Method for varnishing plated parts

a technology of chromium plated parts and varnishing, which is applied in the direction of electrolytic coatings, electrolytic inorganic material coatings, liquid/solution decomposition chemical coatings, etc. it can solve the problems of difficult industrial application, difficult to achieve the effect of reducing the risk of deterioration of non-metal substrates, and relatively expensive methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

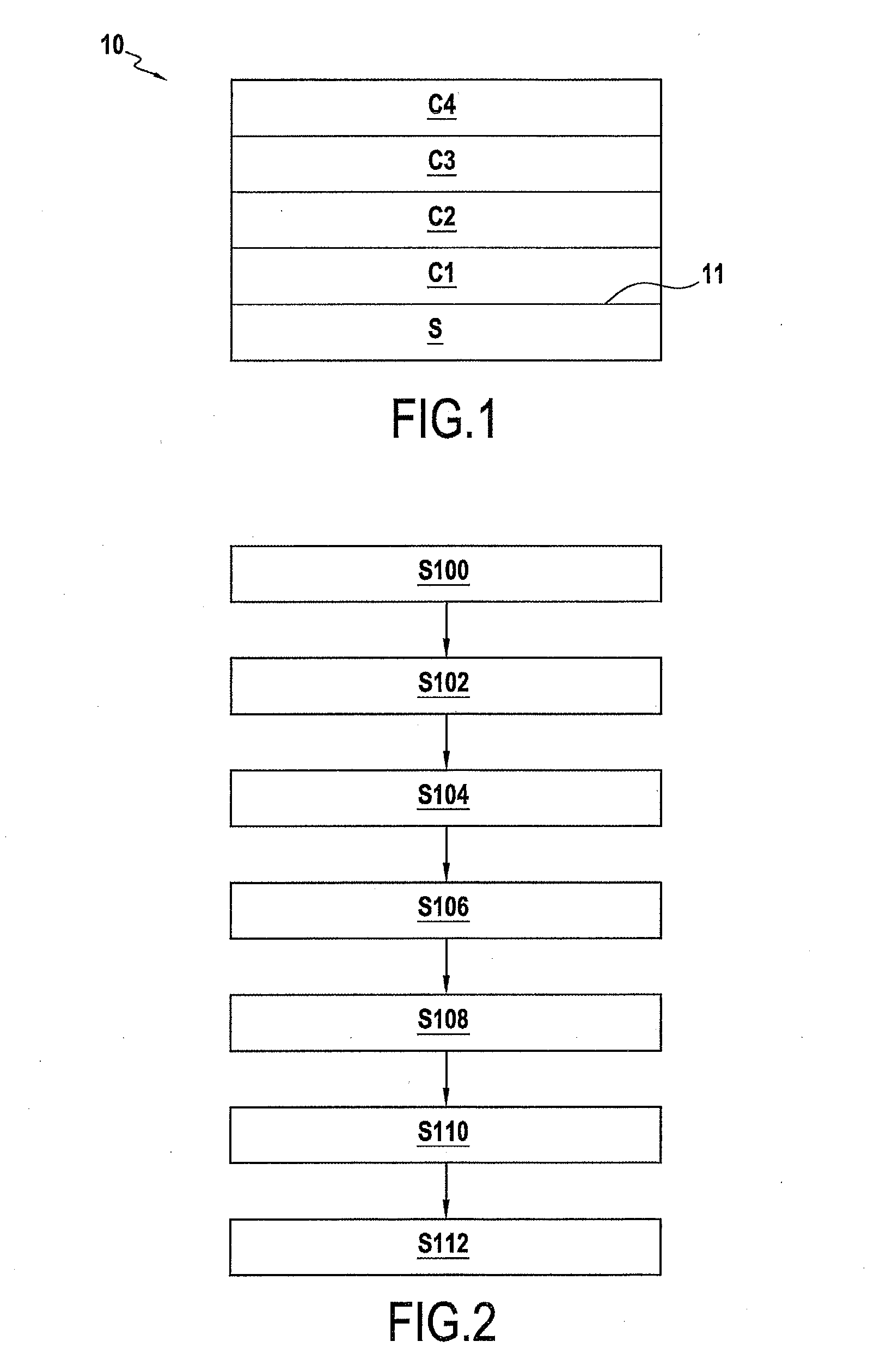

[0055]FIG. 1 schematically illustrates a plated part 10 free of chromium conforming to the invention. This part comprises a non-metal substrate S on which layers C1 to C4 will be deposited. The non-metal substrate S has a surface 11.

[0056]In this example, the non-metal substrate S is a part in plastic material. In this example, the substrate consists of ABS (Acrylonitrile Butadiene Styrene) which has good mechanical strength and corrosion resistance. In one variant, a copolymer is used comprising acrylonitrile butadiene styrene and a polycarbonate.

[0057]In addition, in another example, the metal substrate can composed of a polyamide.

[0058]In another variant, the non-metal substrate S comprises polypropylene.

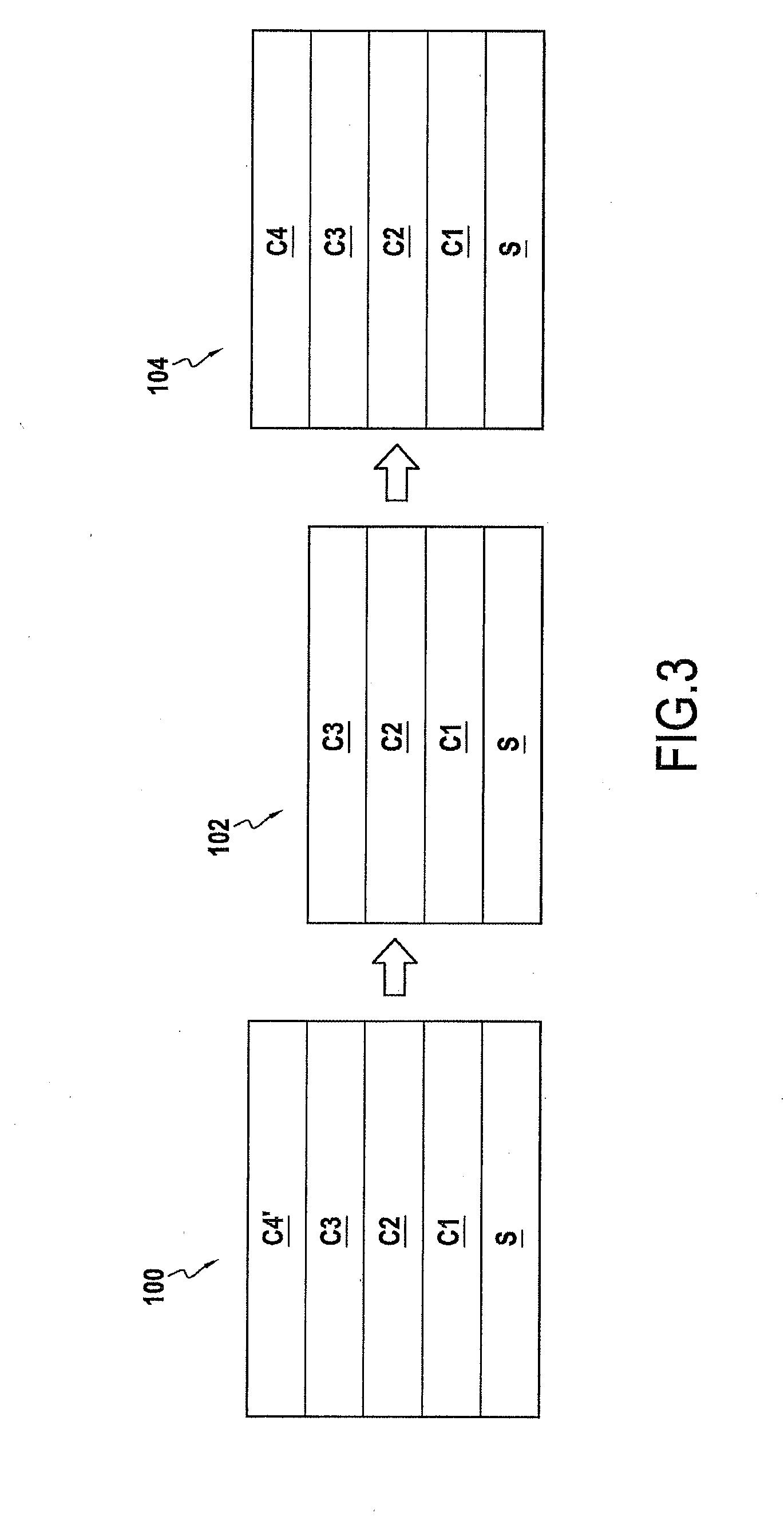

[0059]In FIG. 2, a first step S100 is the step at which the substrate S in plastic material receives chemical treatment on its surface 11 to obtain roughness of said surface 11.

[0060]In this example, the chemical attack of the surface 11 of a part containing an acrylonitrile buta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com