Asphaltene dispersant composition and method for dispersing asphaltene deposits

A technology of asphaltene dispersant and composition, applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, processing of tar asphalt/petroleum asphalt/natural asphalt through mixed fractions, building construction, etc., can solve permanent oil reservoirs Damage, catalyst coking deactivation, affecting transmission efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

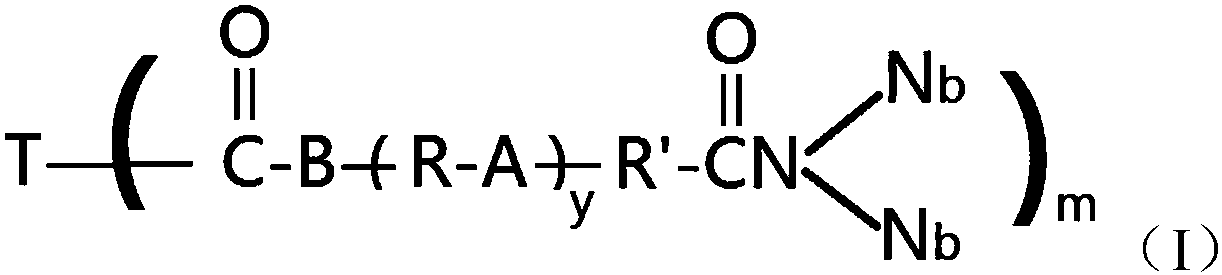

Method used

Image

Examples

preparation example 1

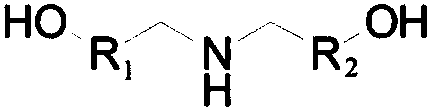

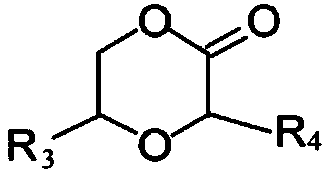

[0060] 10.5 grams of diethanolamine (compound 1, purchased from Beijing Beijing Yinuokai Technology Co., Ltd.) and 10.2 grams of 1,4-dioxane-2-one (compound 2, purchased from Beijing Beijing Yinuokai Technology Co., Ltd.) uniformly mixed and added to a 50 ml round-bottomed flask, heated to 100 ° C for 6 hours, during the heating process, compounds 1 and 2 were in a molten state, cooled and stood still to obtain N,N-di-( 2-Hydroxyethyl)-2-hydroxyethoxyacetamide (compound 3, see the following formula) (20 g) was a colorless oil, which was directly used in the next reaction without further purification.

[0061] Add polyisobutylene maleic anhydride (compound 4, n=15, Mn=994) (0.5 equivalents) into a 50-ml round-bottomed flask, first pass nitrogen gas for 5 minutes, then heat to 160°C, and stir at 160°C After 30 minutes, compound 3 was added to the solution, and the reaction was continued at 160° C. for 3.5 hours, and cooled to room temperature to obtain compound 5, namely yellow ...

Embodiment 1

[0065] 80% by weight of L01 and 20% of span20 (purchased from Best Reagent Co., Ltd.) were mixed and stirred under the condition of 100° C. to obtain dispersant composition EE-01.

Embodiment 2

[0067] 80% by weight of L01 and 20% of span40 (purchased from Best Reagent Co., Ltd.) were mixed and stirred at 100° C. to obtain dispersant composition EE-02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com