Apparatus for the combustion of gas exiting from a furnace, for the preheating of scraps entering the furnace itself and related process

An electric arc furnace and equipment technology, applied in lighting and heating equipment, chemical instruments and methods, preheating costs, etc., can solve problems such as difficult calibration and control, high cost, complexity, etc., to achieve increased efficiency, improved control, and less burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

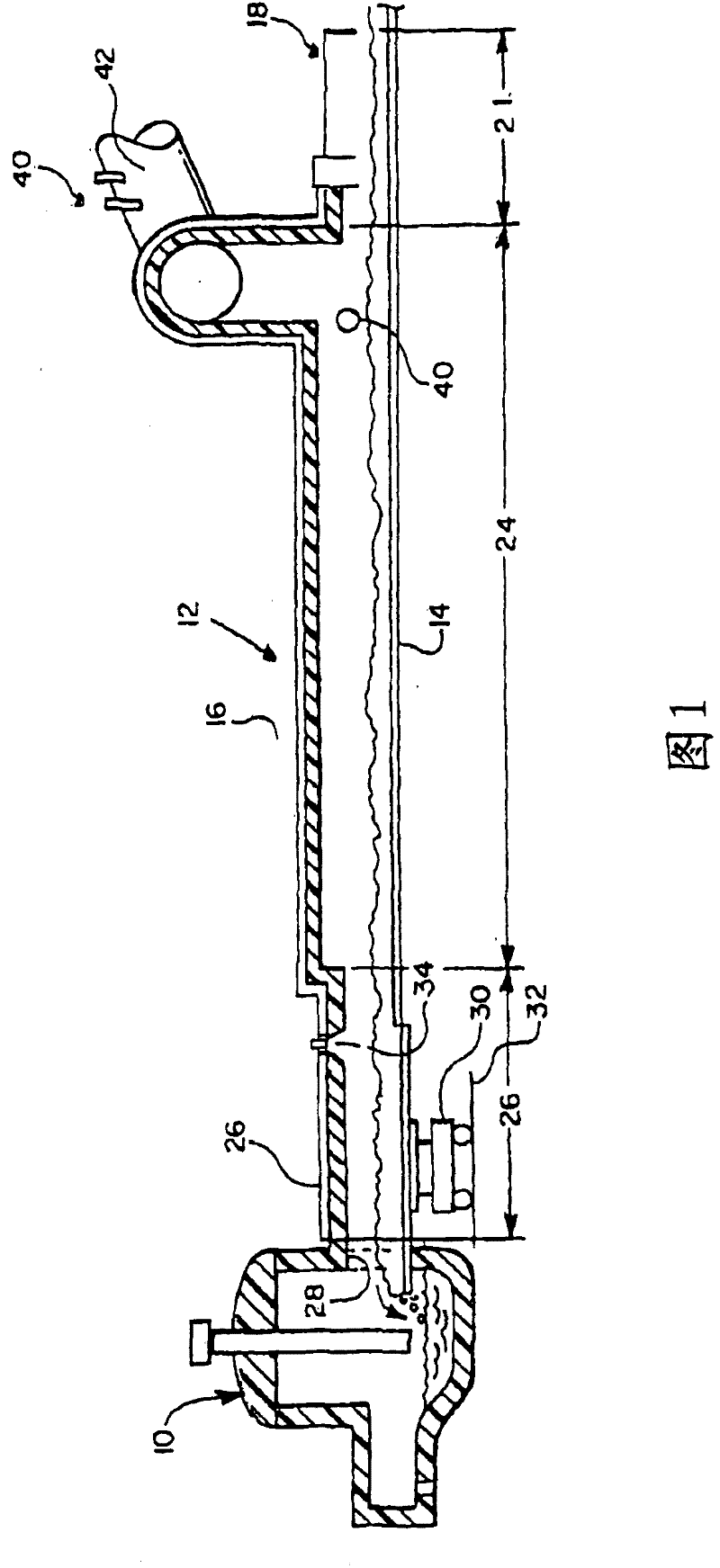

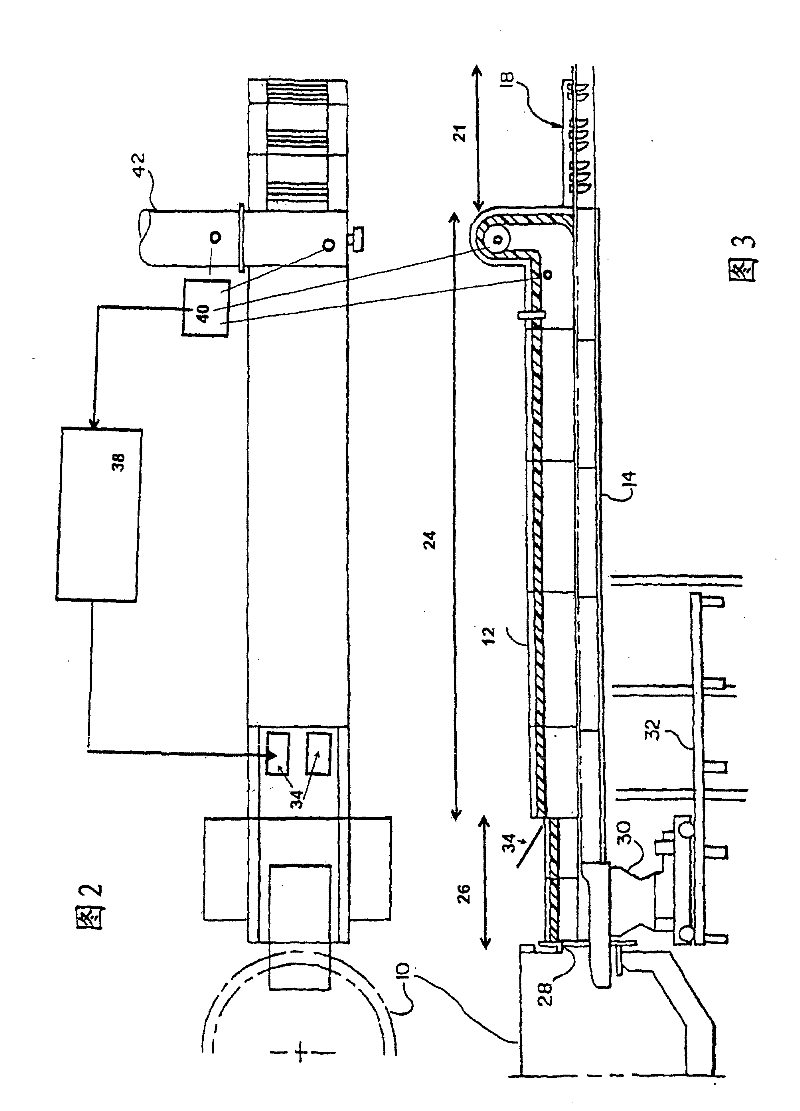

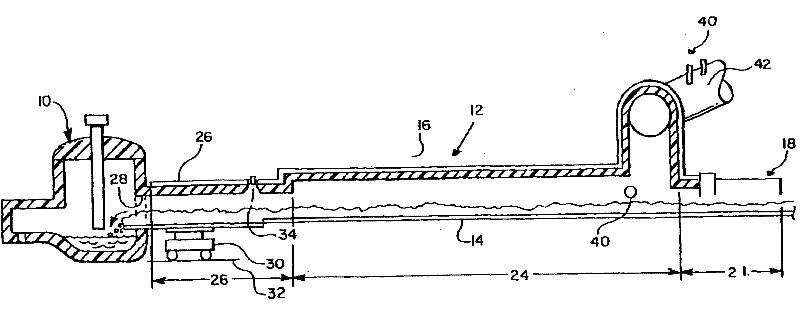

[0068] Referring to the drawings, in general and in particular to Figure 1, there is shown an embodiment of an apparatus according to the invention in which an electric arc furnace 10 for the production of steel has an extended preheating chamber or tunnel 12, preferably a vibrating channel, for the Metallic and non-metallic charges are introduced into the furnace.

[0069] Furnace 10, represented as a three-phase electric furnace, may alternatively be a DC electric furnace, a plasma furnace or an induction furnace.

[0070] The preheating tunnel or cavity 12 has an elongate support 14 covered by a corresponding extension cover, preferably coated with a refractory material.

[0071] The preheating chamber or tunnel 12 has a mechanical seal 18 at and from the inlet end of the charge, which successively comprises: an inlet or introduction section 21 for the charge, comprising a A containment system 18 of controlled access tunnels; one or more heating sections or zones 24; and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com