Method for catalytic synthesis of high quality intermediate phase carbon material with pure aromatic hydrocarbon

A kind of mesophase carbon, high-quality technology, used in the chemical processing of tar pitch/petroleum pitch/natural pitch, tar pitch/petroleum pitch/natural pitch processing, heating processing tar pitch/petroleum pitch/natural pitch, etc. , which can solve the problems that the preparation process has not been promoted, the morphology and structure of the mesophase pitch are not ideal, and the ash content is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for catalytically synthesizing high-quality mesophase carbon materials using pure aromatics, the method comprising the following steps:

[0026] (1) The raw materials of cut naphthalene and anthracene in coal tar are mixed and added to the raw material tank, heated and preheated to 90°C after mixing, and catalyst AlCl is added thereto, the addition is 3% of the total raw material quality, and the temperature is controlled at 160 ℃, fully stirred;

[0027] (2) The mixture liquid in the step (1) is added in the microwave heating reactor through a metering pump, and the residence time in the microwave heating reactor is 1 hour;

[0028] (3) Control the temperature at the liquid outlet of the microwave heating reactor to be 195° C., transfer the liquid that has been reacted in the microwave heating reactor into the still, and slowly raise the temperature in the still to 260° C.;

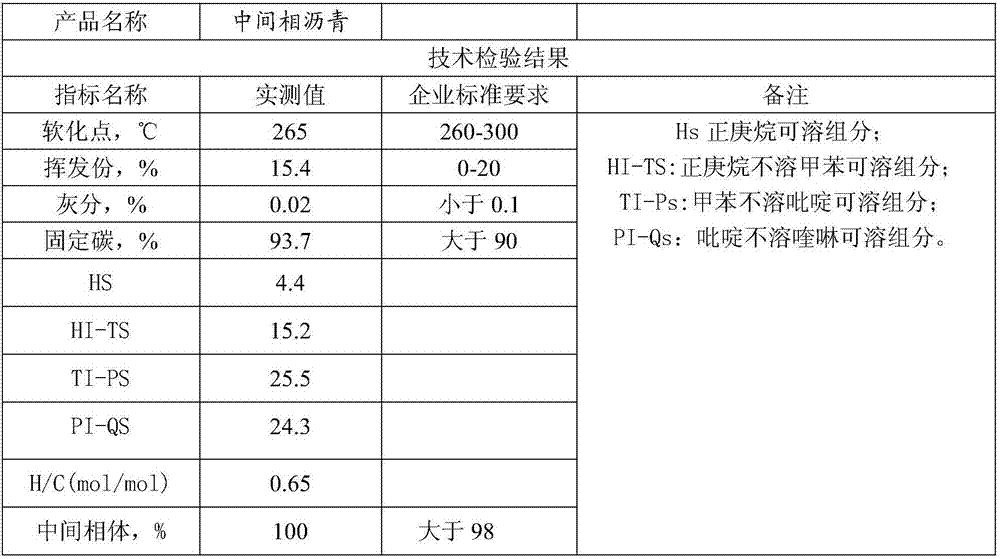

[0029] (4) Cool down the remaining mixed composition after distillation at the botto...

Embodiment 2

[0034] In the process of embodiment 1, the liquid distilled out in the still kettle in the step (3) is returned in the raw material tank of naphthalene and anthracene mixture.

Embodiment 3

[0036] In the process of Example 1, after steps (1) to (5), after the upper layer separation liquid S1, the upper layer separation liquid S2 and the distillate S3 are mixed, the absolute ethanol is distilled out by a fractionation tower and returned to the step (4 ) to continue to use, continue to heat up the mixed solvent that has taken off absolute ethanol to 300 ° C, and distill the fraction that is heated to 300 ° C for subsequent use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com