Method for preparing coal tar pitch having improved compatibility with asphalt and asphalt containing the same

A technology for coal tar pitch and coal tar, which is applied in the field of preparation of pitch and can solve the problems of not considering the improvement of the compatibility of petroleum pitch, and it is difficult to improve the compatibility of coal tar pitch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] According to another exemplary embodiment of the present invention, coal tar and naphtha cracking residue or oil slurry may be further mixed with a ketone solvent having a boiling point of, for example, less than or equal to about 200°C. Examples of ketone solvents may include saturated and unsaturated ketone compounds such as acetone, methyl ethyl ketone, diethyl ketone, pinacolone, isobutyl methyl ketone, diisopropyl ketone, methyl butyl ketone, dipropyl ketone , methyl vinyl ketone, methyl heptanone, cyclopentanone, cyclohexanone, ethylpentyl ketone, hexyl methyl ketone, etc., which may be used alone or in combination. Particularly useful are acetone, methyl ethyl ketone or mixtures thereof.

[0022] According to an exemplary embodiment, coal tar, naphtha cracking residue or oil slurry, and a ketone solvent are mixed under agitation (at a rotation speed of about 100 rpm to 1,000 rpm, especially about 200 rpm to 500 rpm), and the resulting mixture is centrifuged (suc...

Embodiment 1

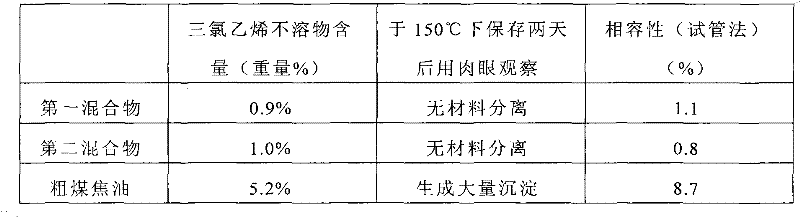

[0032] The first mixture (coal tar: naphtha cracking residue = 5: 1), the second mixture (coal tar: oil slurry = 5: 1) and crude coal tar were subjected to atmospheric distillation respectively at 250 ° C, and then The atmospheric distillation residue was subjected to vacuum distillation at 360° C. to recover coal tar pitch. Afterwards, the obtained coal tar pitch was mixed with petroleum pitch (AP-5, SK energy company) at a weight ratio of 5 (petroleum pitch): 1 (coal tar pitch) at 150° C. and 300 rpm under stirring conditions to prepare Three bitumen samples containing coal tar pitch. The content of trichlorethylene insolubles in coal tar pitch and the properties of pitch containing coal tar pitch were measured. The results are shown in Table 1 and Table 2 below.

[0033] Table 1

[0034] Comparison of Trichlorethylene Insoluble Content in Three Coal Tar Pitch Samples

[0035] Trichlorethylene insoluble content (weight%) first mixture 7% second...

Embodiment 2

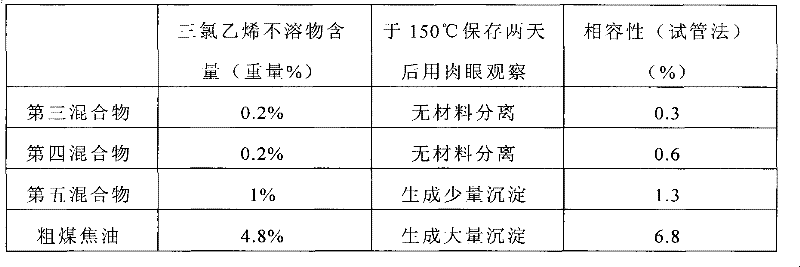

[0041] Under the rotating speed of 3,000rpm, the third mixture (coal tar:naphtha cracking residue:acetone=5:1:1), the fourth mixture (coal tar:oil slurry:acetone=5:1:1), The fifth mixture (coal tar:acetone=5:1) and crude coal tar were centrifuged, and then the supernatant from which the precipitate had been removed was subjected to atmospheric distillation at 250°C. This atmospheric distillation residue was subjected to vacuum distillation at 360°C to obtain coal tar pitch. After that, the obtained coal tar pitch and petroleum pitch (AP-5, SK Energy) were mixed at a weight ratio of 5 (petroleum pitch): 1 (coal tar pitch) at 150° C. and 300 rpm under stirring conditions to prepare four A bitumen sample containing coal tar pitch. The content of trichlorethylene insoluble matter in coal tar pitch and the properties of pitch containing coal tar pitch were measured. The results are shown in Table 3 and Table 4 below.

[0042] table 3

[0043] Comparison of Trichlorethylene Ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com