Patents

Literature

52results about "Metallurgical apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

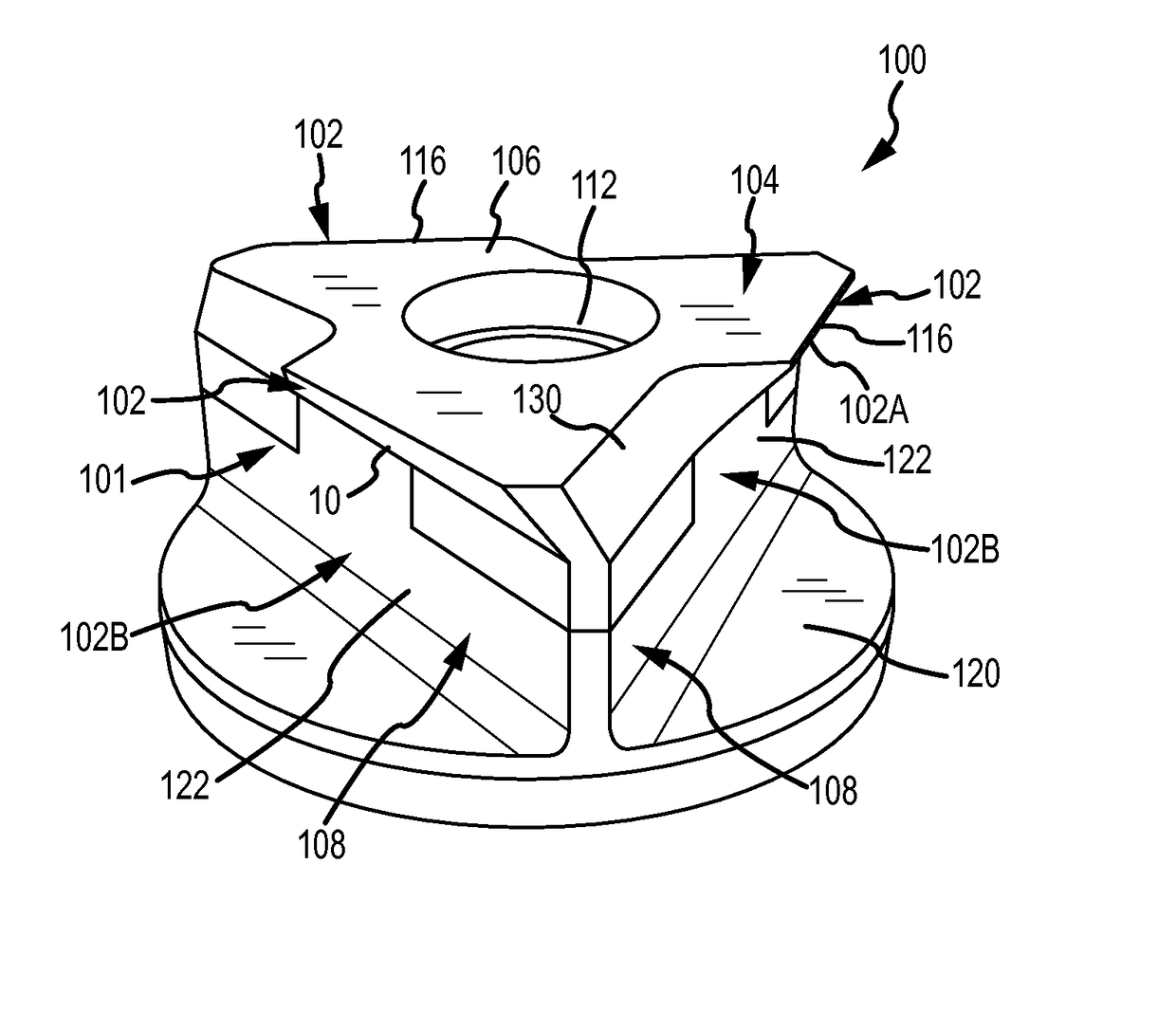

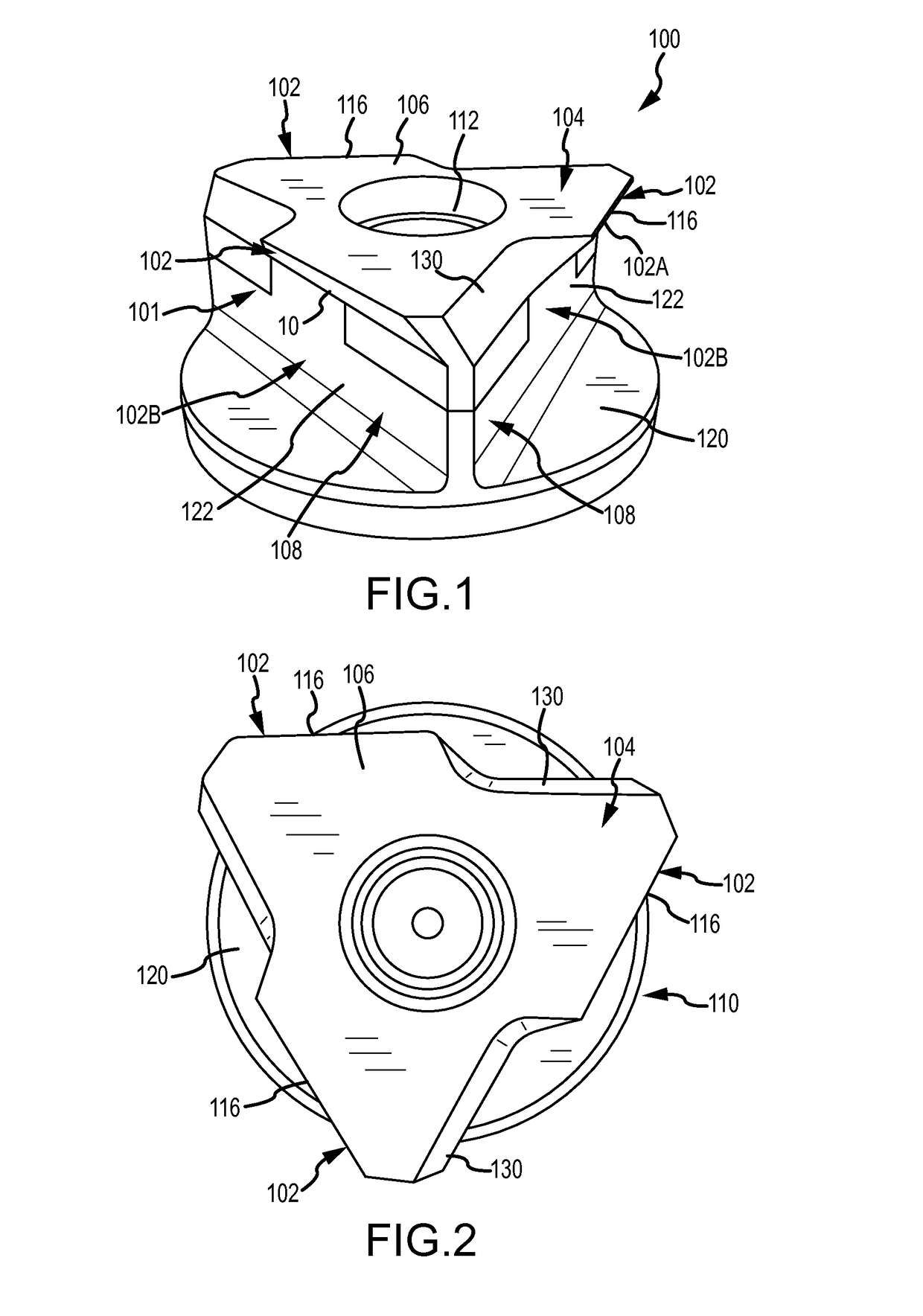

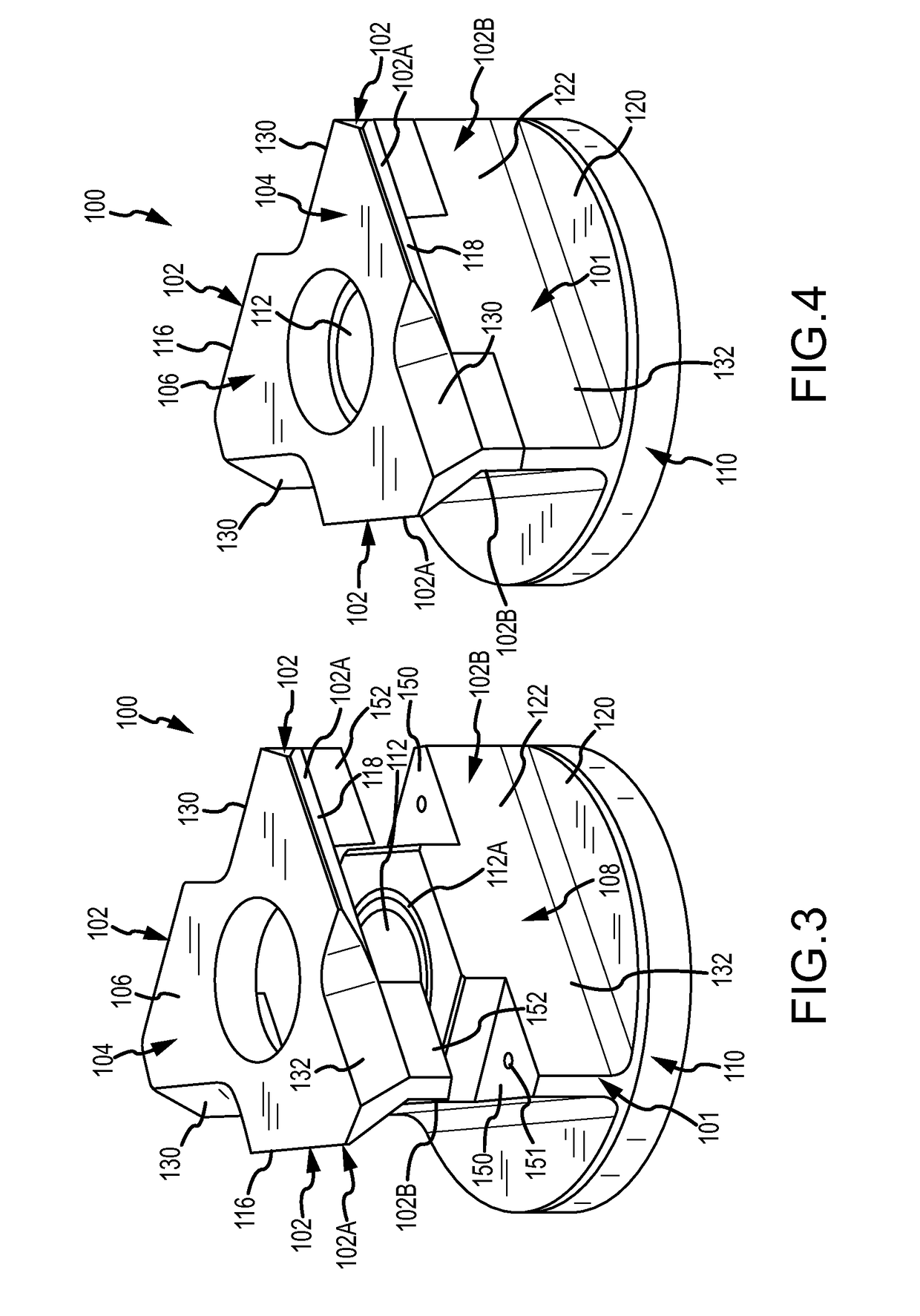

Molten metal rotor with hardened top

Embodiments of the invention are directed to a rotor for a molten metal pump and a molten metal pump including the rotor. The rotor has a main body and a top comprised of a material that is at least twice as hard as the main body. The top, among other things, may form a first portion of each rotor blade wherein the first portion directs molten metal into a pump chamber or other structure in which the rotor is mounted.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

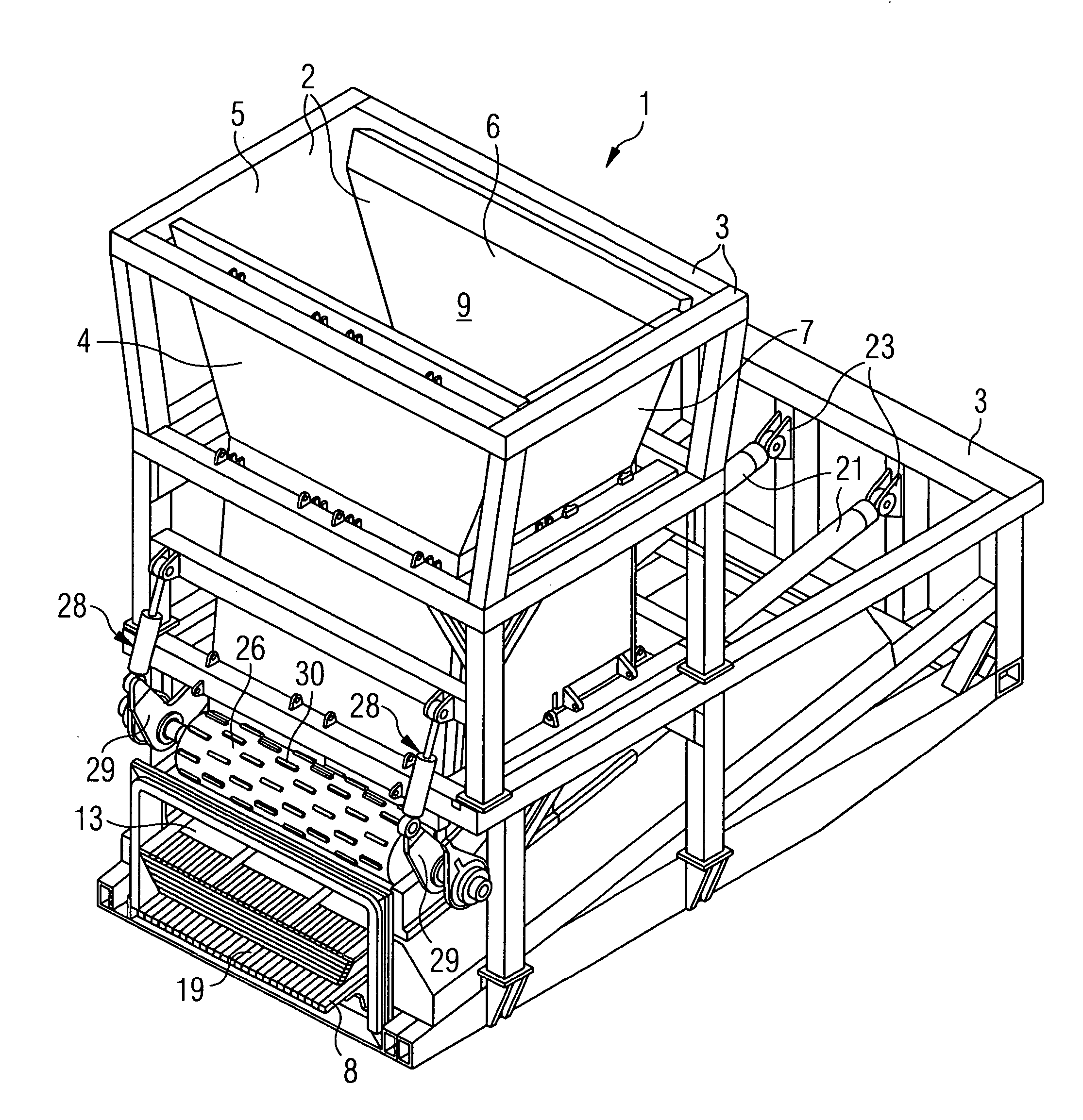

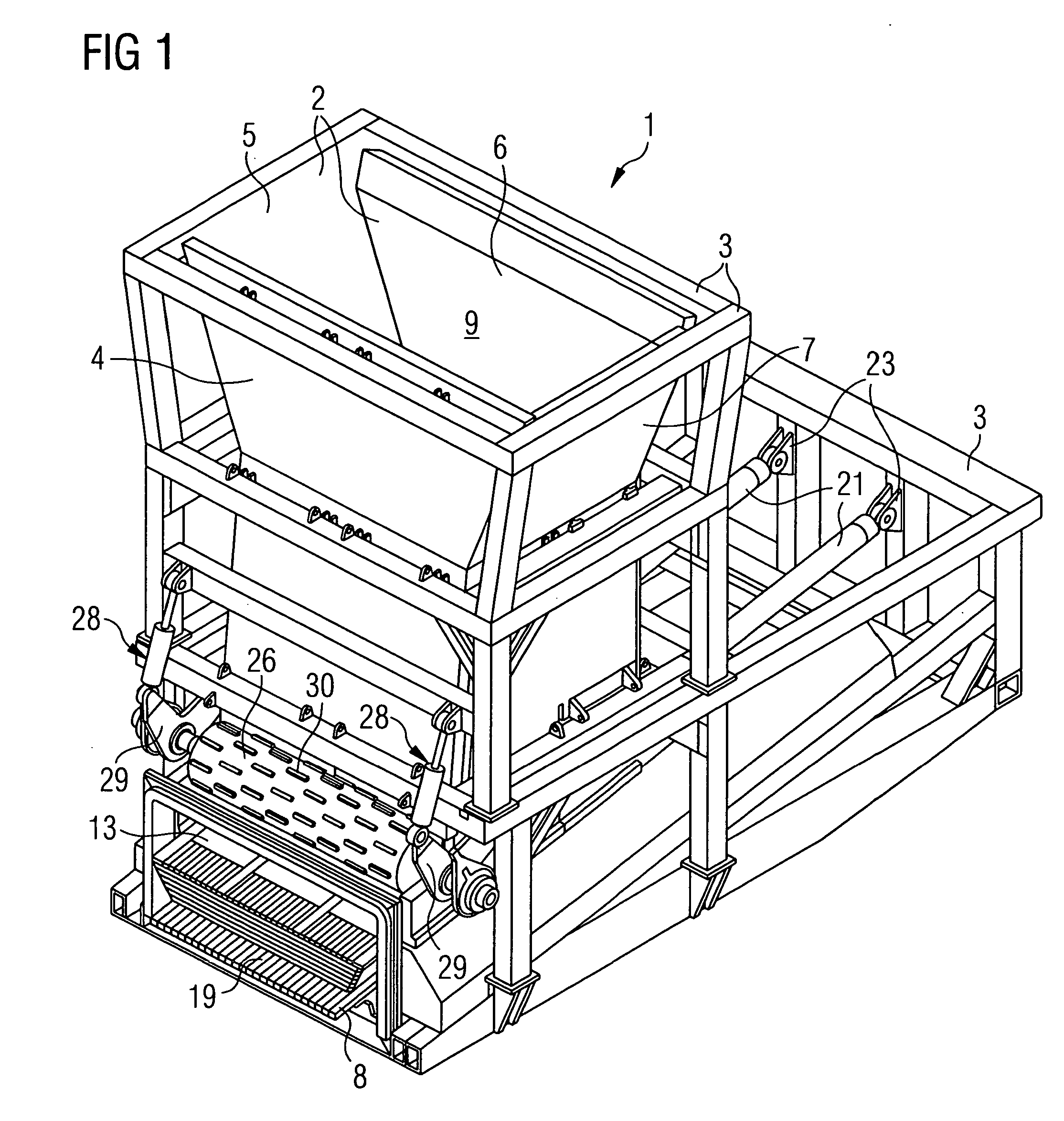

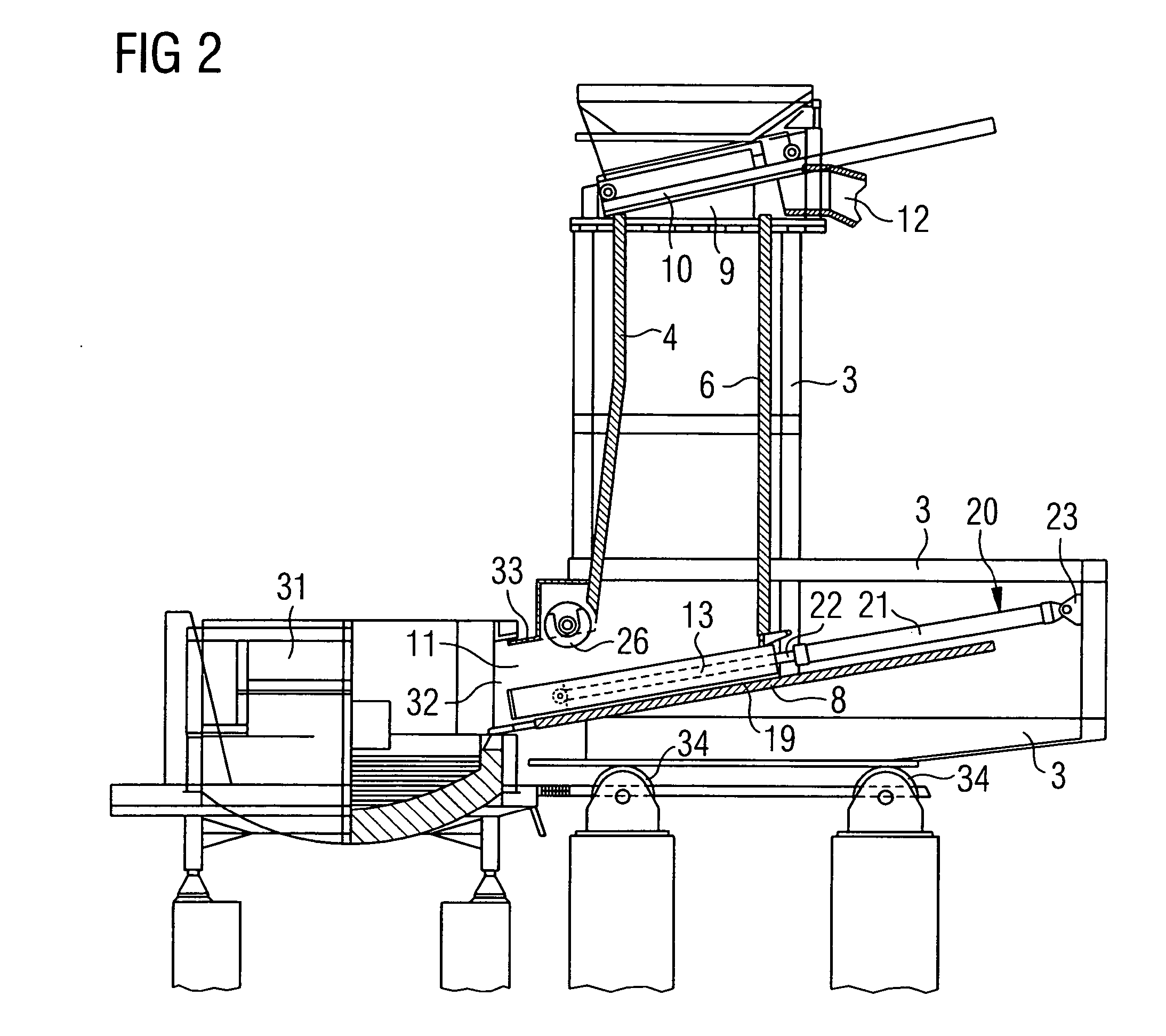

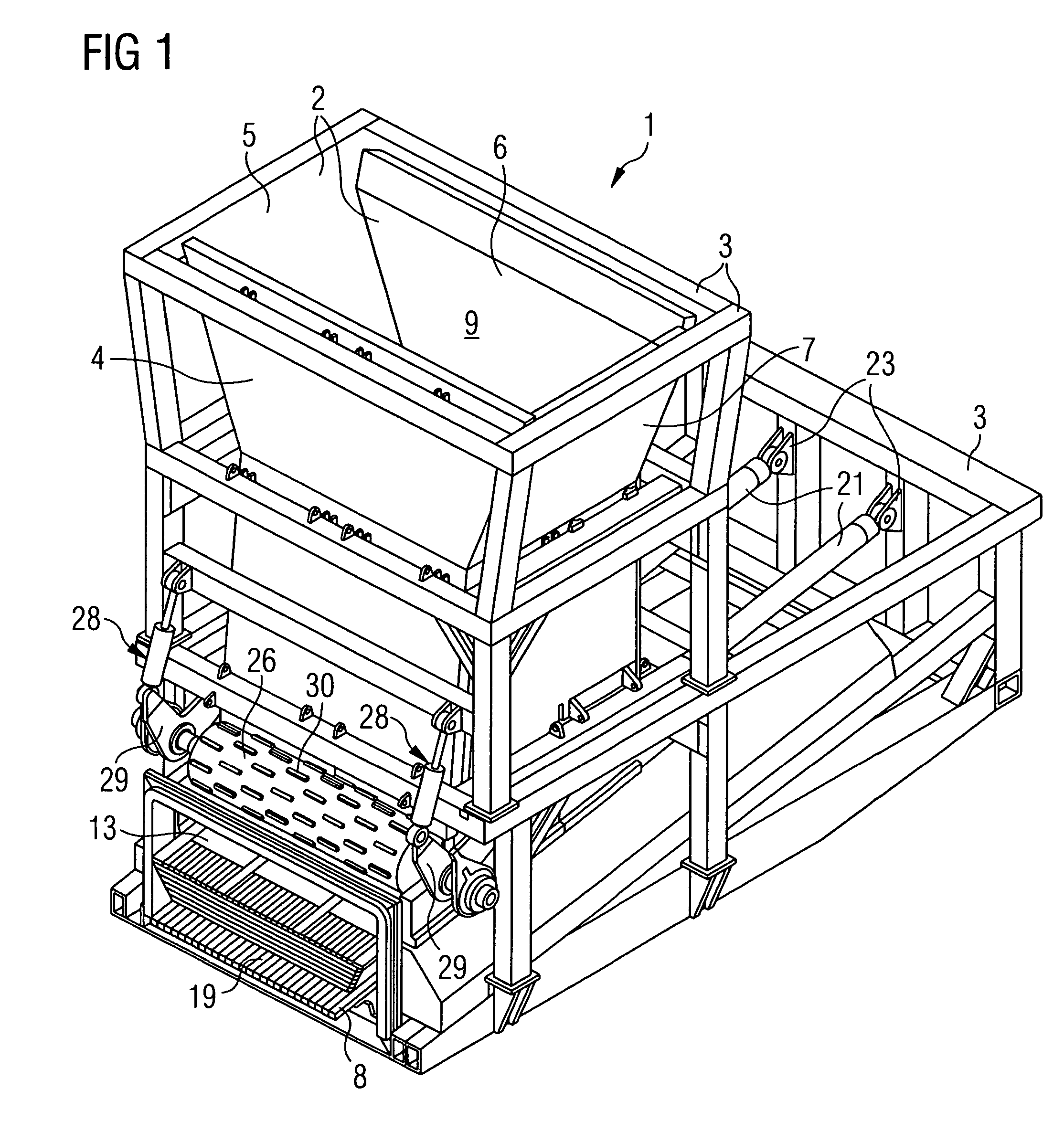

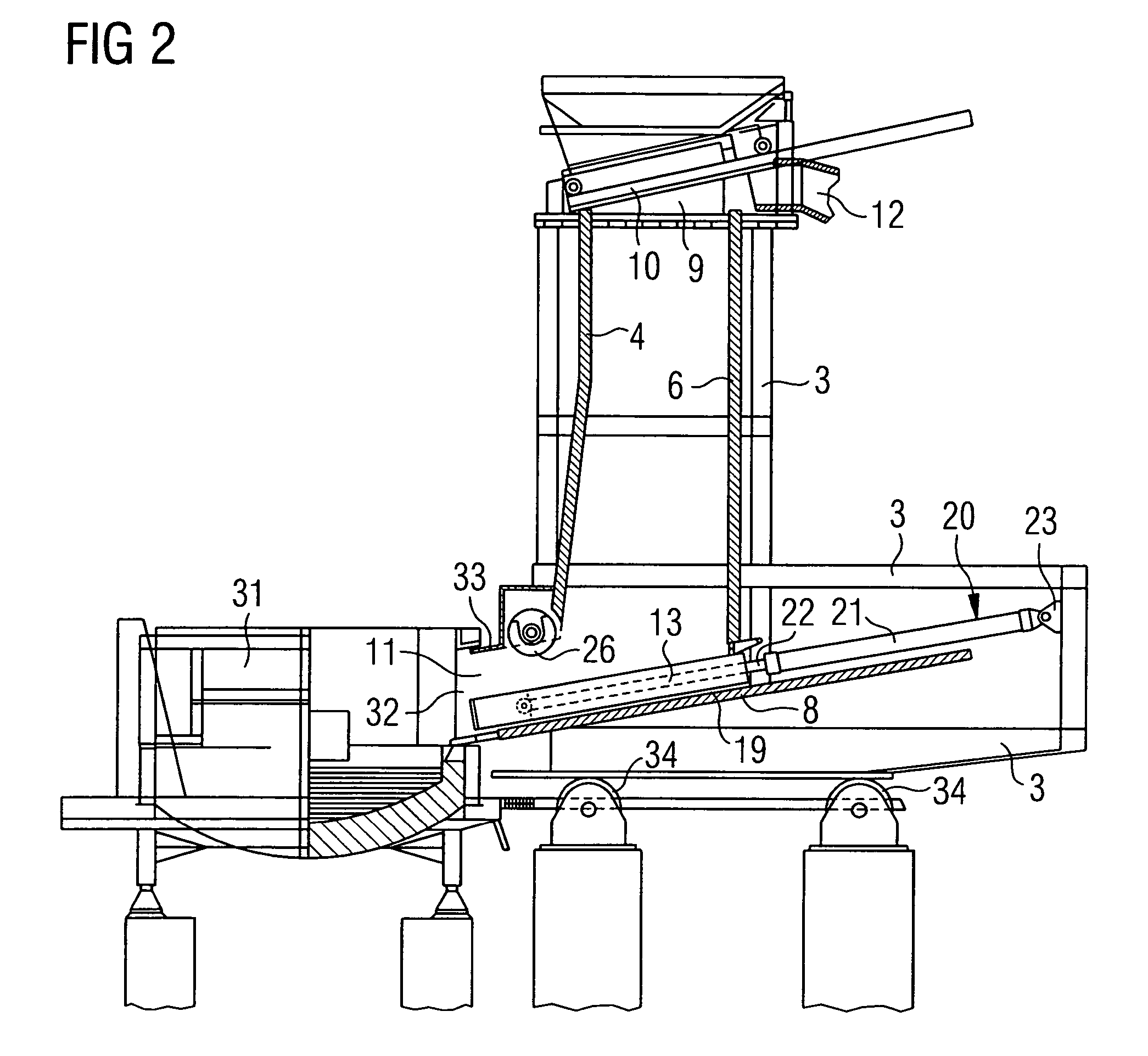

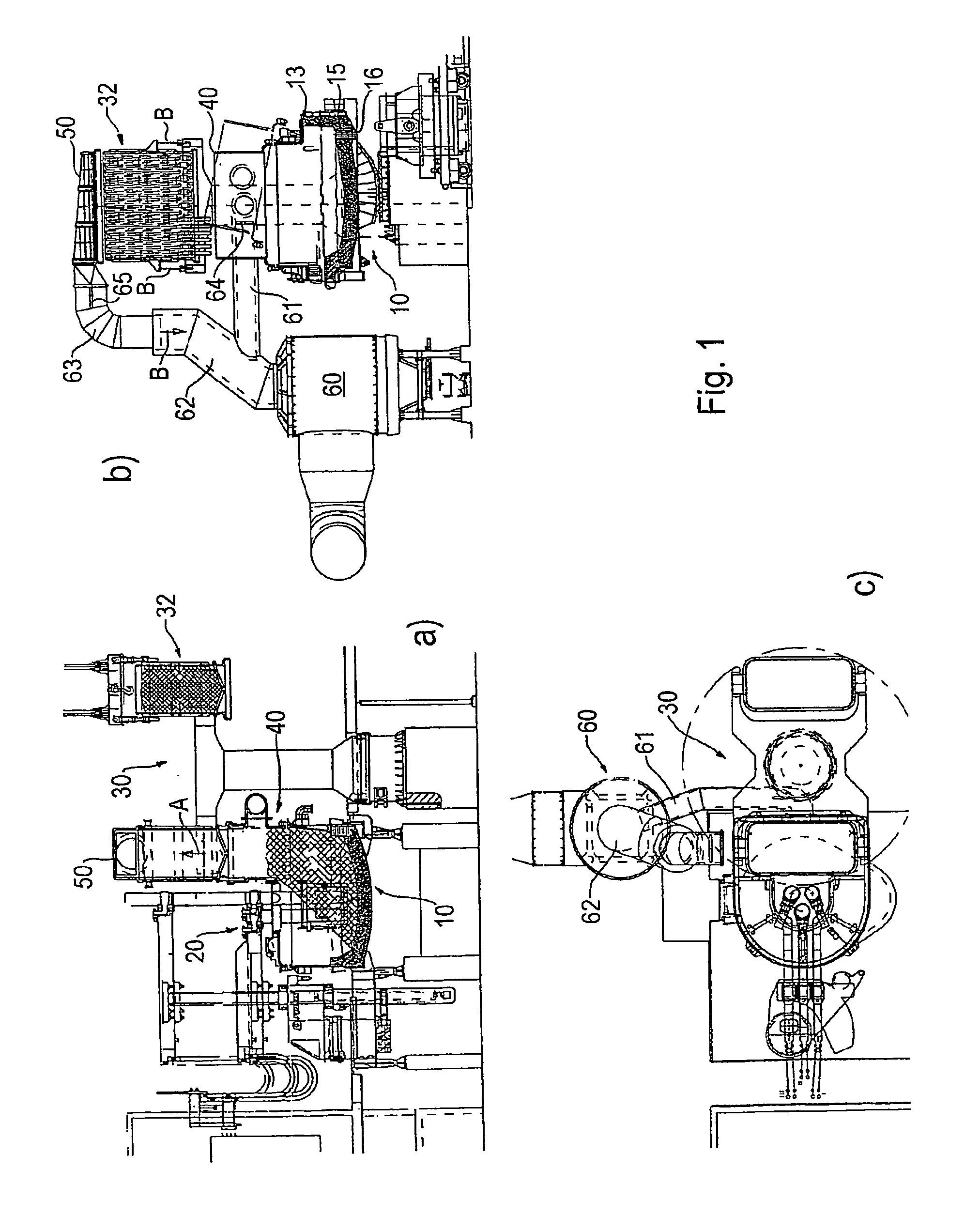

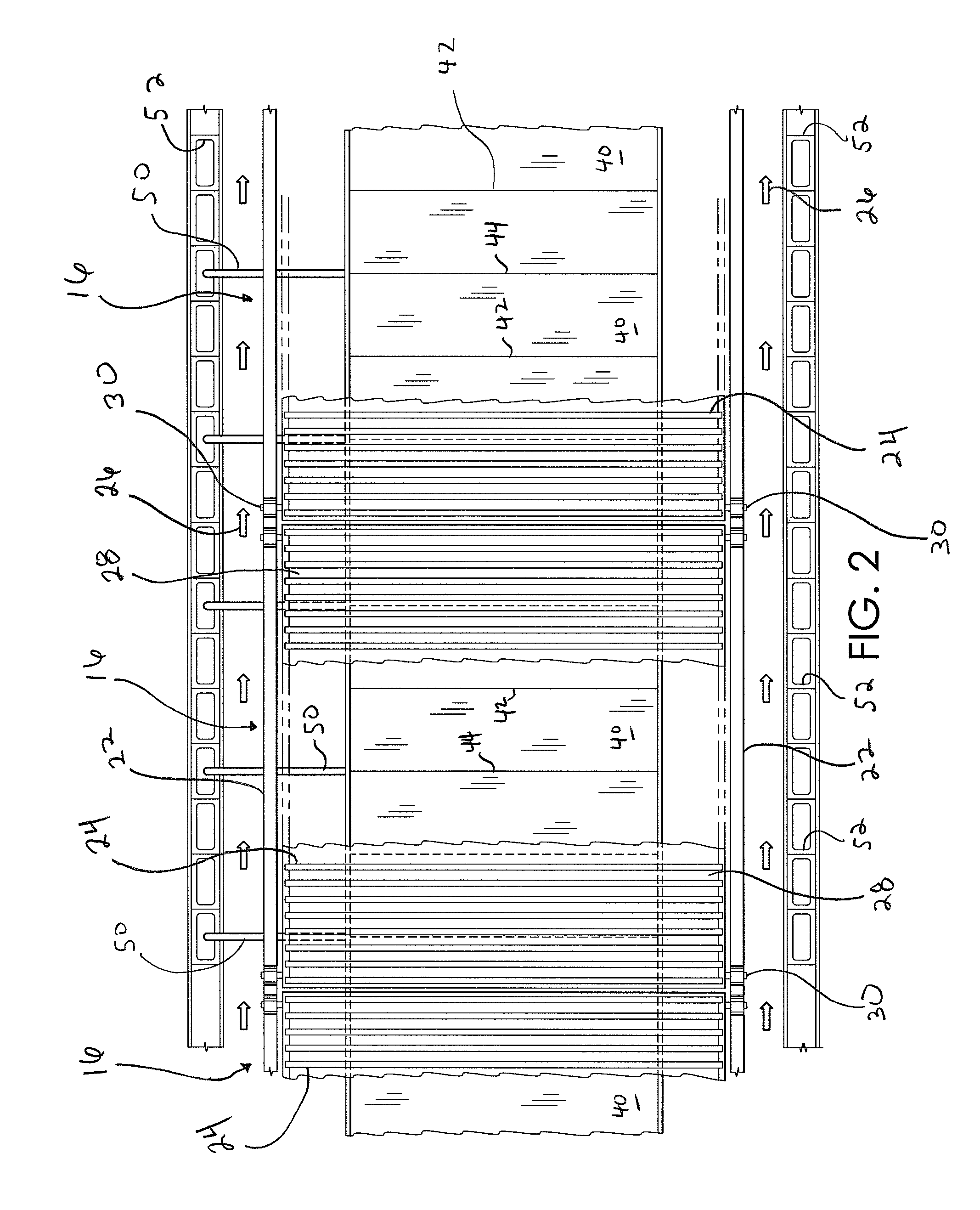

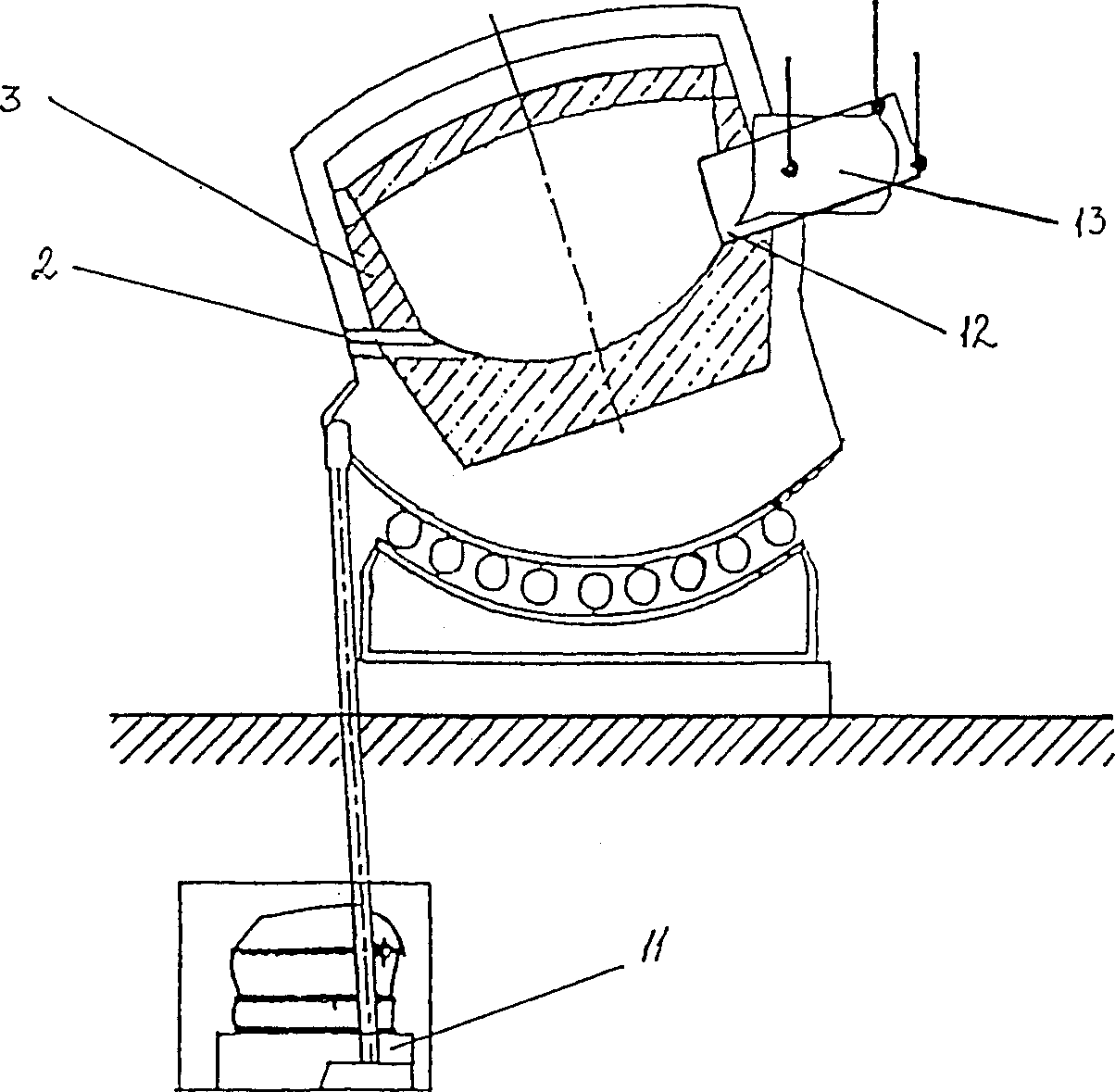

Charging device, especially charging stock preheater

InactiveUS20070013112A1Raise the discharge heightIncrease heightBagsSacksShaped chargeHorizontal axis

To facilitate a trouble-free charging of scrap metal having differing constitutions, such as light and heavy scrap metal, from a lower discharge opening of a shaft-shaped charging device or a charging stock preheater (1) into a melting vessel by a pusher (13), the lateral surfaces of the pusher (13) are formed so as to converge from the upper side to the lower side and the actuating device (2) of the pusher (13) is pivotably supported in a frame structure (3) about a horizontal axis. In addition, the upper boundary of the discharge opening for the charging stock from the shaft (2) is preferably formed by a horizontal, rotatably supported roller (26), more preferably with engaging elements (30) distributed around the circumferential surface. Sections of the charging device that are severely mechanically stressed are preferably formed by steel billet sections connected to form a structural unit.

Owner:FUCHS TECH

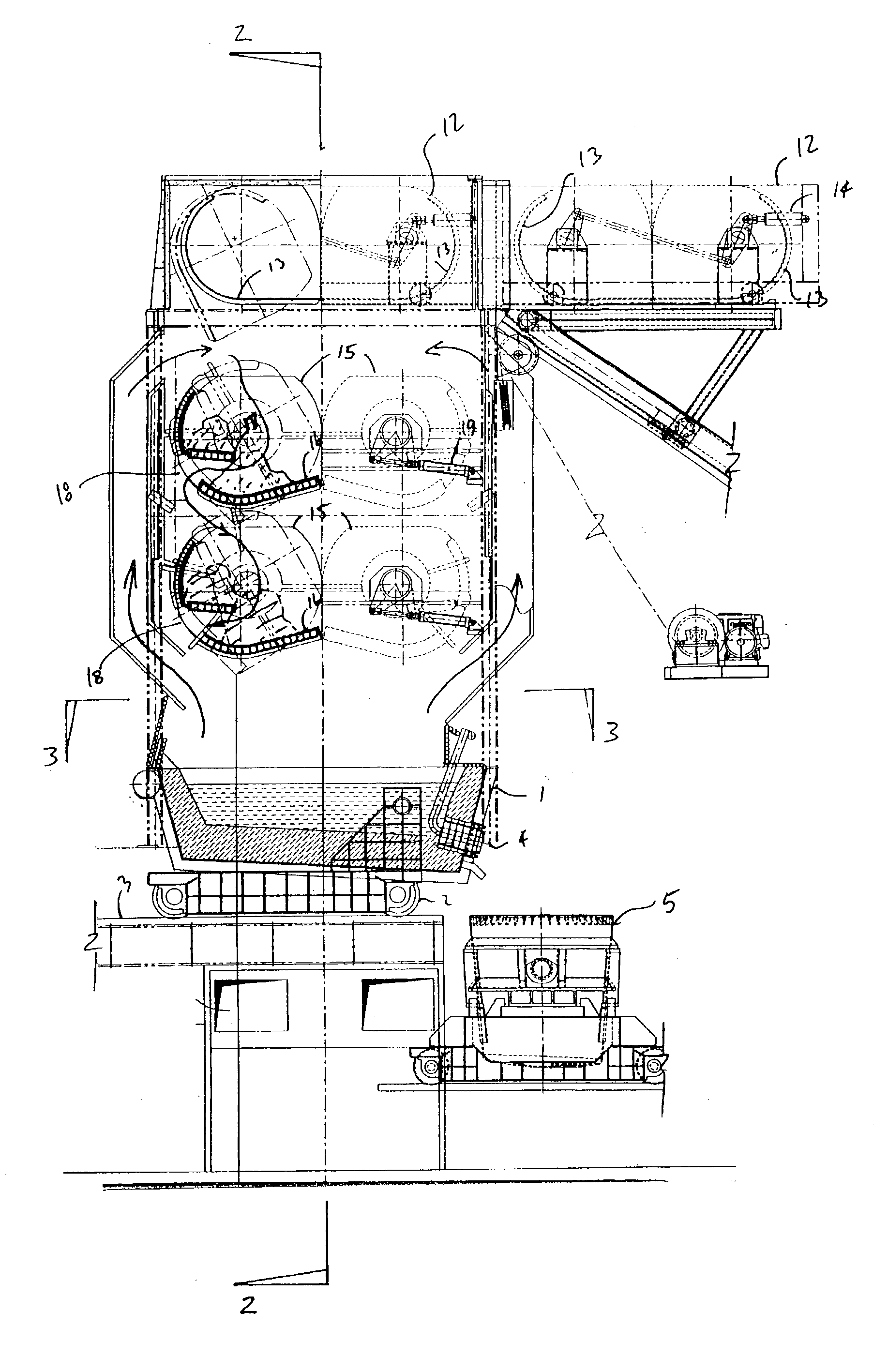

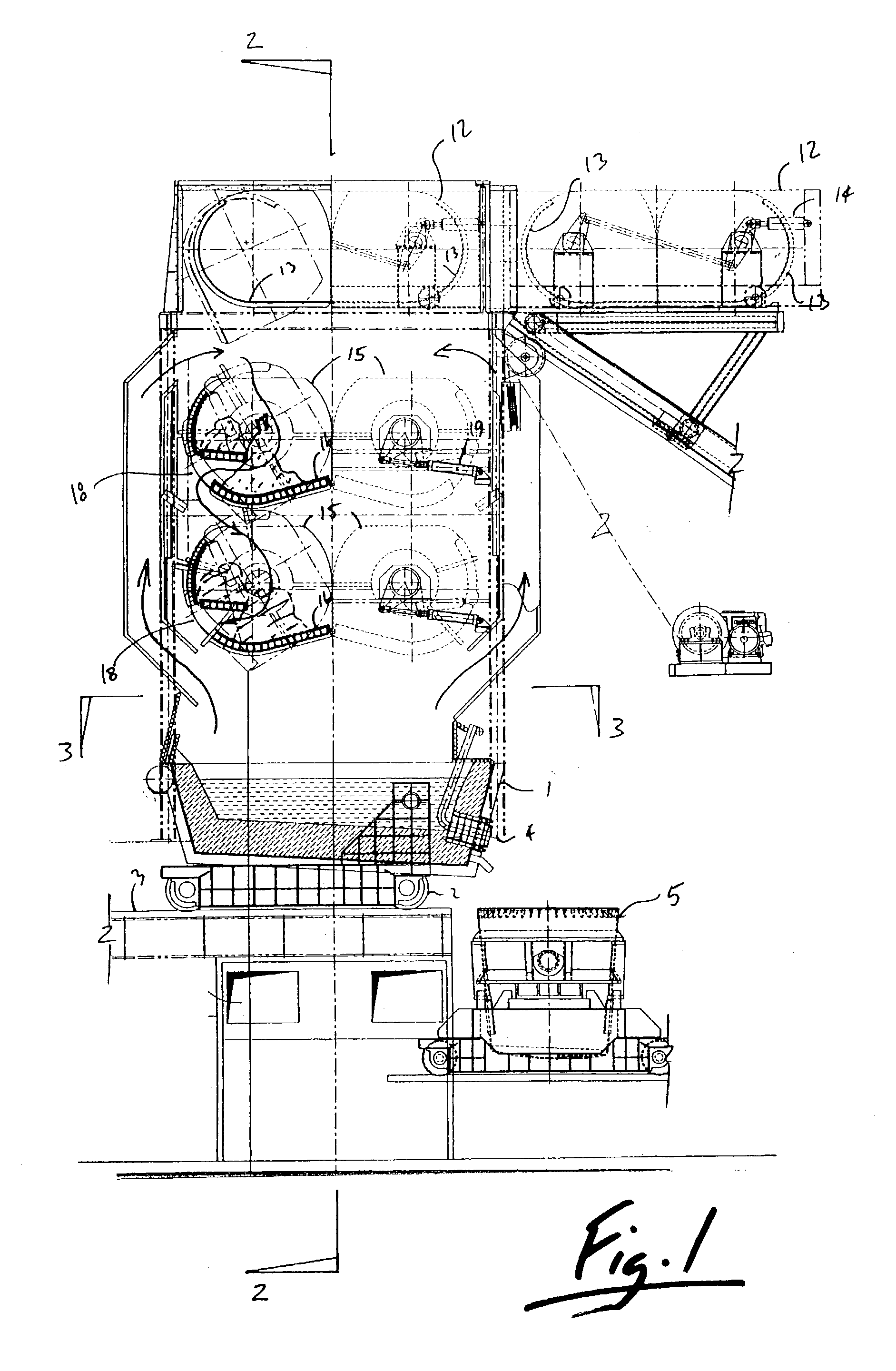

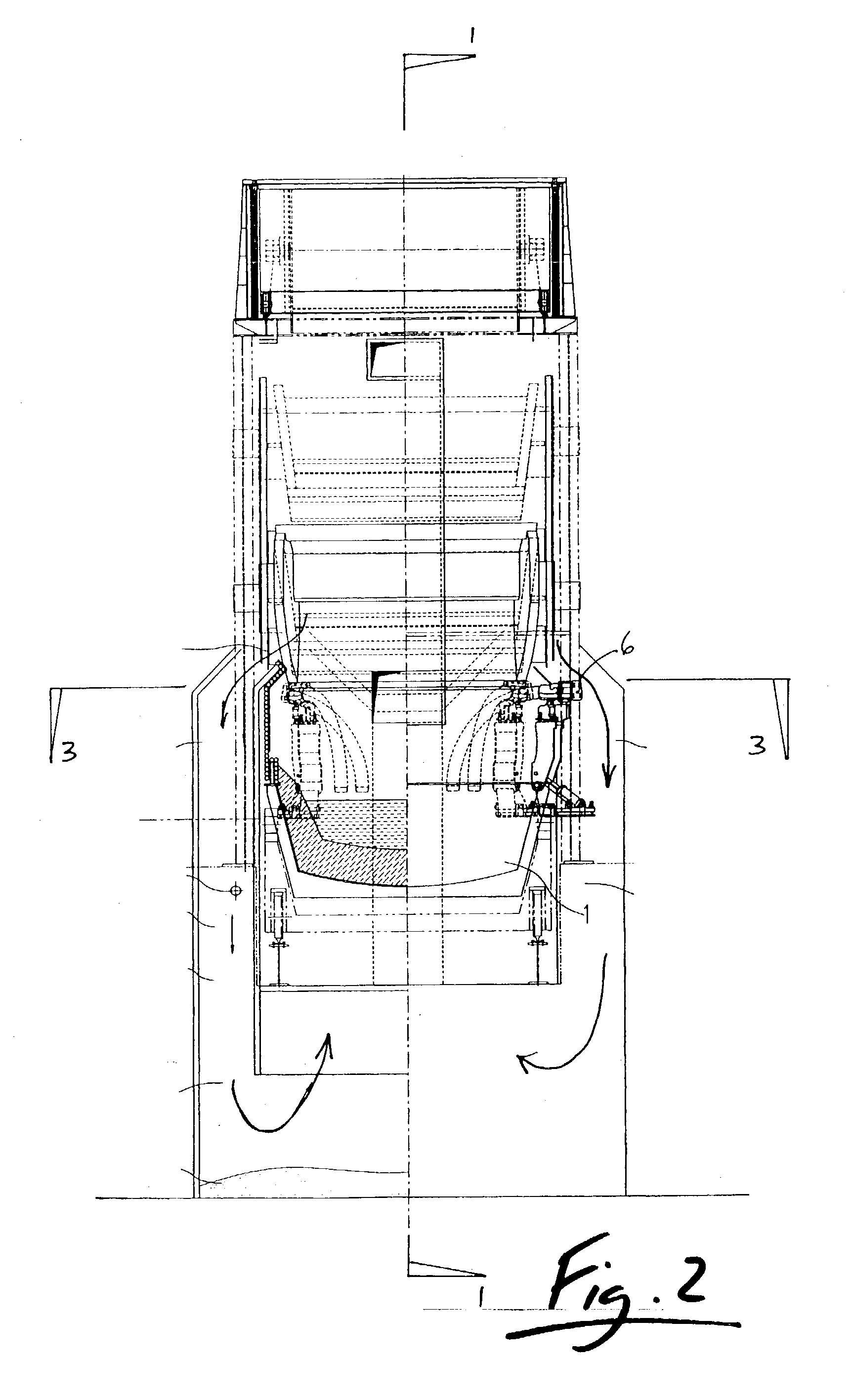

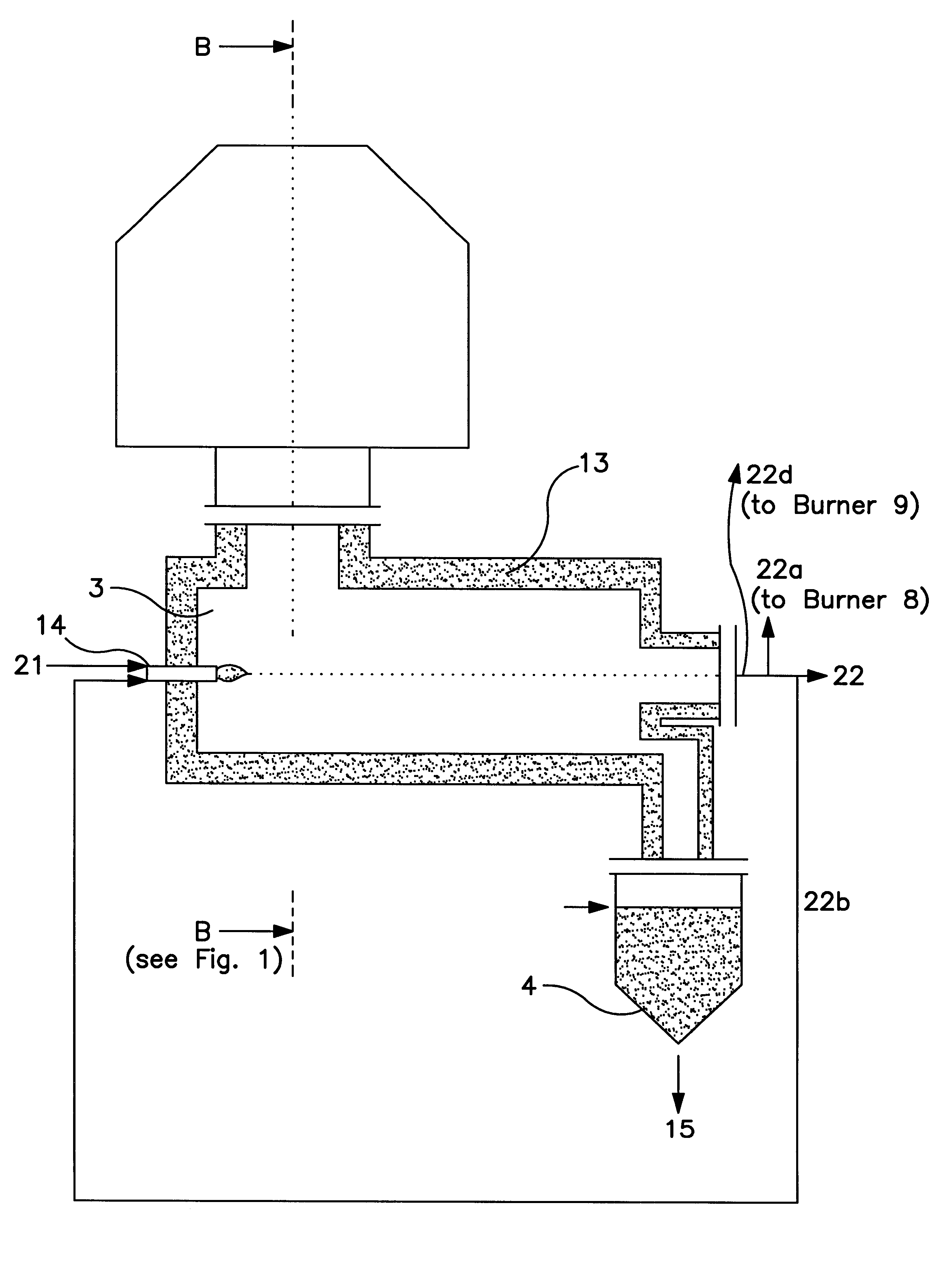

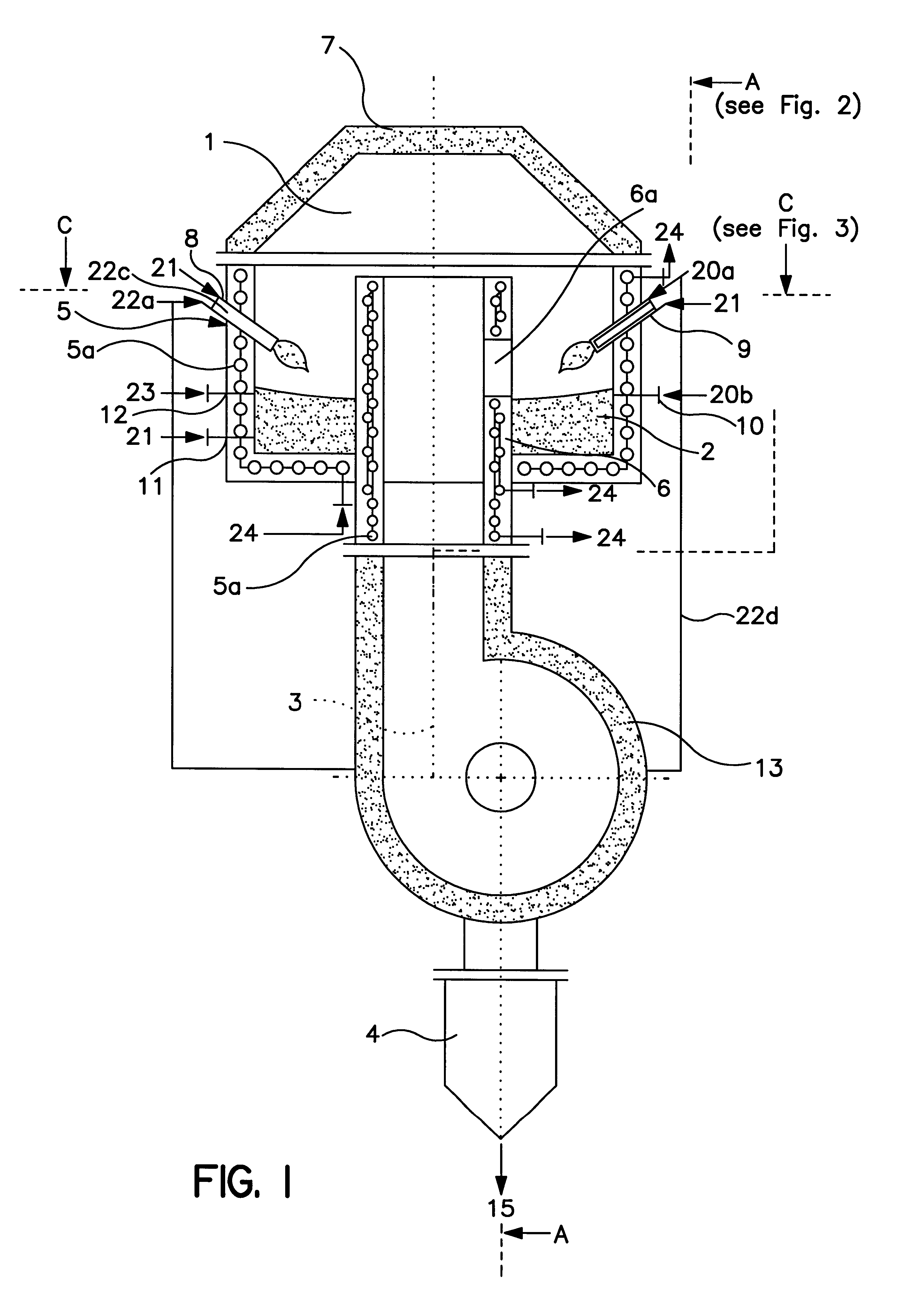

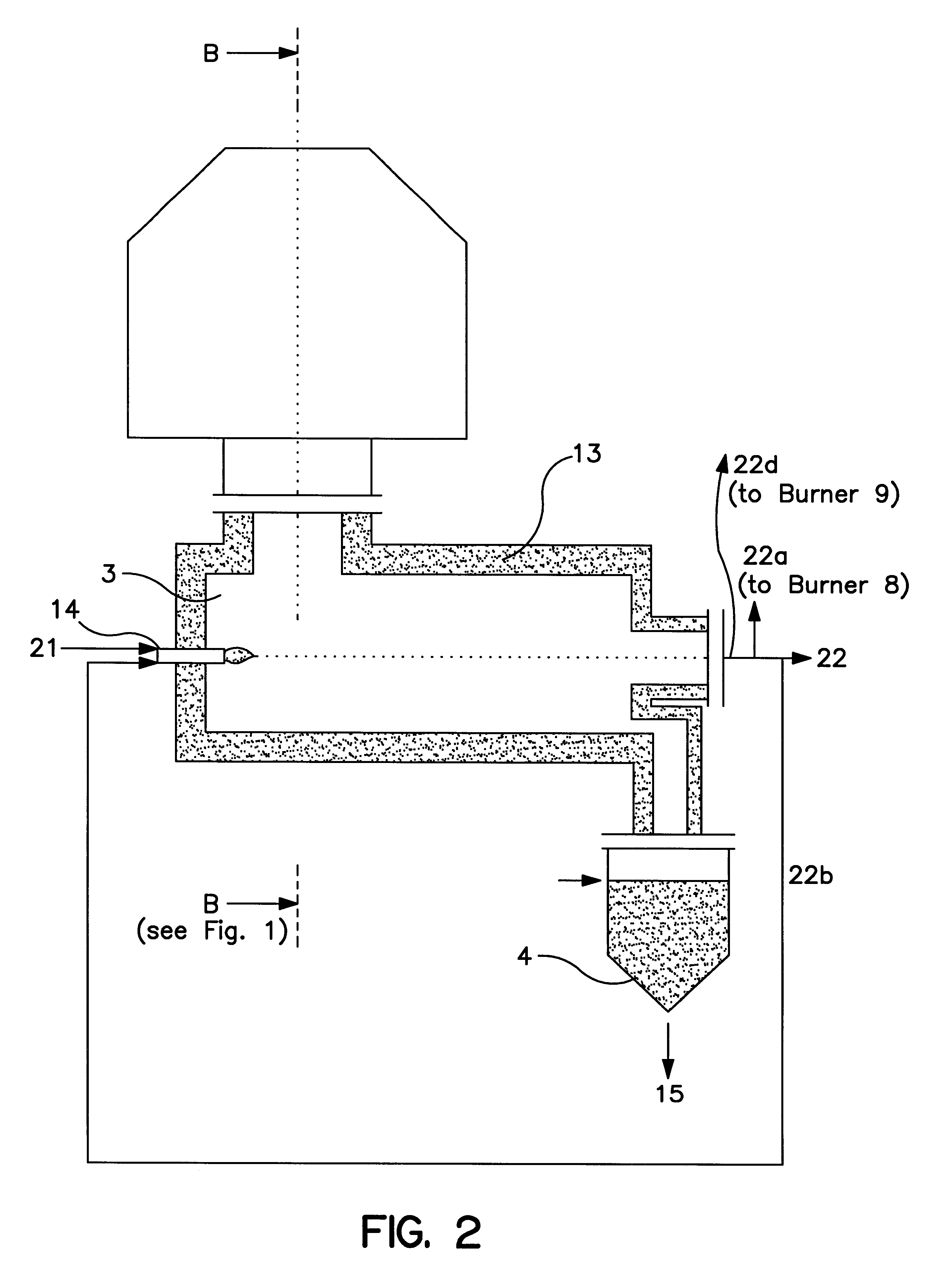

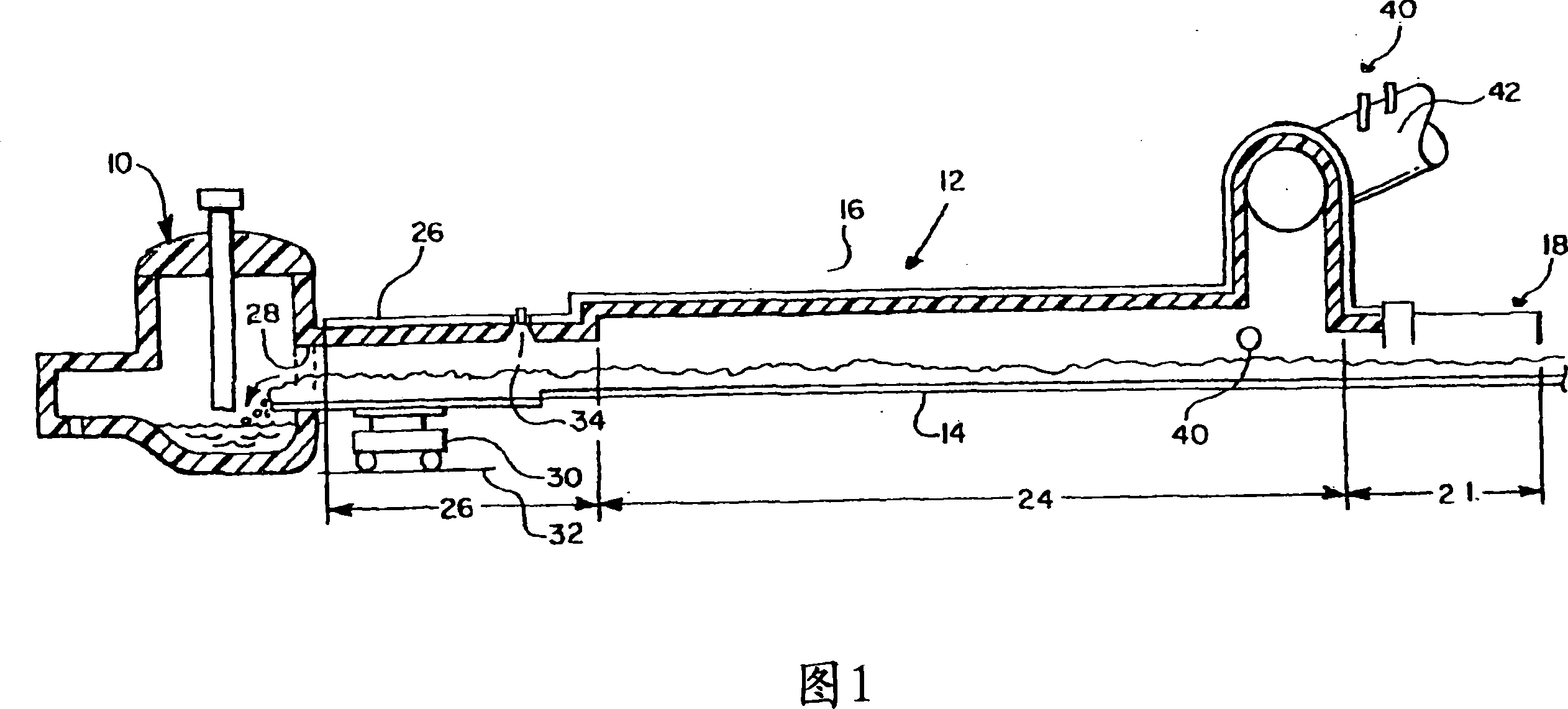

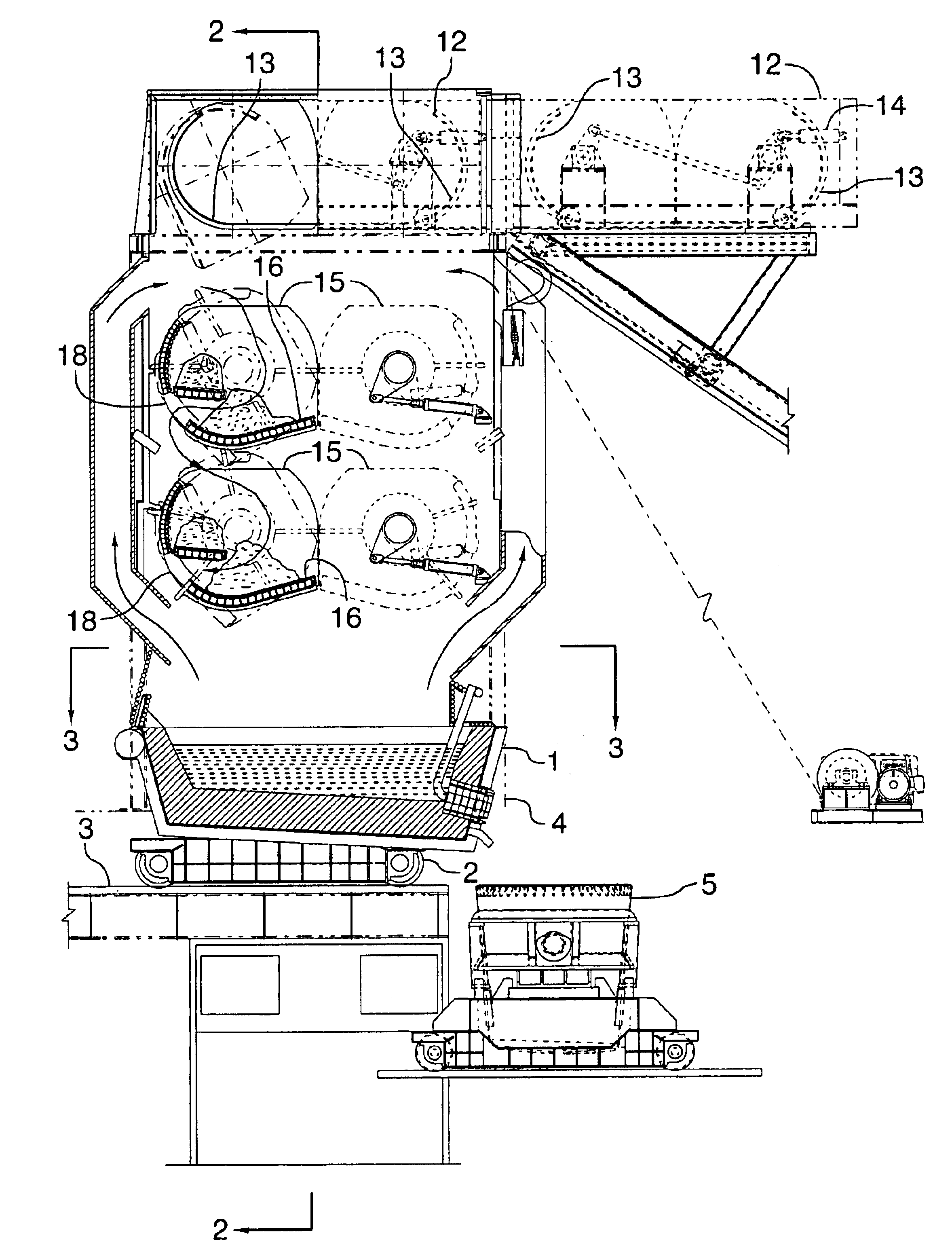

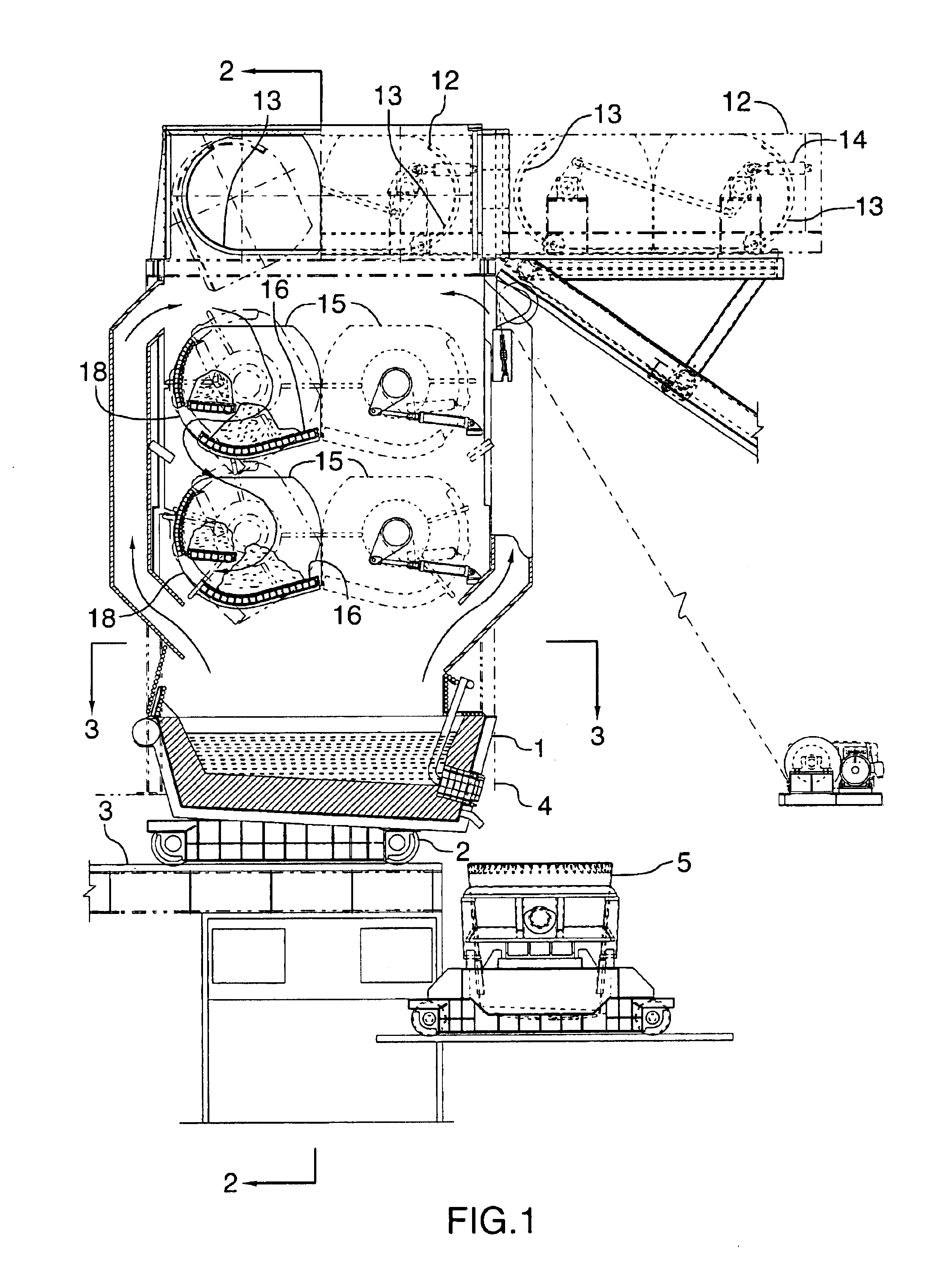

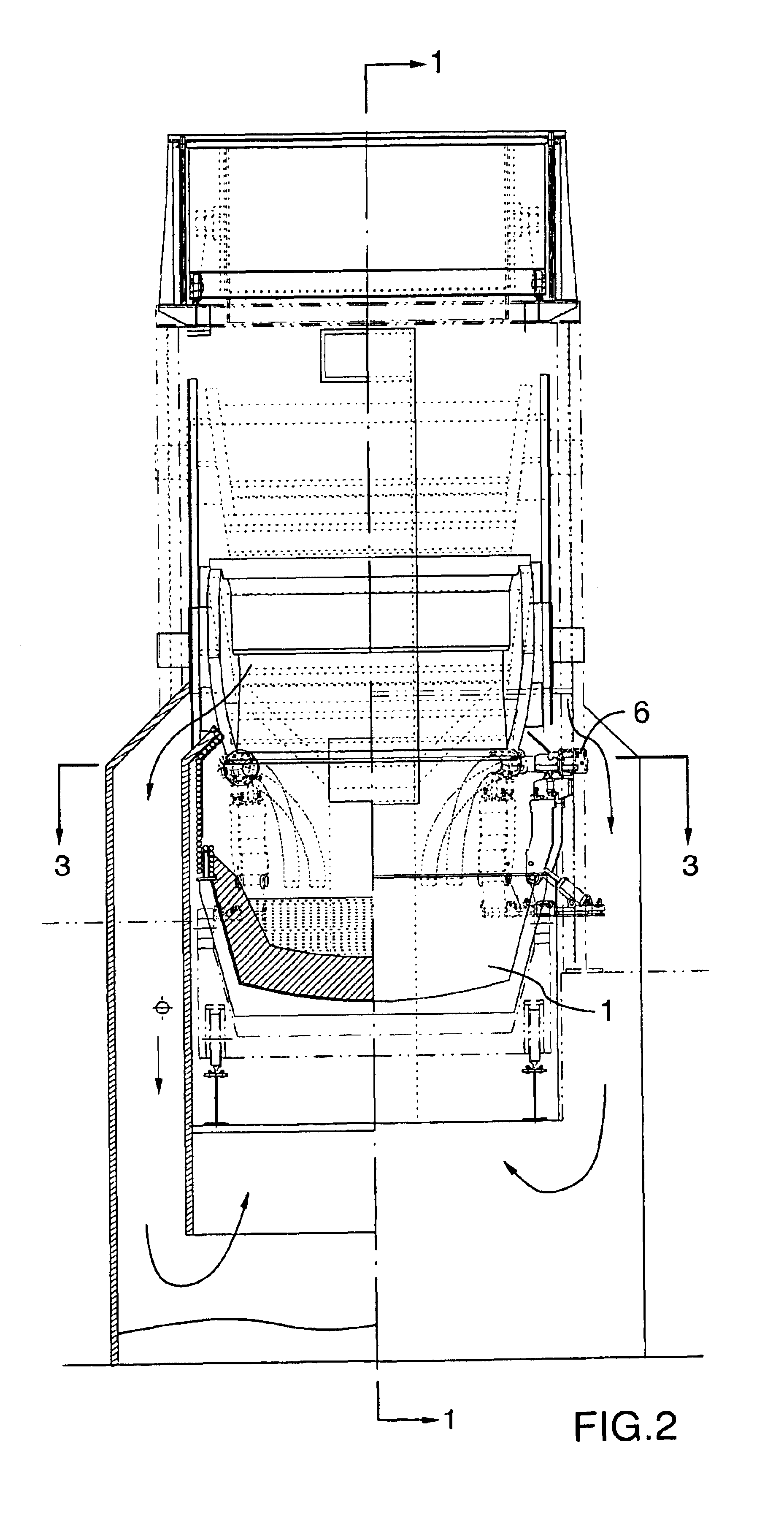

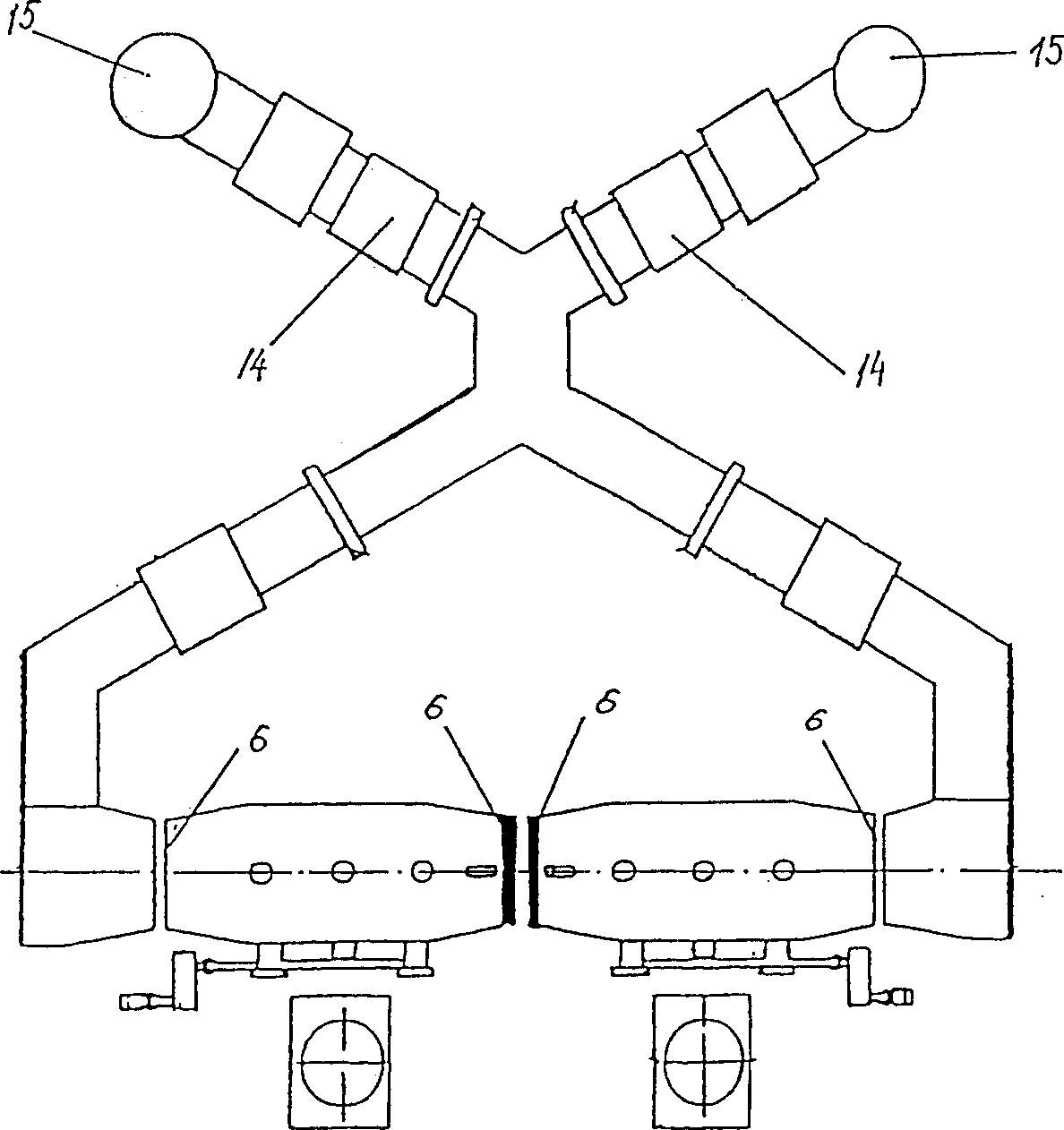

Metallurgical furnace with scrap metal preheater and dispenser

InactiveUS20030122290A1Reduce oxidationSimple and compact designBlast furnace componentsCharge supportsThermal energyProcess systems

A Preheater-Steelmaking Furnace and closed loop Process System for semi-continuous melting of integrally preheated recycled or virgin ferrous charge, by using highly energy efficient combustion process of natural gas combusted by oxygen as the main heat source, after preheating of the cold charge, by fully exploiting thermal energies of the melting process off-gases, in a gas tight, low noise, ecologically friendly PSF with scant CO and drastically reduced CO2 in exhaust gases for semi-continuous, batch self-charging, sealed pairs of eccentrically rotating quasi cylindrical, permeable half drums hoppers creating separate preheating chambers.

Owner:EMPCO (CANADA) LTD

Process and device for gasification of waste

Gasification of waste is performed in a gasifier having a gasification space (1) and a liquid rotating slag bath (2). The slag bath (2) is preferably caused to rotate by tangentially injecting gasification medium and / or at least a portion of the waste via a burner toward the surface of the slag bath. Waste with a diameter of to 5 mm is preferably introduced into gasifier (1) above the slag bath (2), while larger waste is preferably introduced directly into the slag bath. Slag is a removed, together with cracked gas accumulated during gasification through the floor of the gasifier via a slag drain having a lateral opening which protrudes above the slag bath.

Owner:LINDE KCA DRESDEN

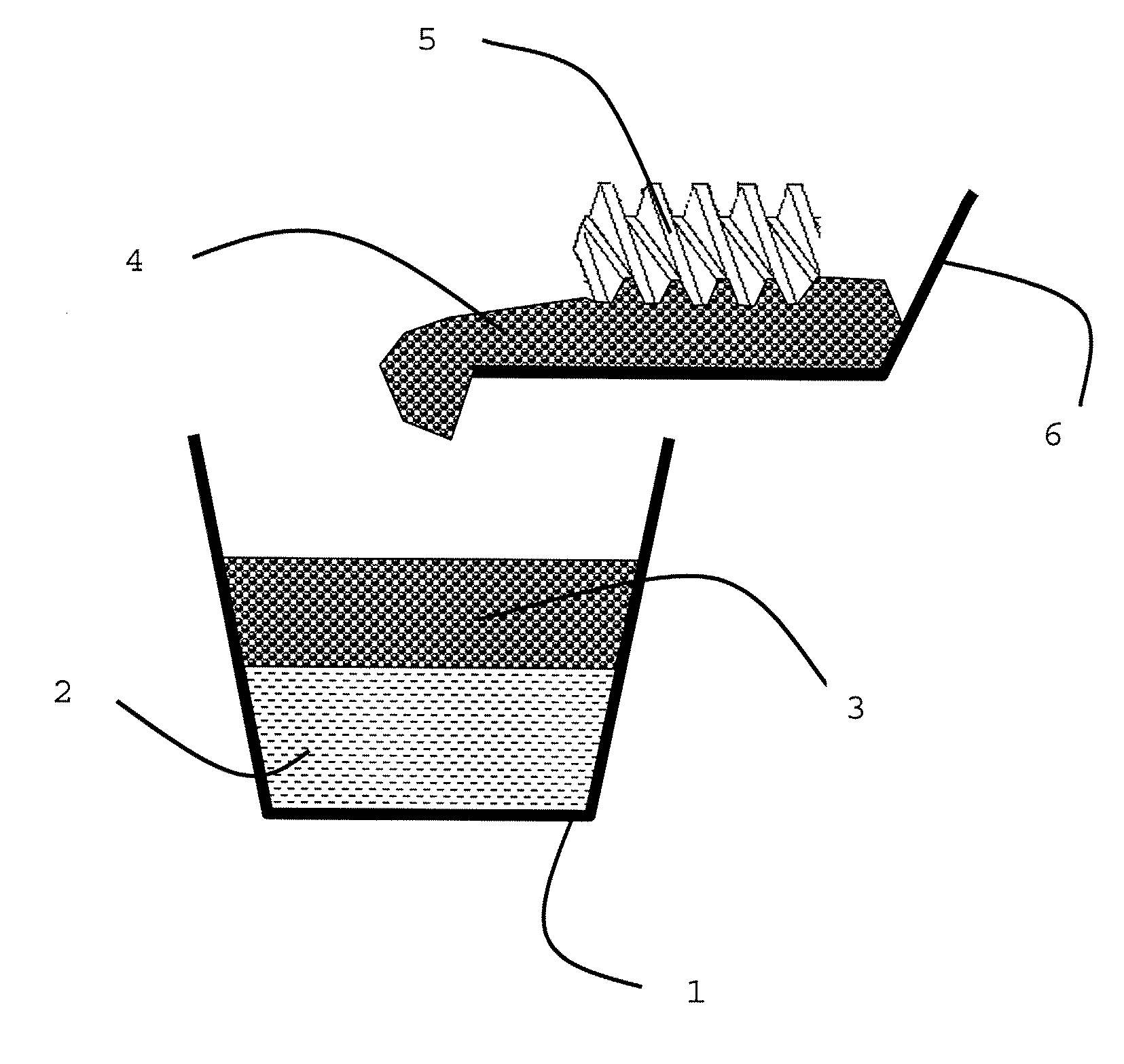

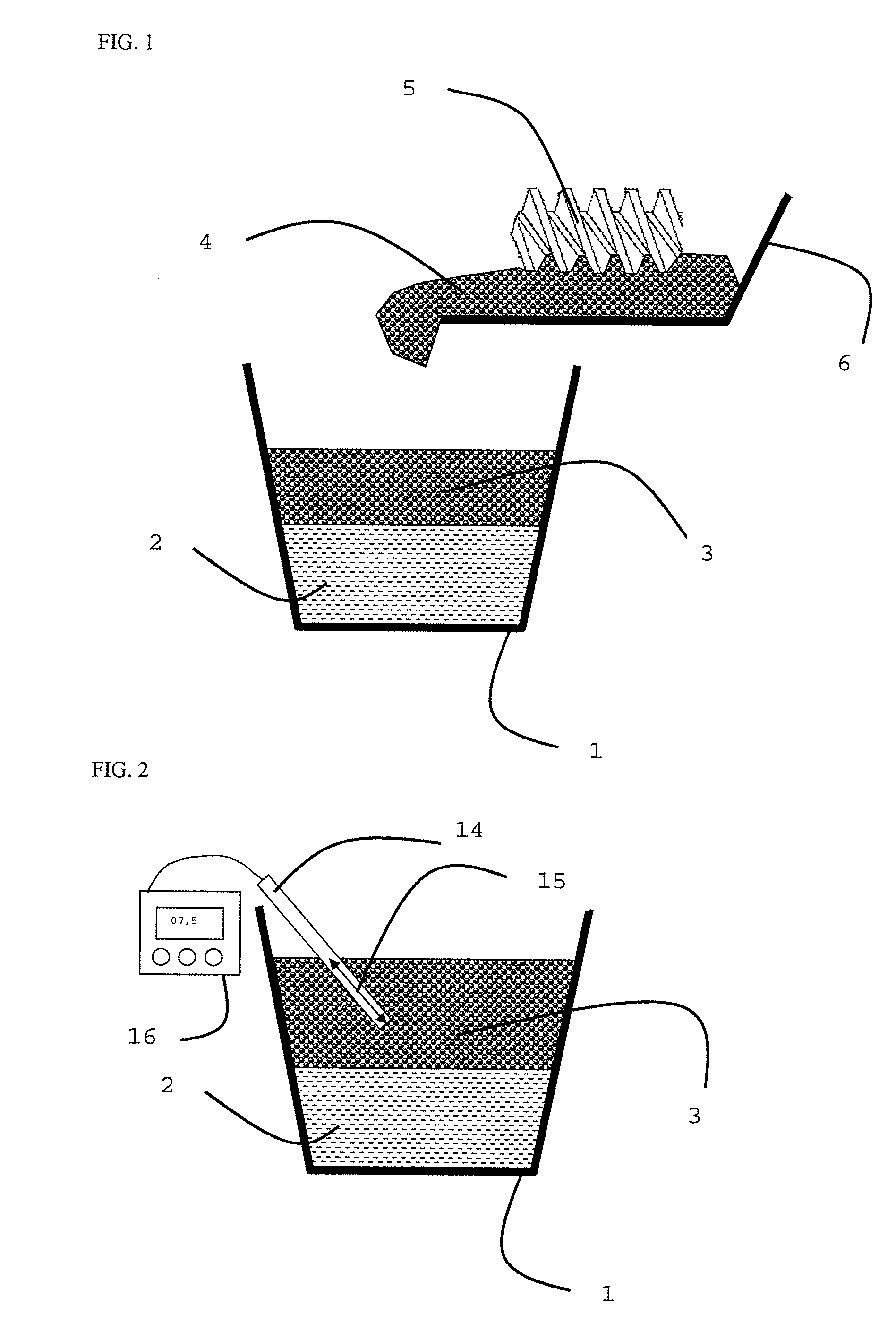

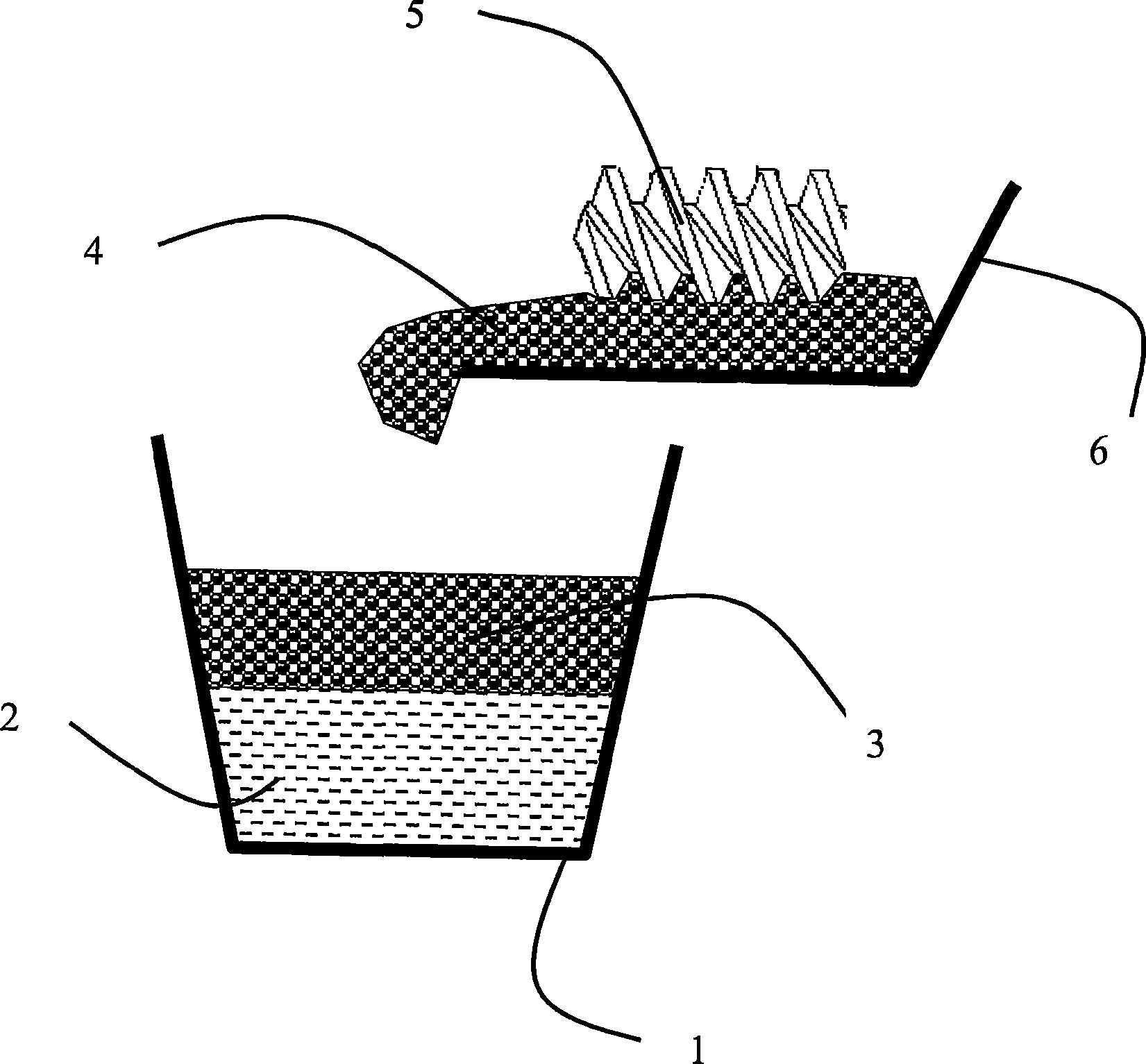

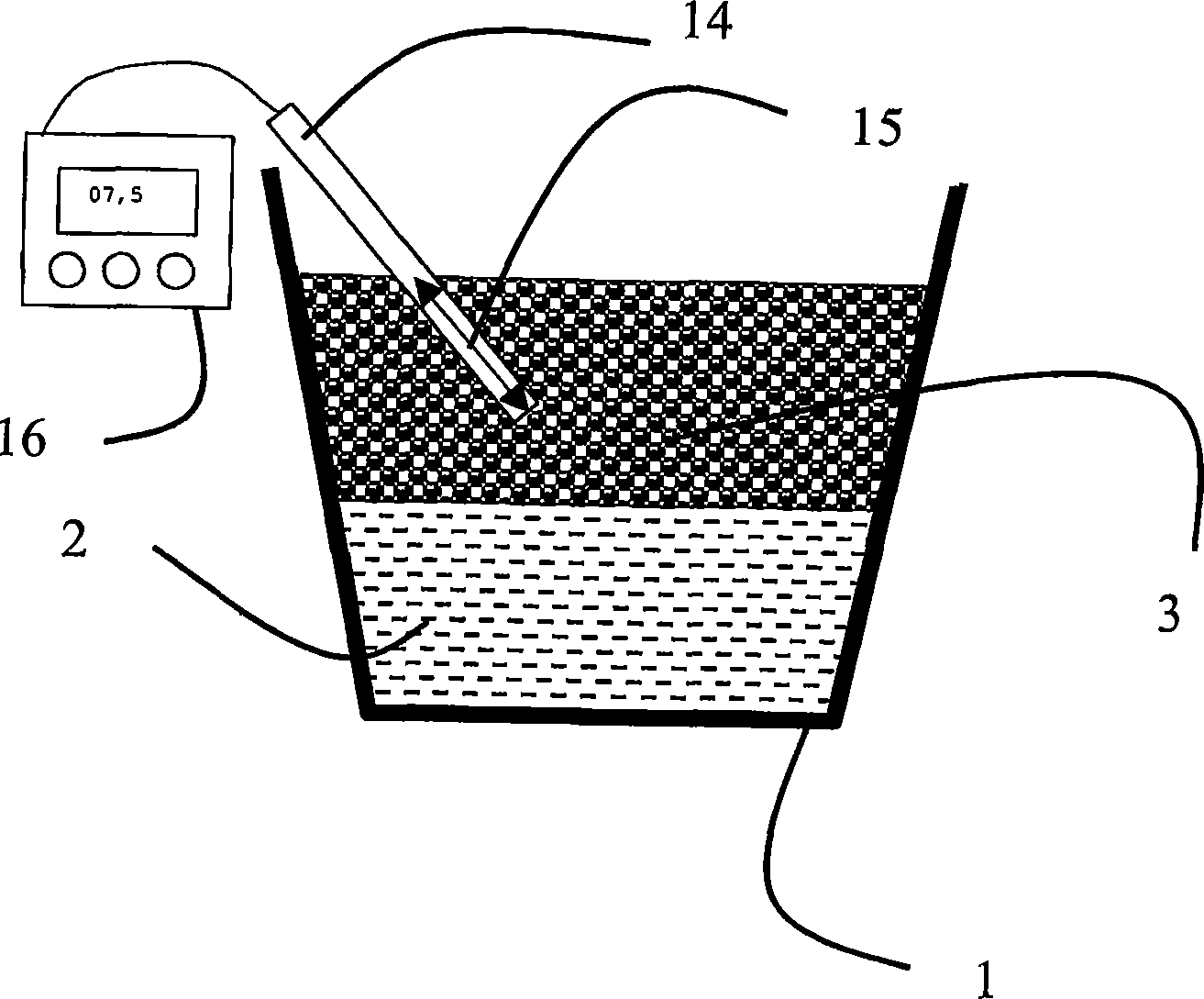

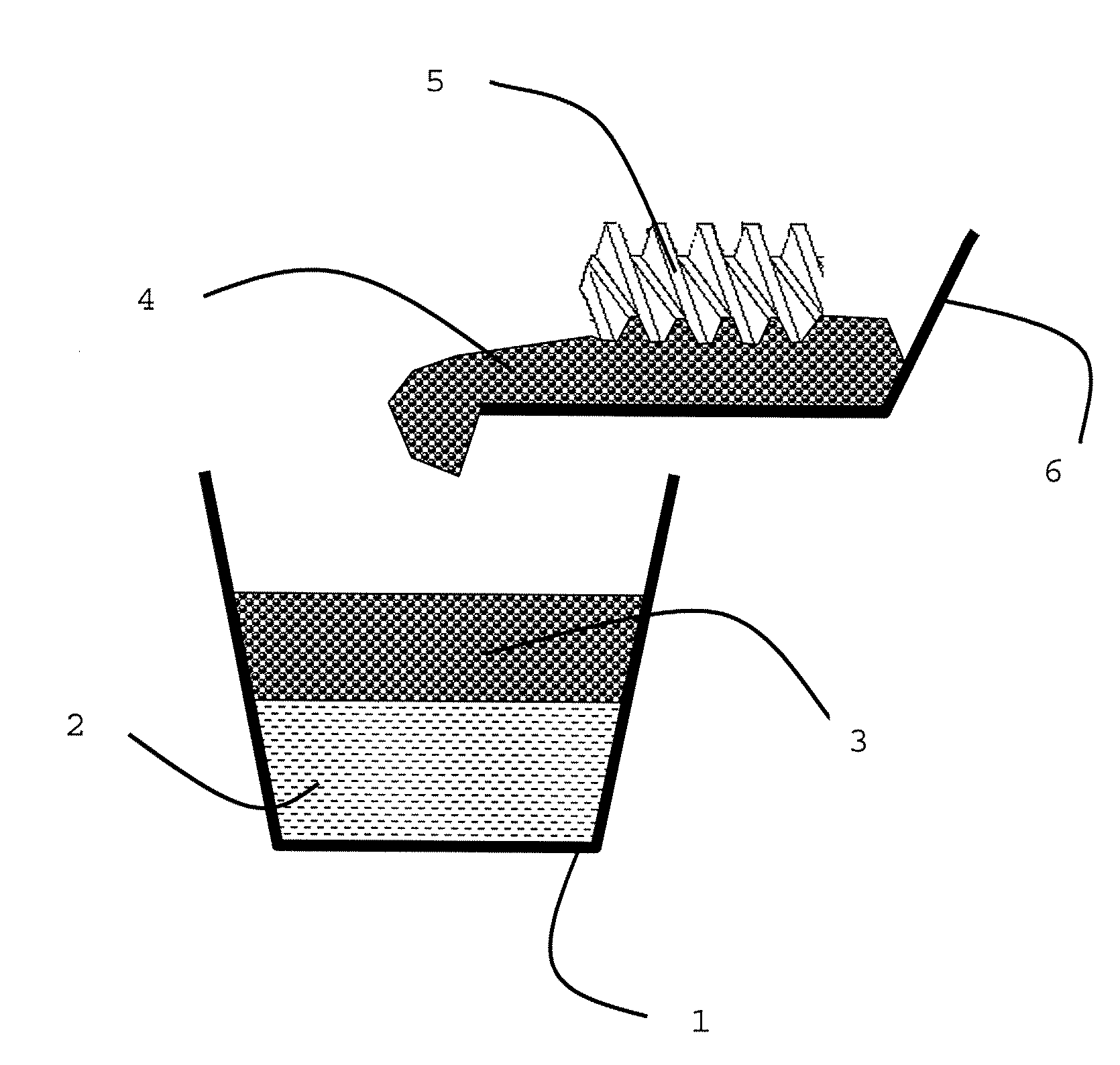

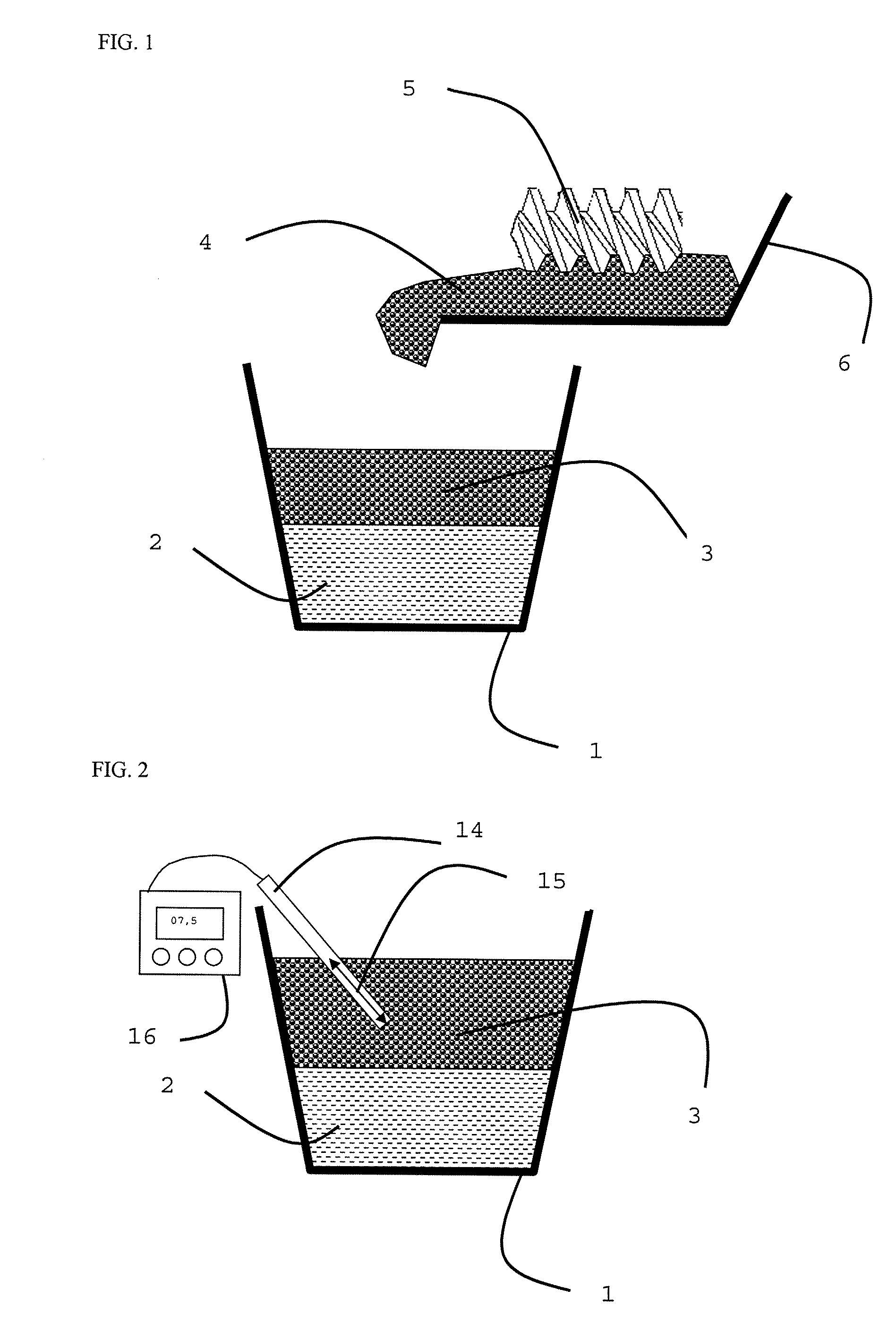

Method for recycling aluminum-lithium-type alloy scrap

InactiveUS7550028B2Limit of consequencesControl oxidationProcess efficiency improvementMetallurgical apparatusLithiumAlloy

The present invention is directed to a method for melting scrap of an aluminum alloy containing lithium. The steps include providing scrap containing aluminum-lithium-type alloys, preparing an initial liquid metal bed of a first composition in a smelting oven, loading the scrap onto the initial liquid metal bed so as to create a floating layer of the scrap with a controlled thickness at the surface of the liquid metal bed, partially melting the floating layer via contact with the metal bed so as to obtain a liquid metal bath having a second composition, and removing the liquid metal from the second composition of the liquid metal bath. The method has technical and economic advantages. It does not require investment in a particular installation and it requires minimal use of expensive expendable materials such as inert gas, because the formation of a floating layer having a controlled thickness makes it possible to effectively protect the surface of the liquid metal from oxidation.

Owner:CONSTELLIUM ISSOIRE

Method for oxy-fuel combustion

InactiveUS7282171B2Improve efficiencyLess fuelSolid waste disposalMaintainance of heating chambersCombustion systemNitrogen

An oxygen fueled combustion system includes a furnace having at least one burner, an oxygen supply for supplying oxygen having a predetermined purity, and a carbon based fuel supply for supplying a carbon based fuel. The oxygen and the carbon based fuel are fed into the furnace in a stoichiometric proportion to one another to limit an excess of either the oxygen or the carbon based fuel to less than 5 percent over the stoichiometric proportion. The combustion of the carbon based fuel provides a flame temperature in excess of 4500° F. The exhaust gas stream from the furnace has substantially zero nitrogen-containing combustion produced gaseous compounds from the oxidizing agent and reduced green-house gases. Substantially less carbon based fuel is required than conventional combustion systems without a loss of energy output.

Owner:JUPITER OXYGEN CORP

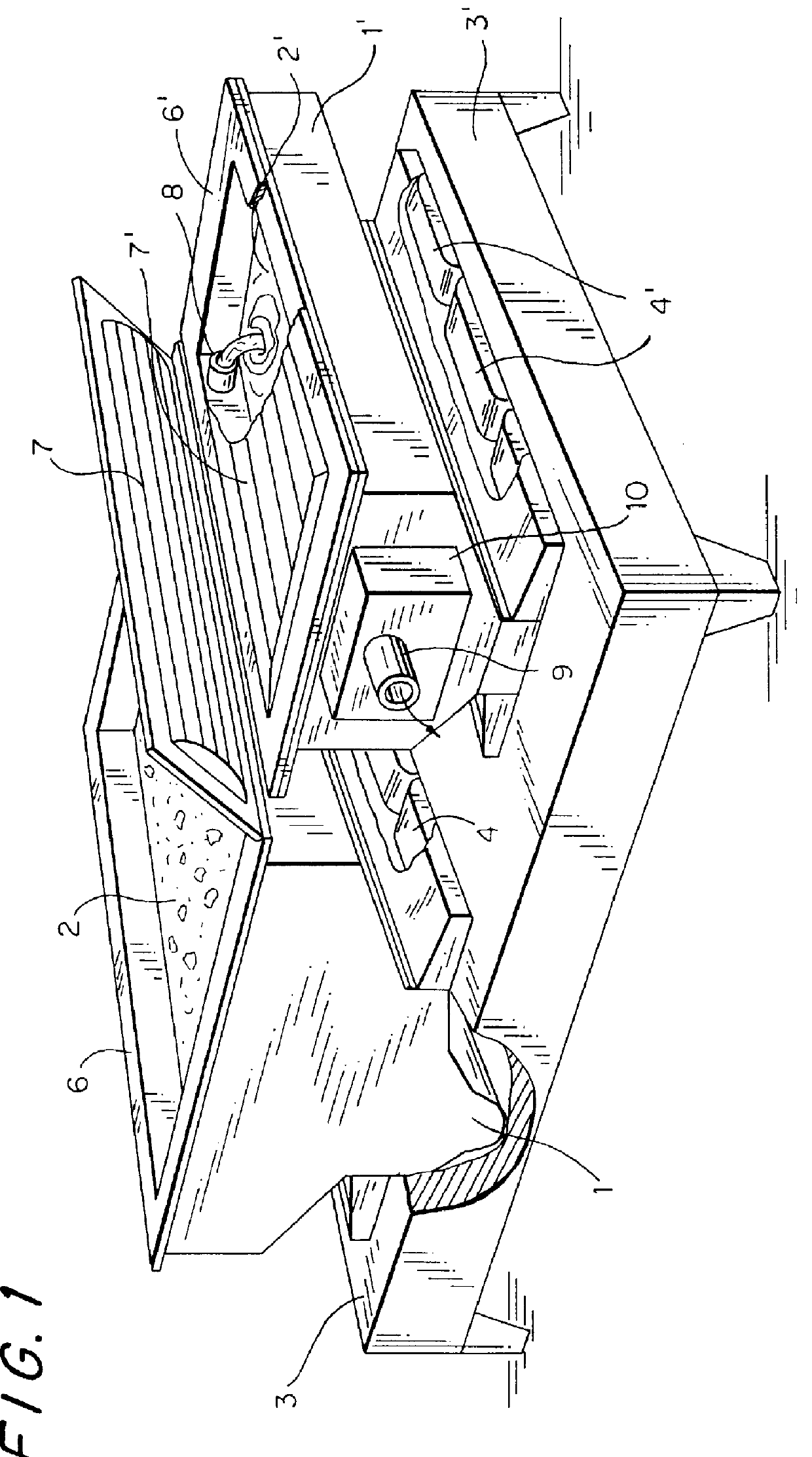

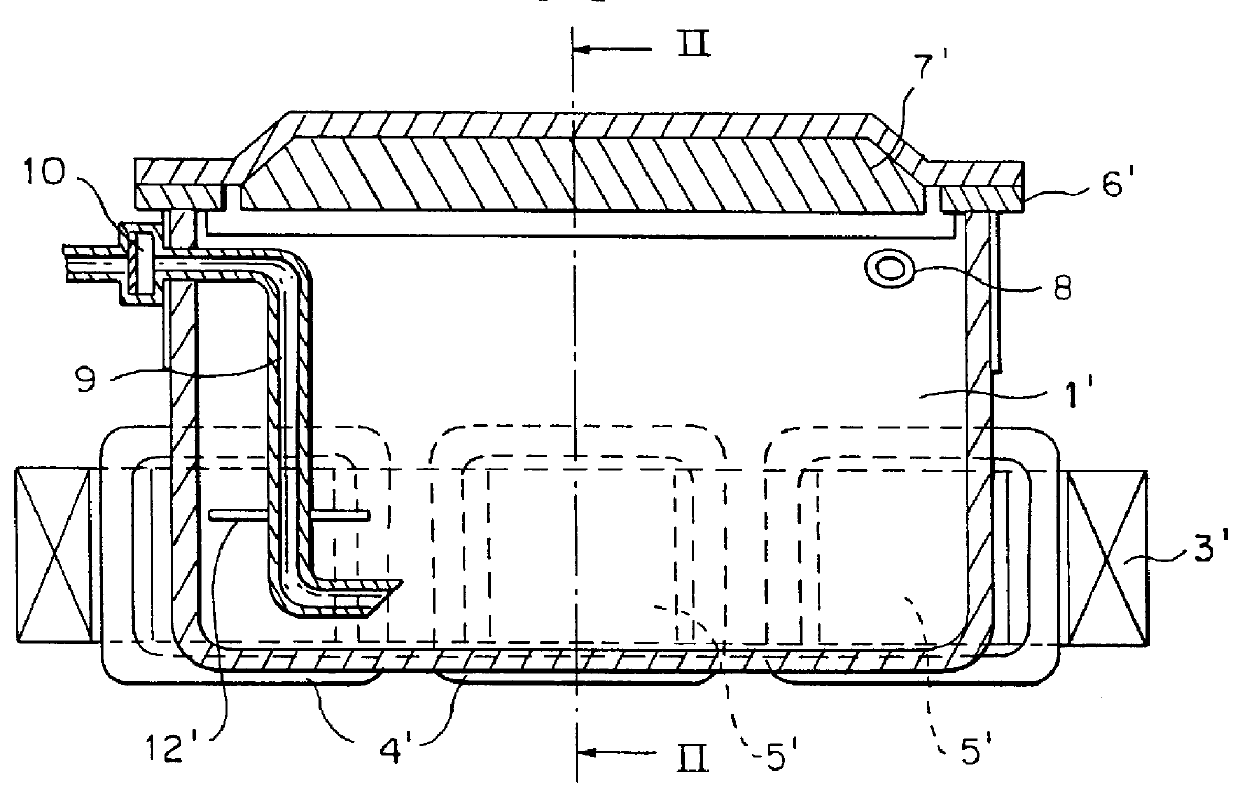

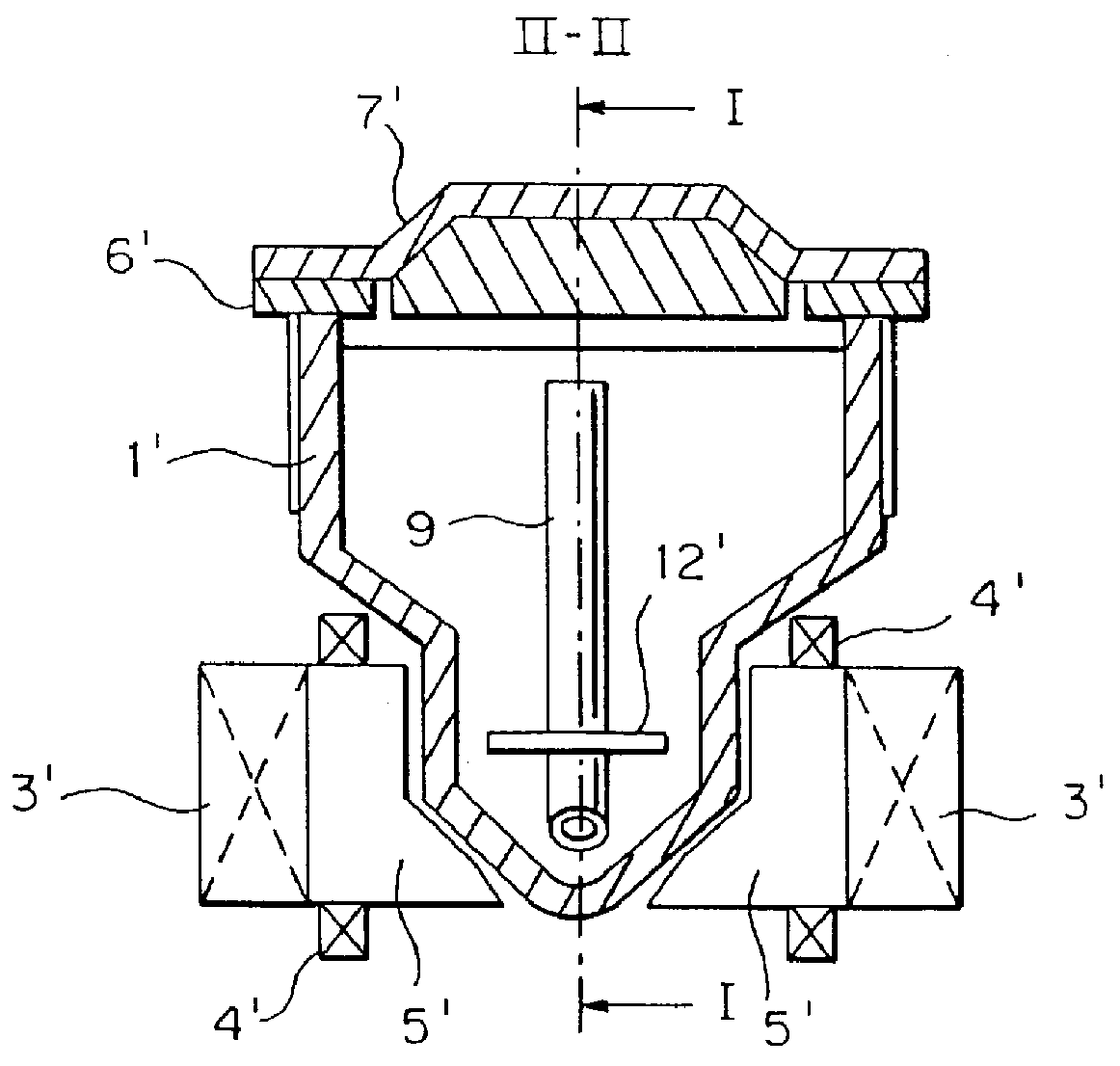

Apparatus for the process of melting and purification of aluminum, copper, brass, lead and bronze alloys

InactiveUS6010552AReduce riskReduced effectivenessTransportation and packagingMixersFiltrationElectromagnetic induction

The present apparatus is comprised by two magnetic induction sets, one for melting of the raw material and the second for purification of molten metal; each set comprises a pot or crucible (1, 1'), an electromagnetic device, a filter (11) and a power supply; each crucible (1, 1') is surrounded in the lower part by a hollow permanent magnet (3, 3') in which three pairs of electromagnets facing each other are arranged; the process consists of the following stages: a) charging of metallic raw material inside a crucible (1); b) electromagnetic induction heating to melt the metallic raw material (2) inside crucible (1) through a three-phase magnetic system creating a horizontal travelling or pules magnetic field which builds a turbulent flux inside the melt (2'); c) whirling stirring of melt (2') by electromagnetic induction and purification of it via extraction of hydrogen and of non-electroconductive inclusions by coagulation of them in agglomerates; d) discharging of purified melt (2') by a magneto-hydrodynamic pump effect for the next treatment or technological actions such as the continuous or periodical casting through a filter for the mechanical filtration of the agglomerates.

Owner:S E TRI

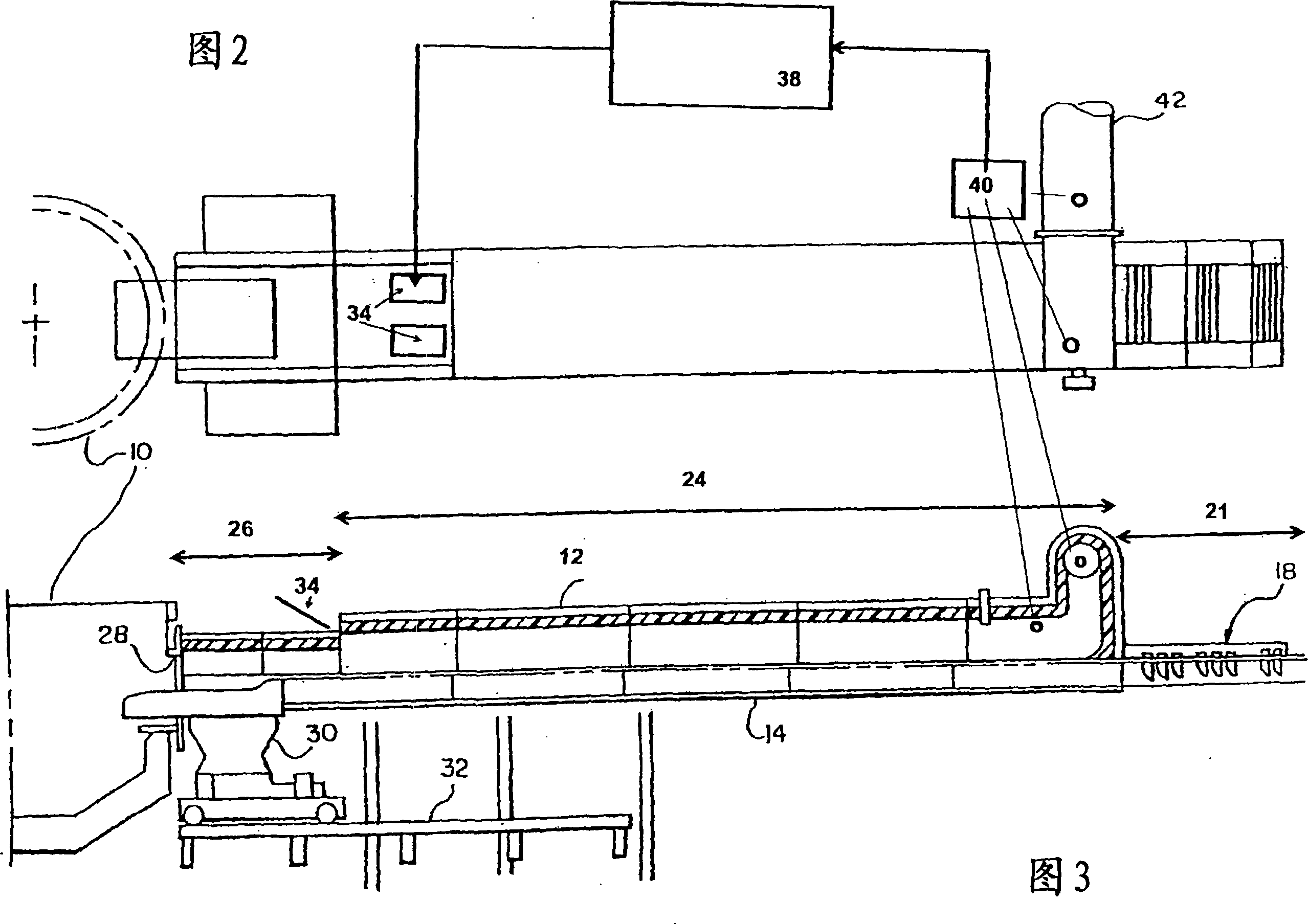

Charging device, especially charging stock preheater

To facilitate a trouble-free charging of scrap metal having differing constitutions, such as light and heavy scrap metal, from a lower discharge opening of a shaft-shaped charging device or a charging stock preheater (1) into a melting vessel by a pusher (13), the lateral surfaces of the pusher (13) are formed so as to converge from the upper side to the lower side and the actuating device (2) of the pusher (13) is pivotably supported in a frame structure (3) about a horizontal axis. In addition, the upper boundary of the discharge opening for the charging stock from the shaft (2) is preferably formed by a horizontal, rotatably supported roller (26), more preferably with engaging elements (30) distributed around the circumferential surface. Sections of the charging device that are severely mechanically stressed are preferably formed by steel billet sections connected to form a structural unit.

Owner:FUCHS TECH

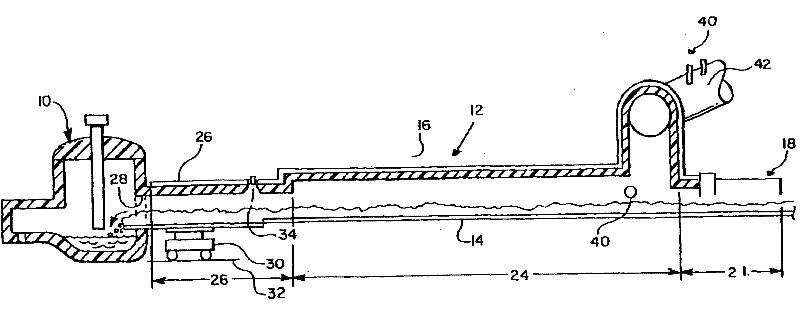

Apparatus for the combustion of gas exiting from a furnace, for the preheating of scraps entering the furnace itself and related process

ActiveCN101120221AImproved Environmental Impact FeaturesShort response timeFurnace typesPreheating chargesElectric arc furnaceHeat of combustion

Apparatus for the combustion of gas exiting from an electric arc furnace where the heat of combustion is used for the preheating of scraps entering the furnace wherein the apparatus has an insertion device for introducing comburent substance into a preheating chamber or loading tunnel for scrap metal where the loding tunnel has an inlet section for scrap metal, a seal section to prevent an uncontrolled entrance of air in the tunnel, a heating section and an unloading section for delivering scrap metal to the furnace. The insertion device for the comburent substance has one or more adjustable openings placed in the loading tunnel, and said apparatus comprises a device or a series of devices.

Owner:ТЕНОВА ТЕКНОЛОДЖИЗ (ТЯНЬЦЗИНЬ) КО., ЛТД.

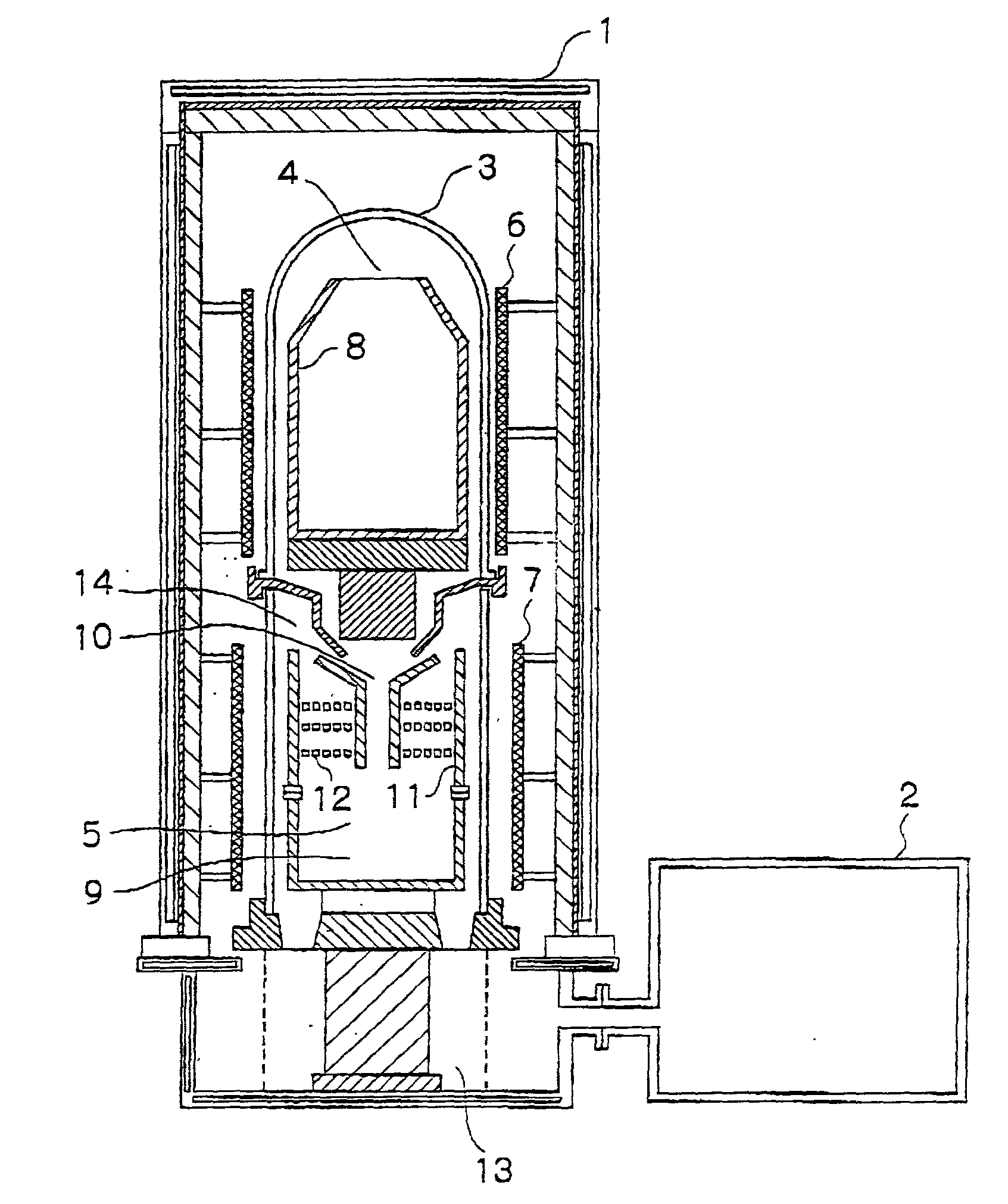

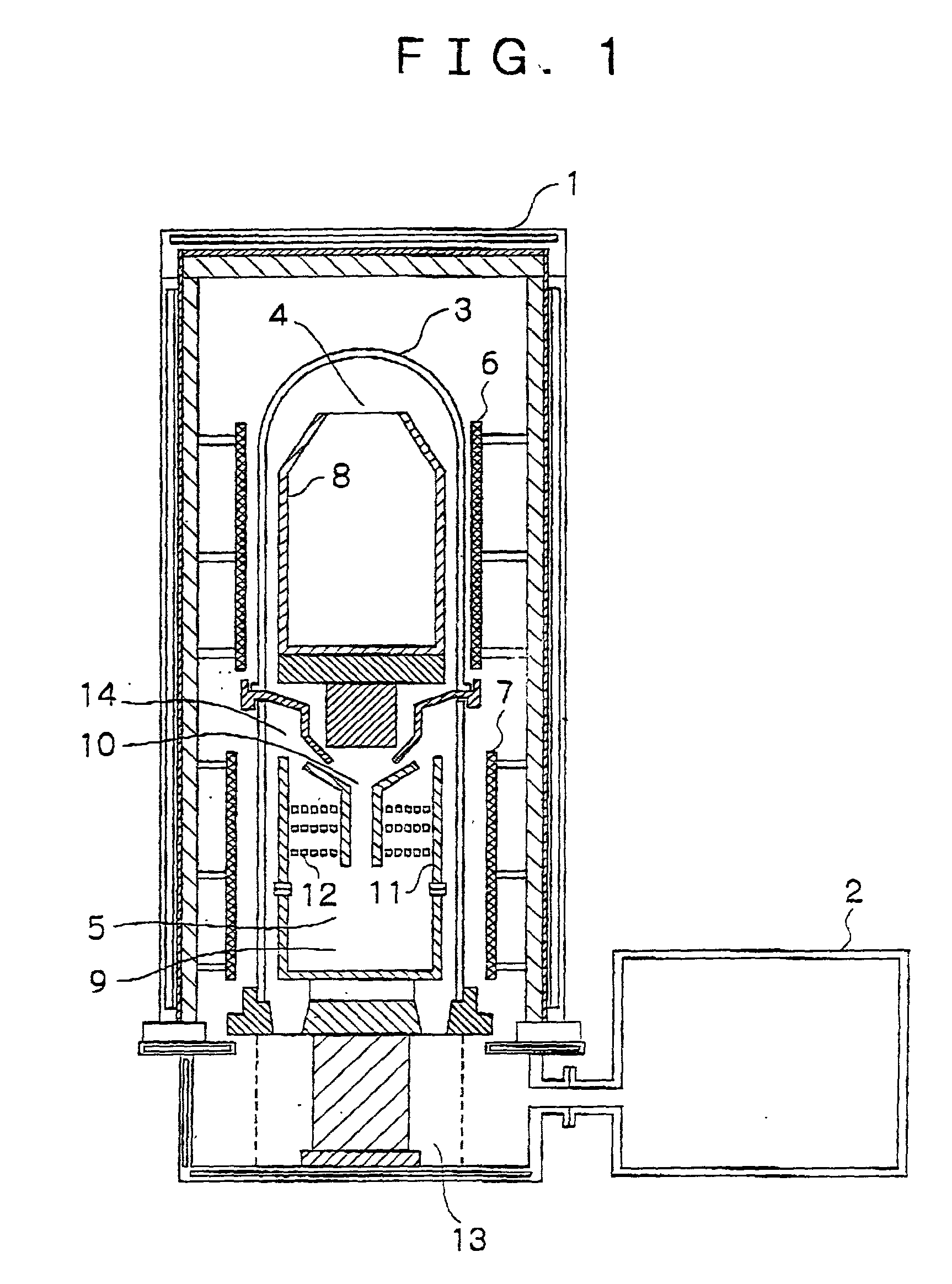

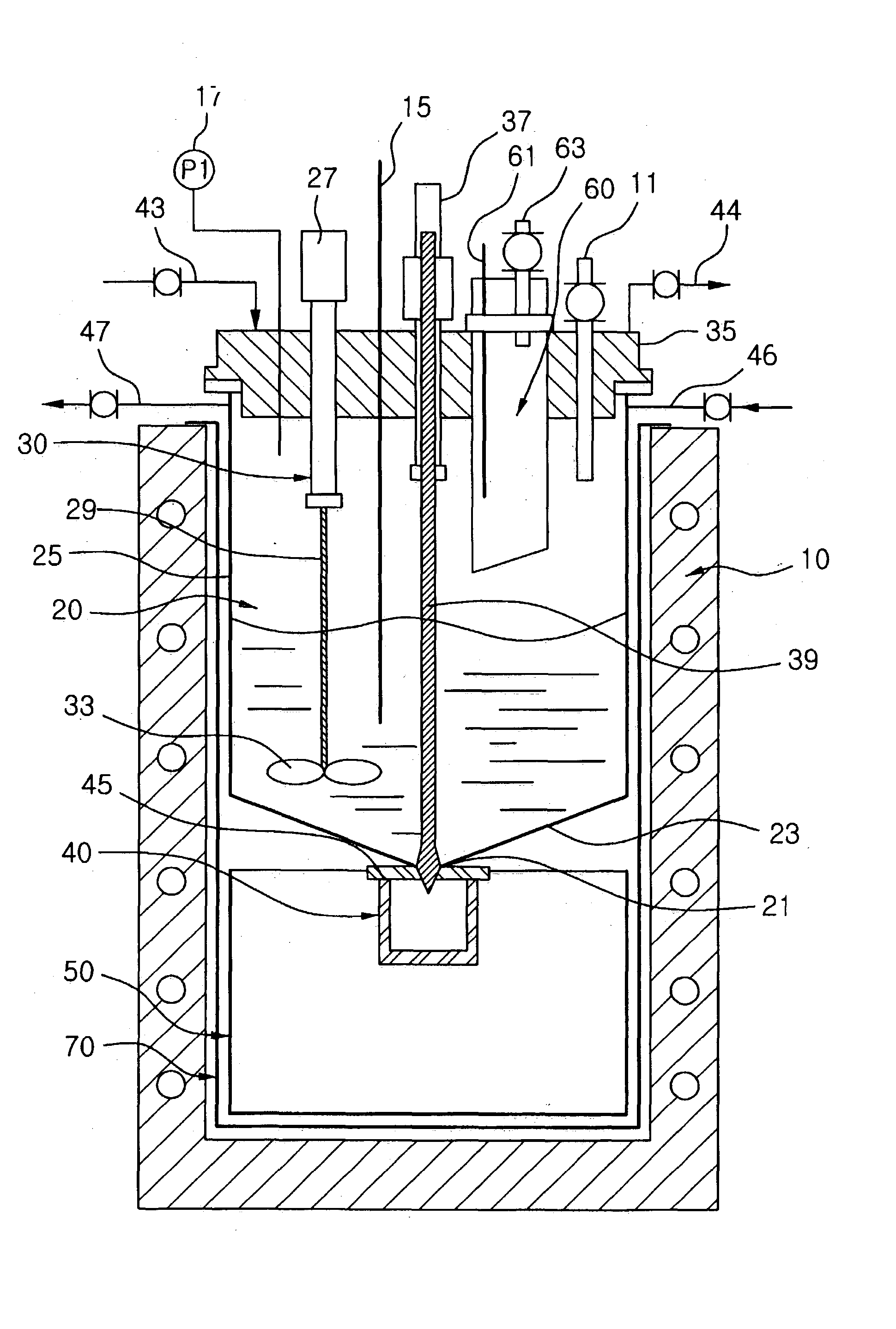

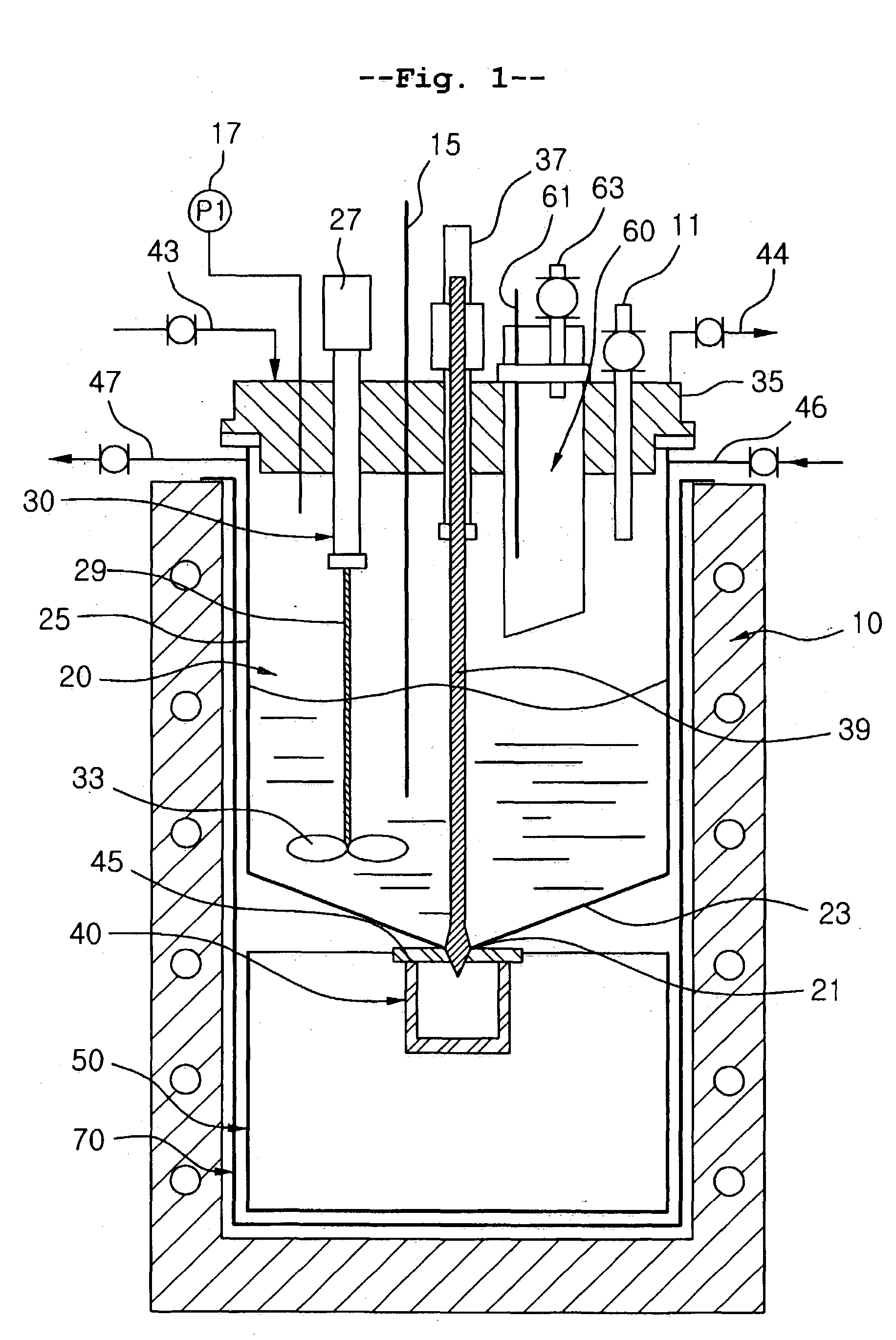

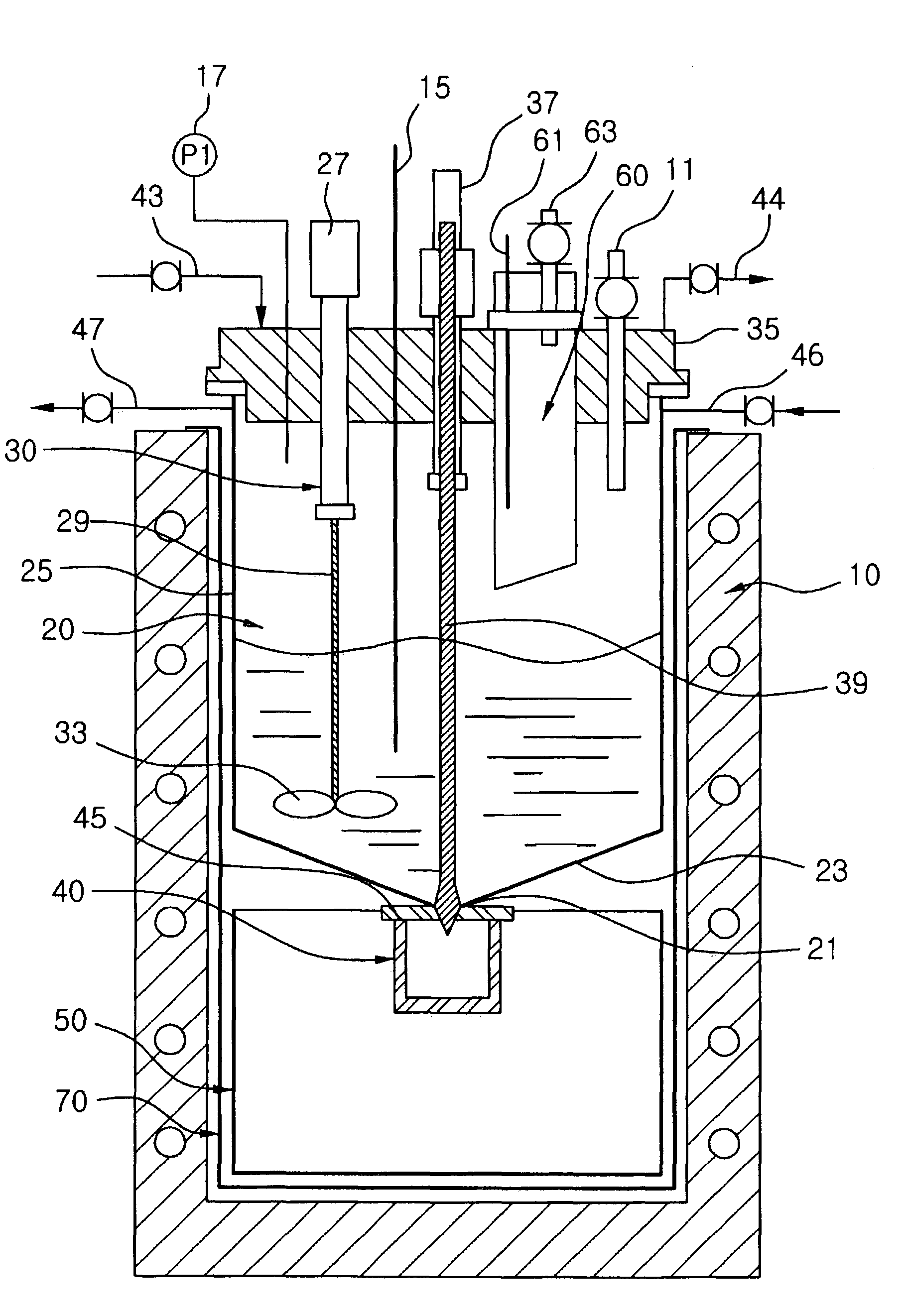

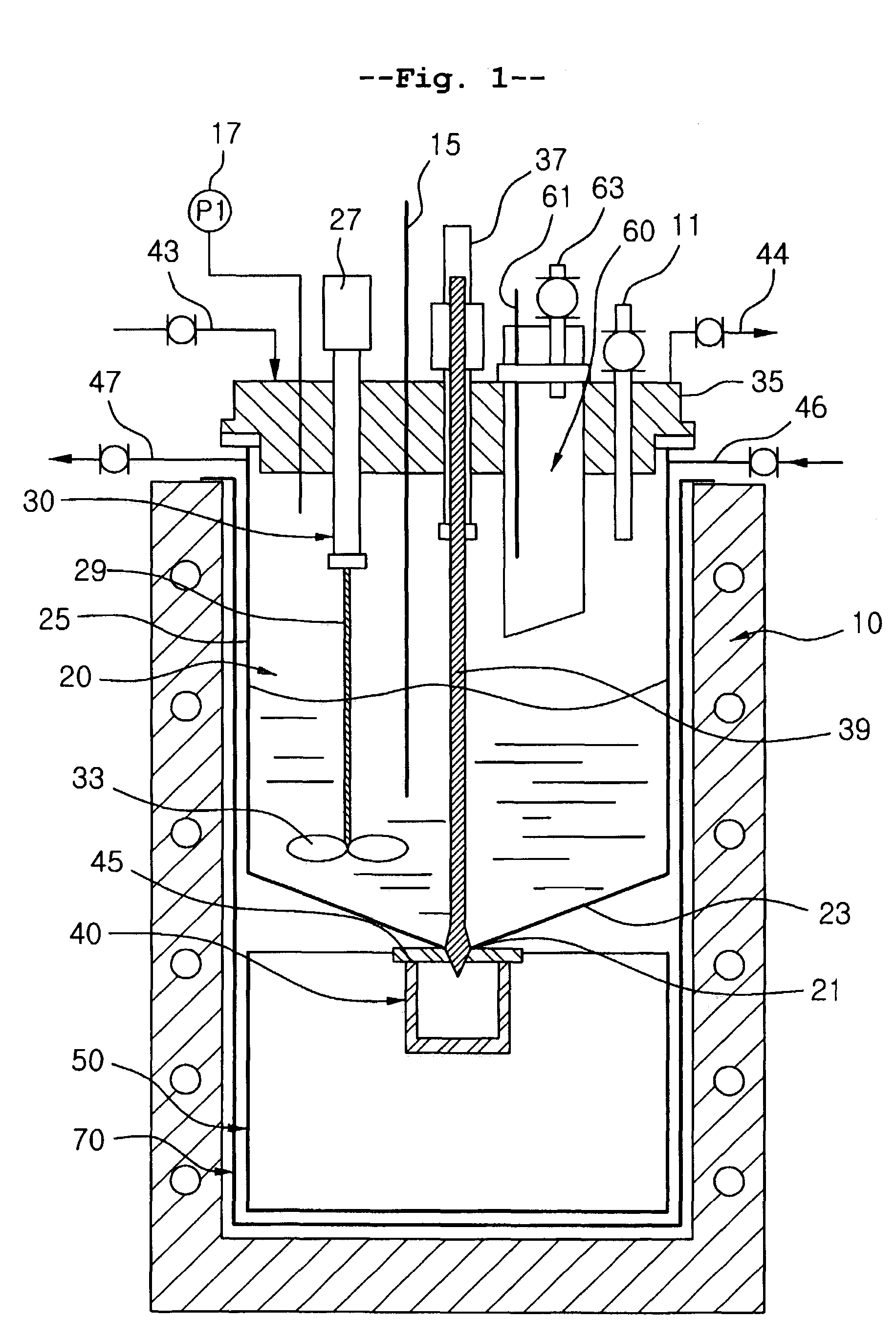

Method and apparatus for enhanced purification of high-purity metals

InactiveUS20030145683A1Accelerate the speed of purificationAvoid recontaminationProcess efficiency improvementMetallurgical apparatusIndiumCrucible

A 99.99% pure indium feed is charged into crucible 8 and heated to 1250° C. by upper heater 6 in a vacuum atmosphere at 1x10-4 Torr, whereupon indium evaporates, condenses on the inner surfaces of inner tube 3 and drips to be recovered into liquid reservoir 9 in the lower part of tubular member 11 whereas impurity elements having lower vapor pressure than indium stay within crucible 8. The recovered indium mass in liquid reservoir 9 is heated to 1100° C. by lower heater 7 and the resulting vapors of impurity elements having higher vapor pressure than indium pass through diffuser plates 12 in the upper part of tubular member 11 to be discharged from the system whereas the indium vapor recondenses upon contact with diffuser plates 12 and returns to liquid reservoir 9, yielding 99.9999% pure indium while preventing the loss of indium.

Owner:DOWA METALS & MINING CO LTD

Metallurgical furnace with scrap metal preheater and dispenser

InactiveUS6696013B2Reduce oxidationSimple and compact designBlast furnace componentsCharge supportsSteelmakingLow noise

Owner:EMPCO (CANADA) LTD

Method for recycling scrap containing aluminium-lithium-type alloys

ActiveCN101238228AMinimize usagePrevent oxidationProcess efficiency improvementMetallurgical apparatusLiquid metalAlloy

The present invention is directed to a method for melting scrap of an aluminum alloy containing lithium. The steps include providing scrap containing aluminum-lithium-type alloys, preparing an initial liquid metal bed of a first composition in a smelting oven, loading the scrap onto the initial liquid metal bed so as to create a floating layer of the scrap with a controlled thickness at the surface of the liquid metal bed, partially melting the floating layer via contact with the metal bed so as to obtain a liquid metal bath having a second composition, and removing the liquid metal from the second composition of the liquid metal bath. The method has technical and economic advantages. It does not require investment in a particular installation and it requires minimal use of expensive expendable materials such as inert gas, because the formation of a floating layer having a controlled thickness makes it possible to effectively protect the surface of the liquid metal from oxidation.

Owner:CONSTELLIUM ISSOIRE

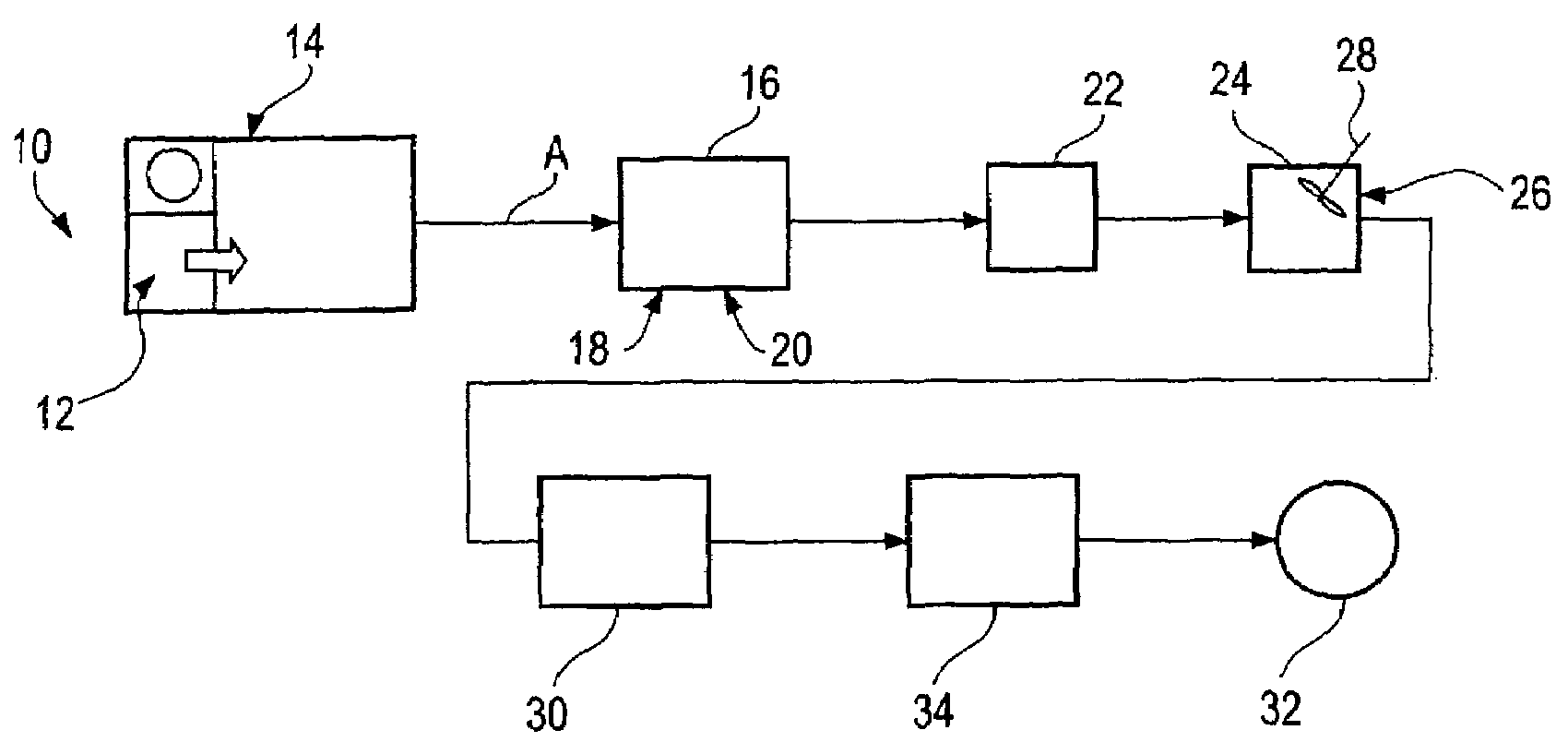

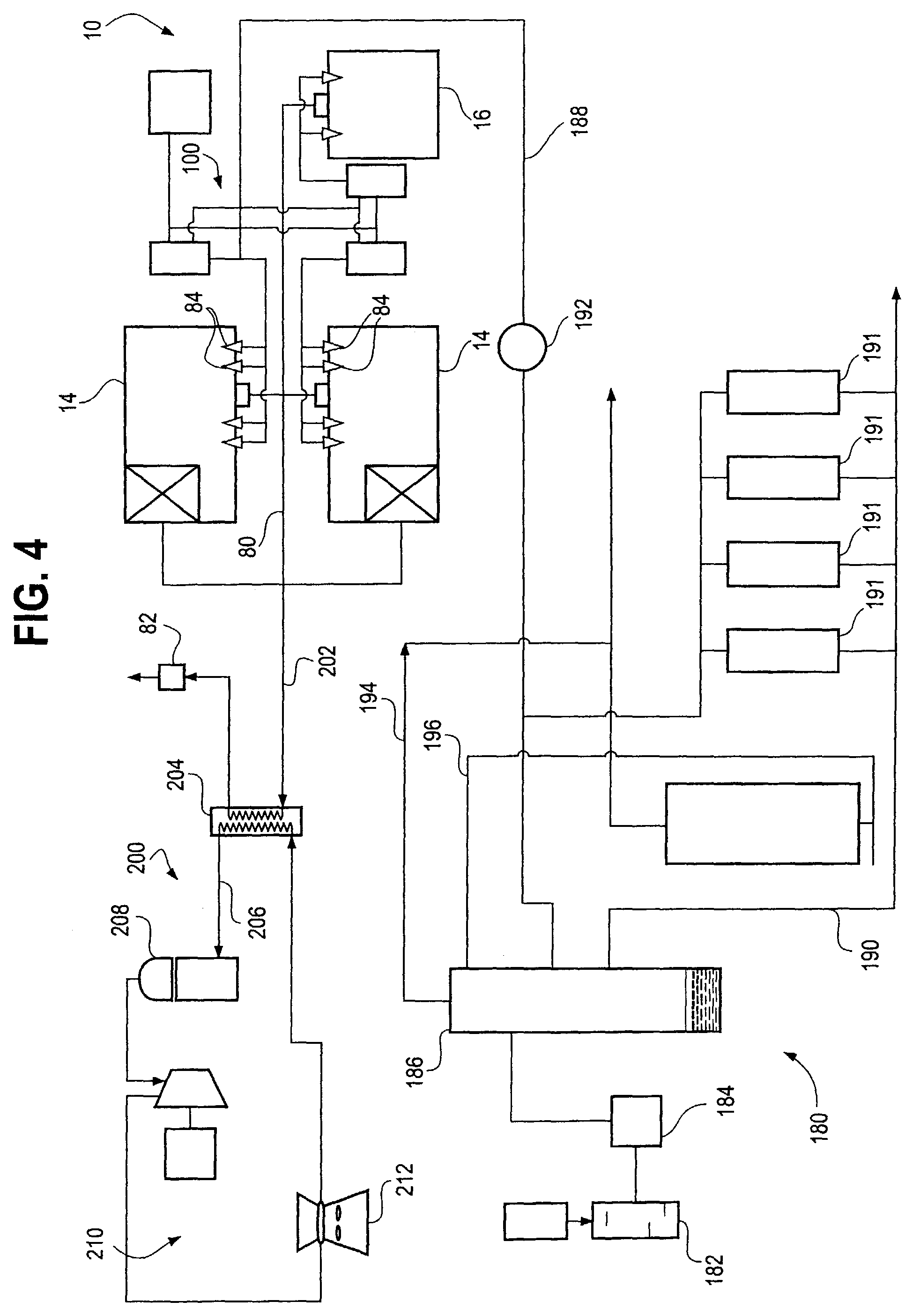

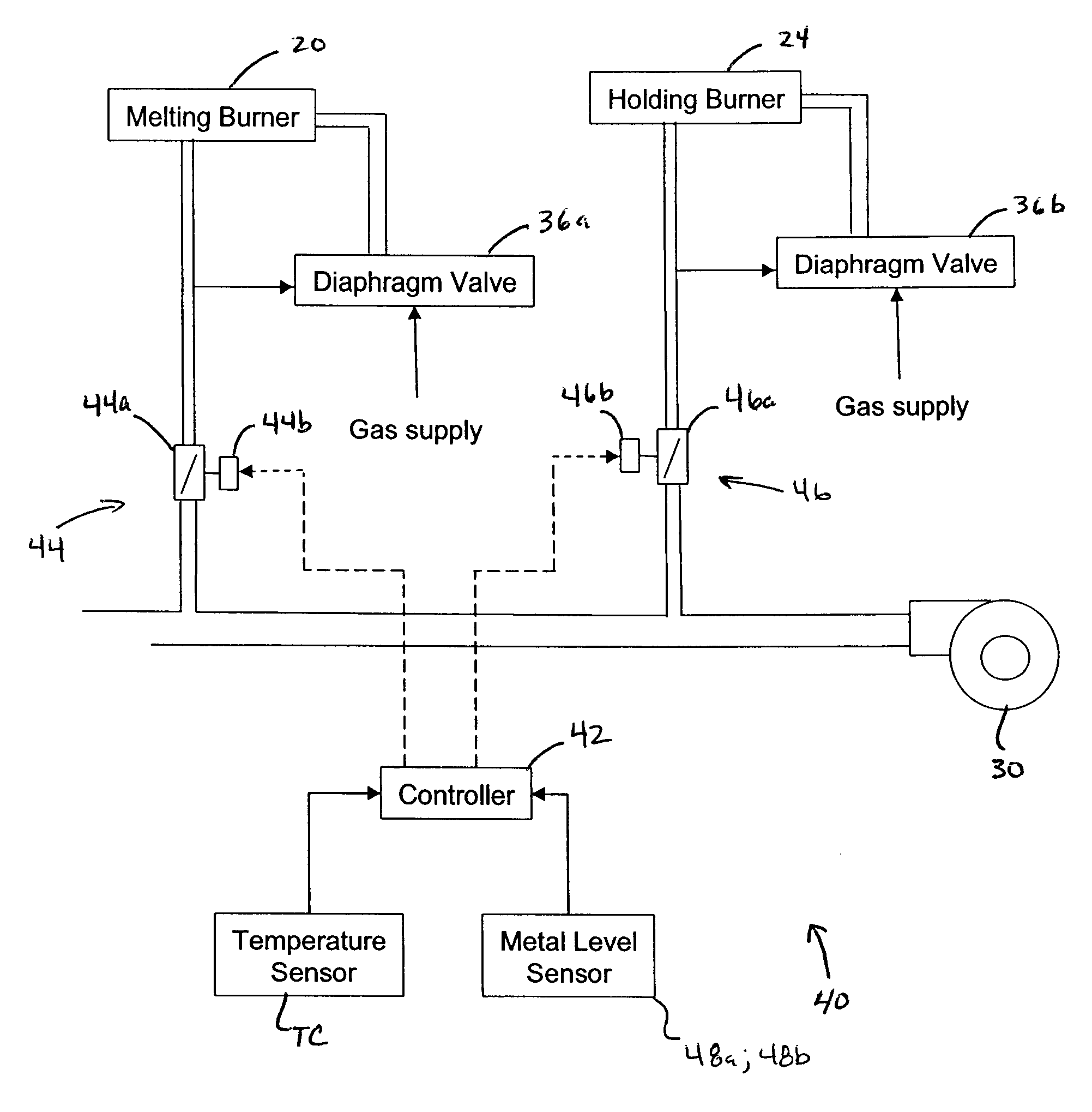

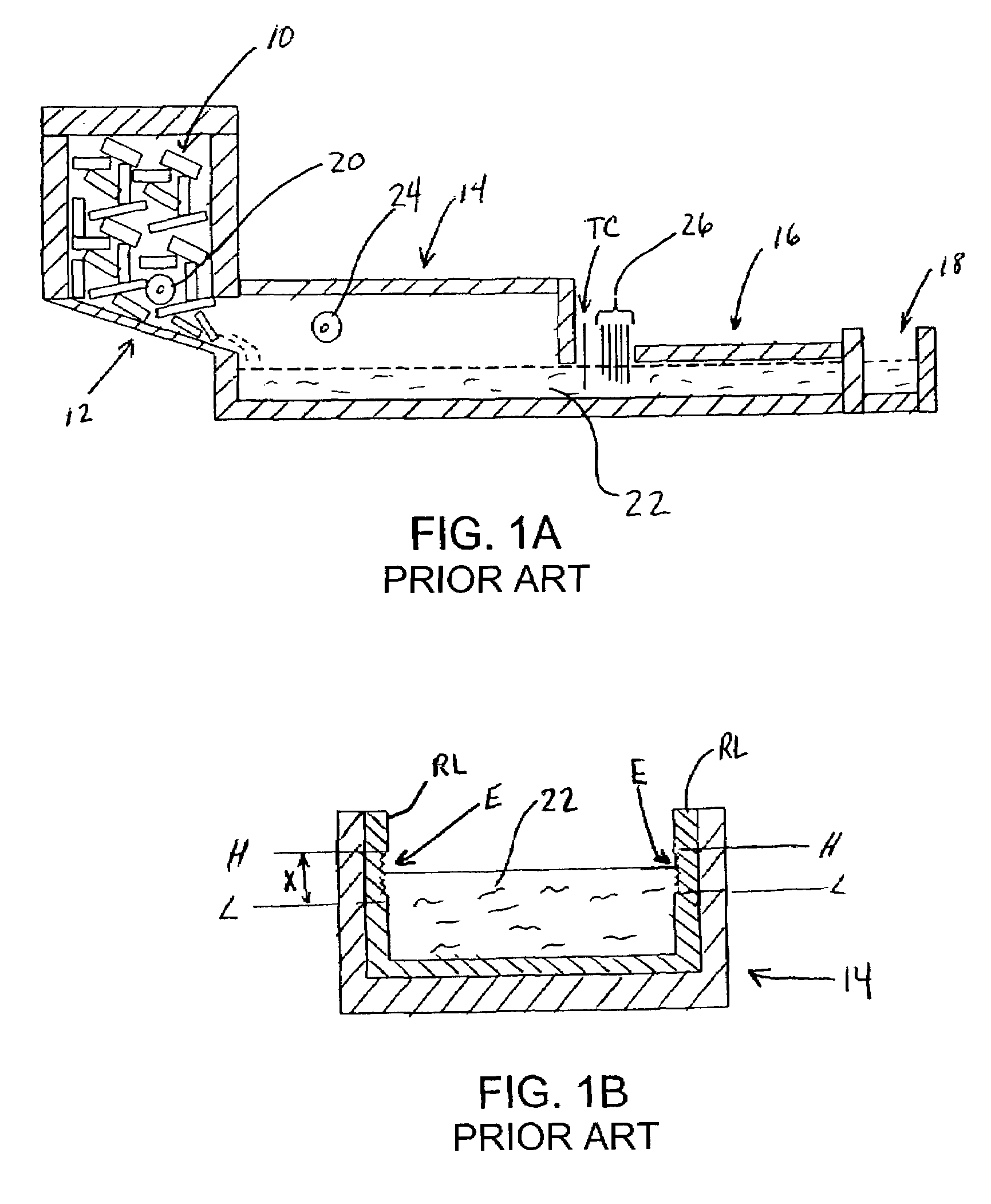

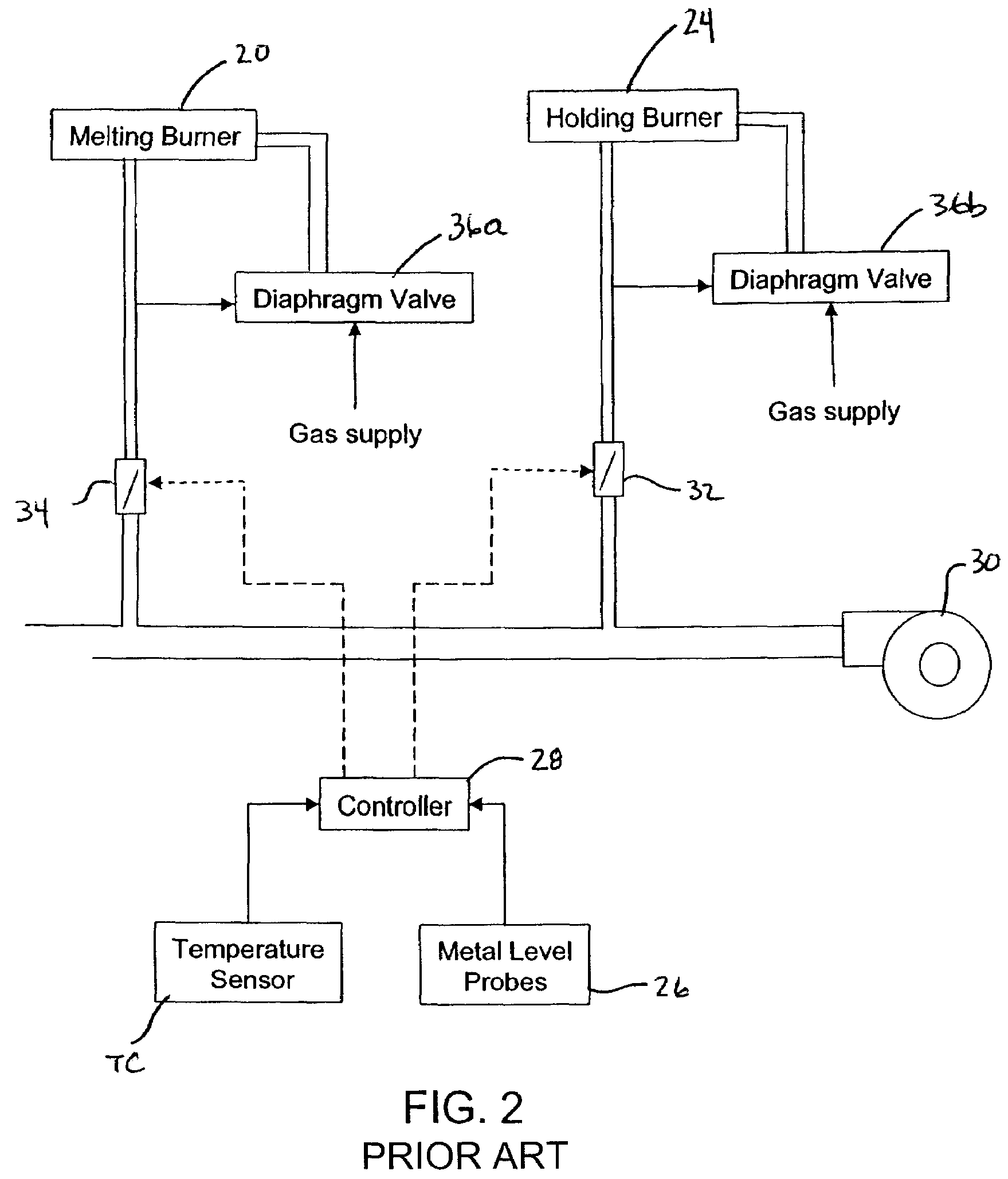

Molten metal level burner output control for aluminum melt furnace

A control system and method for controlling a temperature and molten metal height in a gas-fired metal melting furnace whereby metal height and temperature may be more reliably maintained. The control system includes a controller that receives information on metal temperature and metal height. The controller controls metal melting burners so as to operate at different settings between a high output and a low output based upon sensed metal height.

Owner:HONDA MOTOR CO LTD

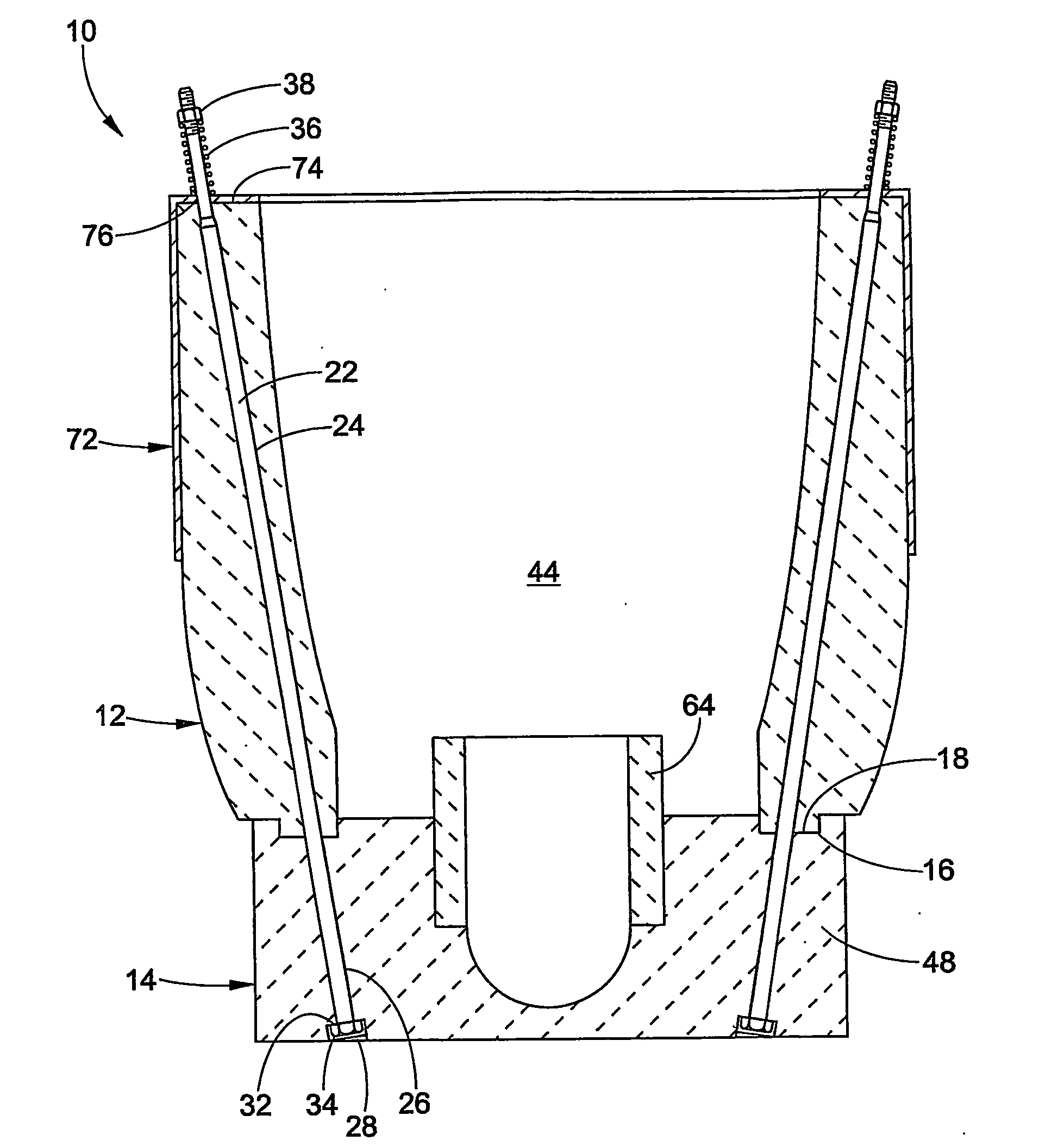

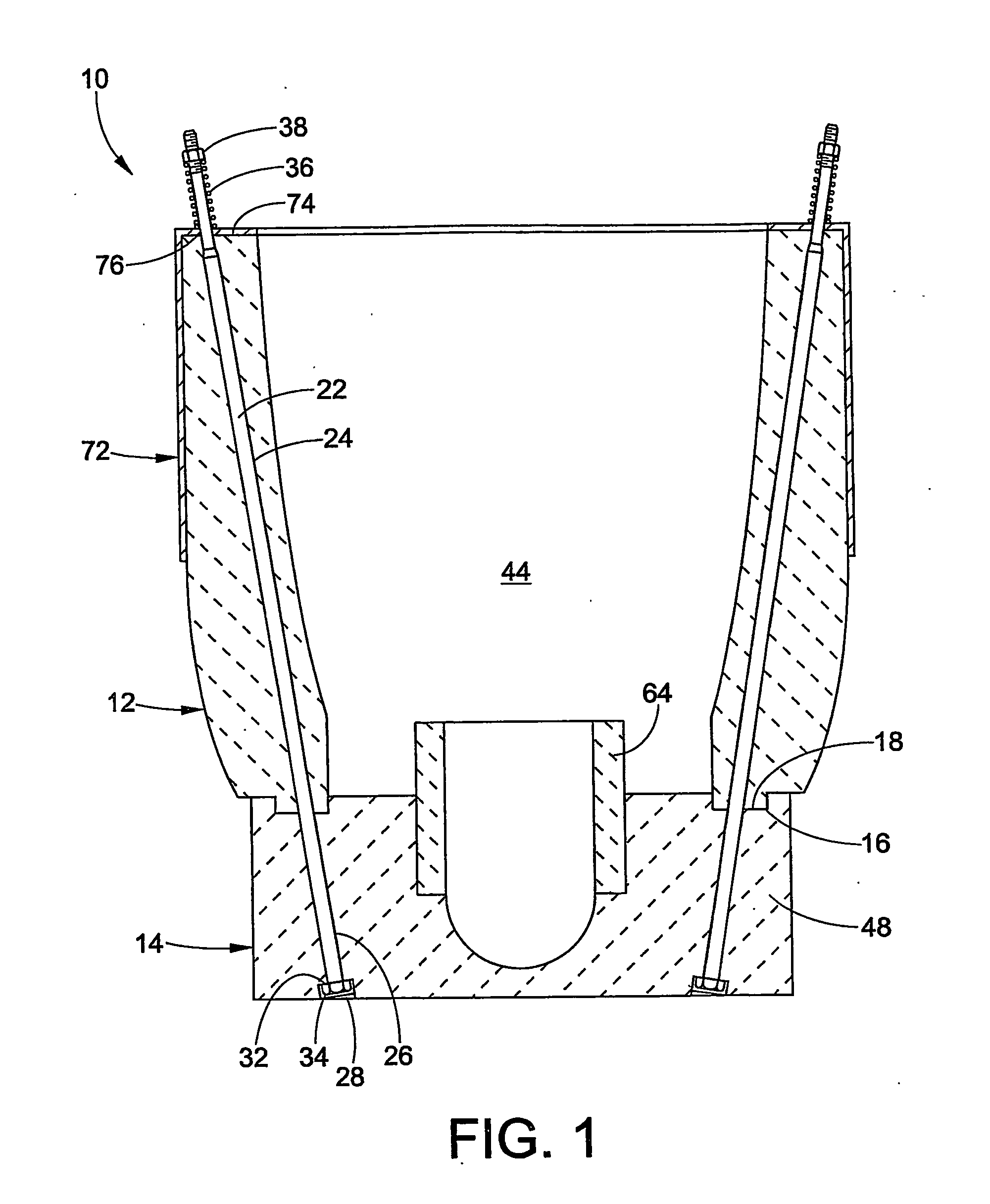

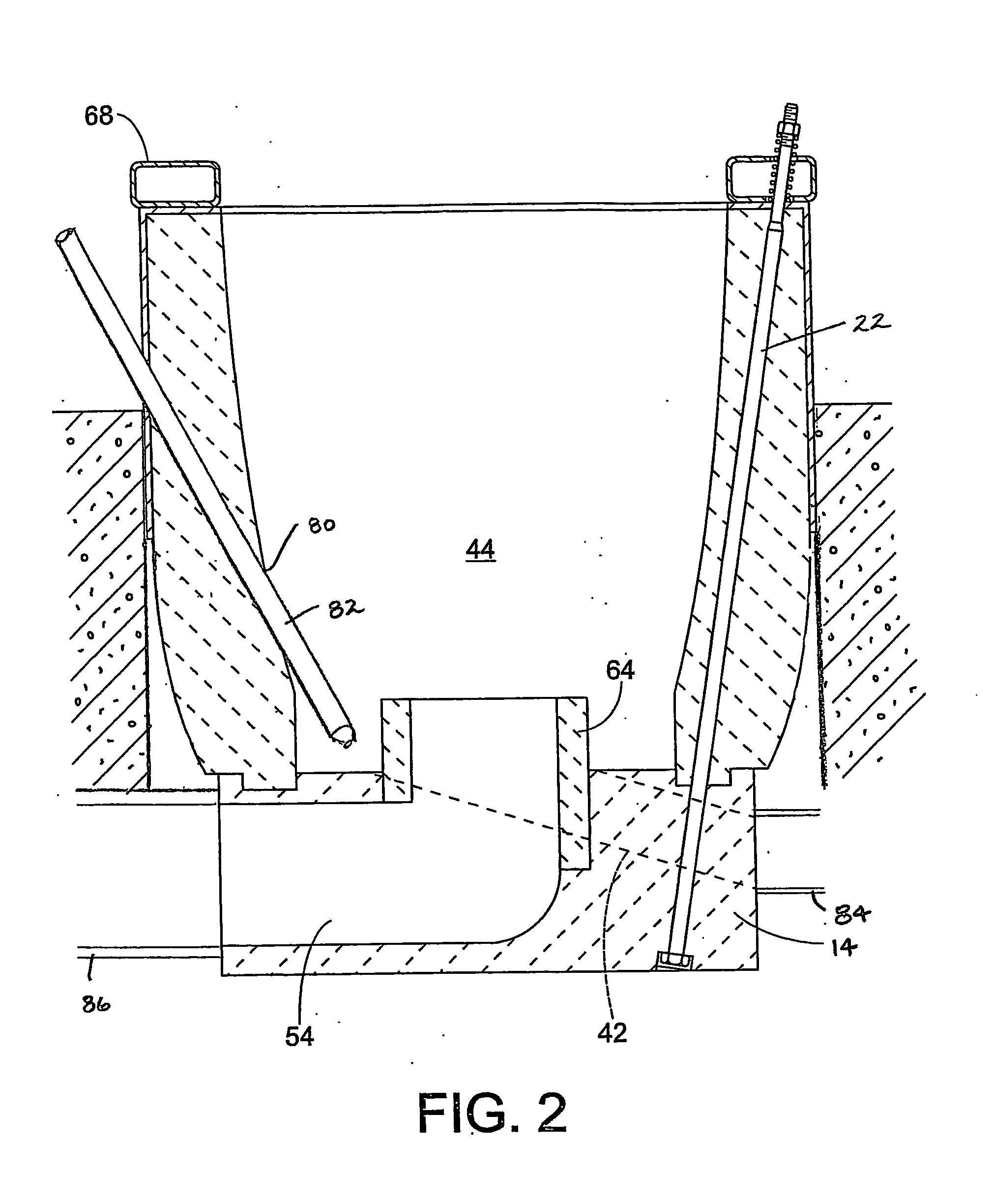

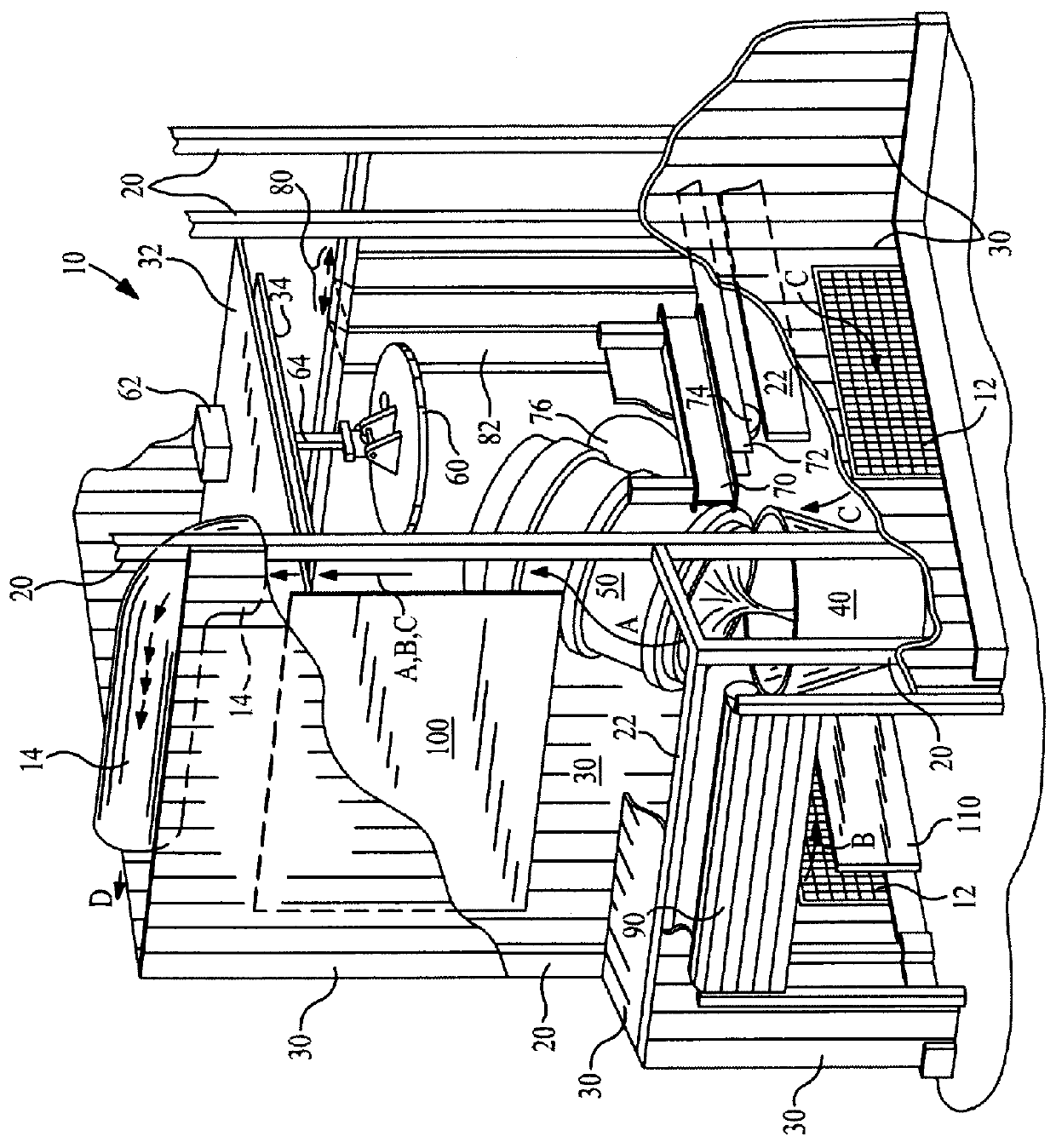

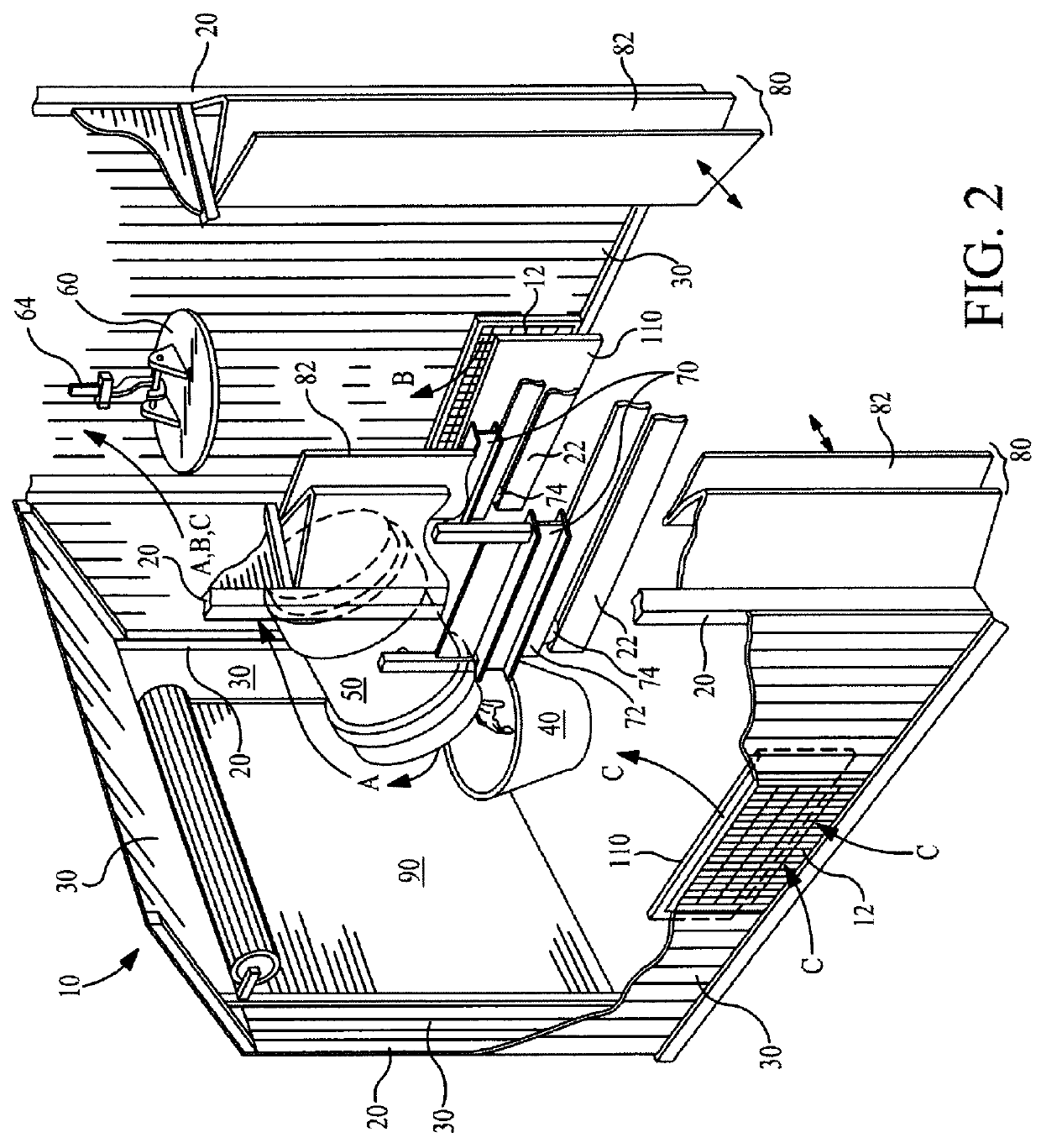

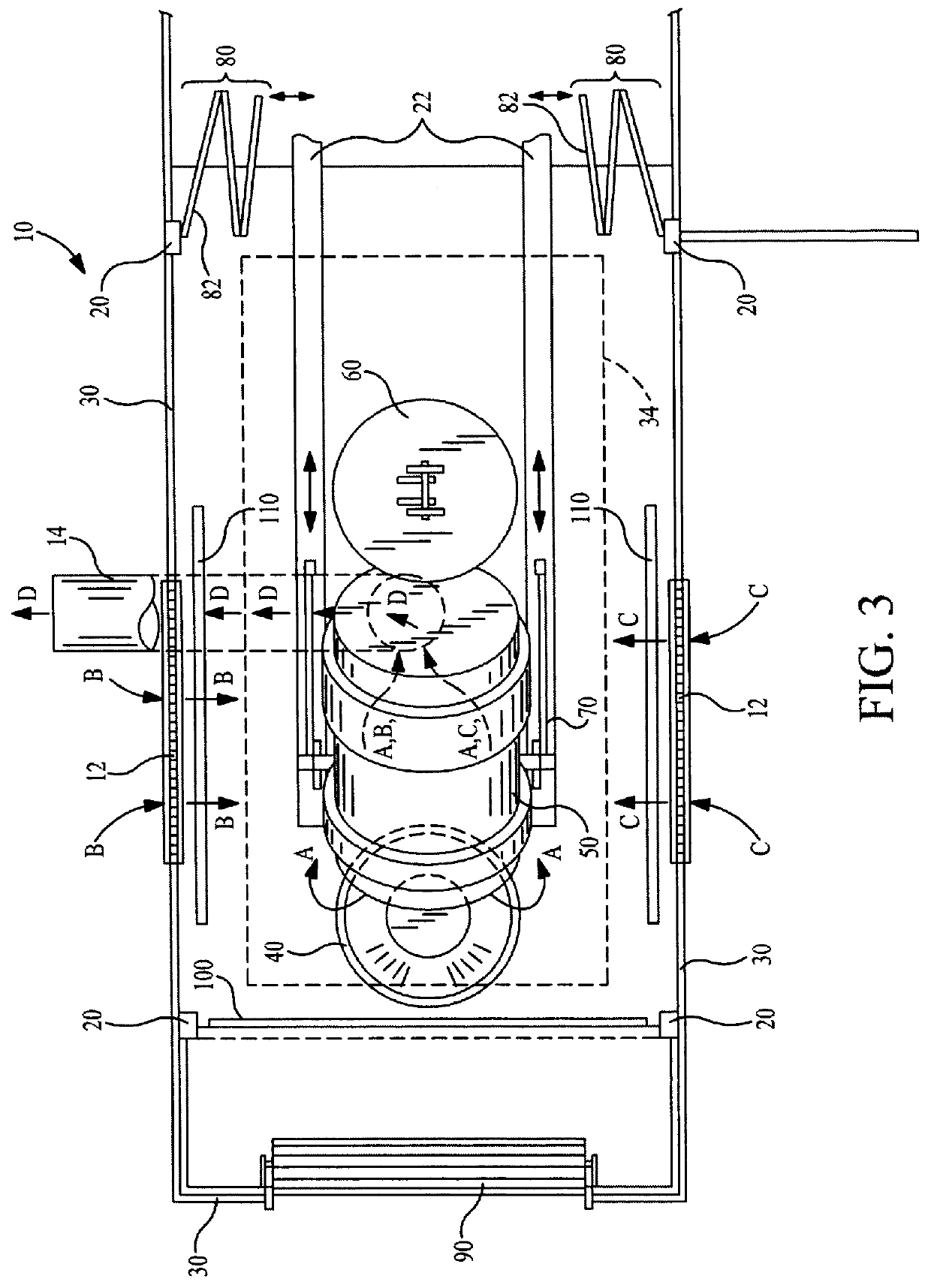

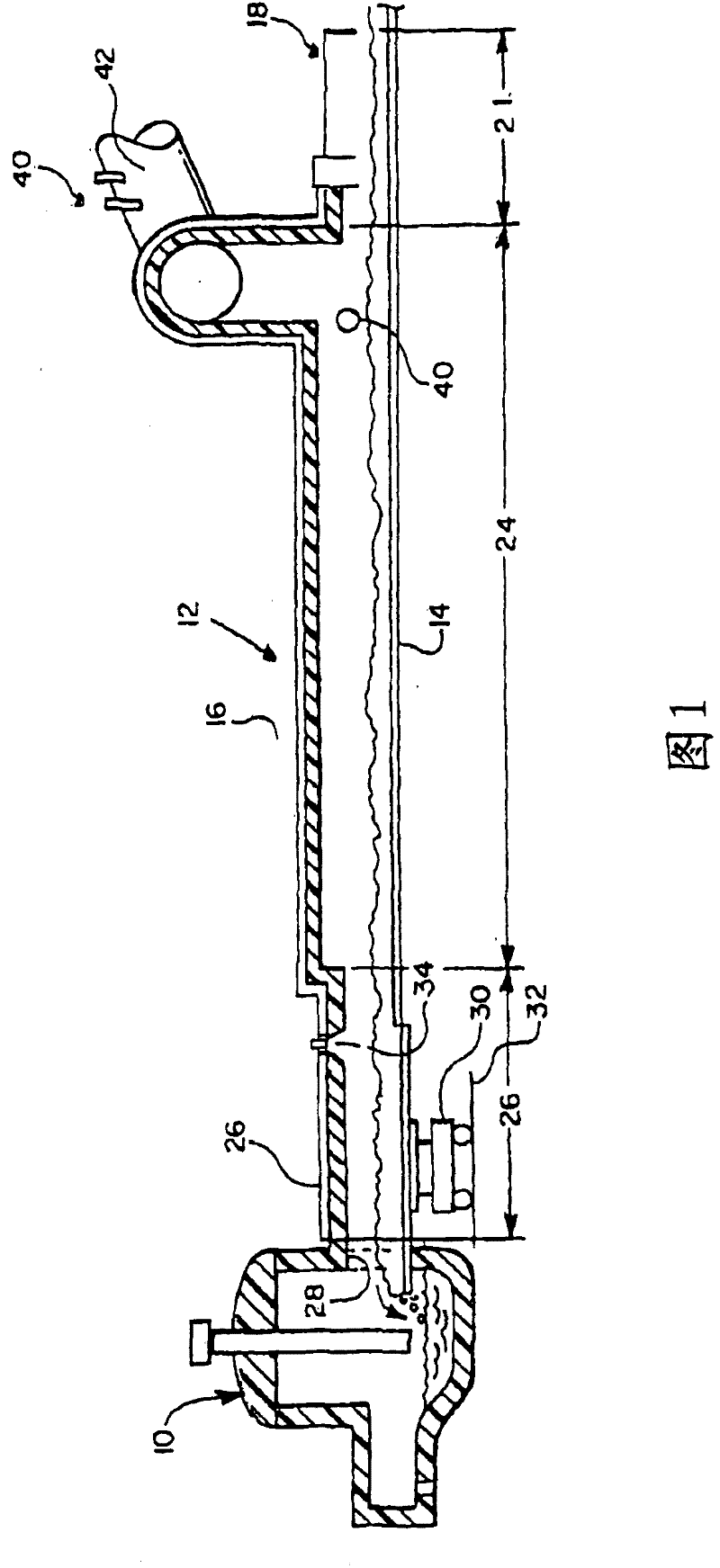

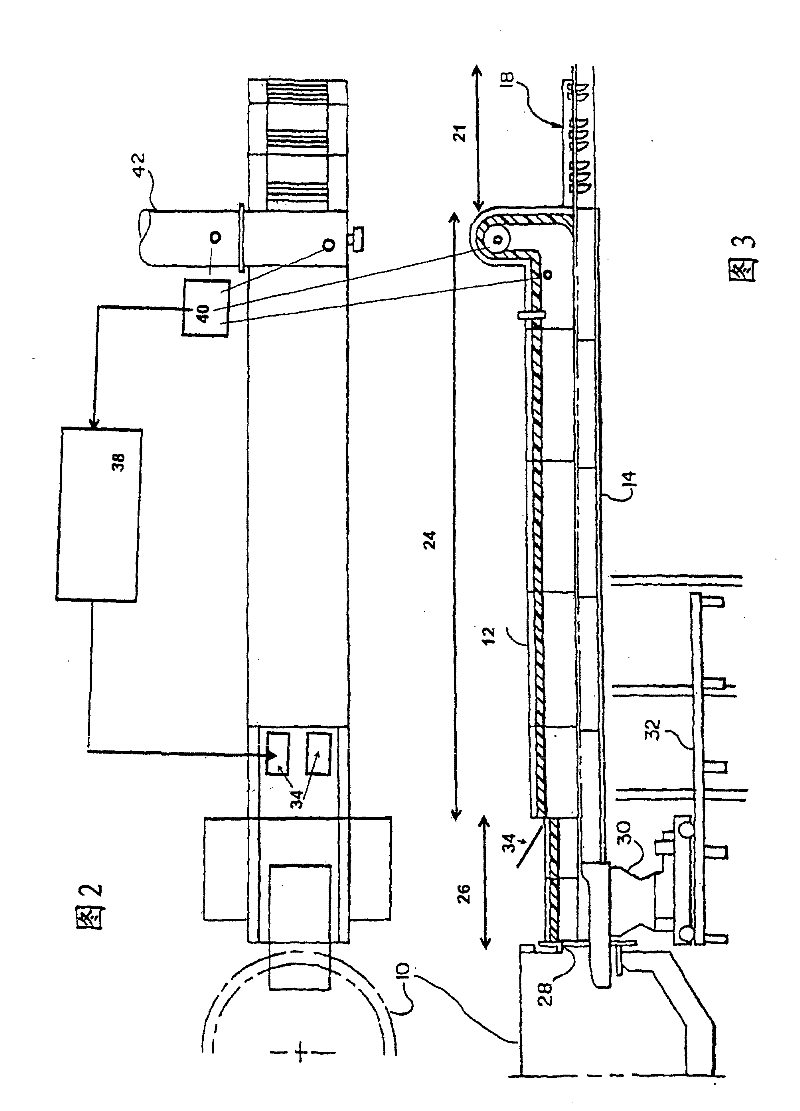

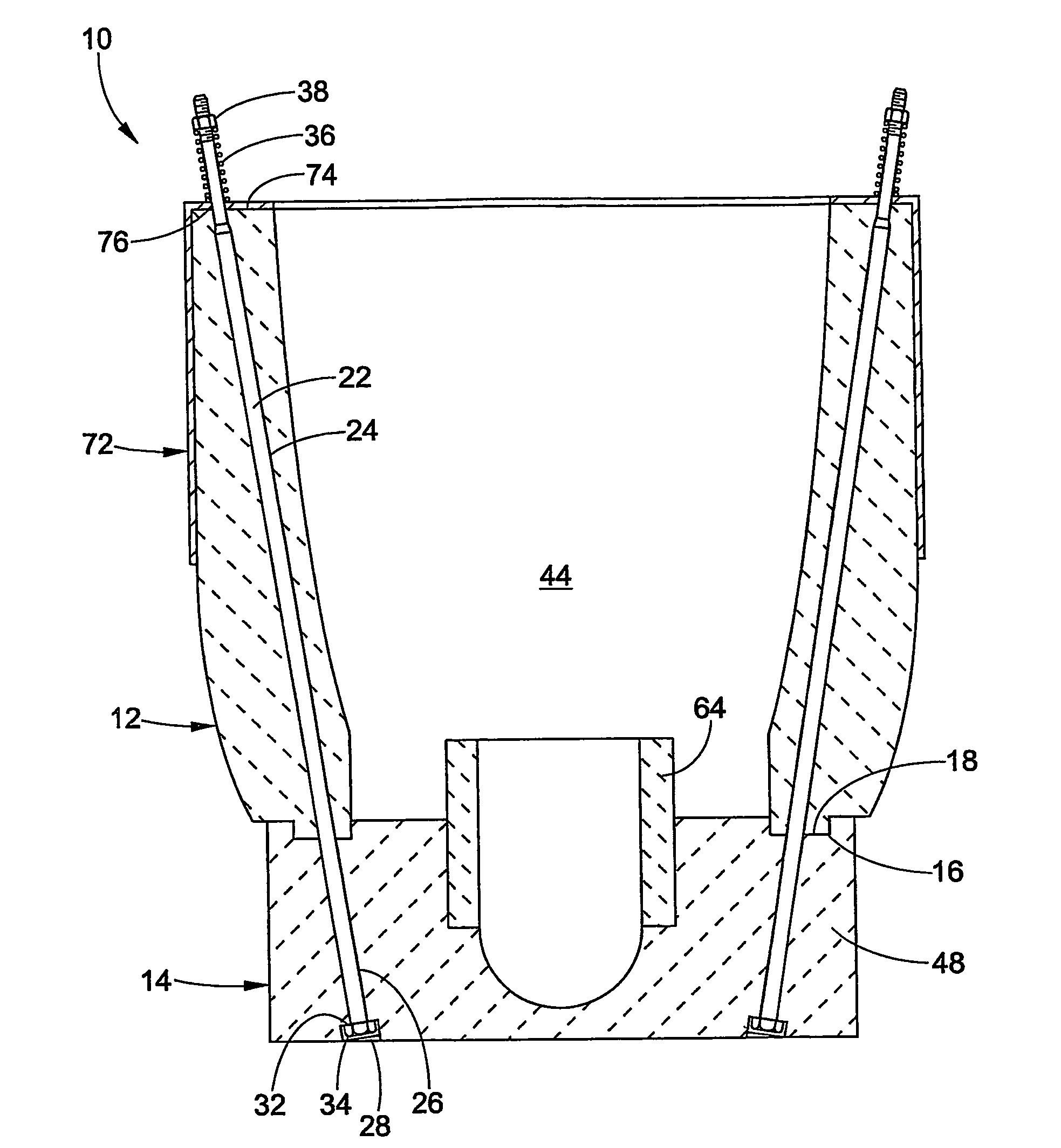

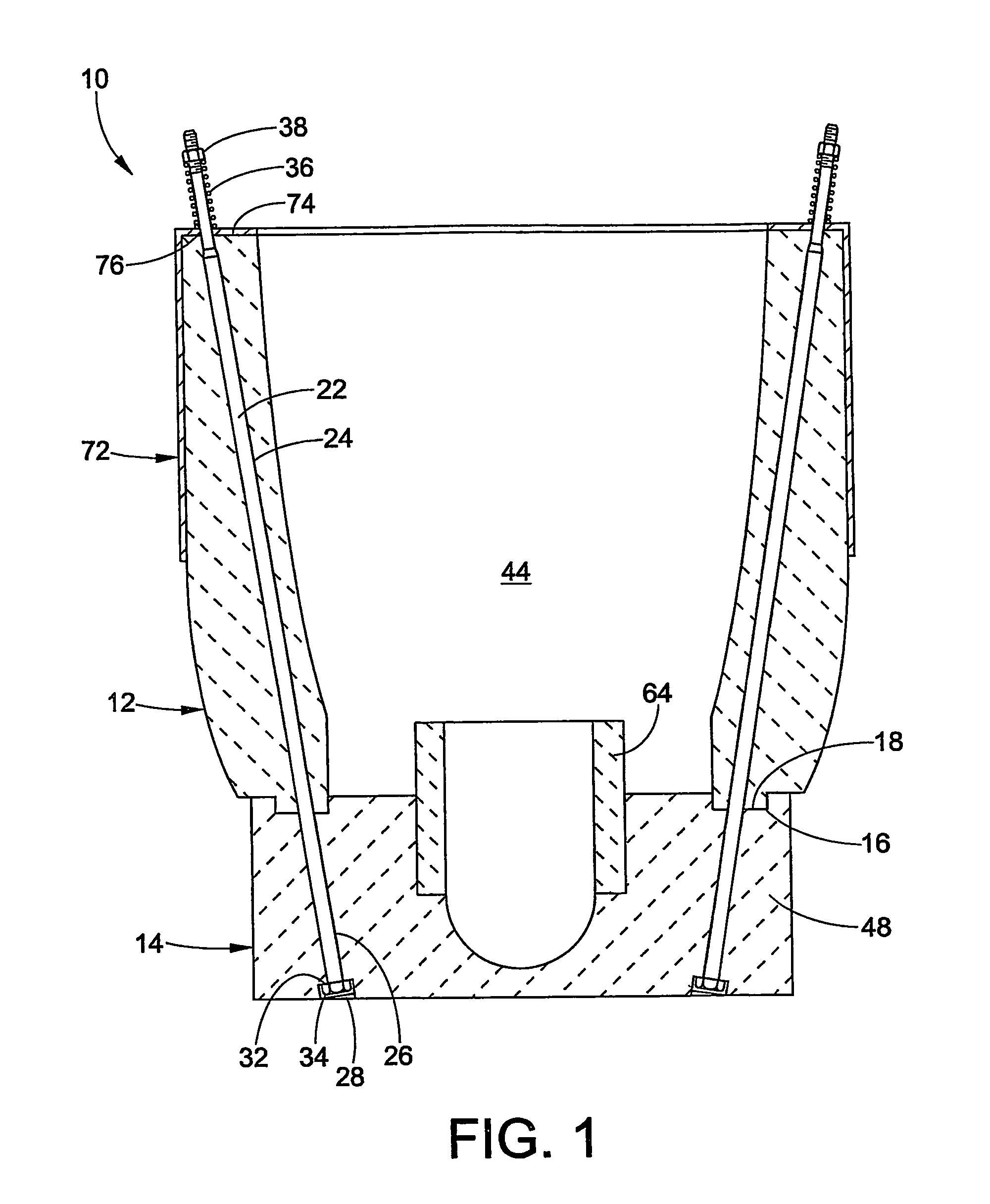

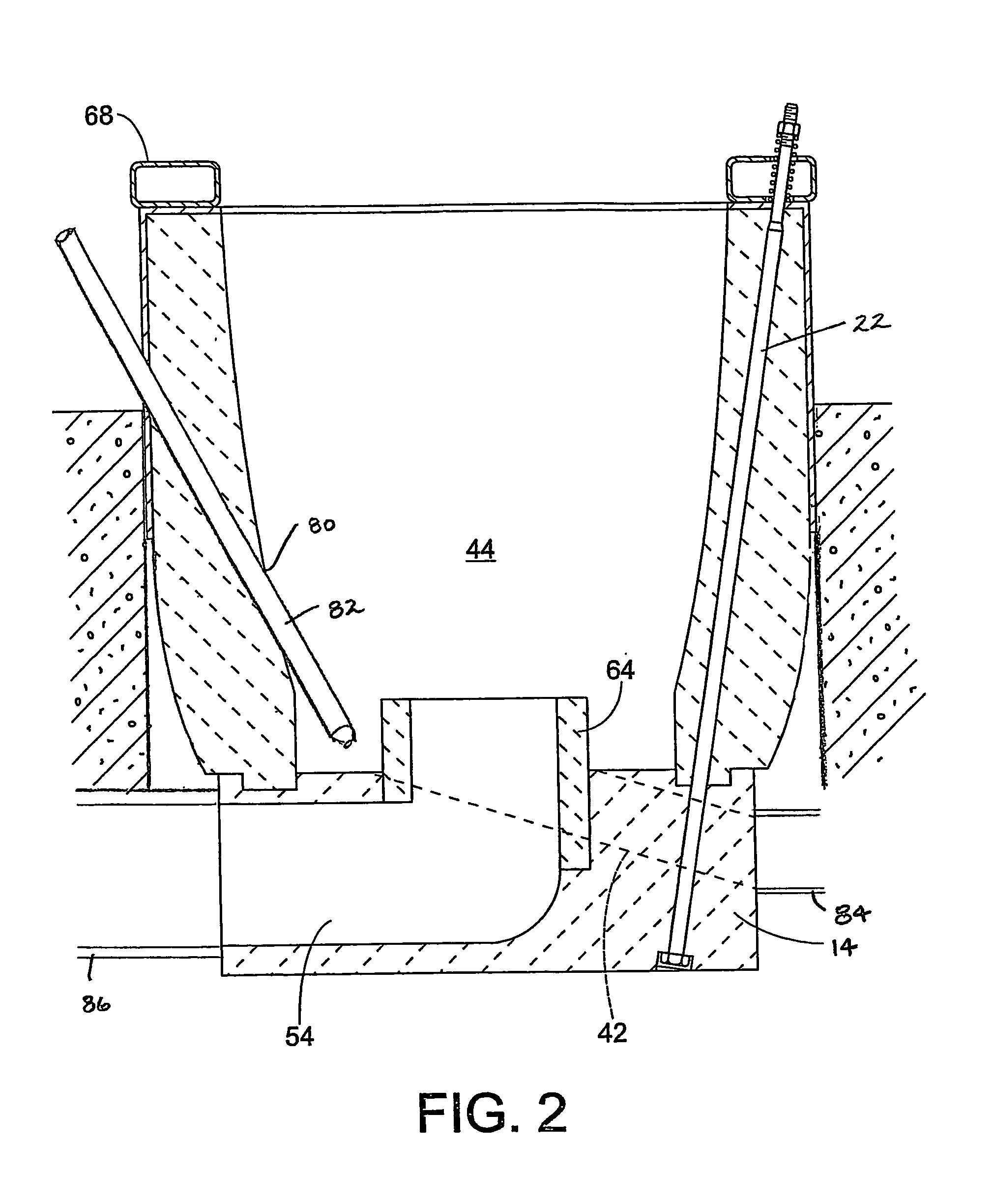

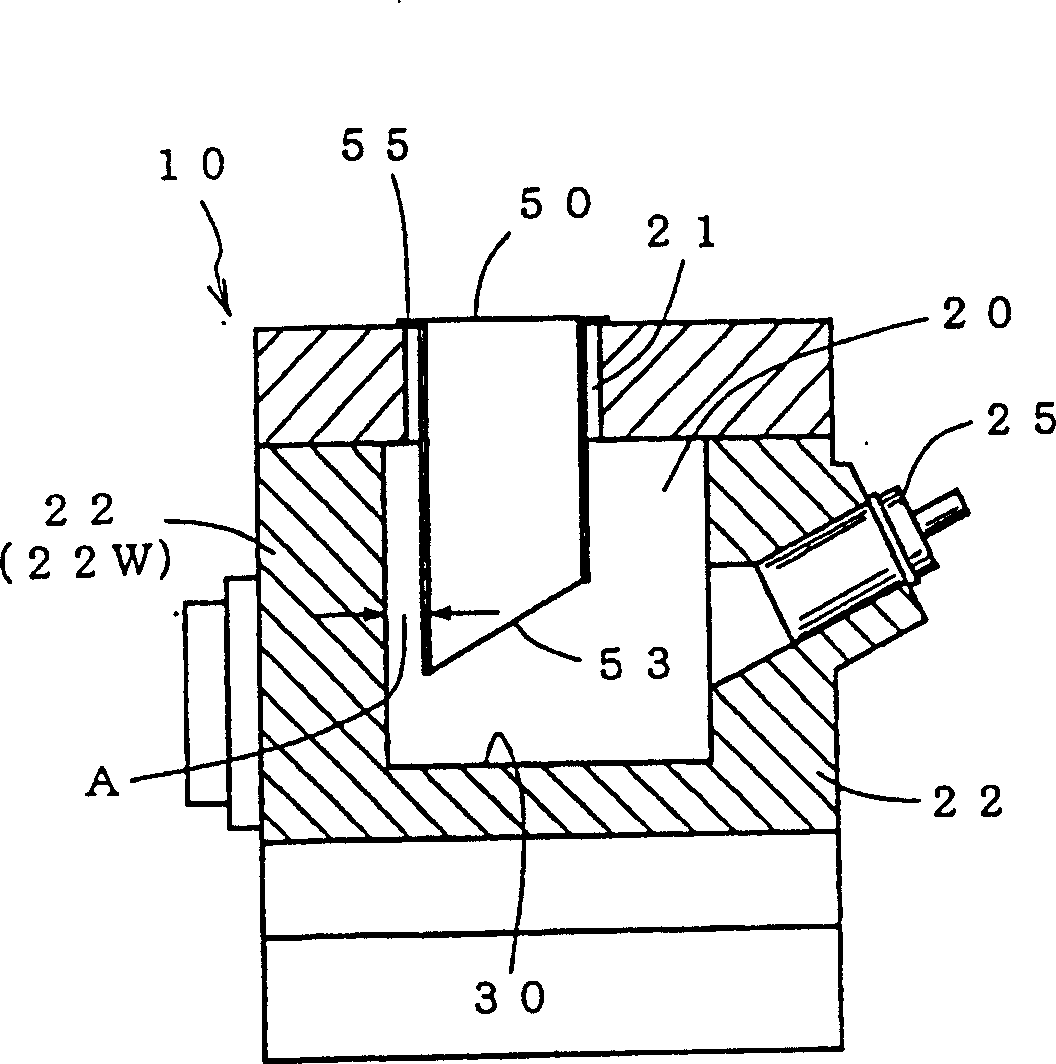

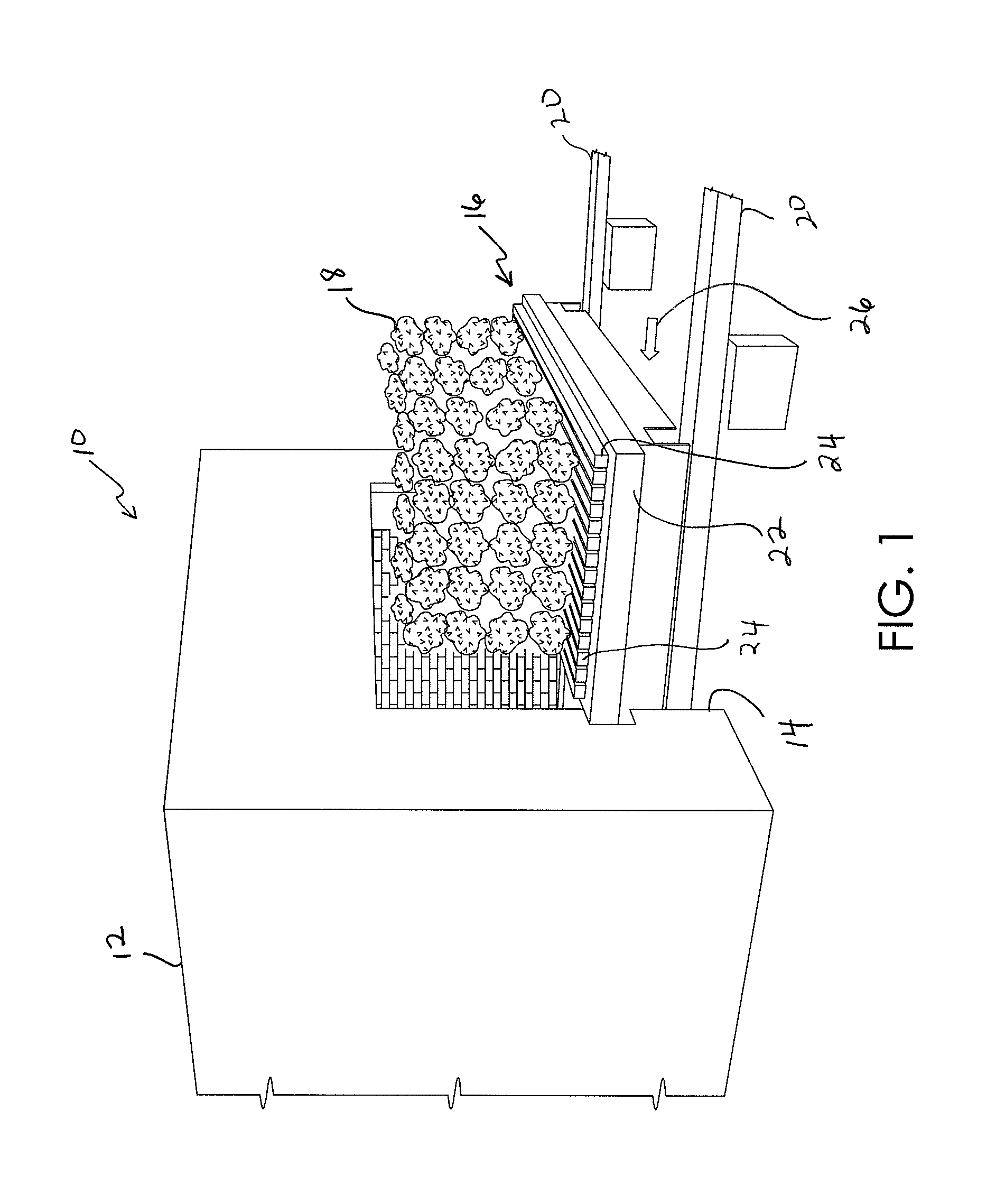

Metal Scrap Submergence Apparatus

A material scrap submergence device comprises a body (10) of heat resistant and / or a refractory material that includes a side wall (12) and a base (14) that define a submergence chamber (10). The refractory body (10) can include passages (24) that receive rods (22). The rods (22) can place the refractory body (10) under compression. In another embodiment, the body is confined by a frame (72) attached to the body. The submergence chamber (10) can also be used as a gas injection chamber.

Owner:PYROTECK INC

Method for recycling aluminum-lithium-type alloy scrap

InactiveUS20070062336A1Limit of consequencesControl oxidationProcess efficiency improvementMetallurgical apparatusLithiumAlloy

The present invention is directed to a method for melting scrap of an aluminum alloy containing lithium. The steps include providing scrap containing aluminum-lithium-type alloys, preparing an initial liquid metal bed of a first composition in a smelting oven, loading the scrap onto the initial liquid metal bed so as to create a floating layer of the scrap with a controlled thickness at the surface of the liquid metal bed, partially melting the floating layer via contact with the metal bed so as to obtain a liquid metal bath having a second composition, and removing the liquid metal from the second composition of the liquid metal bath. The method has technical and economic advantages. It does not require investment in a particular installation and it requires minimal use of expensive expendable materials such as inert gas, because the formation of a floating layer having a controlled thickness makes it possible to effectively protect the surface of the liquid metal from oxidation.

Owner:CONSTELLIUM ISSOIRE

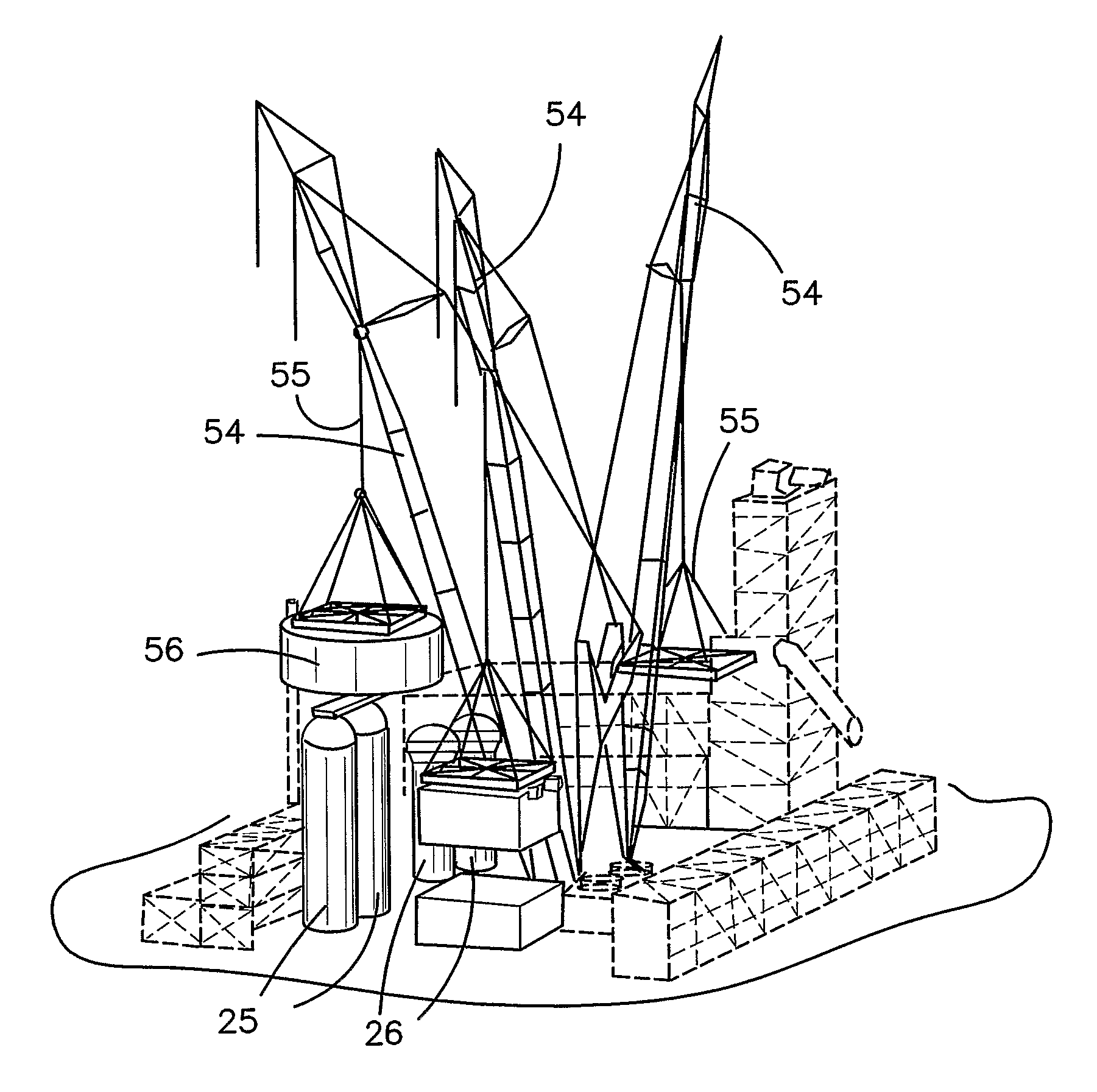

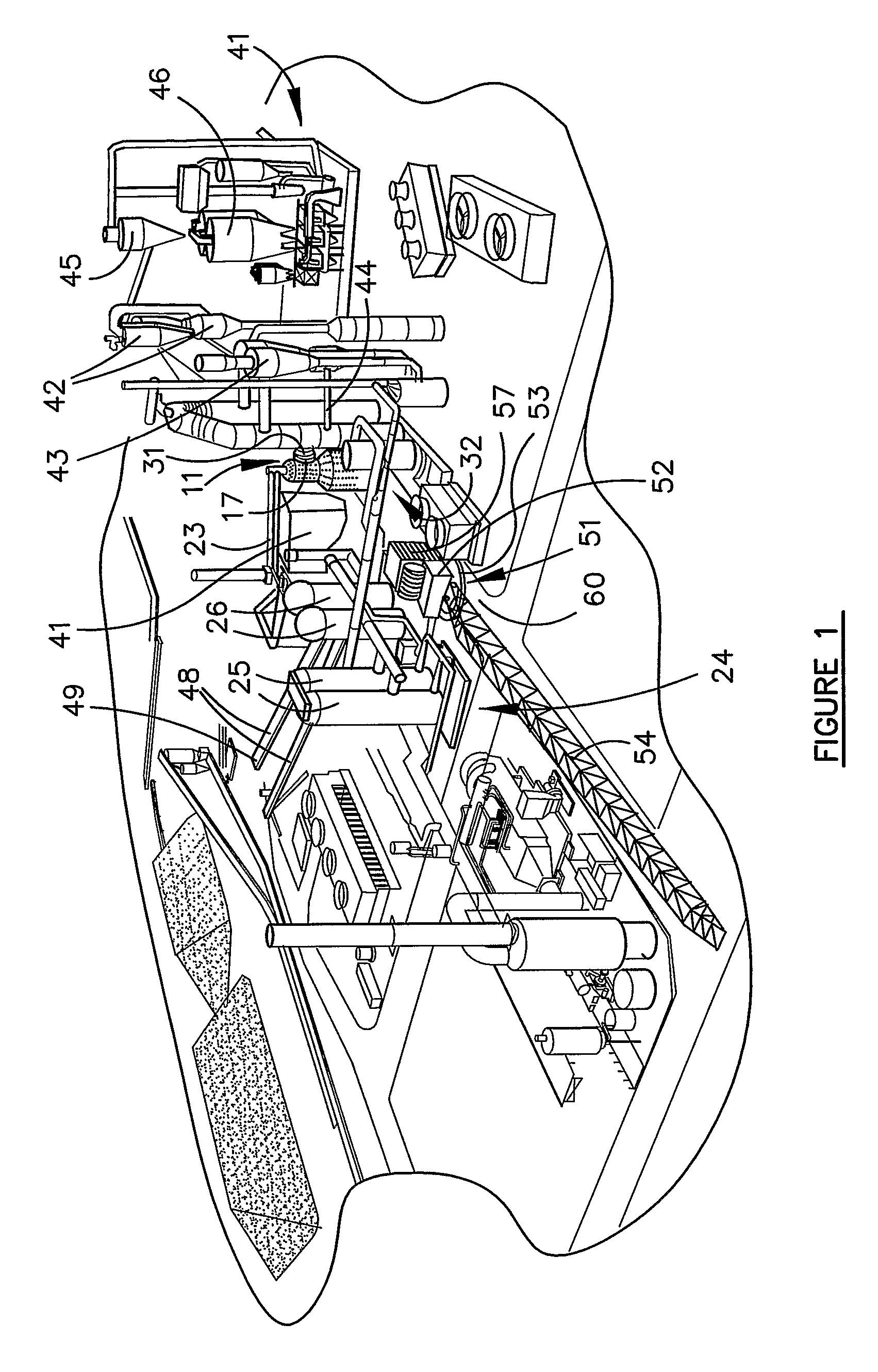

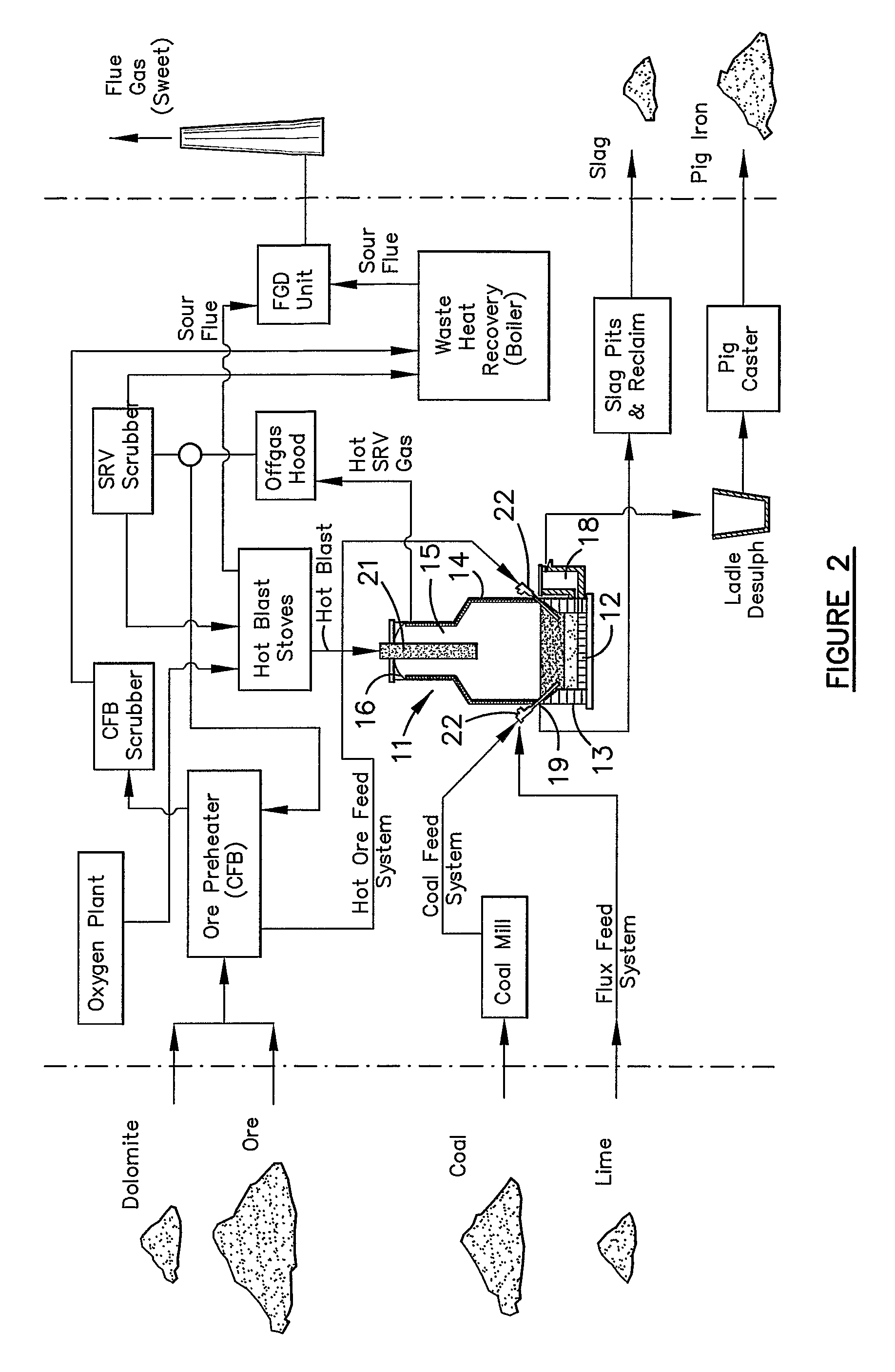

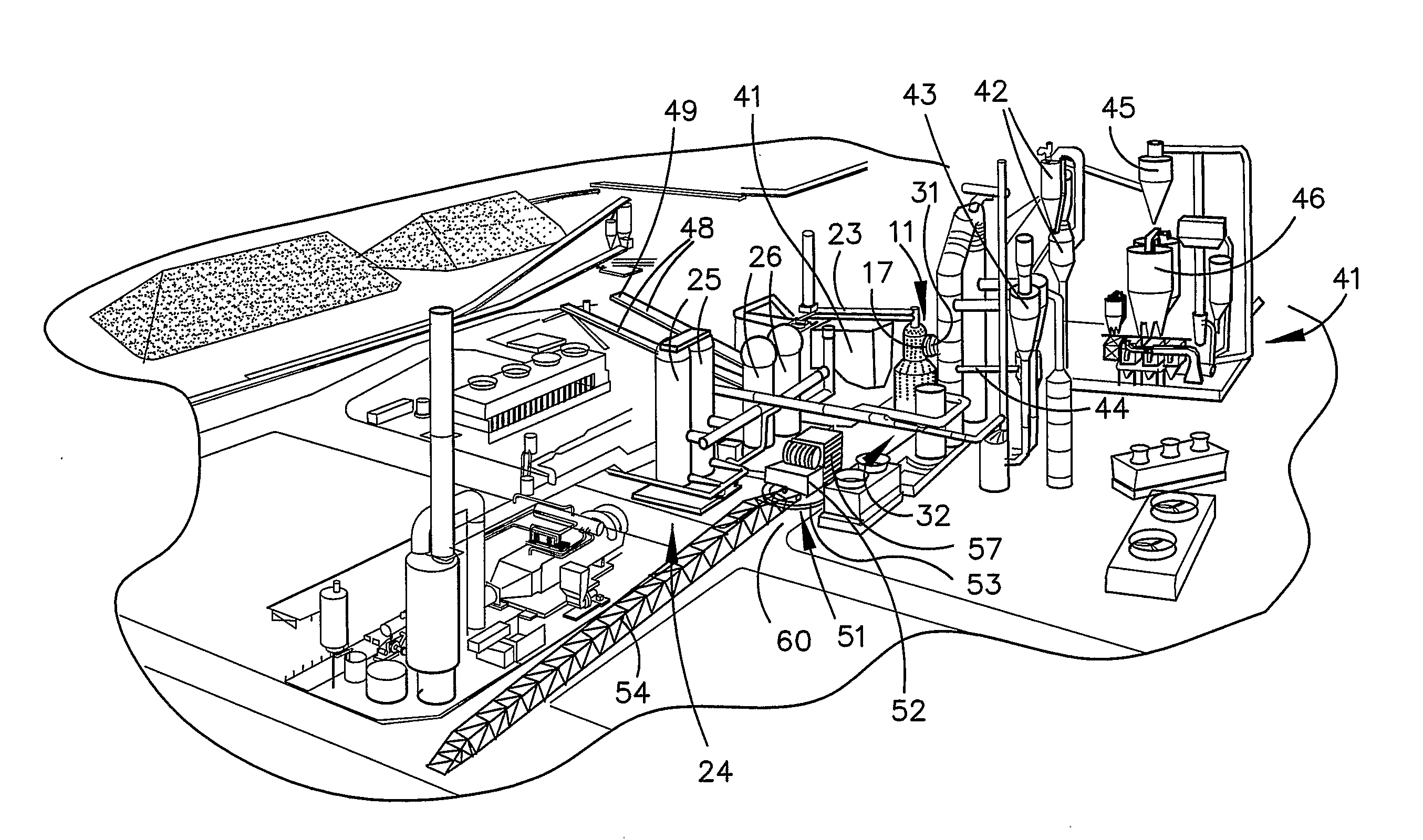

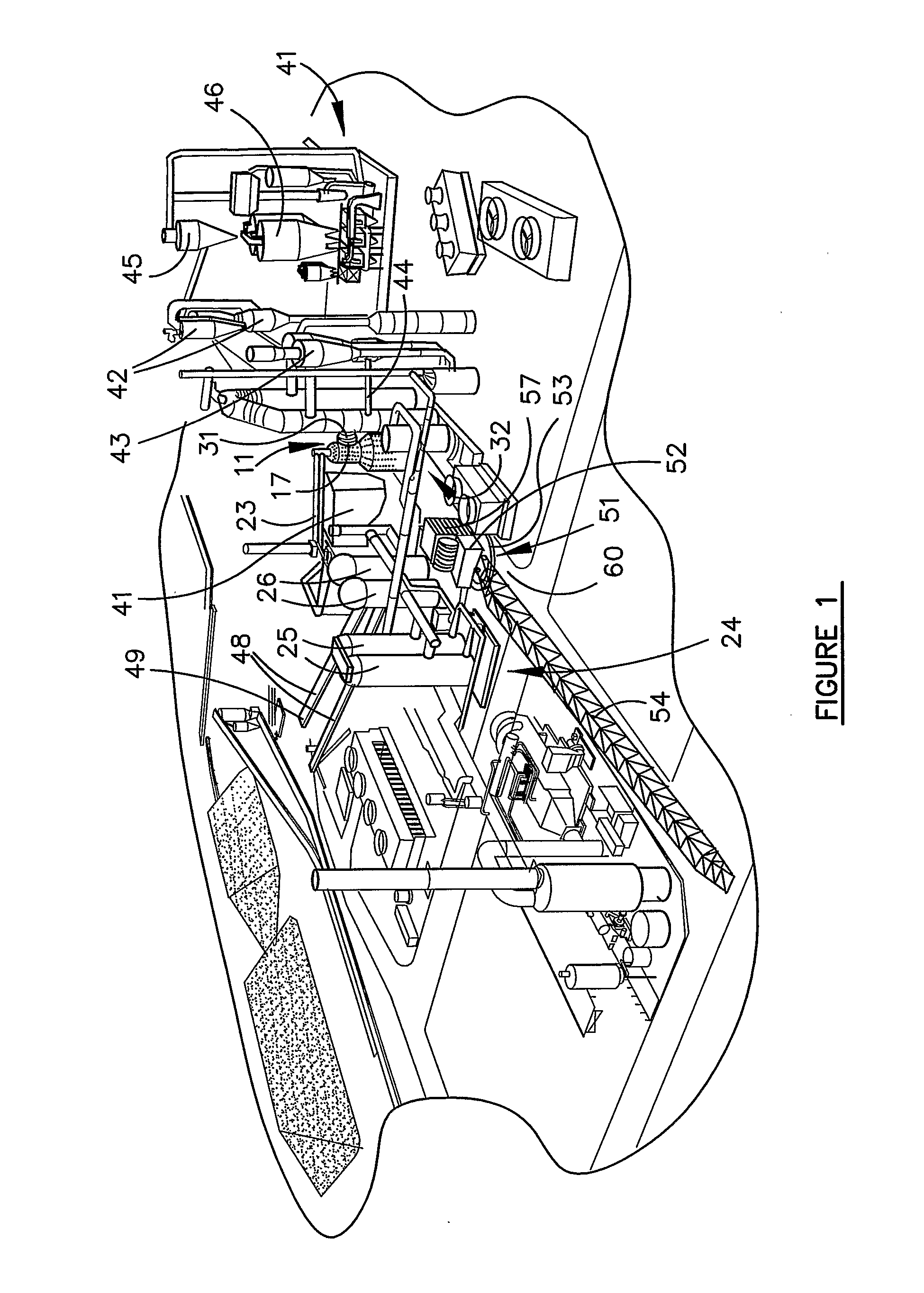

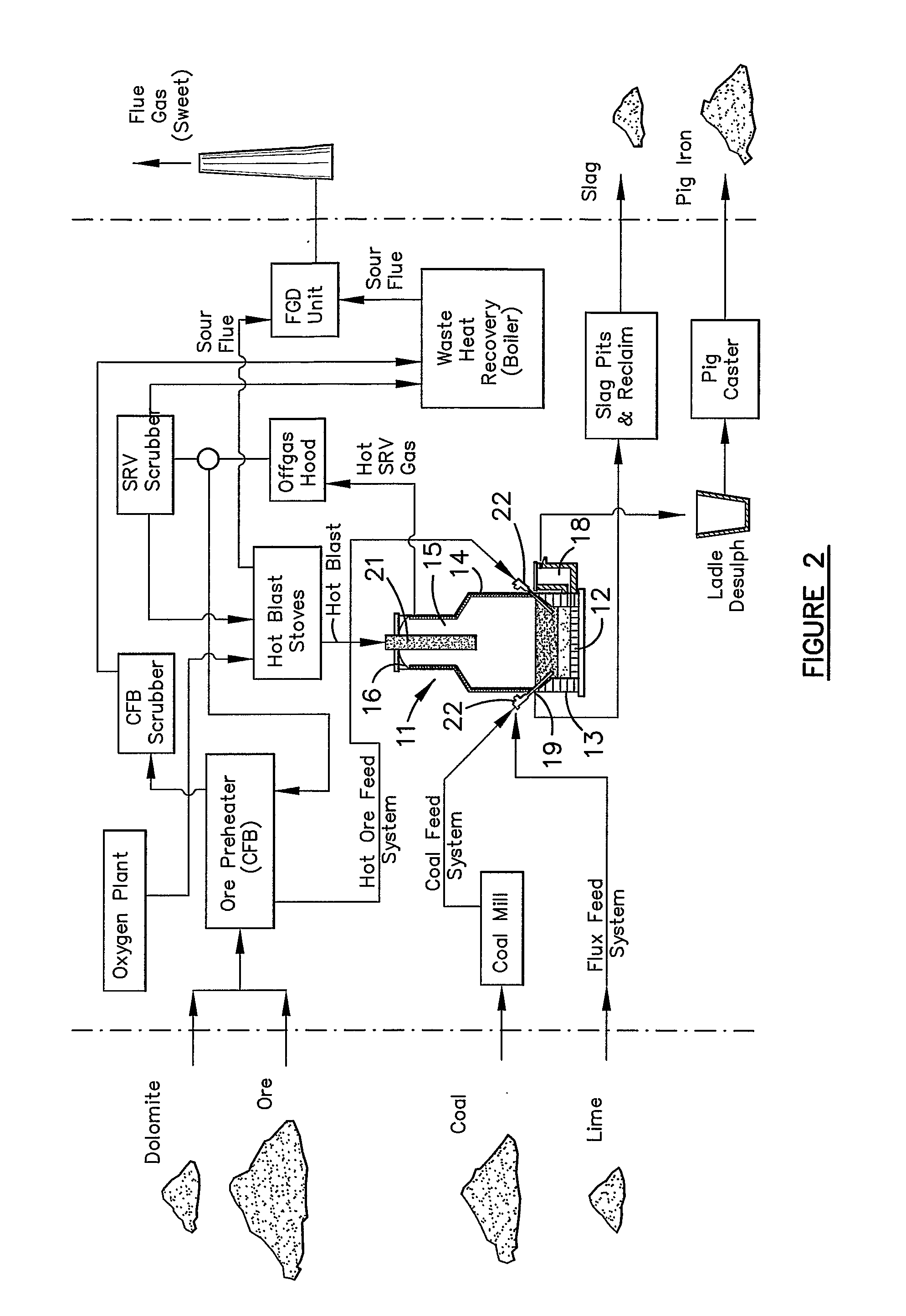

Method of building a direct smelting plant

Method of building a direct smelting plant comprising a metal smelting vessel (11) and ancillary plant components such as the components of a hot air supply station (24), an offgas treatment station (32), a solids feed station (41), a hot metal desulphurization station (47) and hot metal and slag launders extending from the smelting vessel (11). The ring track (53) of a ringer crane (51) is installed in front of location at which vessel (11) is to be installed. Crane boom (54) is laid out along elongate stretch of the building site which becomes a corridor (60) between major ancillary components when plant is fully erected. Boom (54) is connected to crane carriage (52) and hoisted to provide high lift capacity over a ground area embracing proposed site of vessel (11) and ancillary components. Prefabricated components are then lifted by crane (51) into appropriate position for final installation. After installation is completed boom (54) is laid down along corridor (60) and crane (51) is dismantled and removed, leaving corridor (60) as an access laneway.

Owner:TECH RESOURCES PTY LTD

Apparatus for the combustion of gas exiting from a furnace, for the preheating of scraps entering the furnace itself and related process

ActiveCN101120221BImprove economyEliminate dynamic sealsFurnace typesPreheating chargesCombustionElectric arc furnace

An apparatus for the combustion of gas exiting from an electric arc furnace for the preheating of scraps entering the furnace itself foresees an insertion device of comburent substance into a preheating chamber or loading tunnel of the scrap metal having an inlet section of the scrap metal, a seal section to prevent an uncontrolled entrance of air in the tunnel, a heating section and an unloadingsection of the scrap metal in the furnace. Said insertion device of the comburent substance comprises one or more adjustable openings placed in the loading tunnel, and said apparatus comprises a device or a series of devices, also not equipped with autonomous movement, of mechanical seal nature placed in the insertion or inlet section of the scrap metal in the loading tunnel or preheating chamber.

Owner:ТЕНОВА ТЕКНОЛОДЖИЗ (ТЯНЬЦЗИНЬ) КО., ЛТД.

Device for metallizing uranium oxide and recovering uranium

InactiveUS20050072271A1Increase temperatureNuclear energy generationTuyeresUranium oxideLithium chloride

Disclosed is a device for metallizing uranium oxide and recovering uranium, which reacts uranium oxide with a lithium metal to product uranium metal powder, and filters the resulting product using a porous filter to separate the uranium metal powder from lithium chloride molten liquid to recover the uranium metal powder. The device includes a heating furnace including at least one first heating unit, and a reactor includes a reaction vessel having a discharging valve hole located at the center of a bottom thereof and a conical bottom tapered to the discharging valve hole, a sealing lid for sealing the reaction vessel airtight, an argon gas inlet port for feeding argon gas into the reactor therethrough, and an argon gas outlet port for venting argon gas from the reactor therethrough. A valve assembly controls the discharging valve hole of the reaction vessel, and a plurality of agitators mix a mixture in the reactor. A lithium metal feeder includes a second heating unit and is removably installed through the sealing lid. A cooling jacket is set in the sealing lid, and a porous filter is located under the reactor in the heating furnace. Further, a molten salt recovery tank is positioned under the porous filter in the heating furnace.

Owner:KOREA ATOMIC ENERGY RES INST +1

Metal scrap submergence apparatus

A material scrap submergence device comprises a body (10) of heat resistant and / or a refractory material that includes a side wall (12) and a base (14) that define a submergence chamber (10). The refractory body (10) can include passages (24) that receive rods (22). The rods (22) can place the refractory body (10) under compression. In another embodiment, the body is confined by a frame (72) attached to the body. The submergence chamber (10) can also be used as a gas injection chamber.

Owner:PYROTECK INC

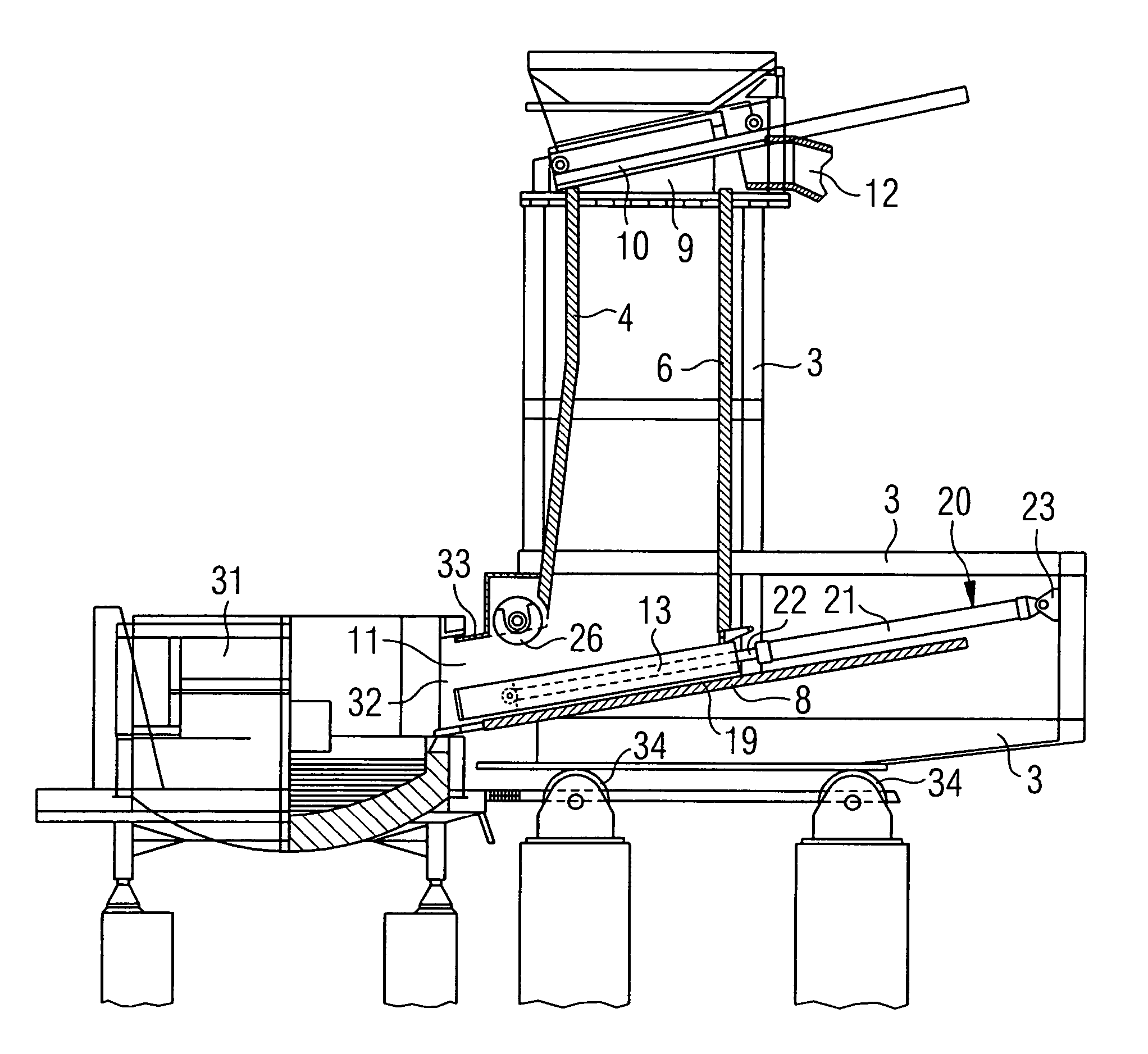

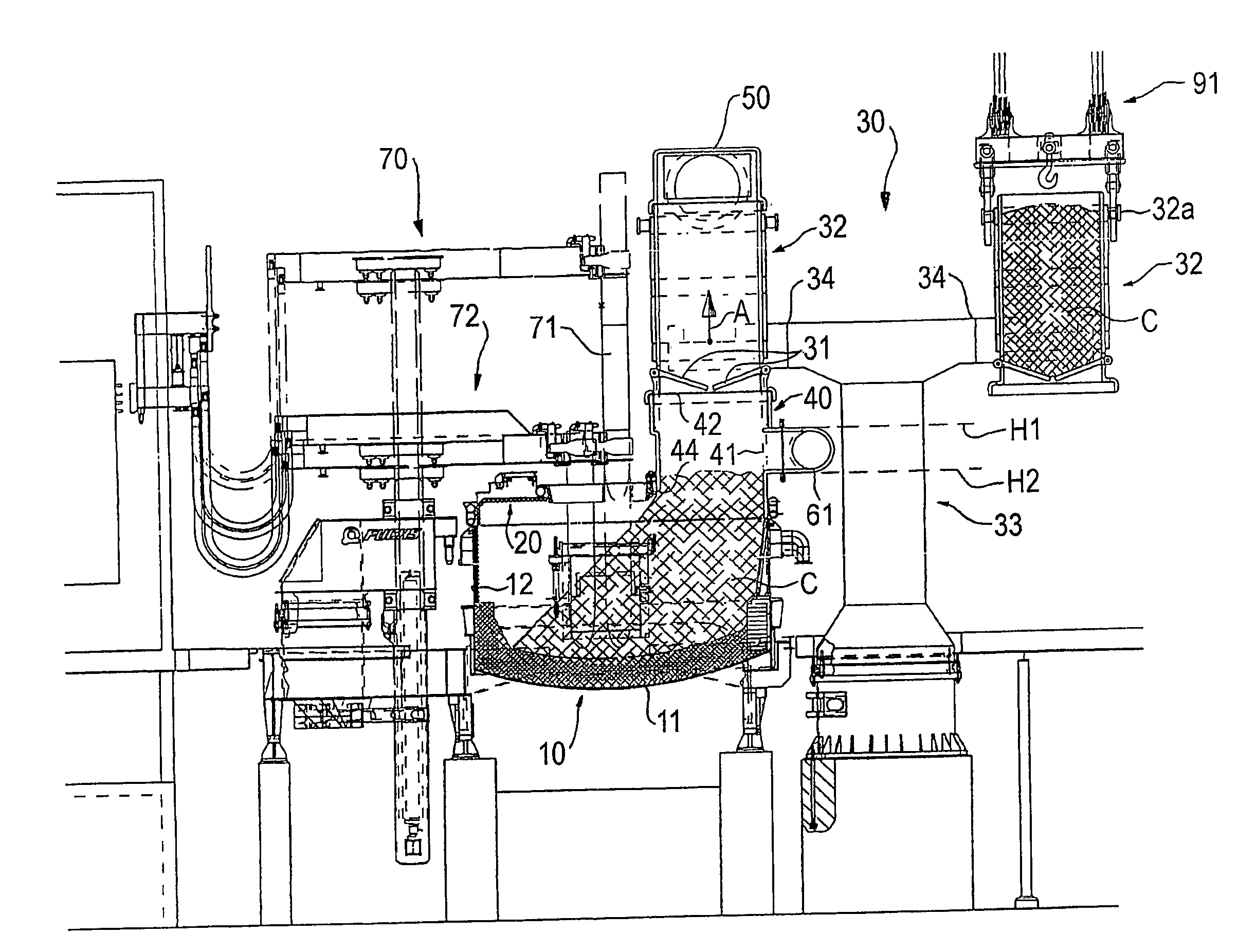

Metallurgical oven and a material basket for a metallurgical oven

InactiveUS7374716B2Short stayLarge heightTuyeresCharge manipulationMechanical engineeringSupport materials

Owner:SIEMENS VAI METALS TECHNOLOGIES GMBH & CO

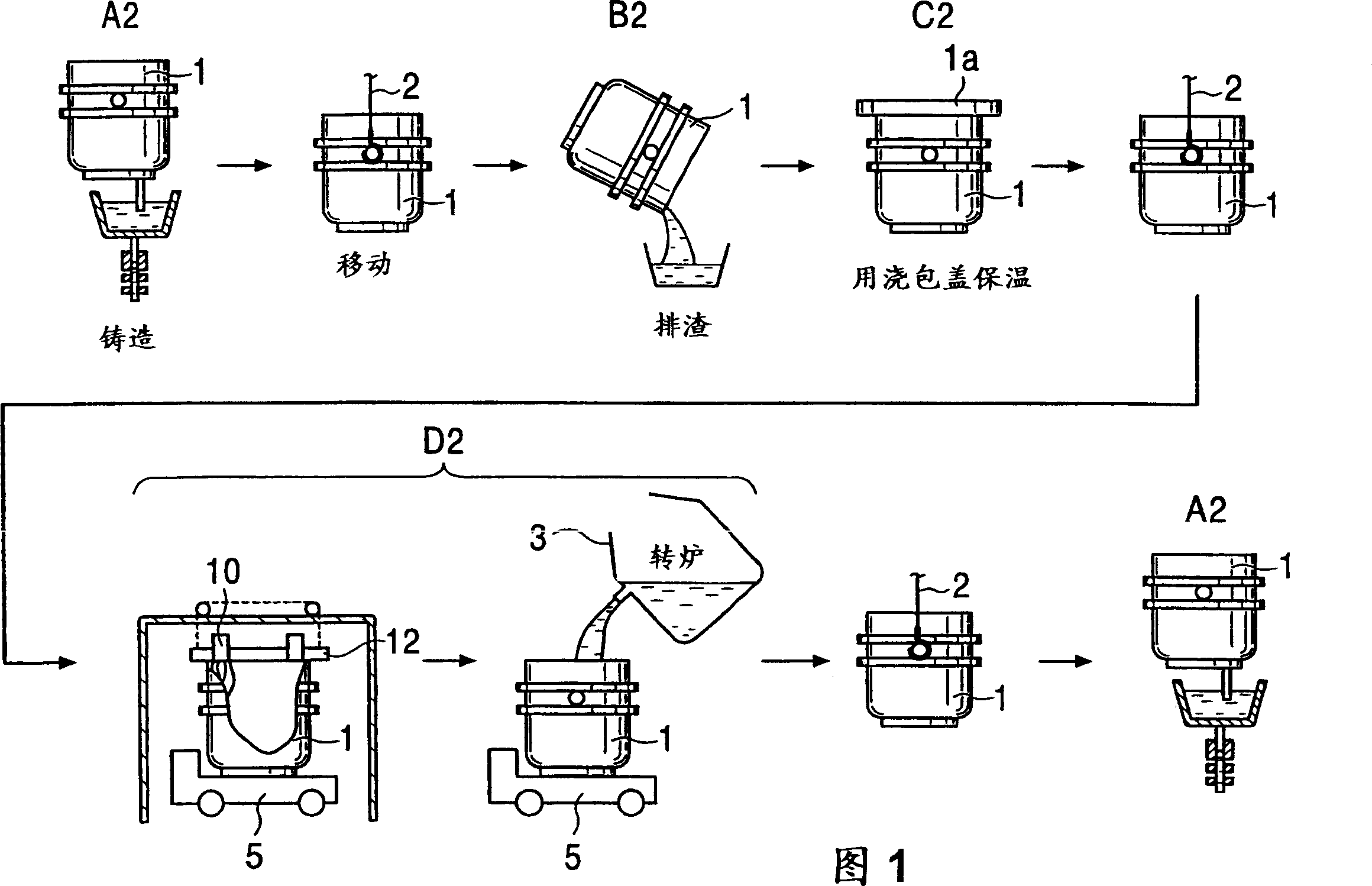

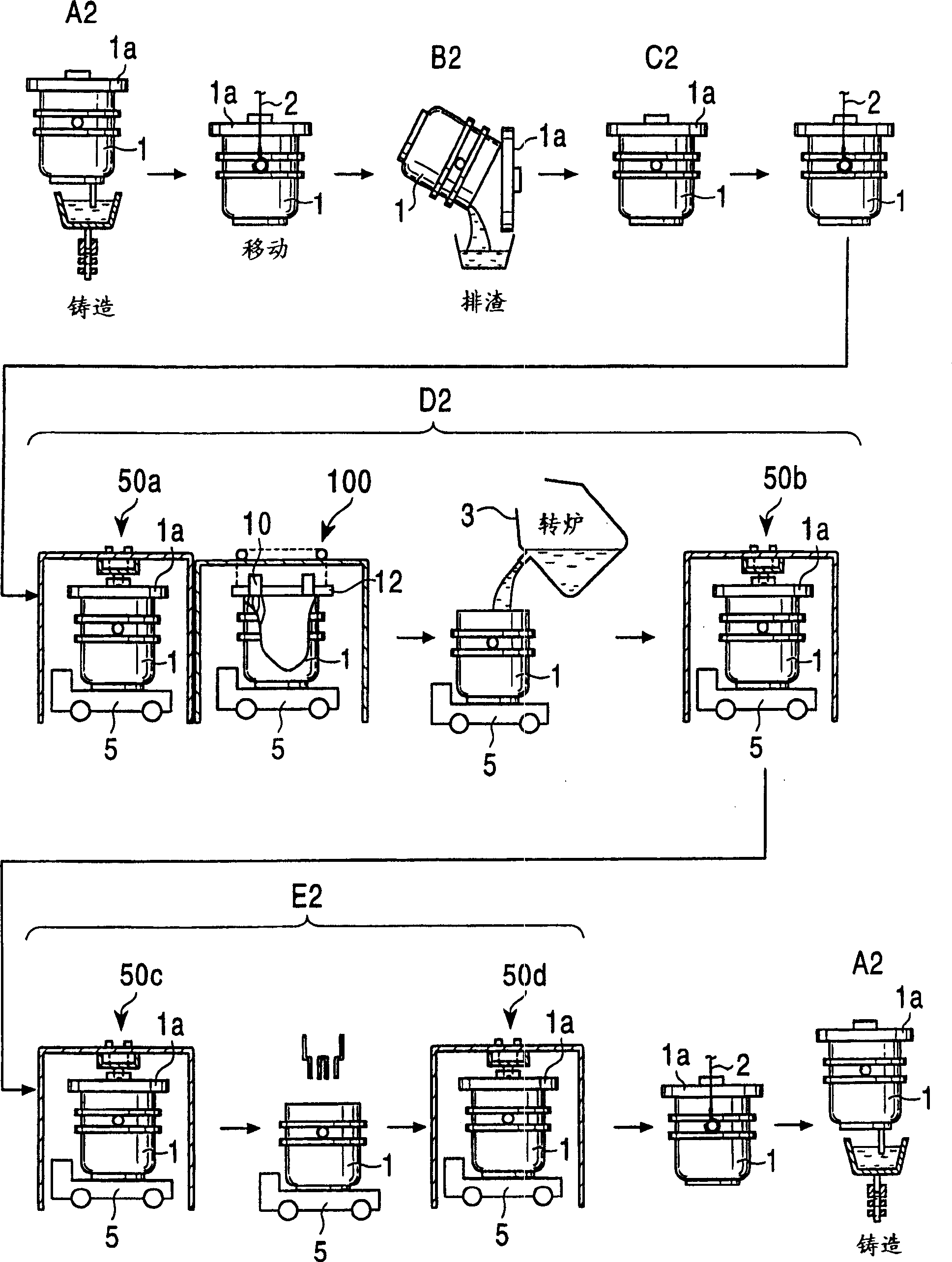

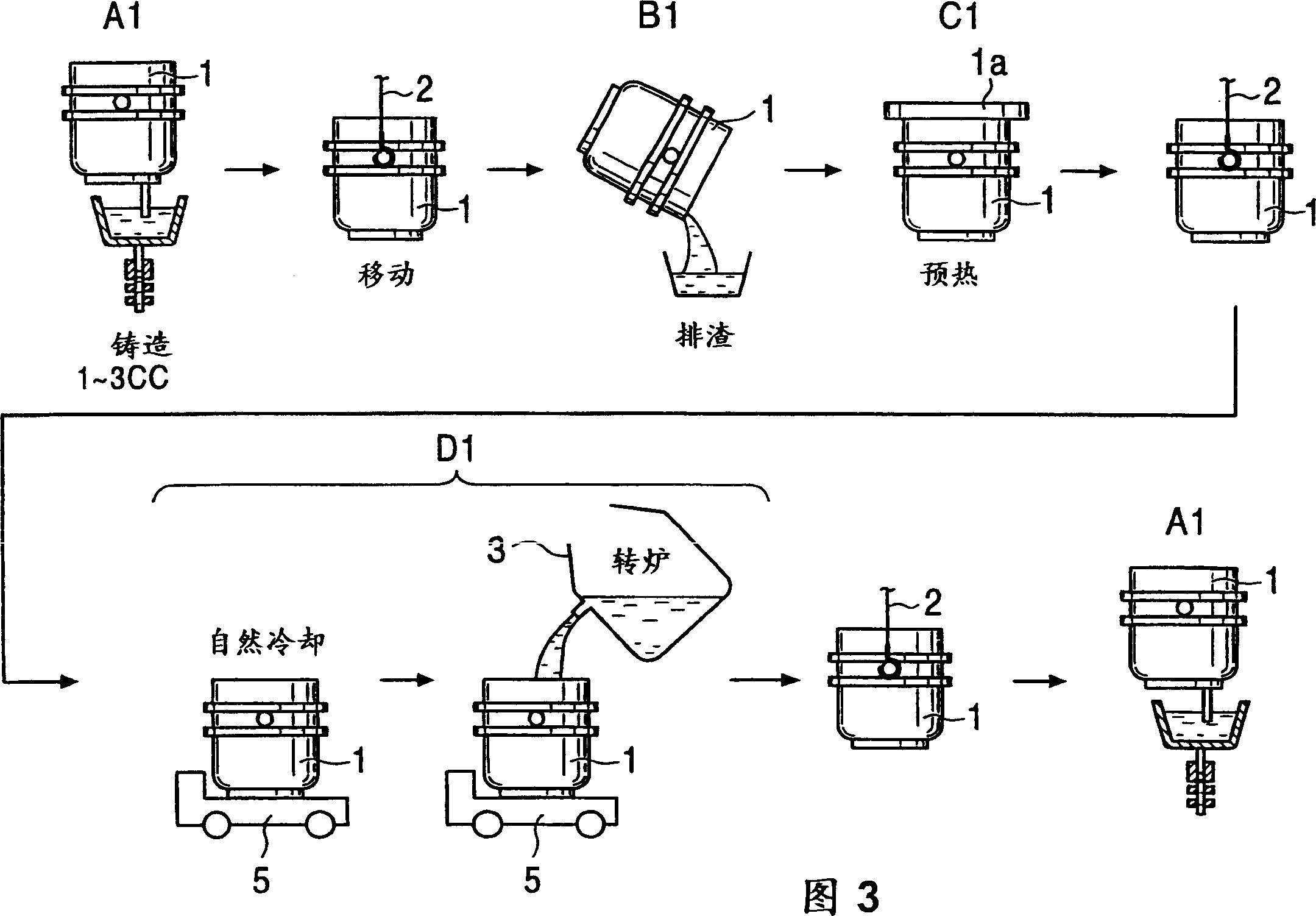

Heating method of ladle

InactiveCN1613583AImprove heating efficiencyAvoid breakingMelt-holding vesselsMetallurgical apparatusCombustorSlag

A method of heating the ladle before receiving molten steel. After continuous casting and slag removal, the ladle is placed on the molten steel trolley, and then transported by the molten steel trolley to the tapping area of the converter, and then placed on the molten steel trolley 1. Stand by in the tapping area for a specified time to form a standby state. After the standby, the molten steel flowing out from the converter is immediately received, and the ladle is heated before receiving the molten steel. In the tapping area of the converter, it is in a standby state. The ladle is heated rapidly within a specified time. This rapid heating is carried out by means of a regenerative burner installed on the ladle cover covering the upper opening of the ladle.

Owner:JFE STEEL CORP

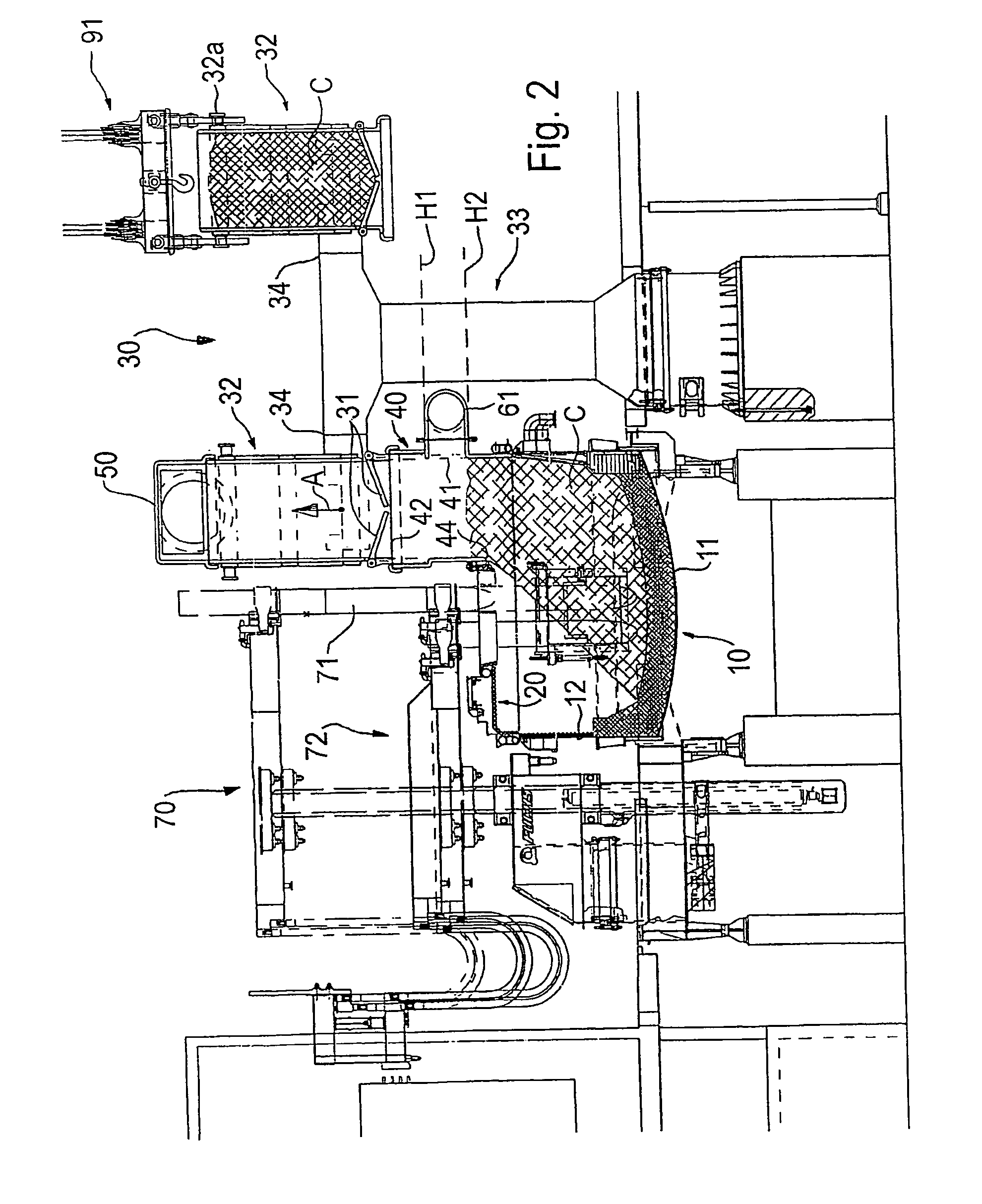

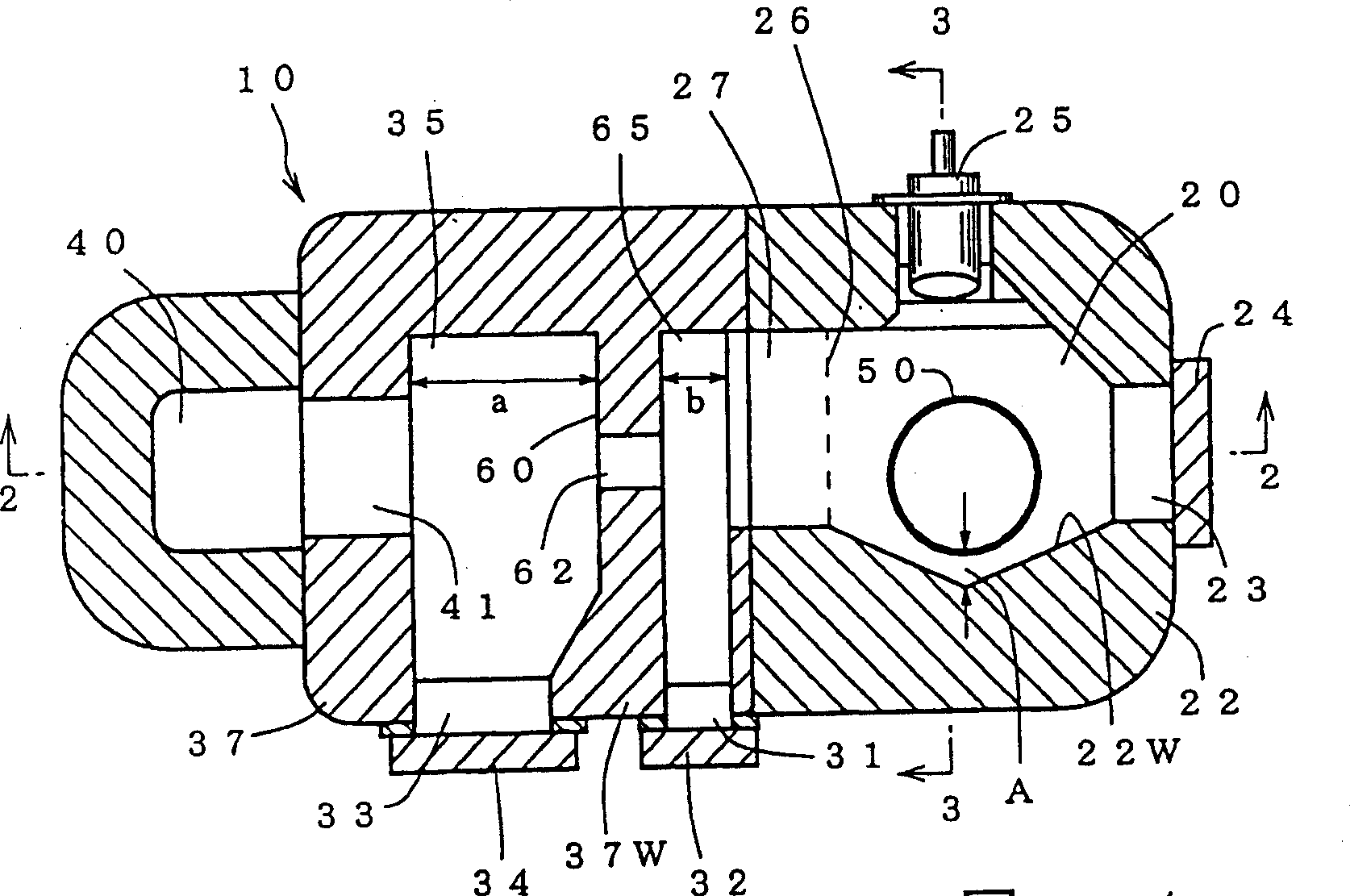

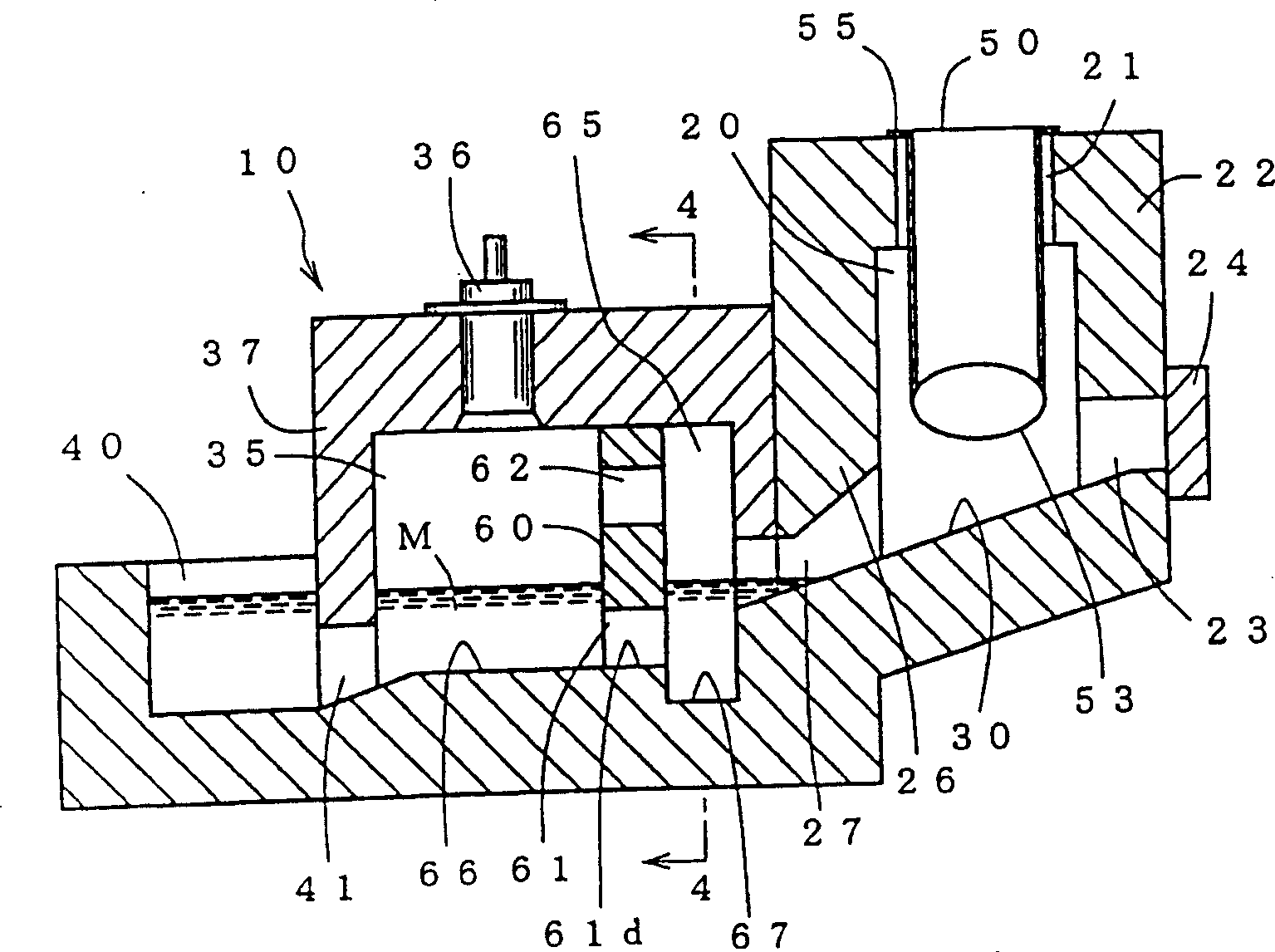

Metal melting furnace

In a metal melting furnace, a separation wall 60 is provided between an inclined hearth 30 and a molten metal reservoir 35 to define a molten metal processing portion 65 . The separation wall is provided with a connecting passage 61 for the molten metal, between the molten metal reservoir and the molten metal processing portion, at a height level higher than a bottom surface 67 of the molten metal processing portion. The separation wall is also provided on its upper portion with an exhaust gas passage which permits exhaust gas discharged from the molten metal reservoir to pass therethrough. An inspection opening 31 with a door 32 is provided in a furnace wall surface 37 W to open into the molten metal processing portion.

Owner:MEICHU

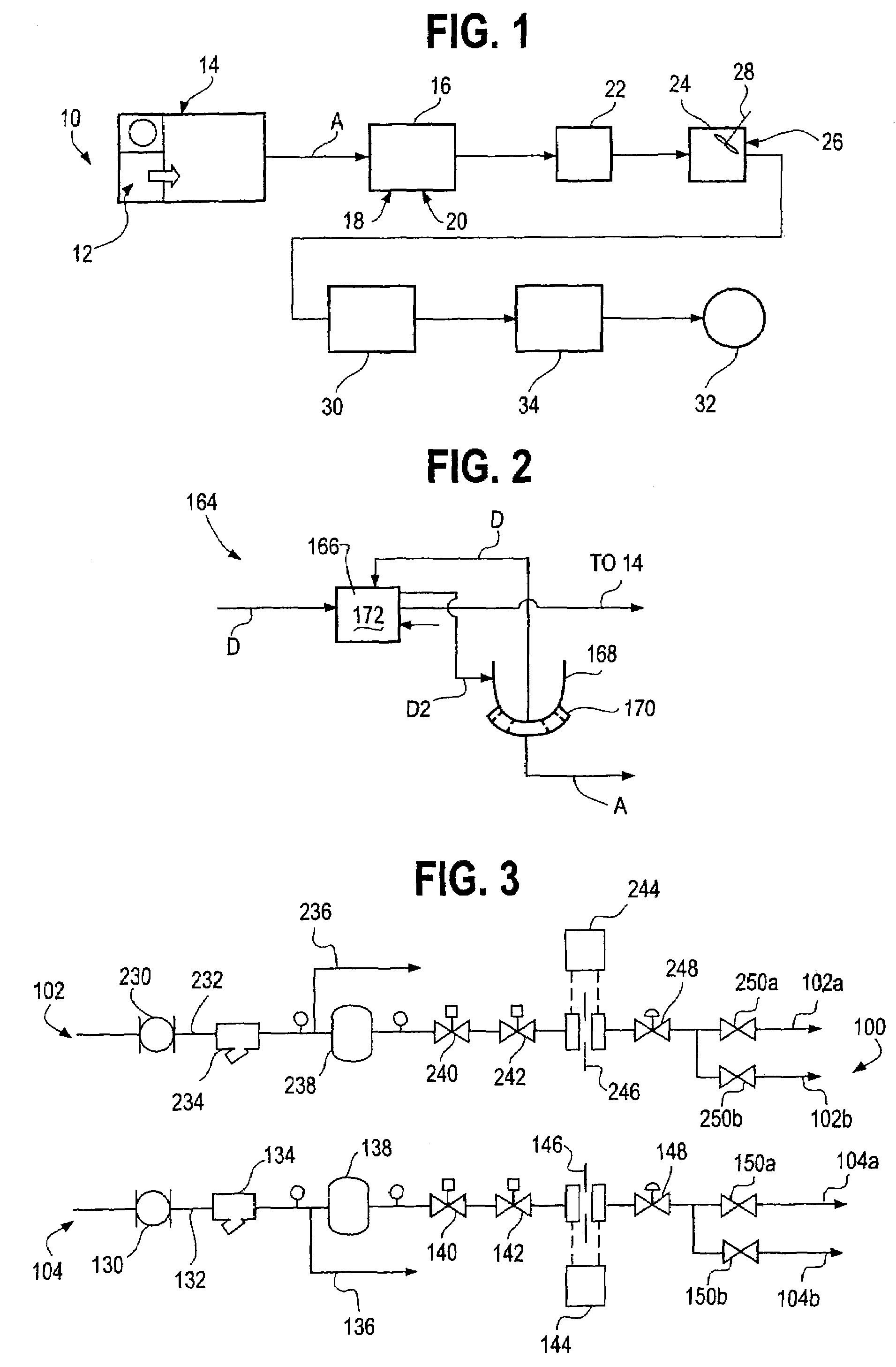

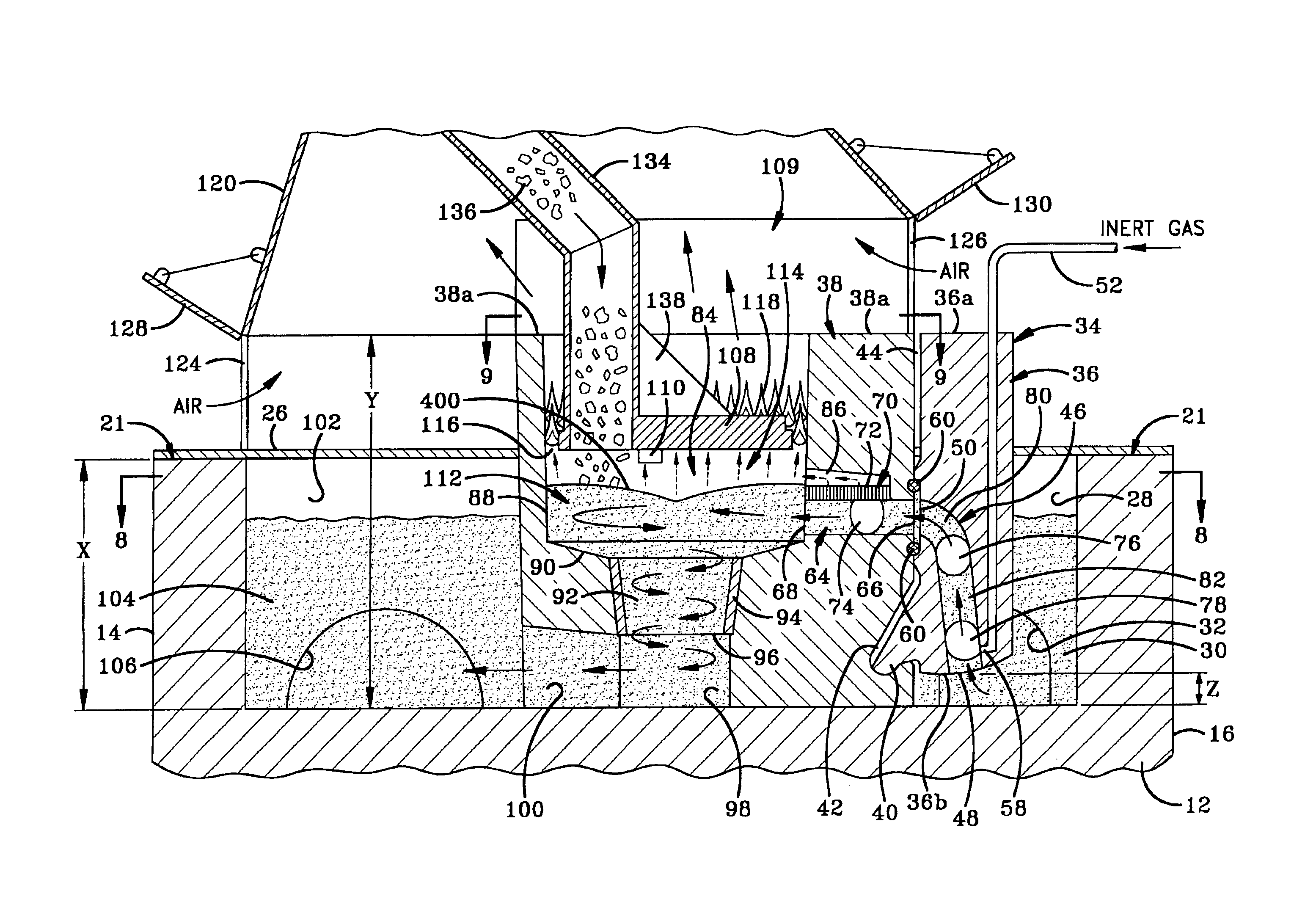

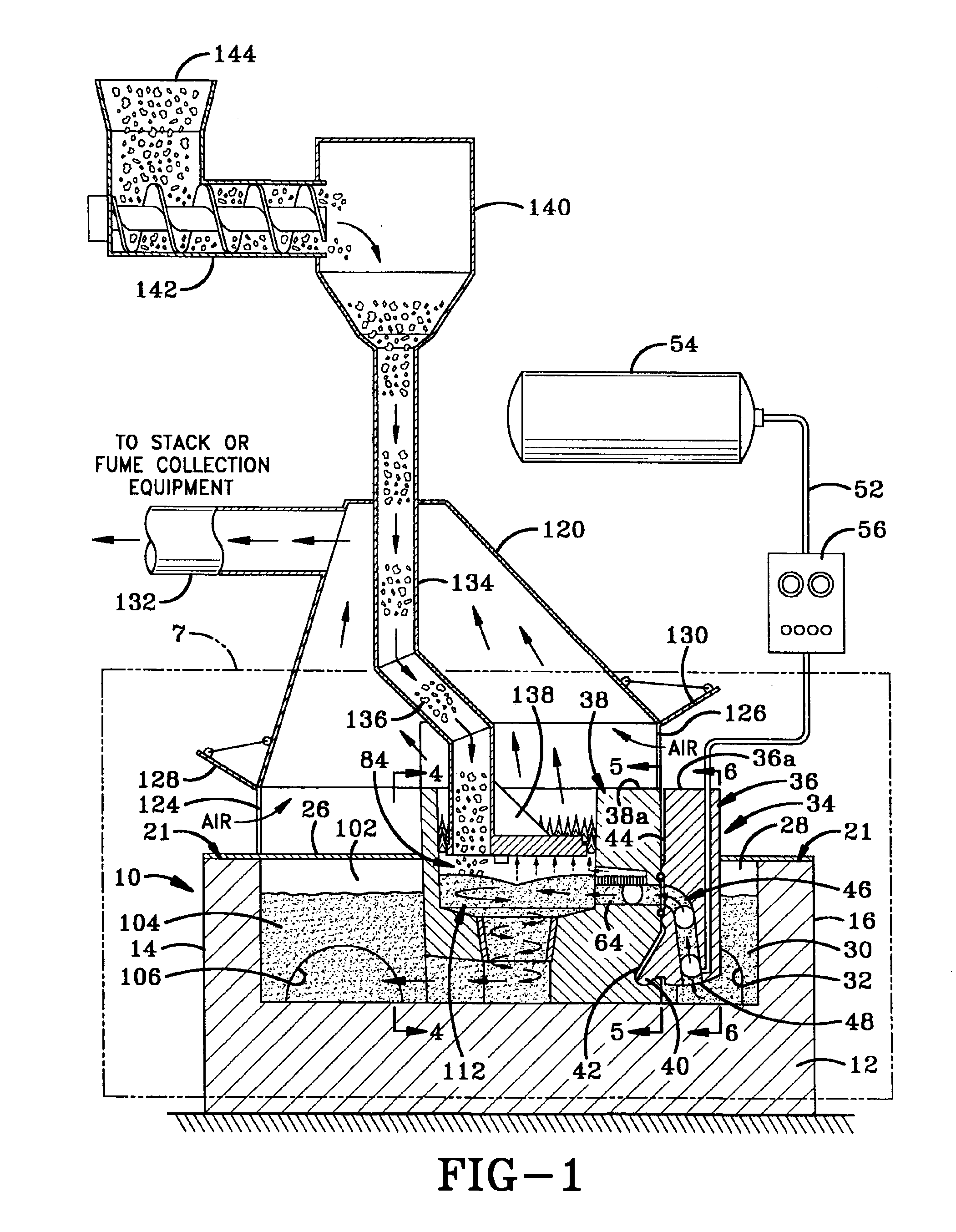

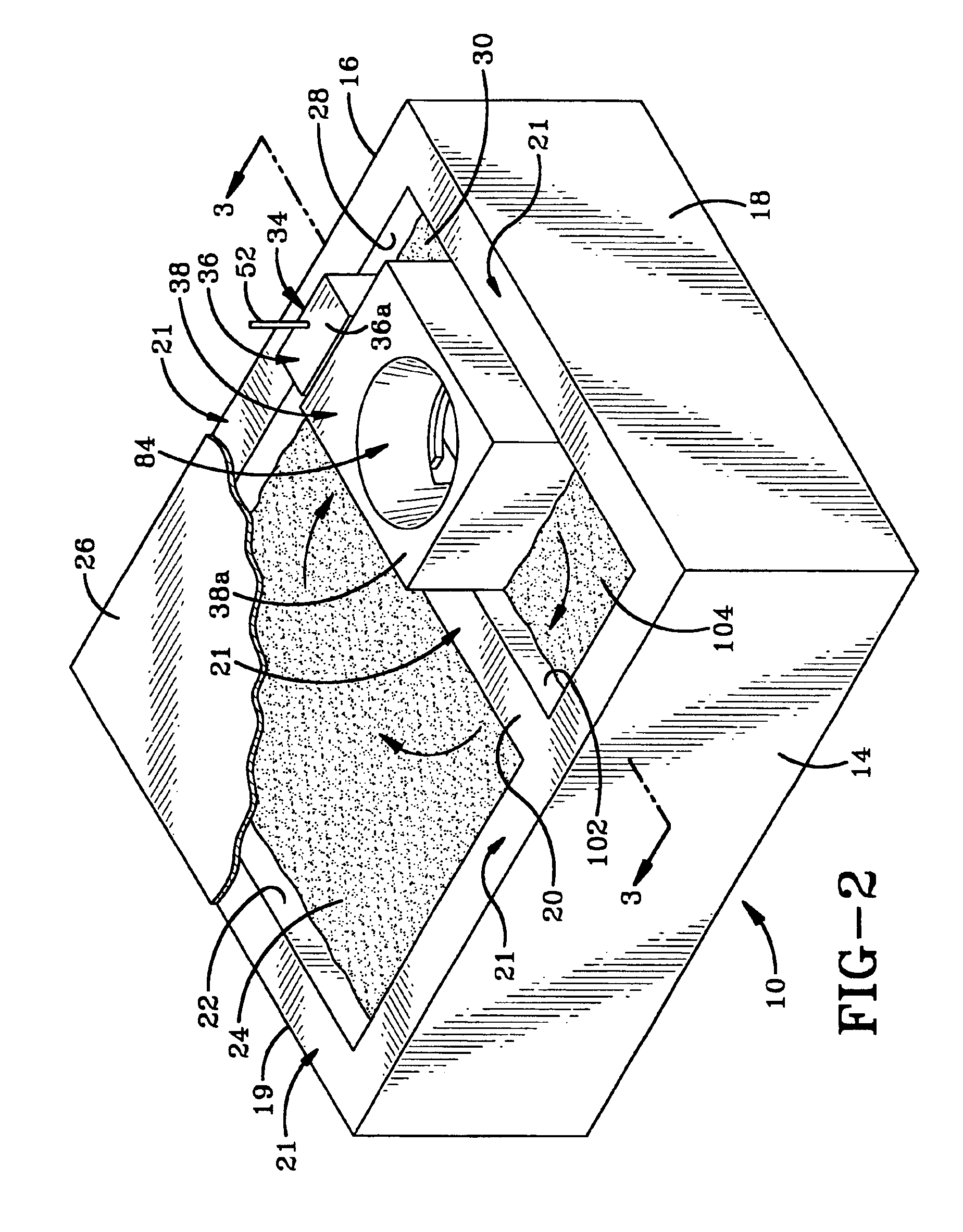

Elevated discharge gas lift bubble pump and furnace for use therewith

InactiveUS6893607B2Reducing metal lossReducing metal lossesMelt-holding vesselsMechanical apparatusMaximum levelMetallurgy

A metal melting closed furnace which includes a main chamber, a circulation well connected to the main chamber by a communications passageway and a vortex well having a exit outlet for molten metal into the main chamber. A cover is emplaced over the vortex well. An inert gas bubble activated molten metal pump is provided in which there is an entry port in the circulation well and exit port into the vortex well. The exit port is positioned to lie at least partially or entirely above the maximum level of molten metal in the vortex well. This exit port will typically be at or near the top of the vortex well. In order to reduce oxidation, inert gas bubbles are captured from this molten metal pump and creating an inert gas atmosphere or blanket above the molten metal vortex.

Owner:AREAUX MR LARRY

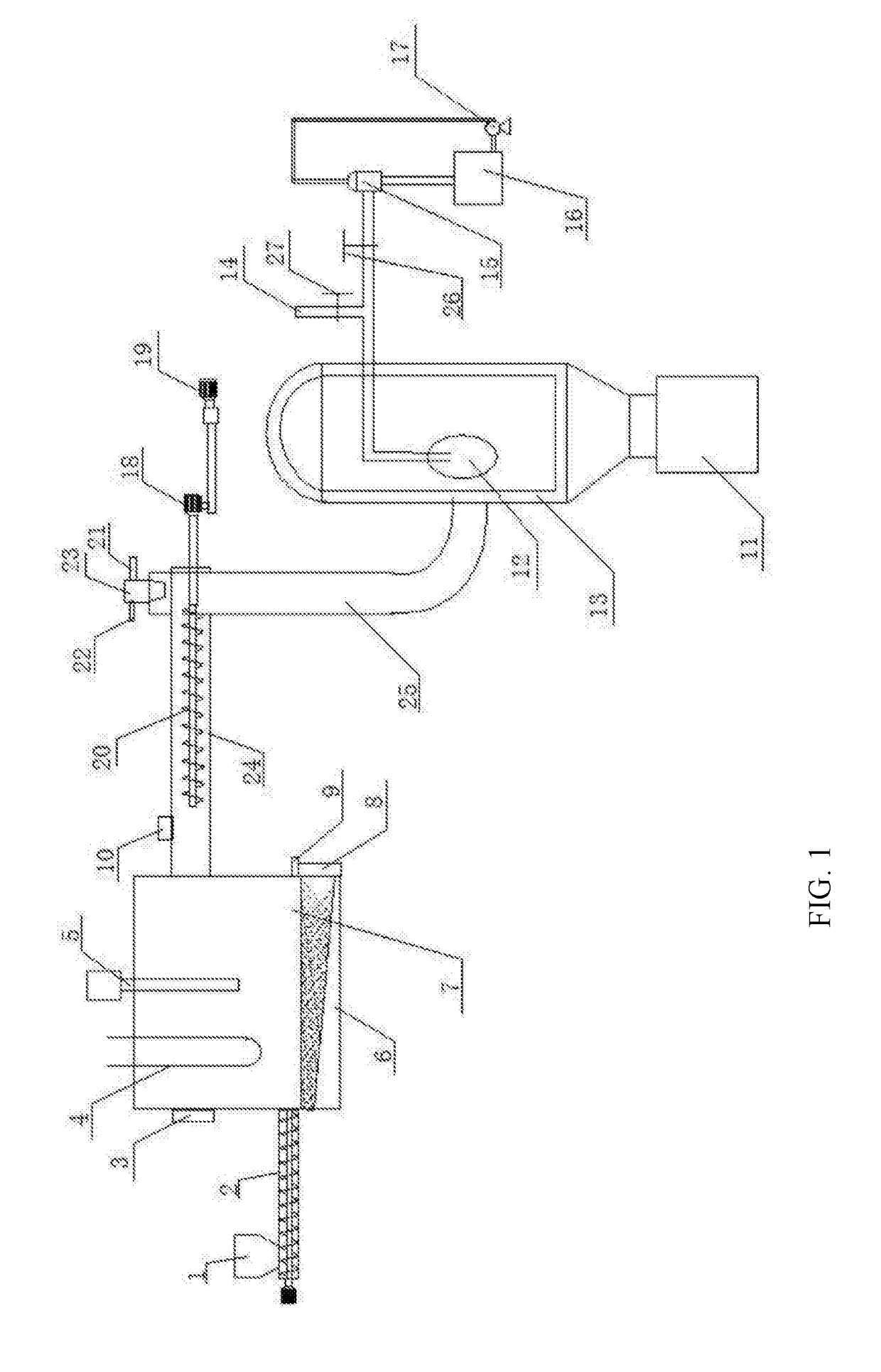

Device and method for producing high-purity NANO molybdenum trioxide

ActiveUS20180346344A1Improve efficiencyHigh recovery rateMaterial nanotechnologyHandling discharged materialEngineeringMolybdenum trioxide

A device and a method for producing high-purity nano molybdenum trioxide are provided. The device comprises a raw material bin (1), a feeding machine (2), a subliming furnace (7), a first vent tube (24), a second vent tube (25), a spraying device (23) and a filtering assembly. The sublimated molybdenum trioxide is cooled with clean and dehumidified air so as to finally obtain the nano molybdenum trioxide, and the recycling mode is reliable, pollution-free and high in efficiency.

Owner:HUBEI ZHONGAO NANO MATERIAL TECH CO LTD

Method of Building a Direct Smelting Plant

InactiveUS20070261321A1Flexible operationSmall and large loadFurnace componentsBlast furnace detailsMarine engineeringSlag

Method of building a direct smelting plant comprising a metal smelting vessel (11) and ancillary plant components such as the components of a hot air supply station (24), an offgas treatment station (32), a solids feed station (41), a hot metal desulphurization station (47) and hot metal and slag launders extending from the smelting vessel (11). The ring track (53) of a ringer crane (51) is installed in front of location at which vessel (11) is to be installed. Crane boom (54) is laid out along elongate stretch of the building site which becomes a corridor (60) between major ancillary components when plant is fully erected. Boom (54) is connected to crane carriage (52) and hoisted to provide high lift capacity over a ground area embracing proposed site of vessel (11) and ancillary components. Prefabricated components are then lifted by crane (51) into appropriate position for final installation. After installation is completed boom (54) is laid down along corridor (60) and crane (51) is dismantled and removed, leaving corridor (60) as an access laneway.

Owner:TECHNOLOGICAL RESOURCES

Device for metallizing uranium oxide and recovering uranium

Disclosed is a device for metallizing uranium oxide and recovering uranium, which reacts uranium oxide with a lithium metal to product uranium metal powder, and filters the resulting product using a porous filter to separate the uranium metal powder from lithium chloride molten liquid to recover the uranium metal powder. The device includes a heating furnace including at least one first heating unit, and a reactor includes a reaction vessel having a discharging valve hole located at the center of a bottom thereof and a conical bottom tapered to the discharging valve hole, a sealing lid for sealing the reaction vessel airtight, an argon gas inlet port for feeding argon gas into the reactor therethrough, and an argon gas outlet port for venting argon gas from the reactor therethrough. A valve assembly controls the discharging valve hole of the reaction vessel, and a plurality of agitators mix a mixture in the reactor. A lithium metal feeder includes a second heating unit and is removably installed through the sealing lid. A cooling jacket is set in the sealing lid, and a porous filter is located under the reactor in the heating furnace. Further, a molten salt recovery tank is positioned under the porous filter in the heating furnace.

Owner:KOREA ATOMIC ENERGY RES INST +1

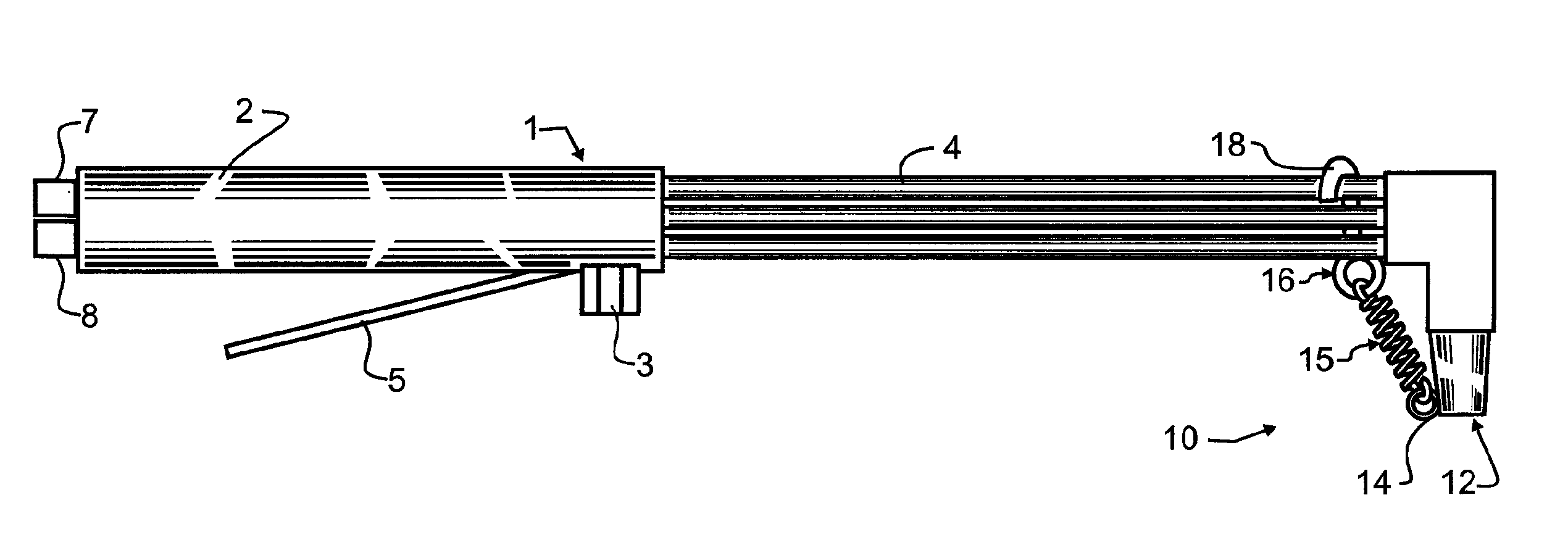

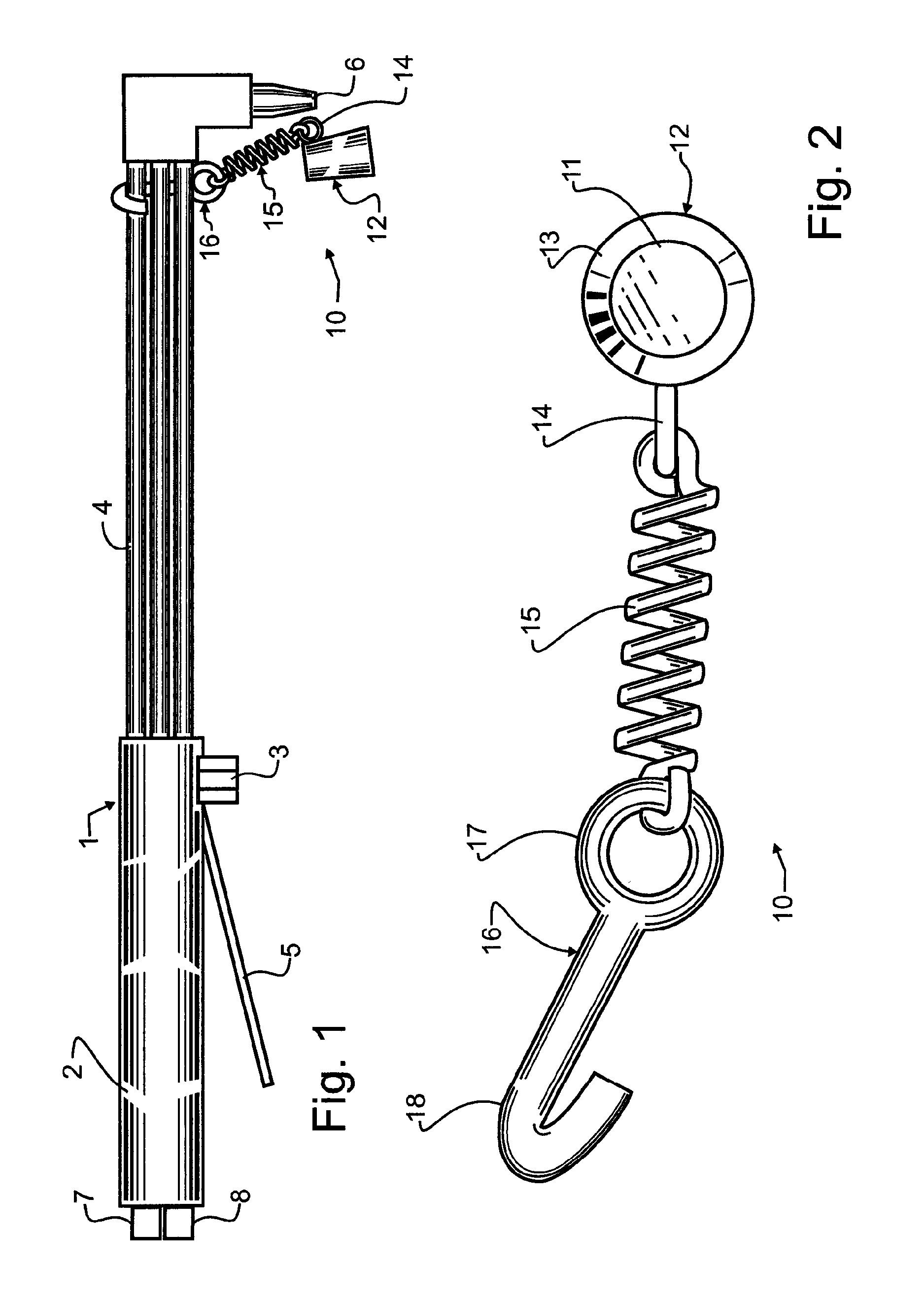

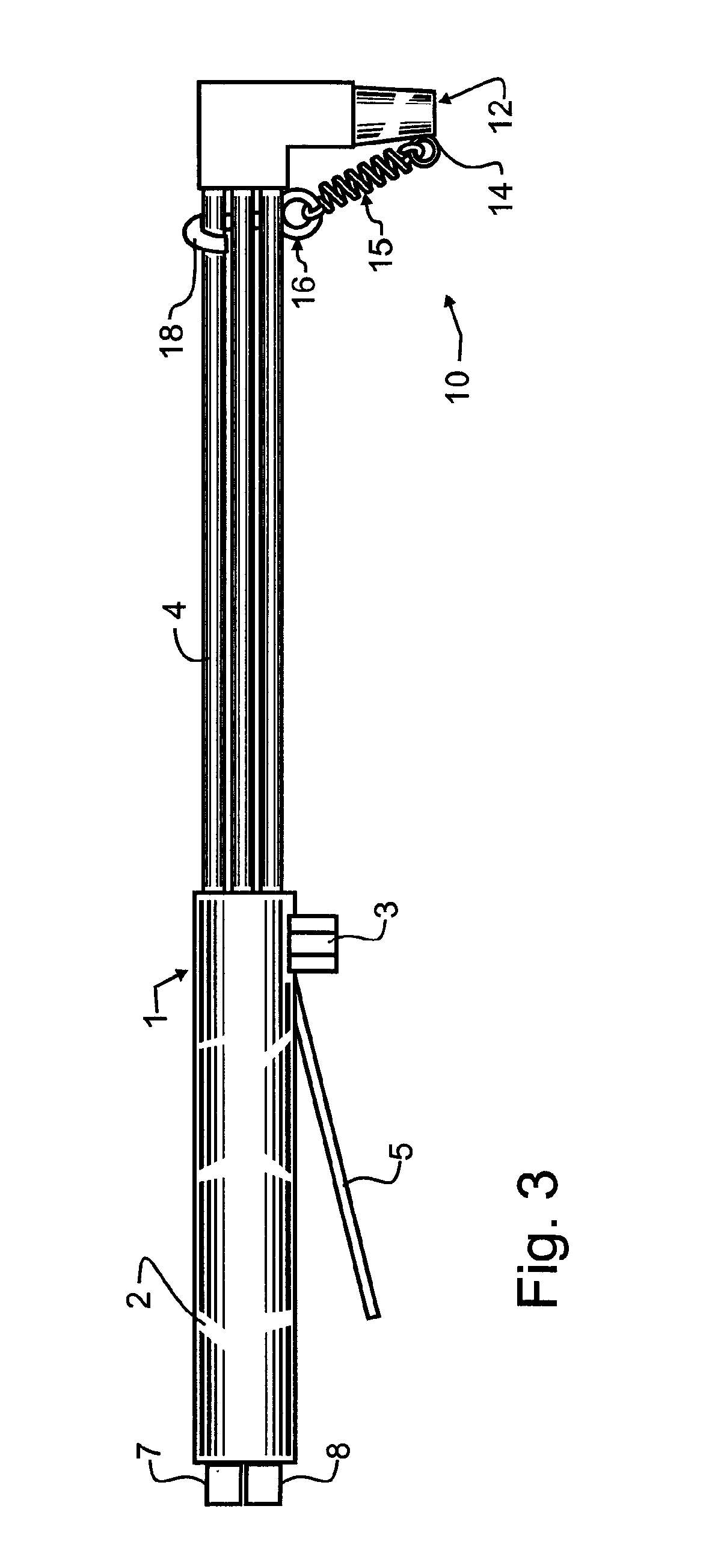

Torch Tip Protector

ActiveUS20140145380A1Easy to manufactureLow costGaseous fuel burnerMetallurgical apparatusTorchEngineering

A torch tip protector is elastically retained to an oxyacetylene cutting torch tip during transport. The torch tip protector in the preferred embodiment has a protector cap having a generally disc-shaped base and a truncated conical side wall that together form a cup or thimble-shaped torch tip cover. This torch tip cover operatively encompasses a torch tip and thereby operatively blocks access and fouling of the torch tip. To ensure that the protector cap stays engaged with torch tip, a hook secures to and is manually removable from at least one of the torch gas lines. A spring couples to the hook and couples with the protector cap to provide an elastic tension force that draws the protector cap towards hook and thereby secures the protector cap onto the torch tip.

Owner:PLUT TRAVIS J

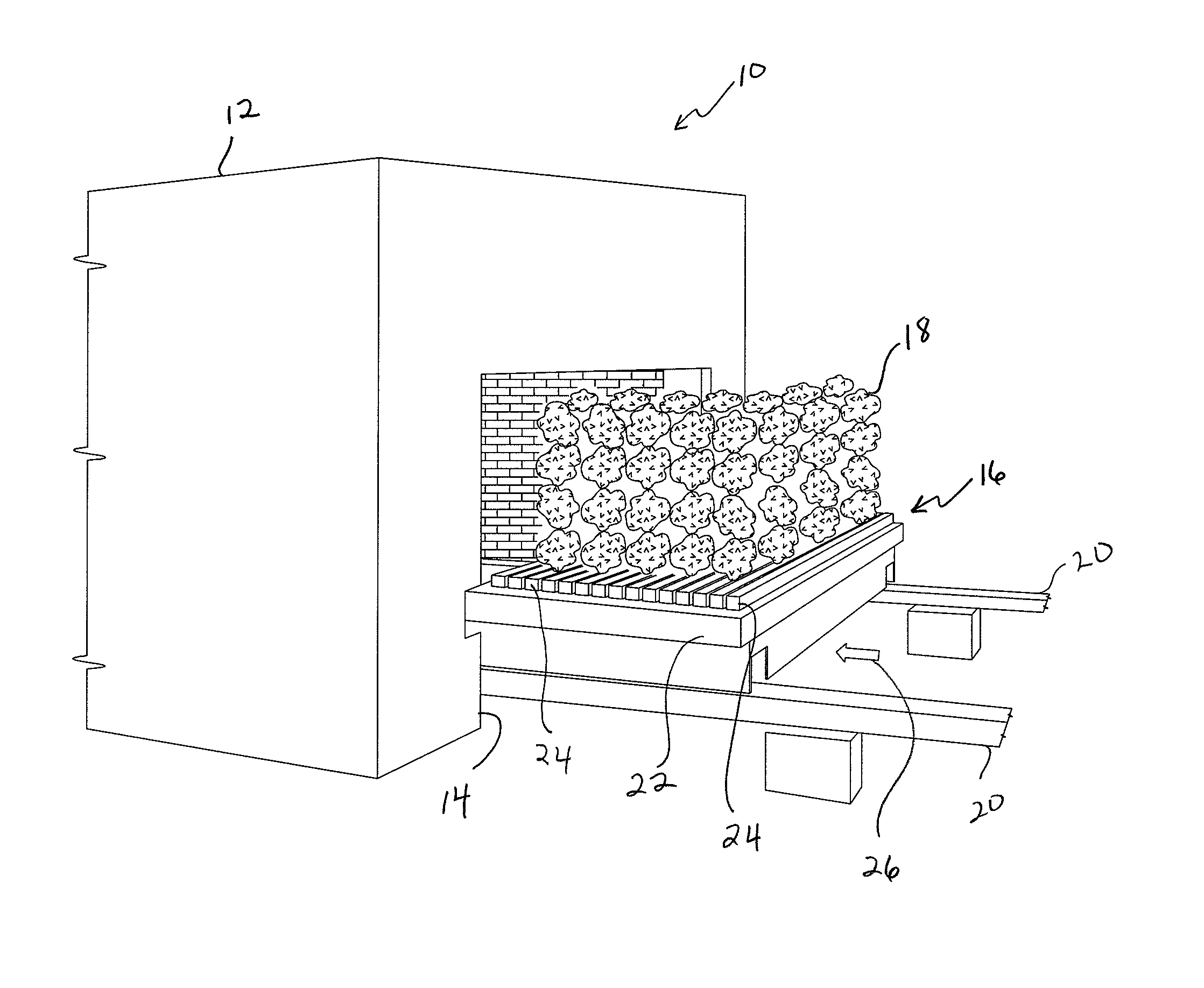

Metal recovery system

A thermal system for separating out co-mingled metals in almost pure form, the system including a tunnel kiln having temperature zones through which the co-mingled metals are conveyed and progressively heated until at least one metal of the co-mingled metals melts thereby separating the melted metal from the other metal or metals of the co-mingled metals. The system includes molten metal catch basins for collecting the melted metal which are arranged beneath a conveyor on which the co-mingled metals are transported within the kiln. The catch basins are tapped to the outside of the kiln so that as the various metals melt out at progressively higher temperatures, they can be collected into cast iron chills or other collection devices to form pure ingots.

Owner:GAWI

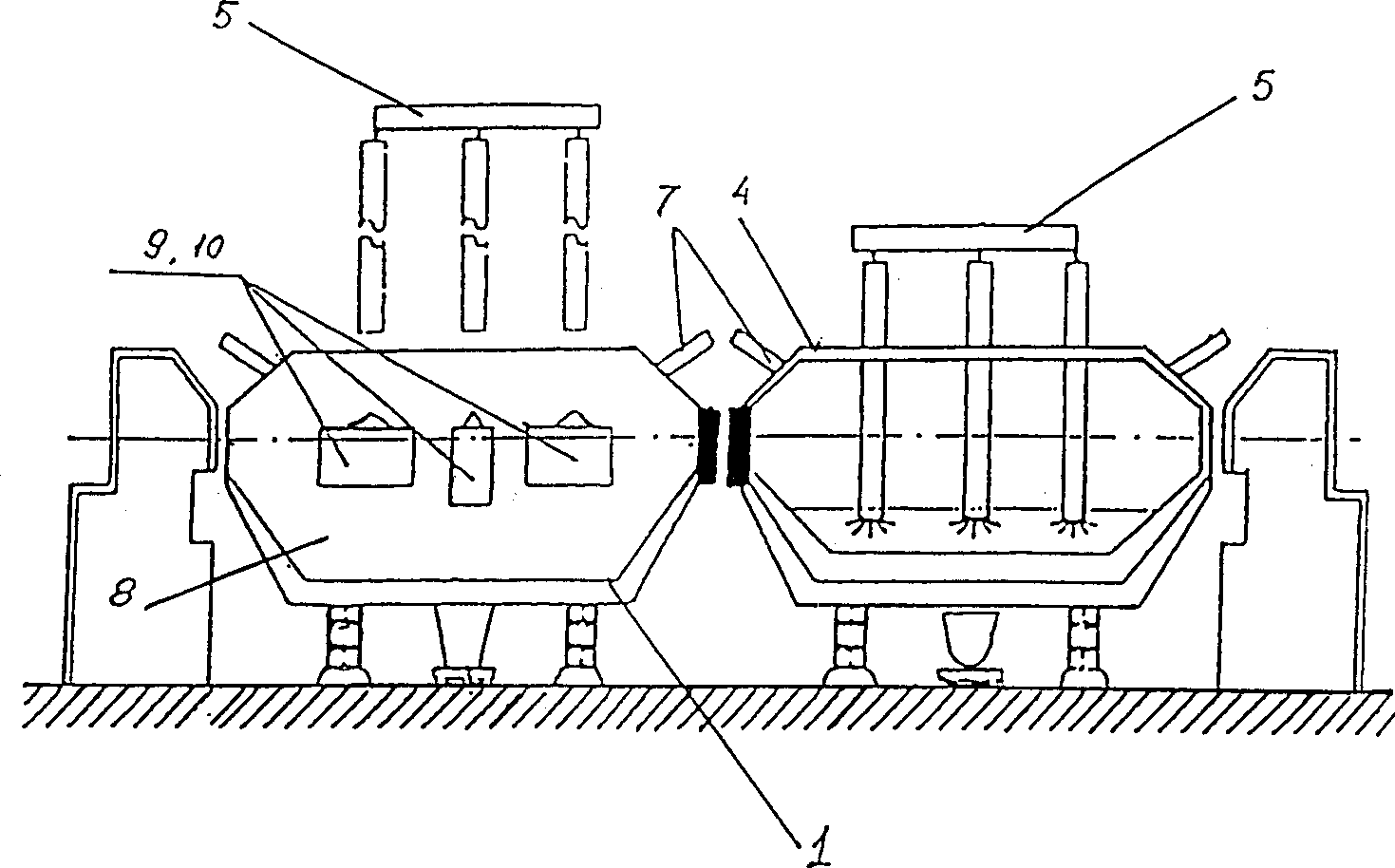

Multichambered stellmaking apparatus and method of steelmaking using this apparatus

InactiveCN1350629AReduce consumptionHigh strengthCharge manipulationManufacturing convertersSteelmakingCombustor

The invention pertains to the art of ferrous metallurgy, and more particularly, to a multichambered steelmaking apparatus and to a method of steelmaking. A multichambered steelmaking apparatus contains smelting chambers communicating with each other through their upper portions. Process input ports are provided in the chamber side wall, and the smelting chambers are provided with gas-oxygen burners installed on the walls of the smelting chambers facing each other. A method of steel making employs the apparatus in a unique manner. During operation, the smelting chambers are tilted in the direction of the input port and during the discharge of steel they are tilted in the direction of the outlet. During the melting stage carbon monoxide (CO) is afterburned by gas-oxygen burners forming carbon dioxide (CO) in the exit gasses supplied to the gas exhaust system through the coaxial chamber. A portion of a slag from the previous heat is retained.

Owner:洛马金·弗拉德米尔·马克斯莫维奇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com