Patents

Literature

92results about "Working-up pitch/asphalt/bitumen by mixing fractions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfur-in-oil in asphalt and polymer composition and process

InactiveUS6133351AImprove liquidityImprove permeabilityIn situ pavingsWorking-up pitch/asphalt/bitumen by mixing fractionsSulfurSlurry

A sulfur in oil in asphalt and polymer blend is disclosed. An asphalt and polymer blend is first prepared and then a slurry of solid sulfur in liquid oil added. Addition of a slurry of solid sulfur in oil or oil containing sulfur compounds, permits rapid and effective uniform dispersion of the sulfur component in the asphalt / polymer blend. Uneven mixing, which can occur when sulfur is separately added as a solid to the asphalt blend, is avoided. Polymer use is optimized because polymer matrix development (digestion / swelling) can be completed before cross-linking occurs. The method is safer because formation of explosive clouds of sulfur dust is avoided.

Owner:MARATHON PETROLEUM

Method for recycling waste FCC (fluid catalytic cracking) catalyst

InactiveCN104479712AMaximize the use of resourcesMaximize utilizationWorking-up pitch/asphalt/bitumen by mixing fractionsSolid waste disposalBituminous materialsLarge particle

The invention relates to a method for recycling a waste FCC (fluid catalytic cracking) catalyst. The specific method is as follows: screening the waste FCC catalyst, wherein the waste FCC catalyst with the particle size of more than 40 mu m is used as a fine aggregate or filler in an asphalt mixture, and the waste FCC catalyst with the particle size of less than 40 mu m is used for modifying asphalt. The method provided by the invention has the beneficial effects that 1) the waste FCC catalyst with the particle size of less than 40 mu m is used for preparing the modified asphalt, and the waste FCC catalyst with the large particle size is used as the filler or a coarse aggregate, thereby realizing maximum utilization of the waste FCC catalyst; and 2) after surface treatment of the waste FCC catalyst, the compatibility with the asphalt is improved, and the high-temperature stability, low-temperature anti-cracking property, and the like of the ordinary asphalt material are significantly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

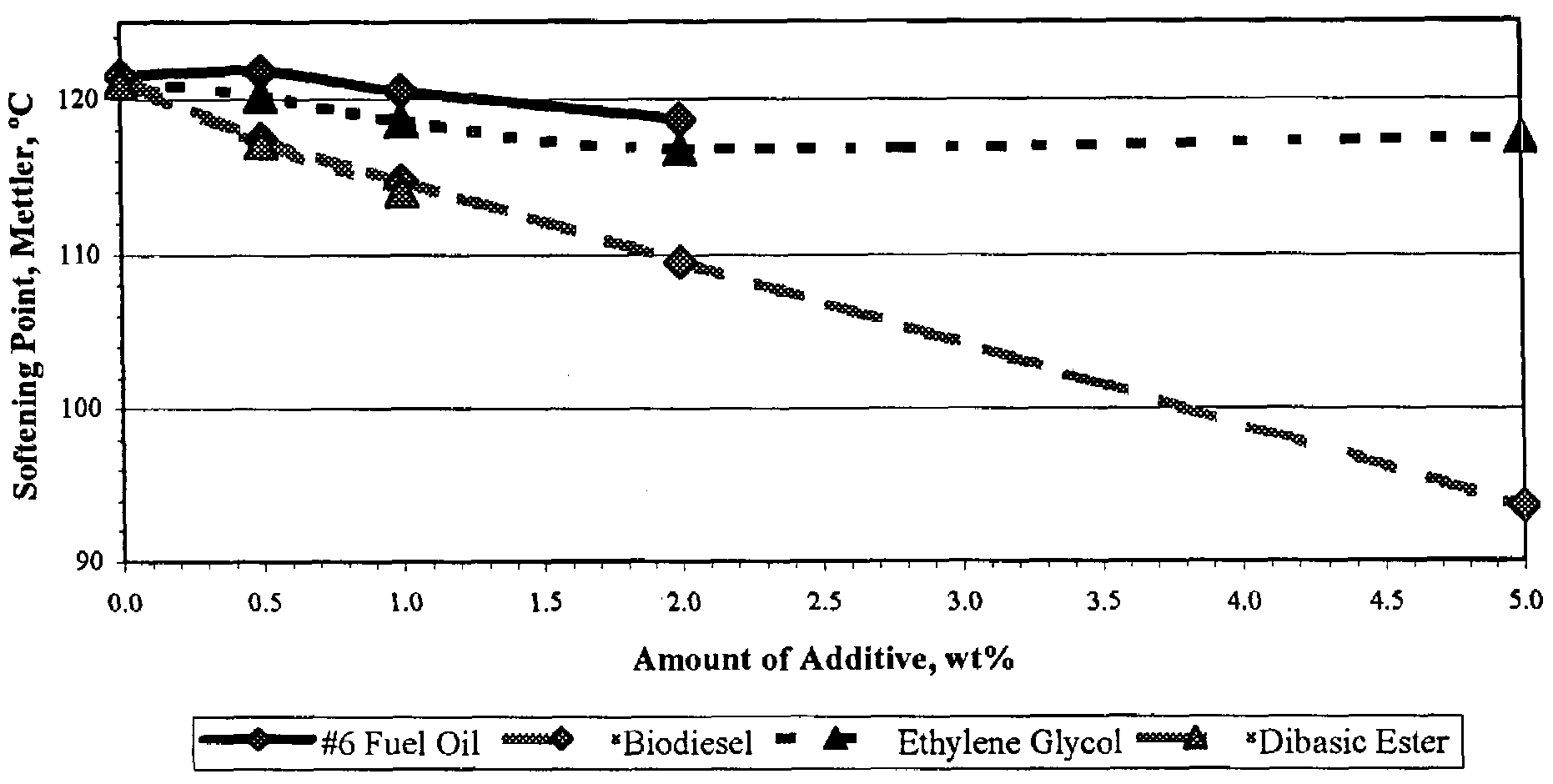

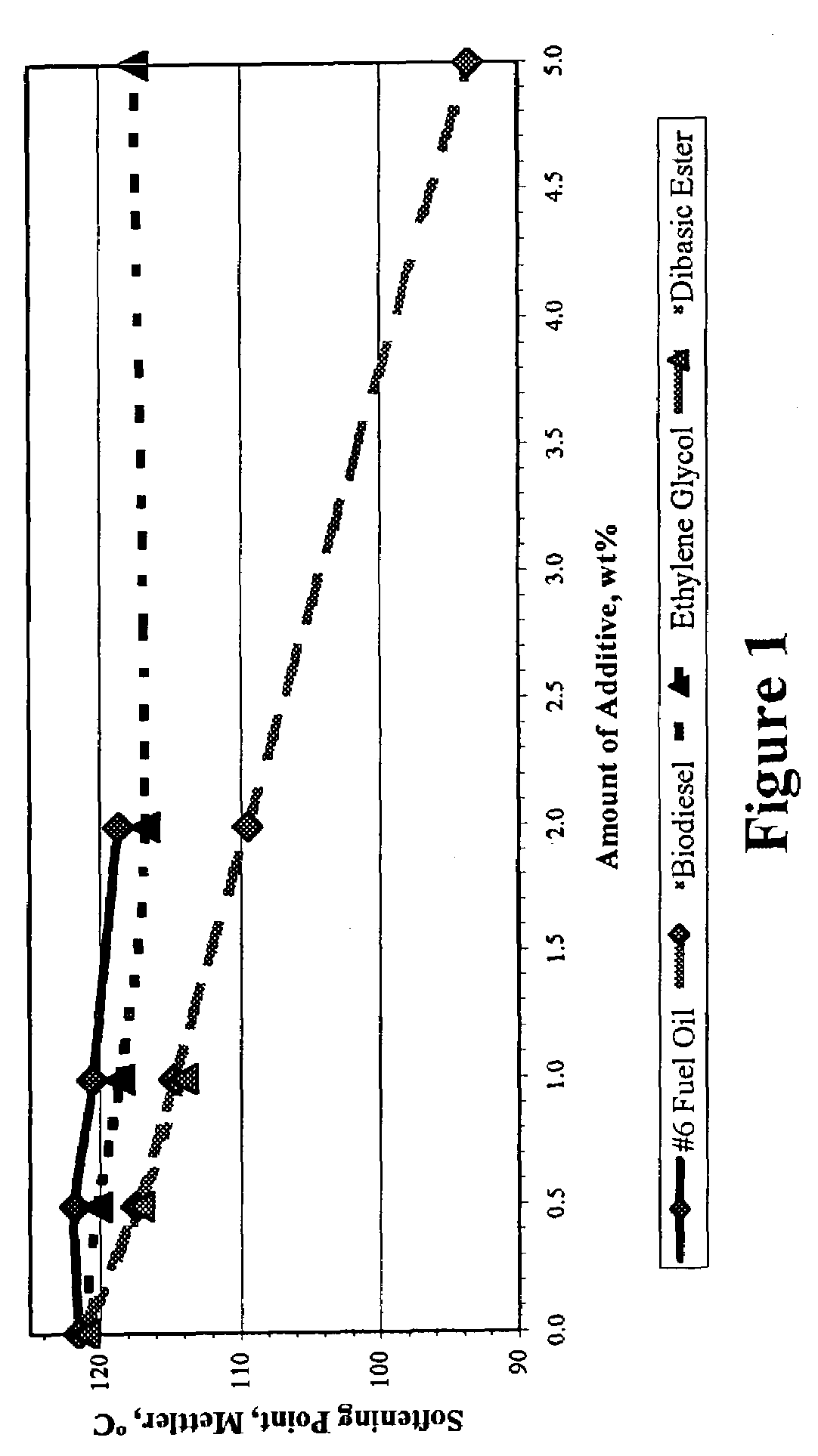

Viscosity modification of heavy hydrocarbons

ActiveUS7252755B2Low viscosityPoint becomes highWorking-up pitch/asphalt/bitumen by mixing fractionsWorking-up pitch/asphalt/bitumen by chemical meansBiodieselViscosity

A low-viscosity, high-softening point heavy hydrocarbon material having a viscosity-reducing amount of at least one biodiesel material dissolved in a heavy hydrocarbon, and a method for producing such low-viscosity, high-softening point heavy hydrocarbon material are disclosed.

Owner:MARATHON PETROLEUM

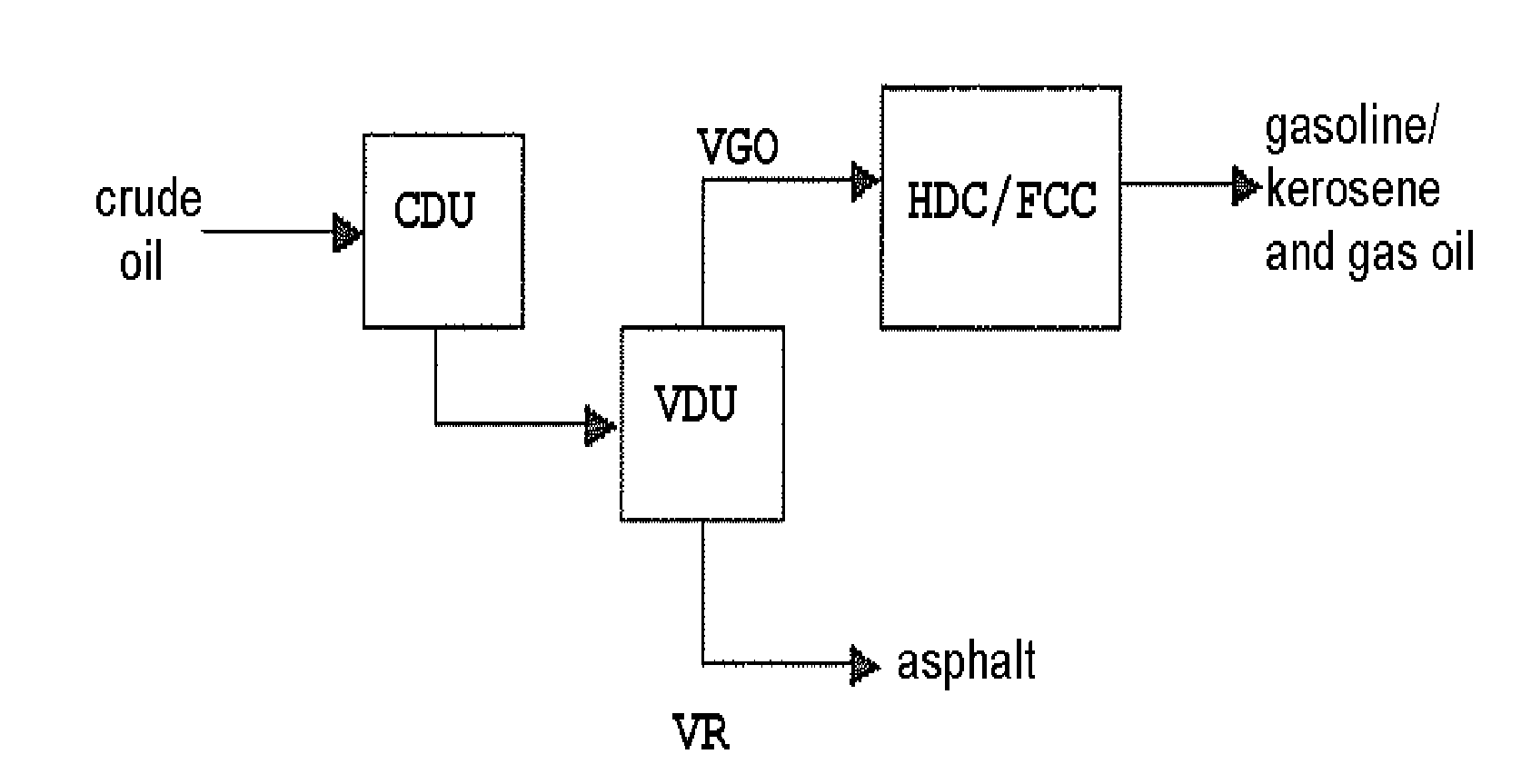

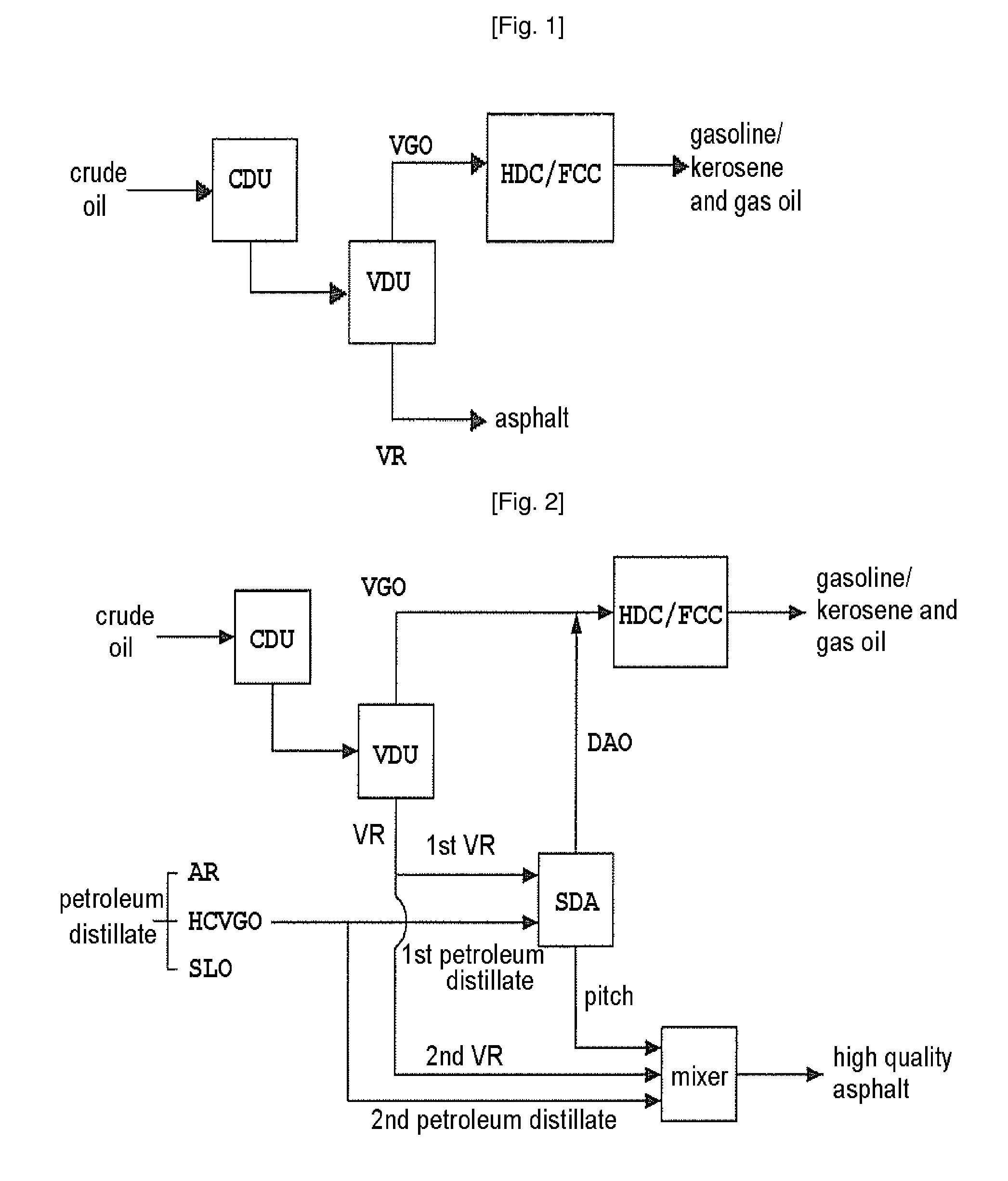

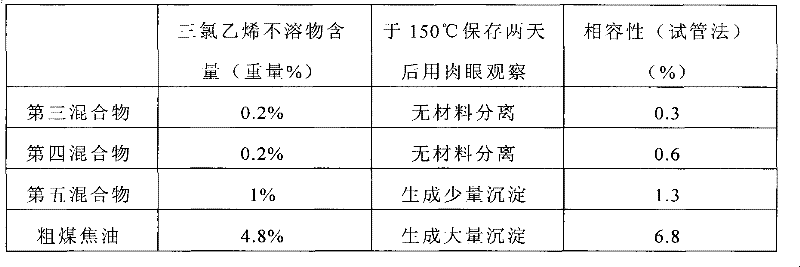

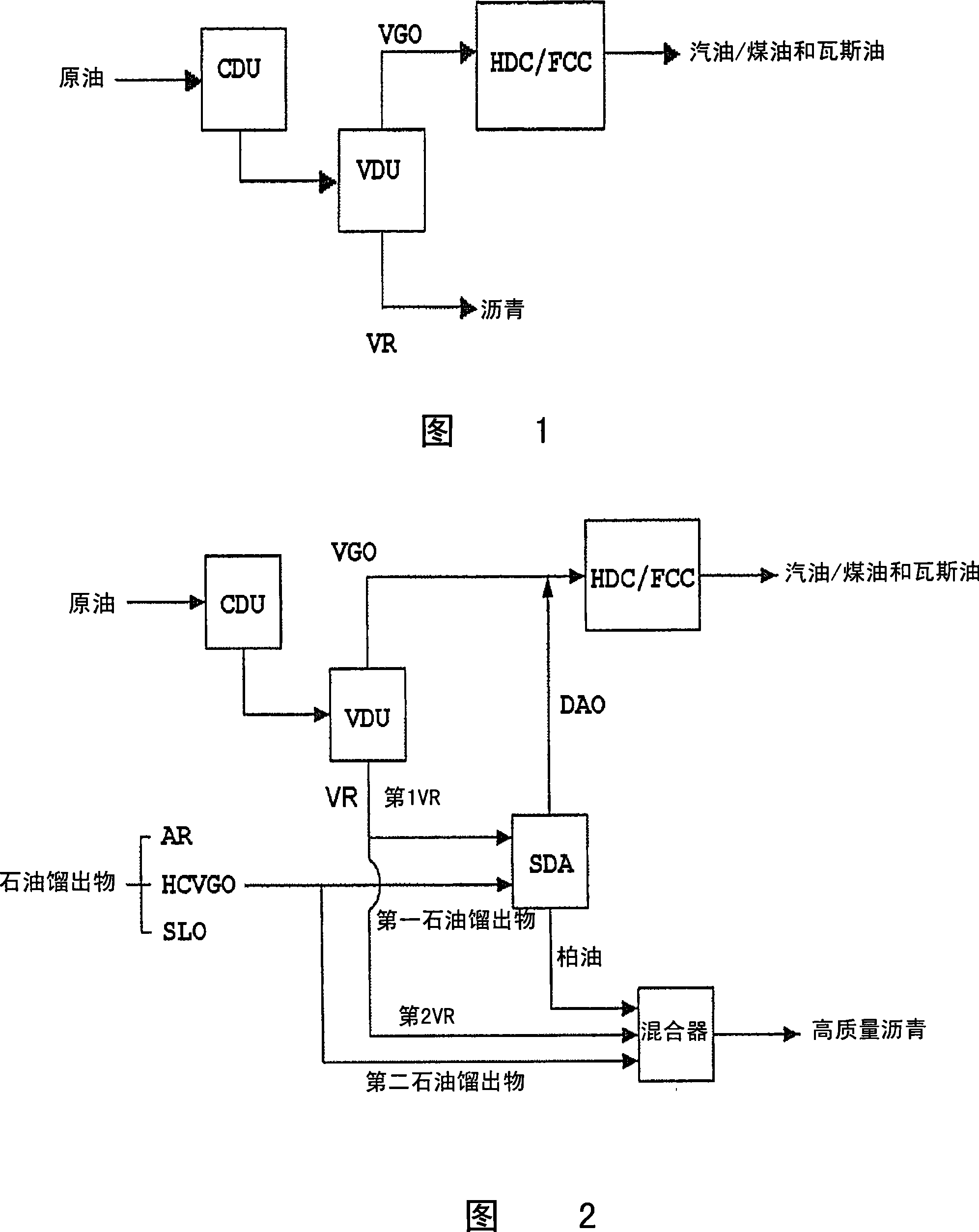

High Quality Asphalt Containing Pitch and Method of Preparing the Same

InactiveUS20080210597A1Quality improvementIncrease contentWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by mixing fractionsSolventPetroleum

A high quality asphalt containing pitch is generated as a by-product in a solvent deasphalting process and a method of preparing the same. The pitch is obtained by subjecting a mixture comprising a first vacuum residue and a first petroleum distillate, which is lighter than the vacuum residue and has high amounts of aromatic and resin, to solvent deasphalting. The operation conditions of the solvent deasphalting process are appropriately controlled, such that aromatic and resin components contained in the atmospheric residue and vacuum residue can be distributed to the pitch, and as well, a saturate can be removed.

Owner:SK INNOVATION CO LTD 50 ASSIGNMENT

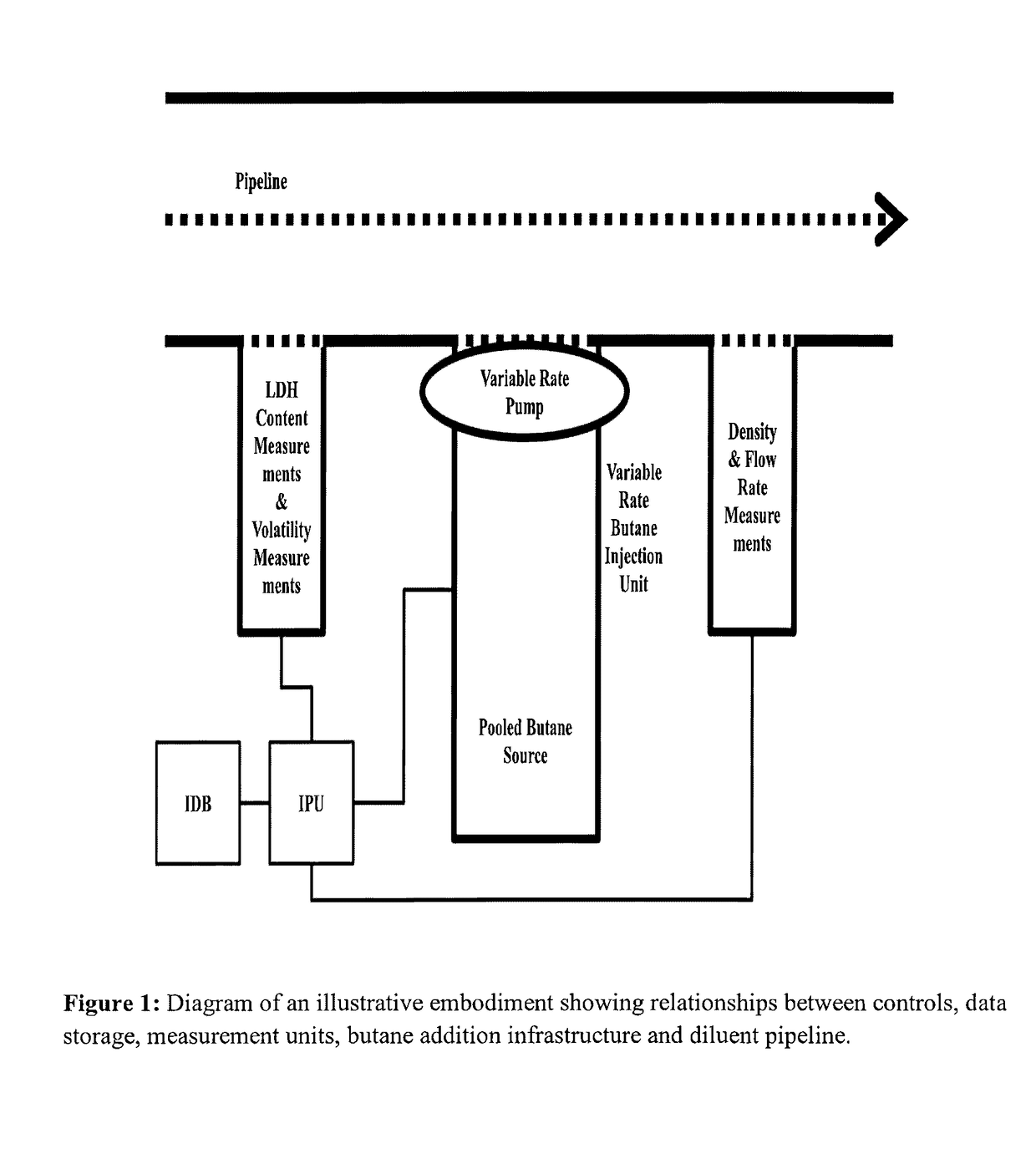

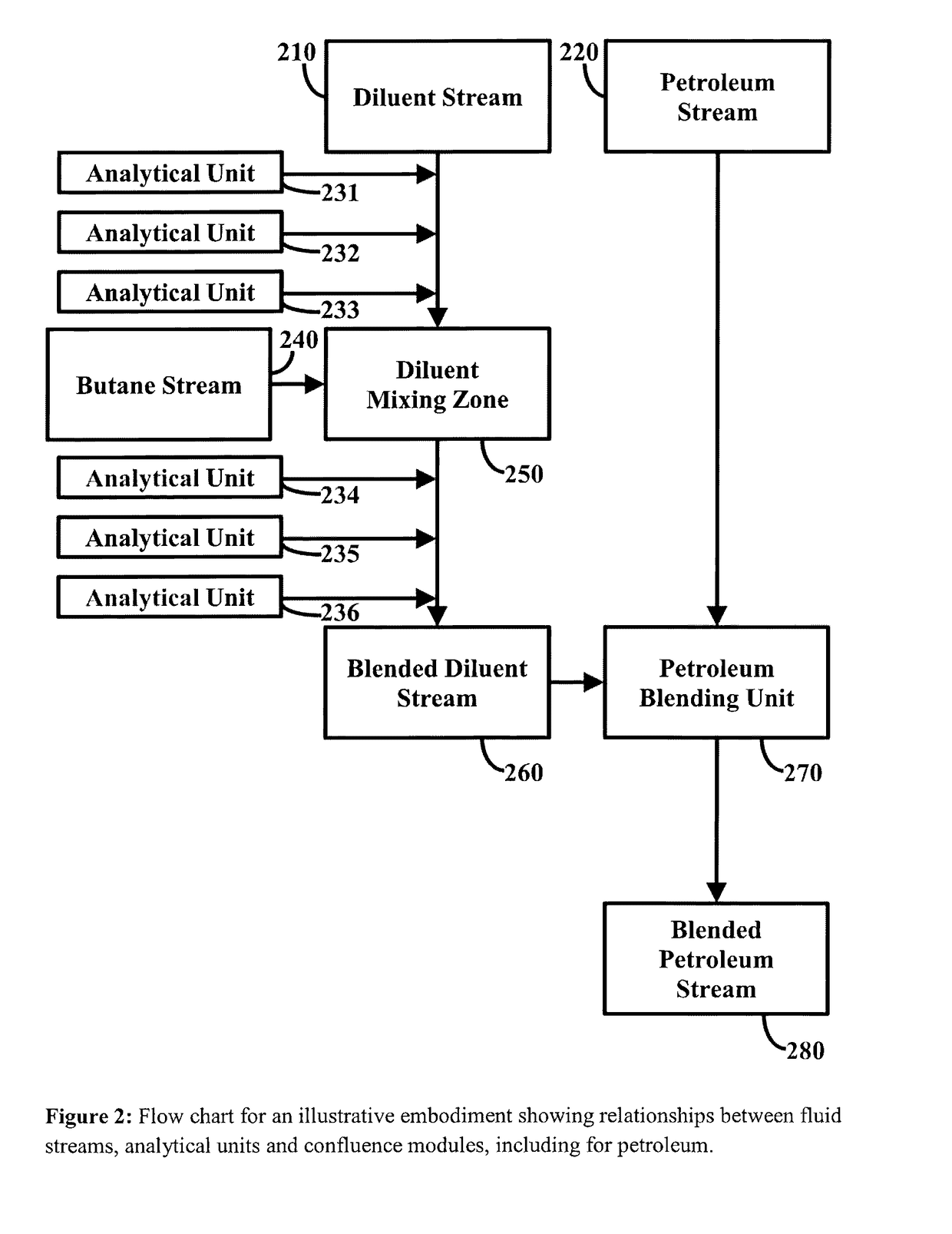

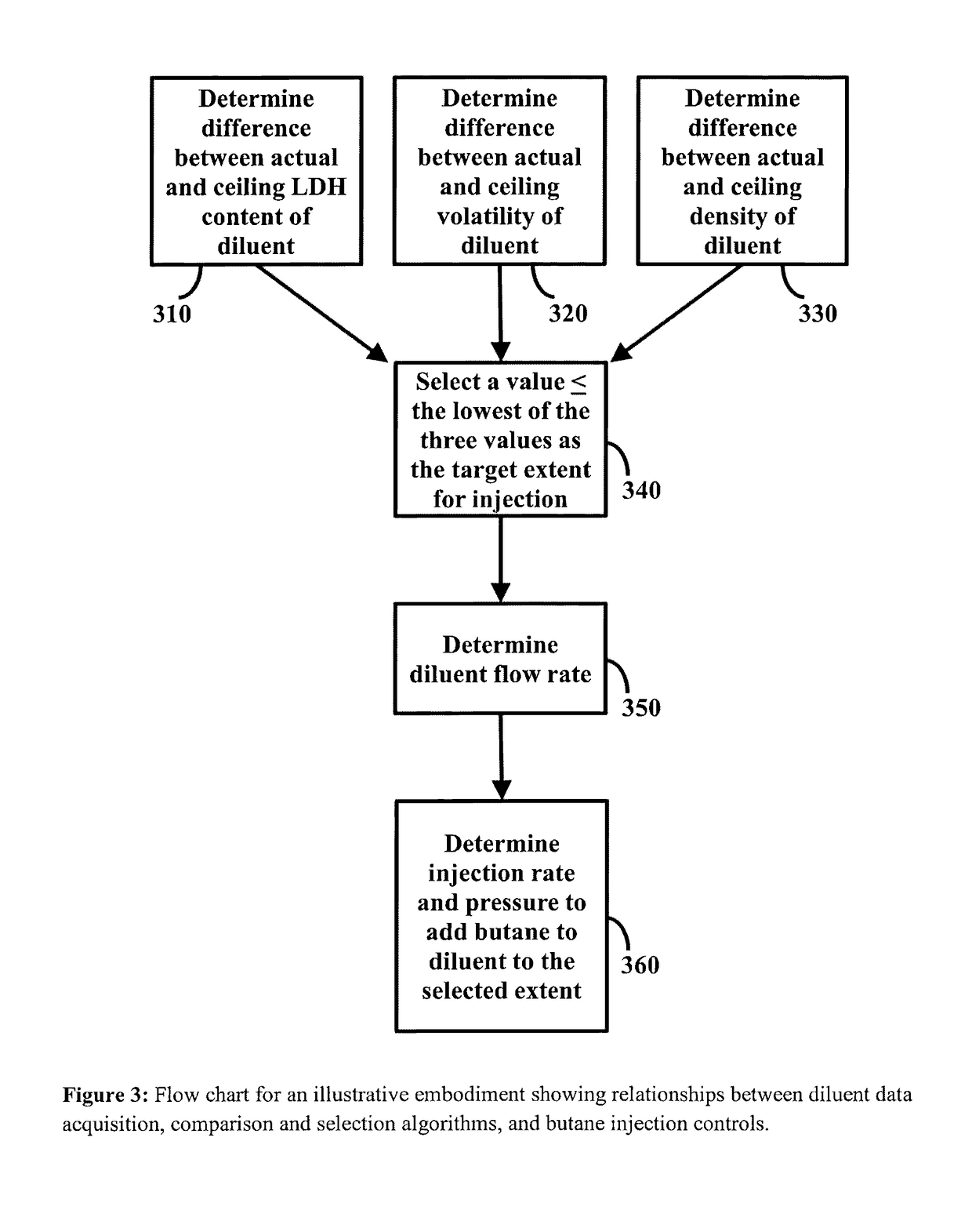

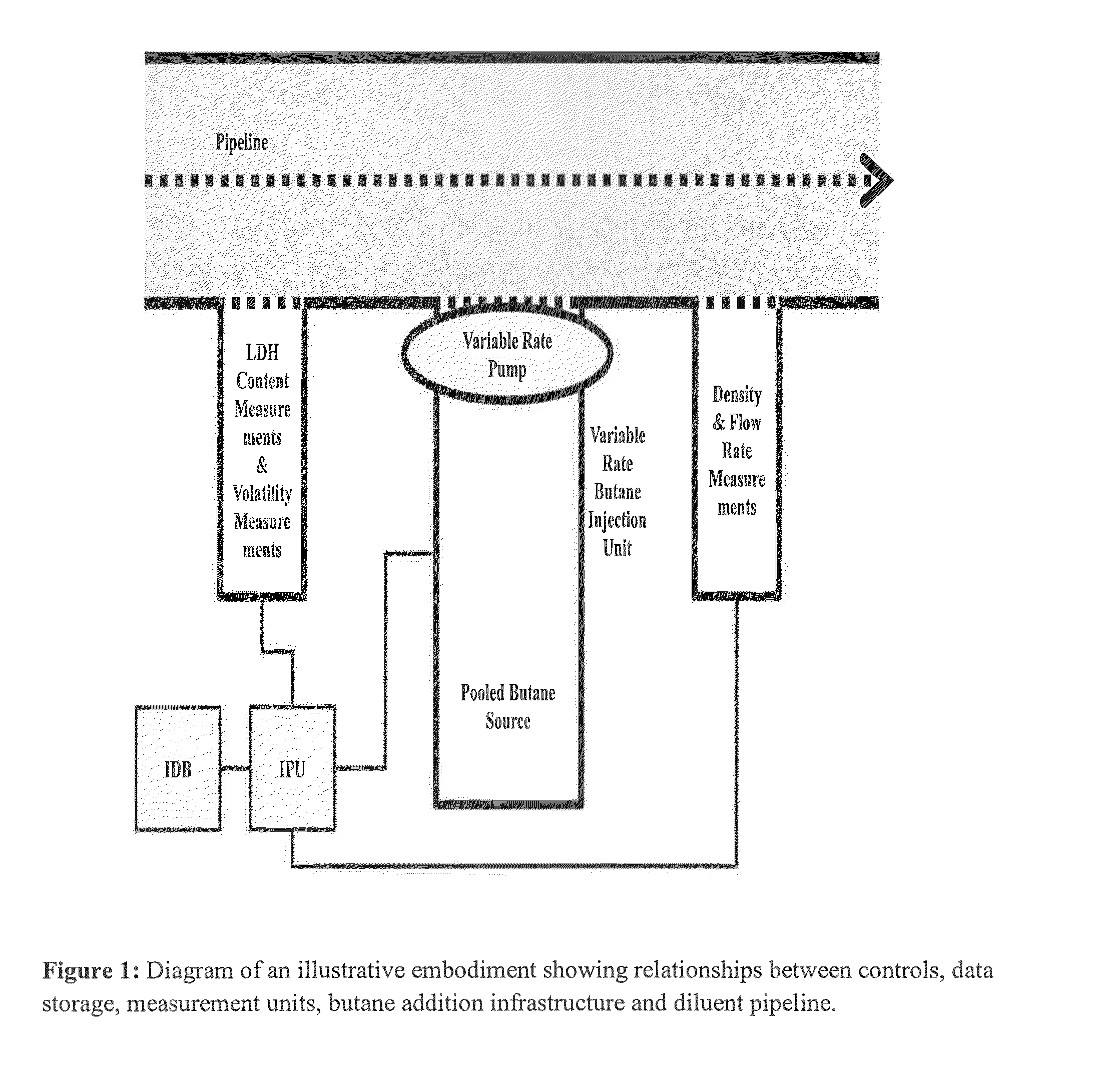

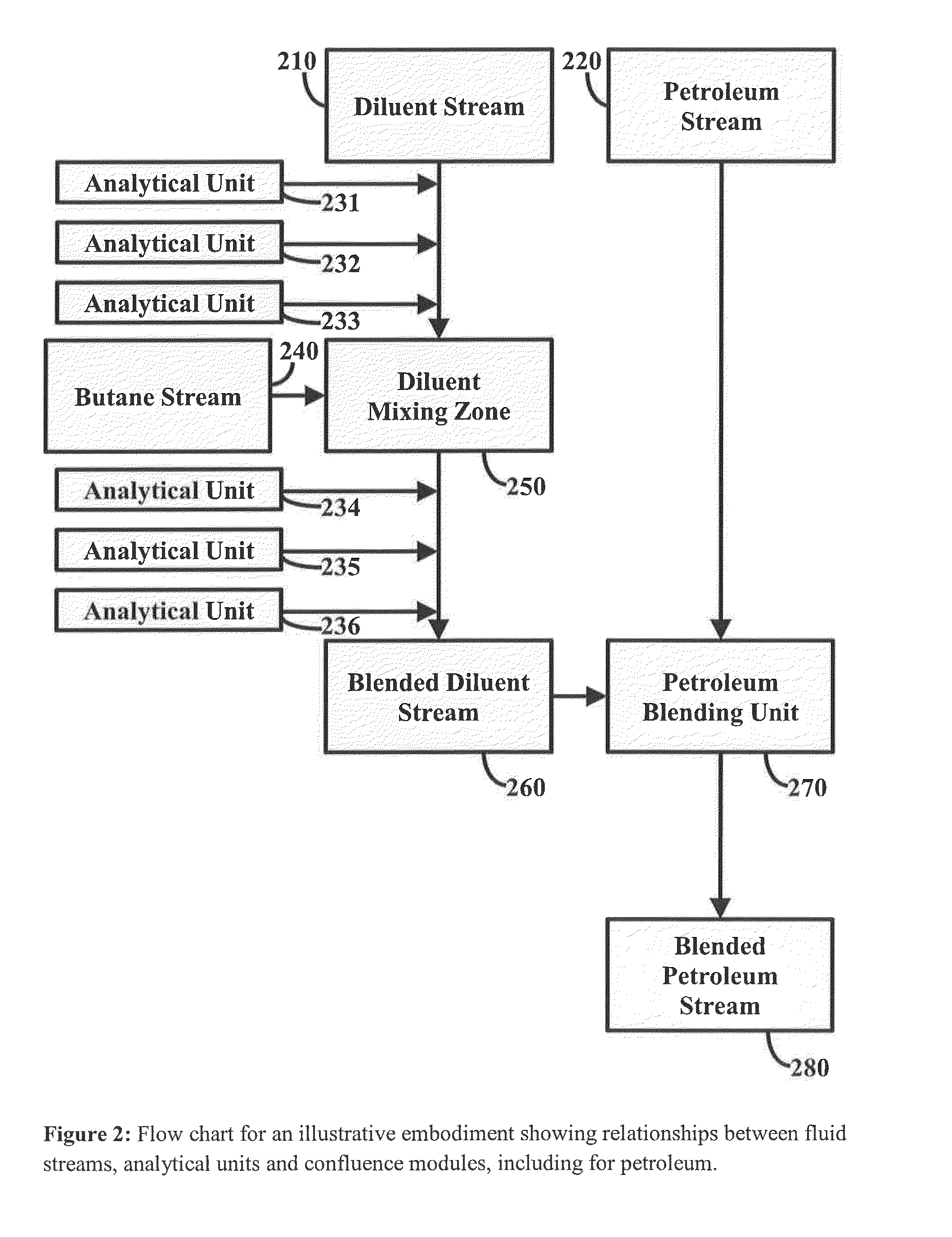

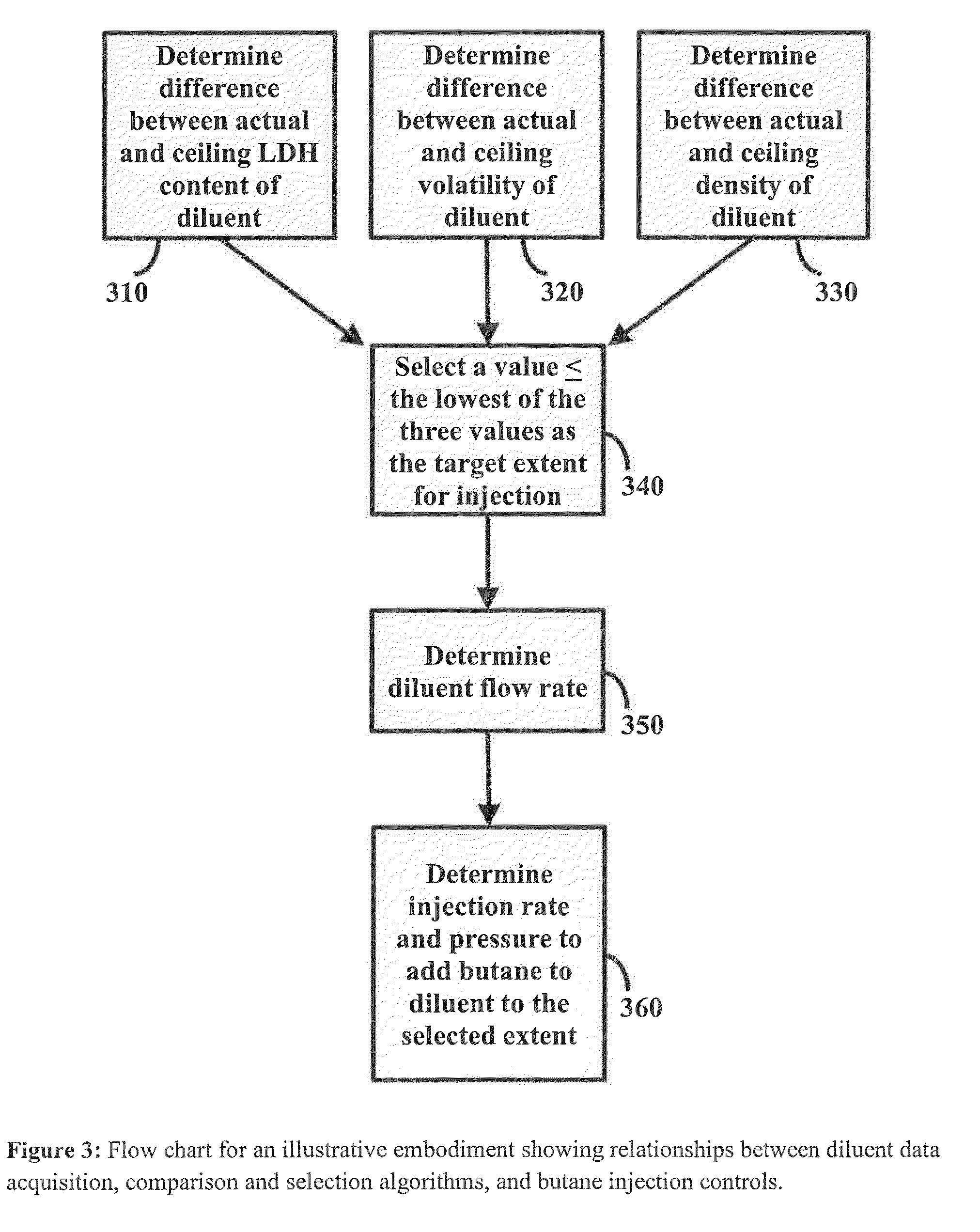

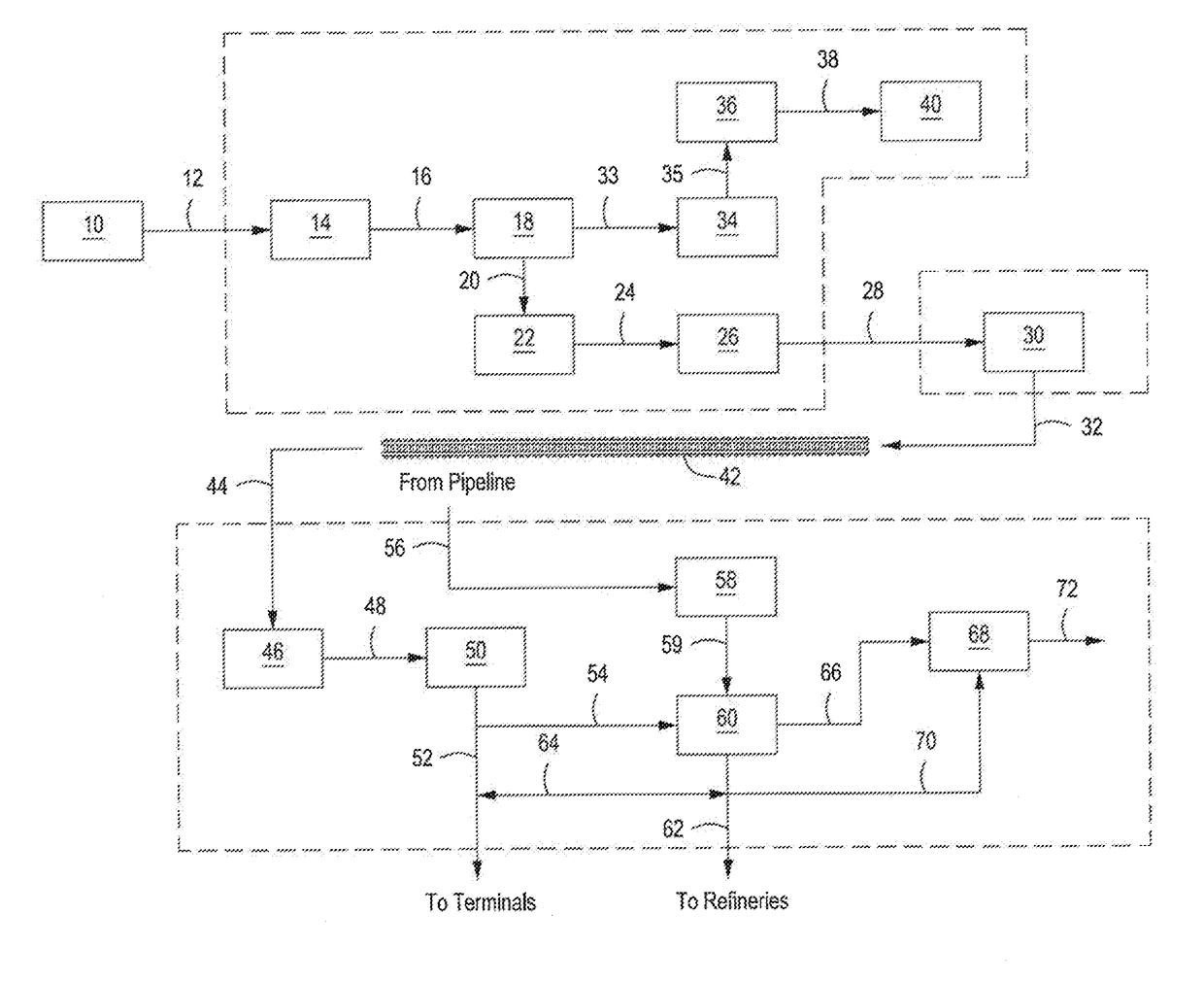

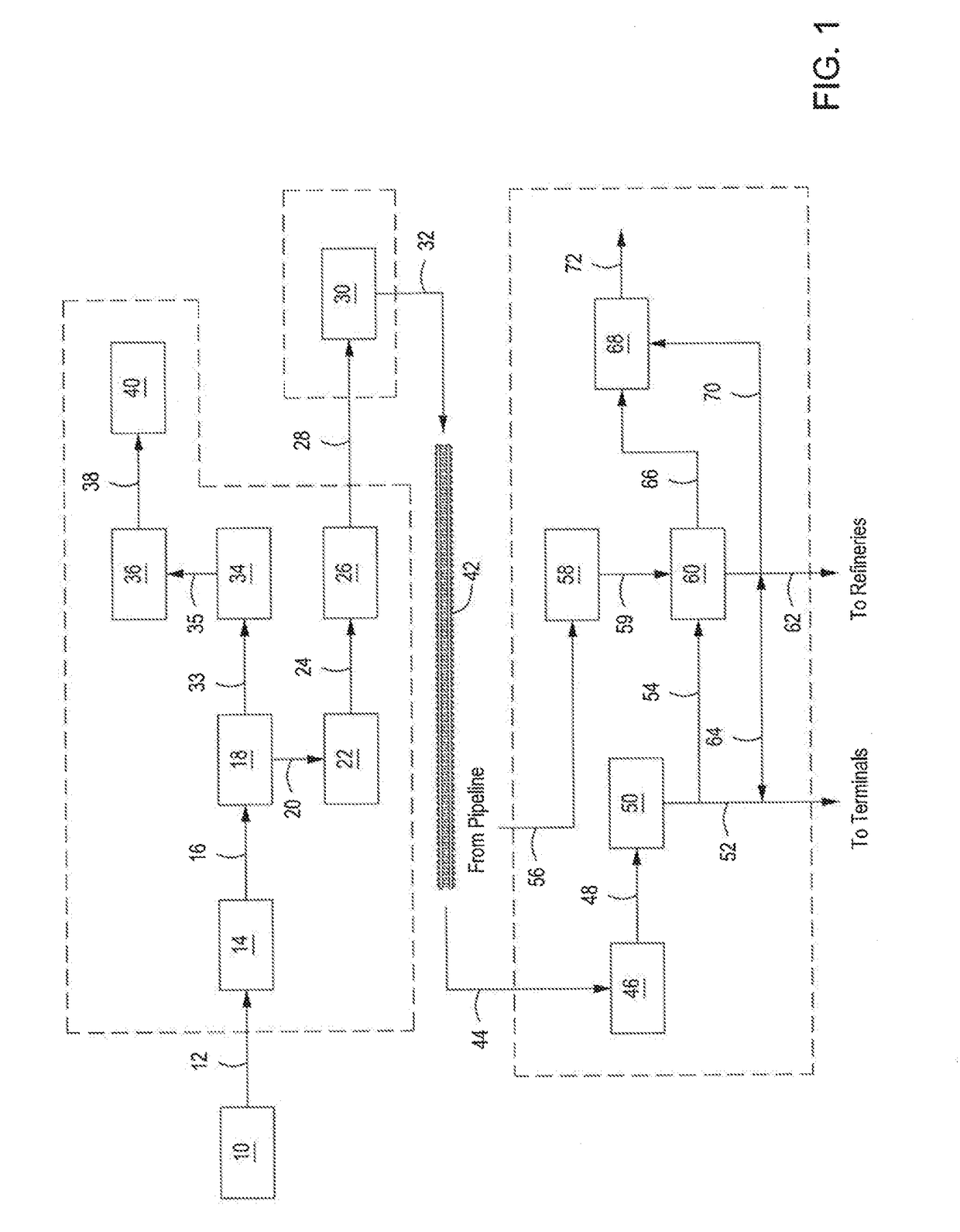

Methods for expanding and enriching hydrocarbon diluent pools

ActiveUS9637685B2Increase supplyImprove physical propertiesControlling ratio of multiple fluid flowsWorking-up pitch/asphalt/bitumen by mixing fractionsLiquid hydrocarbonsDiluent

The invention provides a method for enriching diluents with butane so as not to violate pre-defined limits for liquid hydrocarbon fuels with respect to density, volatility and low density hydrocarbon content.

Owner:TEXON

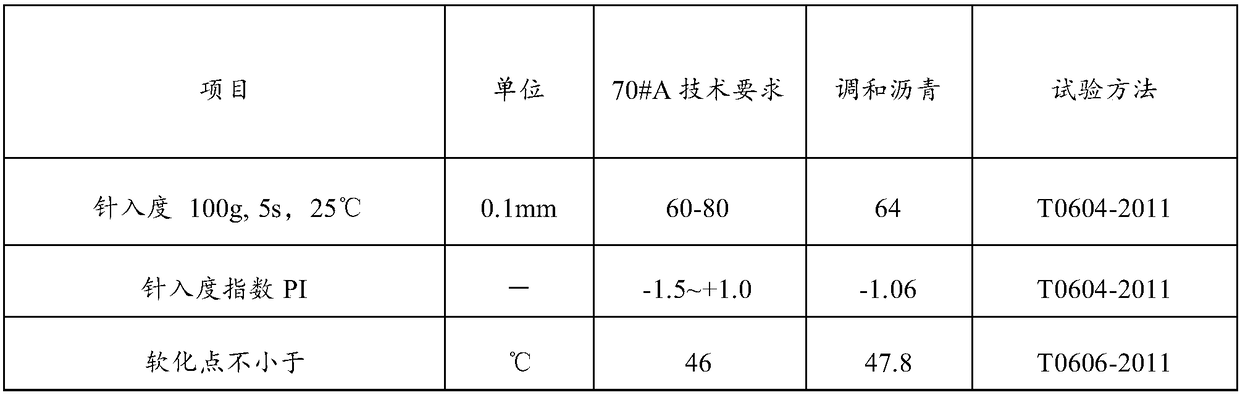

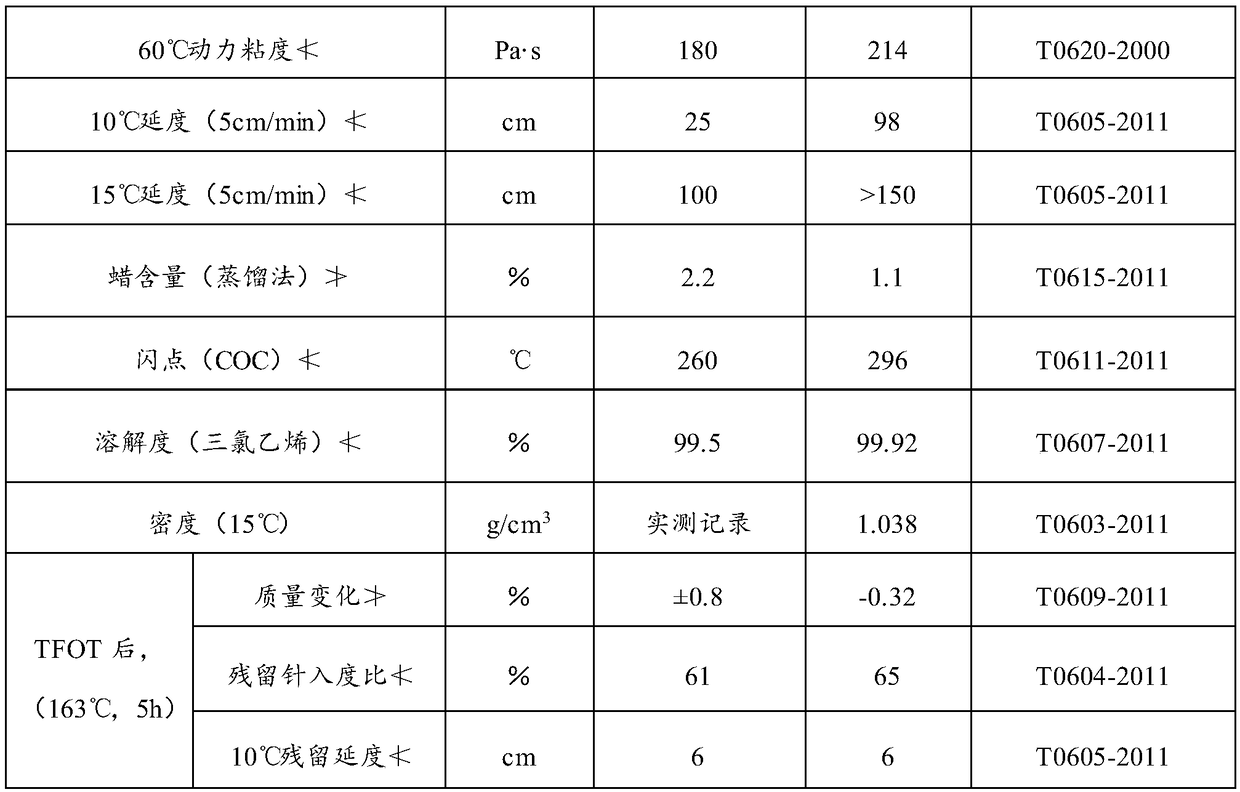

Blending asphalt and preparation method thereof

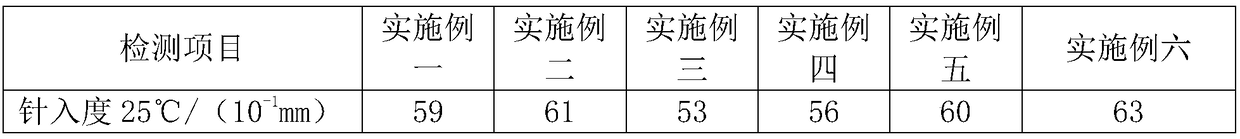

ActiveCN108179017ASimple production processIncrease added valueWorking-up pitch/asphalt/bitumen by mixing fractionsWaxAsphalt

The invention provides blending asphalt obtained by blending deoiled asphalt, vacuum residue and petroleum asphalt in the mass ratio of (1-5): (1-5): (2-8). Compared with the prior art, the deoiled asphalt, the vacuum residue and the petroleum asphalt which cannot meet asphalt index requirements of (JTG F40-2004 heavy traffic asphalt grade A) are blended to obtain a qualified product (heavy traffic asphalt grade A). On the one hand, sources of asphalt raw materials are broadened, waxy crude oil can also be used as an asphalt raw material to obtain the deoiled asphalt as an asphalt blending rawmaterial; on the other hand, the asphalt production process is enriched, the unqualified vacuum residue is used as an asphalt blending raw material is fully used, and the added value of the vacuum residue is improved.

Owner:SHANDONG JINGBO PETROCHEM +1

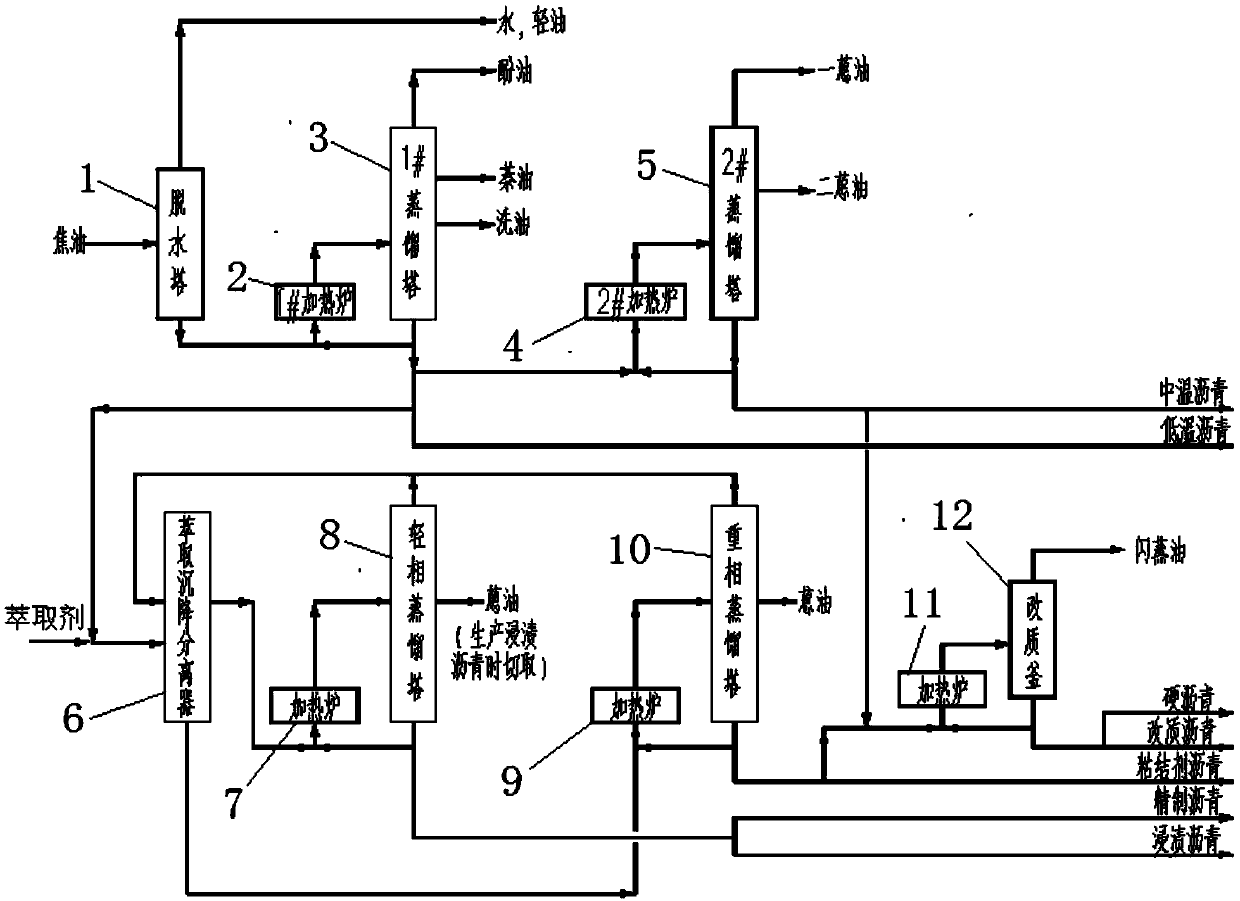

Process and device for producing various asphalt products by combining distillation and extraction

PendingCN109517614AMeet needsSolve the problem of low single added valueWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionDistillationTar

The invention relates to a process and a device for producing various asphalt products by combining distillation and extraction. The device comprises a dehydration tower, a distillation system, an extraction system and an asphalt modification system. Coal tar is used as a raw material to produce low-temperature asphalt, medium-temperature asphalt, modified asphalt, low-quinoline insoluble refinedasphalt, impregnated asphalt, hard asphalt, binder asphalt and other products by using a combined production process of distillation, extraction and asphalt modification. A variety of high value-addedasphalt products can be produced simultaneously with a set of production device, the utilization of the device is maximized, and the process and the device are adaptive to the needs of large-scale tar processing.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

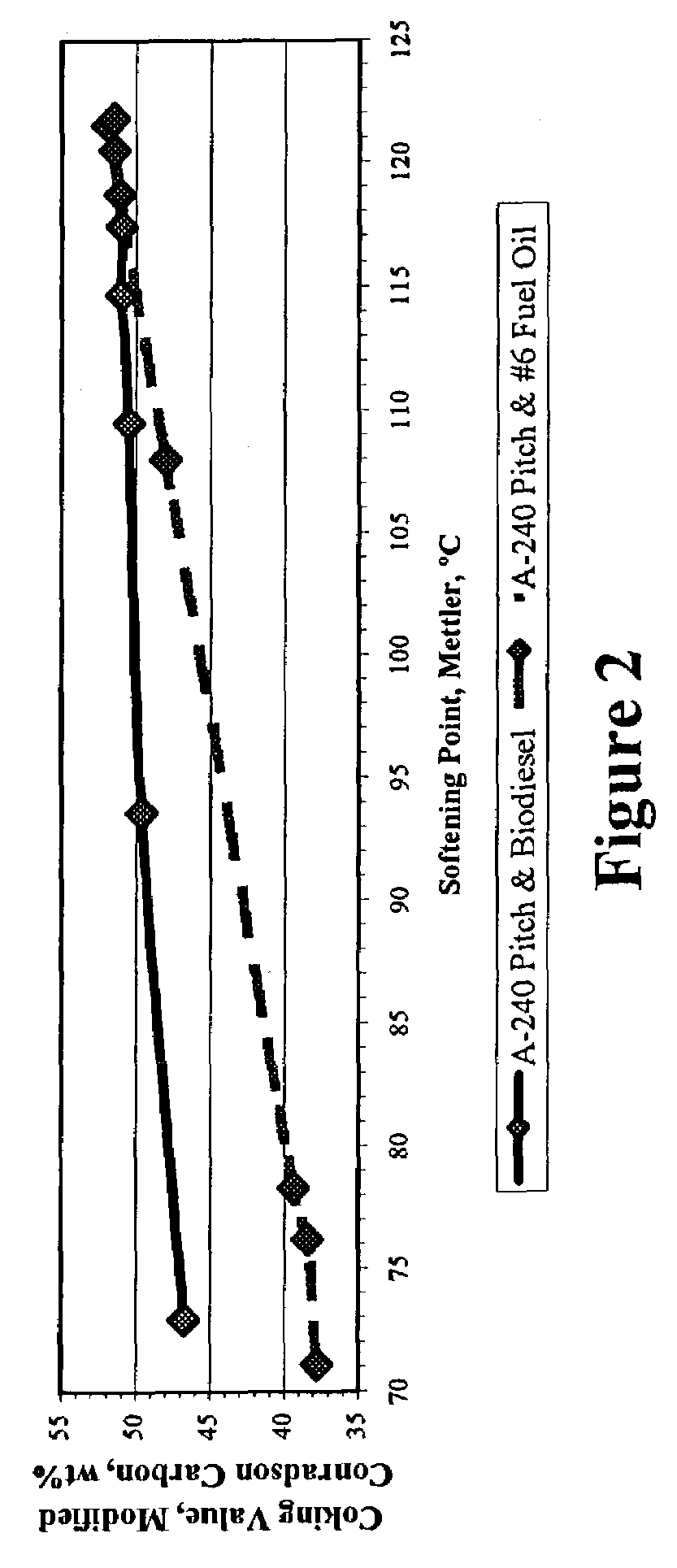

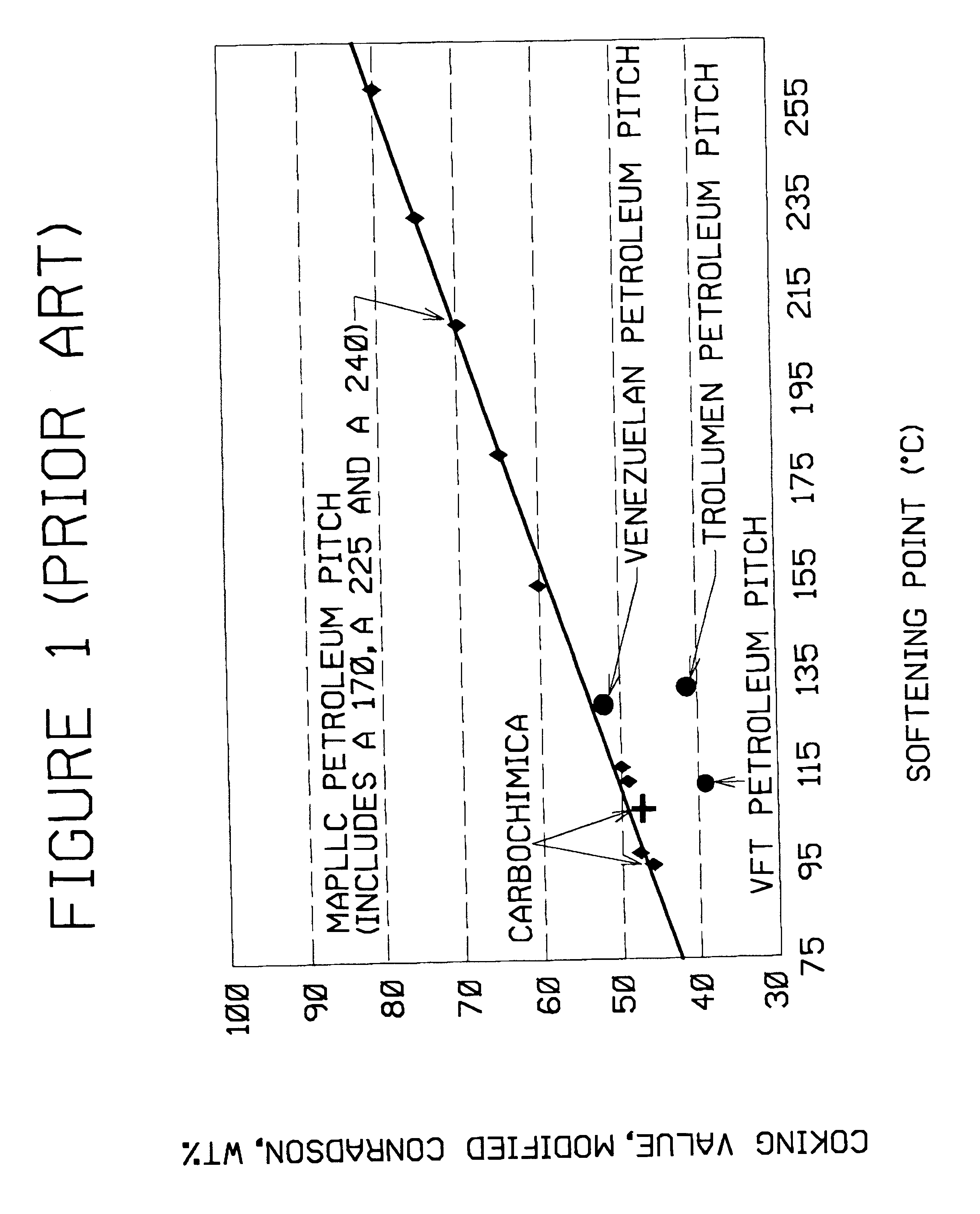

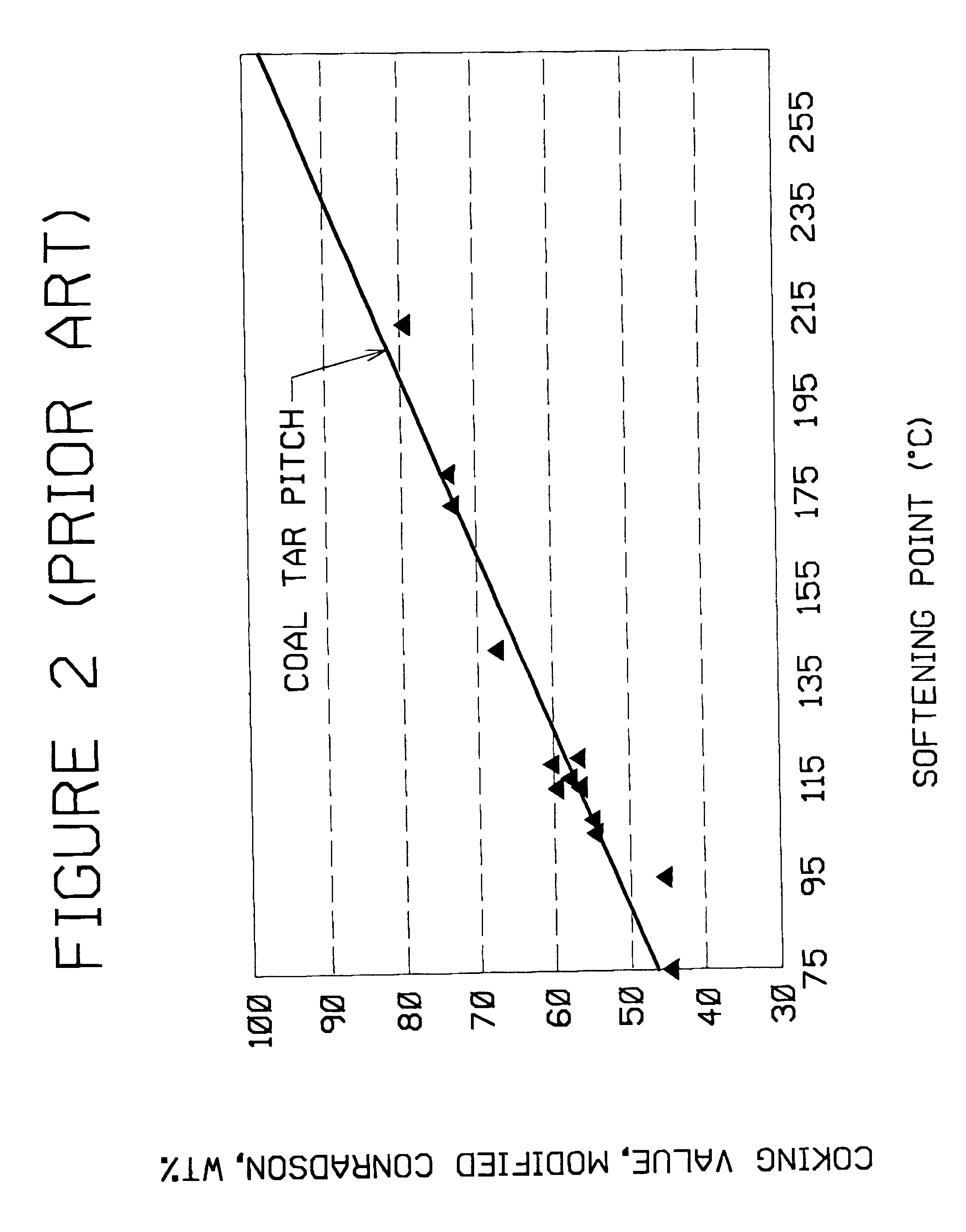

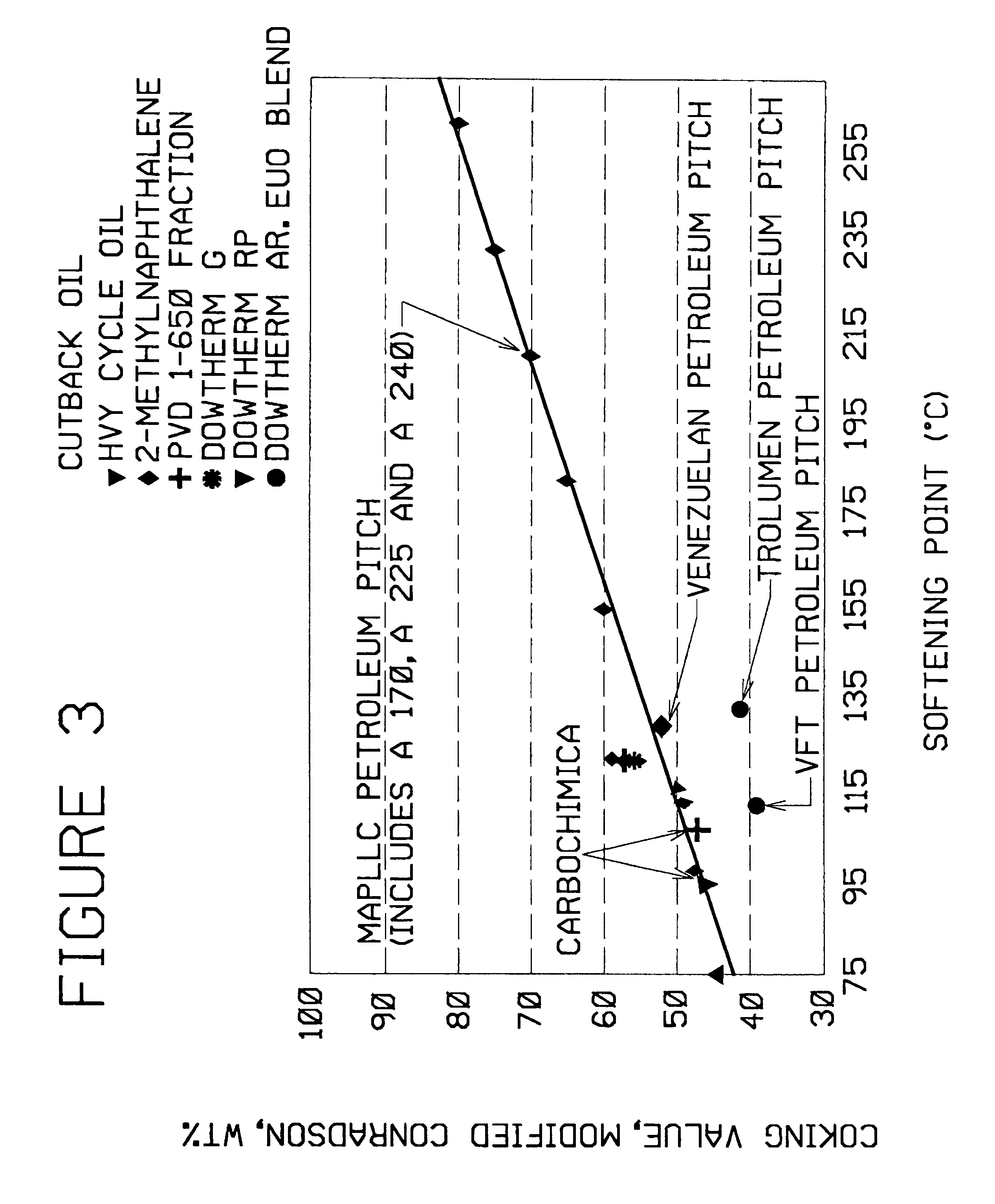

High coking value pitch

InactiveUS6352637B1Increase valueImprove workabilityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by mixing fractionsBoiling pointLiquid hydrocarbons

A high coking value pitch with a relatively low softening point is disclosed. A pitch is distilled or thermally processed to produce an intermediate pitch with an increased coking value and relatively high softening point, then blended with a cutter solvent of a liquid hydrocarbon stream to form a product pitch. The process may be used to increase the coking value of either petroleum or coal tar pitch. Preferably the cutter solvent is methylnaphthalene, or a highly aromatic, low viscosity oil or similar aromatic rich stream having a substantially lower boiling point than the intermediate pitch product.

Owner:MARATHON PETROLEUM

Low softening point petroleum pitch and sealer

InactiveUS6383365B1Promote resultsTolerate large amountWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by mixing fractionsEmulsionBoiling point

A 40 petroleum pitch is disclosed. A high melting point petroleum pitch is blended with a high boiling normally liquid petroleum derived hydrocarbon stream to form a mixture having a softening point of 35-45 C. as a partial or complete replacement for coal tar pitch used in driveway sealer and other sealer applications. Driveway sealer (an emulsion of clay, water and binder) made with A 40 has excellent durability and can have a greatly reduced amount of, or be essentially free of, coal tar pitch, greatly reducing the toxicity and odor of the sealer.

Owner:MARATHON PETROLEUM

Coal liquefaction residue modified asphalt and preparation method and application thereof

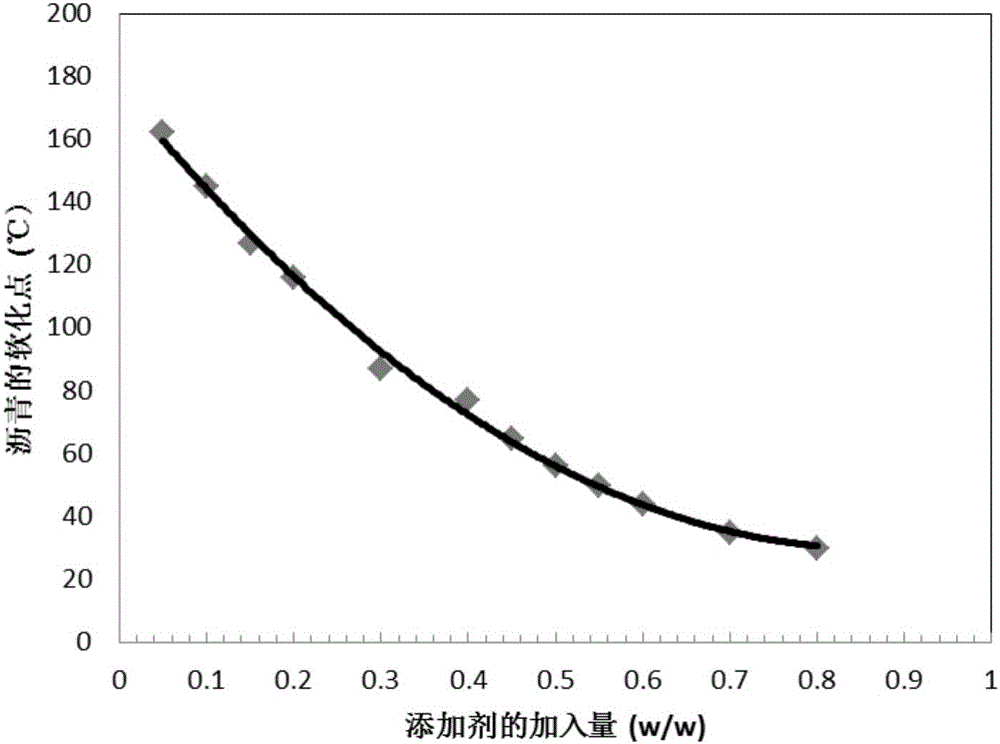

ActiveCN105802652AWide range of softening pointsSmall reproducibility errorWorking-up pitch/asphalt/bitumen by mixing fractionsSlurryAsphalt

The invention relates to the field of coal liquefaction residue modified asphalt and discloses coal liquefaction residue modified asphalt and a preparation method and application thereof.The coal liquefaction residue modified asphalt is obtained by mixing coal direct liquefaction residues and an additive, the aromatic content in the additive is 60% or above, and the additive is catalytic cracking oil slurry, extracted oil, coking oil, cracking tail oil or aromatic oil or a mixture formed by mixing at least two of catalytic cracking oil slurry, extracted oil, coking oil, cracking tail oil and aromatic oil.The process is simple, operation is easy, production cost is low, and product property controllability is high.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

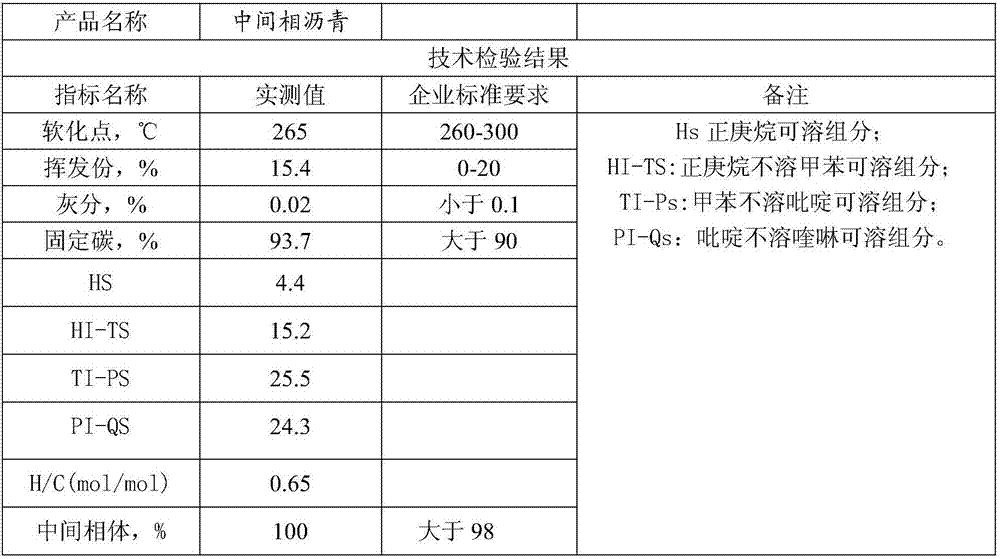

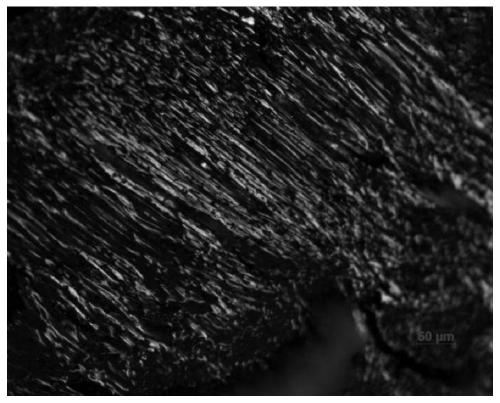

Method for catalytic synthesis of high quality intermediate phase carbon material with pure aromatic hydrocarbon

ActiveCN106967450AImprove performanceLarge specific surface areaWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionAnthraceneDistillation

The invention relates to a method for catalytic synthesis of a high quality intermediate phase carbon material with pure aromatic hydrocarbon. The method includes the steps of: (1) taking one or two of fraction naphthalene and anthracene in coal tar as the raw material, conducting blending and adding the raw material into a raw material tank, performing mixing and heating, then adding a catalyst and conducting full stirring; (2) adding the liquid mixture of step (1) into a microwave heating reactor through a metering pump; (3) controlling the temperature of a liquid outlet of the microwave heating reactor at 195DEG C; (4) cooling a mixed compound left by distillation at the bottom of a distillation kettle to 160DEG C, and performing full stirring till stratification; (5) heating a lower separated liquid X2 obtained by step (4) to 180-200DEG C, then passing the liquid through a fractionating tower to obtain a distilled liquid S3; (6) transferring high purity asphalt Z obtained in step (5) into a growth furnace, and performing stirring, at the same time introducing nitrogen, and conducting heat preservation for 6h to generate an intermediate phase carbon material, i.e. intermediate phase asphalt; and (7) taking the product obtained by cooling in step (6) out rapidly, and loading the product into a nitrogen protected sealed barrel. The method provided by the invention improves the content of the intermediate phase, and the preparation method is simple and is convenient for popularization and use.

Owner:亚太中碳(山西)新材料科技有限公司

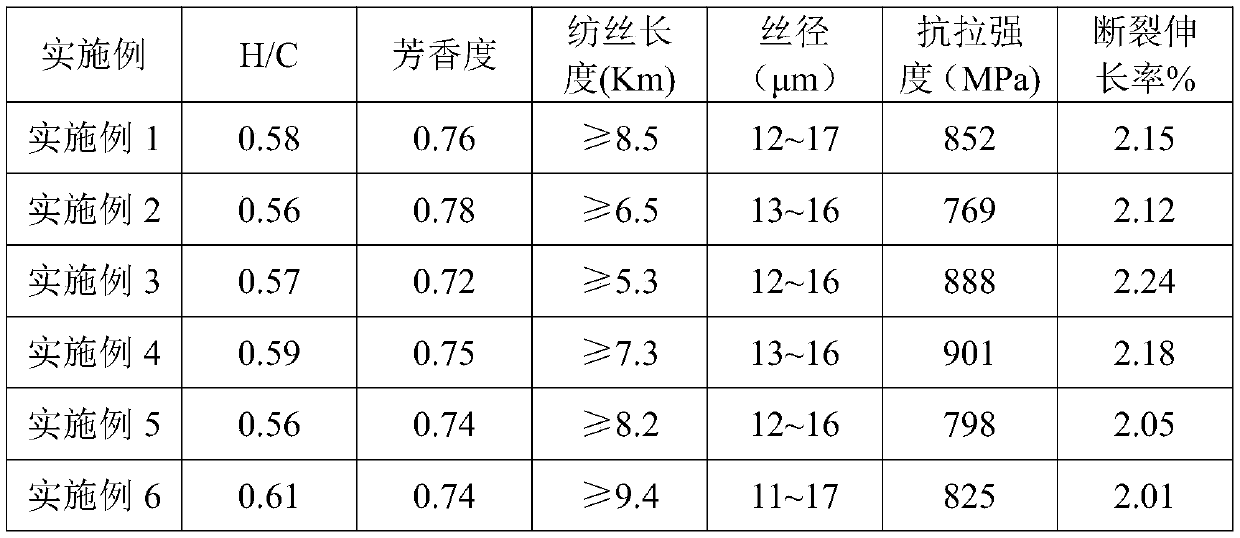

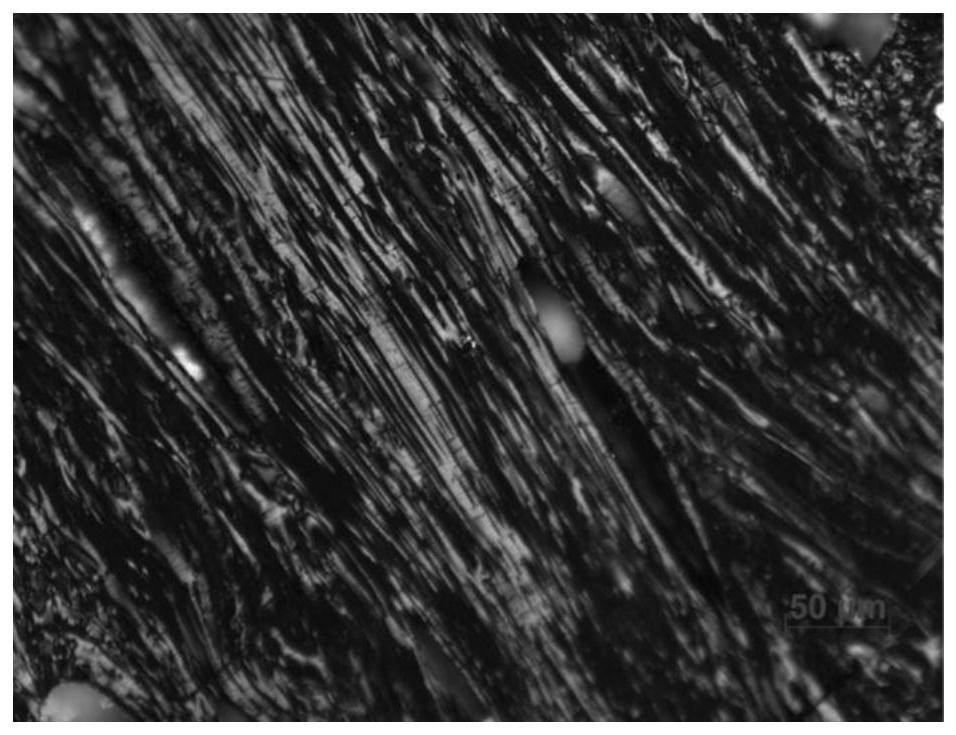

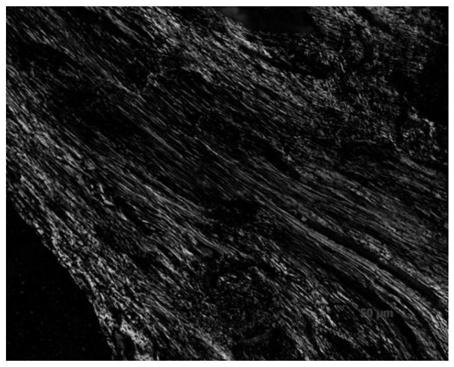

Spinnable asphalt and preparation method thereof

InactiveCN111004641AHigh softening pointContinuous spinningWorking-up pitch/asphalt/bitumen by mixing fractionsSide chainSimple aromatic ring

The invention discloses spinnable asphalt and a preparation method thereof, wherein the spinnable asphalt comprises the following raw materials in parts by weight: 20-50 parts of medium and low temperature coal pitch-based refined asphalt and 50-80 parts of petroleum asphalt. The preparation method comprises the following steps: uniformly mixing 20-50 parts by weight of medium and low temperaturecoal pitch-based refined asphalt and 50-80 parts by weight of crushed petroleum asphalt, and putting the mixture into a reactor; and introducing inert gas into the reactor under normal pressure, heating to 370-450 DEG C at a speed of 2-9 DEG C / min, and reacting for 4-9 hours to obtain spinnable asphalt. According to the invention, high aromaticity is provided through refined asphalt, the aromaticcomponents and the asphaltene in petroleum asphalt are combined to provide a small amount of aromatic rings, and saturated components and colloid provide alkyl side chains and naphthenic structures, so that the high-quality spinnable asphalt having high softening point and narrow melting range and capable of continuously spinning can be obtained, the petroleum asphalt is used for replacing a modifier, and the preparation technological process of the spinnable asphalt can be simplified.

Owner:西安郎格飞博科技有限公司

Methods for expanding and enriching hydrocarbon diluent pools

ActiveUS20130303809A1Improve physical propertiesIncrease supplyWorking-up pitch/asphalt/bitumen by mixing fractionsSolid fuelsDiluentLiquid hydrocarbons

The invention provides a method for enriching diluents with butane so as not to violate pre-defined limits for liquid hydrocarbon fuels with respect to density, volatility and low density hydrocarbon content.

Owner:TEXON

Australian C-320 asphalt and production method thereof

ActiveCN109266374AOvercome the problem of not being able to meet the Australian C-320 bitumen quality indexSimple production processWorking-up pitch/asphalt/bitumen by mixing fractionsBuilding insulationsPetroleumAsphalt

The invention discloses Australian C-320 asphalt and a production method thereof. The asphalt provided by the invention is prepared from the following components in parts by mass: 100 parts of vacuumresidues, 0-5 parts of extract oil and 0-10 parts of hard asphalt. Specific appropriate crude oil is subjected to a specific mixed refining proportion and a specific production technology to produce the vacuum residues, then the vacuum residues are mixed with the extract oil and hard asphalt of specific requirements according to specific conditions, and thus an asphalt product meeting the standardrequirements of the Australian C-320 asphalt is produced; and therefore the problem that an asphalt product produced by traditional petroleum refining raw materials and production process cannot meetthe quality standards of the Australian C-320 asphalt is solved.

Owner:CHINA PETROLEUM & CHEM CORP

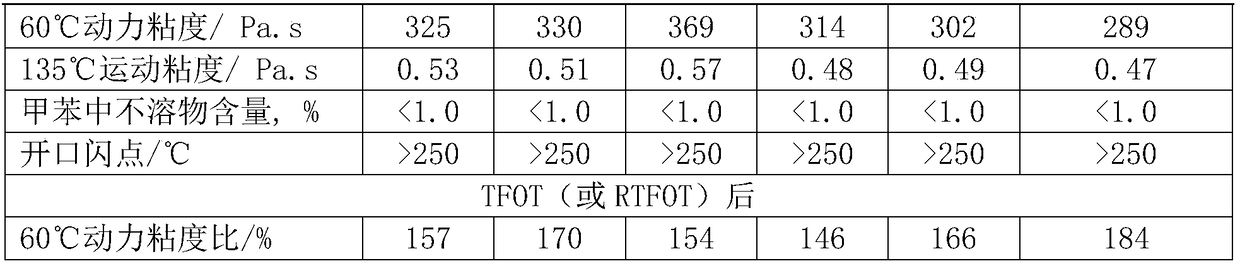

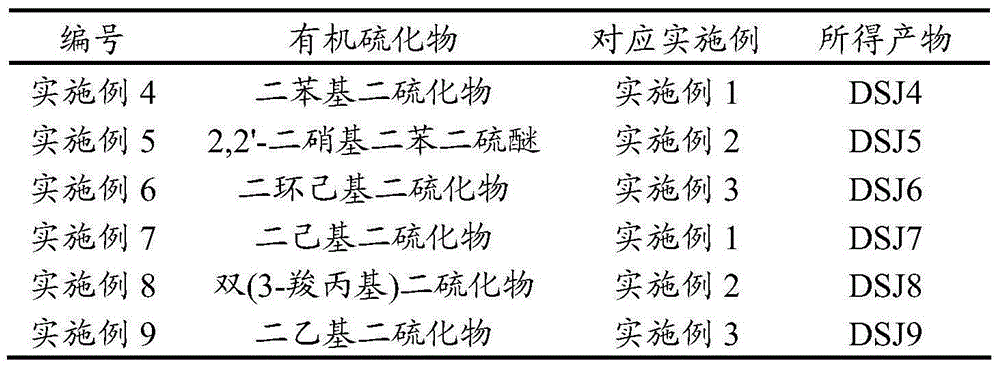

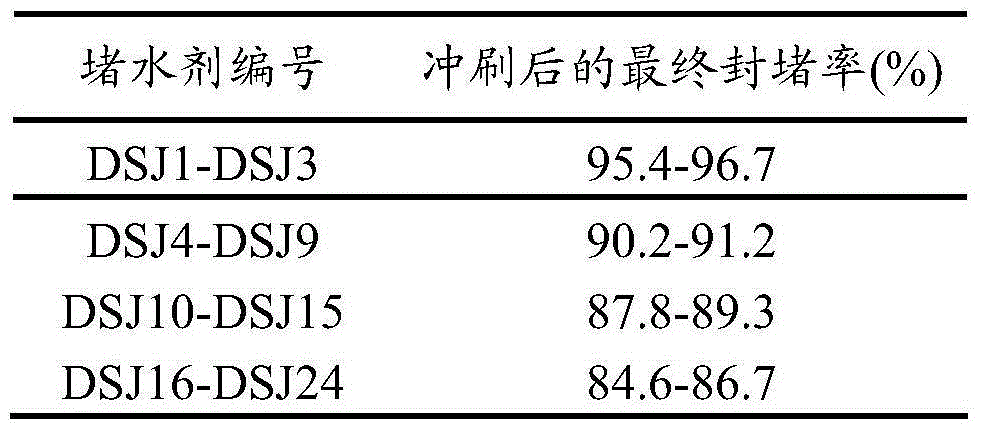

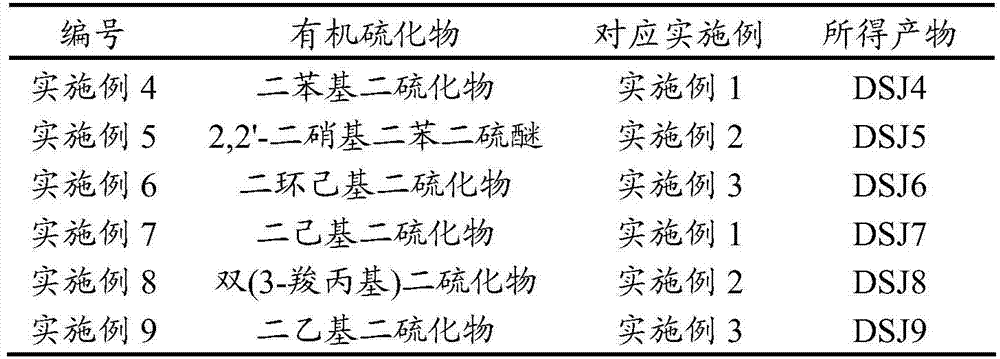

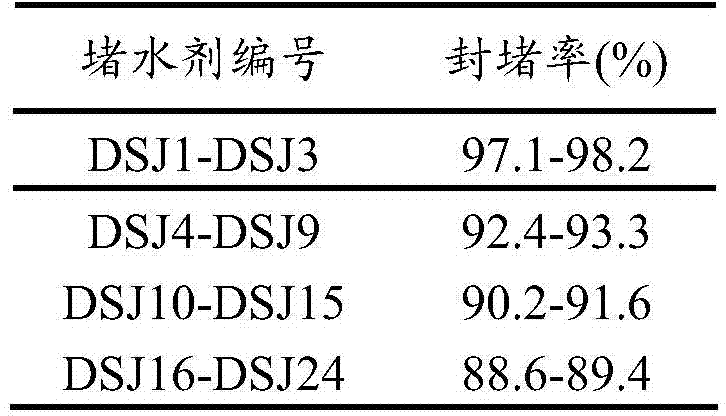

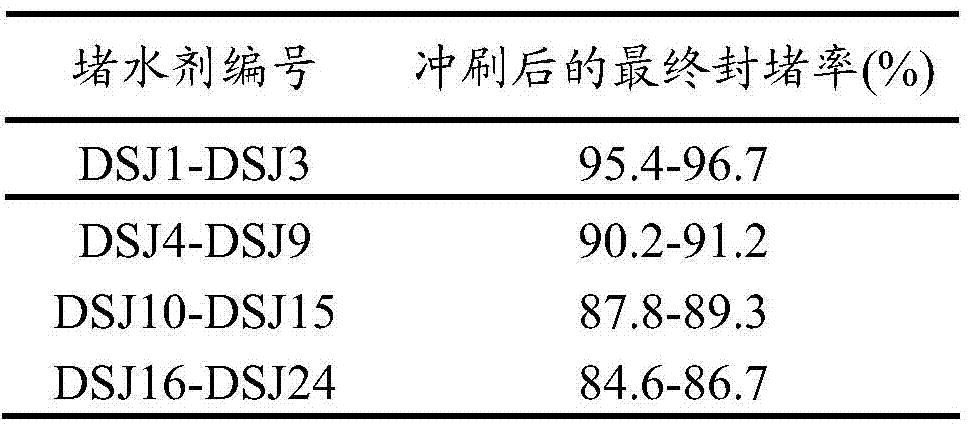

Chemical reactive modified asphalt profile modifying/water plugging agent and preparation method and application of profile modifying/water plugging agent

ActiveCN105038747AGood profile controlEasy to plug inWorking-up pitch/asphalt/bitumen by mixing fractionsWorking-up pitch/asphalt/bitumen by chemical meansVulcanizationAmmonium compounds

The invention relates to a chemical reactive modified asphalt profile modifying / water plugging agent and a preparation method and application of the profile modifying / water plugging agent. The preparation method comprises the following steps: S1, performing modification on petroleum asphalt by vulcanization to obtain sulphurized petroleum asphalt; S2, performing cationic modification on petroleum asphalt to obtain cation-modified petroleum asphalt; S3, adding the sulphurized petroleum asphalt and the cation-modified petroleum asphalt into naphtha, and then adding organic ammonium compounds, fully stirring for reaction for 40-60 min to obtain the chemical reactive modified asphalt profile modifying / water plugging agent. According to the chemical reactive modified asphalt profile modifying / water plugging agent and the preparation method and application of the profile modifying / water plugging agent, provided by the invention, by specific preparation steps, selection of components and technological parameters, the finally obtained profile modifying / water plugging agent has good plugging performance, erosion resistance property, high-temperature resistance and pH-resistance, and further has a good application prospect and industrial potential in the field of petroleum industry.

Owner:DAQING TIANMAN PETROCHEM CO LTD

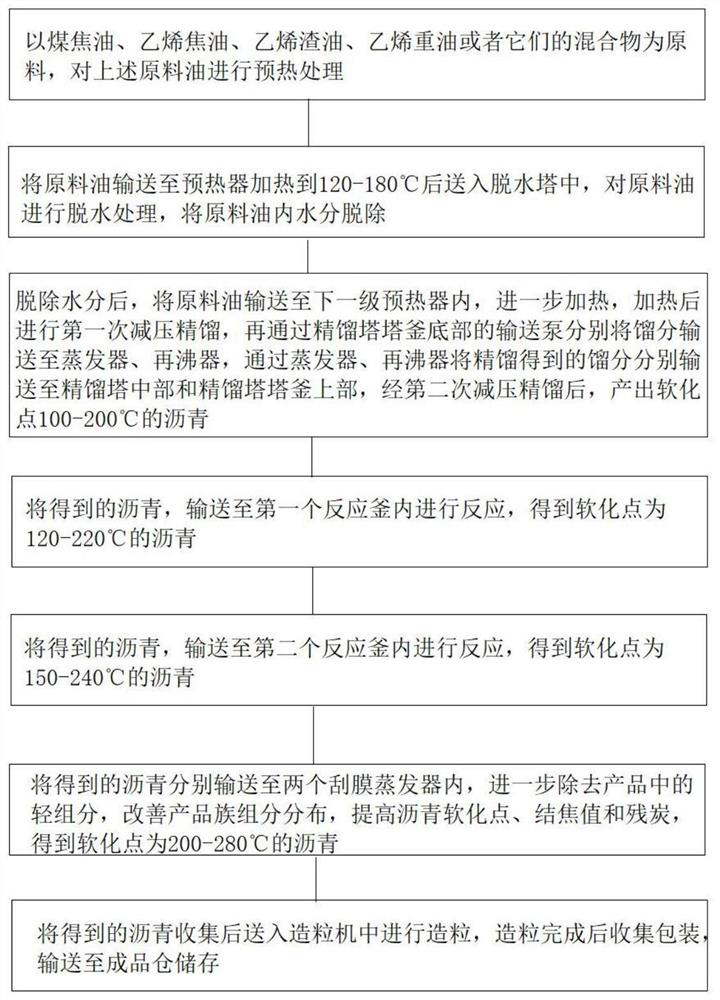

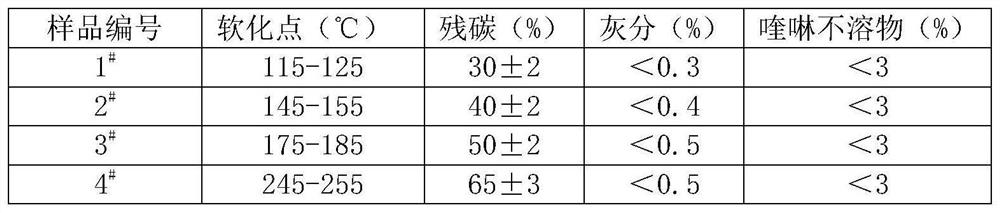

Continuous production method of graphite coated material

PendingCN113337304AWide variety of sourcesRealize industrializationWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by mixing fractionsReboilerProcess engineering

The invention provides a continuous production method of a graphite coated material. The continuous production method comprises the following steps: preheating raw oil; conveying the raw oil to a preheater, heating to 120-180 DEG C and then conveying the raw oil to a dehydration tower to be subjected to dehydration treatment; conveying the raw oil into a next-stage preheater, heating, carrying out primary vacuum rectification, respectively conveying fractions to an evaporator and a reboiler through a conveying pump at the bottom of a rectifying tower kettle, respectively conveying the fractions obtained by rectification to the middle part of the rectifying tower and the upper part of the rectifying tower kettle, carrying out secondary vacuum rectification to produce asphalt with the softening point of 100-200 DEG C; conveying the asphalt into a first reaction kettle for reaction to obtain asphalt with the softening point of 120-220 DEG C; then conveying the asphalt into a second reaction kettle for reaction to obtain asphalt with the softening point of 150-240 DEG C; and finally, conveying the asphalt into two wiped-film evaporators to obtain the asphalt with the softening point of 200-280 DEG C. According to the invention, continuous production is realized, the production cost is obviously reduced, and product industrialization can be realized.

Owner:天津北海石化工程有限公司

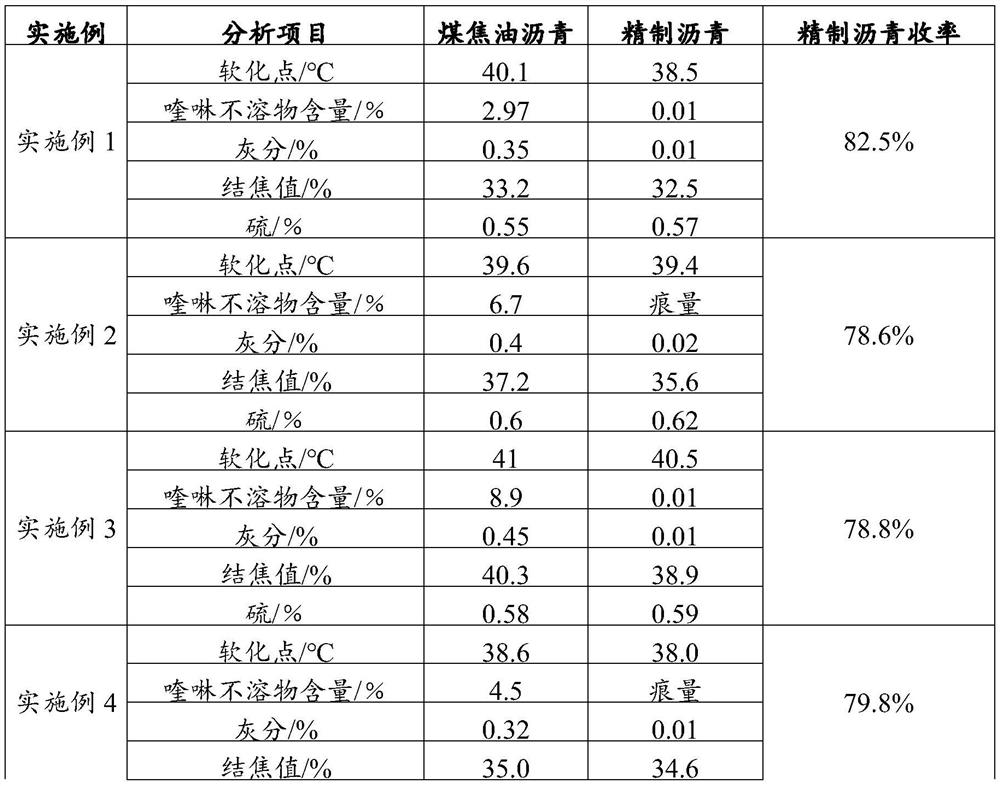

Pretreatment process of raw materials for preparing coal-based needle coke

PendingCN114806620AHigh yieldReduce manufacturing costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by mixing fractionsDistillationQuinoline

The invention discloses a pretreatment process of raw materials for preparing coal-based needle coke. The pretreatment process comprises the following steps: (1) mixing the raw materials; (2) primary sedimentation; (3) secondary sedimentation; (4) heavy phase distillation; (5) distilling a light phase; and (6) solvent circulation. According to the method, two different solvents are mixed into a mixed solvent according to the principle of solvent extraction and sedimentation, in order to improve the efficiency, two times of extraction and sedimentation separation are carried out, then a heavy phase and a light phase which are separated are separated according to different densities, and finally distillation is carried out to recover the solvent. Through innovation and improvement of the process, on one hand, the yield of the intermediate product refined pitch is increased, on the other hand, the quinoline insoluble component can be effectively removed, the requirement for the quinoline insoluble content in the coal tar pitch is lowered, the selection range of raw materials is widened, and finally the purposes of increasing the yield of the needle coke and reducing the production cost of the needle coke are achieved.

Owner:宁夏百川新材料有限公司 +1

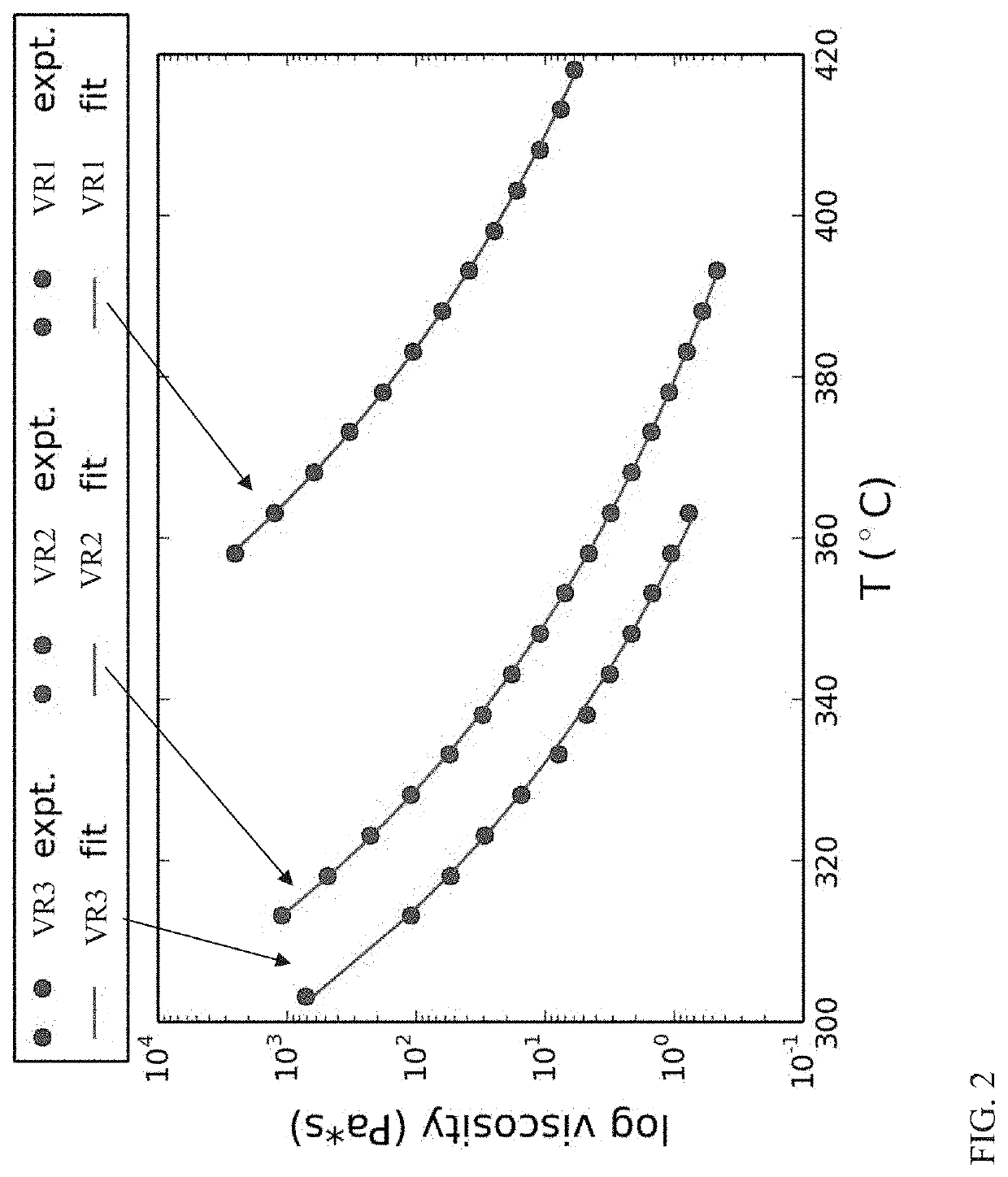

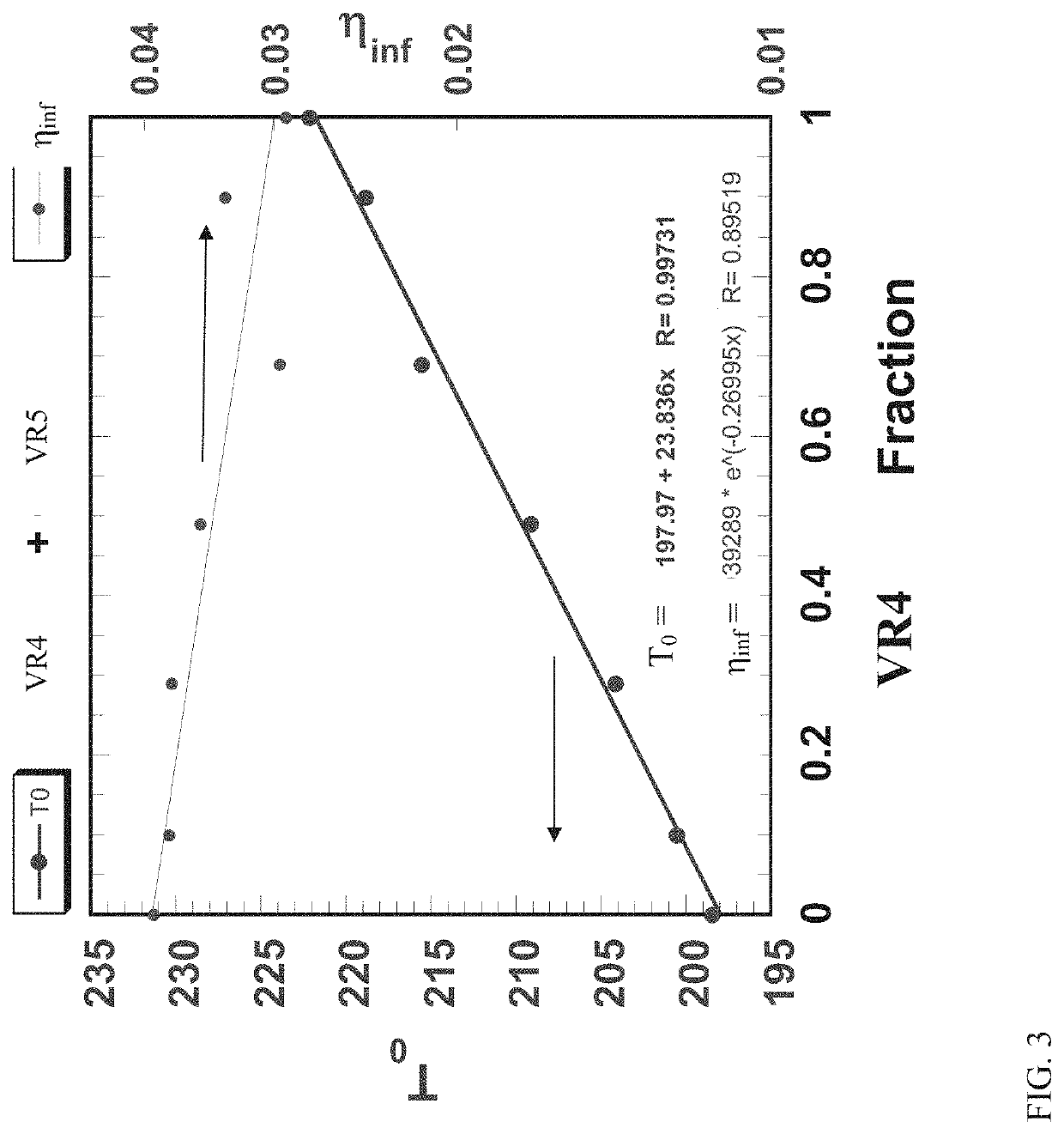

Modification of temperature dependence of pitch viscosity for carbon article manufacture

InactiveUS20190382664A1Working-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by mixing fractionsSolventChemistry

Methods are provided for reducing or minimizing the temperature dependence of a pitch feed or fraction for use in carbon fiber production, such as a mesophase pitch feed or fraction or an isotropic pitch feed or fraction. A pitch sample can be characterized to determine a characteristic temperature and a characteristic viscosity for the sample. One or more solvent extraction processes can also be performed on the pitch and / or the extract and raffinate fractions formed by the solvent extraction(s). The resulting raffinate and extract fractions are then used to form a modified pitch fraction with a T0 value that is lower than the T0 value of the original pitch. The modified pitch fraction can optionally also have a different ηinf value relative to the original pitch.

Owner:EXXON RES & ENG CO

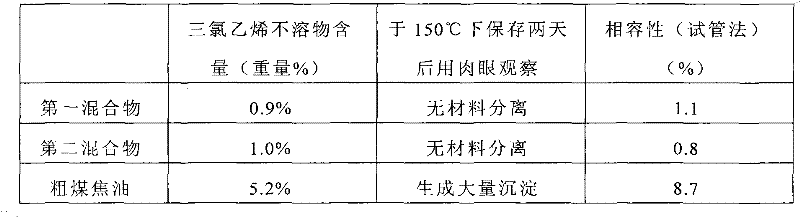

Method for preparing coal tar pitch having improved compatibility with asphalt and asphalt containing the same

ActiveCN102533303AWorking-up pitch/asphalt/bitumen by mixing fractionsTar working-up by distillationEngineeringTrichloroethylene

The invention relates to a method for preparing coal bar pitch having improved compatibility with asphalt and asphalt containing the same, with the prepared pitch applicable to road paving and comprising the mixture of coal tar pitch and petroleum asphalt. The method is characterized by employing oil fraction having large quantity of aromatic ingredients to prepare the coal tar pitch having improved compatibility with asphalt, thus to inhibit the increase of the triclene undissolved substance and the separation of the material while the coal tar pitch and the petroleum asphalt are simply mixed. The invention also relates to a method for preparing the pitch containing the coal tar pitch. The pitch containing coal tar pitch can be employed as road-paving material effectively.

Owner:SK INNOVATION CO LTD

High quality asphalt containing pitch and preparing method thereof

ActiveCN101228252AExcellent Wax ContentImprove ductilityWorking-up pitch/asphalt/bitumen by mixing fractionsRefining by solvent de-asphaltingSolventPetroleum

A high quality asphalt containing pitch is generated as a by-product in a solvent deasphalting process and a method of preparing the same. The pitch is obtained by subjecting a mixture comprising a first vacuum residue and a first petroleum distillate, which is lighter than the vacuum residue and has high amounts of aromatic and resin, to solvent deasphalting. The operation conditions of the solvent deasphalting process are appropriately controlled, such that aromatic and resin components contained in the atmospheric residue and vacuum residue can be distributed to the pitch, and as well, a saturate can be removed.

Owner:SK INNOVATION CO LTD +1

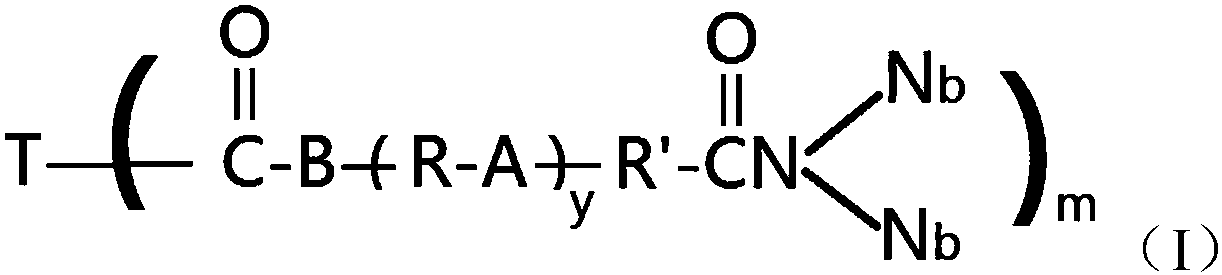

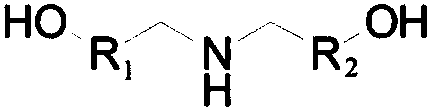

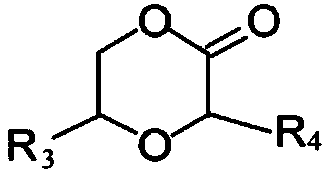

Asphaltene dispersant composition and method for dispersing asphaltene deposits

ActiveCN109553988AWorking-up pitch/asphalt/bitumen by mixing fractionsBuilding insulationsSorbitanPolymer

The present invention provides an asphaltene dispersant composition and a method of dispersing asphaltene deposits. The asphaltene dispersant composition comprises an ester-based polymer, sorbitan fatty acid ester and / or alkylbenzene, and the structure of the ester-based polymer is shown in the specification, wherein group T represents the main chain of the ester-based polymer; group B is selectedfrom O and S; y groups R are same or different from each other, and are independently selected from C1-10 alkyl; y groups A are same or different from each other, and are independently selected fromO, S or NH; R' is preferably a C1-10 alkyl group, and y is preferably an integer between 1 and 6; and two Nb in the repeating unit are independently selected from H or -R''-BH, R'' is preferably C1-10alkyl, at least one of the two Nb is selected from - R''-BH, and m is an integer between 1 and 10. The composite dispersant disclosed by the invention has very excellent dispersing properties and isparticularly suitable as a dispersant for the asphaltene deposits.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing needle coke from medium-low temperature coal tar pitch by four-stage variable-temperature refining one-step method

ActiveCN111607420AHigh yieldImprove qualityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionThermodynamicsCoke

The invention provides a process for preparing needle coke from medium-low temperature coal tar pitch by a four-stage variable temperature refining one-step method and belongs to the technical field of needle coke preparation. The process specifically comprises the following steps of: (1) performing medium-low temperature coal tar fraction distilling; (2) carrying out four-stage variable-temperature refining to obtain refined raw material maltha; (3) carrying out a thermal polymerization reaction to prepare semicoke; and (3) performing calcining, and performing cooling to room temperature to obtain the needle coke. The needle coke prepared by the preparation method of the needle coke is high in yield, stable in yield and high in quality.

Owner:NORTHWEST UNIV

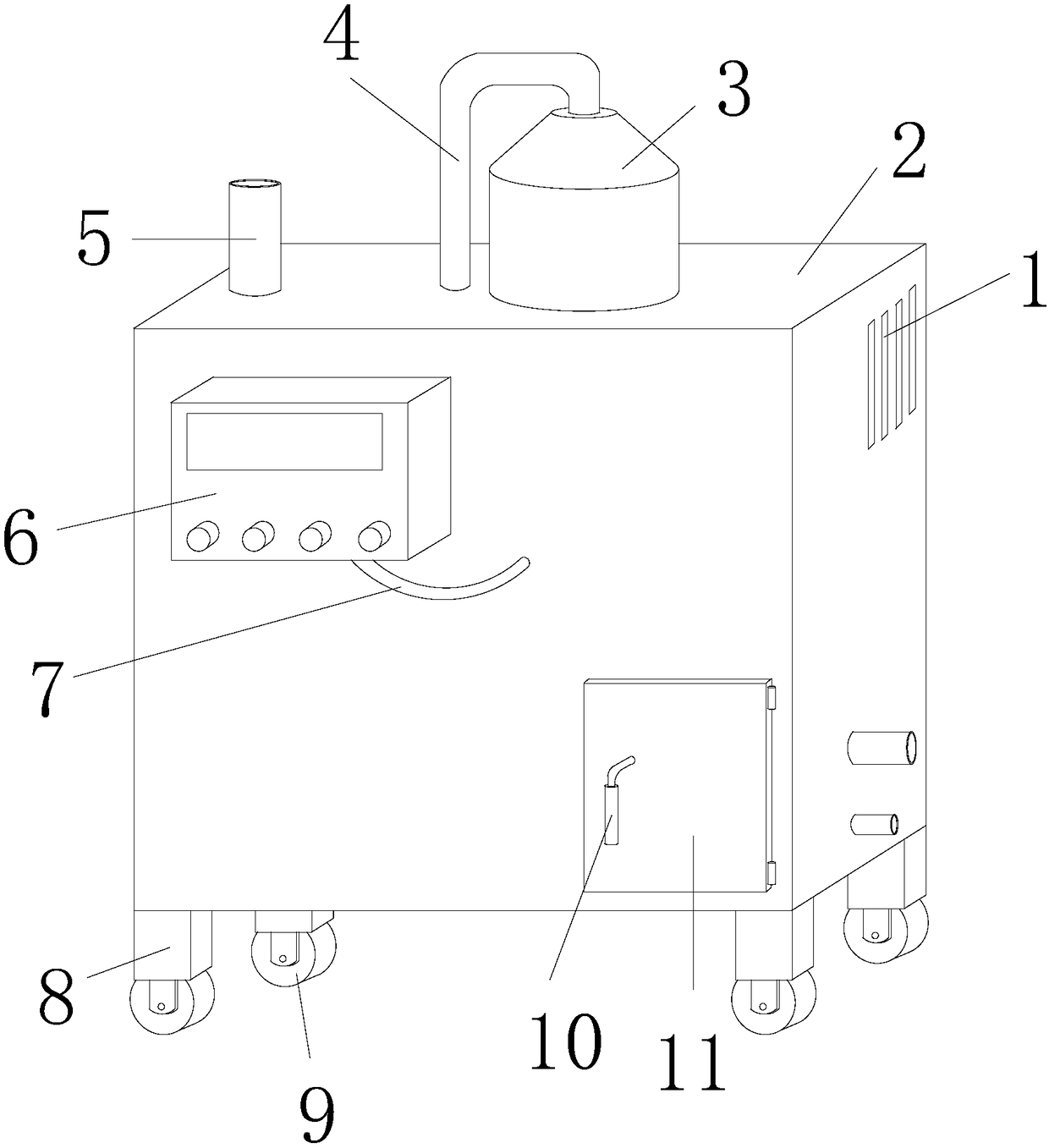

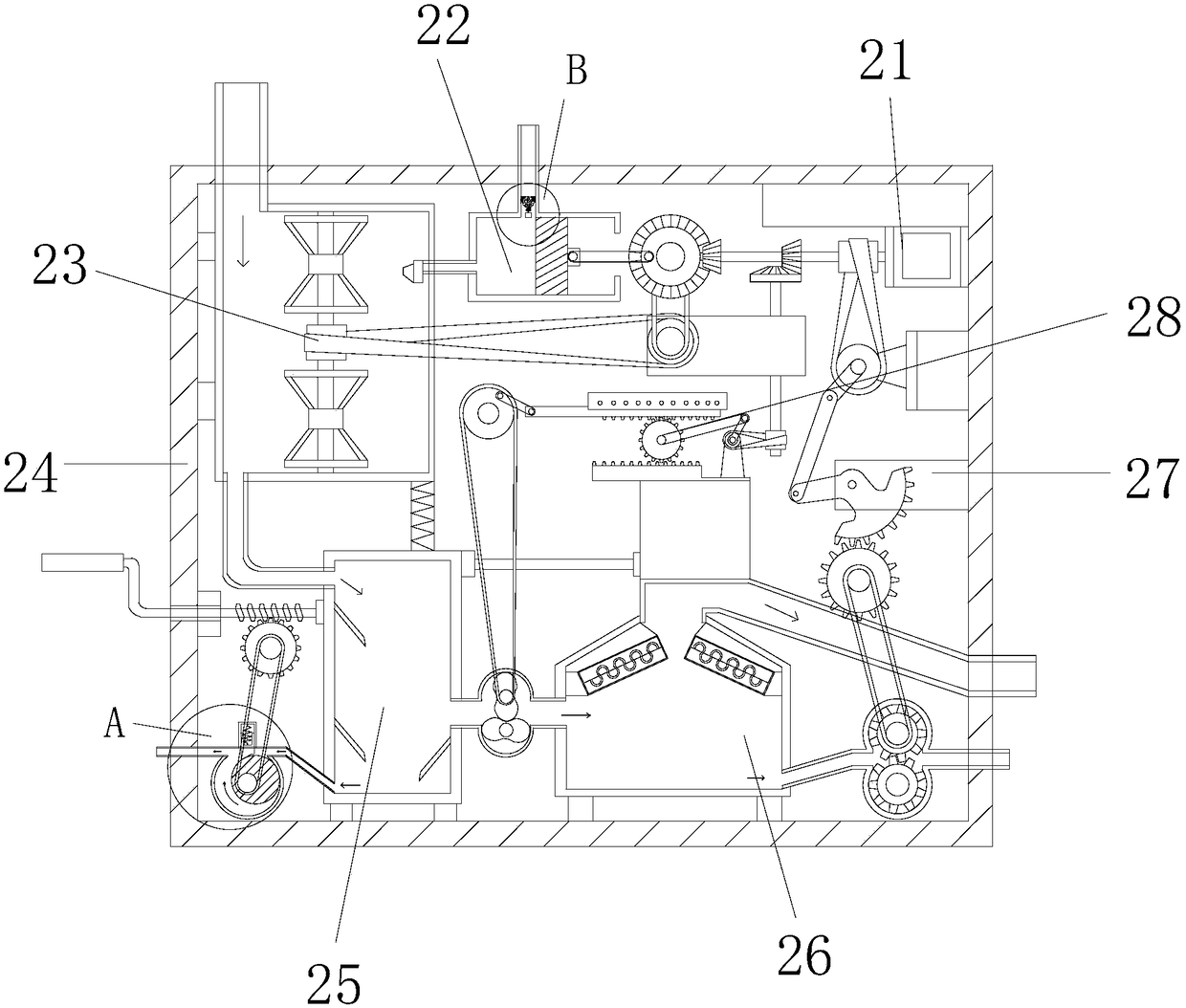

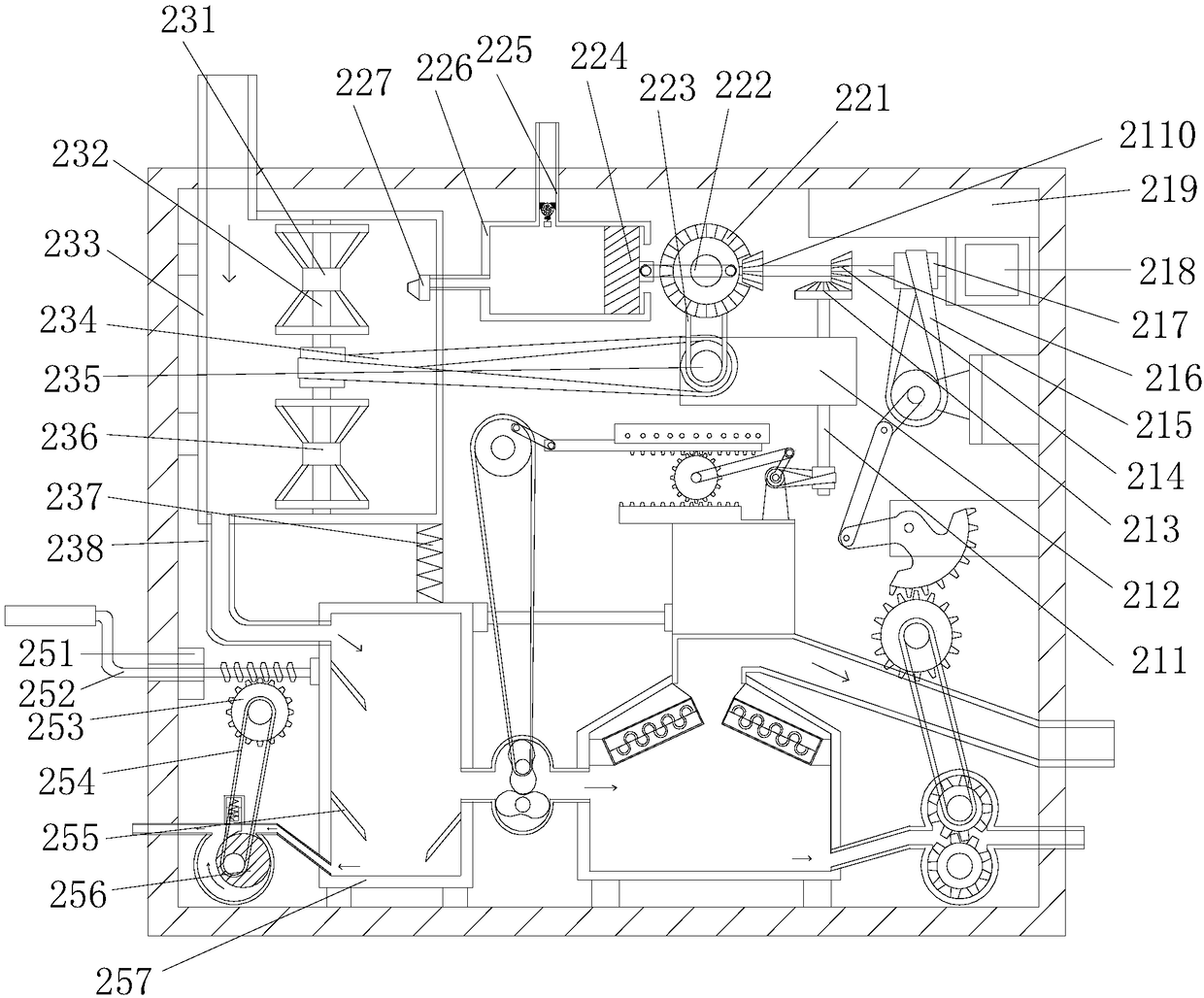

Solvent mixing device used for petroleum asphalt production

InactiveCN108371903AEasy to separateHigh purityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by mixing fractionsDissolutionSolvent

The invention discloses a solvent mixing device used for petroleum asphalt production. The solvent mixing device comprises a ventilation hole, a petroleum asphalt stirring and purifying device, a solvent tank, a solvent pipeline, a vacuum residue input pipe, a control panel, a transmission wire, a supporting column, a guide pulley, a handle and an open-close door, wherein the ventilation hole is embedded in the upper end of the right surface of the petroleum asphalt stirring and purifying device, the solvent tank fits the center of the upper surface of the petroleum asphalt stirring and purifying device, the upper end of the solvent pipeline is connected with the upper end of the solvent tank by virtue of glue, and the vacuum residue input pipe is welded at the left end of the upper surface of the petroleum asphalt stirring and purifying device. The solvent mixing device disclosed by the invention has the advantages that the petroleum asphalt stirring and purifying device is arranged,vacuum residues and a solvent are completely mixed during stirring, dissolution rate is improved, asphalt is completely separated, then moisture in the asphalt is removed, the purity of the asphalt isfurther improved, and the finished product processing and application of asphalt in a later period are facilitated.

Owner:郑长泉

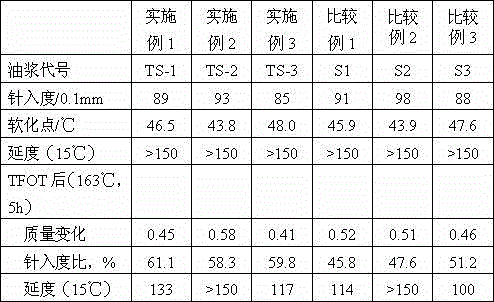

Preparation method for slurry oil mixed asphalt

InactiveCN104560085AImprove propertiesImprove anti-aging propertiesWorking-up pitch/asphalt/bitumen by mixing fractionsProcess engineeringAsphalt

The invention discloses a preparation method for slurry oil mixed asphalt. The preparation method comprises the following steps: (1) adding a sulfhydryl compound into slurry oil for mixing reaction to obtain modified slurry oil; (2) adding the modified slurry oil into a molten asphalt stock for mixing to obtain the slurry oil mixed asphalt. The slurry oil mixed asphalt prepared by adopting the preparation method has a relatively high penetration ratio, and the anti-aging performance of asphalt is improved; the preparation method expands the application approaches of slurry oil resources in asphalt, and facilitates the increase of utilization benefits of slurry oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

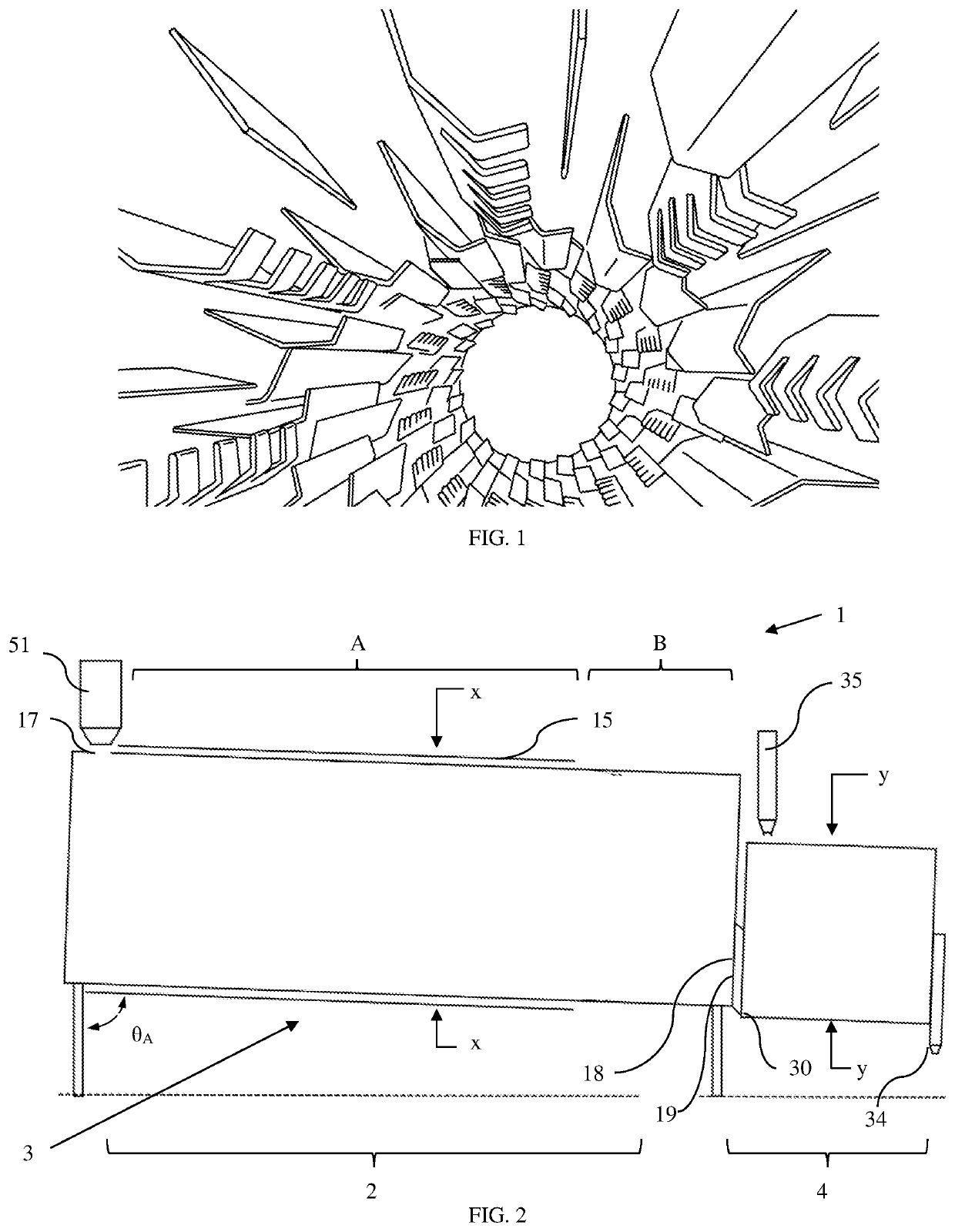

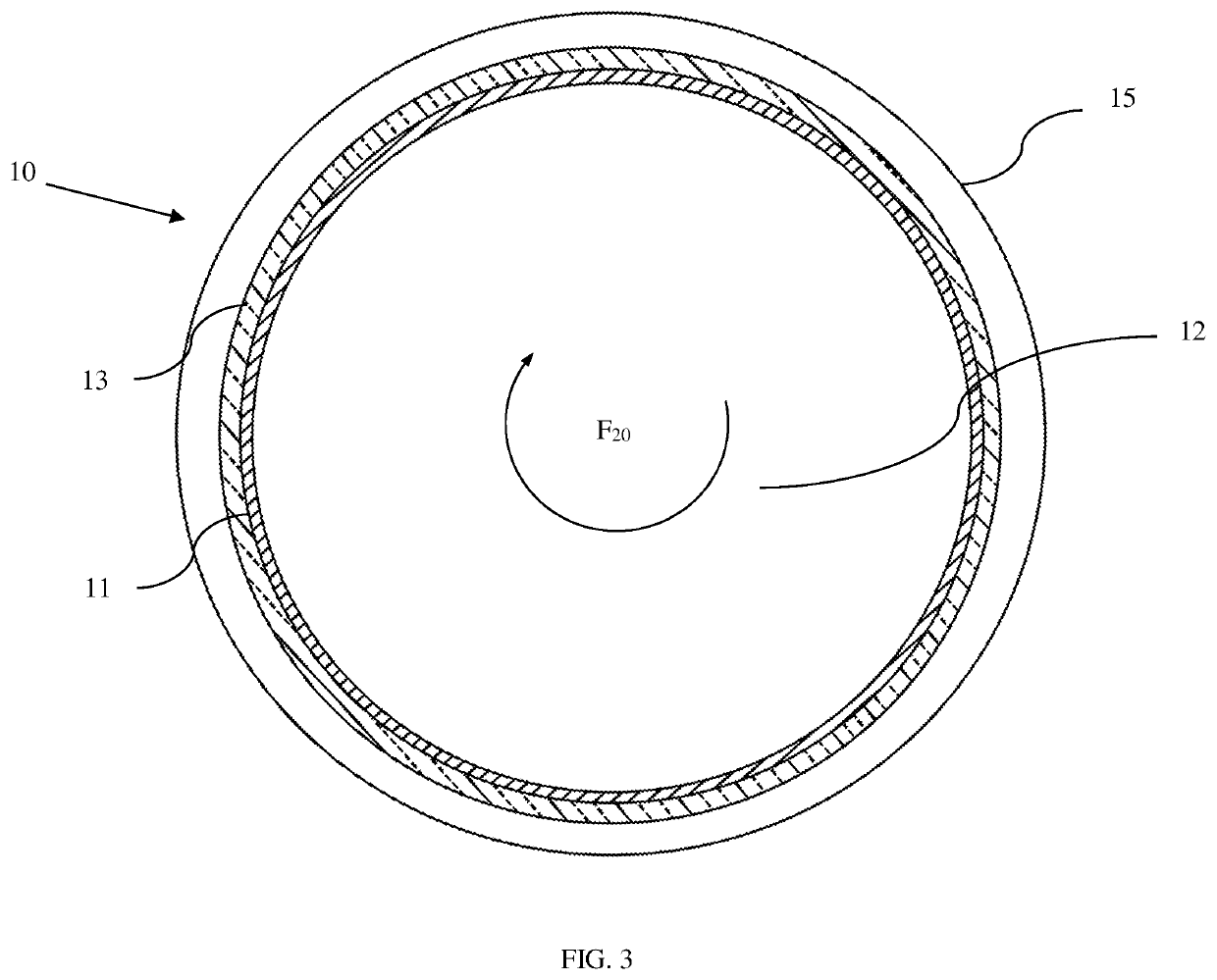

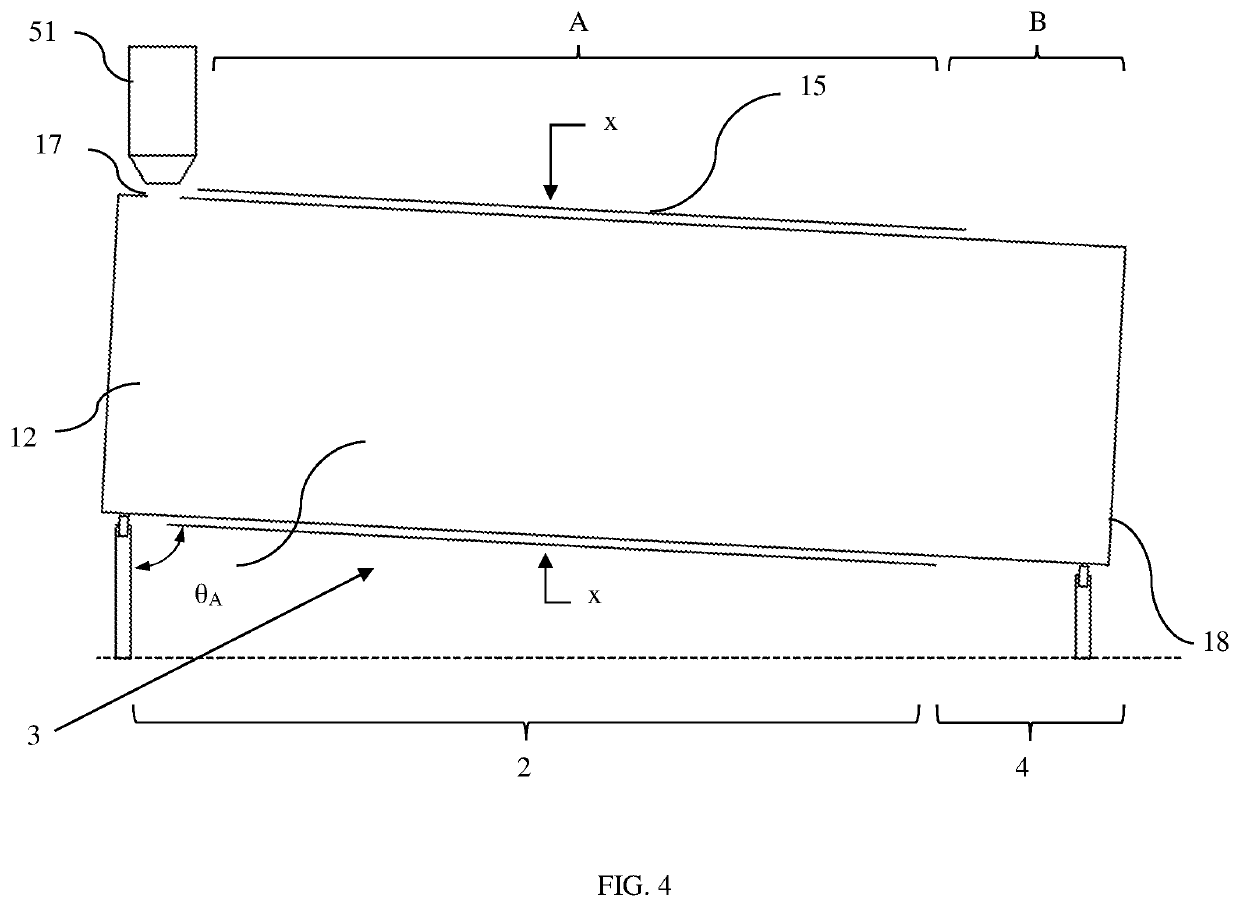

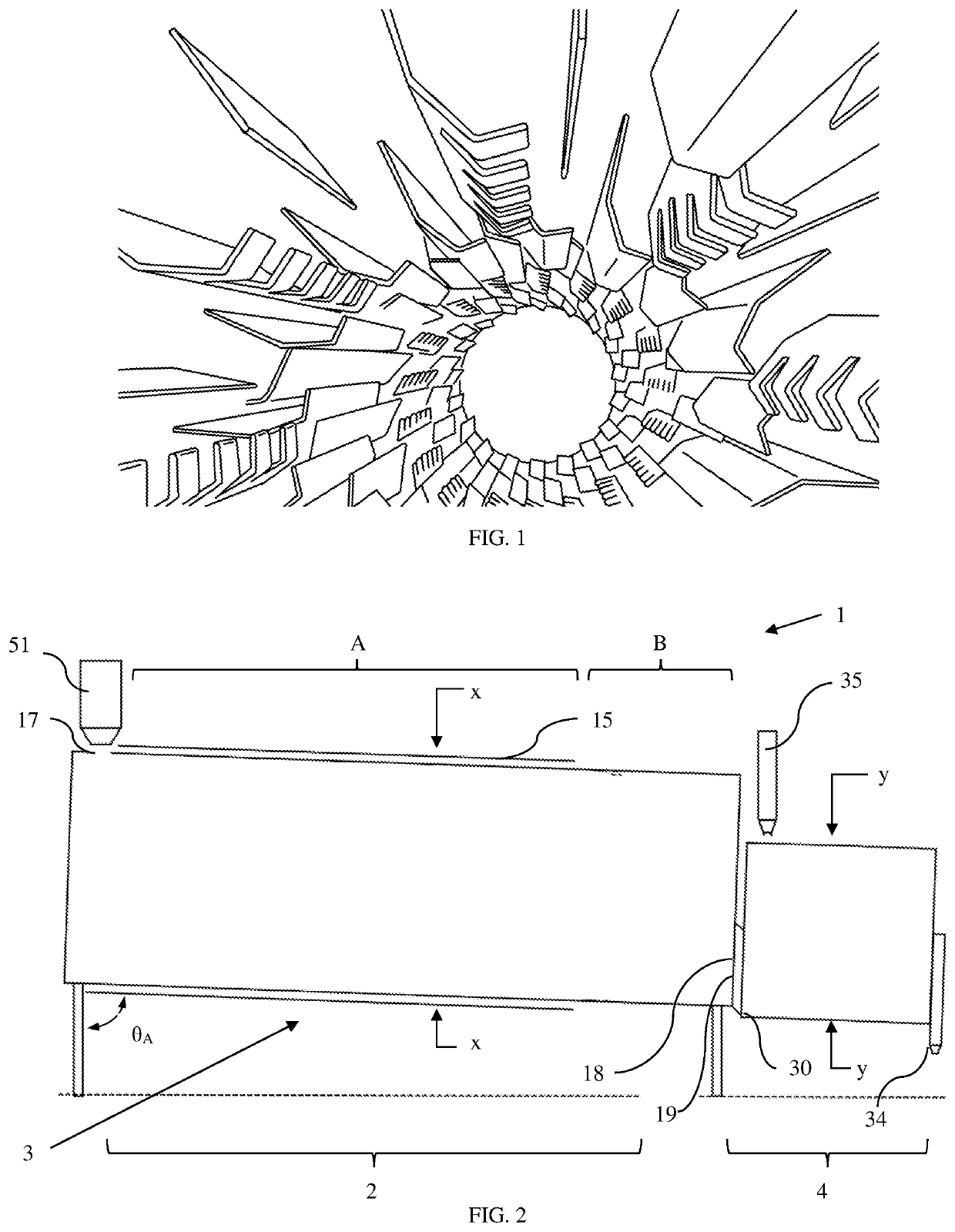

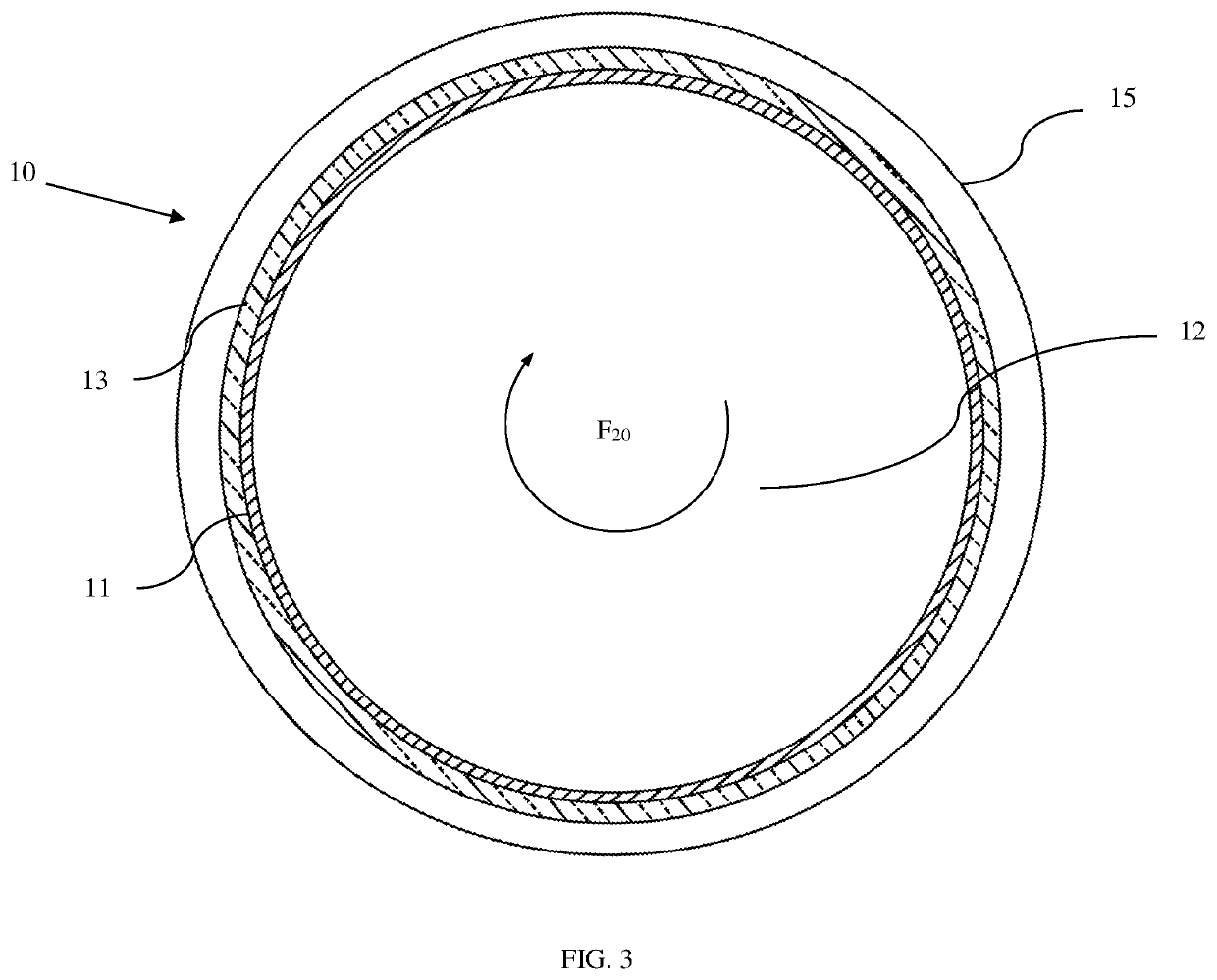

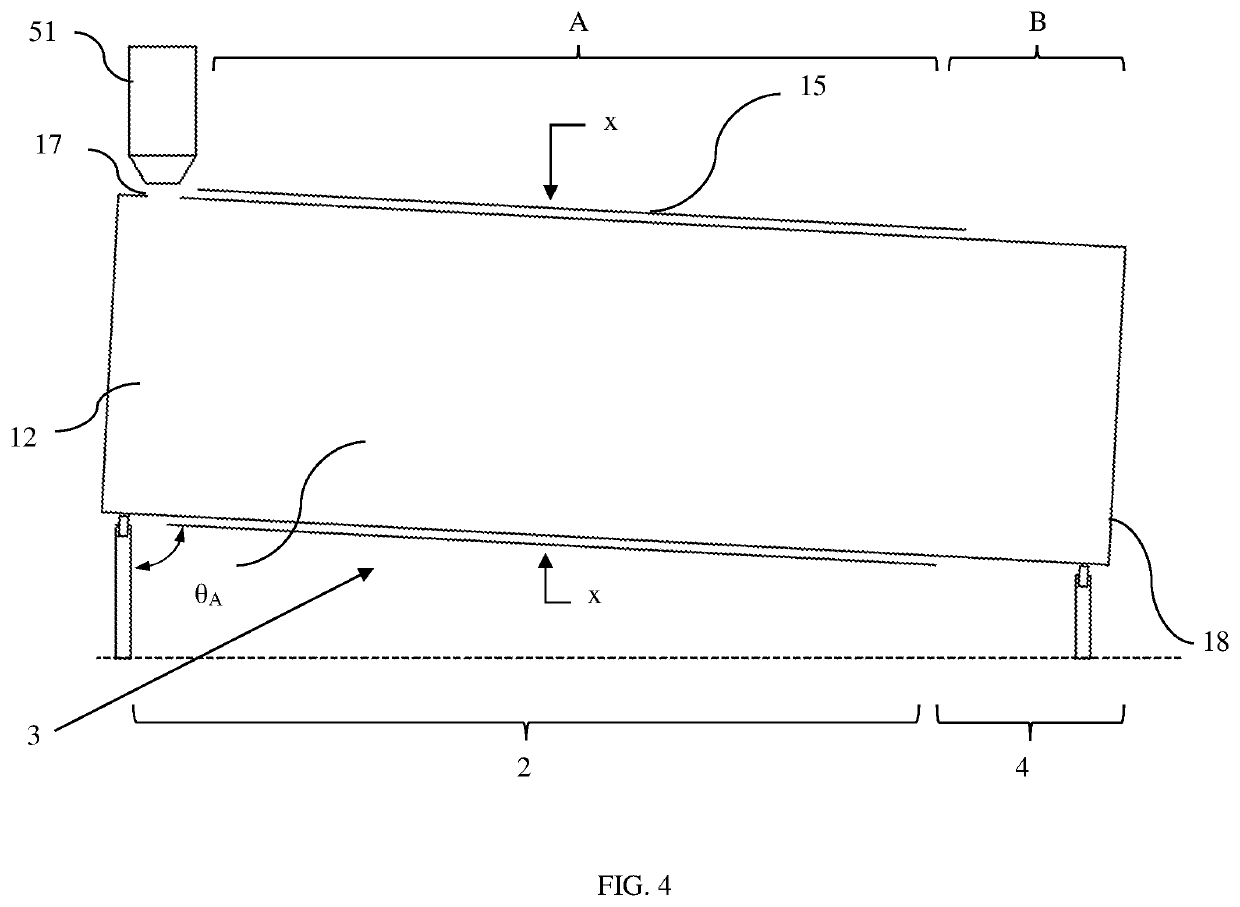

Rotational Mixing and Induction Heating System and Method for Recycling Asphalt Using the Same

ActiveUS20200248410A1Easy to transportEasy to changeRotating receptacle mixersIn situ pavingsThermodynamicsEngineering

An asphalt processing system is formed from a heating drum and an induction heating system. Flights move asphalt through the heating drum, which concurrently heat the asphalt along with the heating drum wall. A mixing drum can be connected to the heating drum, and include paddles or flights to move the asphalt, while concurrently mixing the material to ensure consistent temperatures through the asphalt cement. The asphalt is heating using one or more induction heating systems to quickly heat the asphalt to between 275° F. and 750° F., followed by moving the asphalt to between 275° F. and 350° F. The system can include a convection system that heats recirculated air through the heating drum. A water condenser can be employed to remove moisture during air recirculation, and reduce asphalt moisture content. The asphalt cement is optionally modified by addition of one or more rejuvenation oils. This system is particularly useful for recycled asphalt pavement, but can be used for all asphalt products.

Owner:CRUPI FRANCESCO

Rotational mixing and induction heating system and method for recycling asphalt using the same

ActiveUS10889940B2Easy to transportEasy to changeRotating receptacle mixersIn situ pavingsThermodynamicsEngineering

An asphalt processing system is formed from a heating drum and an induction heating system. Flights move asphalt through the heating drum, which concurrently heat the asphalt along with the heating drum wall. A mixing drum can be connected to the heating drum, and include paddles or flights to move the asphalt, while concurrently mixing the material to ensure consistent temperatures through the asphalt cement. The asphalt is heating using one or more induction heating systems to quickly heat the asphalt to between 275° F. and 750° F., followed by moving the asphalt to between 275° F. and 350° F. The system can include a convection system that heats recirculated air through the heating drum. A water condenser can be employed to remove moisture during air recirculation, and reduce asphalt moisture content. The asphalt cement is optionally modified by addition of one or more rejuvenation oils. This system is particularly useful for recycled asphalt pavement, but can be used for all asphalt products.

Owner:CRUPI FRANCESCO

Asphalt comprising unconventional asphalt base

PendingCN114106570AWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by mixing fractionsHydrogen contentOrganic chemistry

Owner:INST FR DU PETROLE

Preparation method of bituminous waterproof sheet material

InactiveCN105860553ASimple preparation stepsNo need for high temperature meltingWorking-up pitch/asphalt/bitumen by mixing fractionsWorking-up pitch/asphalt/bitumen by chemical meansBituminous waterproofingUltrasonic dispersion

The invention discloses a method for preparing an asphalt waterproof coiled material, which belongs to the technical field of waterproof coiled material preparation. The present invention weighs asphalt, soaks it repeatedly in acid and alkali, turns it in the sun until dry, crushes, grinds and sieves to obtain asphalt powder, adds concentrated sulfuric acid to acidify, mixes it with polyacrylamide, and then undergoes shaker oscillation and ultrasonic dispersion treatment Afterwards, high-temperature melting is carried out, and carbon black is sprayed on the surface of the melt at the same time, and N,N-diphenyl-p-phenylenediamine and tall oil are added for heat preservation to prepare bitumen waterproof membrane. The beneficial effects of the invention are: the preparation steps of the invention are simple, and the obtained product does not need to be melted at high temperature when used, saving time and effort; the construction period is short, the cost is reduced by 20-30%, and the water resistance is good.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

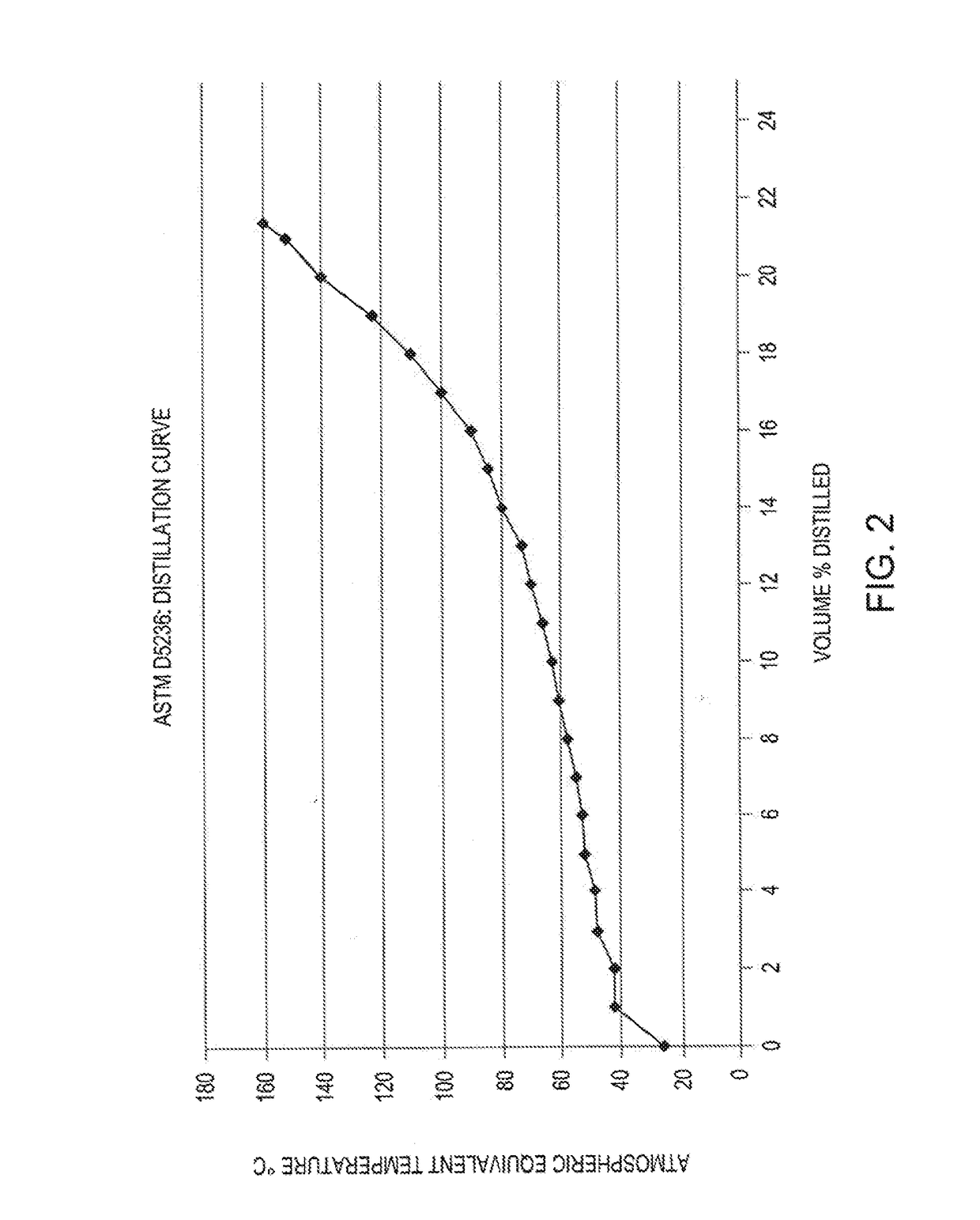

Methods for treating bitumen mixtures

InactiveUS20180119024A1Desirable initial boiling point (IBP)Improve performanceWorking-up pitch/asphalt/bitumen by distillationGas treatmentDiluentViscosity

Disclosed are methods for preparing a high-viscosity non-hazardous bitumen composition for transportation in a railcar, wherein the method may include: (a) providing to a fractionator system a low-viscosity bitumen composition previously residing in a pipeline having a first viscosity and comprising a miscible blend of hydrocarbons, which blend was prepared by mixing a first diluent composition with a first bitumen composition; (b) heating the low-viscosity bitumen composition in the fractionator system at an operating temperature of from 170 C to 232 C to provide a first light fraction and a first heavy fraction; (c) removing at least a portion of the first heavy fraction from the fractionator system, wherein the first heavy fraction has a second viscosity that is higher than the first viscosity; (d) forming a high-viscosity non-hazardous bitumen composition from at least a portion of the first heavy fraction; and (e) directing the high-viscosity non-hazardous bitumen composition to a railcar.

Owner:USD GRP LLC

A chemical reaction modified asphalt profile control water blocking agent and its preparation method and application

ActiveCN105038747BEasy to plug inWorking-up pitch/asphalt/bitumen by mixing fractionsWorking-up pitch/asphalt/bitumen by chemical meansNaphthaVulcanization

The invention relates to a chemical reactive modified asphalt profile modifying / water plugging agent and a preparation method and application of the profile modifying / water plugging agent. The preparation method comprises the following steps: S1, performing modification on petroleum asphalt by vulcanization to obtain sulphurized petroleum asphalt; S2, performing cationic modification on petroleum asphalt to obtain cation-modified petroleum asphalt; S3, adding the sulphurized petroleum asphalt and the cation-modified petroleum asphalt into naphtha, and then adding organic ammonium compounds, fully stirring for reaction for 40-60 min to obtain the chemical reactive modified asphalt profile modifying / water plugging agent. According to the chemical reactive modified asphalt profile modifying / water plugging agent and the preparation method and application of the profile modifying / water plugging agent, provided by the invention, by specific preparation steps, selection of components and technological parameters, the finally obtained profile modifying / water plugging agent has good plugging performance, erosion resistance property, high-temperature resistance and pH-resistance, and further has a good application prospect and industrial potential in the field of petroleum industry.

Owner:DAQING TIANMAN PETROCHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com