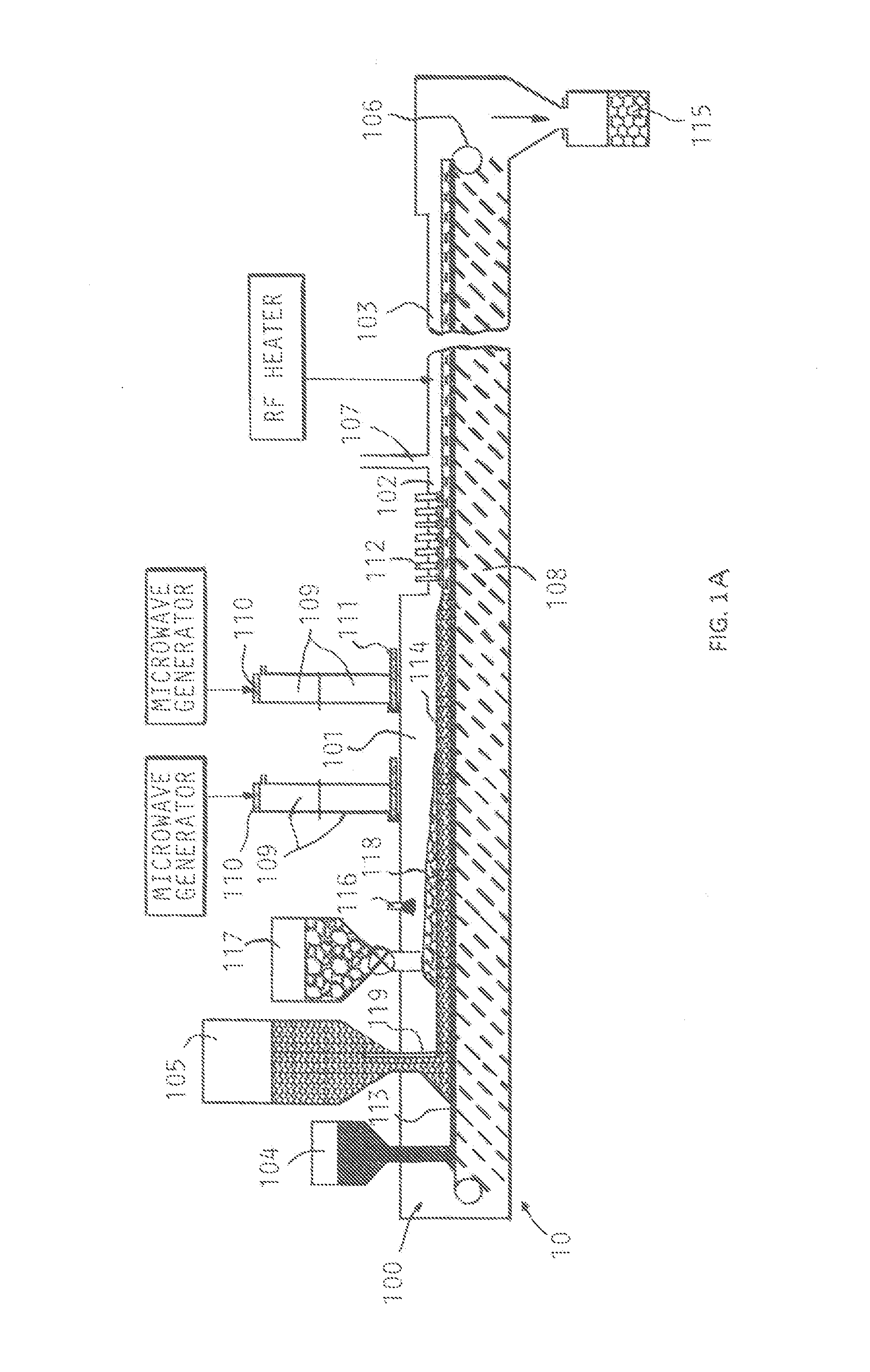

Method and apparatus for coproduction of pig iron and high quality syngas

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

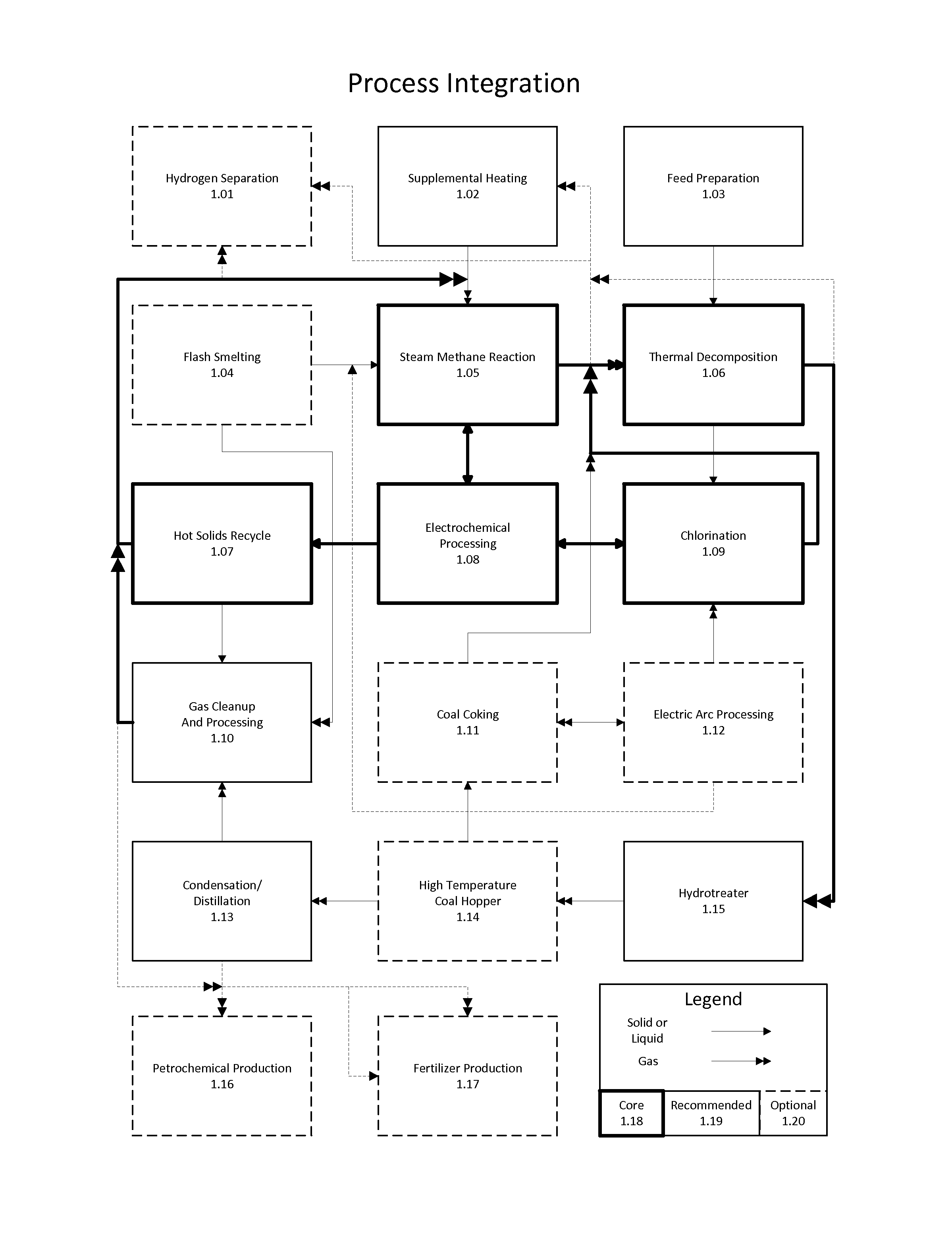

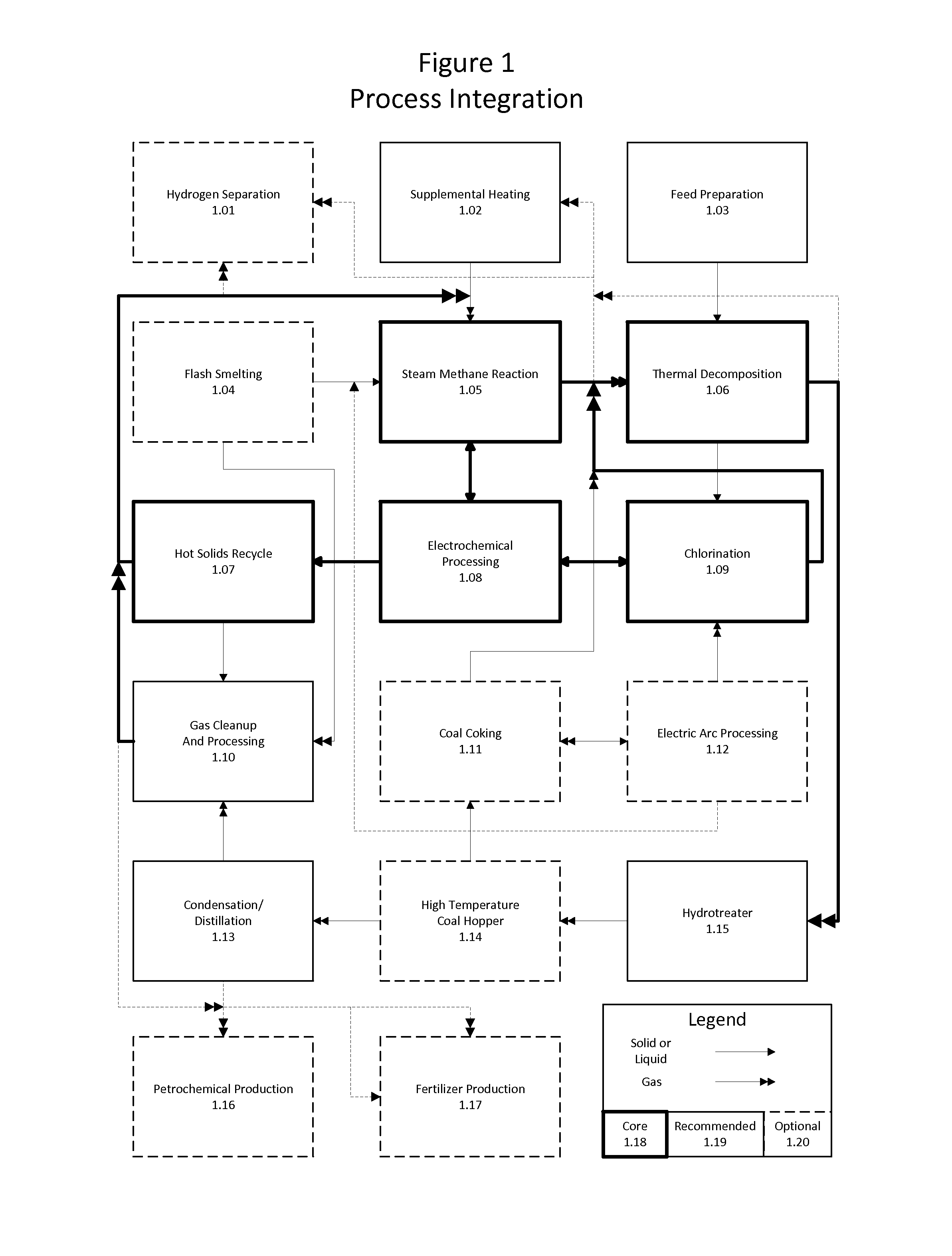

Method for the integration of carbochlorination into a staged reforming operation as an alternative to direct residue oxidation for the recovery of valuable metals

Method of combining industrial processes having inherent carbon capture and conversion capabilities offering maximum flexibility, efficiency, and economics while enabling environmentally and sustainably sound practices. Maximum chemical energy is retained throughout feedstock processing. A hybrid thermochemical cycle couples staged reforming with hydrogen production and chlorination. Hydrogen generated is used to upgrade feedstocks including bitumen, shale, coal, and biomass. Residues of upgrading are chlorinated, metals of interest are removed, and the remainder is reacted with ammonia solution and carbon dioxide to form carbonate minerals. The combination provides emissions free production of synthetic crude oil and derivatives, as well as various metals and fertilizers. Sand and carbonate minerals are potentially the only waste streams. Through this novel processing, major carbon dioxide reduction is afforded byminimizing direct oxidation. Supplemental heat to run the reactions is obtained through external means such as concentrated solar, geothermal, or nuclear.

Owner:BLUE SKIES RES INC

Method of agglomerating silicon/silicon carbide from wiresawing waste

The process of the present invention begins with a source of silicon and silicon carbide from wafer production. The silicon / silicon carbide waste material is dewatered as need be and passed to a mixer where the waste material is agglomerated. A binder is applied to the waste material either during agglomeration or during pelletizing. A variety of organic binders may be used such as polyvinyl alcohol, molasses, sodium silicate and polyethylene glycol; however, the preferred binder is a lignosulsulfonate. The amount of binder used will depend upon the particular binder and the feed material used. The silicon / silicon carbide-containing waste material is pelletized. The invention also provided silicon / silicon carbide-containing pellets that may be used as reduction material in smelting furnaces for the production of metals and alloys.

Owner:ALTERNATIVE CHARGE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com