Patents

Literature

41results about How to "Improve environmental impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

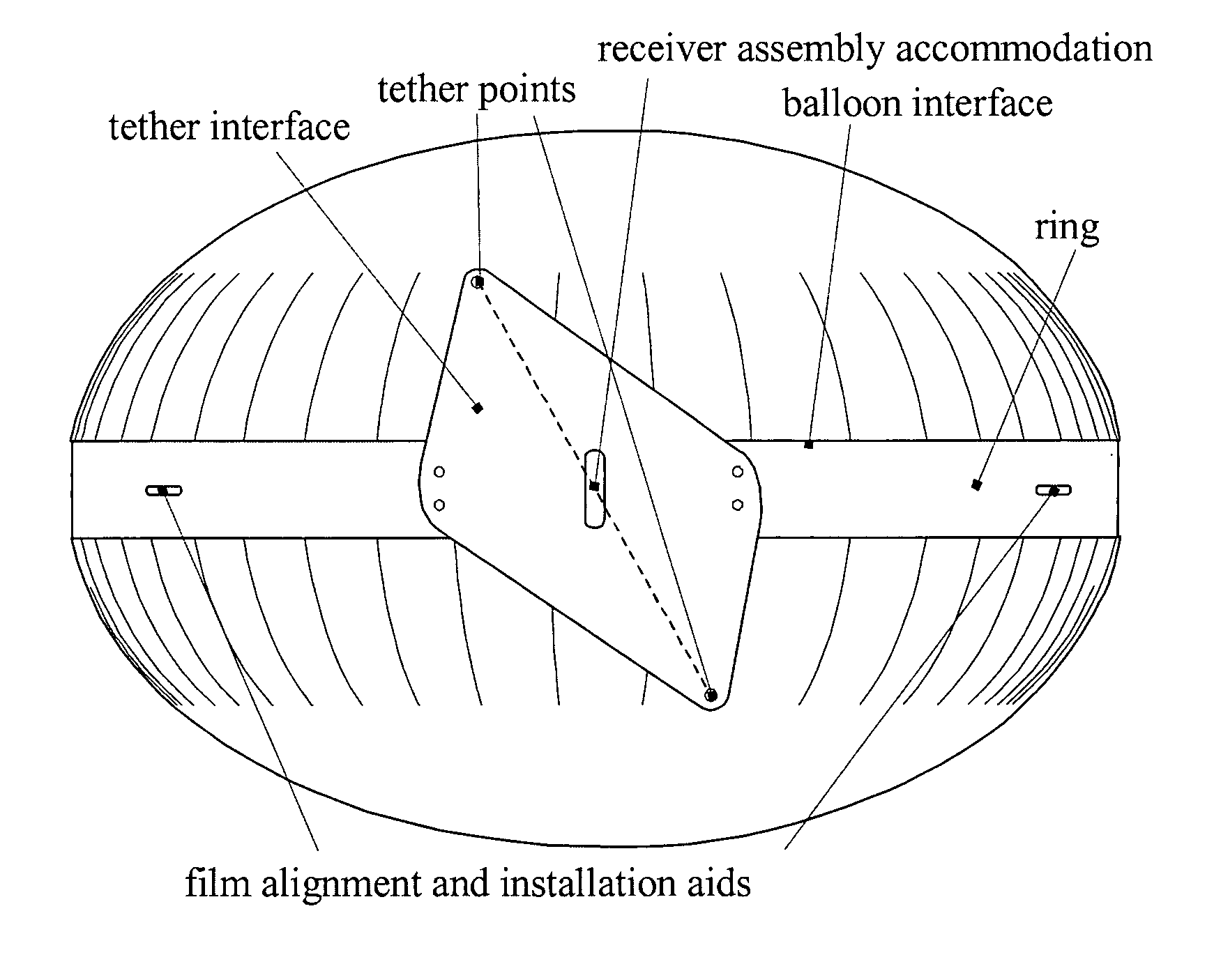

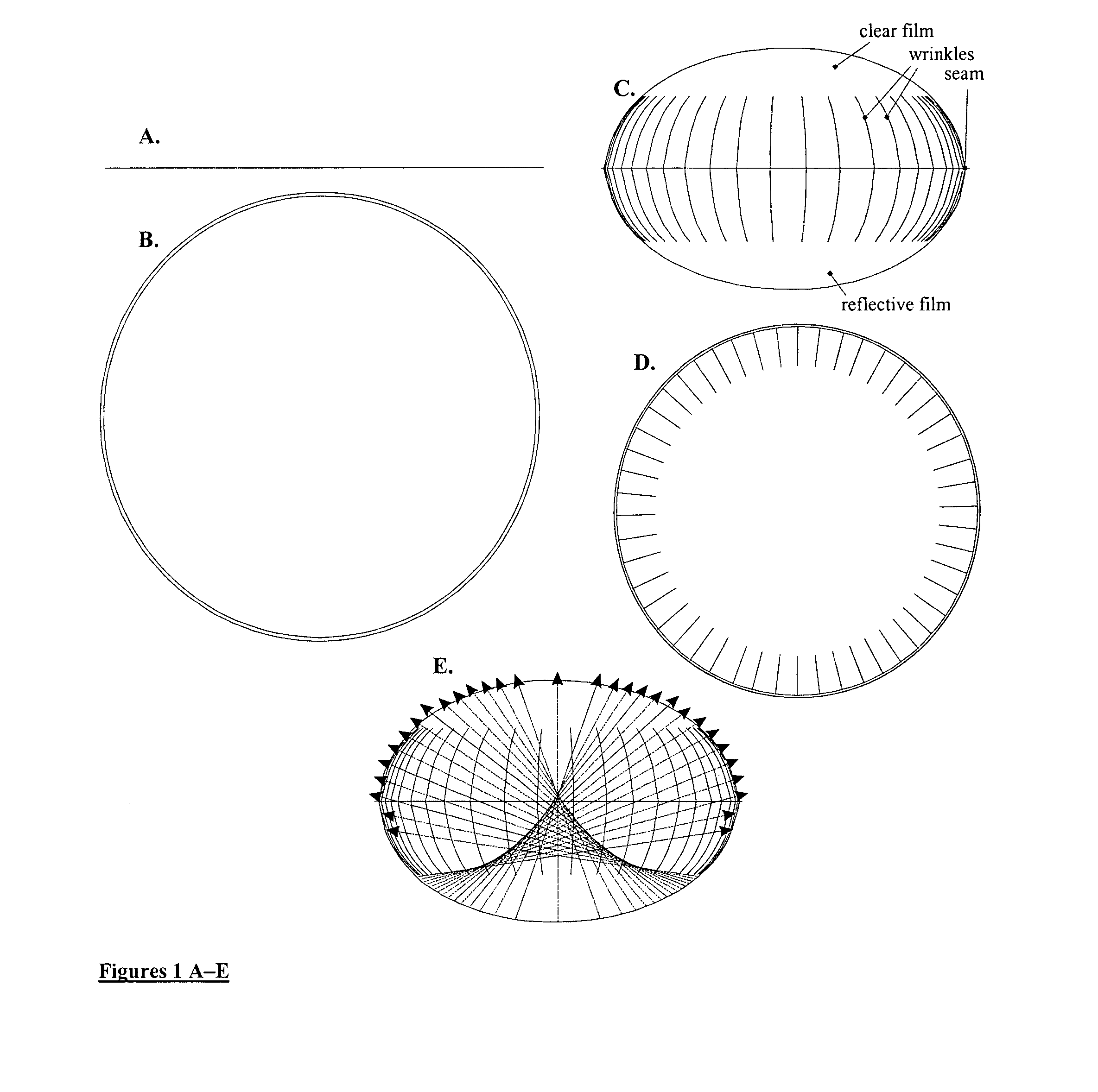

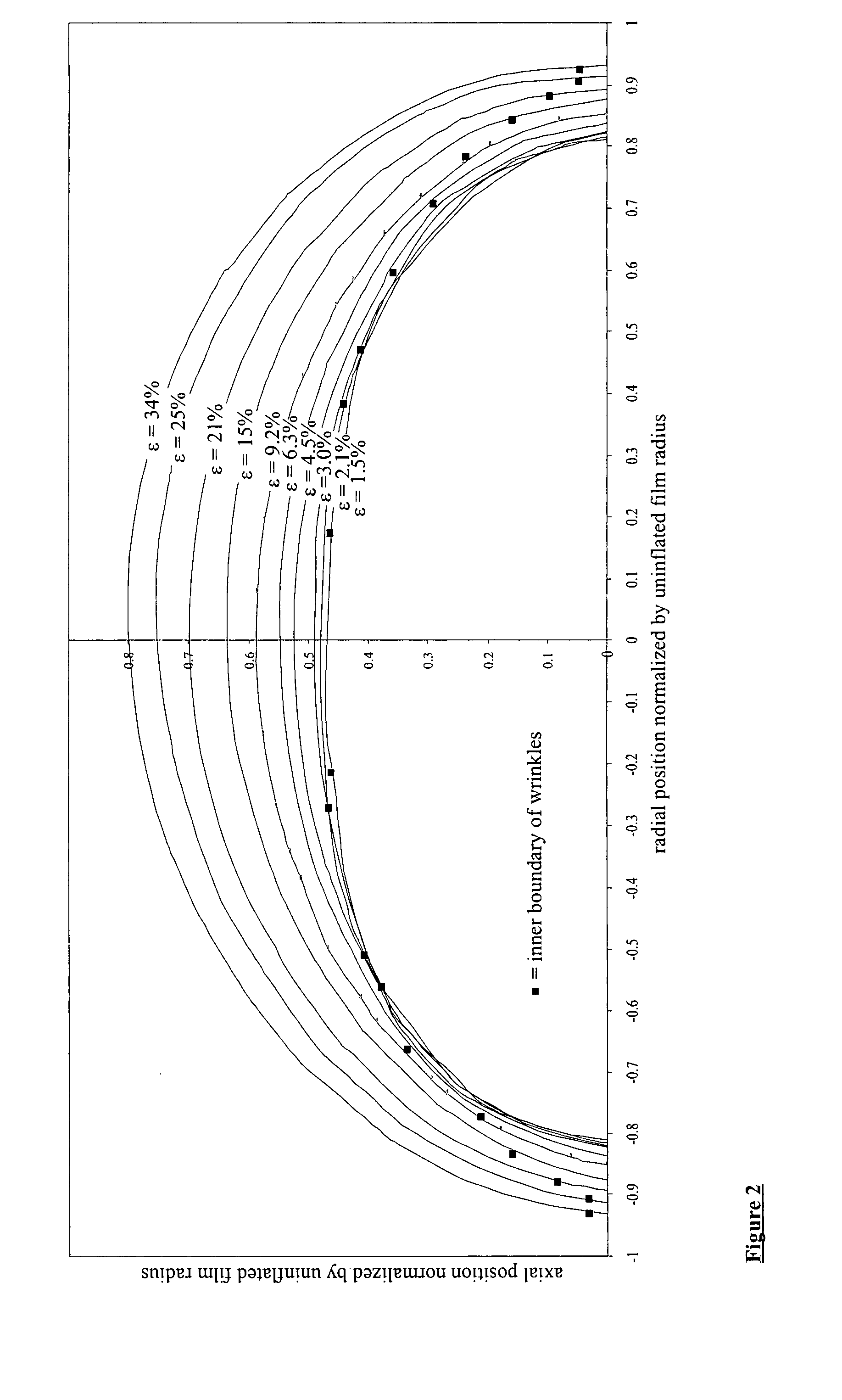

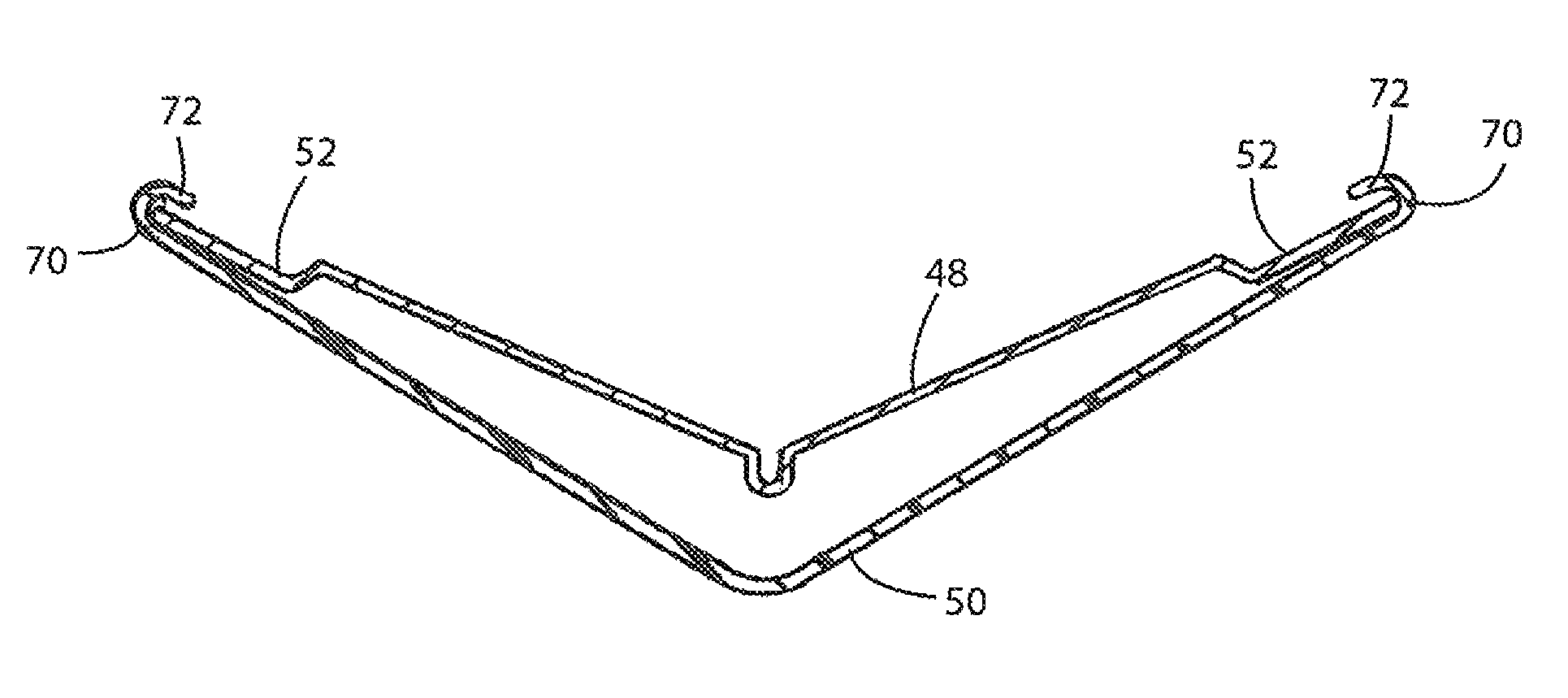

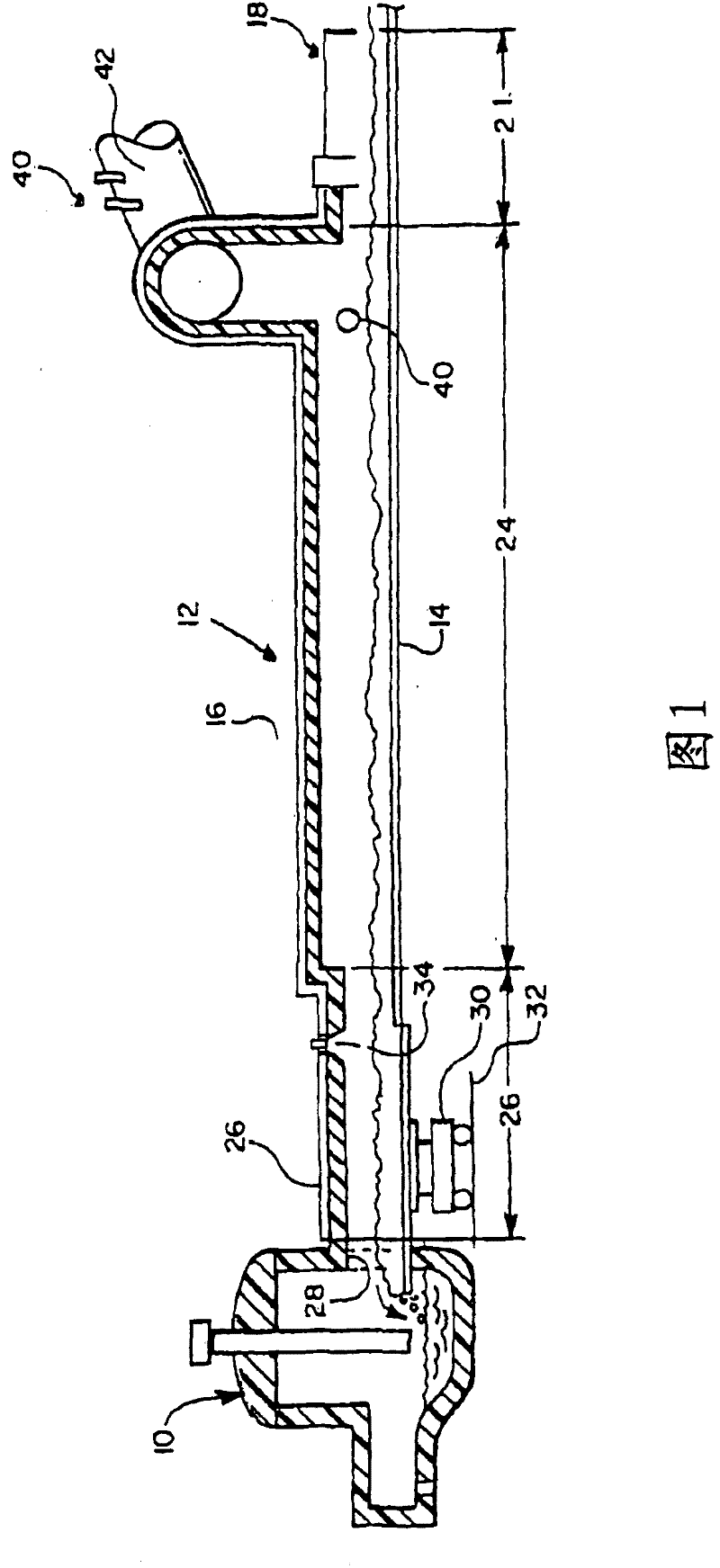

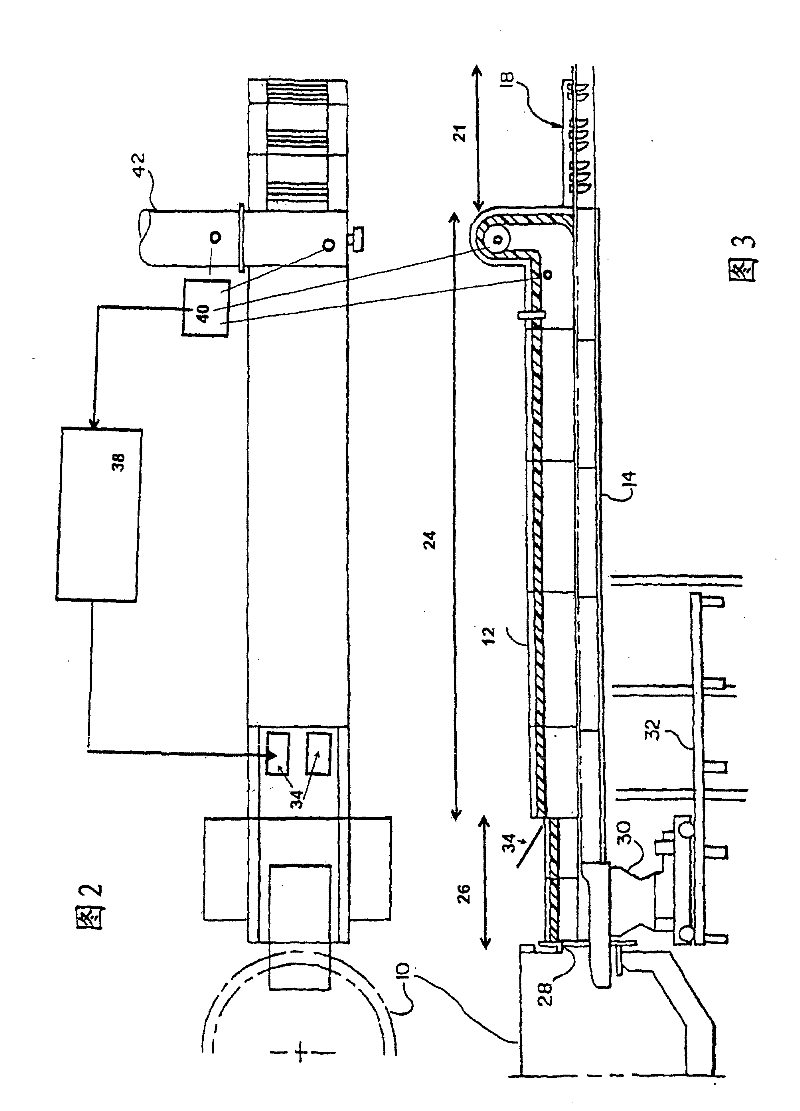

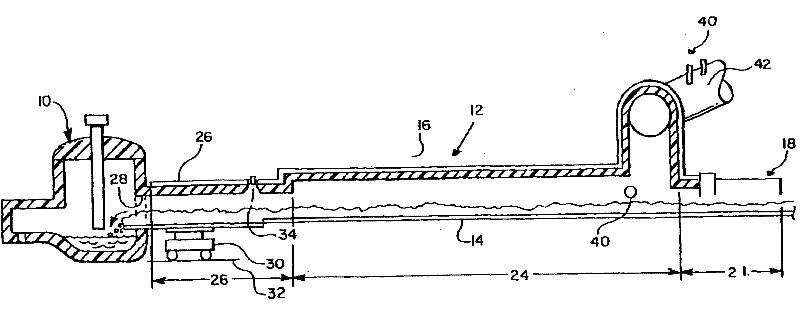

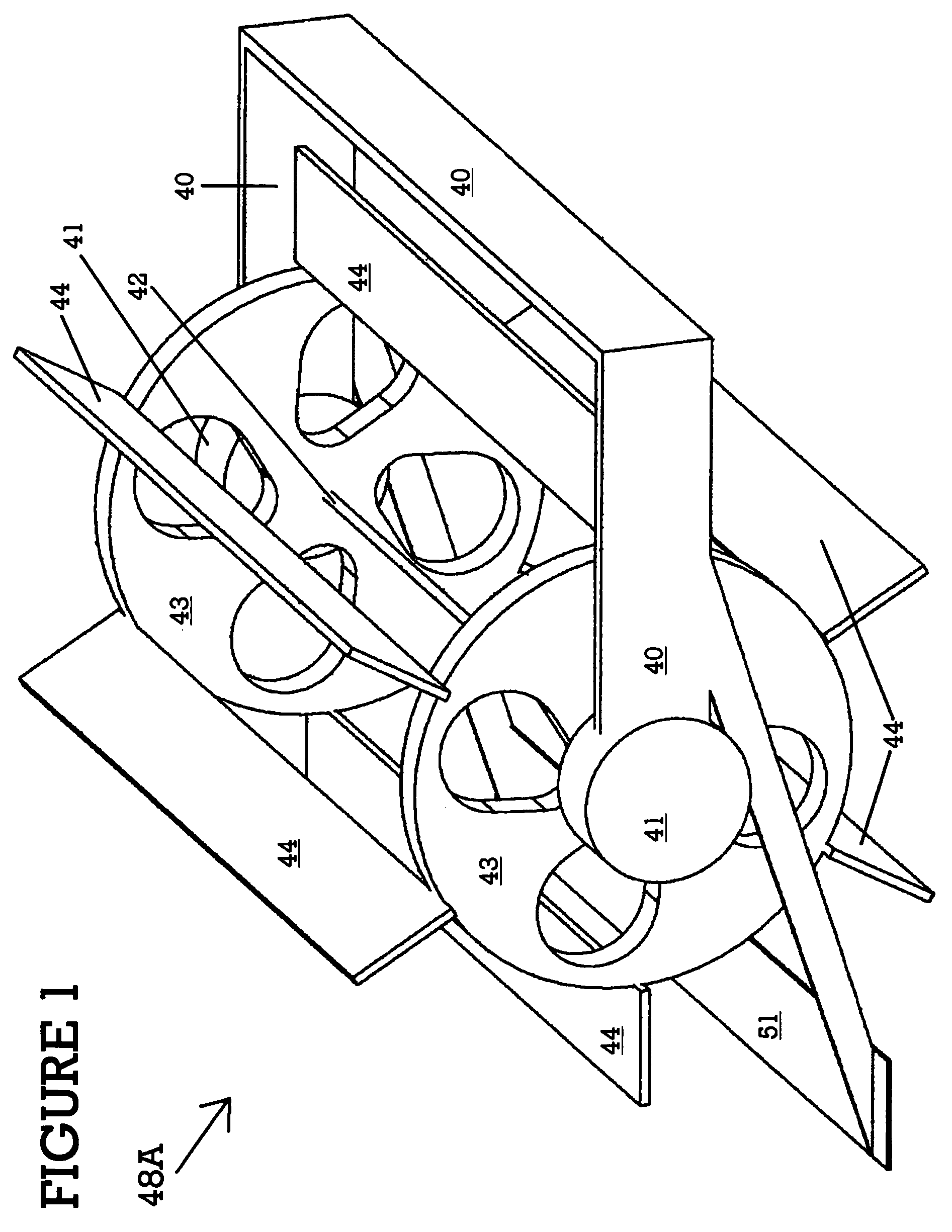

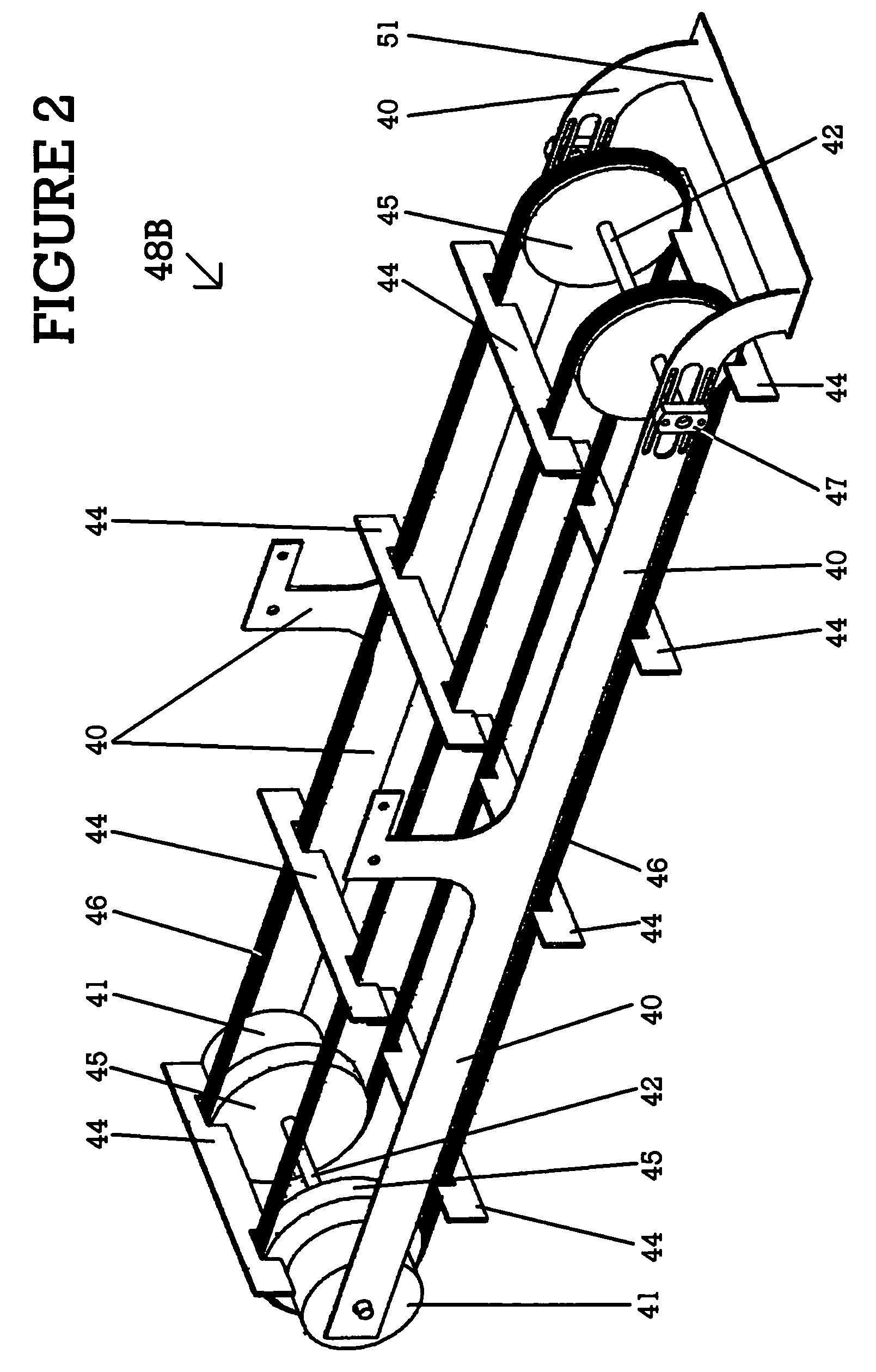

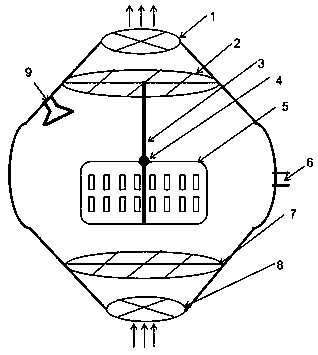

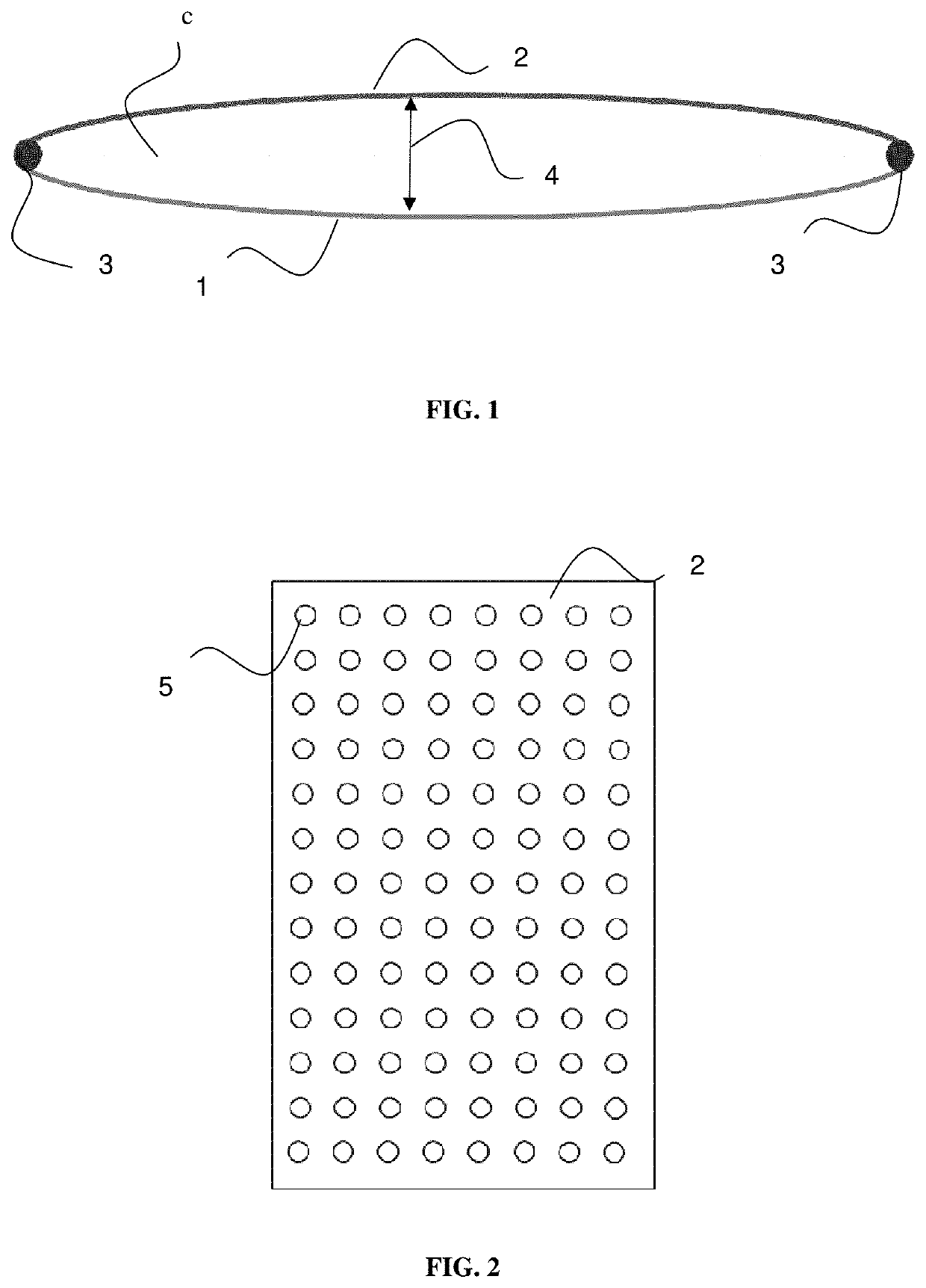

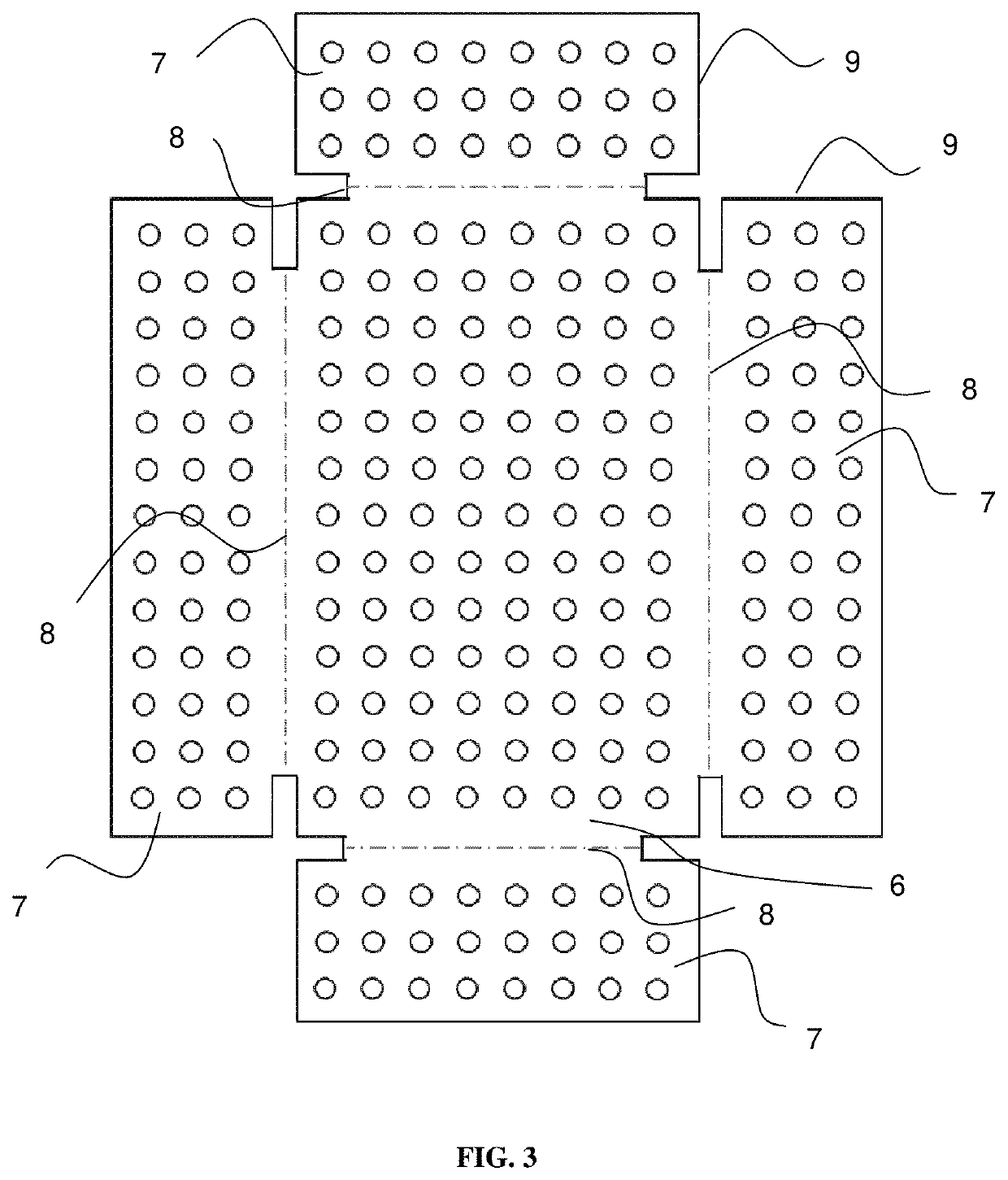

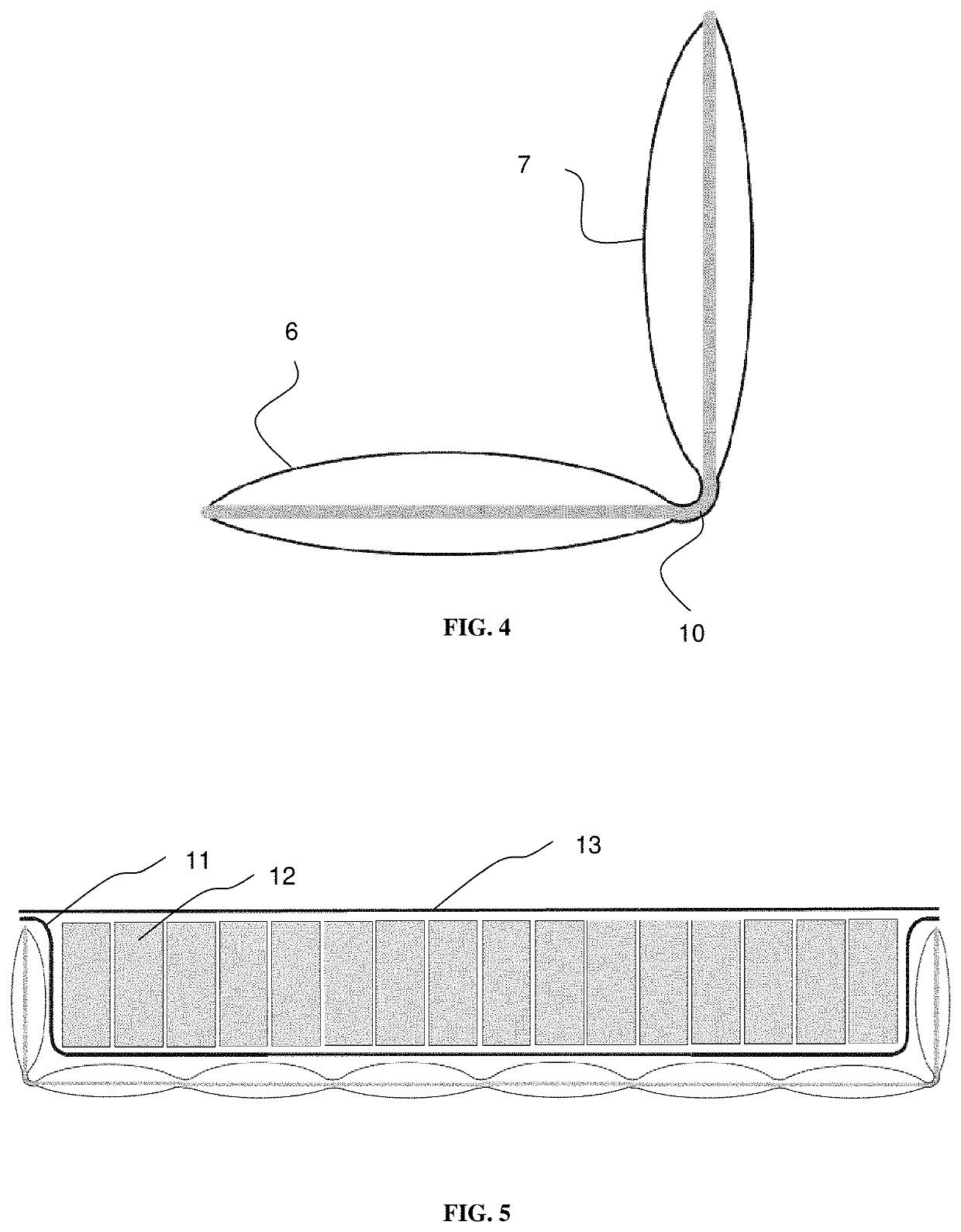

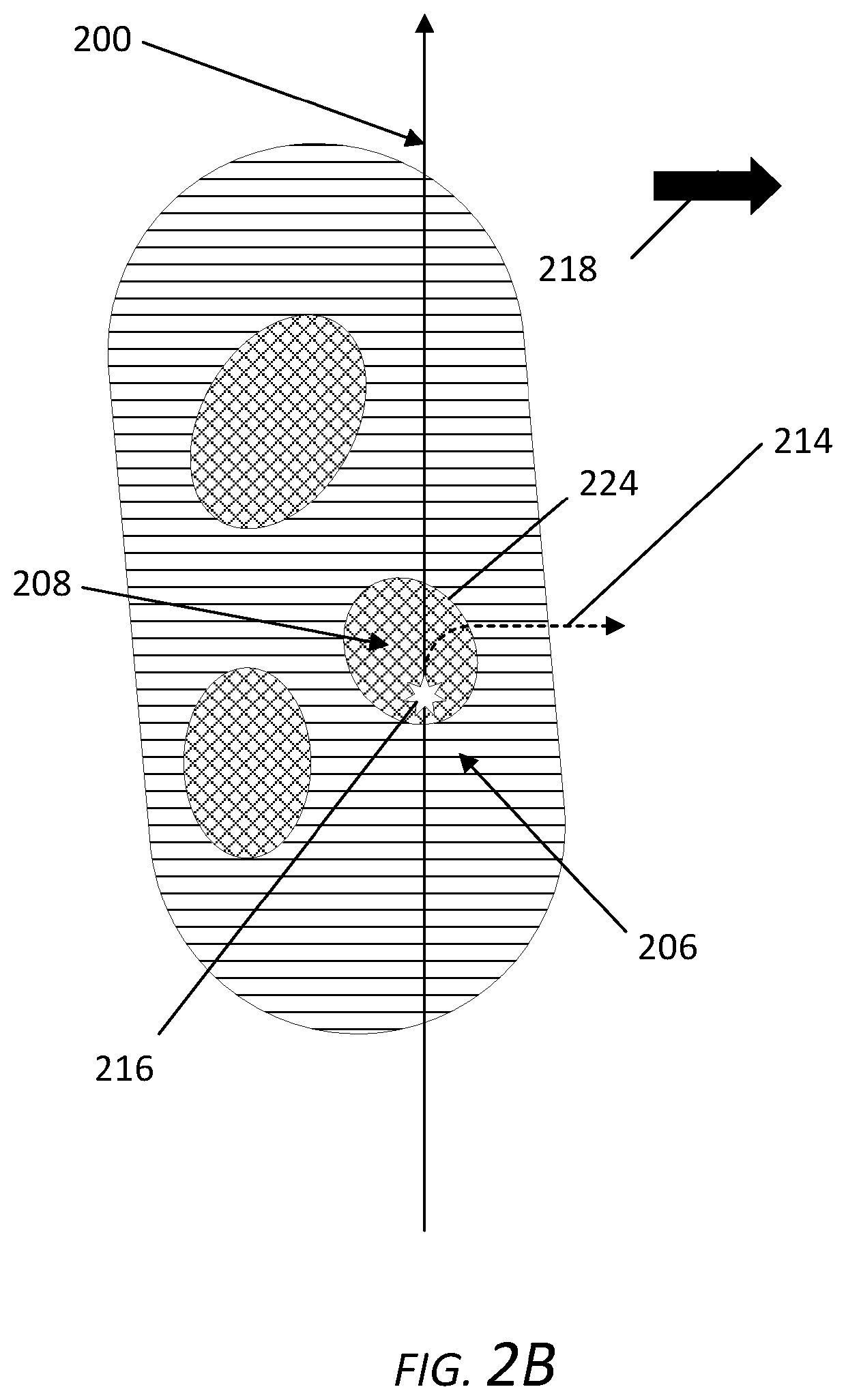

Inflatable solar concentrator balloon method and apparatus

ActiveUS8074638B2Avoid skewImprove environmental impactSolar heating energyCollapsable antennas meansStress concentrationManufacturing technology

Embodiments of the present invention relate to concentrating solar radiation using an assembly of at least one clear and one reflective film that inflates into a shape reflecting parallel rays of light to a concentrated focus in the interior or immediate proximity of the assembly. Embodiments of the present invention can be assembled in a substantially flat stack with bonds or welds between the films, compatible with conventional high-throughput film manufacturing processes. Embodiments in accordance with the present invention may employ external circumferential rings or a “harness” assembly to support and point the balloon against wind forces and the like without severe stress localization. Embodiments in accordance with the present invention may also employ film attachments to facilitate feedthroughs, reduce stress concentrations, and modify the inflated shape. Embodiments in accordance with the present invention may also employ film modifiers, including laminated films, adhesives, printing, etc. to facilitate installation, feedthroughs, and other functions.

Owner:COOLEARTH SOLAR

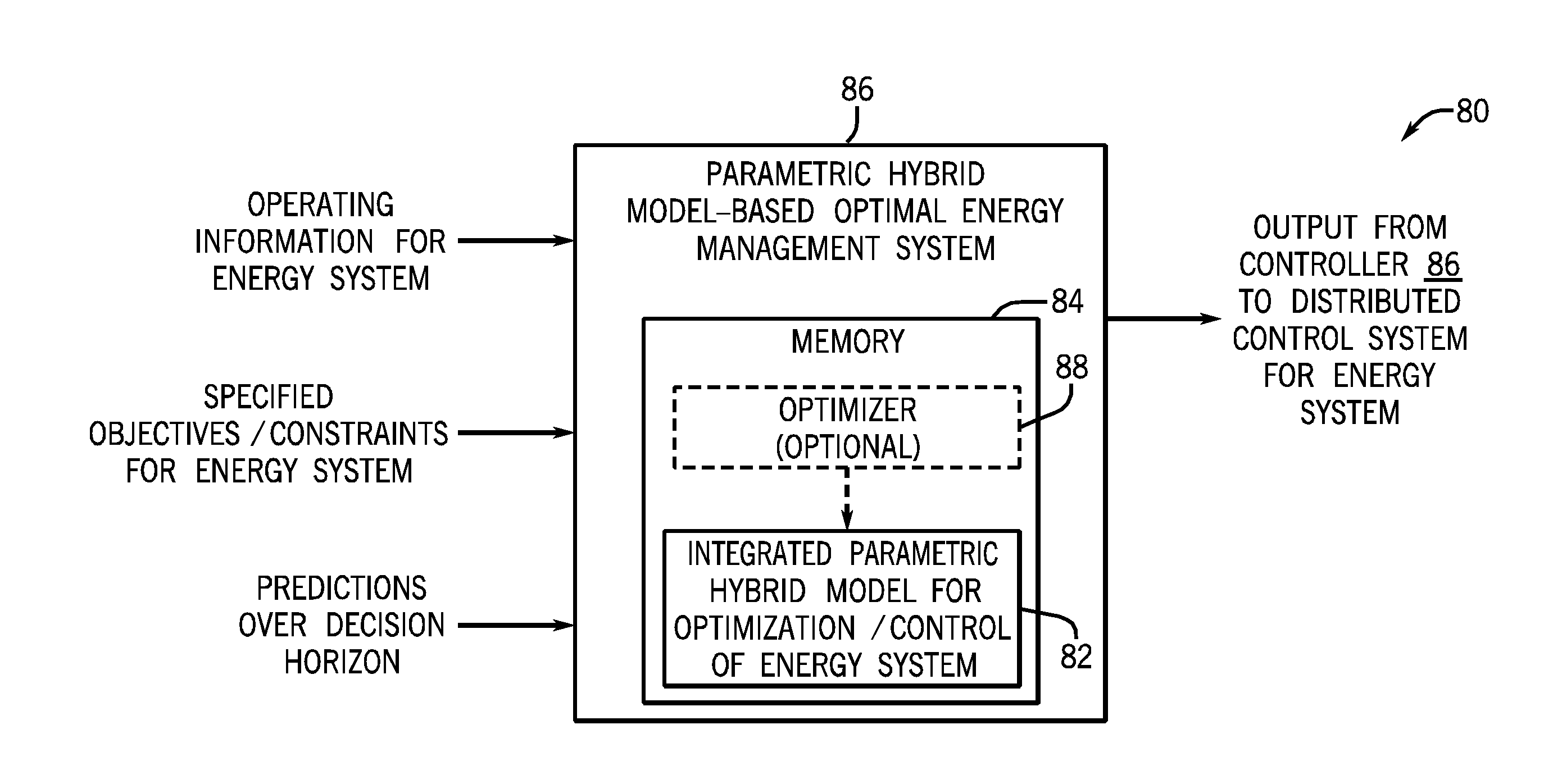

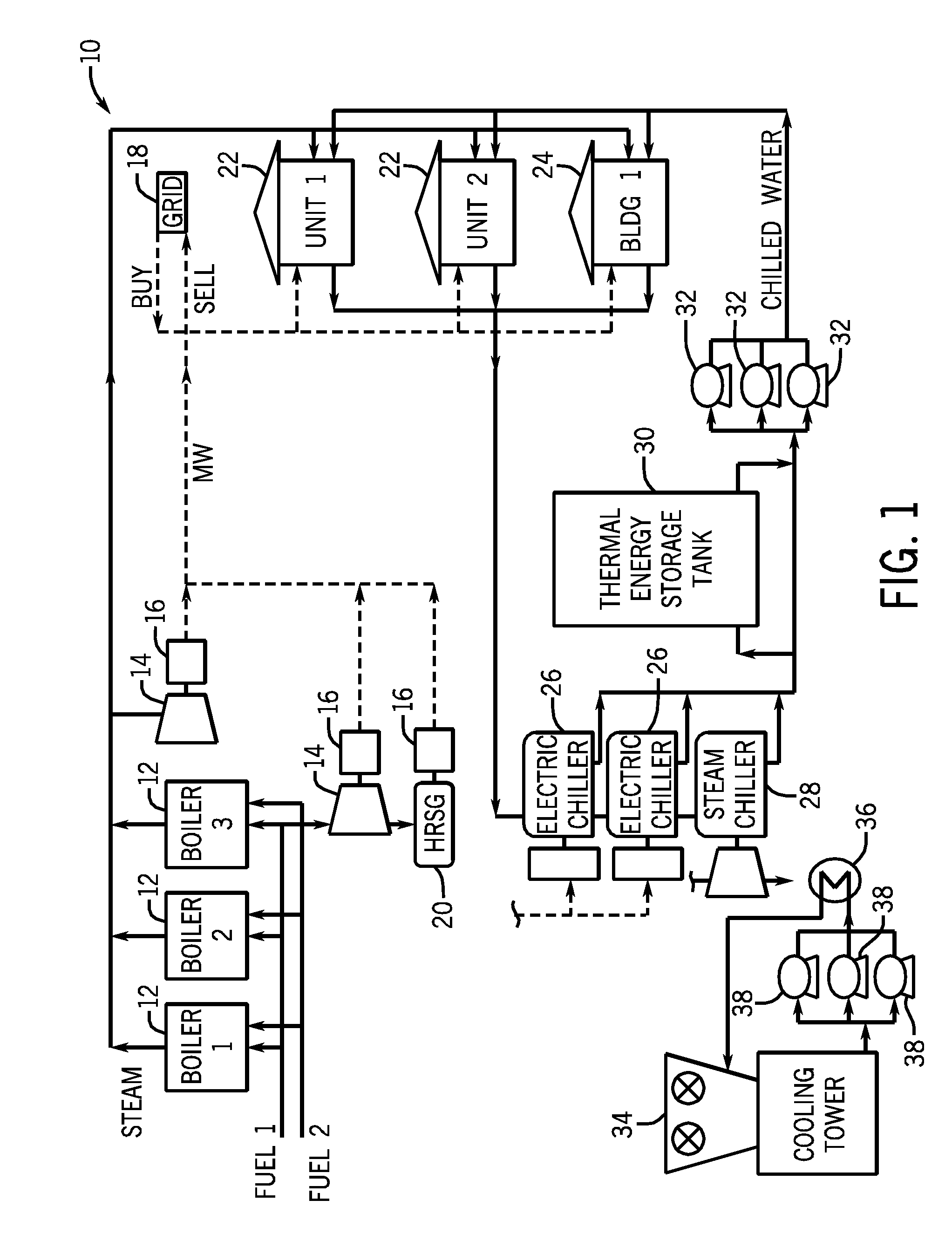

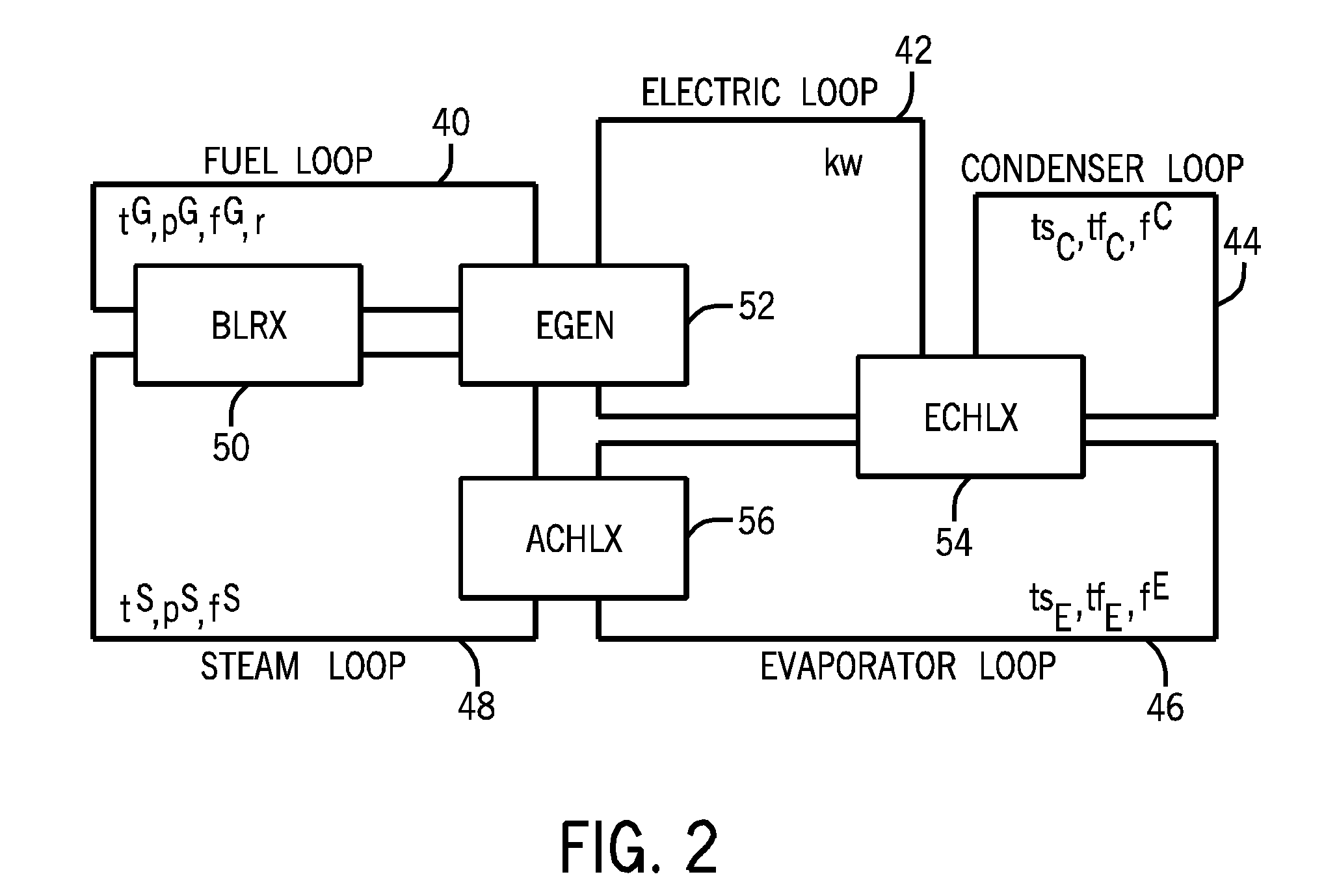

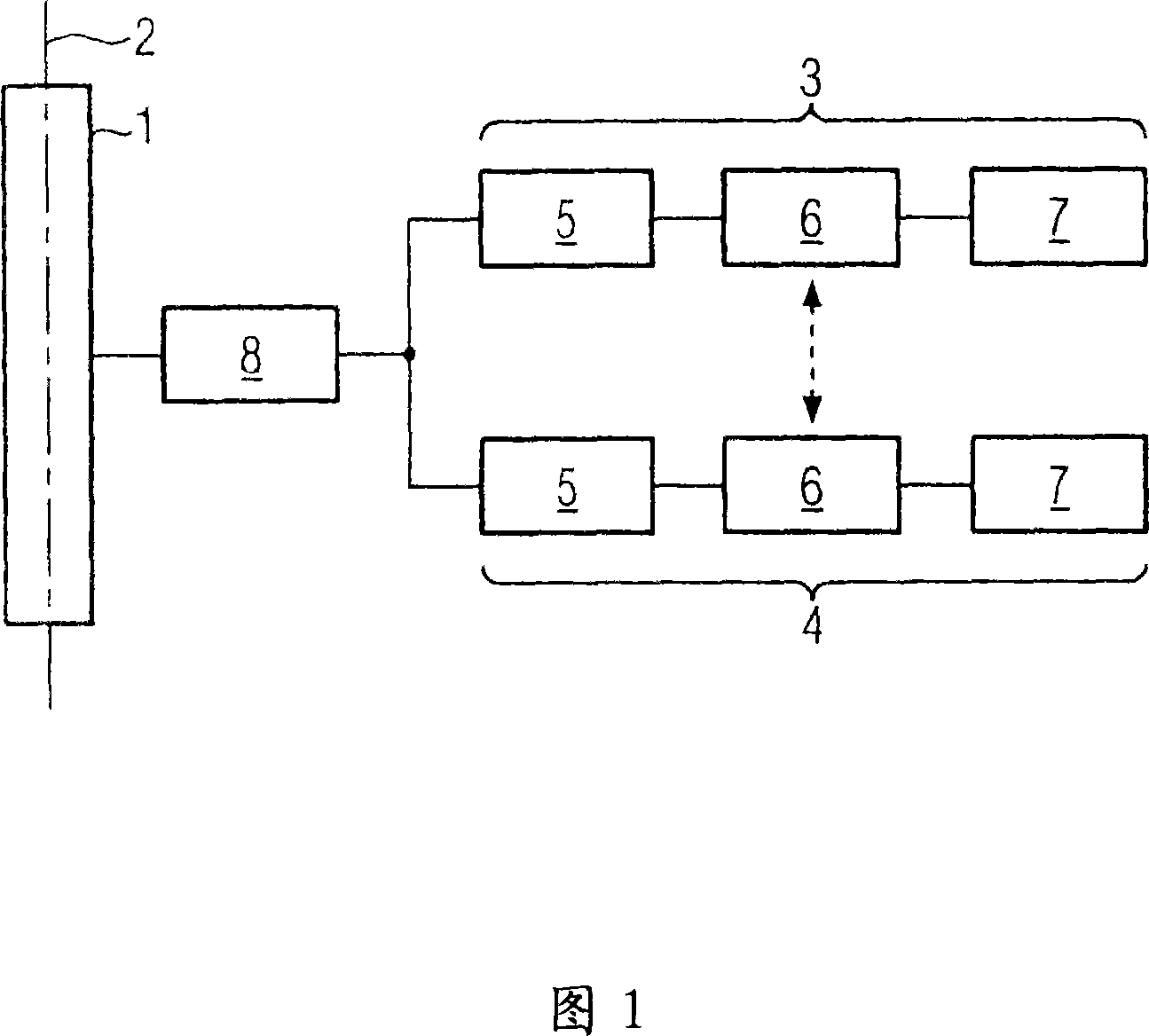

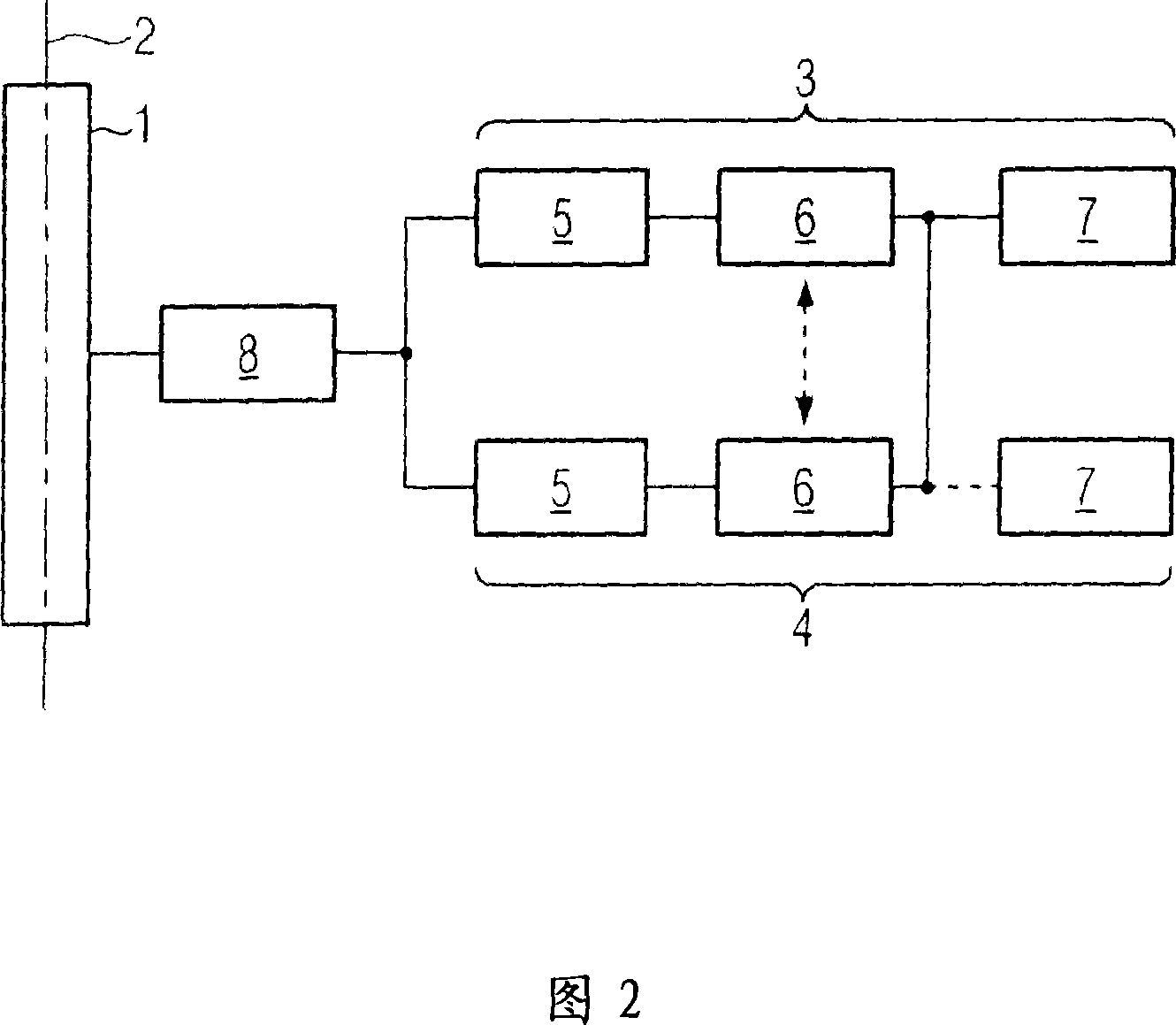

Optimal self-maintained energy management system and use

ActiveUS8682635B2Improve energy efficiencyReduce energy consumptionMechanical power/torque controlLevel controlDynamic modelsProcess engineering

Owner:ROCKWELL AUTOMATION TECH

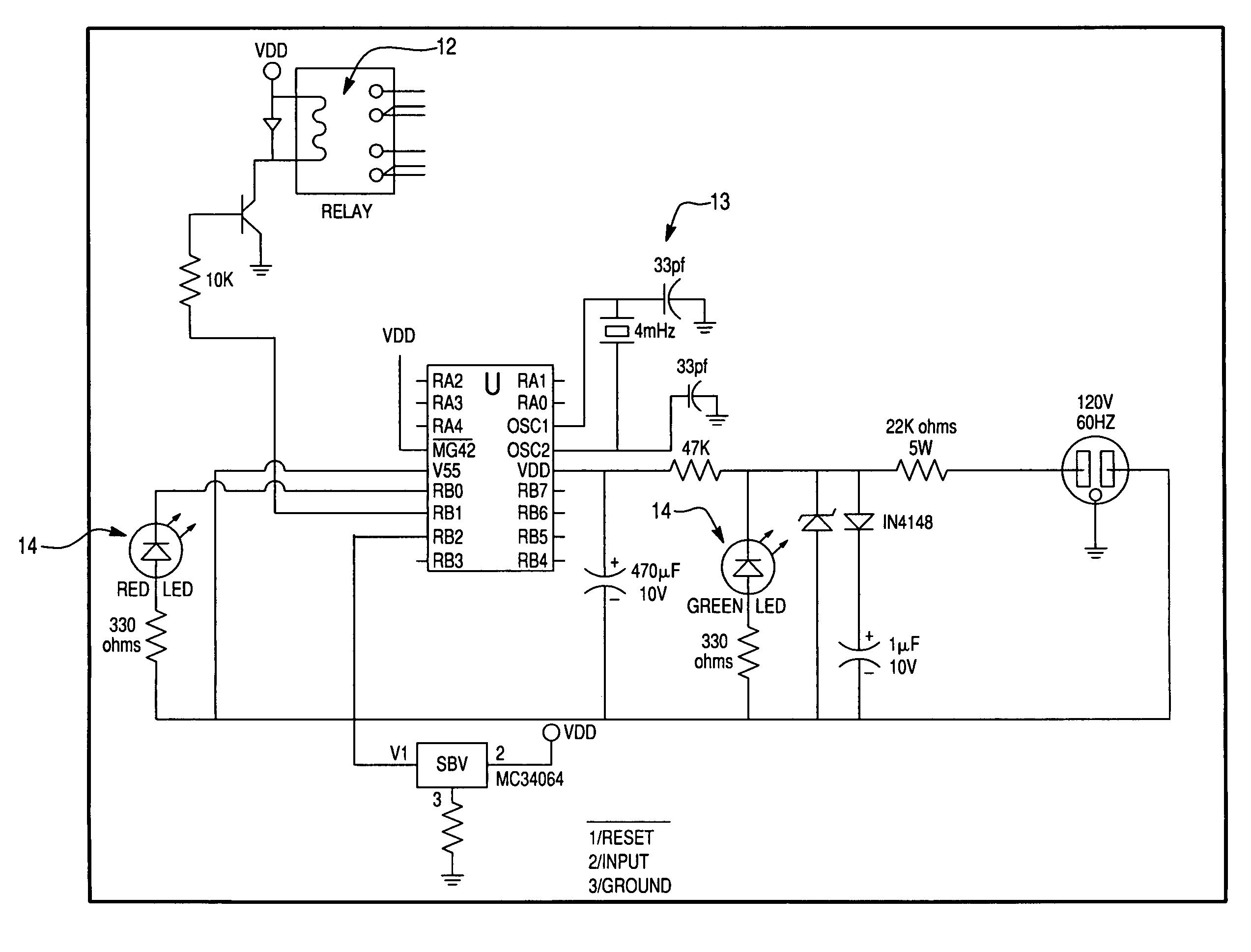

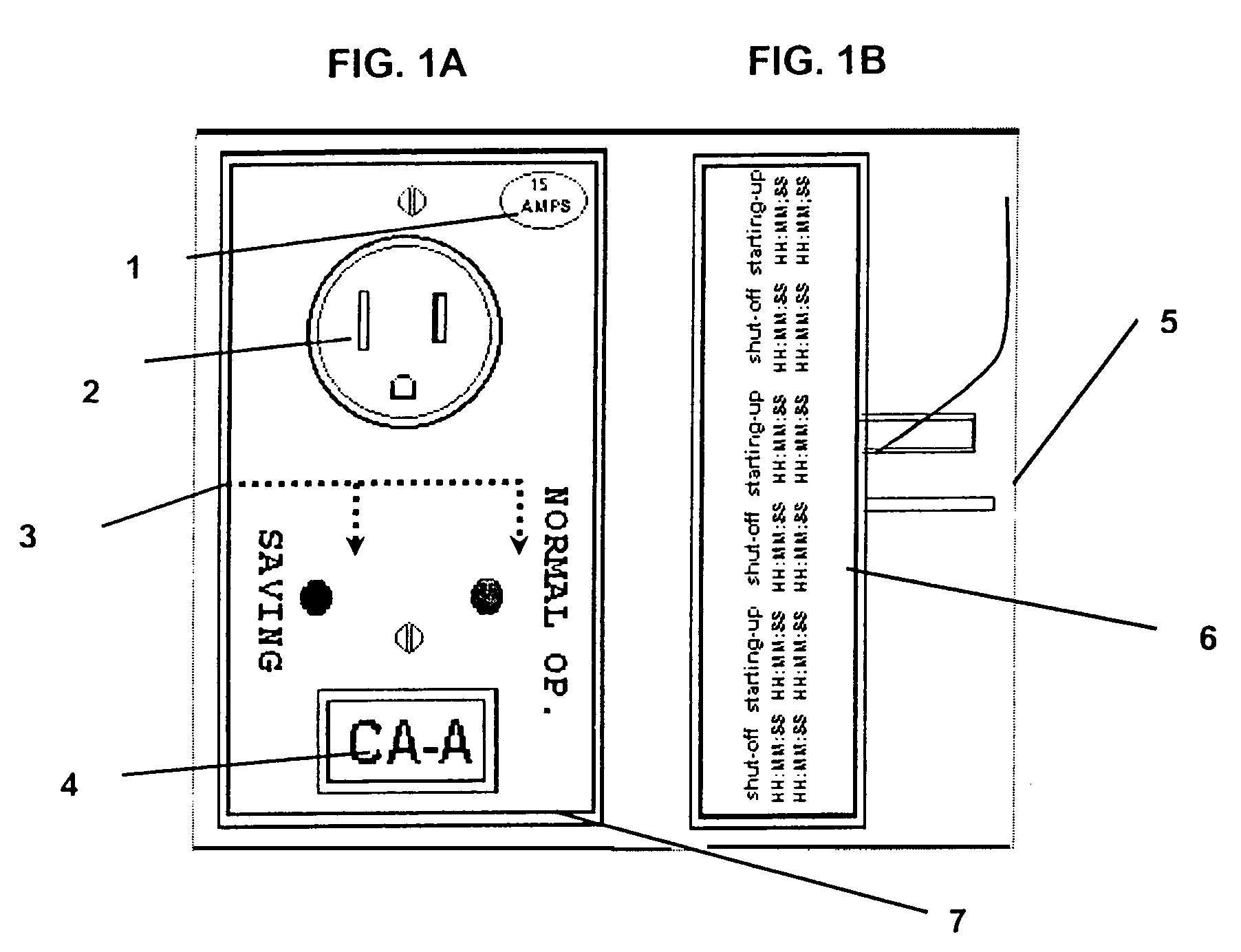

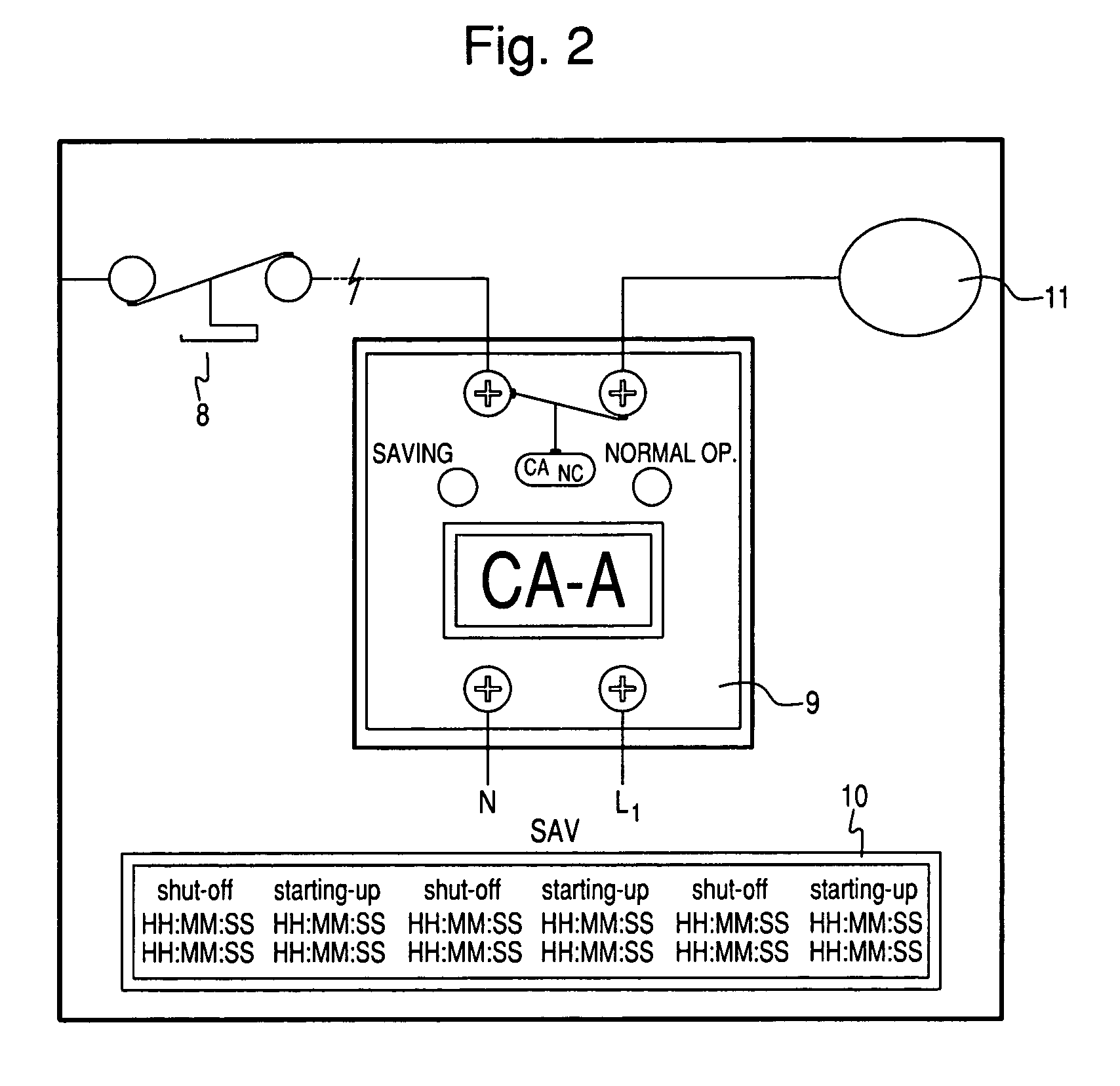

Electrical energy saving system

InactiveUS7582985B2Reduce power consumptionLoad is generatedMechanical power/torque controlDc network circuit arrangementsEngineeringEnergy requirement

An electric energy saving system characterized in that it consists on detecting the time span when there is an overload in the demand of energy of a region; providing a controller in certain number of devices and equipment connected to the energy distribution system of a region according to the overload registered at said region; programming the controllers to shutoff said devices or equipment for several short time periods, and in a staggered form, during said time span wherein there is an overload of the demand in the region, in such a way that a group of devices will be shut-off for one period, the expiration of which will indicate another group to do the same thing, and so forth.

Owner:MURGUIA JOSE TOMAS ORTEGA

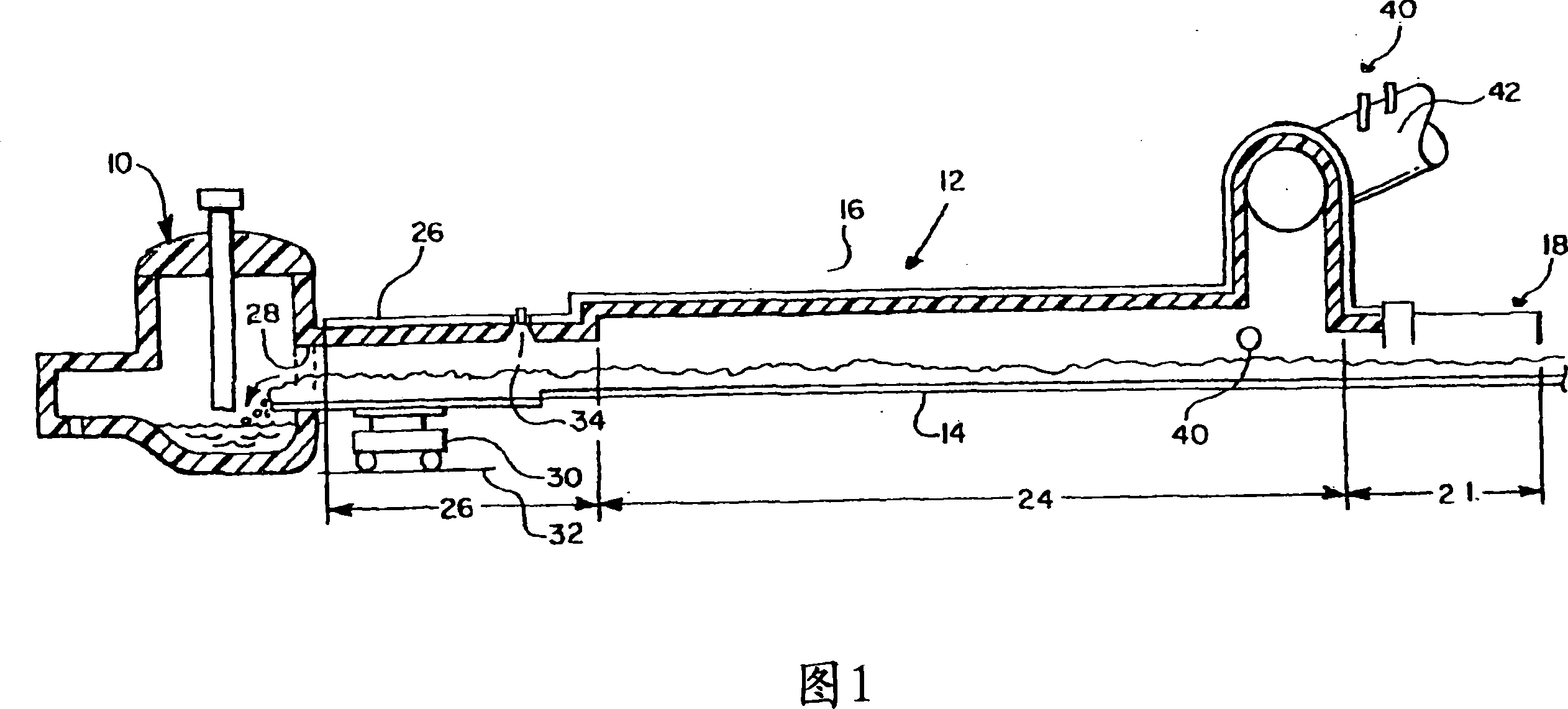

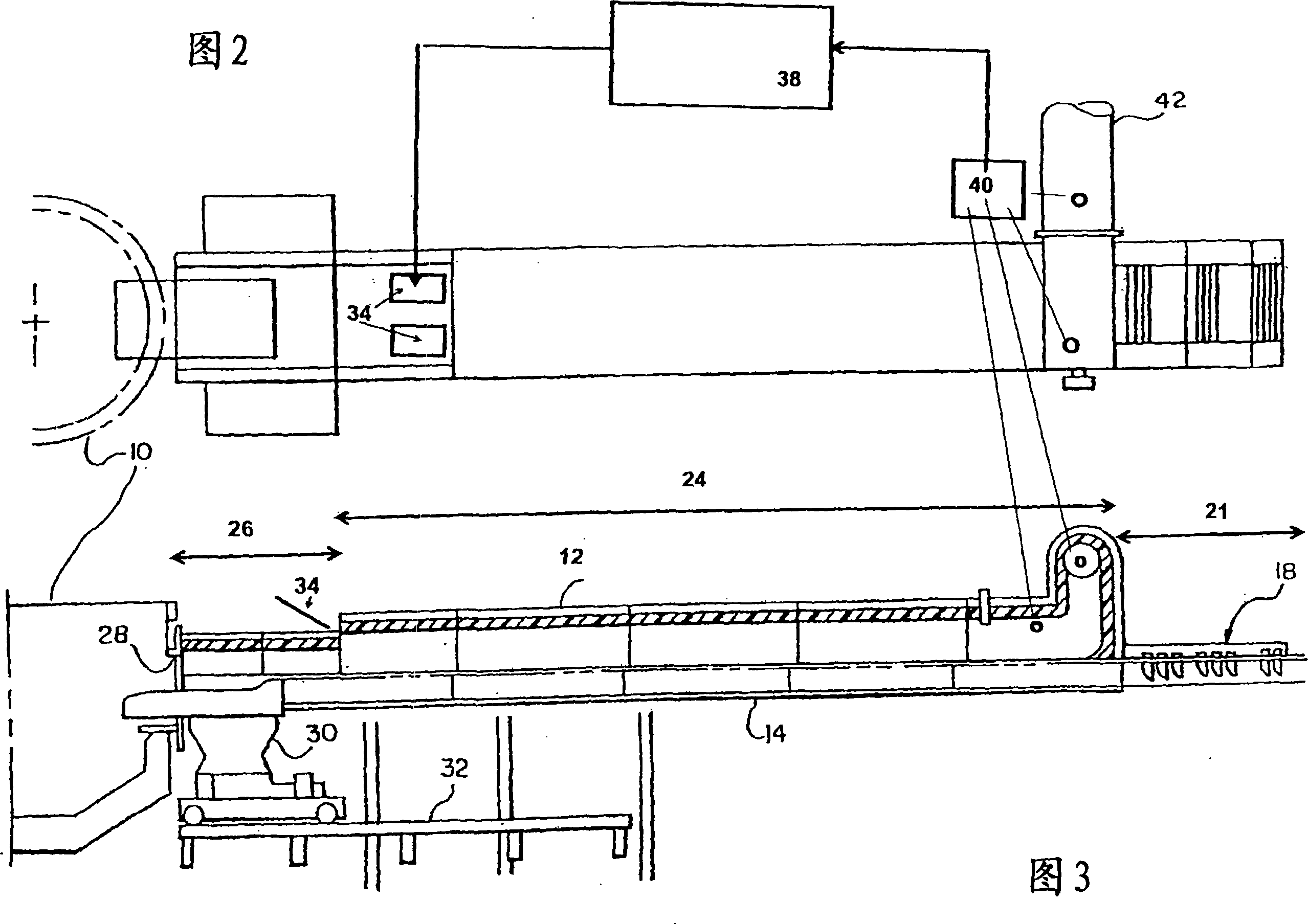

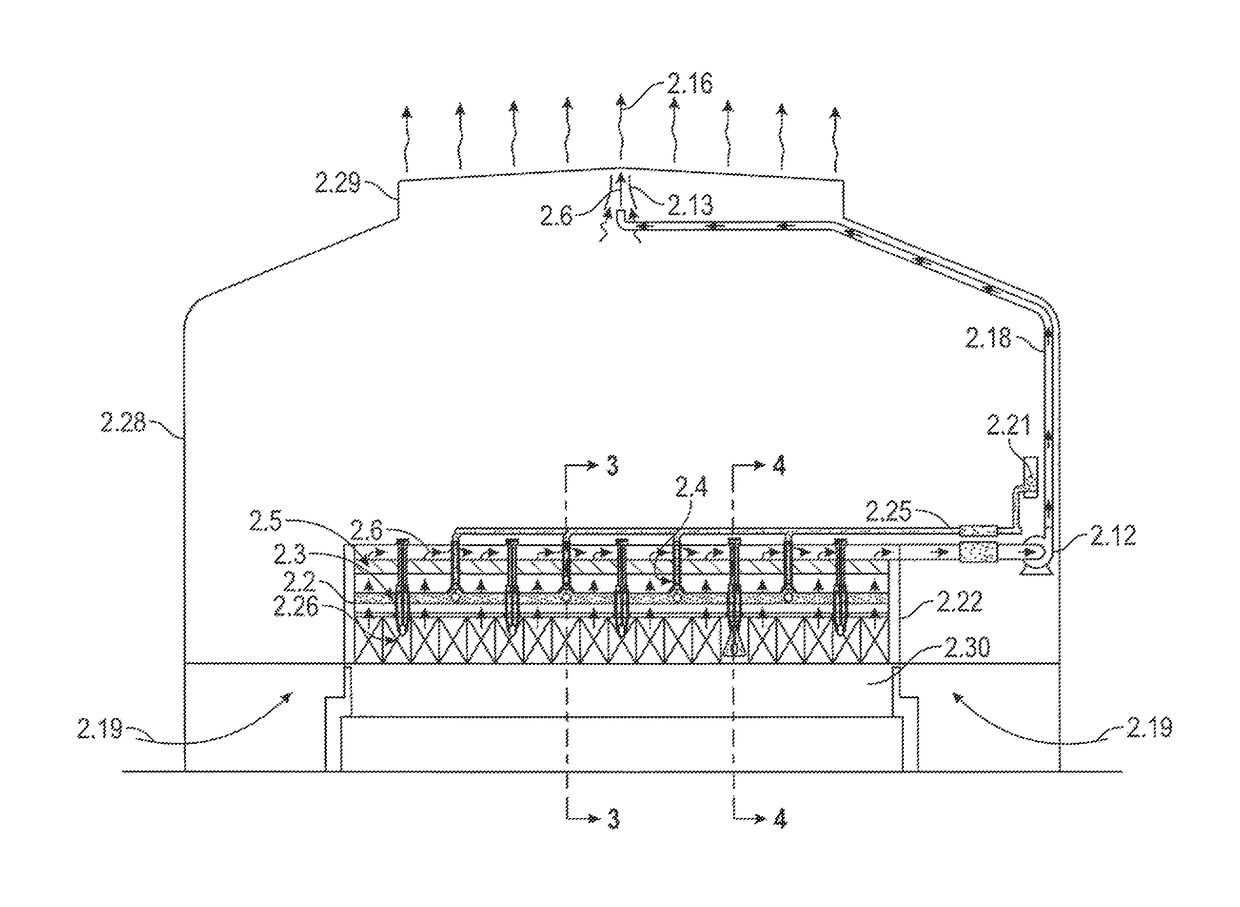

Apparatus for the combustion of gas exiting from a furnace, for the preheating of scraps entering the furnace itself and related process

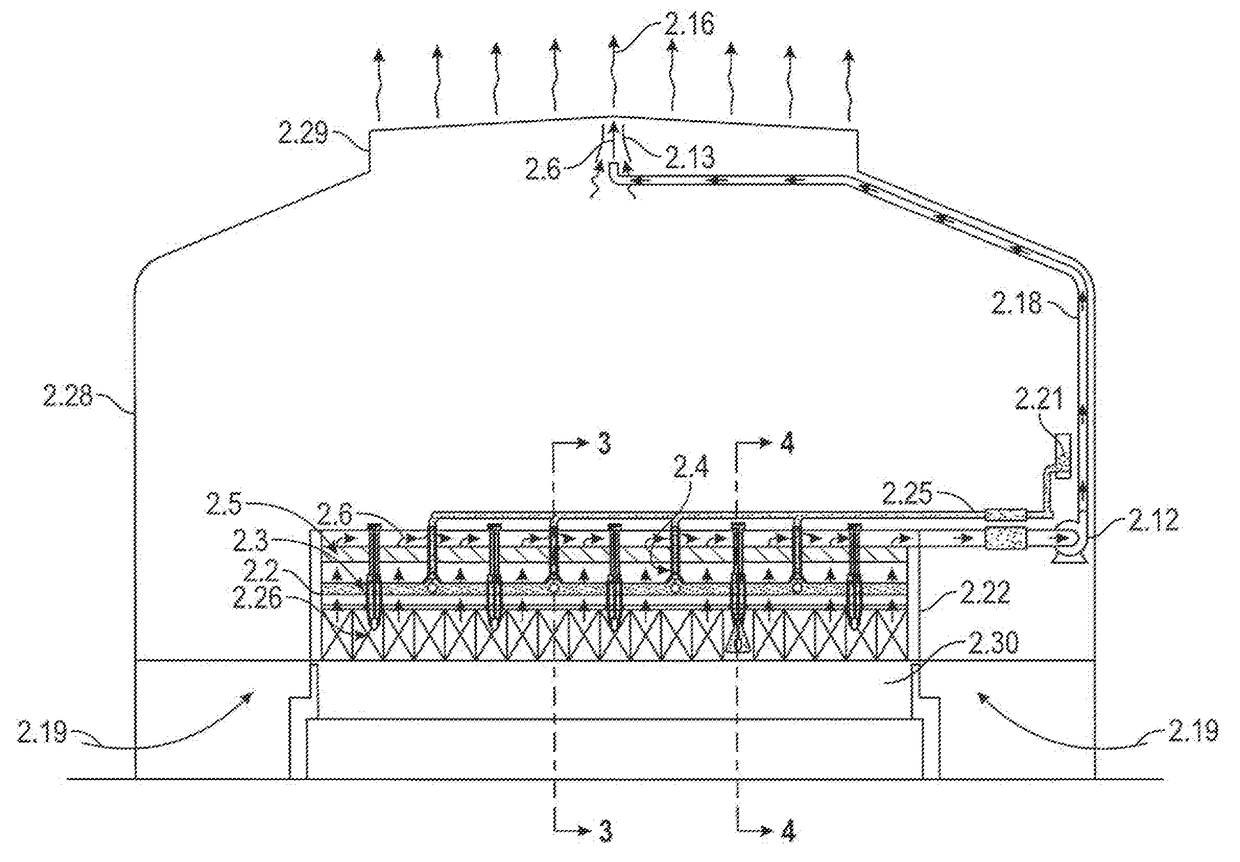

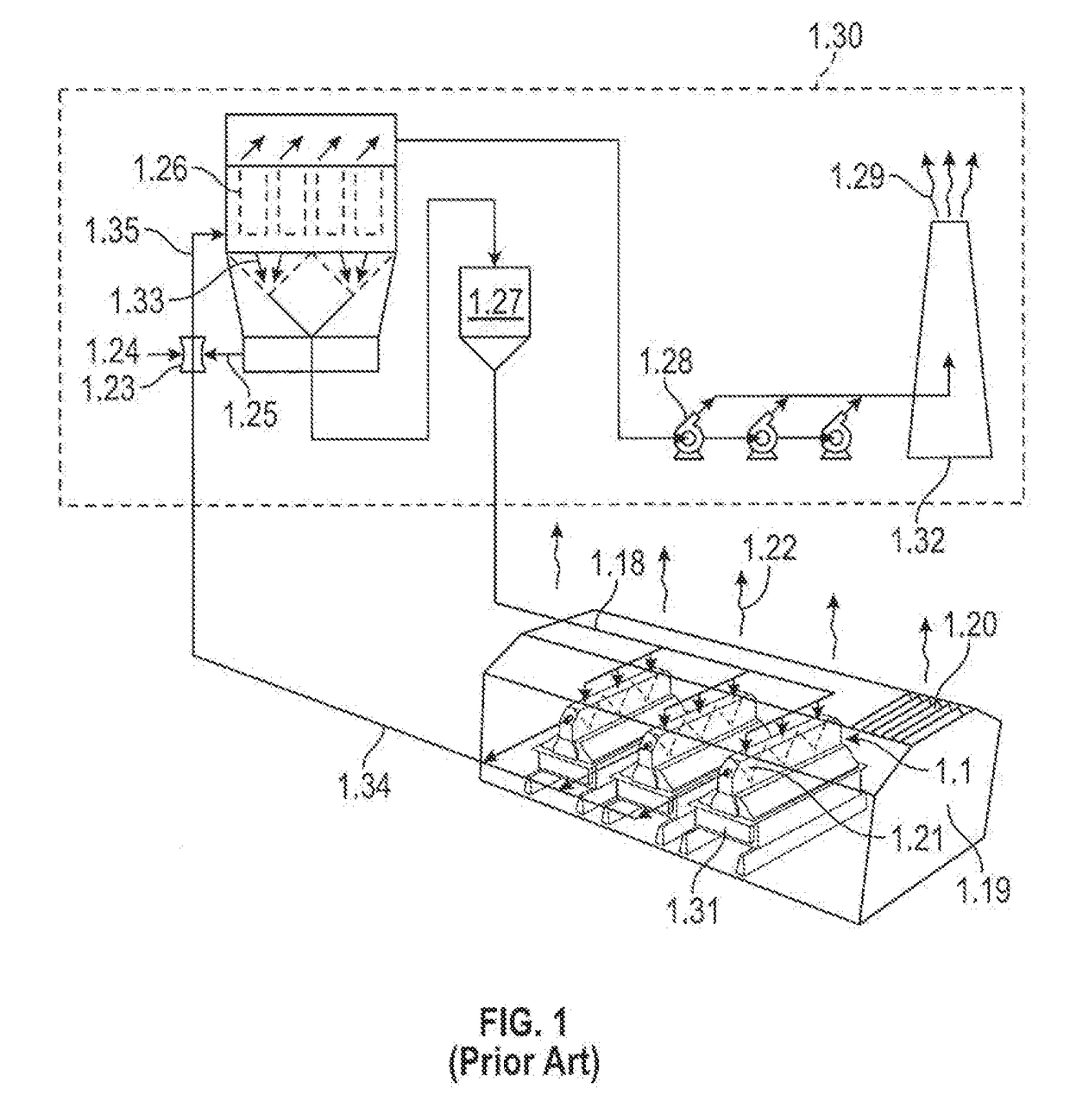

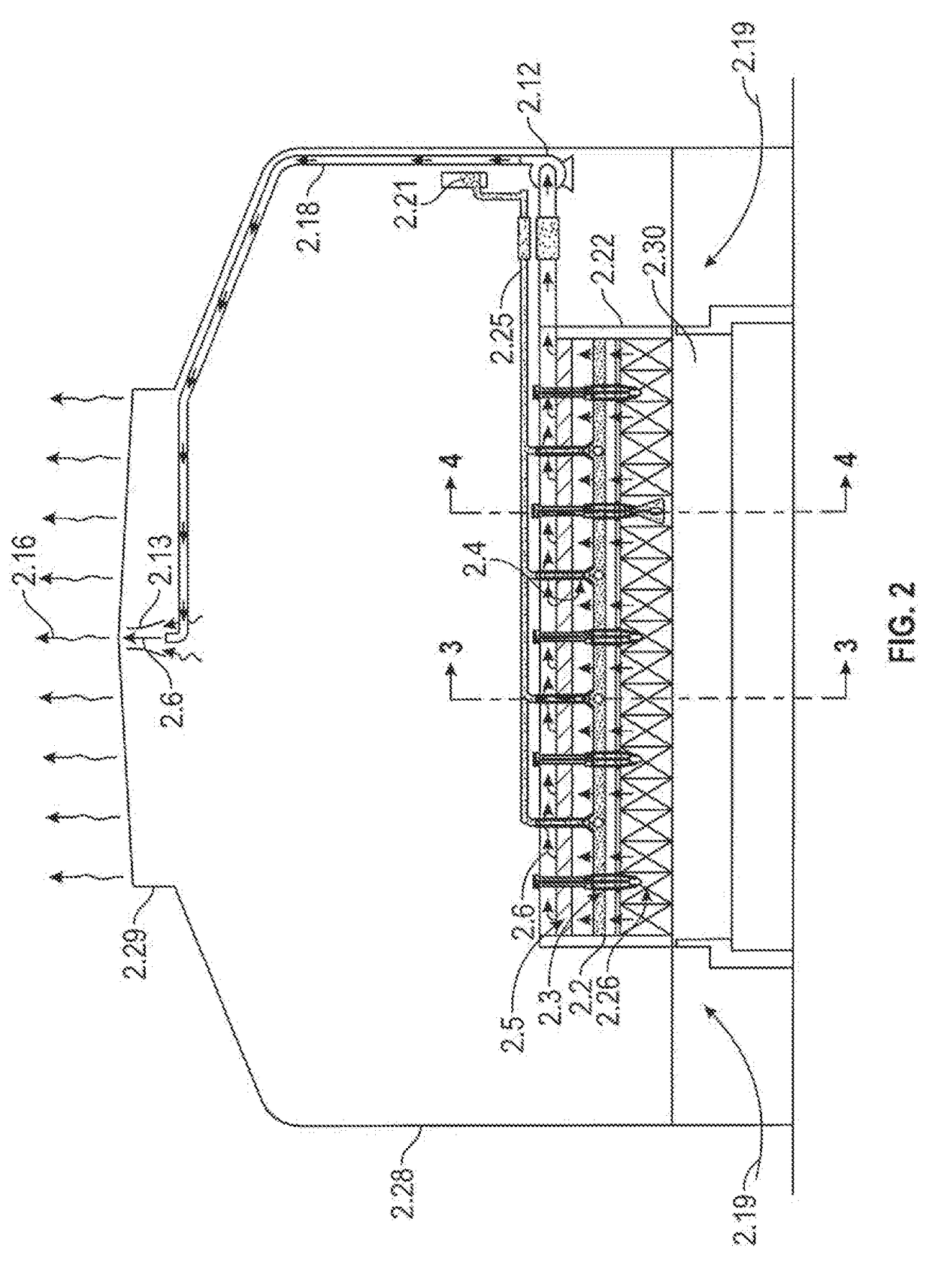

ActiveCN101120221AImproved Environmental Impact FeaturesShort response timeFurnace typesPreheating chargesElectric arc furnaceHeat of combustion

Apparatus for the combustion of gas exiting from an electric arc furnace where the heat of combustion is used for the preheating of scraps entering the furnace wherein the apparatus has an insertion device for introducing comburent substance into a preheating chamber or loading tunnel for scrap metal where the loding tunnel has an inlet section for scrap metal, a seal section to prevent an uncontrolled entrance of air in the tunnel, a heating section and an unloading section for delivering scrap metal to the furnace. The insertion device for the comburent substance has one or more adjustable openings placed in the loading tunnel, and said apparatus comprises a device or a series of devices.

Owner:ТЕНОВА ТЕКНОЛОДЖИЗ (ТЯНЬЦЗИНЬ) КО., ЛТД.

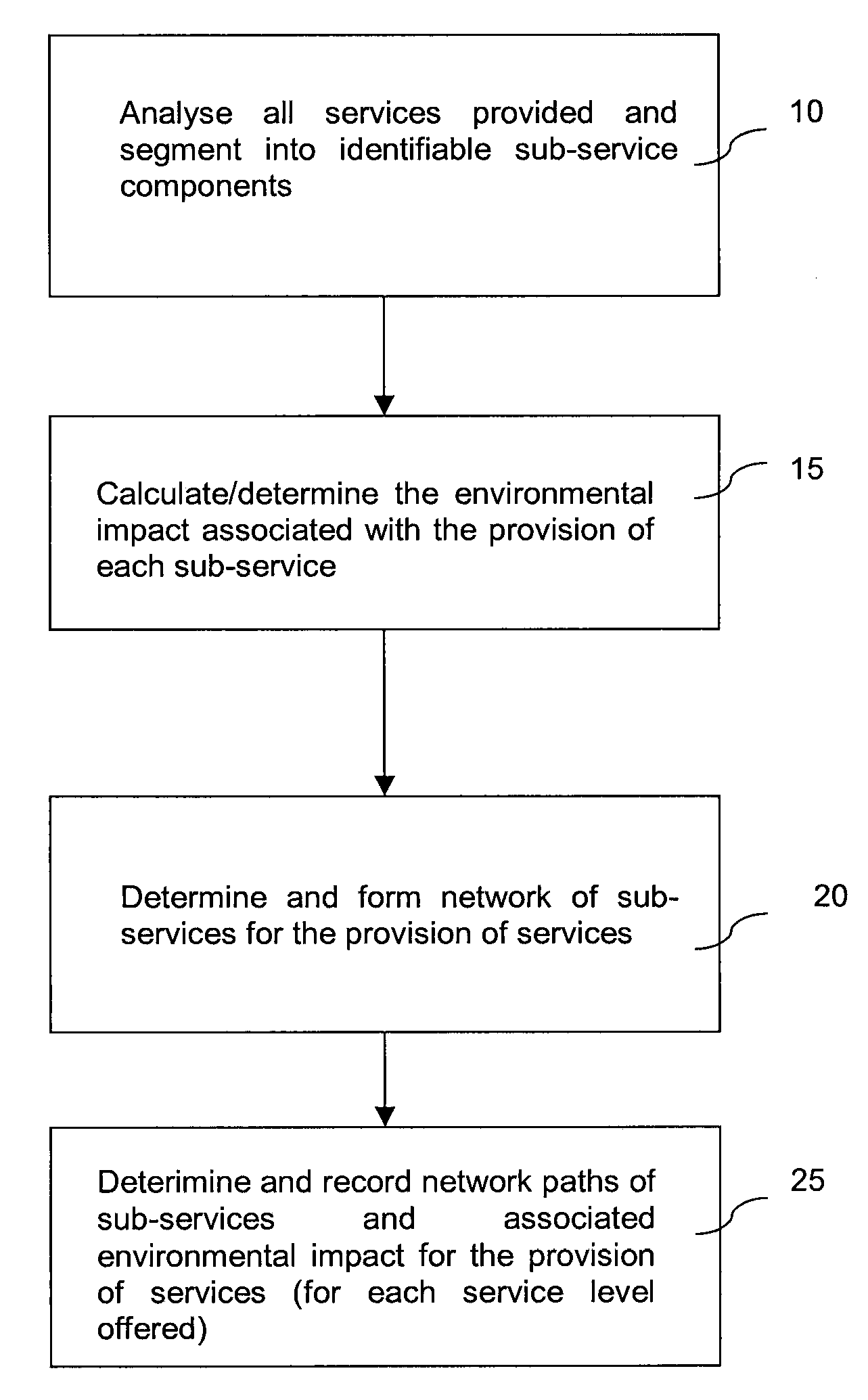

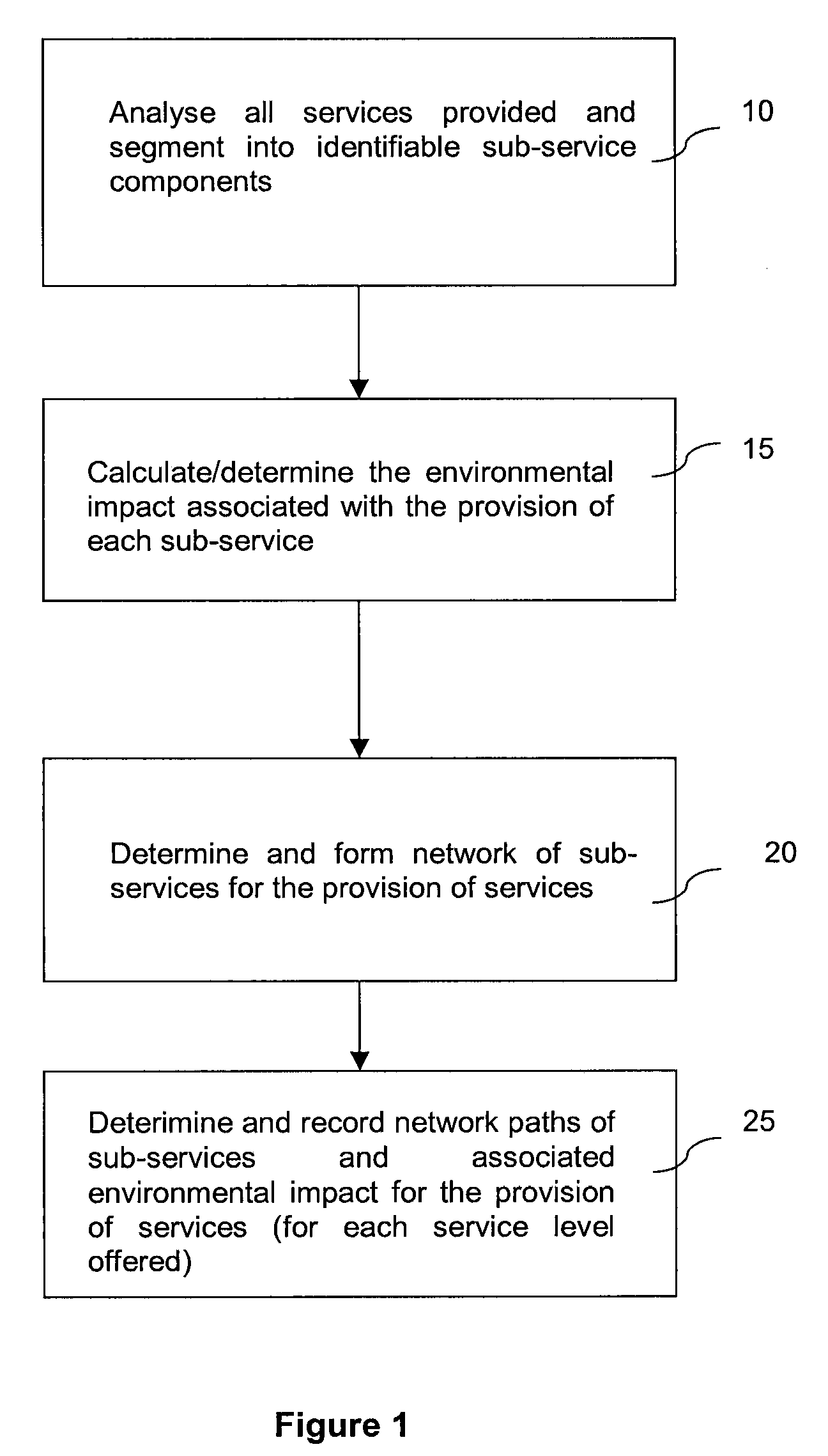

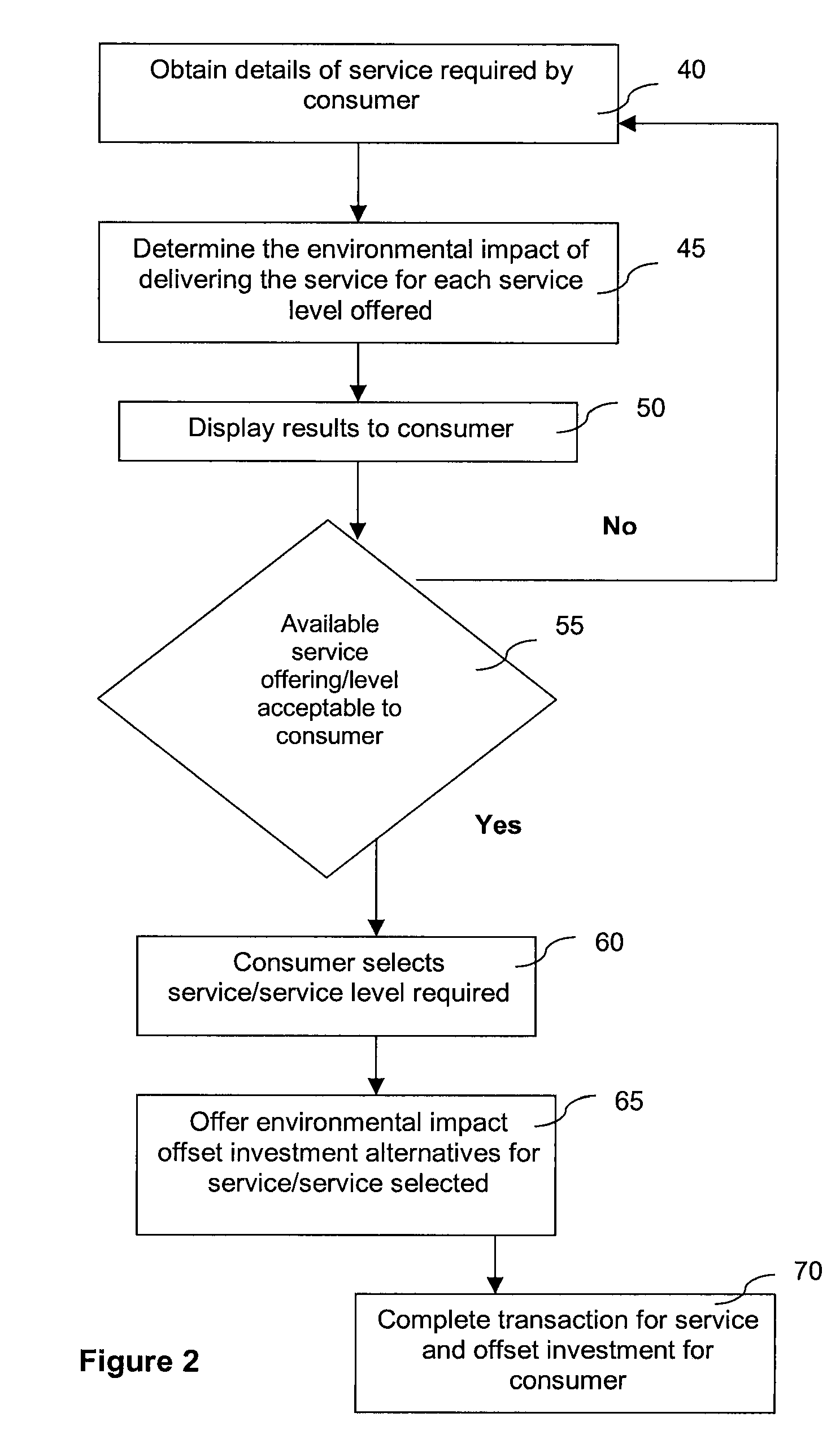

Environmental offsets for services

InactiveUS20090094078A1Promote effective engagementReduce environmental impactMarket predictionsSpecial data processing applicationsEnvironment effectService provision

Techniques for providing services in a manner that takes into account the environmental impact of such service delivery are provided. In one embodiment, in response to a request for services from a prospective customer, the environmental impact of the requested service is determined based on analysis of each sub-service constituting the service. The resulting estimate of the environmental impact as well as any alternative delivery options having an effect on the estimated environmental impact may be presented to the prospective customer. In another embodiment, the potential customer may be provided the option to pursue an offset against the estimated environmental impact. In this manner, potential customers may be provided with more environmentally-conscious options when selecting a potential service provider.

Owner:ACCENTURE GLOBAL SERVICES LTD

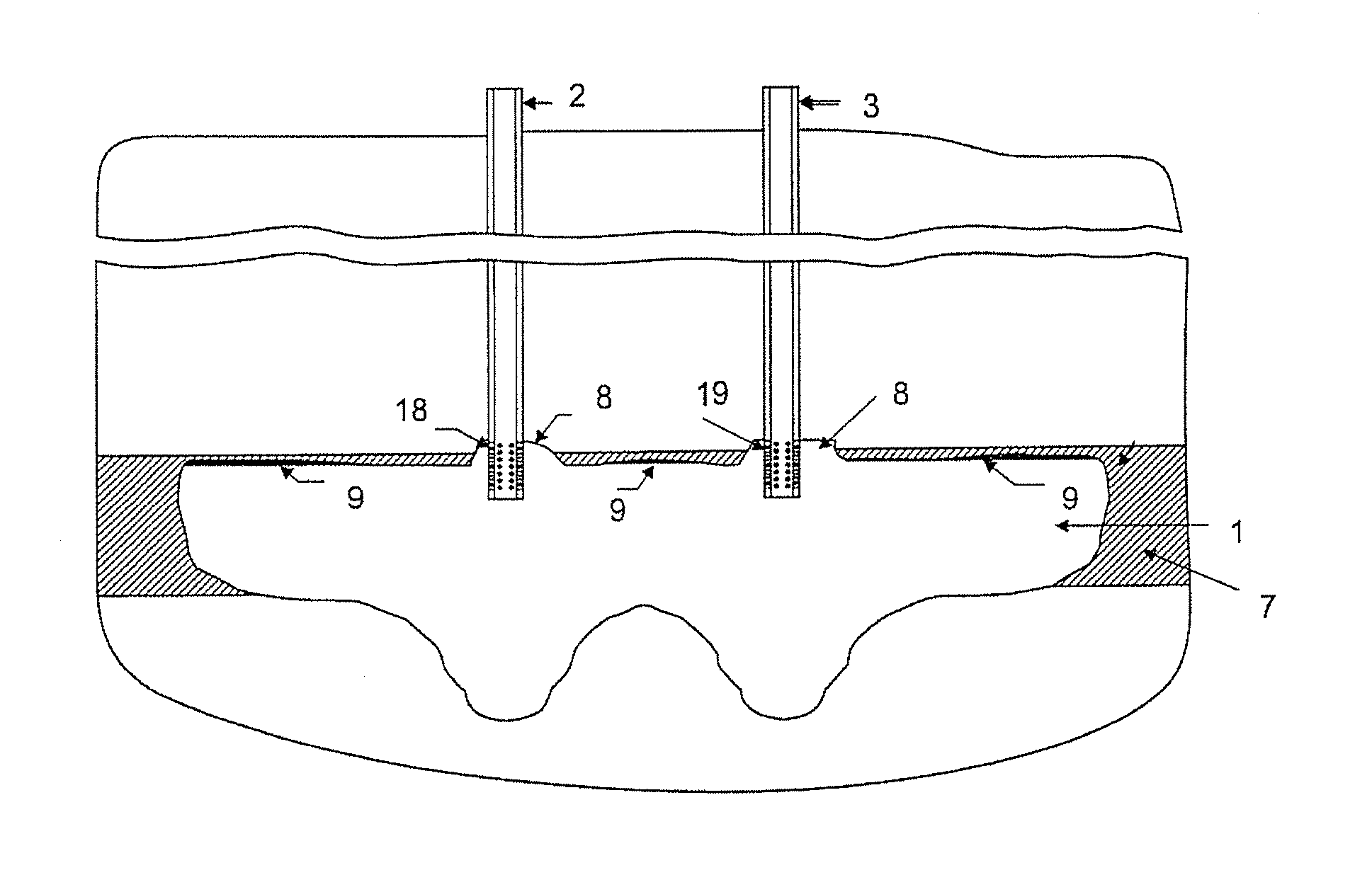

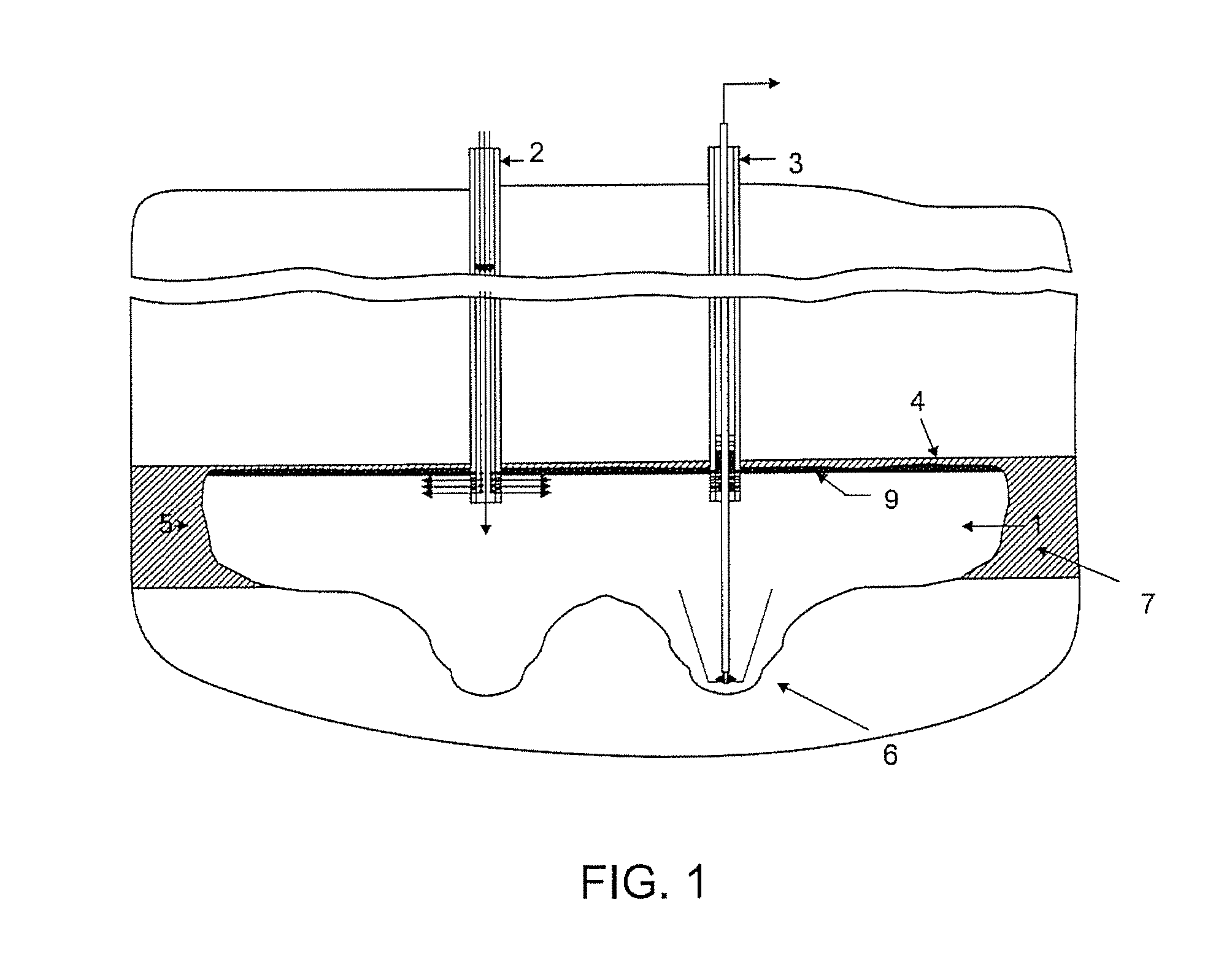

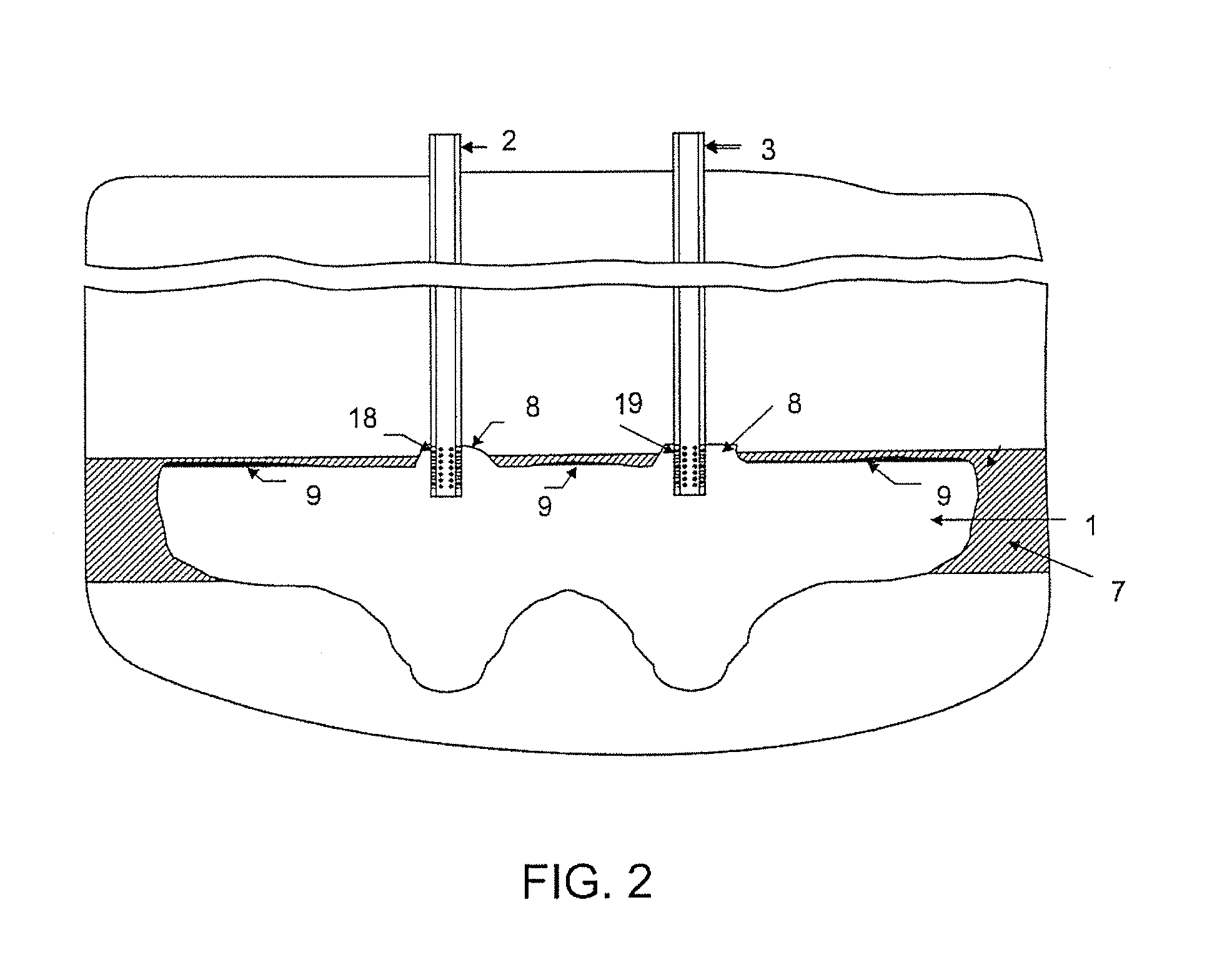

Method of exploiting potassium salts from an underground deposit

ActiveUS20150137578A1Improve environmental impactImprove efficiencyConstructionsFluid removalChlorideSolvent

The present invention pertains to a mineral exploitation method and, more specifically, to a method for extracting potassium salts from underground deposits. In the method according to the present invention, an intermediary stage is carried out between the primary mining and secondary mining stages, and in this intermediary stage sinks (8) are created that receive the water-immiscible fluid (9) used in the primary mining stage, exposing an amount of potassium chloride remaining on the cavern ceiling, at the end of the primary mining stage, which will be dissolved by a second solvent during the secondary mining stage.

Owner:VALE FERTILIZANTES

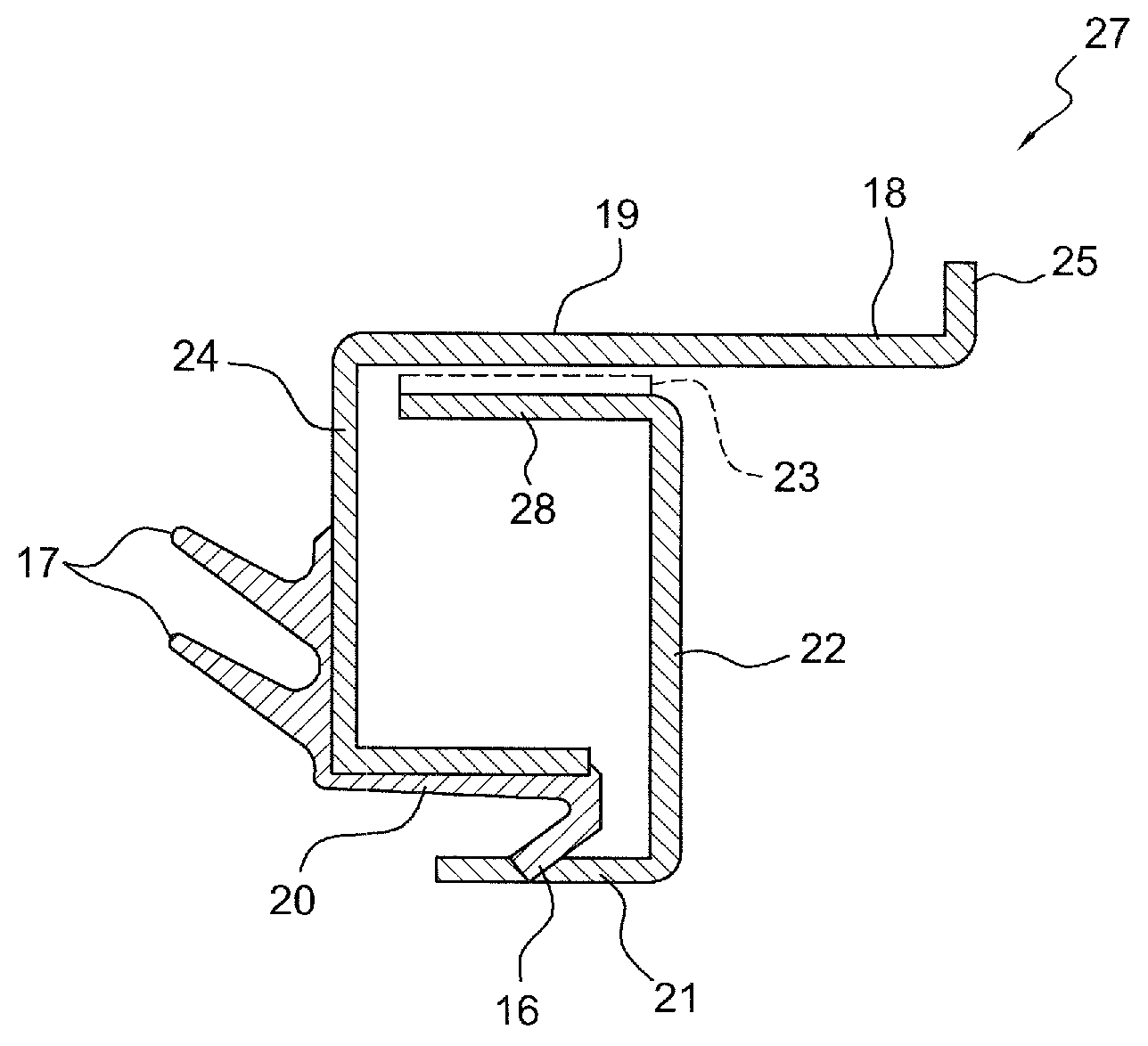

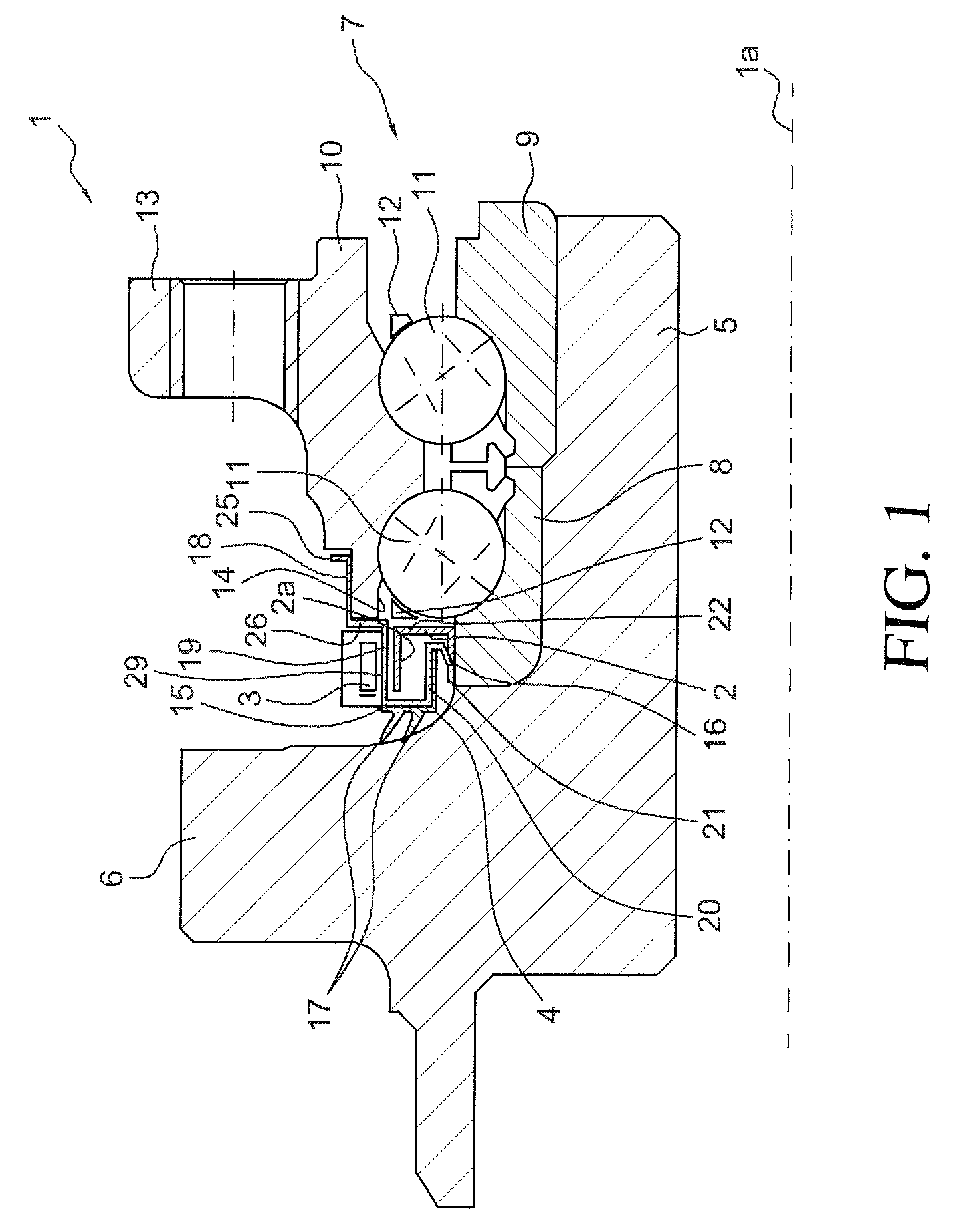

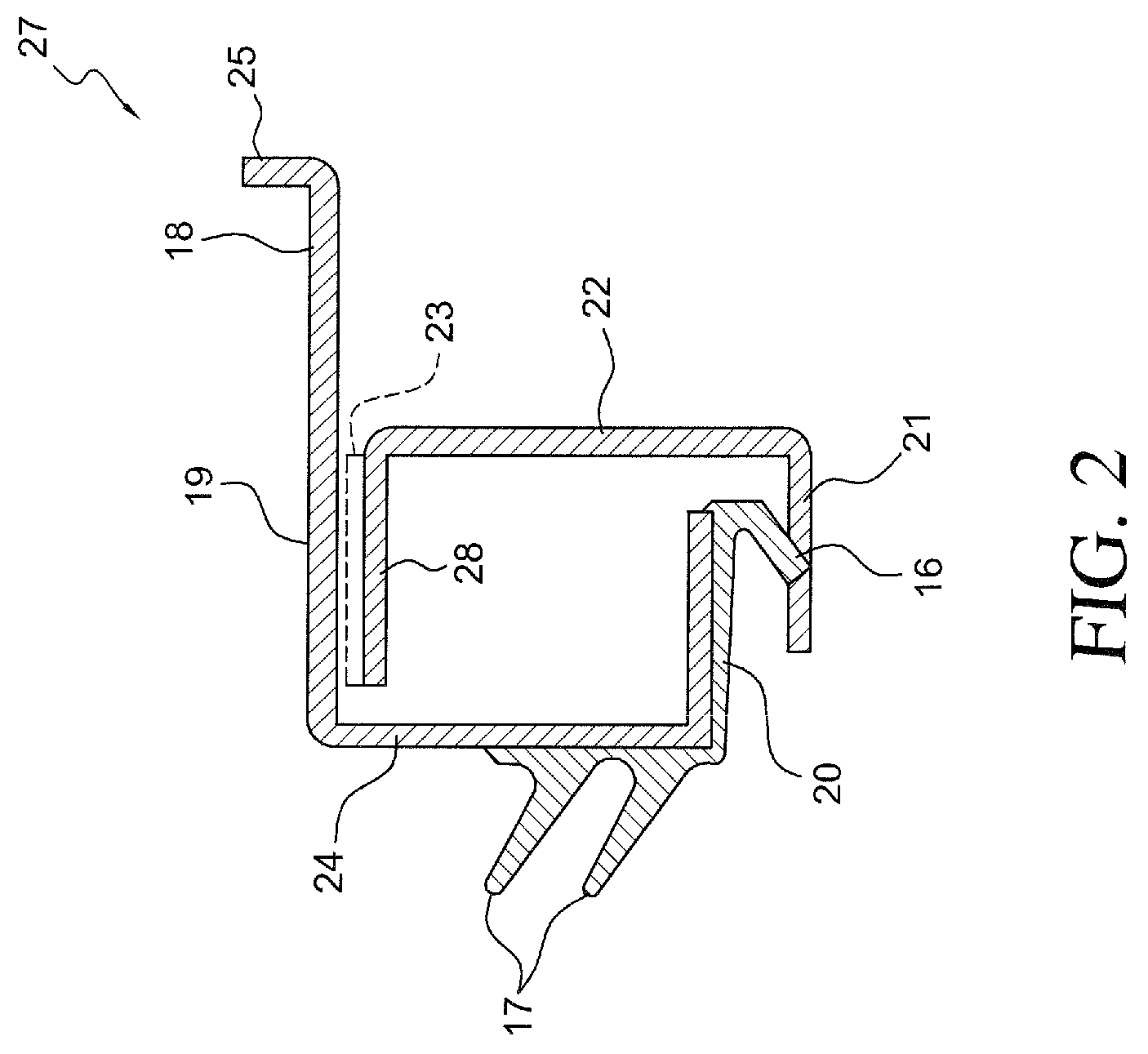

Wheel bearing arrangement comprising an encoder and a sensor

InactiveUS7618191B2Good protectionImprove environmental impactRolling contact bearingsBearing assemblyRotational axisEngineering

Owner:SCHAEFFLER TECH AG & CO KG

Low softening point petroleum pitch and sealer

InactiveUS6383365B1Promote resultsTolerate large amountWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by mixing fractionsEmulsionBoiling point

A 40 petroleum pitch is disclosed. A high melting point petroleum pitch is blended with a high boiling normally liquid petroleum derived hydrocarbon stream to form a mixture having a softening point of 35-45 C. as a partial or complete replacement for coal tar pitch used in driveway sealer and other sealer applications. Driveway sealer (an emulsion of clay, water and binder) made with A 40 has excellent durability and can have a greatly reduced amount of, or be essentially free of, coal tar pitch, greatly reducing the toxicity and odor of the sealer.

Owner:MARATHON PETROLEUM

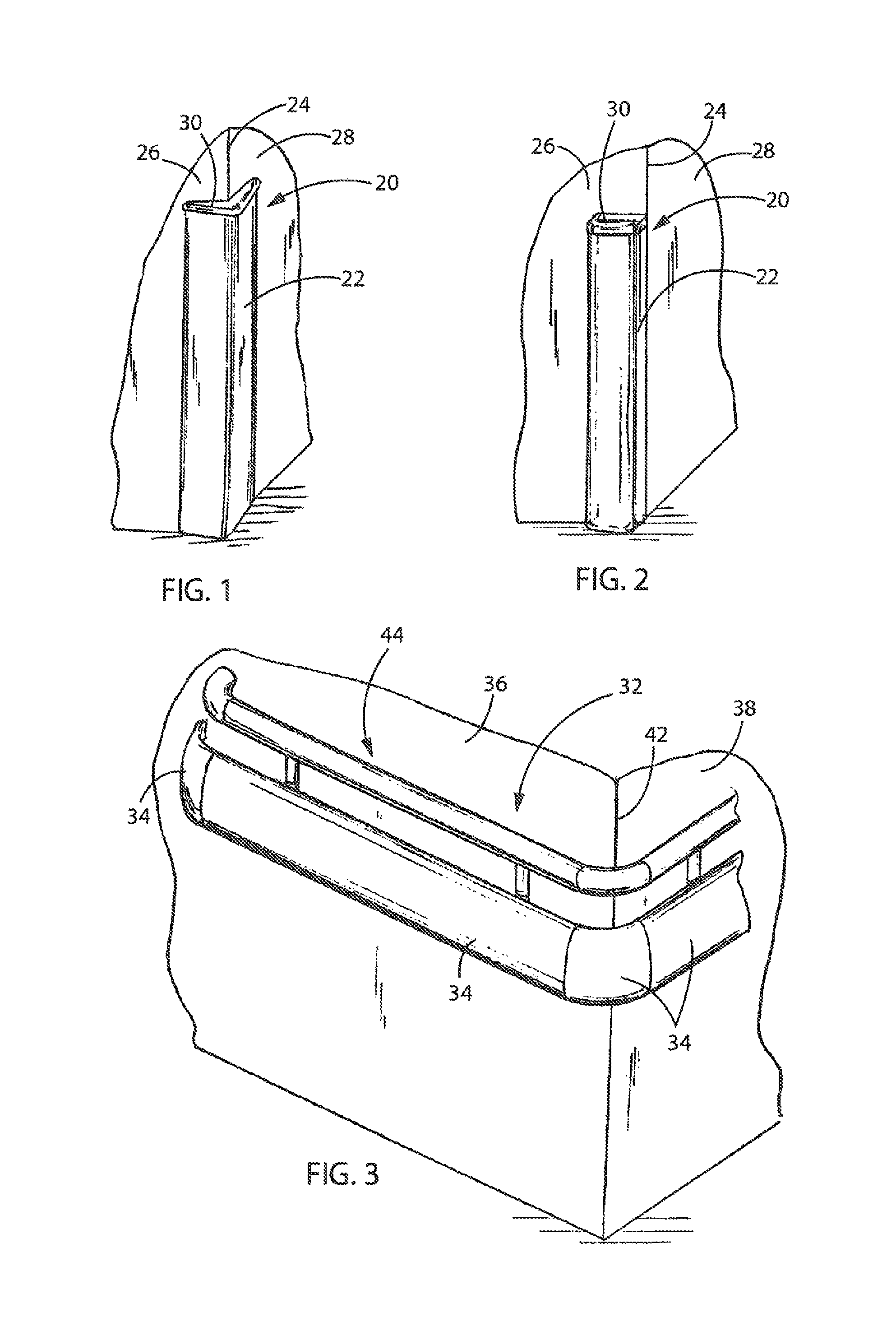

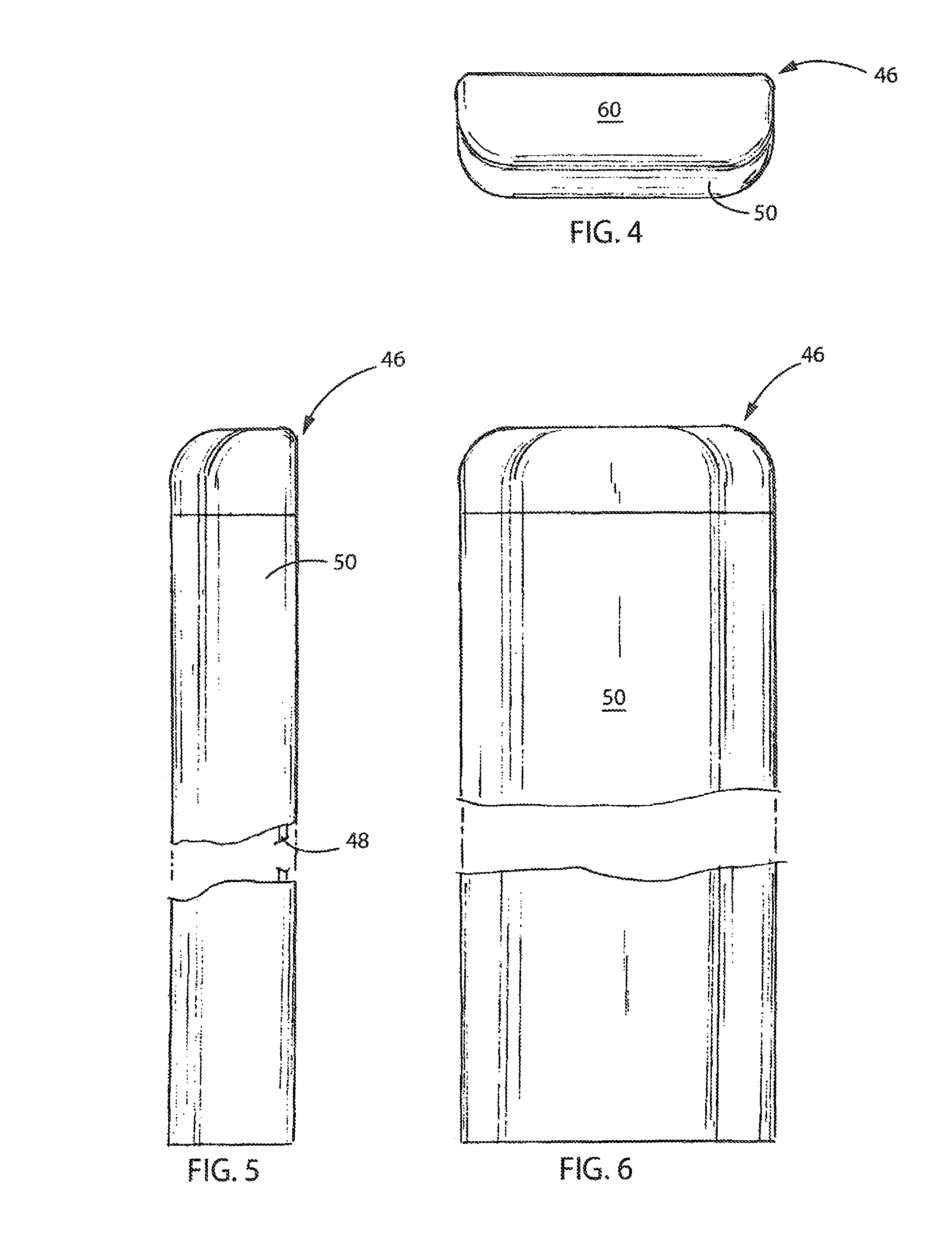

Door and wall protection structures and material for producing the same

ActiveUS8828522B1Improve environmental impactLayered productsThin material handlingBiopolymerEngineering

The invention relates to a composition for use in the production of an article of manufacture, and in particular, to the manufacture of wall and corner guards. The composition includes a biopolymer in combination with PETG as well as a modifier. The biopolymer and modifier are preferably produced from an annually renewable source such as corn or sugar as opposed to traditionally used petroleum based plastics. In this manner, the composition of the invention is relatively environmentally friendly as compared to known compositions while maintaining many of the desirable qualities thereof. In addition, the production of the articles of manufacture results in the consumption of fewer fossil fuels and less production of pollutants.

Owner:INPRO CORP

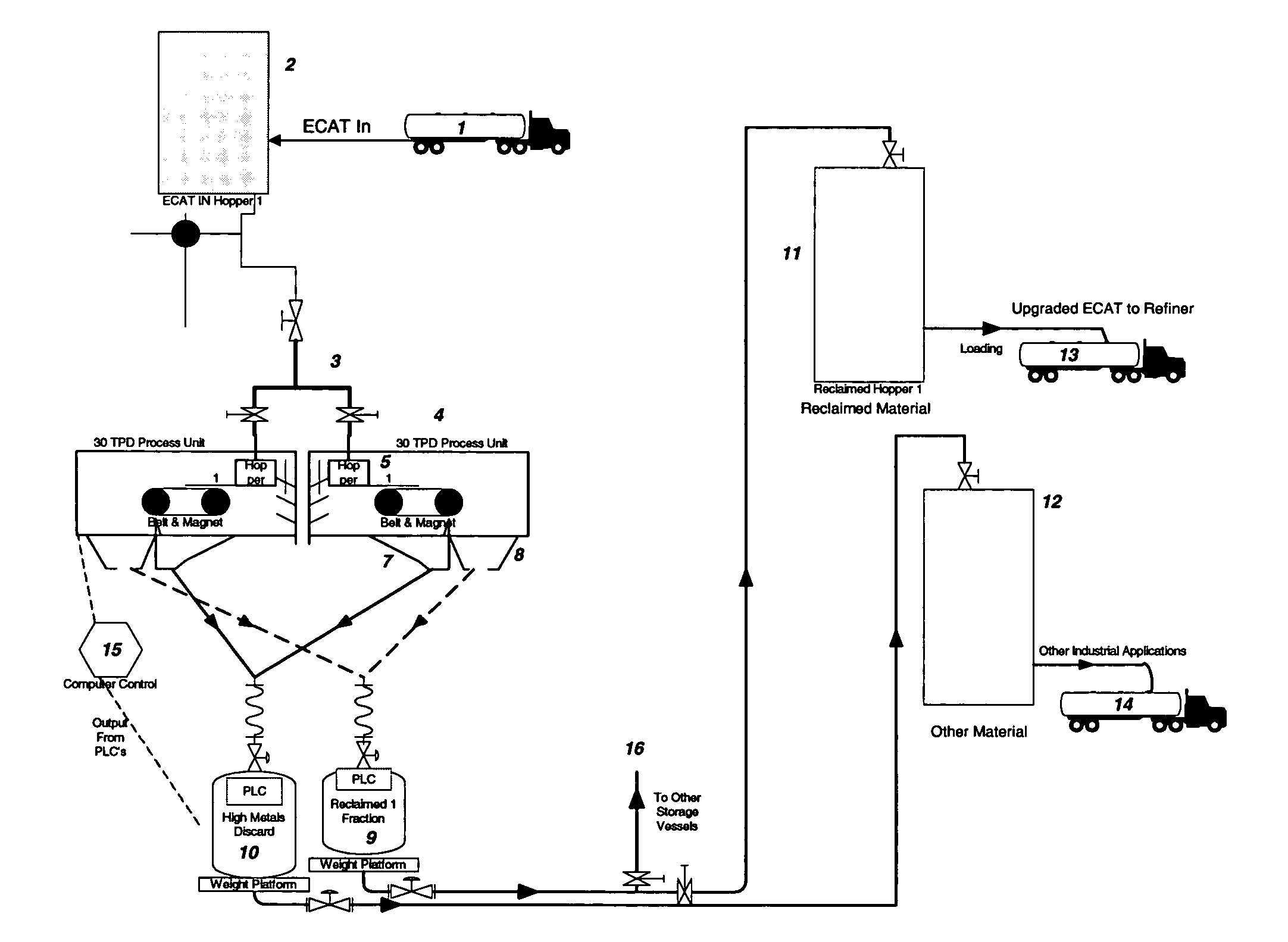

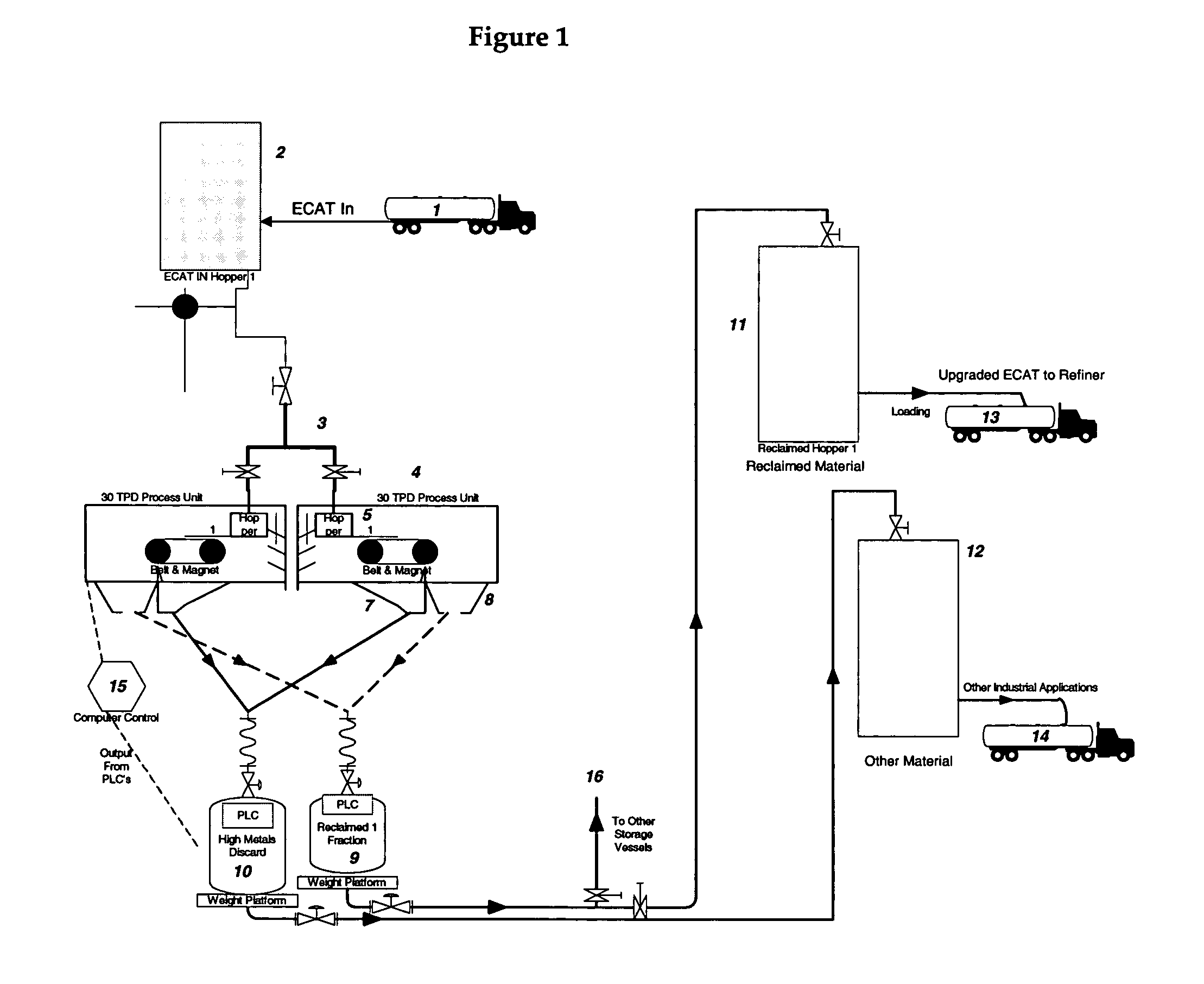

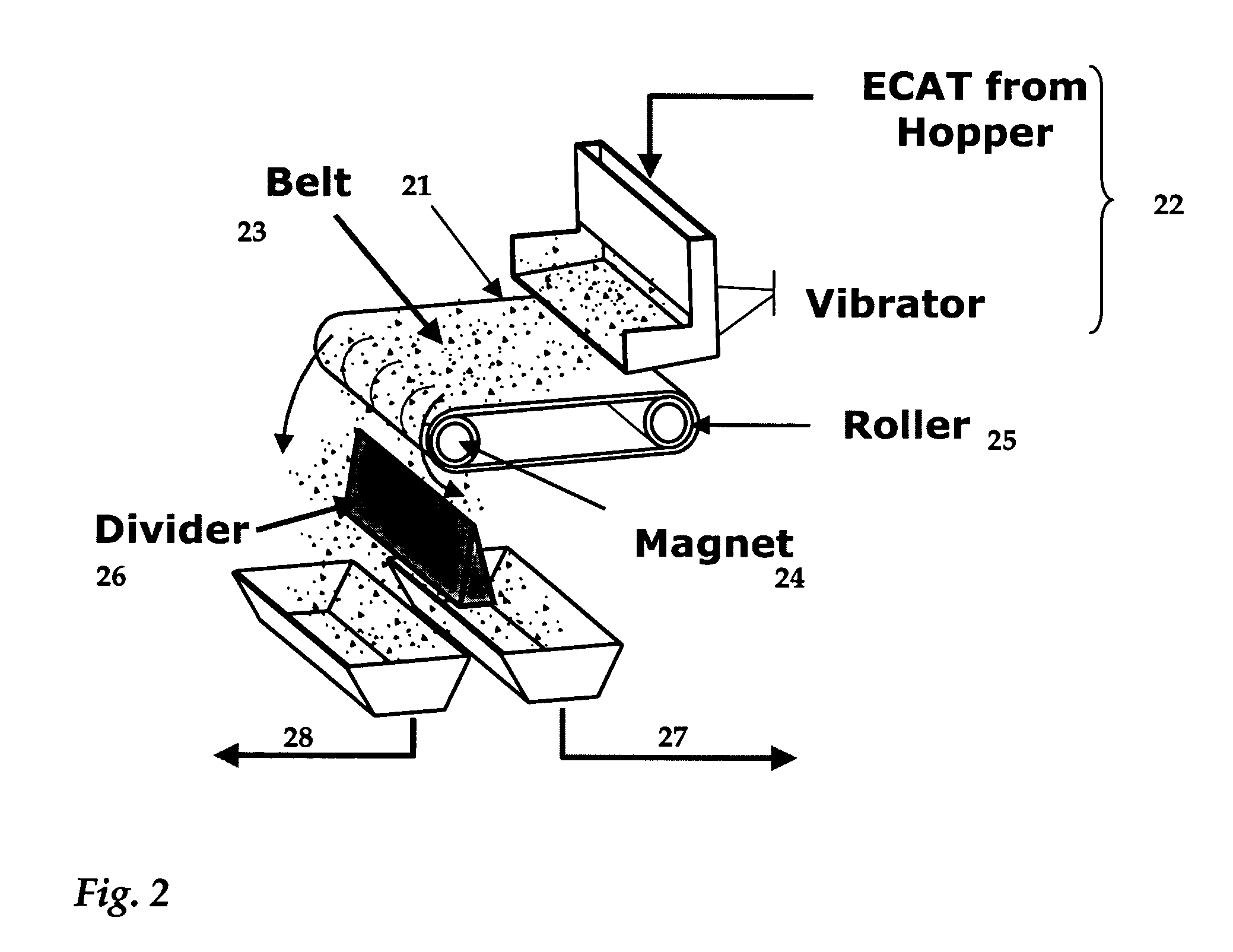

Discarded FCC equilibrium catalyst through reclamation

InactiveUS7431826B2Safety of the reclamation process is increasedImprove environmental impactCatalytic crackingSolvent extractionLiquid wasteMomentum

The invention relates to the partial recovery of discarded, spent, or waste fluid catalytic cracking (FCC) equilibrium catalyst by use of a separation device located off site, away from any FCC Process unit or Petroleum Refining area, whereby the separation of recoverable material is achieved by means of both magnetic properties exhibited from contaminated metals deposited on individual catalyst particles and inertial or momentum contributions based on size and density of each individual catalyst particle. The invention provides a process to recover twenty to forty percent of the original discarded, spent, or waste FCC equilibrium catalyst for reuse.

Owner:METAL ALLOY RECLAIMERS INC II

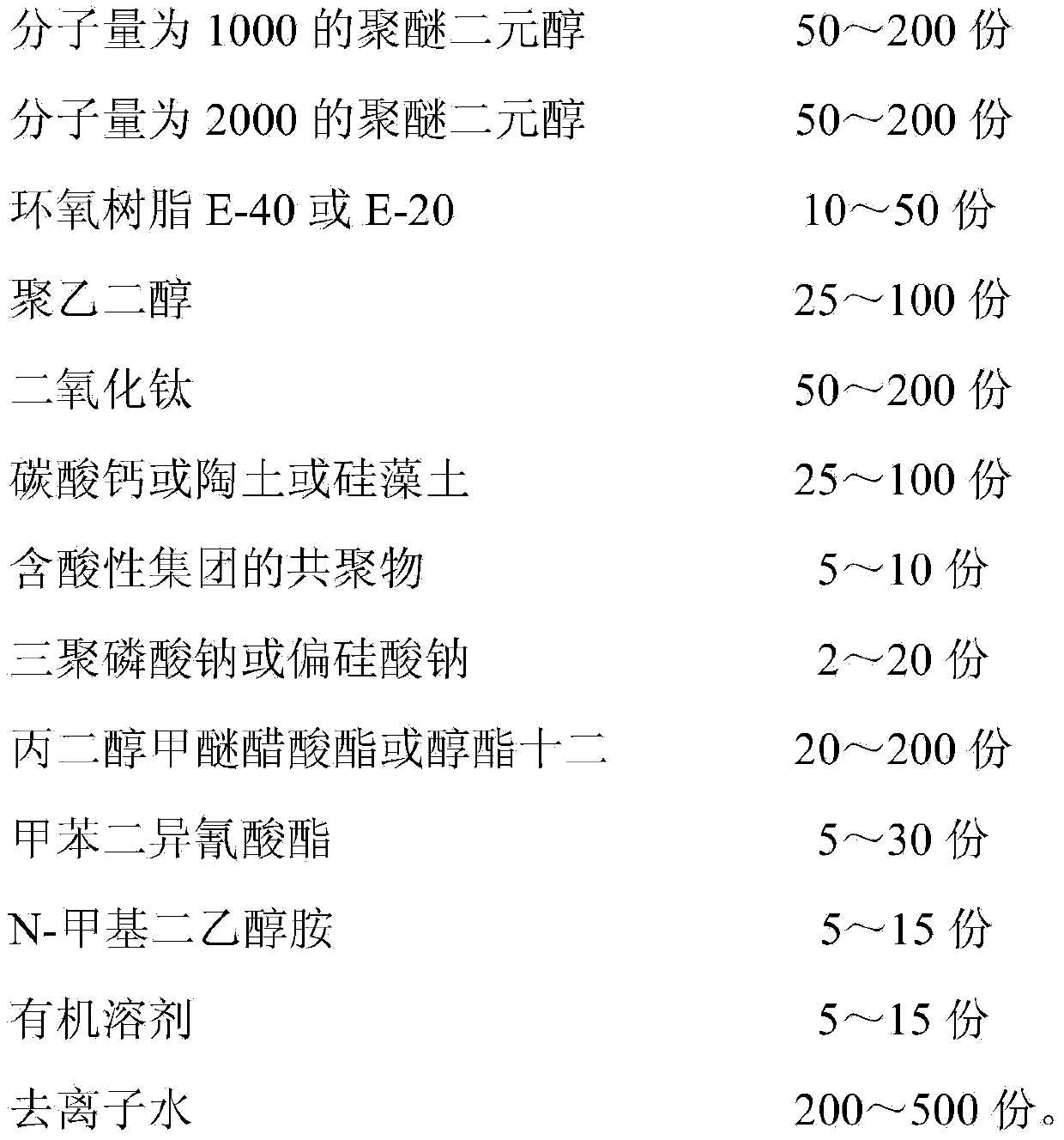

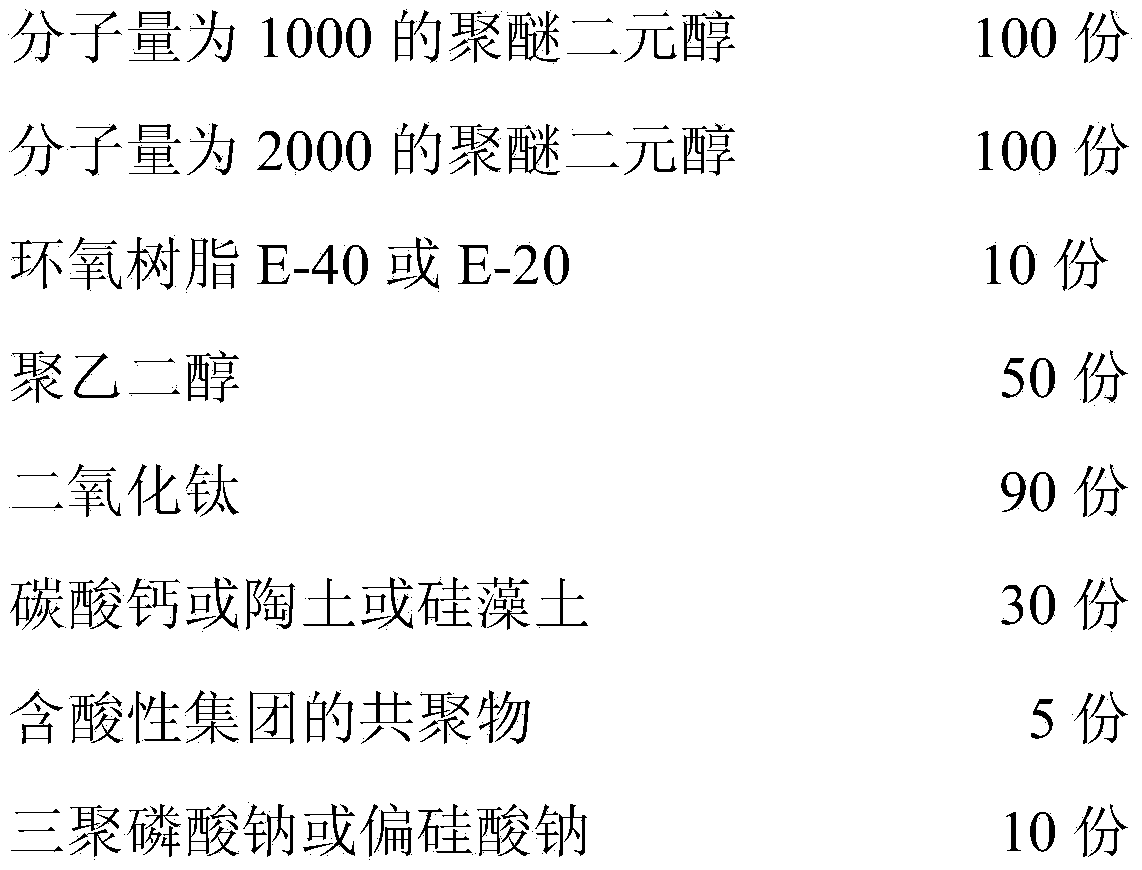

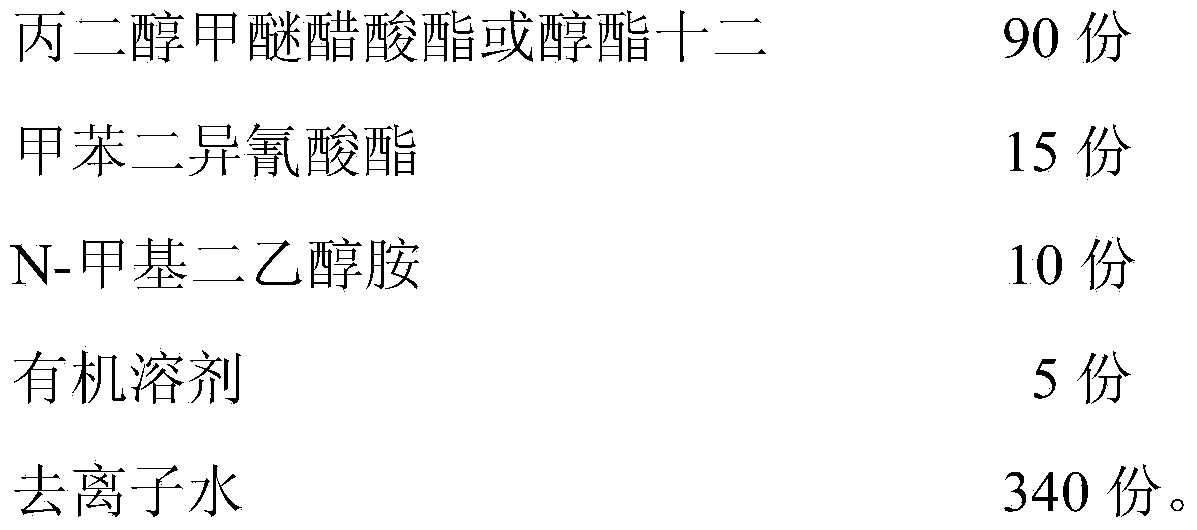

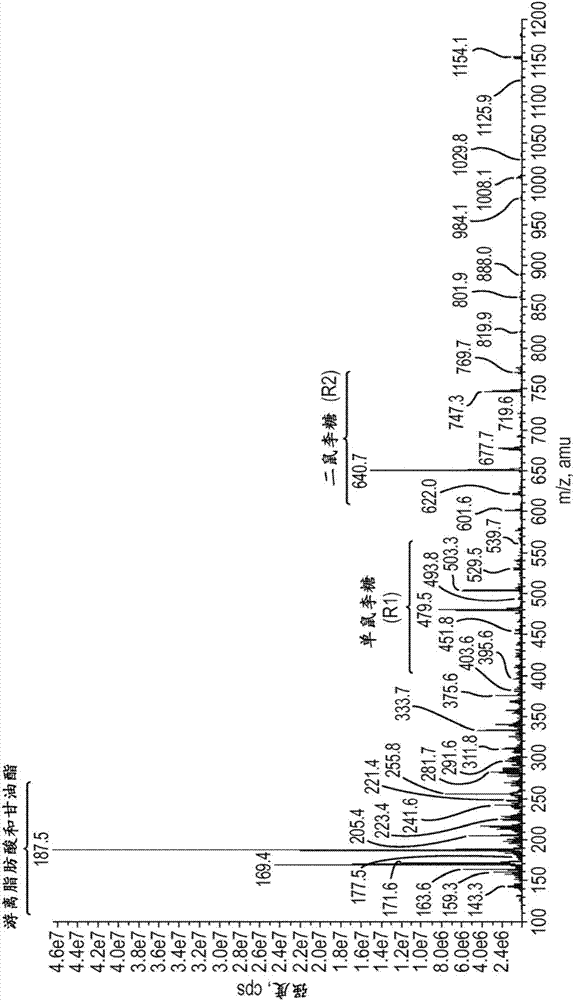

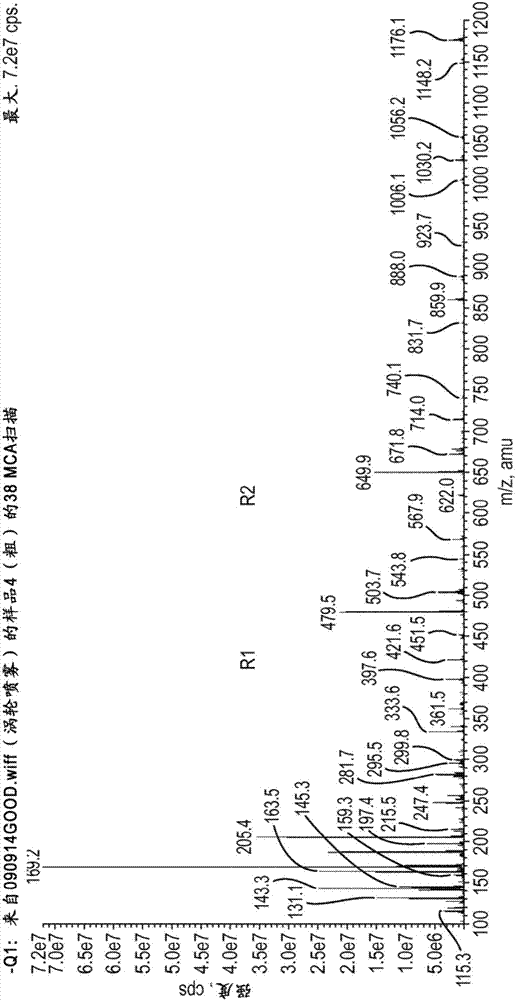

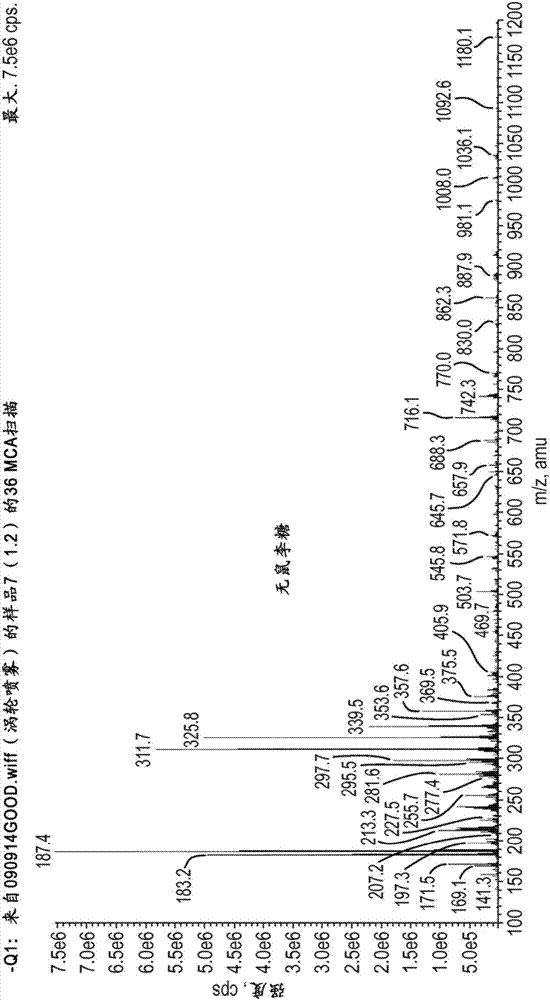

White dust suppressant and preparation method and application thereof

ActiveCN103834364AEasy to manageImprove environmental impactOther chemical processesEpoxySodium metasilicate

The invention belongs to the technical field of prevention and controlling of unorganized emission of dust in storing and transporting processes of coal, and discloses a white dust suppressant and a preparation method and application thereof. The white dust suppressant is prepared by the following raw materials in parts by weight: 50-200 parts of polyether diol with molecular weight of 1000, 50-200 parts of polyether diol with molecular weight of 2000, 10-50 parts of epoxy resin E-40 or E-20, 25-100 parts of polyethylene glycol, 50-200 parts of titanium oxide, 25-100 parts of calcium carbonate or argil or diatomite, 5-10 parts of copolymer containing acid group, 2-20 parts of sodium tripolyphosphate or sodium metasilicate, 20-200 parts of propylene glycol methyl ether acetate or 2,2,4-trimethyl-1,3-amyl glycol monoisobutyrate, 5-30 parts of toluene diisocynate, 5-15 parts of N-methyldiethanolamine, 5-15 parts of organic solvent, and 200-500 parts of deionized water.

Owner:广州普凯热伏微能源科技有限公司

Removal of phosphorus from water

ActiveUS20200247699A1Easily and effectively scalableThe process is convenient and fastIron oxides/hydroxidesWater contaminantsSoil scienceOxidizing agent

The present invention relates to removal of phosphorus from water. A method of removing phosphorus from water includes contacting an oxidizer with water including phosphorus to form water including oxidized phosphorus. The method also includes contacting the water including the oxidized phosphorus with a reactive media to capture the oxidized phosphorus on the reactive media, in the reactive media, or a combination thereof, as a solid salt comprising the oxidized phosphorus.

Owner:PHOSPHORUS FREE WATER SOLUTIONS LLC

A method of separating rhamnolipids from a fermentation broth

ActiveCN107405537AImprove accuracyImprove environmental impactSugar derivativesSolvent extractionChemistryCo solvent

A method of extracting at least one rhamnolipid compound from a rhamnolipid fermentation mixture, the method comprising the steps of: (a) admixing an inert adsorbing support with a rhamnolipid fermentation mixture; (b) dissolving the mixture in an organic solvent at a temperature higher than 31 DEG C and at a pressure higher than 73 bars; (c) separating at least one fatty compound; (d) adding a co-solvent to said organic solvent; (e) modifying temperature and / or pressure; (f) separating a first rhamnolipid compound; and (g) separating a second rhamnolipid compound.

Owner:UNILEVER IP HLDG BV

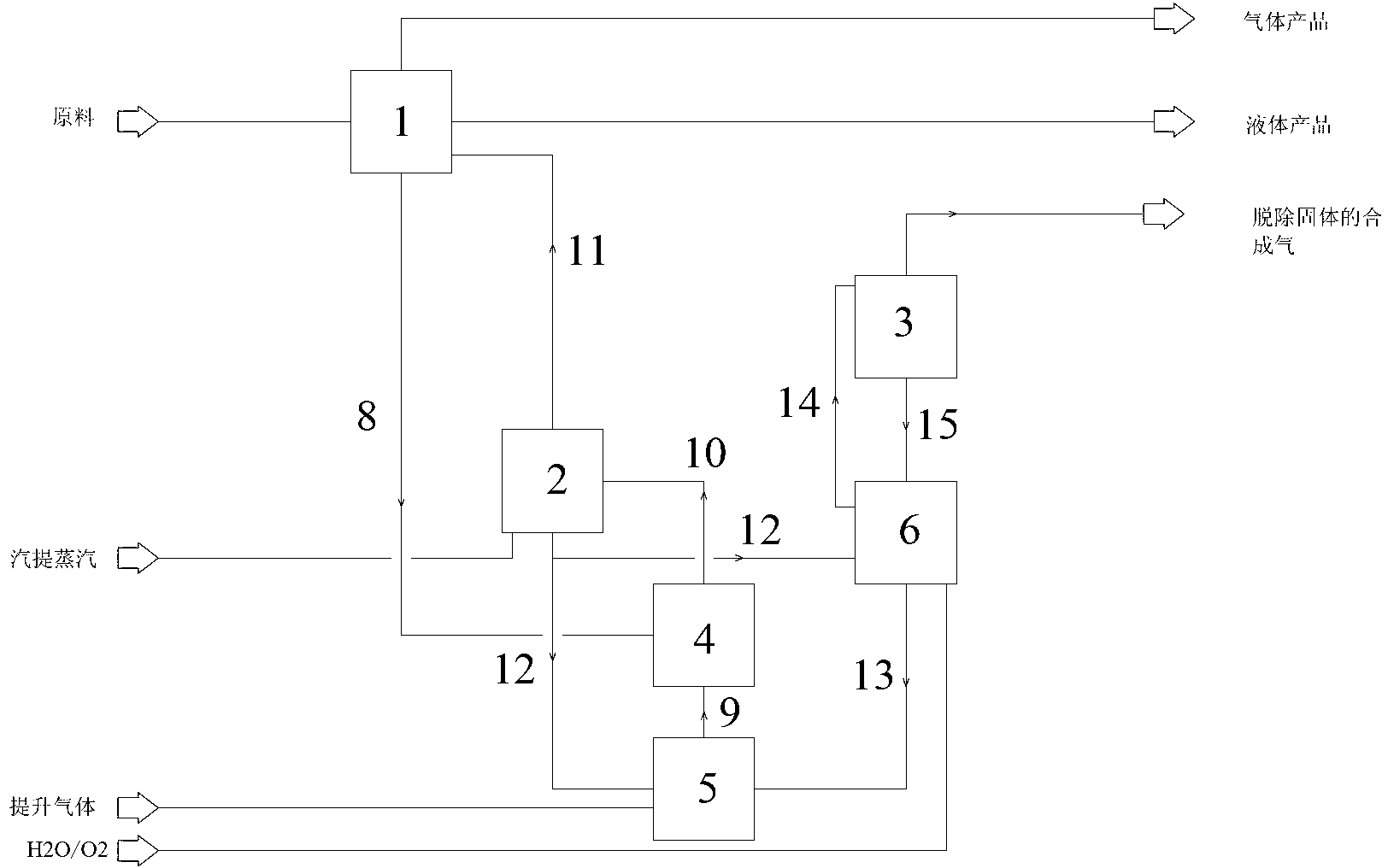

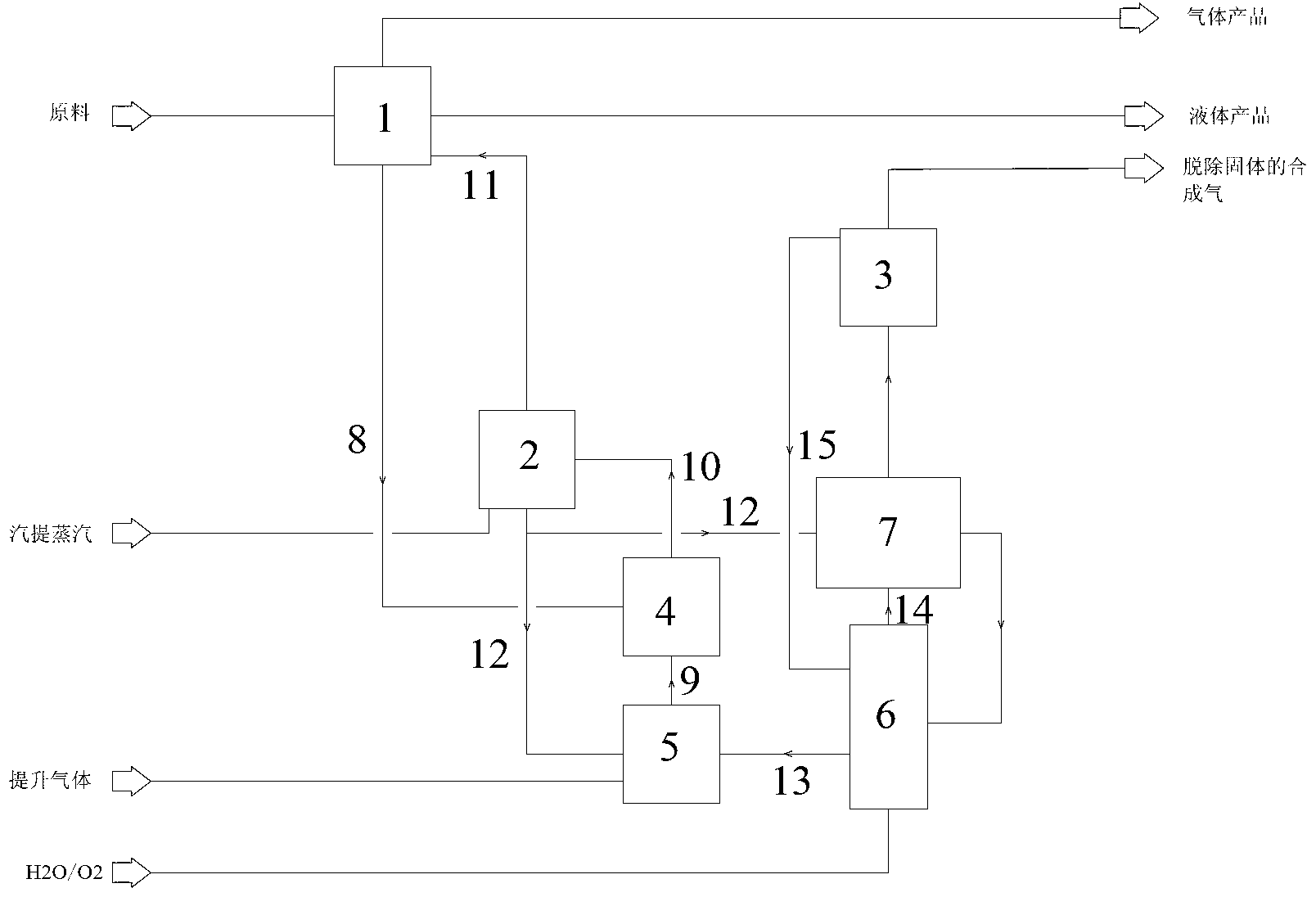

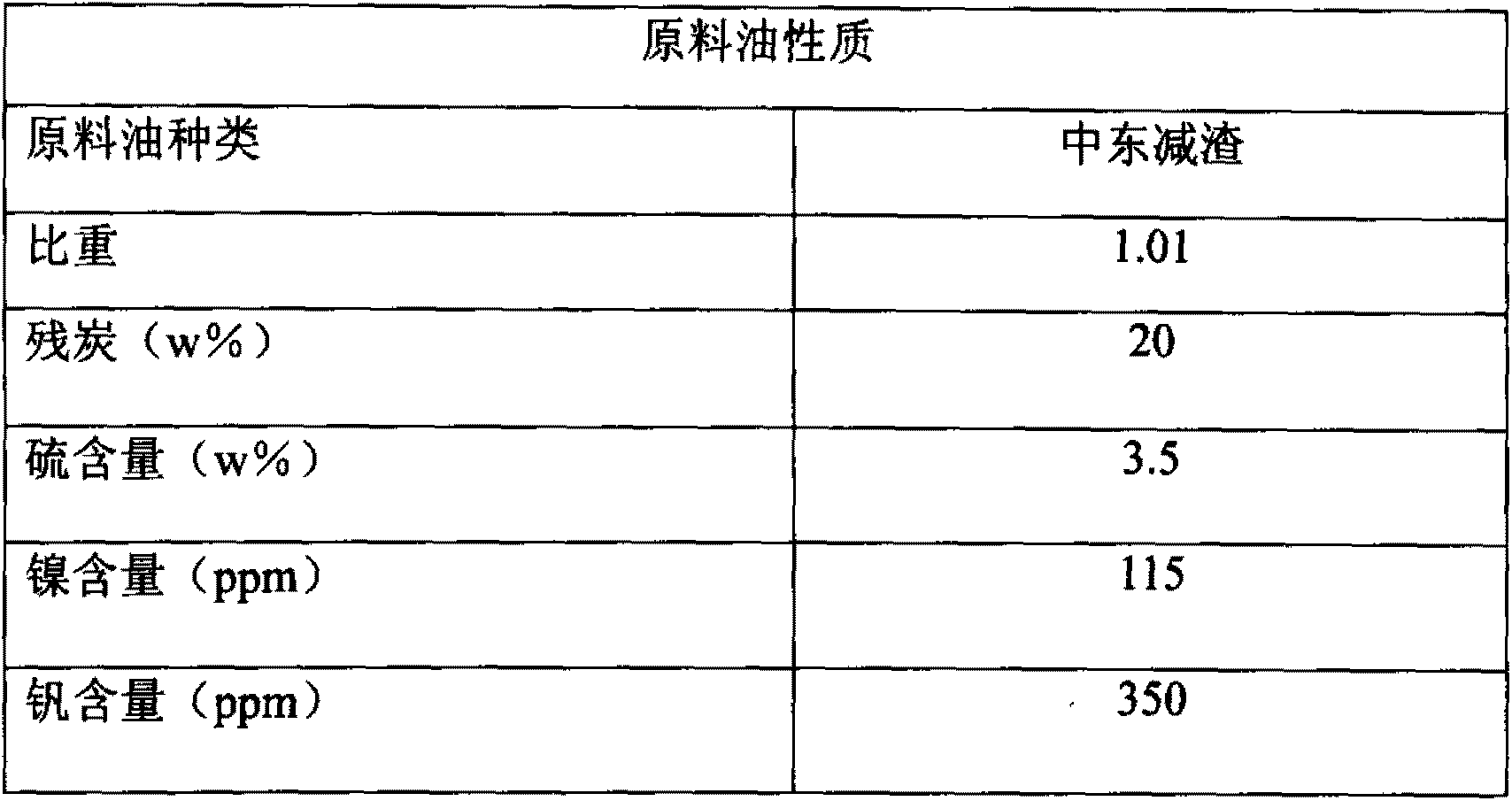

Inferior heavy oil fluidization conversion technology

ActiveCN103224808ALow calorific valueQuality improvementTreatment with plural serial stages onlyGranular/pulverulent flues gasificationSyngasThermal energy

The invention relates to an inferior heavy oil fluidization conversion technology. The inferior heavy oil fluidization conversion technology comprises that raw material oil is treated by a fractionating tower, then enters into a lifting pipe reactor, undergoes a contact reaction with coke carriers from a coke carrier mixer, then enters into a first gas-solid separation device and is separated; the separated reaction oil gas is fed into the fractionating tower and is subjected to product division; the coke carriers with coke is stripped and is divided into two parts, one of the two parts is fed into the coke carrier mixer, then is mixed with the high-temperature coke carriers from a vaporizer and then is fed back to the lifting pipe reactor, and other one of the two parts is fed into the vaporizer, contacts with oxygen-containing gas and water vapor and undergoes a gasification reaction; the produced synthetic gas is separated by a second gas-solid separation device, is fed into a follow-up section, and is subjected to heat recovery and conversion; and the vaporized coke carriers are fed into the coke carrier mixer and is mixed with the coke carriers with the coke. Compared with the prior art, the inferior heavy oil fluidization conversion technology has the advantages of simple process, low investment, strong raw material adaptability, good product distribution and good environmental benefits.

Owner:SHANGHAI HOTO PETROCHEM ENG

Apparatus for the combustion of gas exiting from a furnace, for the preheating of scraps entering the furnace itself and related process

ActiveCN101120221BImprove economyEliminate dynamic sealsFurnace typesPreheating chargesCombustionElectric arc furnace

An apparatus for the combustion of gas exiting from an electric arc furnace for the preheating of scraps entering the furnace itself foresees an insertion device of comburent substance into a preheating chamber or loading tunnel of the scrap metal having an inlet section of the scrap metal, a seal section to prevent an uncontrolled entrance of air in the tunnel, a heating section and an unloadingsection of the scrap metal in the furnace. Said insertion device of the comburent substance comprises one or more adjustable openings placed in the loading tunnel, and said apparatus comprises a device or a series of devices, also not equipped with autonomous movement, of mechanical seal nature placed in the insertion or inlet section of the scrap metal in the loading tunnel or preheating chamber.

Owner:ТЕНОВА ТЕКНОЛОДЖИЗ (ТЯНЬЦЗИНЬ) КО., ЛТД.

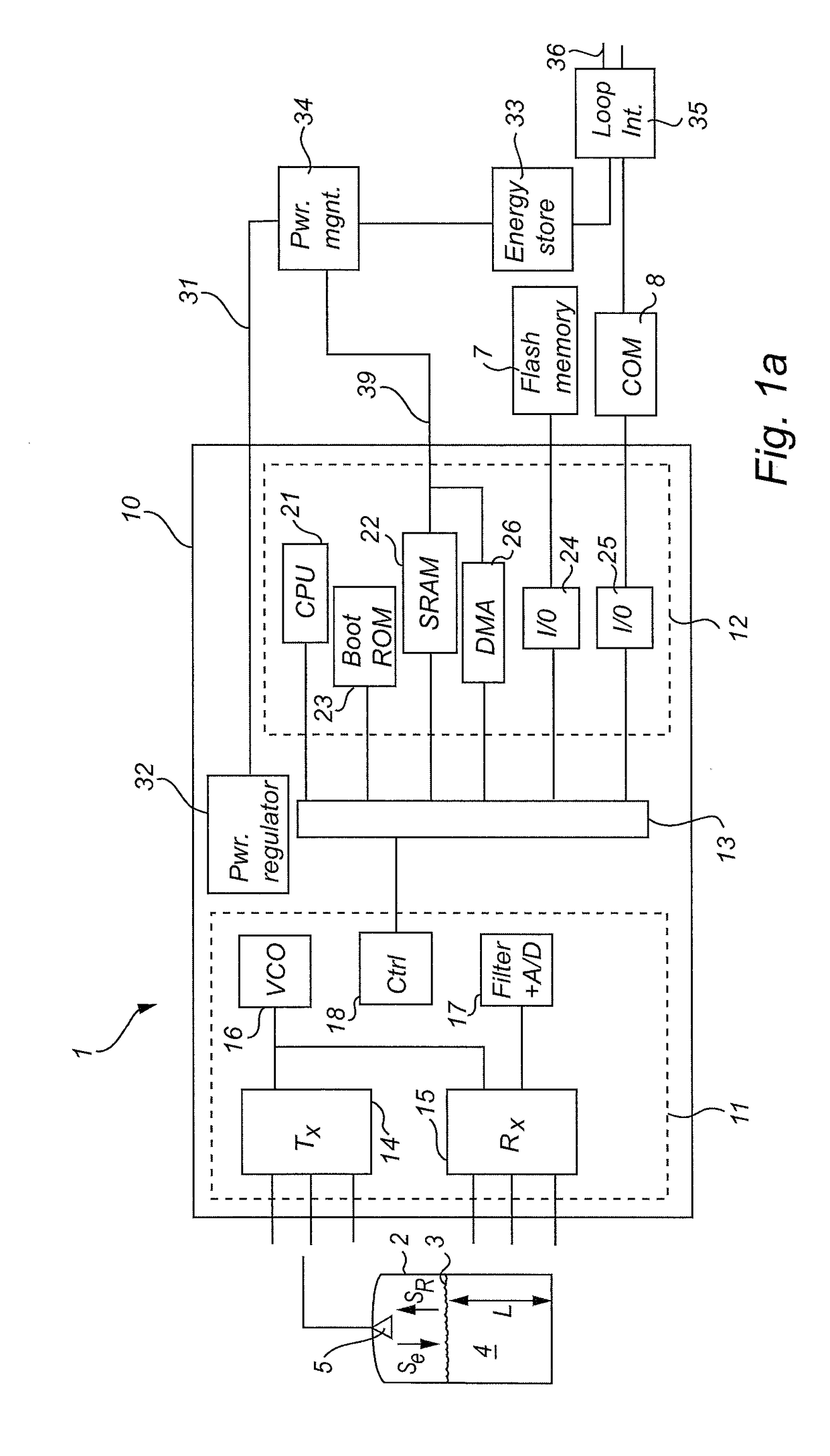

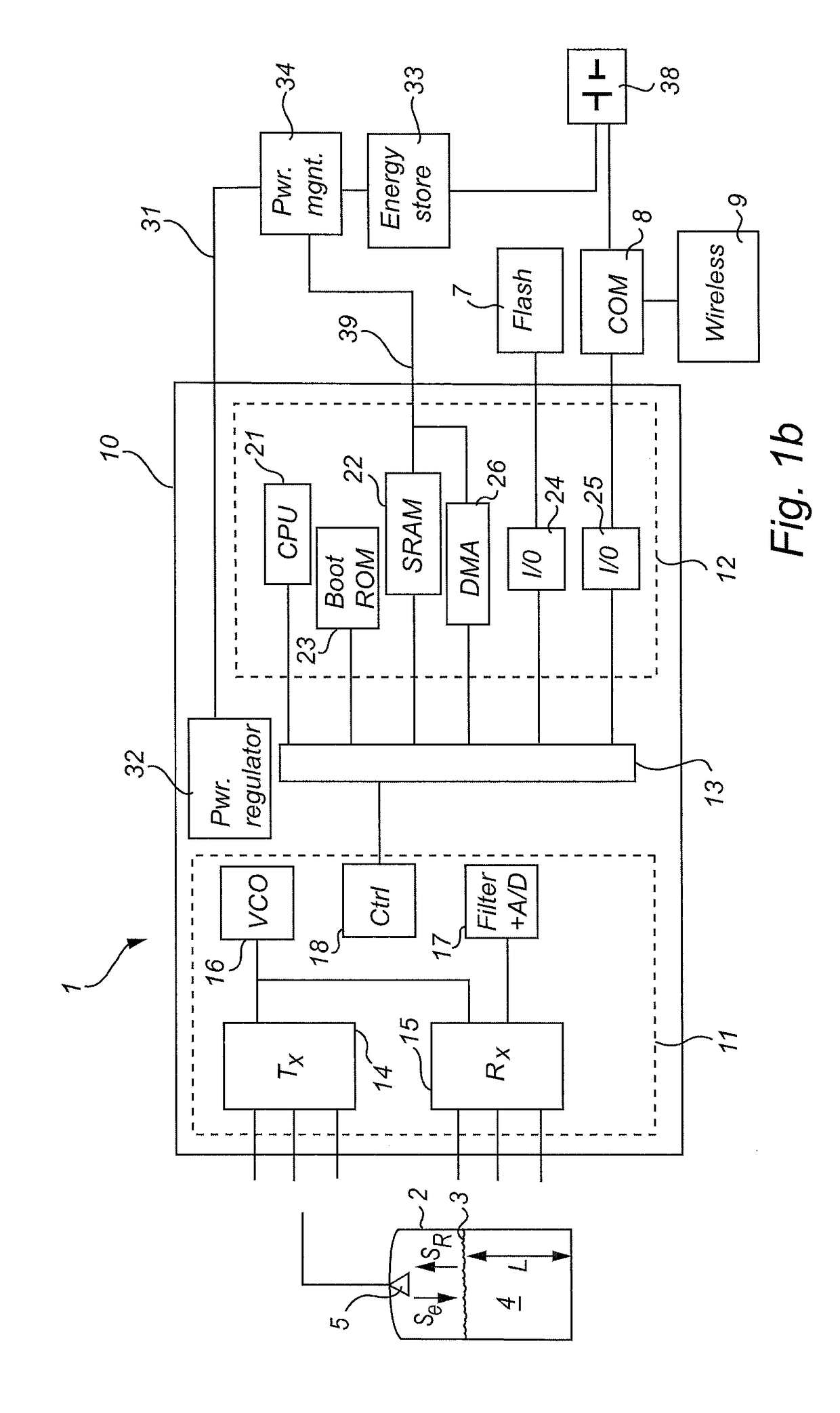

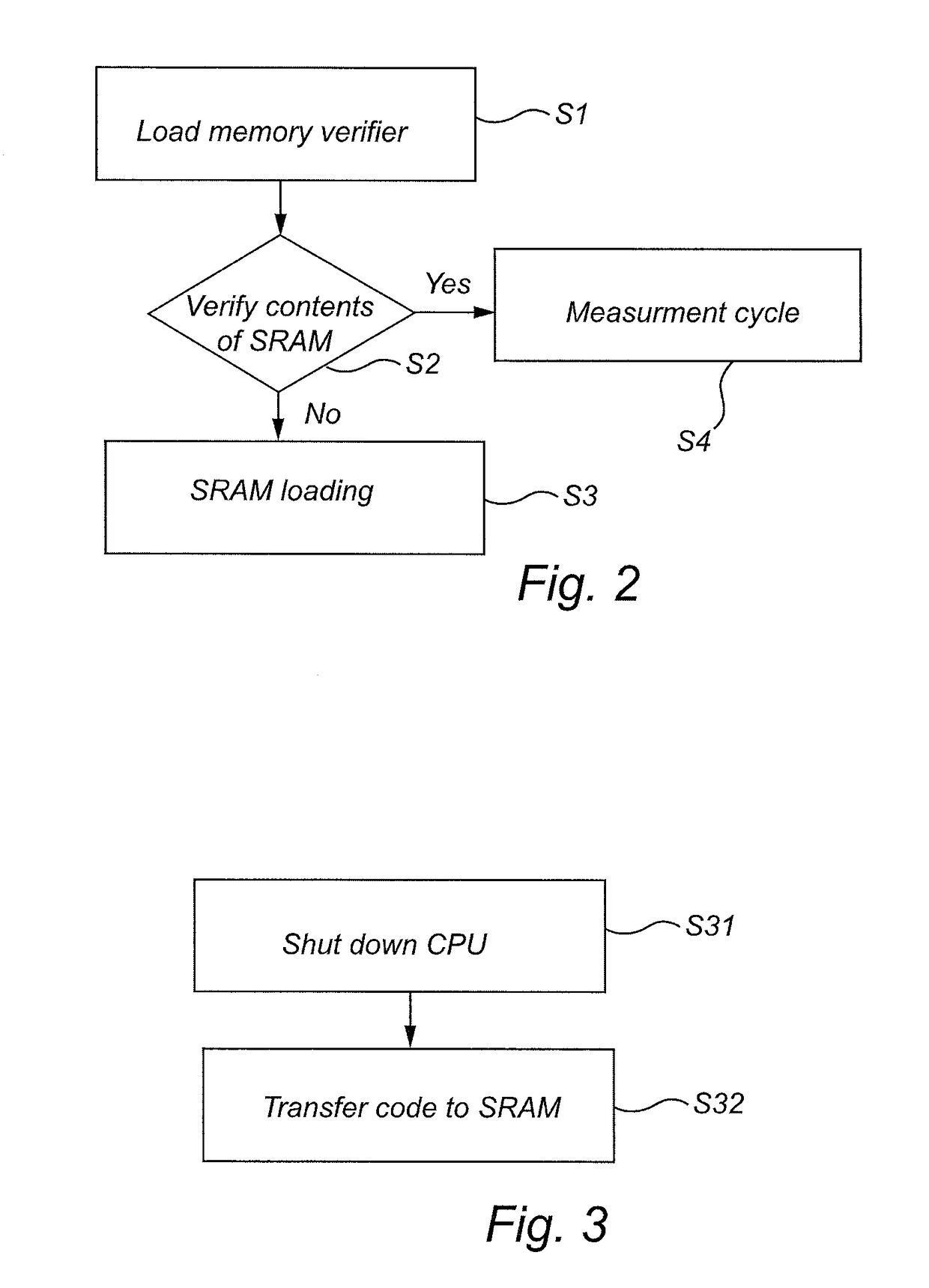

Radar level gauge

InactiveUS20180348038A1Reduce sizeImprove environmental impactDigital storageLevel indicators by physical variable measurementActive modeSoftware

A radar level gauge for determining a filling level of a product in a tank, comprising a volatile high-speed working memory, a first processing unit connected to the volatile high-speed working memory, the first processing unit having an active mode in which the first processing unit is turned on and accesses the working memory, and an inactive mode where the first processing unit is turned off, memory loading circuitry, separate from the processor, configured to transfer software code from a non-volatile memory into the volatile high-speed working memory while the processor is in inactive mode, and an auxiliary power connection configured to provide power only to the volatile high-speed working memory and the memory loading circuitry.With this design, the memory loading circuitry and working memory can be powered separately, thereby allowing loading of software code from the non-volatile memory into the volatile high-speed working memory without activating the relatively power-hungry processor.

Owner:ROSEMOUNT TANK RADAR

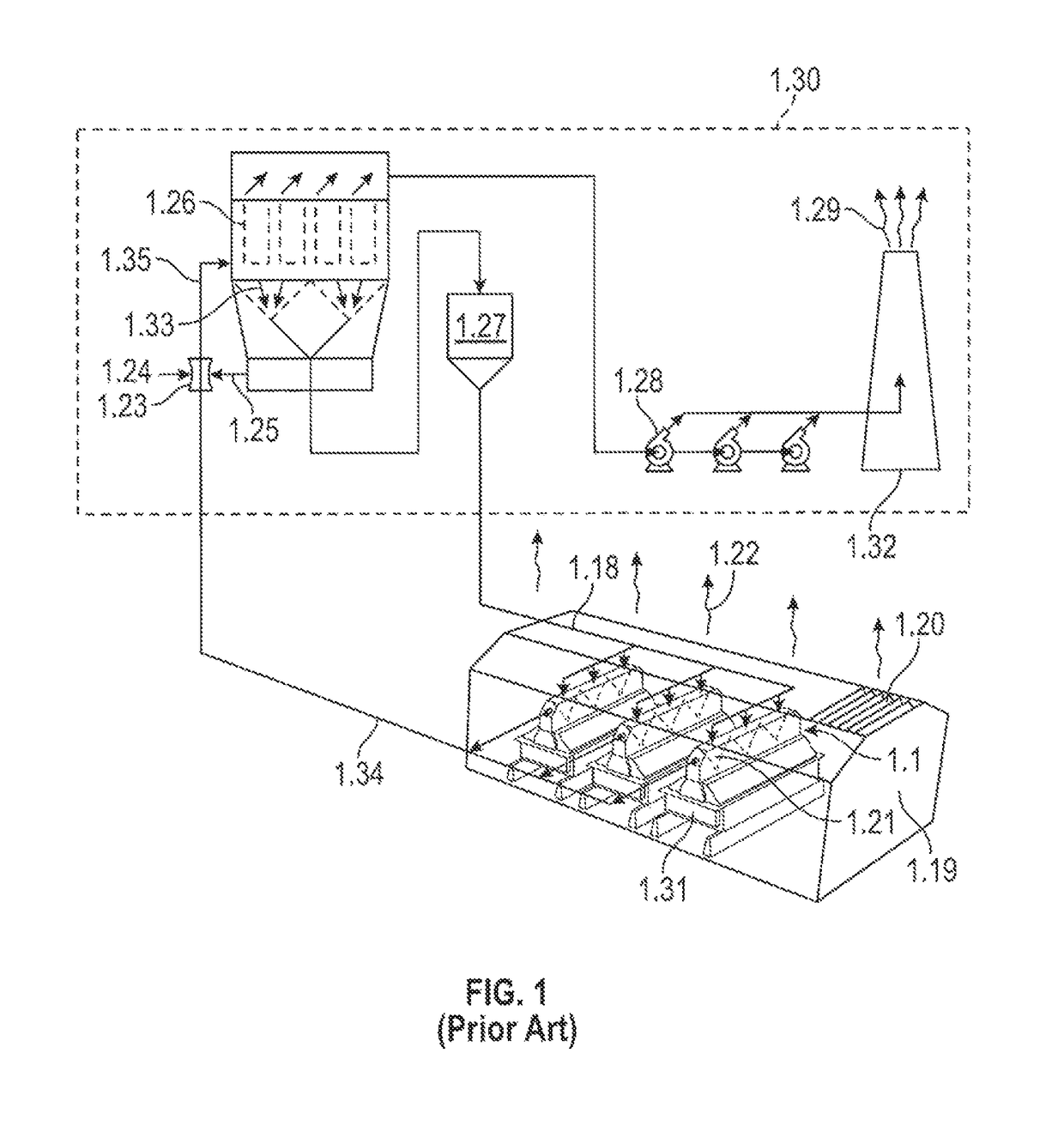

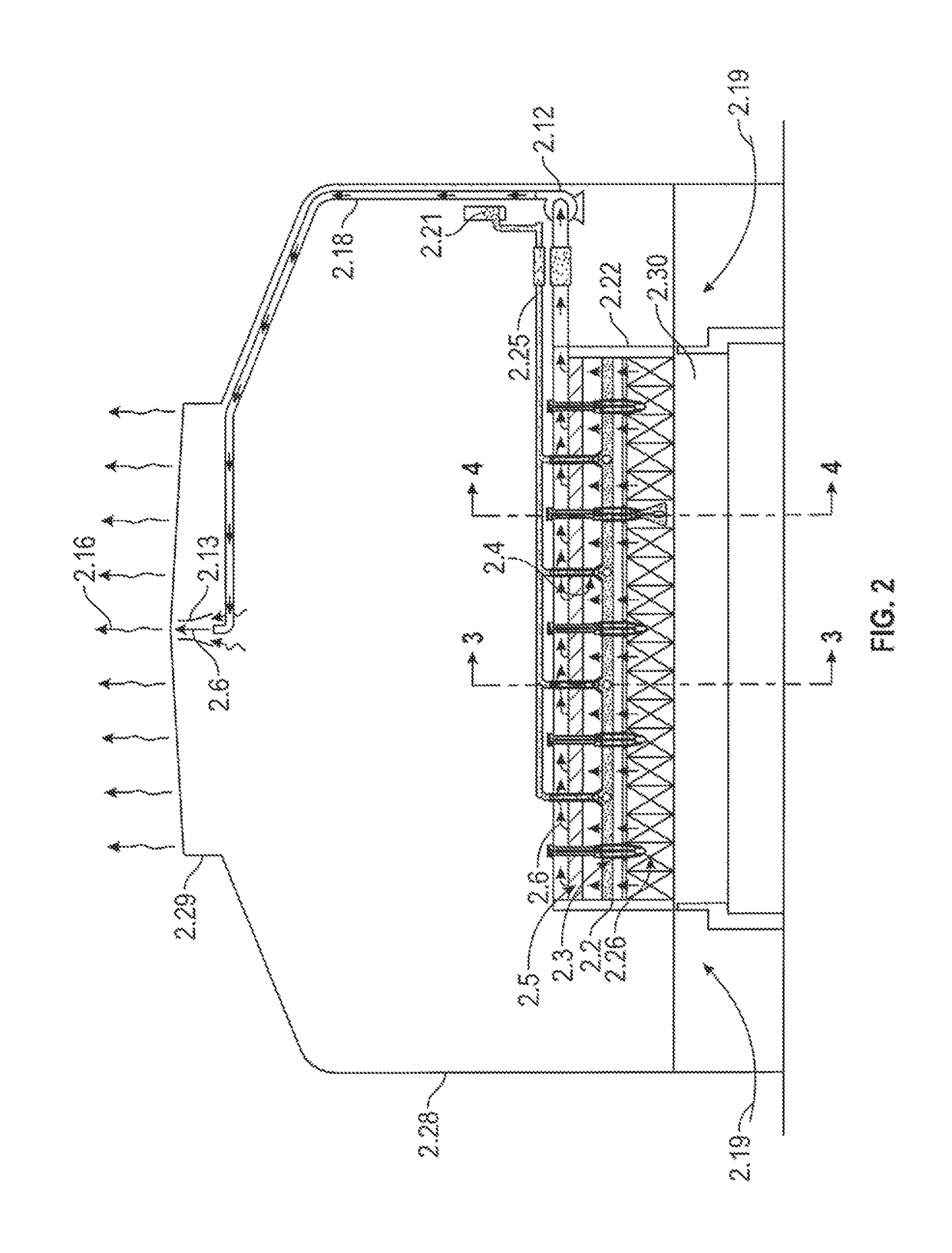

Integrated gas treatment

InactiveUS9920442B2Reducing capital and operating costImprove environmental impactGas treatmentDispersed particle separationParticulatesOperating point

Owner:BECHTEL MINING & METALS

Integrated gas treatment

InactiveUS20170121833A1Reducing capital and operating costImprove environmental impactGas treatmentDispersed particle separationParticulatesOperating point

Systems and methods for reducing the capital and operating costs of a smelting process system and improving the environmental impact of the smelting process using an IGT system to remove and filter environmentally hazardous gases and particulates from each electrolytic cell in the smelting process system.

Owner:BECHTEL MINING & METALS

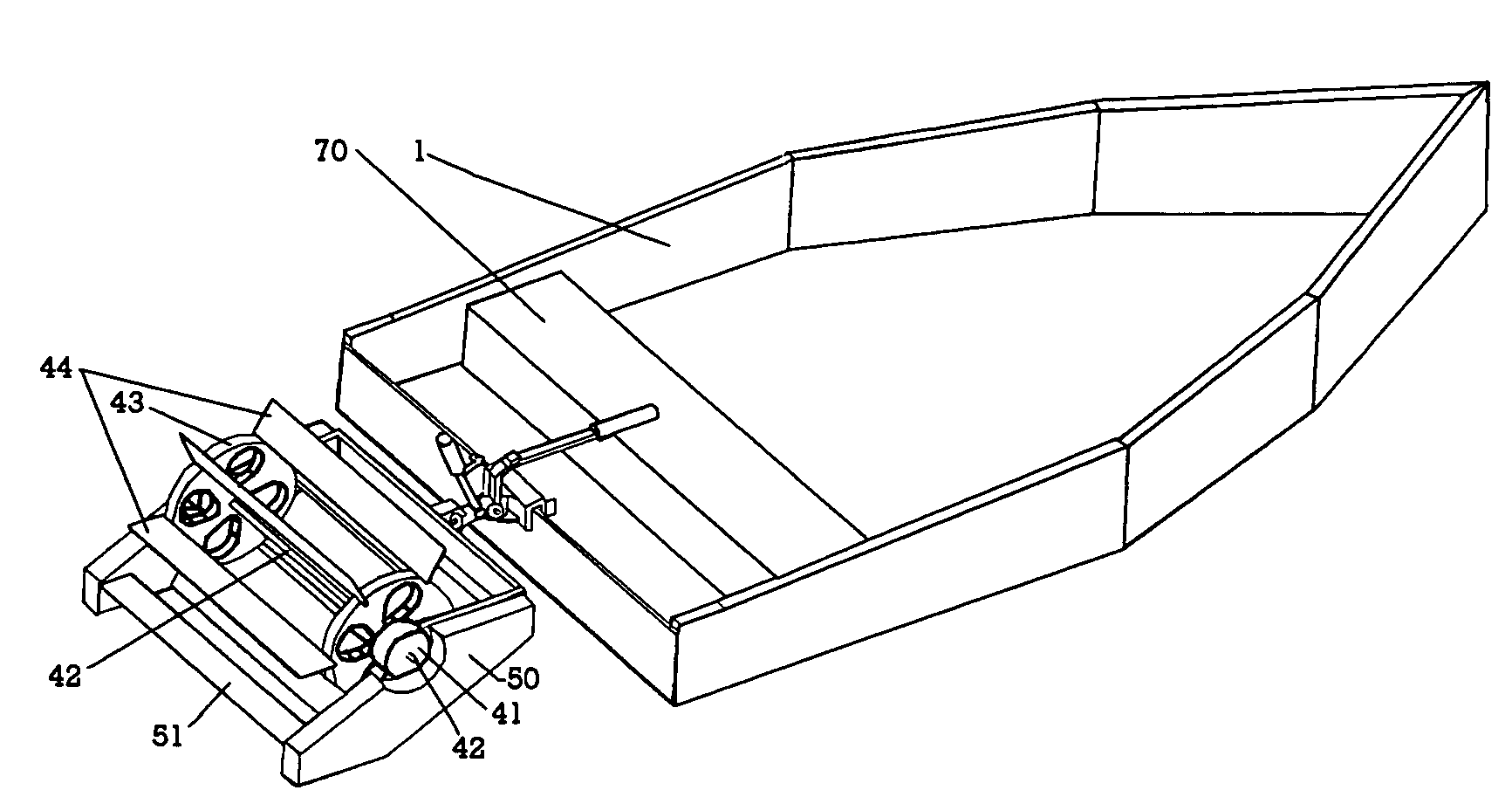

Paddlewheel vessel thruster

InactiveUS7448930B2Improve energy efficiencyImprove environmental impactPropulsive elements of rotary typeRudderBuoyancy

Owner:DIGGINS PETER

Vehicle with a main body having a longitudinal axis and with a tilting unit

InactiveCN101041377AAvoid lostImprove environmental impactCycle standsAxle suspensionsVertical planeEngineering

The invention concerns a vehicle with a main body having a longitudinal axis, and with a tilting unit for tilting the main body relative to a vertical plain through the longitudinal axis, whereby the tilting unit comprises an actuator, a control unit and a power provision unit for providing a power transmitting medium via the control unit to the actuator, whereby the control unit is configured to control the power intake of the actuator, characterized in comprising at least two redundant tilting units.

Owner:FONDAZIONE TORINO WIRELESS

Removal of phosphorus from water

ActiveUS11267733B2Easily and effectively scalableThe process is convenient and fastIron oxides/hydroxidesWater contaminantsSoil scienceOxidizing agent

A method of removing phosphorus from water includes contacting an oxidizer with water including phosphorus to form water including oxidized phosphorus. The method also includes contacting the water including the oxidized phosphorus with a reactive media to capture the oxidized phosphorus on the reactive media, in the reactive media, or a combination thereof, as a solid salt comprising the oxidized phosphorus.

Owner:PHOSPHORUS FREE WATER SOLUTIONS LLC

Drying method for cultured spirulina mud

ActiveCN109539726AEfficient heat dissipationImprove qualityDrying solid materials without heatDrying gas arrangementsTemperature controlWater vapor

The invention discloses a drying method for cultured spirulina mud. A spray drying chamber is included and comprises an exhaust fan, upper stainless steel gauze, a rotary shaft, a temperature controlsensor, a heat conduction oil radiator, a drying outlet, lower stainless steel gauze, an air inlet fan and a spirulina mud inlet. The exhaust fan and the air inlet fan are arranged at the top and thebottom of the spray drying chamber correspondingly. The heat conduction oil radiator fixed to the rotary shaft is arranged in the middle. The upper stainless steel gauze and the lower stainless steelgauze are correspondingly installed above and below the heat conduction oil radiator with the temperature control sensor. Heat conduction oil serves as a heat source carrier, uniform heat is generatedthrough rotary heat dissipation, thus temperature is adjusted and controlled, dry powder is guided out selectively through centrifugal force generated by rotary heat dissipation, wet powder continuesbeing dried, the air inlet fan and the exhaust fan act jointly, humidity of the spray drying chamber is ensured through water vapor emission, and the drying method has the characteristics that mechanized, automatic and flow line production is easy to achieve, and processing quality is good.

Owner:LIJIANG CHENGHAI BAOER BIOLOGICAL DEV +1

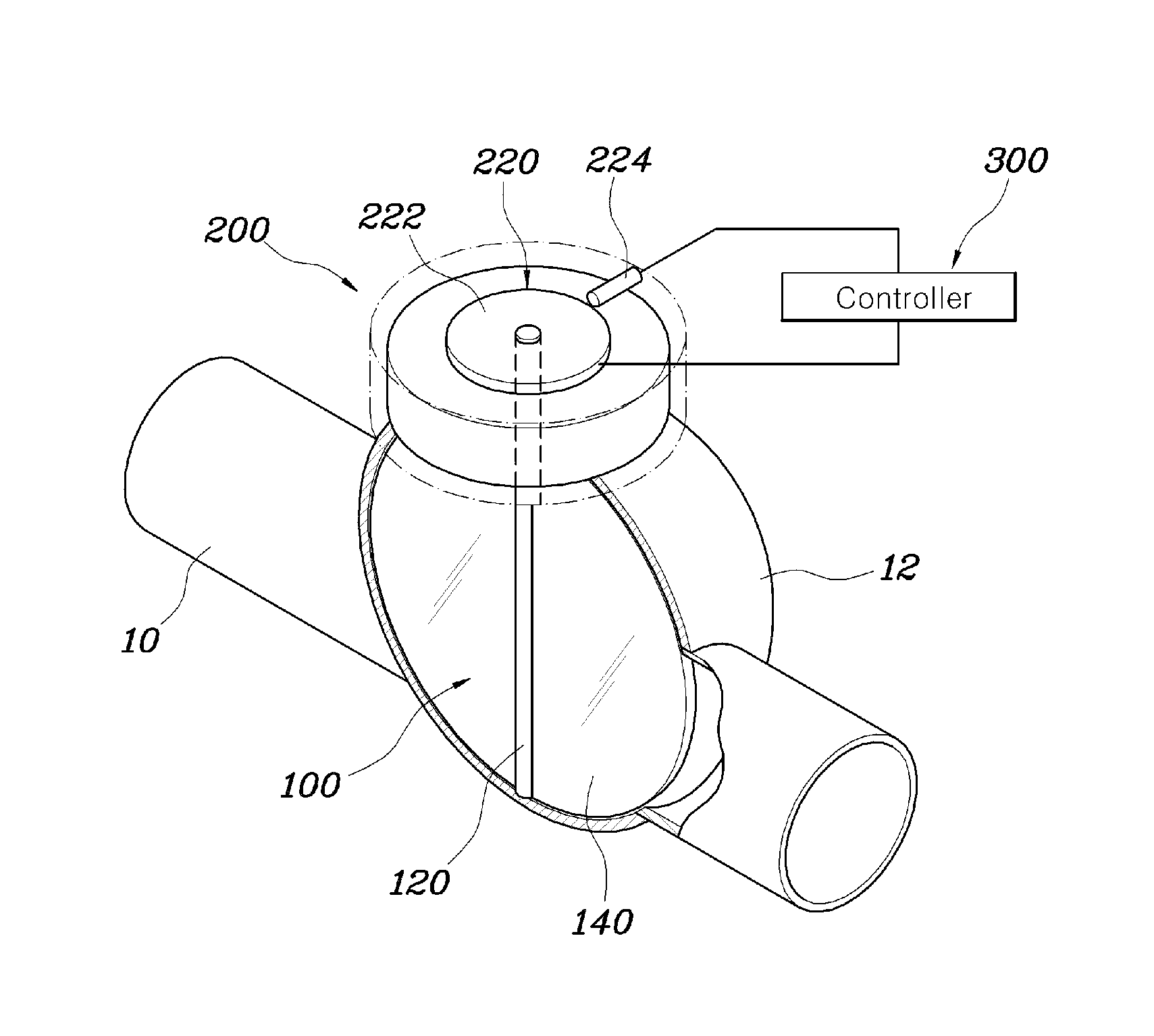

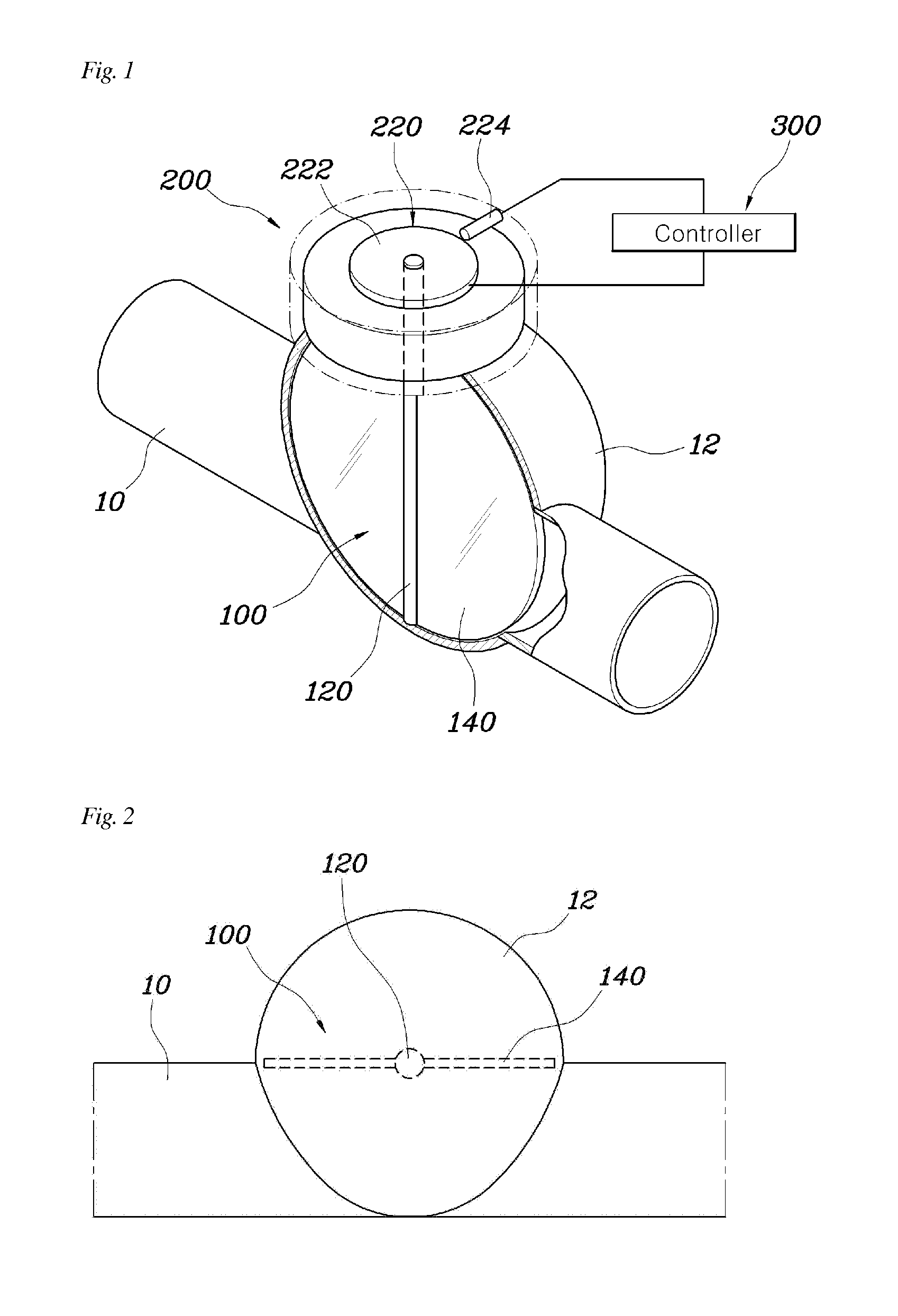

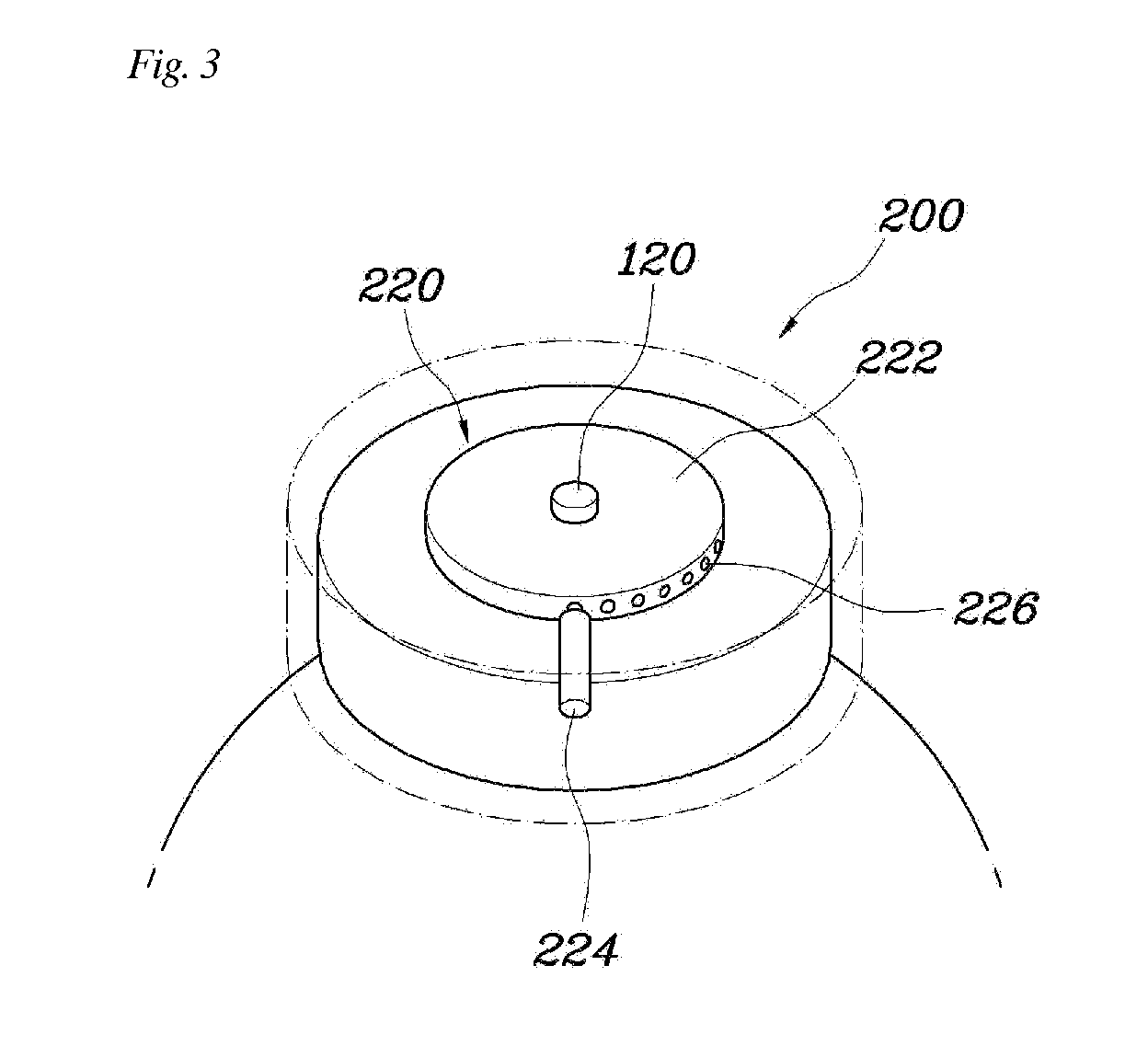

Apparatus and method for recovering exhaust kinetic energy

ActiveUS20130328308A1Improve environmental impactProtect environmentInternal combustion piston enginesExhaust apparatusElectricityRotation velocity

An apparatus and method for recovering exhaust kinetic energy. The apparatus includes a valve assembly, a motor generator and a controller. The valve assembly includes a rotary shaft which is disposed in an exhaust gas pipe and a flap which is disposed on the rotary shaft. The flap is rotated by an exhaust gas that is ejected. The motor generator is connected to the rotary shaft of the valve assembly, and in a first instance generates electricity using a rotational force transmitted from the rotary shaft and in a second instance applies a torque to the rotary shaft. The controller fixes the rotary shaft of the valve assembly at a predetermined angle in the first instance and adjusts the speed of rotation of the rotary shaft by controlling the motor generator in the second instance.

Owner:HYUNDAI MOTOR CO LTD

Method for manufacturing a crash frame of a battery compartment for battery electric vehicles

PendingUS20210351469A1Reduction cost advantageReduce weightBattery isolationElectric propulsion mountingElectrical batteryElectric drive

The invention relates to a manufacturing method for a crash frame of a battery compartment for electric drive vehicles by using metallic sheets which are arranged on top of one another and fixed together and which form in a following step a space by using an inner active media forming process to create walls of a crash frame whereby the space works as a deformation space to protect the battery modules inside the battery compartment against an impact. The invention further relates to the use of the crash frame for a battery compartment.

Owner:OUTOKUMPU OY

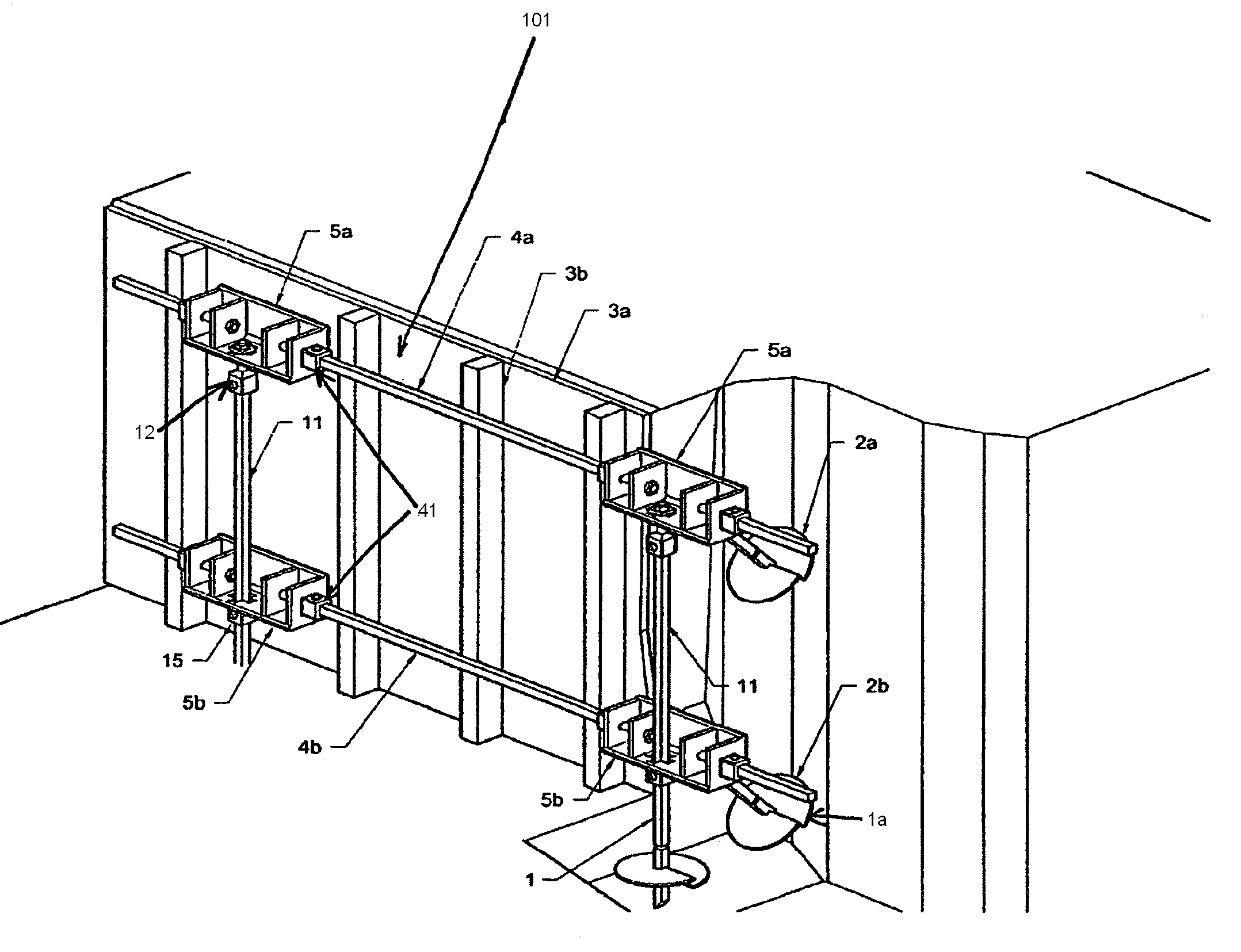

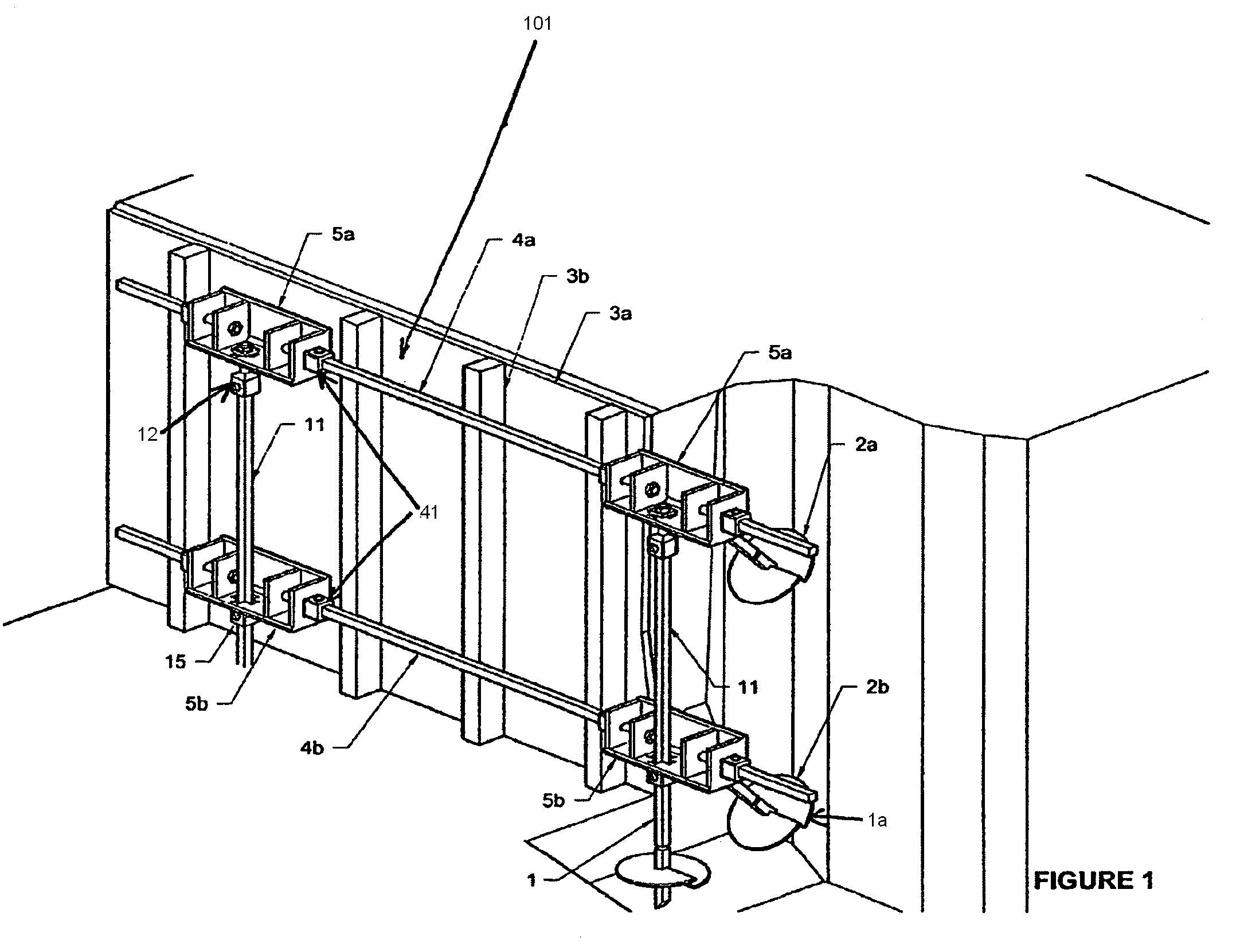

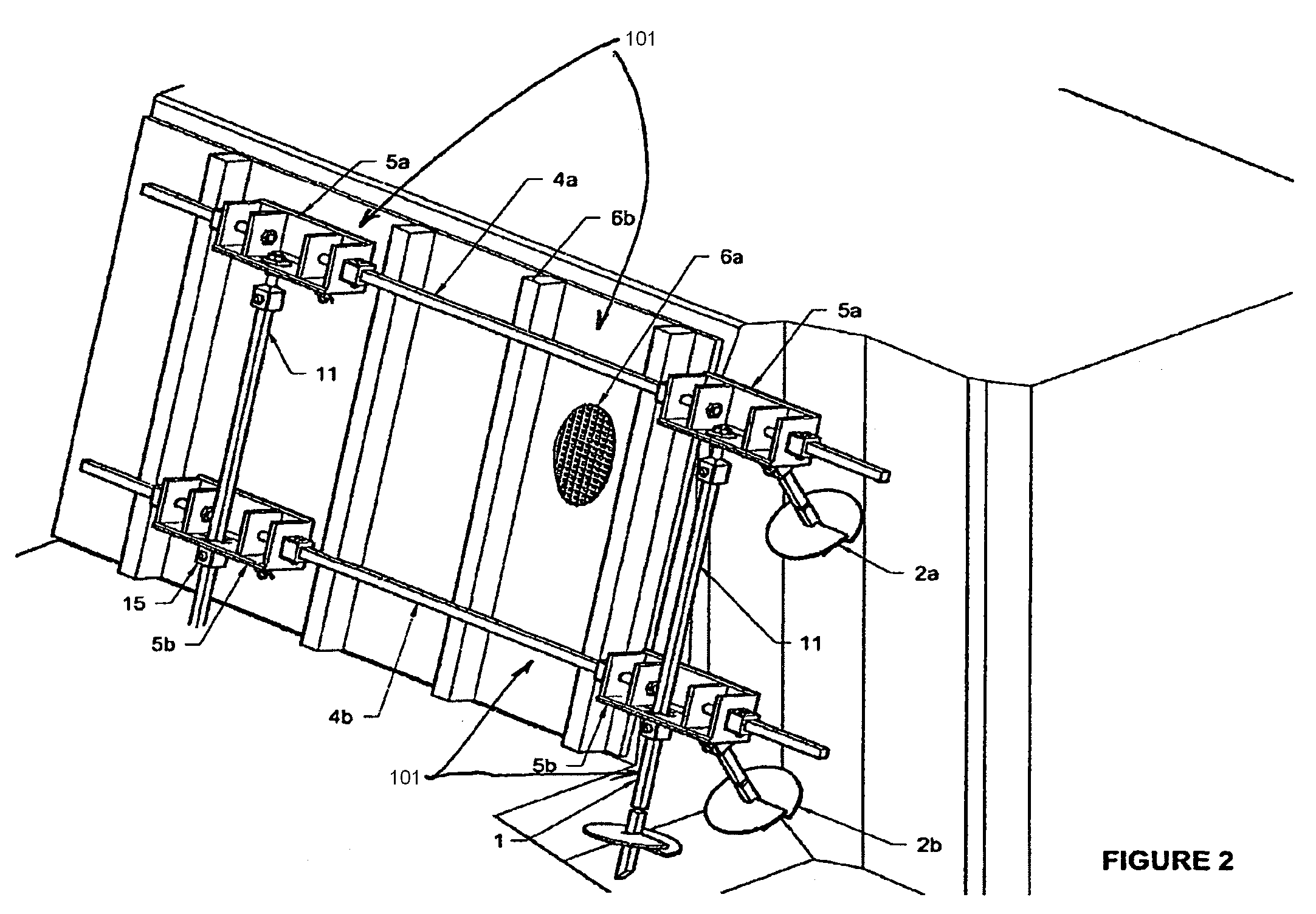

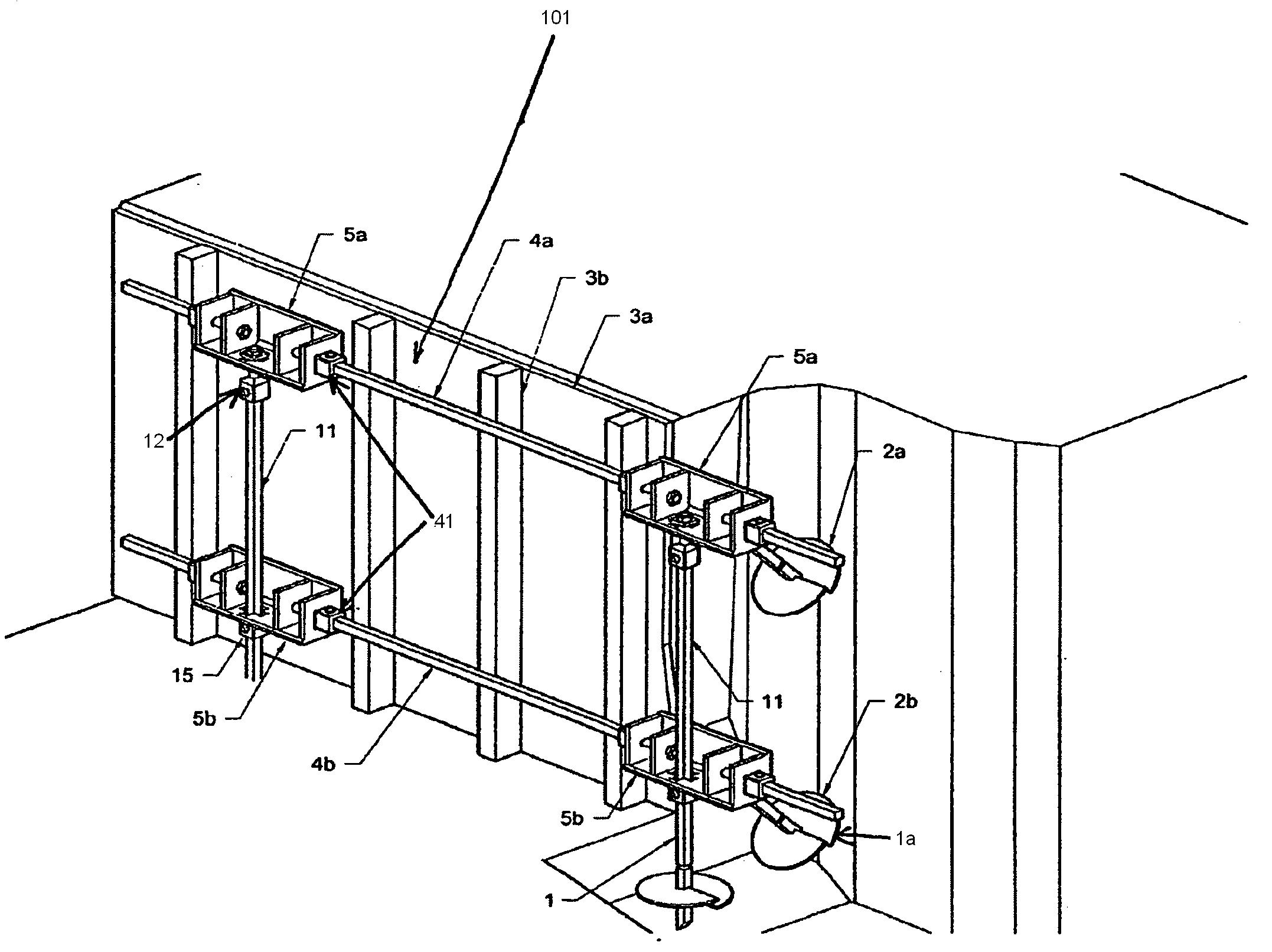

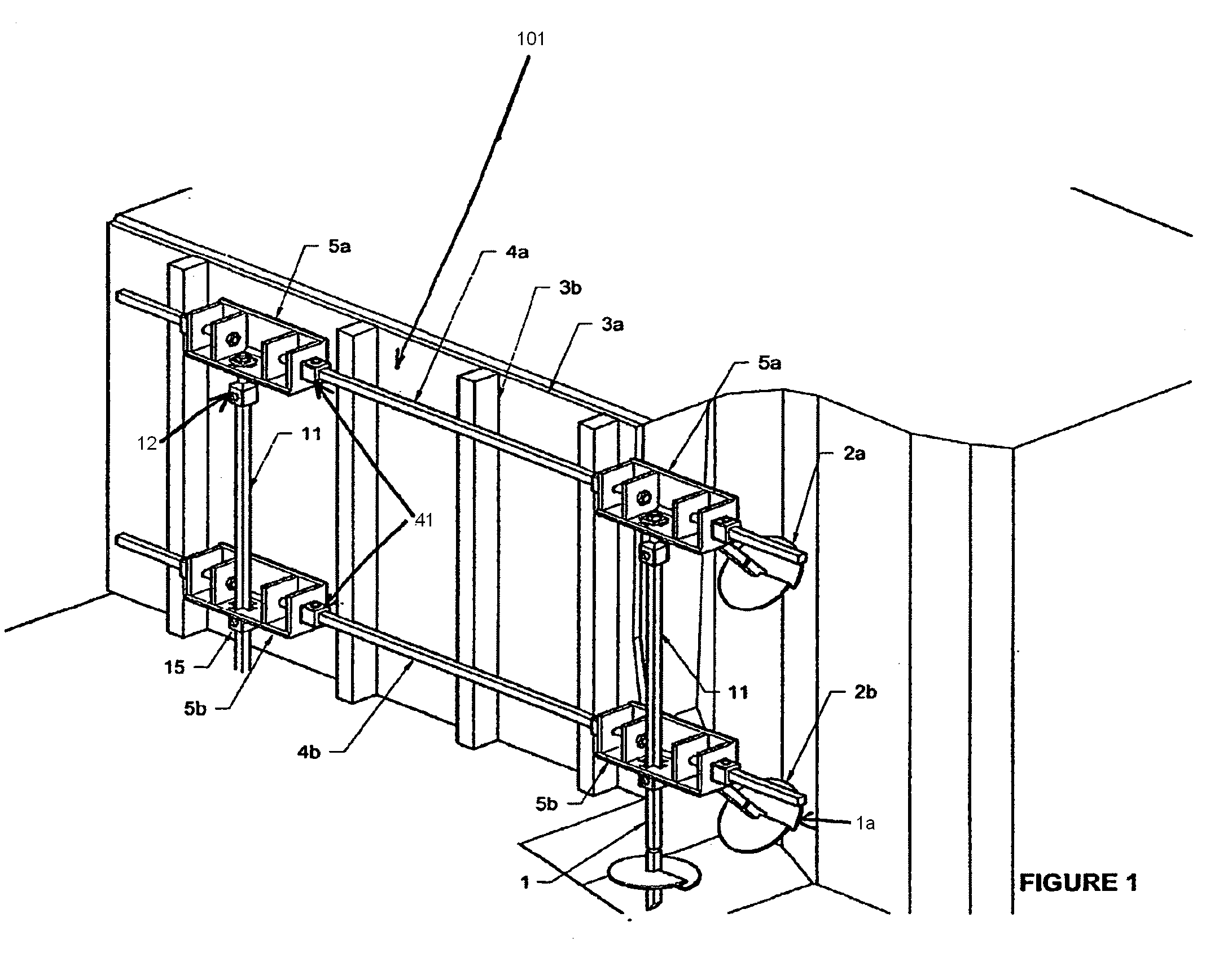

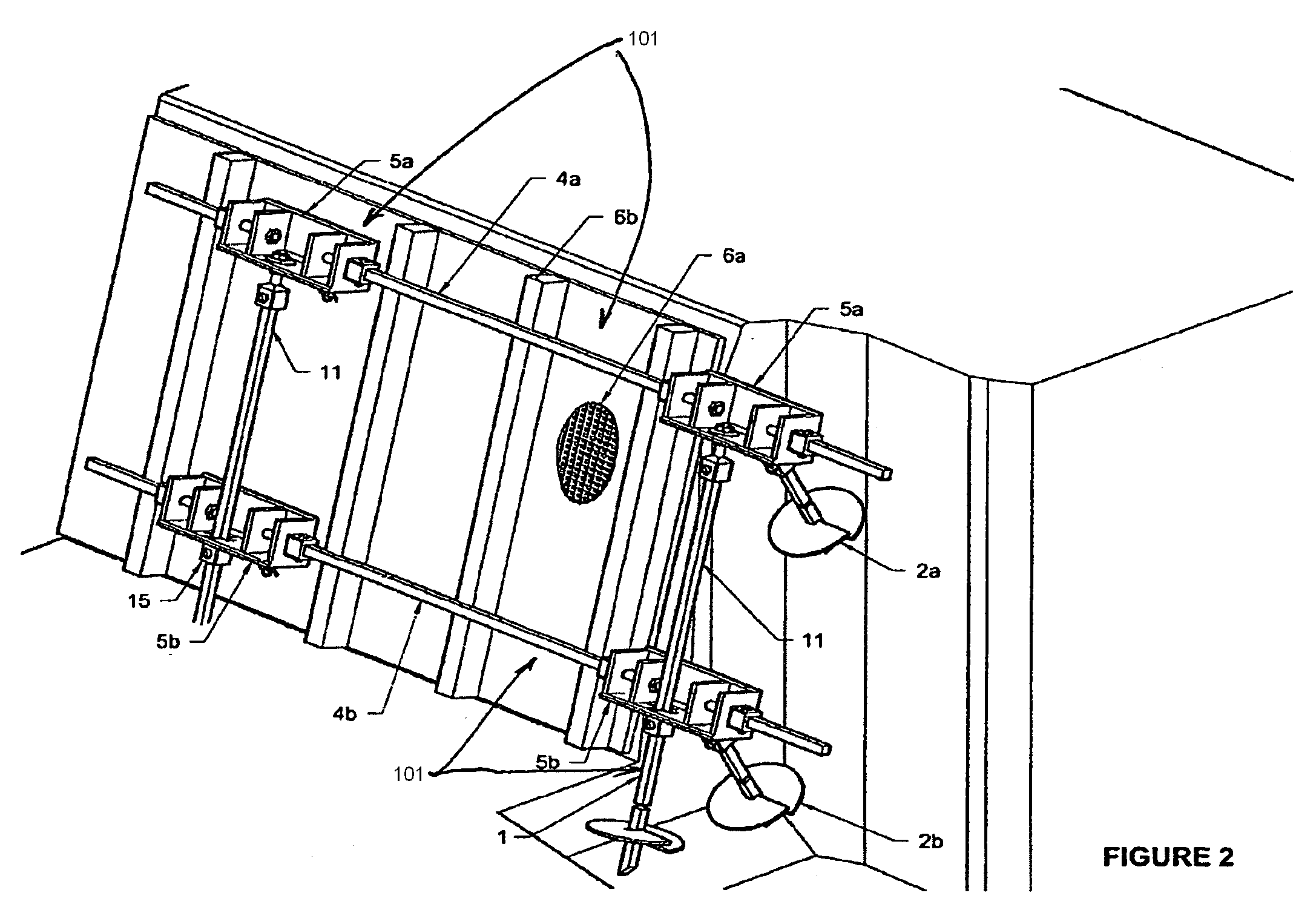

Green retaining wall utilizing helical piers

InactiveUS7677840B2Low costMinimize impactArtificial islandsExcavationsEnvironmental effectEngineering

The present invention provides a system and a method for a retaining wall which minimizes cost, assembly time and environmental impact while providing substantial load-bearing capacity. The system includes: a plurality of vertical helical piers driven into the ground, tie-back helical piers driven at a non-vertical angle into the ground, substantially horizontal waler rods, and substantially vertical extensions, which are interconnected through interlocking connectors. Multiple levels of the load-bearing structure can be built on top of each other depending on the height of the soil to be retained. Loads from the retained soil may be transferred to the extension bars and waler rods through wood lagging, wood planks, different types of plates, or some other intermediary. A mesh support for the soil can be provided in addition to the load-bearing structure. Trees, bushes or other plants can be planted through the mesh in the retained soil to improve the environmental impact of the invention.

Owner:RABICHEV VAL +1

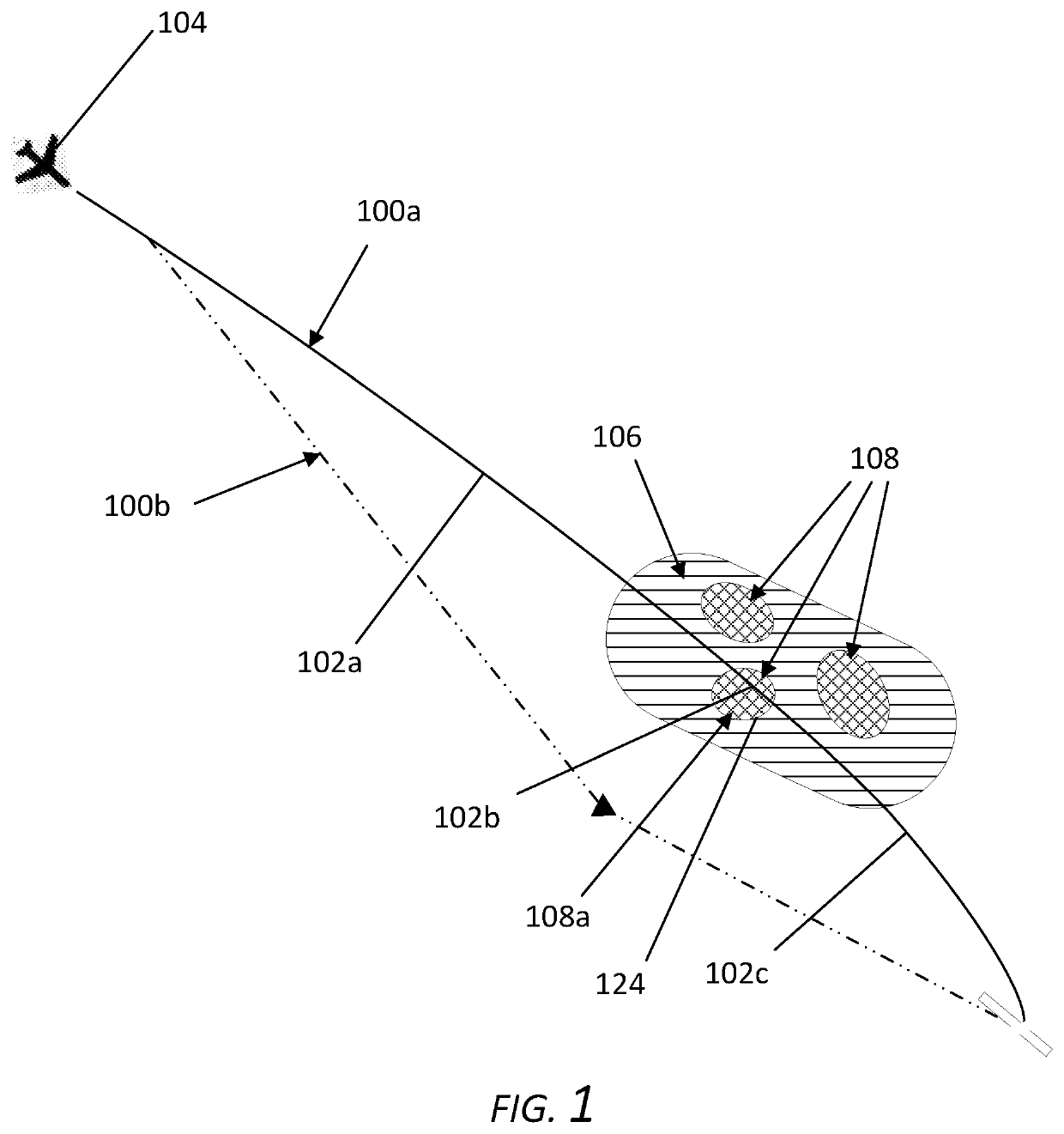

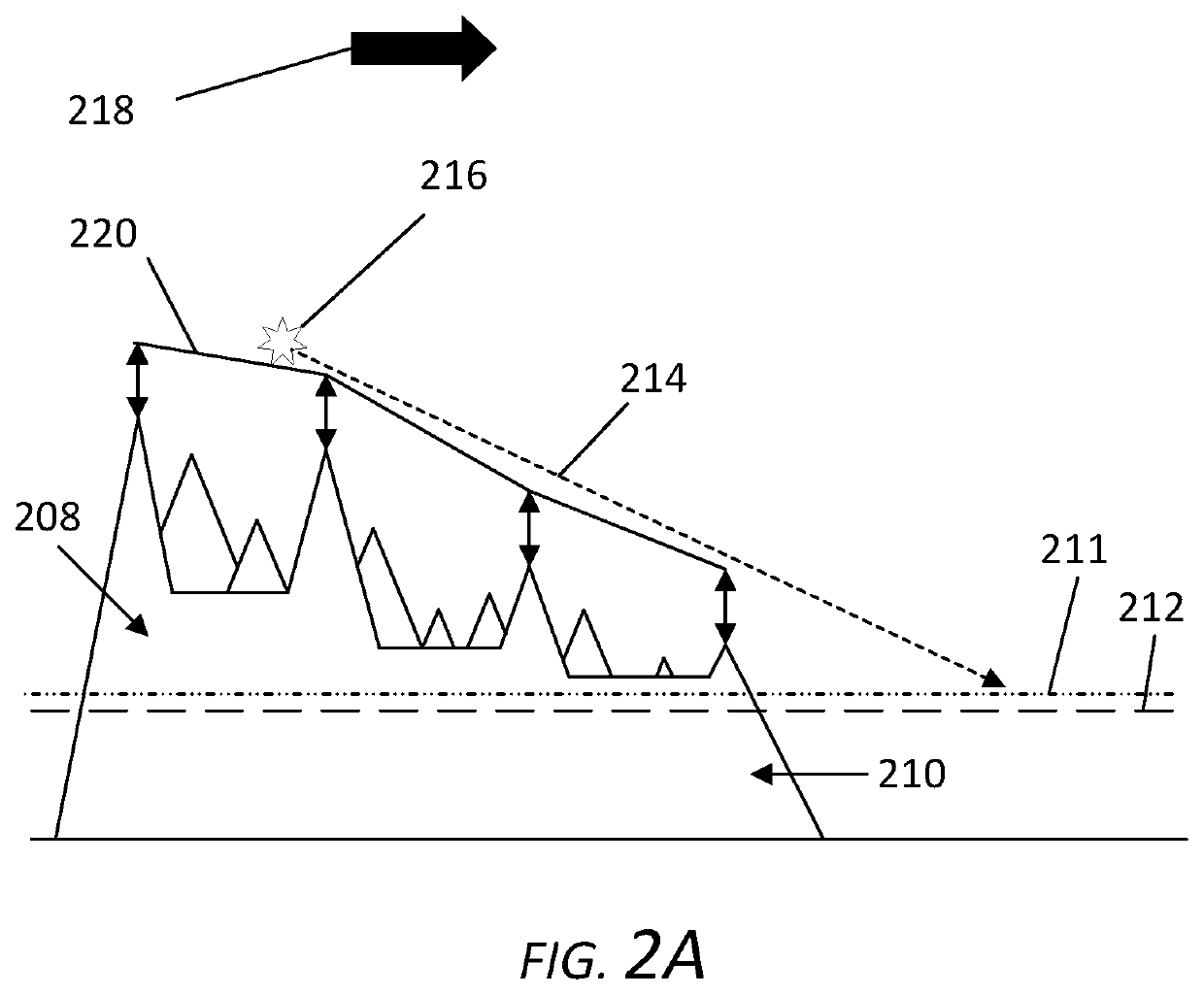

Efficient flight planning for regions with high elevation terrain

ActiveUS20210358312A1Reduce riskLess availabilityFlight plan managementAutomatic aircraft landing aidsFlight vehicleFlight zone

Certain aspects of the present disclosure provide a method for determining a flight plan for an aircraft, including: determining one or more regions that intersect an initial flight path and comprise at least one terrain feature having an elevation greater than an elevation threshold; for each respective region: determining a flight area based on the initial flight path and an elevation threshold line; determining one or more segments of the initial flight path that comprise one or more terrain features having an elevation greater than the elevation threshold; and determining a modified flight path for each respective segment by: determining a plurality of descent gradients along the respective segment; and moving the respective segment of the initial flight path in the safe descent direction if any of the plurality of descent gradients would collide with any of the one or more terrain features.

Owner:THE BOEING CO

Green Retaining Wall Utilizing Helical Piers

InactiveUS20090202309A1Low costMinimize impactArtificial islandsExcavationsEnvironmental effectEngineering

The present invention provides a system and a method for a retaining wall which minimizes cost, assembly time and environmental impact while providing substantial load-bearing capacity. The system includes: a plurality of vertical helical piers driven into the ground, tie-back helical piers driven at a non-vertical angle into the ground, substantially horizontal waler rods, and substantially vertical extensions, which are interconnected through interlocking connectors. Multiple levels of the load-bearing structure can be built on top of each other depending on the height of the soil to be retained. Loads from the retained soil may be transferred to the extension bars and waler rods through wood lagging, wood planks, different types of plates, or some other intermediary. A mesh support for the soil can be provided in addition to the load-bearing structure. Trees, bushes or other plants can be planted through the mesh in the retained soil to improve the environmental impact of the invention.

Owner:RABICHEV VAL +1

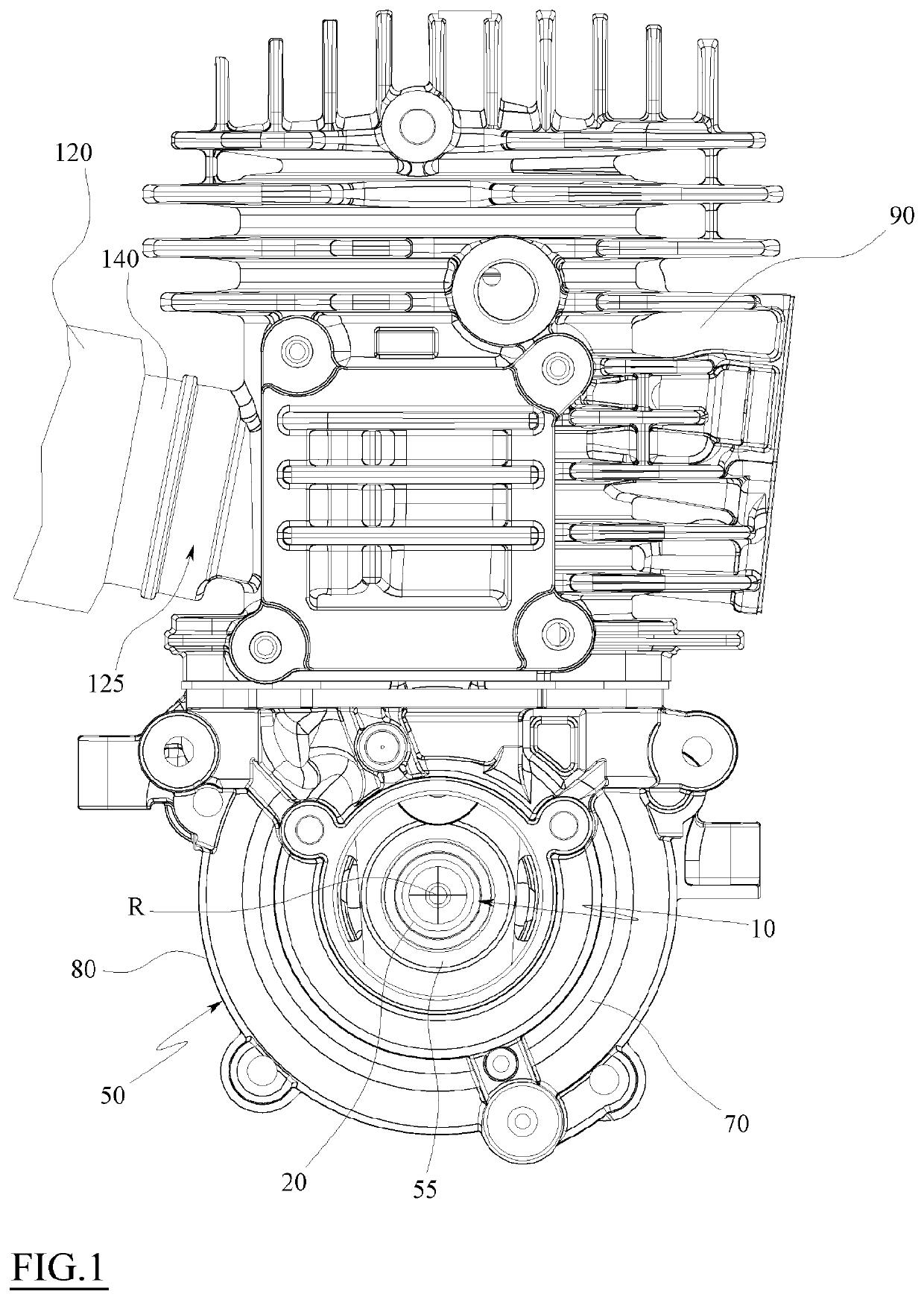

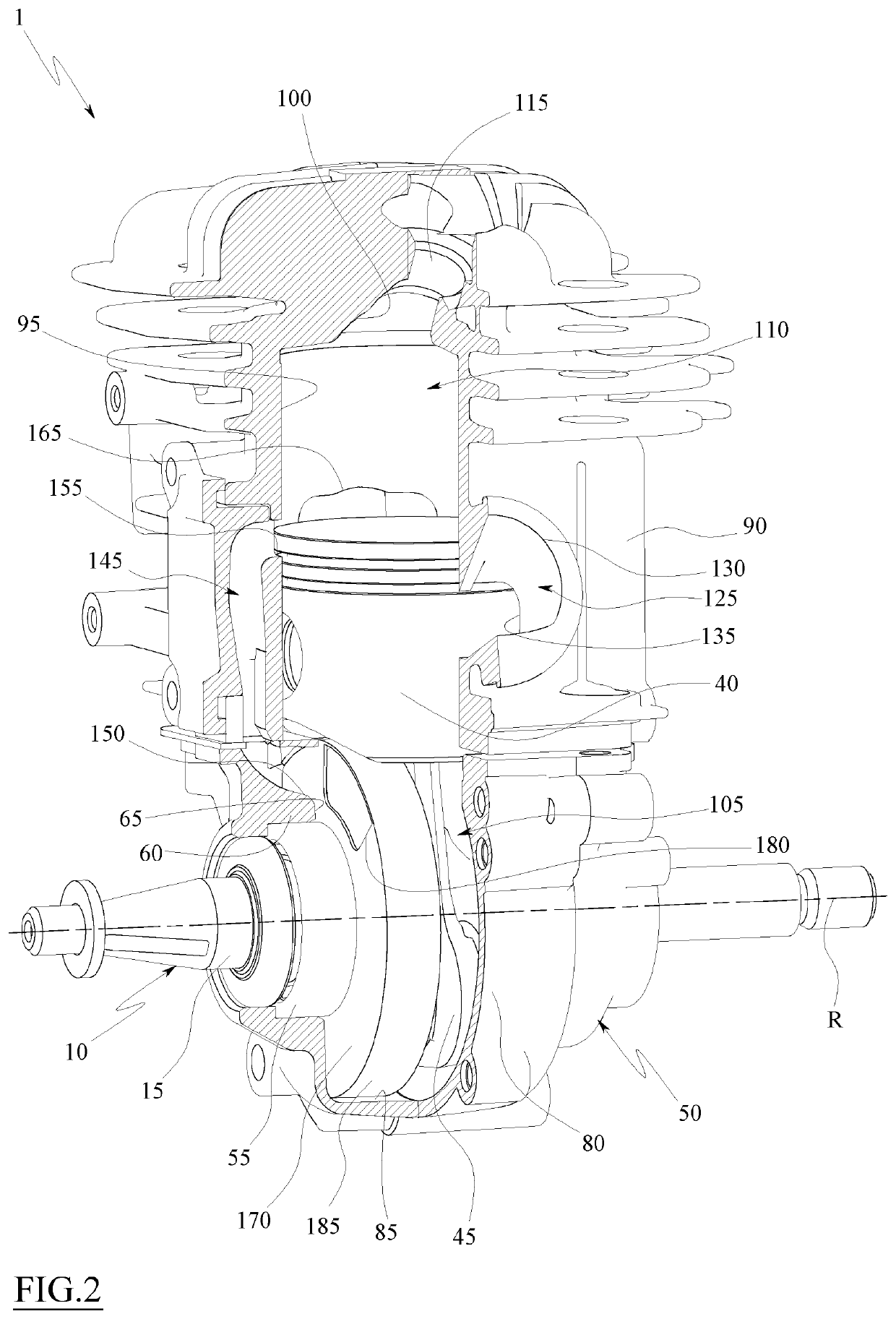

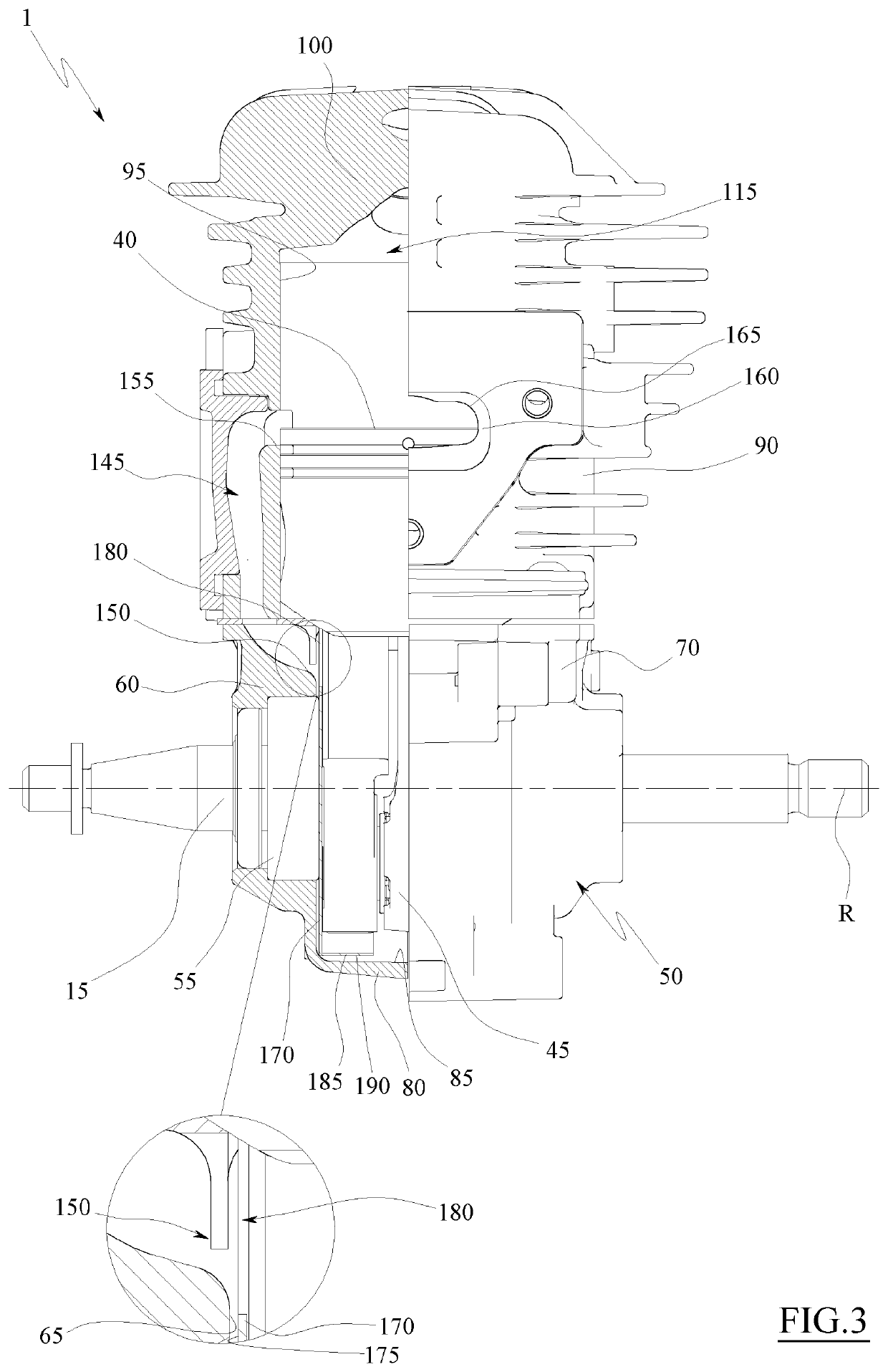

Two-stroke internal combustion engine

ActiveUS20220065159A1Improve environmental impactReduce consumptionCombustion enginesRotary slide valveCombustion chamberTop dead center

A two-stroke internal combustion engine includes:—a base;—a head, fixed to the base, and having a cylindrical cavity;—a piston slidable in the cylindrical cavity, to define a combustion chamber and a pumping chamber, and movable in the cylindrical cavity between a bottom and a top dead center;—a transfer duct having an inlet mouth in fluid communication with the pumping chamber, and an outlet mouth in fluid communication with the combustion chamber;—an exhaust duct having an inlet mouth in fluid communication with the combustion chamber,—a crank shaft partially housed in the pumping chamber;—a connecting rod connecting the piston to the crank shaft;—a movable partition housed inside the pumping chamber operatively connected to the crank shaft to occlude the transfer duct inlet mouth and to put in fluid communication the transfer duct inlet mouth with the pumping chamber.

Owner:EMAK

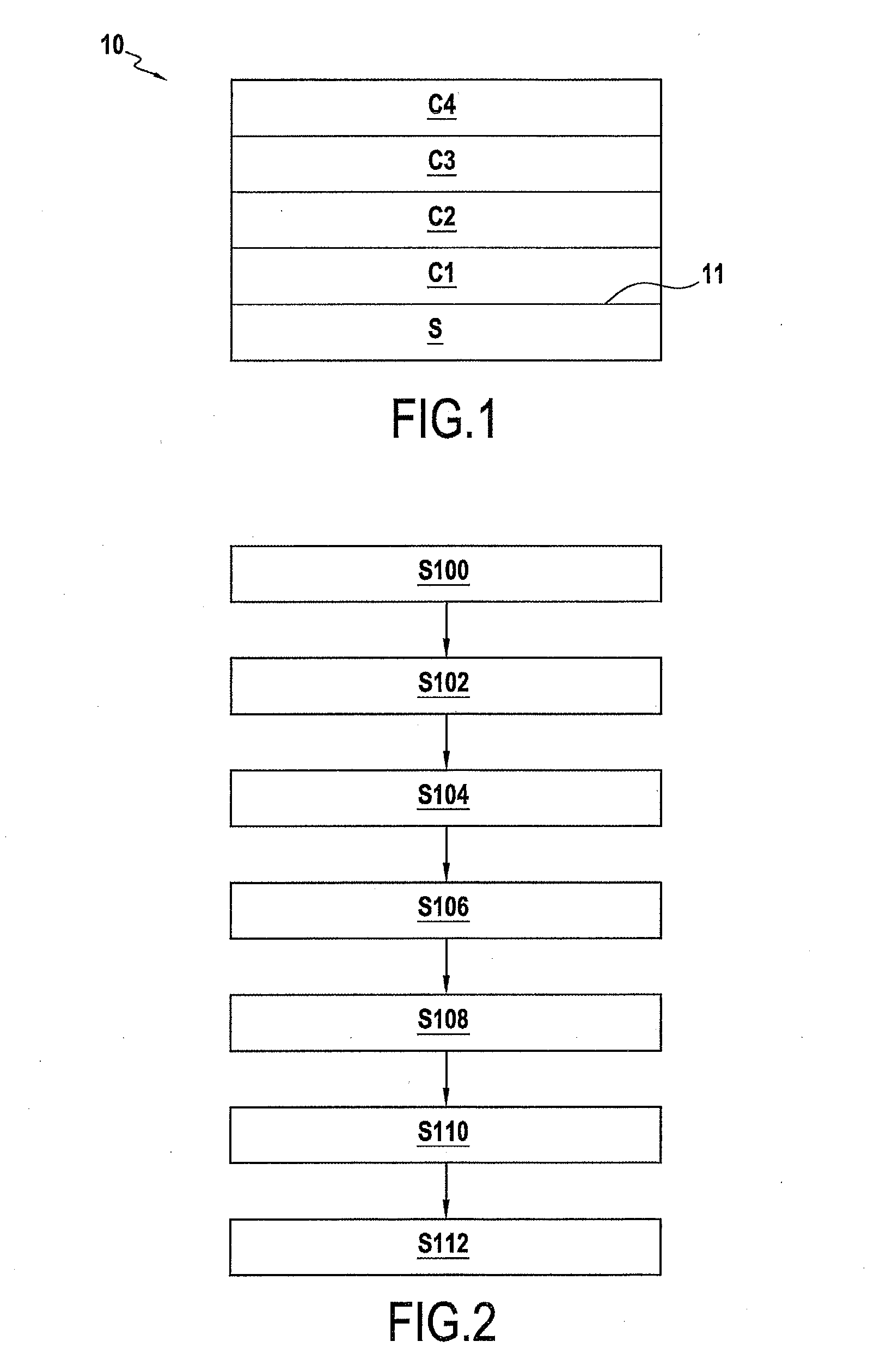

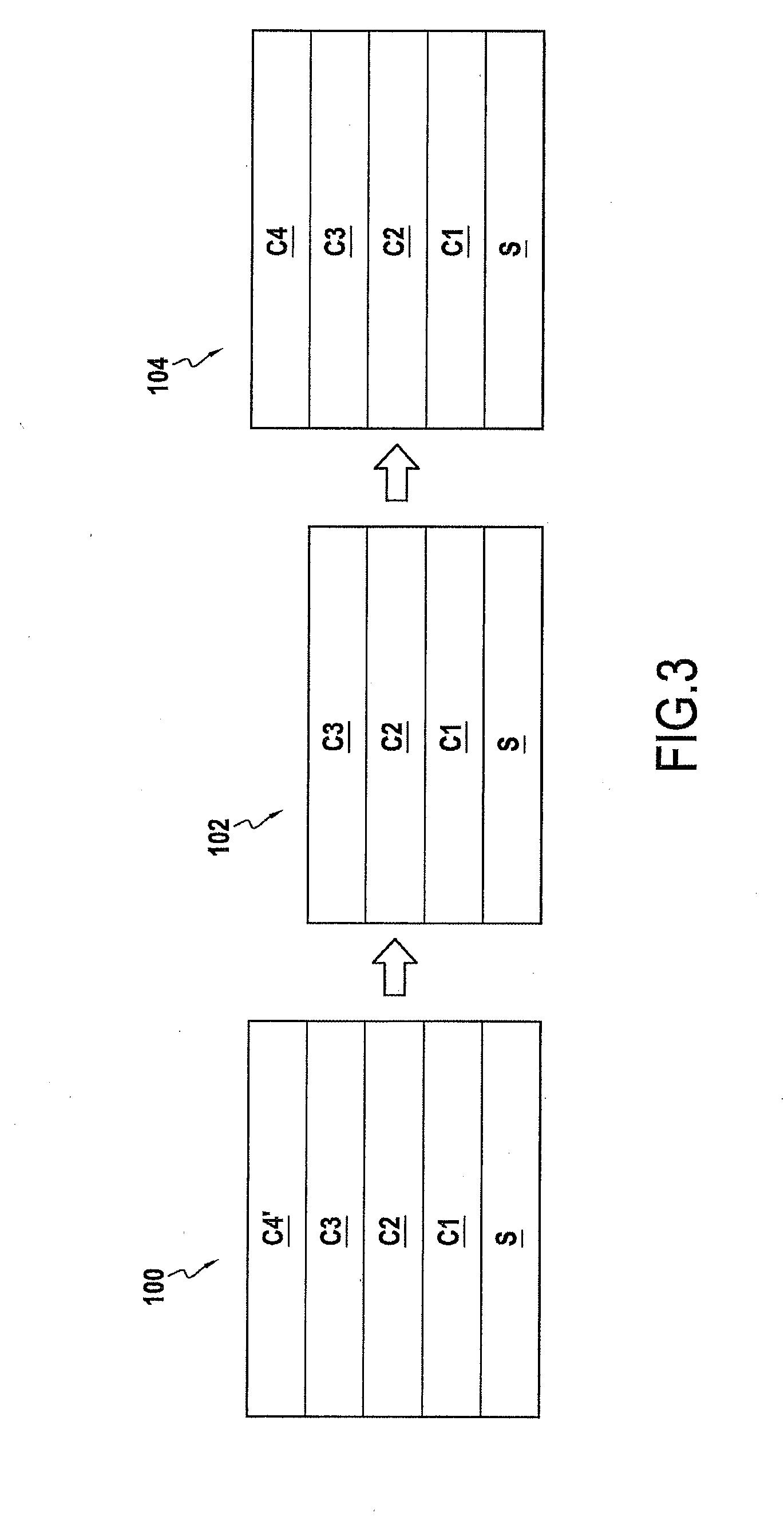

Method for varnishing plated parts

InactiveUS20160122893A1Reduce riskLower temperature rangeElectrolytic inorganic material coatingElectrophoretic coatingsUltraviolet radiationOptoelectronics

A method is provided for plating a non-metal substrate (S), allowing a plated part to be obtained. The method includes steps of: (a) providing a non-metal substrate (S) having a surface (11); (b) forming a bonding layer (C1) on the surface (11); (c) forming at least one reinforcement layer (C2) on the bonding layer (C1); (d) forming a varnish layer (C4) above the reinforcement layer (C2); and performing a drying step to dry the varnish layer, wherein the varnish layer is exposed to ultraviolet radiation.

Owner:DOURDIN

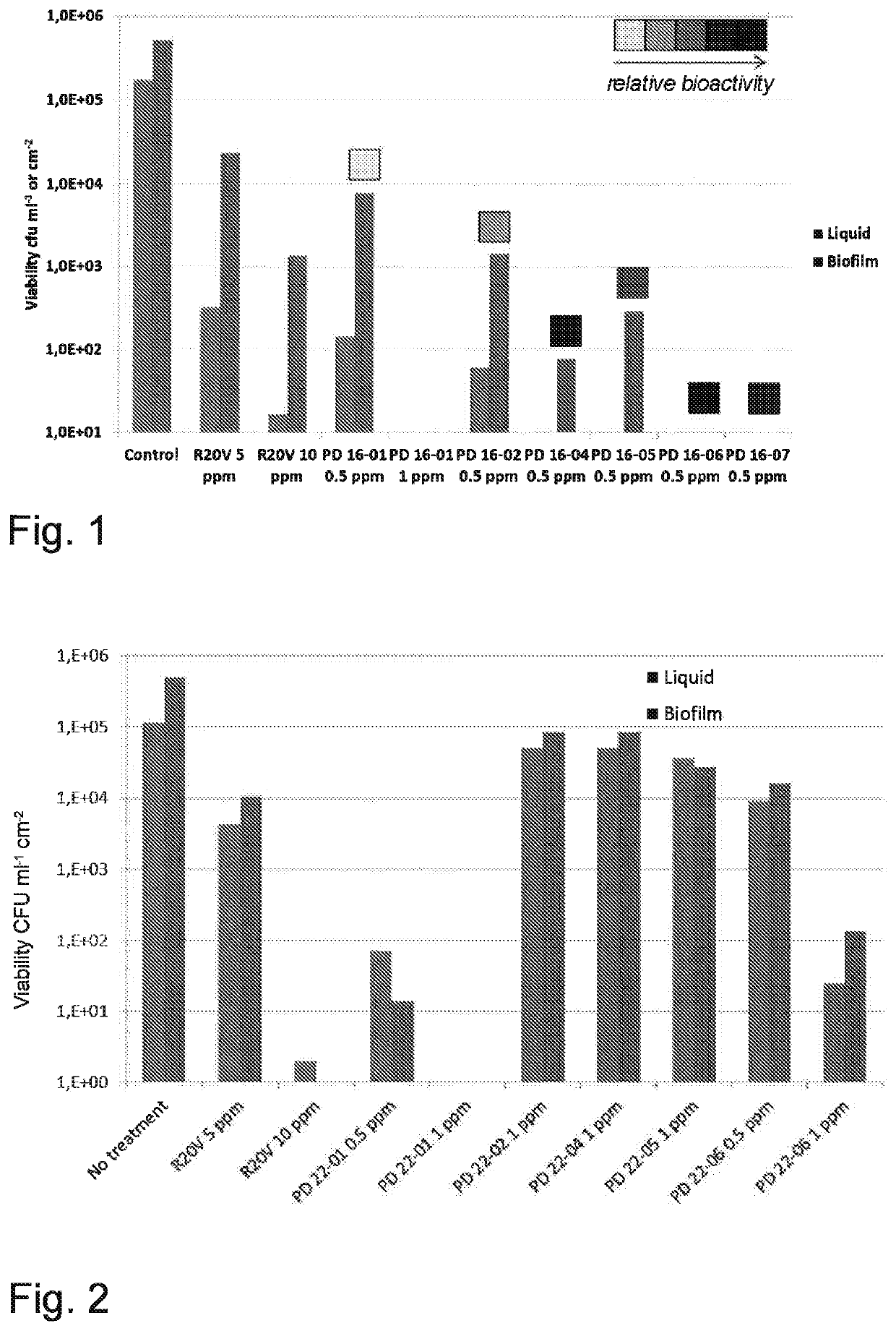

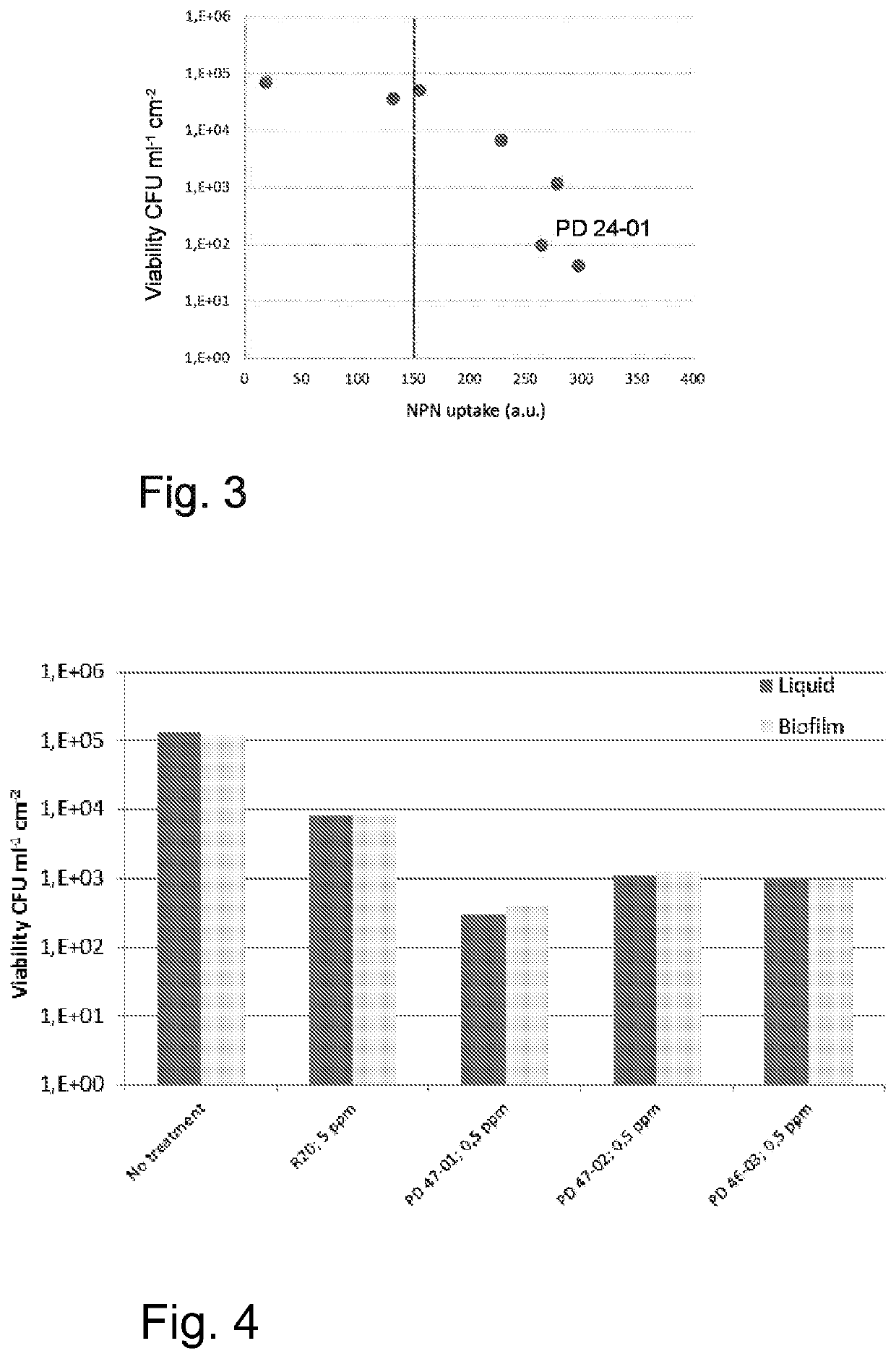

Biocide formulation and method for treating water

ActiveUS10912296B2Reduce health risksReduce the valueBiocideWater treatment compoundsBiofilmMicroorganism

The present invention provides a biocide formulation comprising a biocide in a micelle, wherein the micelle comprises a block copolymer having a biocide-solubilizing part and a water-soluble part, and a quaternary ammonium stabilizing compound. The present invention also provides a method for controlling microorganisms by eliminating and / or preventing biofilm formation in an aqueous environment.

Owner:KEMIRA OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com