Spinnable asphalt and preparation method thereof

A pitch and coal tar pitch technology, applied in the field of spinnable pitch and its preparation, can solve the problems of increasing the production process of spinnable pitch and complicating the production of spinnable pitch, achieving narrow melting range, high softening point, and simplified preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

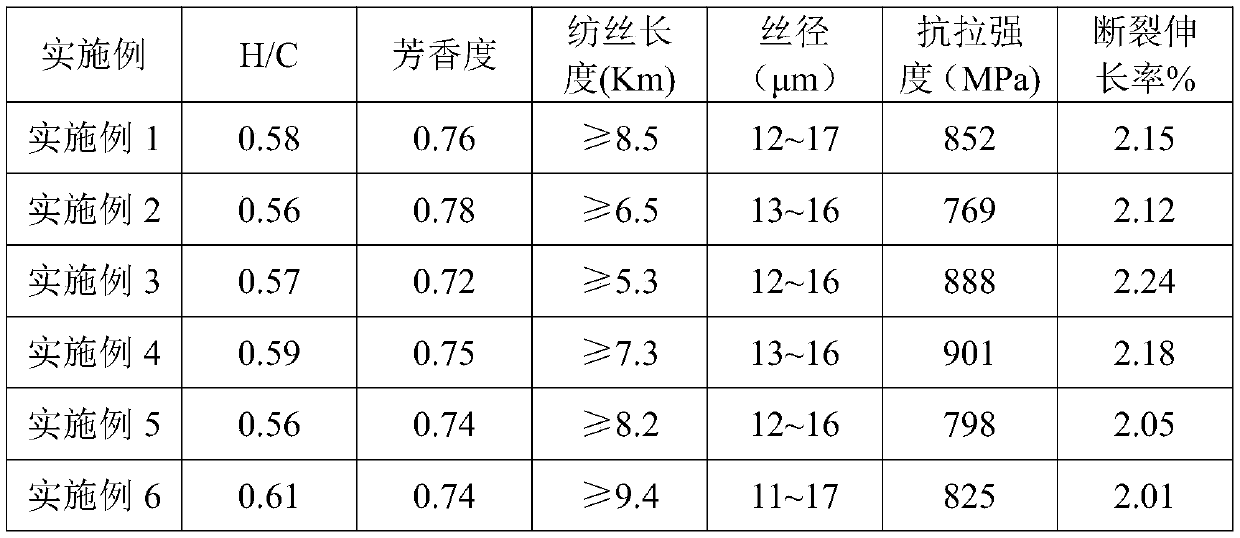

Examples

Embodiment 1

[0039] Another embodiment of the present invention is a method for preparing spinnable asphalt, comprising the following steps:

[0040] Step S1, using medium and low temperature coal tar pitch with an ash content ≤ 0.2 wt% as raw material, preparing medium and low temperature coal tar pitch based refined pitch. The specific method for preparing medium and low temperature coal tar pitch-based refined pitch is as follows:

[0041] Step S1.1: Grinding the medium and low temperature coal tar pitch to a size smaller than 20 meshes to obtain powdered medium and low temperature coal tar pitch.

[0042] Step S1.2, extracting the powdered medium-low temperature coal tar pitch with tetrahydrofuran to obtain a first extract; in the extraction, the weight ratio of medium and low temperature coal tar pitch to tetrahydrofuran is 1:4˜1:10.

[0043] Step S1.3, after filtering the first extract, recover the tetrahydrofuran therein to obtain the first soluble component. Wherein, the filtrati...

Embodiment 1

[0053] The softening point is 88°C, the ash content is 0.2wt% medium and low temperature coal tar pitch is crushed to ≤20 mesh, mixed with tetrahydrofuran at a mass ratio of 1:4, the soluble components of medium temperature coal tar pitch are extracted and filtered, and after vacuum drying for 12 hours, tetrahydrofuran is soluble Mix the mixture with toluene at a mass ratio of 1:4, recover the toluene, and dry in vacuum for 12 hours to obtain refined asphalt with an ash content of 0.02wt% and a softening point of 73°C.

[0054] Mix the obtained refined asphalt with petroleum asphalt with a softening point of 98°C and an ash content of 0.02wt% at a ratio of 1:4 (weight ratio), put it into the reactor, and continuously feed nitrogen at a rate of 15mL / min·g , heated to 390°C at a heating rate of 9°C / min, and stayed for 8 hours.

[0055] The obtained spinnable pitch has a softening point of 198°C, a softening melting range of 198-208°C, and a single yield of 66.0%. The spinnable ...

Embodiment 2

[0057] Grind medium-low temperature coal tar pitch (softening point: 86°C, ash content 0.2wt%) to ≤20 mesh, mix with tetrahydrofuran at a mass ratio of 1:8, extract and filter out the soluble components of medium-temperature coal tar pitch, and vacuum-dry for 12 hours. The mass ratio of soluble matter and toluene was mixed at 1:8, the toluene was recovered, and after vacuum drying for 12 hours, refined asphalt with an ash content of 0.01wt% and a softening point of 77°C was obtained.

[0058] Mix the obtained refined asphalt with petroleum asphalt (softening point: 105°C, ash content: 0.02wt%) at a ratio of 1:2 (weight ratio), put it into the reactor, and continuously feed it at a rate of 30mL / min·g Nitrogen, heated to 400°C at a heating rate of 5°C / min, and stayed for 7 hours.

[0059] The obtained spinnable pitch has a softening point of 204°C, a softening melting range of 204-222°C, and a single yield of 57.0%. The spinnable pitch is melt spun at 265°C, the spinning pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com