Patents

Literature

200results about "Working-up pitch/asphalt/bitumen by thermal means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

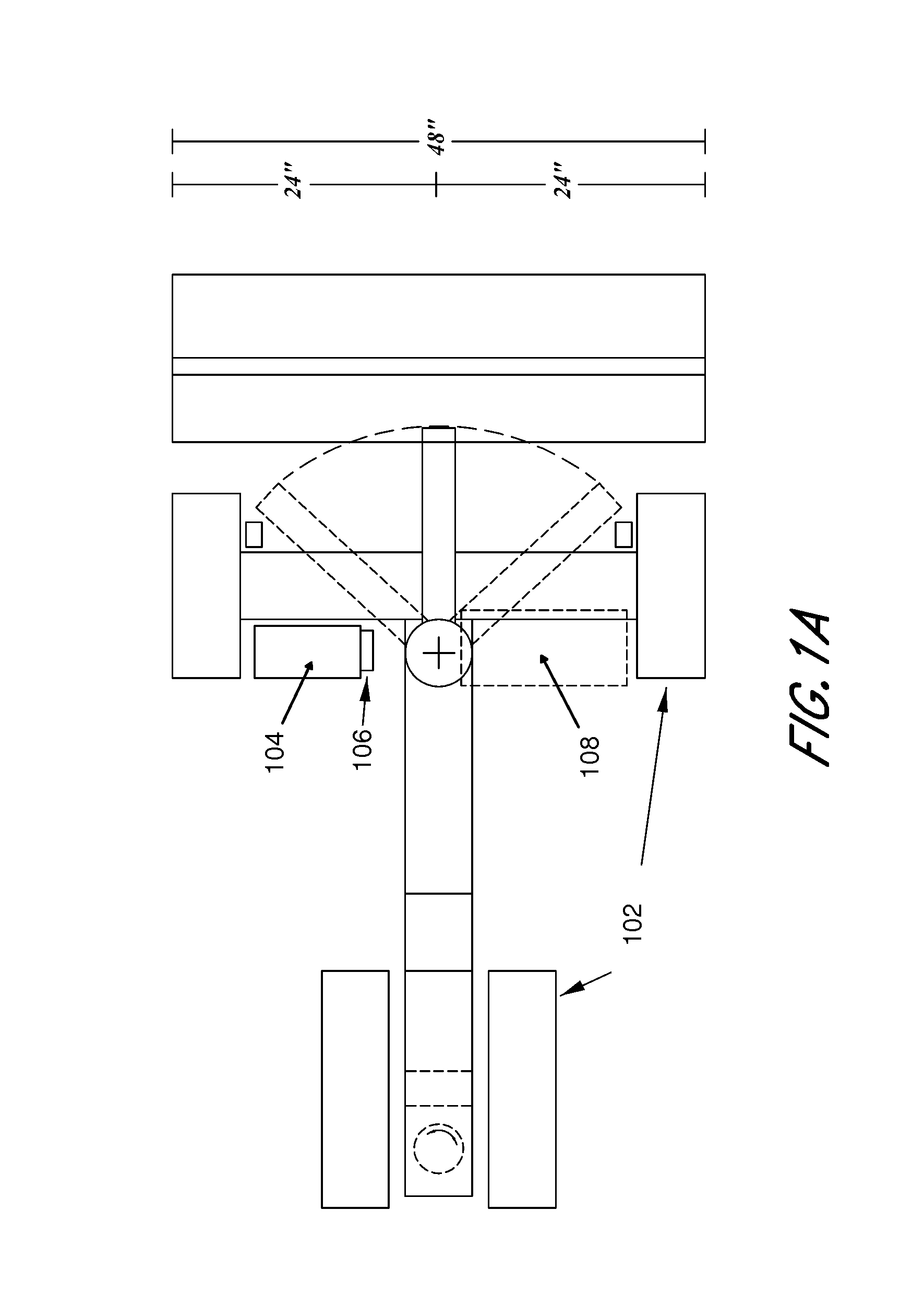

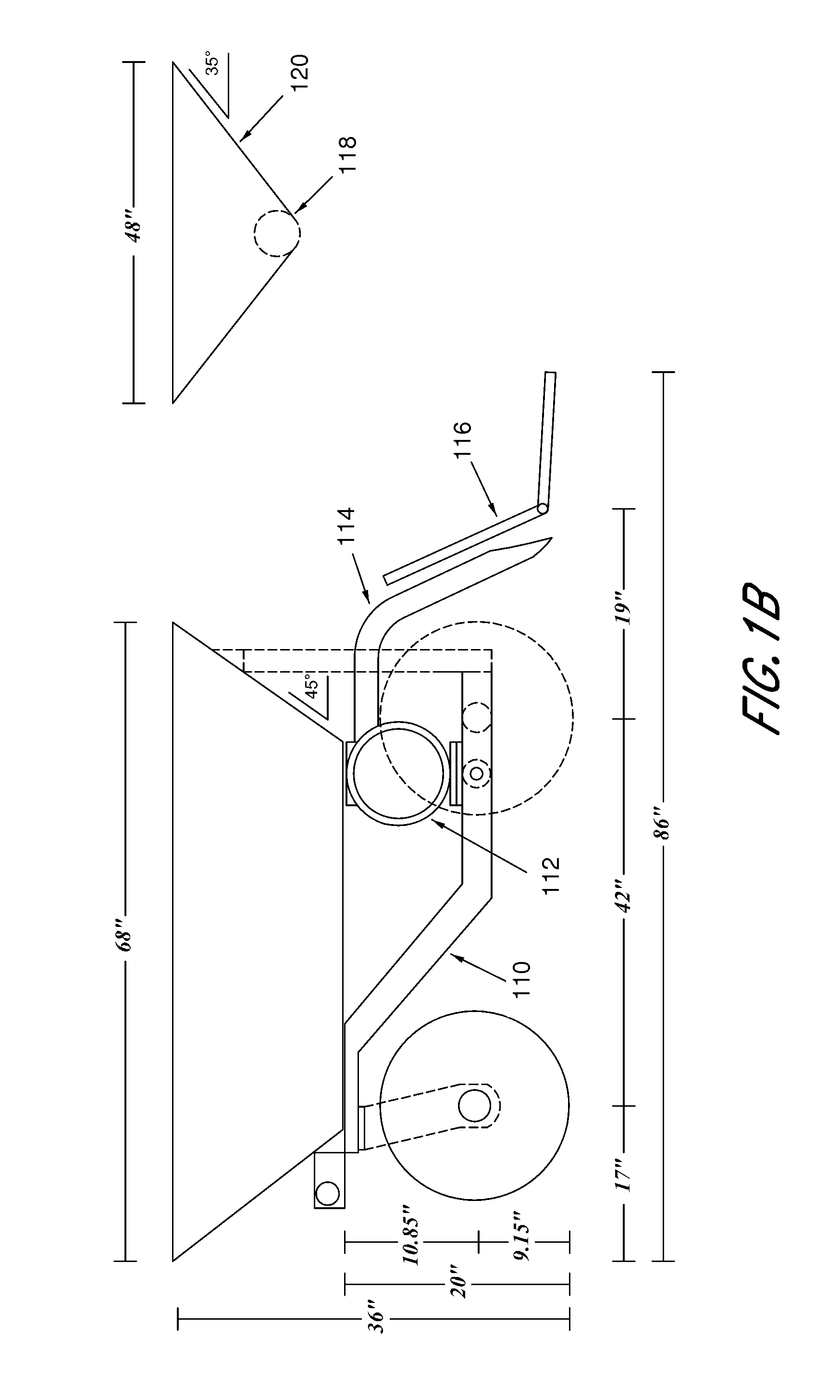

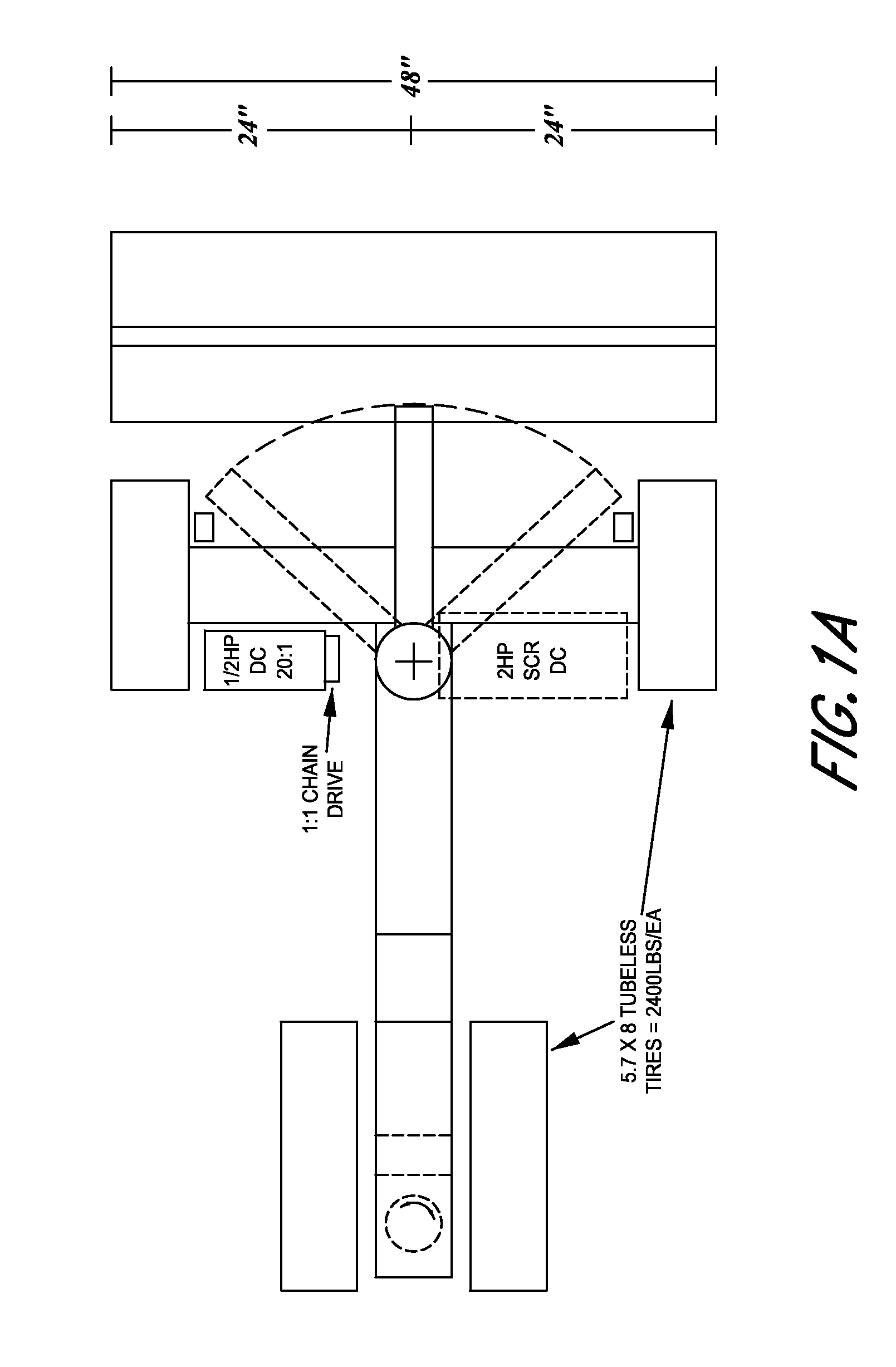

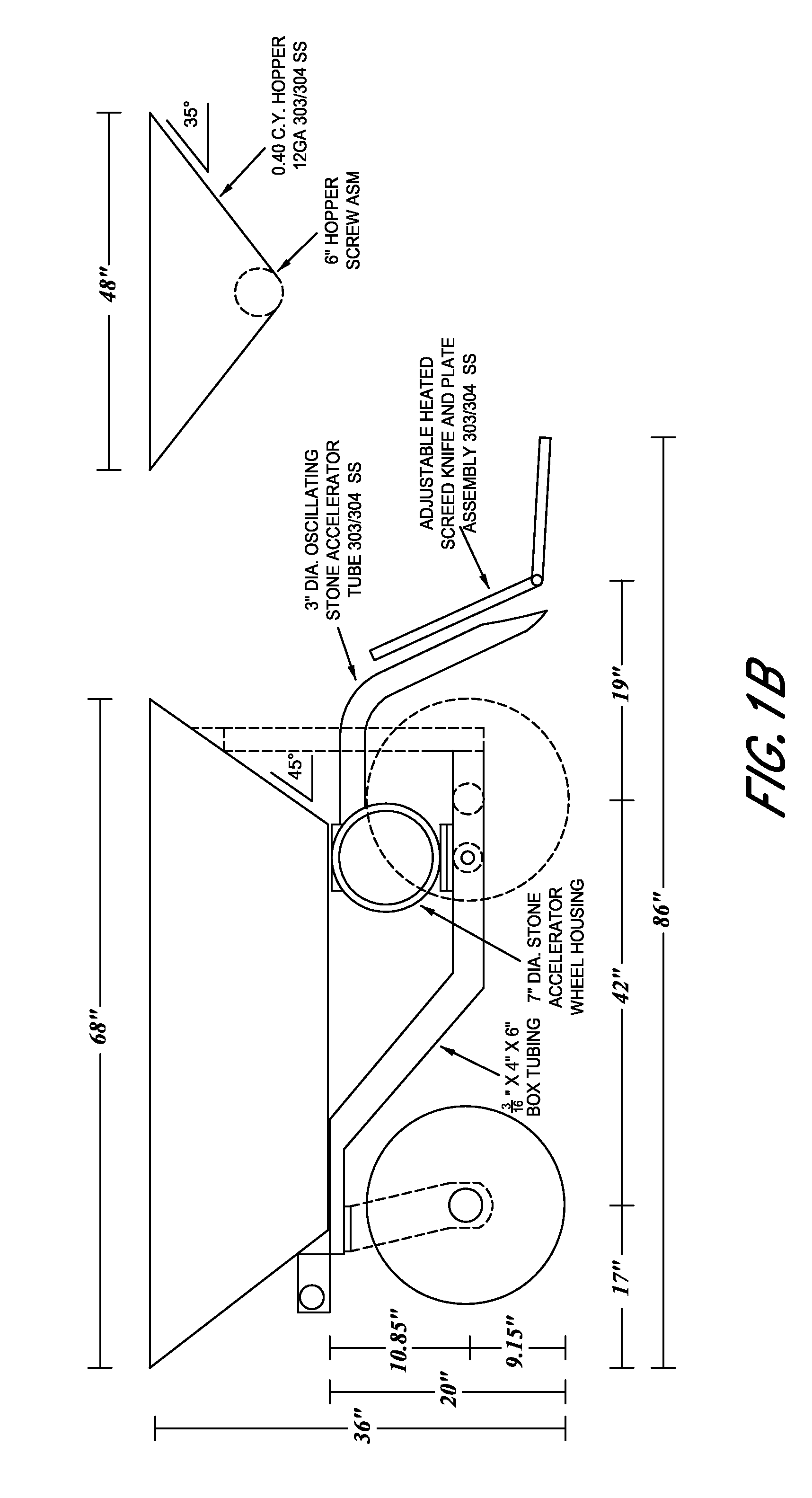

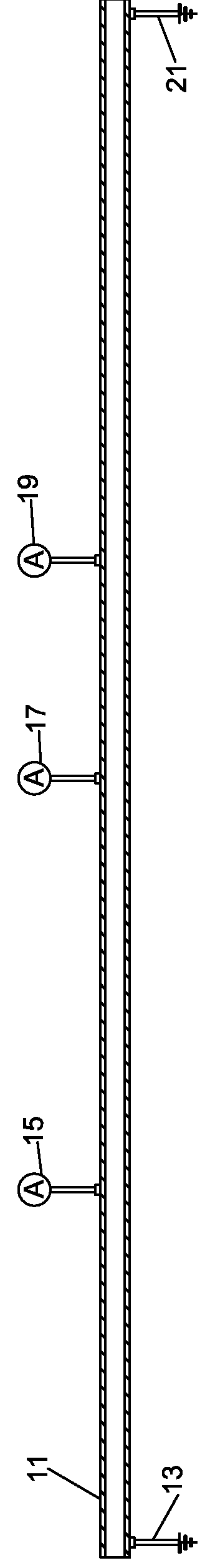

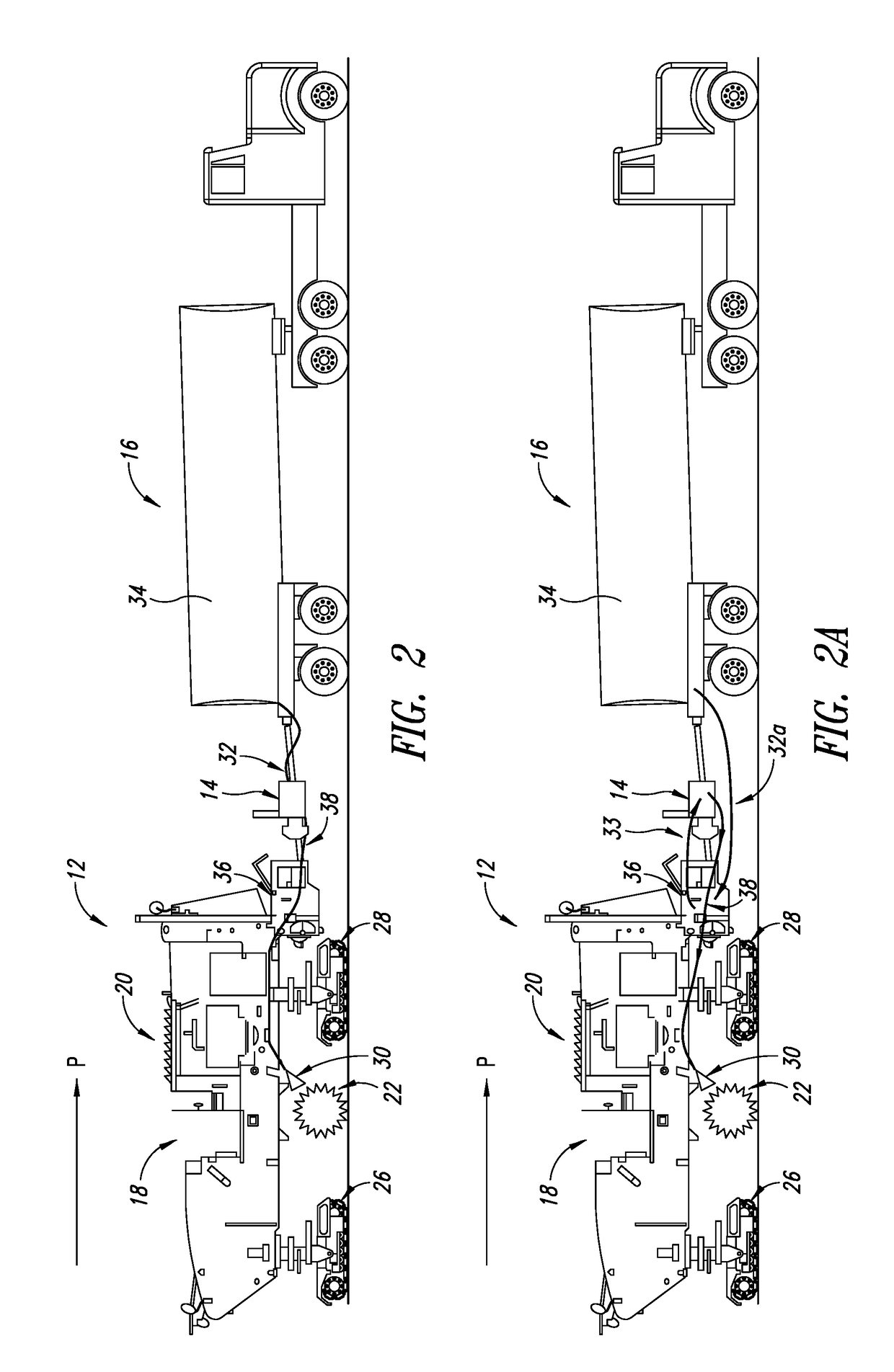

Pavement repair system utilizing solid phase autoregenerative cohesion

ActiveUS8992118B2Long and longer useful lifePaving propertyPaving reinforcementsIn situ pavingsOligomerEmulsion

A method for repairing an aged or damaged asphalt pavement is provided. The method involves preparing a surface of the aged or damaged asphalt pavement by filling in deviations from a uniform surface plane with dry aggregate and compacting the dry aggregate; applying a reactive asphalt emulsion to the prepared surface; and passing an emitter over the prepared pavement, wherein the emitter generates electromagnetic radiation having a wavelength of from 2-5 mm that penetrates into the pavement to a depth of at least 2 inches. The asphalt pavement is repaired by disturbing voids and interstices in the damaged pavement without dehydrogenation of the asphalt, such that oligomers present in the aged asphalt are linked together into longer polymer chains to improve ductility of the aged asphalt.

Owner:COE WILLIAM B

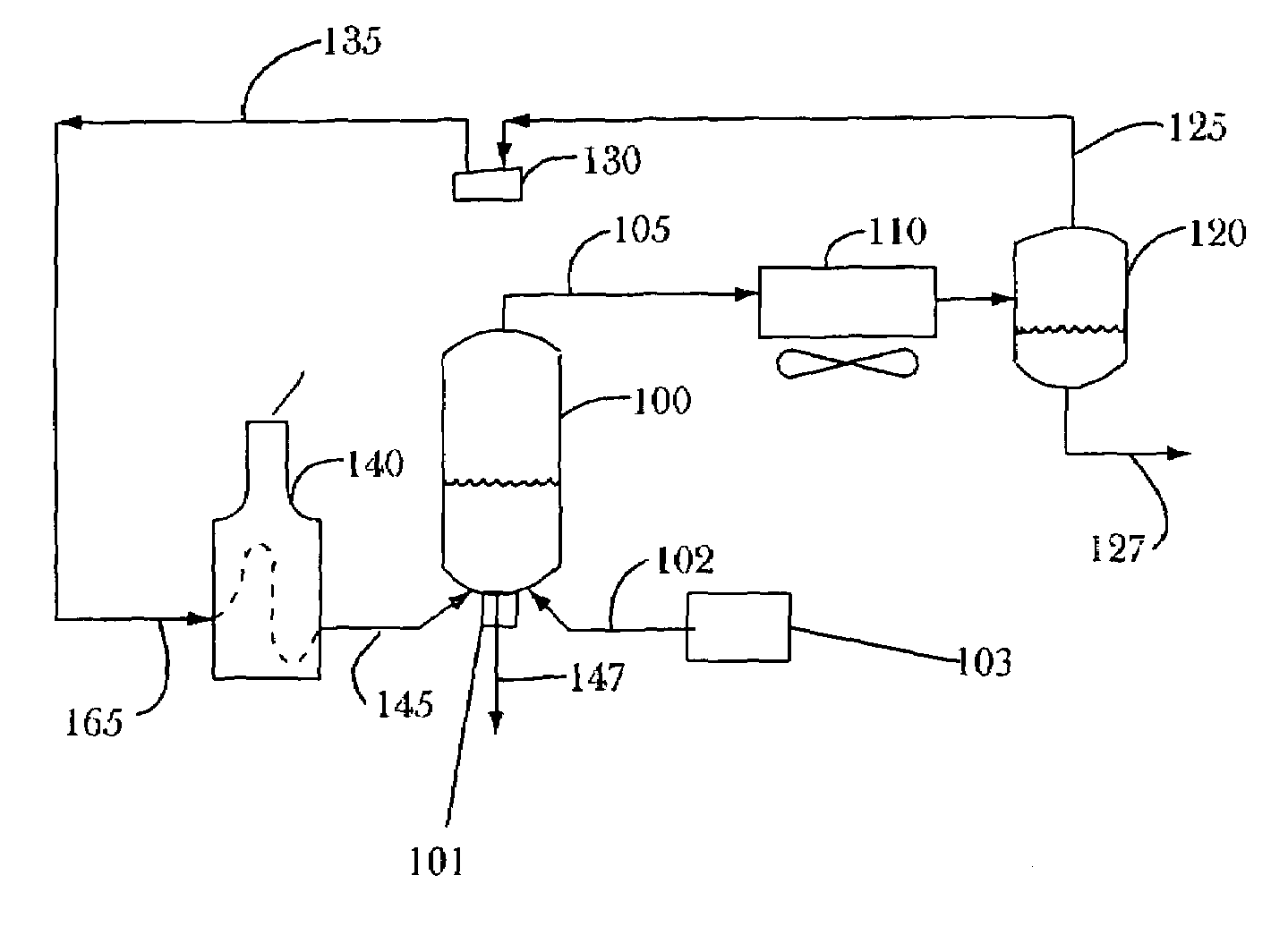

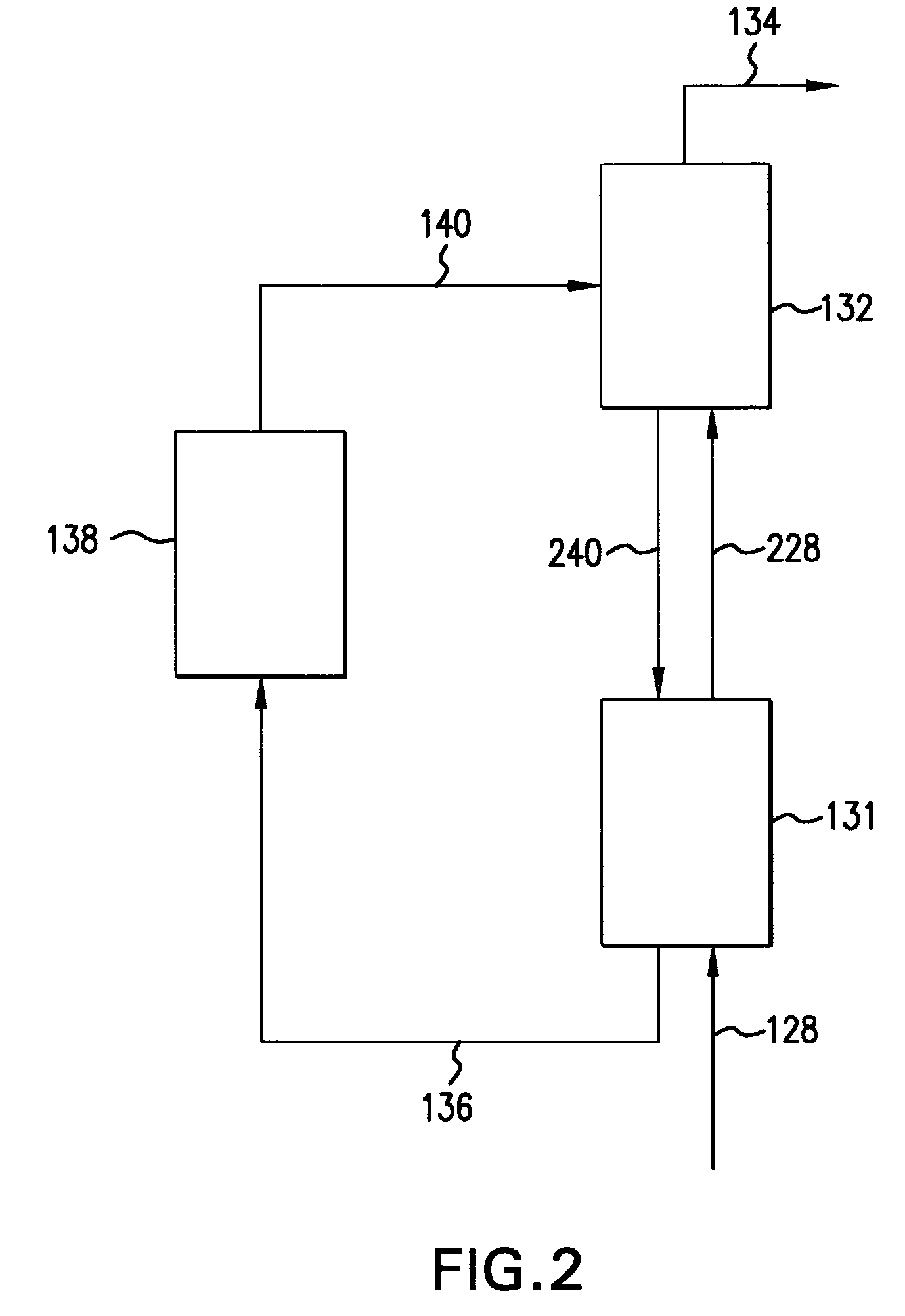

Method of producing high softening point pitch

InactiveUS7220348B1Reduce partial pressureMinimizes decompositionWorking-up pitch/asphalt/bitumen by distillationCatalytic crackingSuperheated steamHydrocarbon

The present invention provides a way to increase the softening point of heavier hydrocarbons in a relatively low cost and low pressure process using superheated steam to i) increase the carbon yield of the heavier hydrocarbons, while simultaneously ii) removing volatile components with a steam stripping process.

Owner:MARATHON PETROLEUM

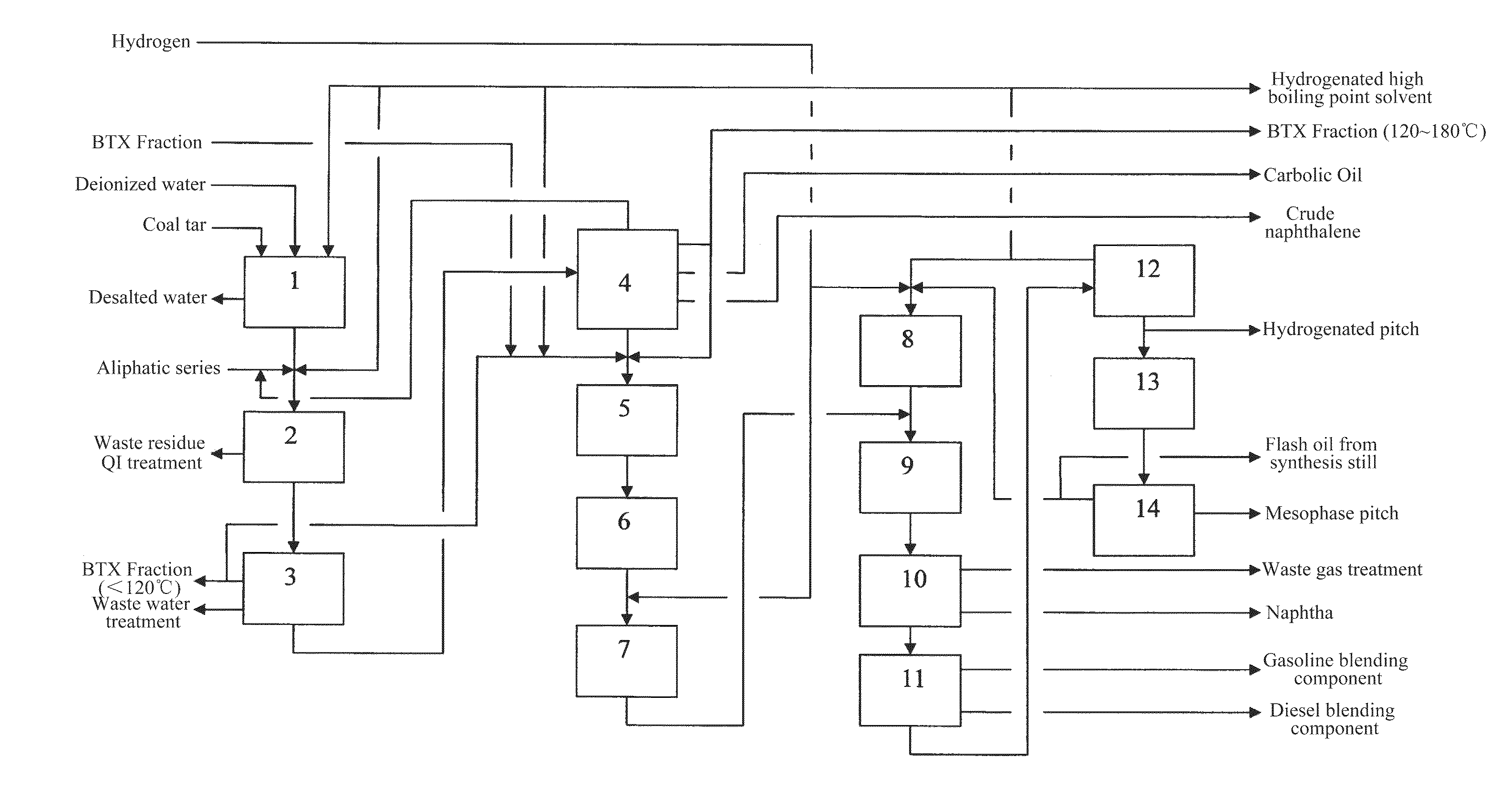

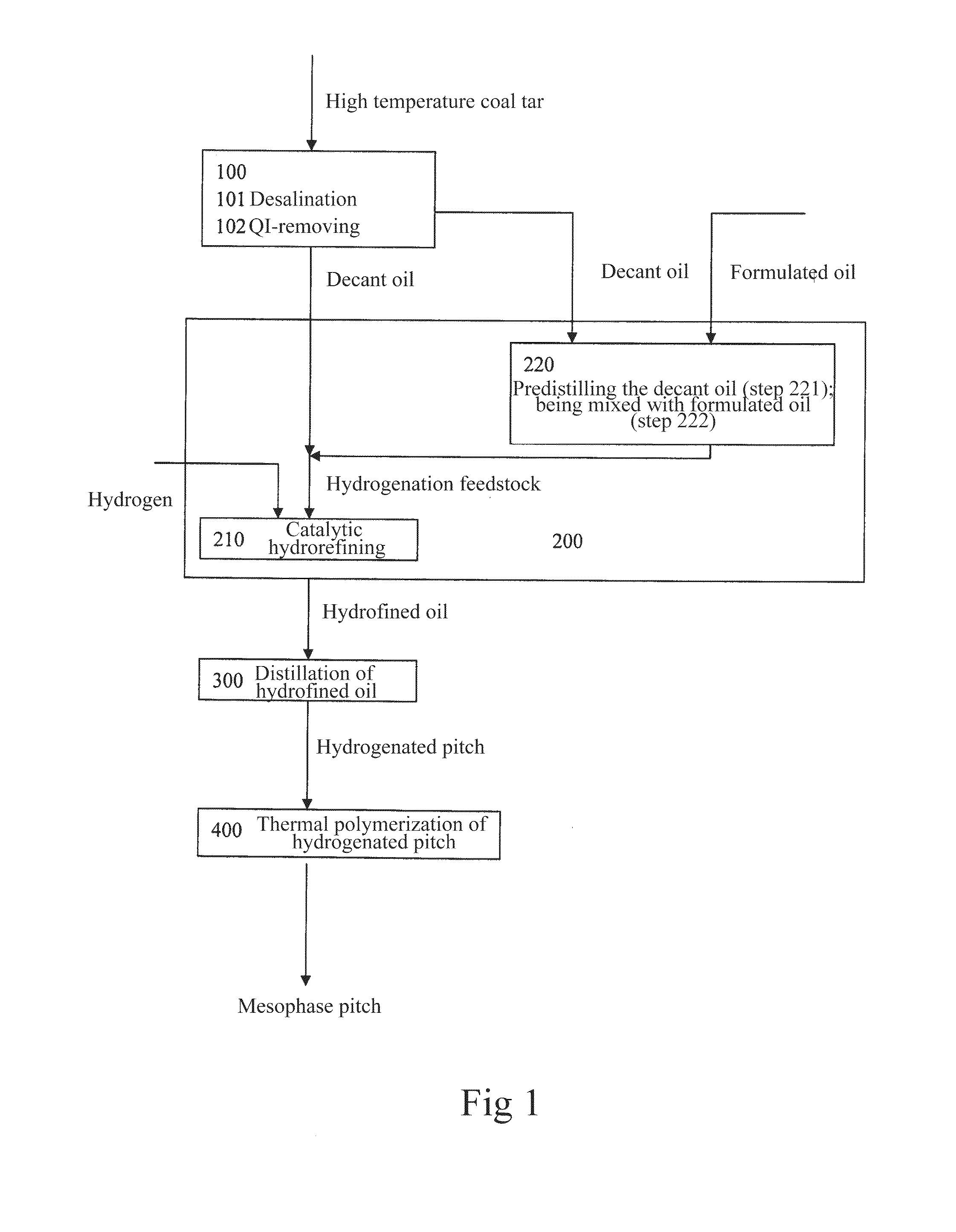

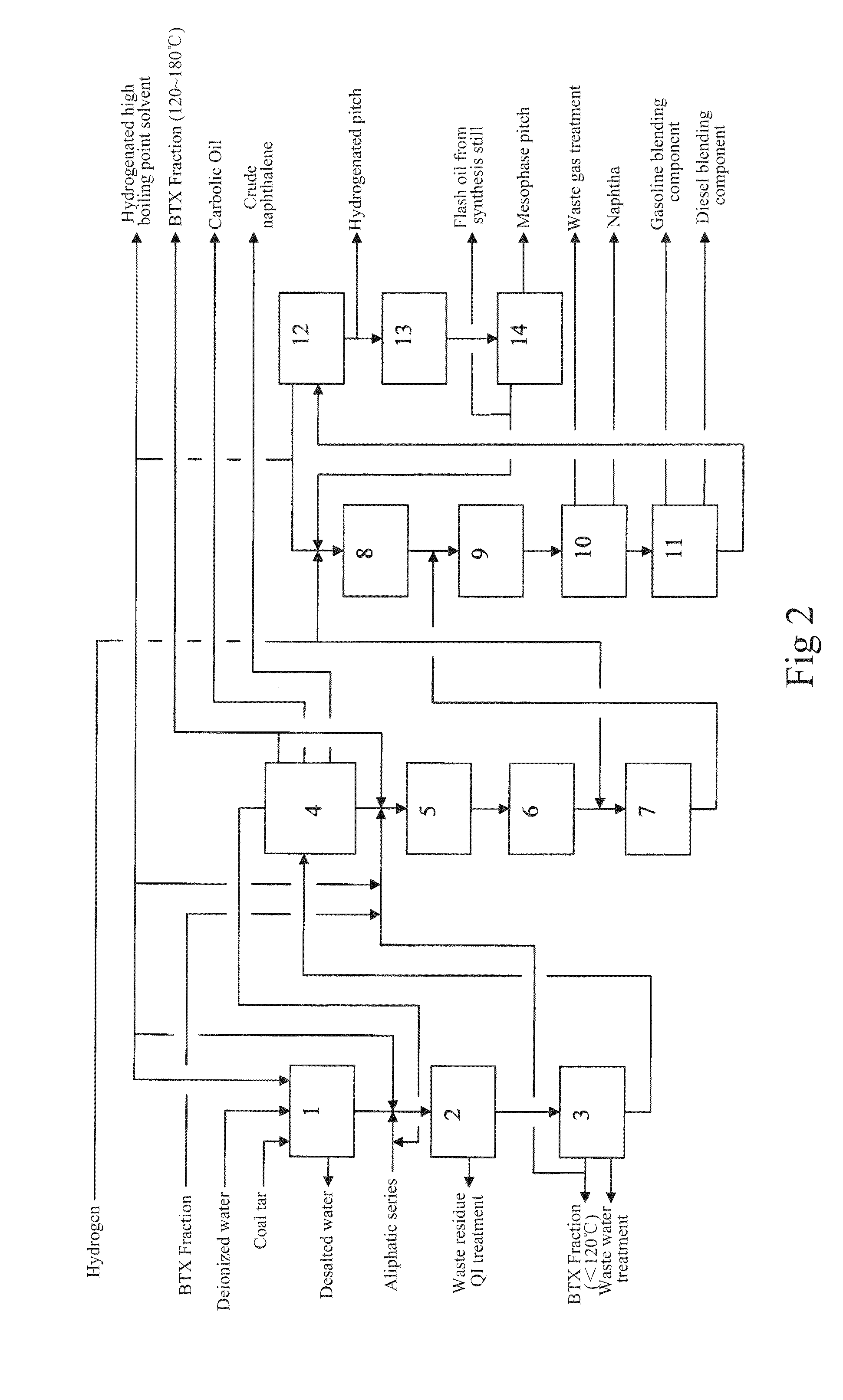

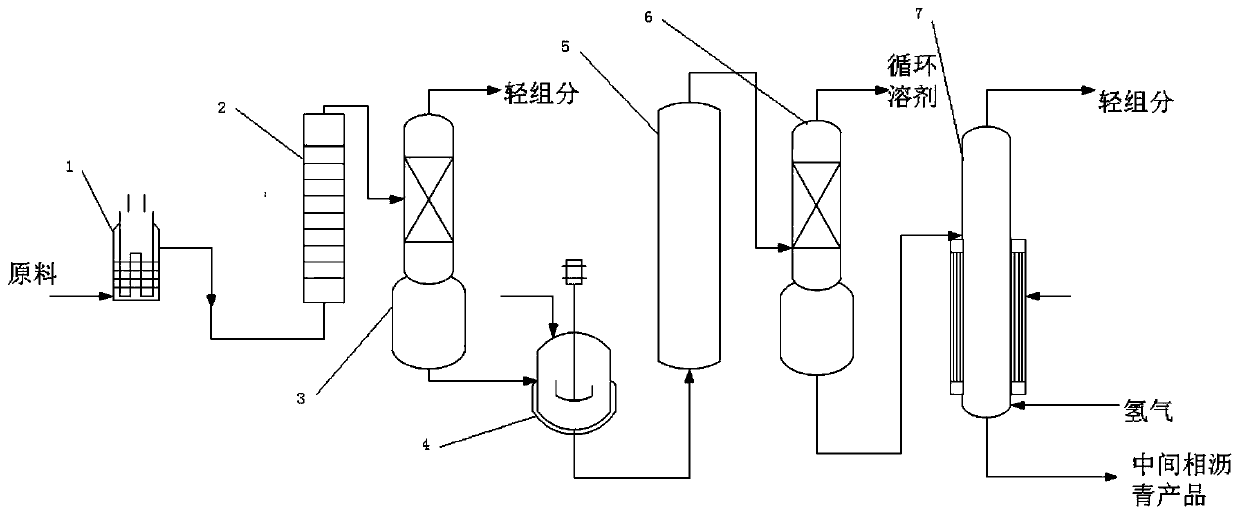

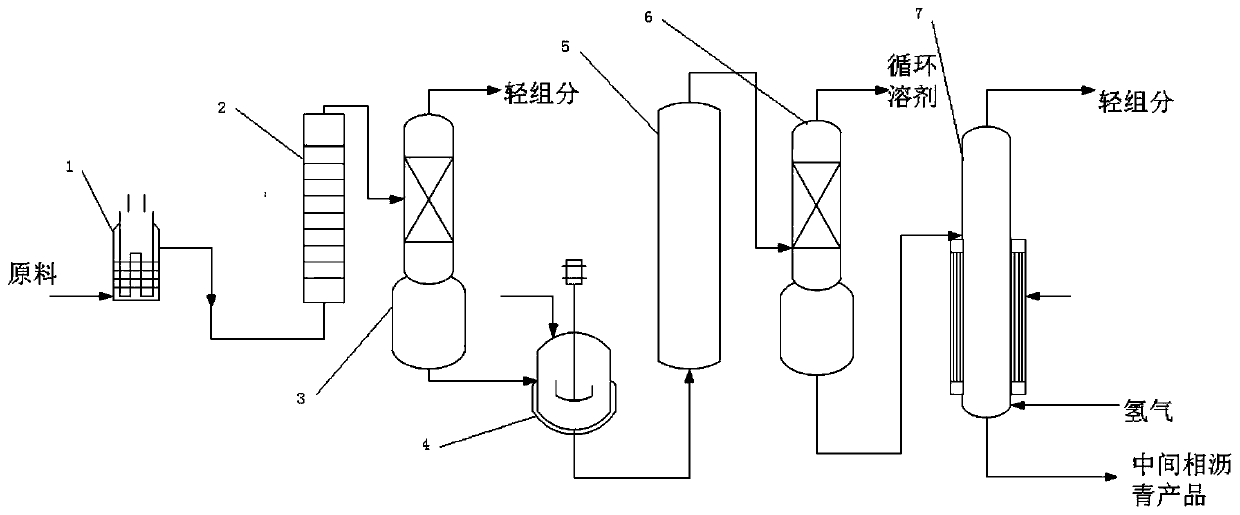

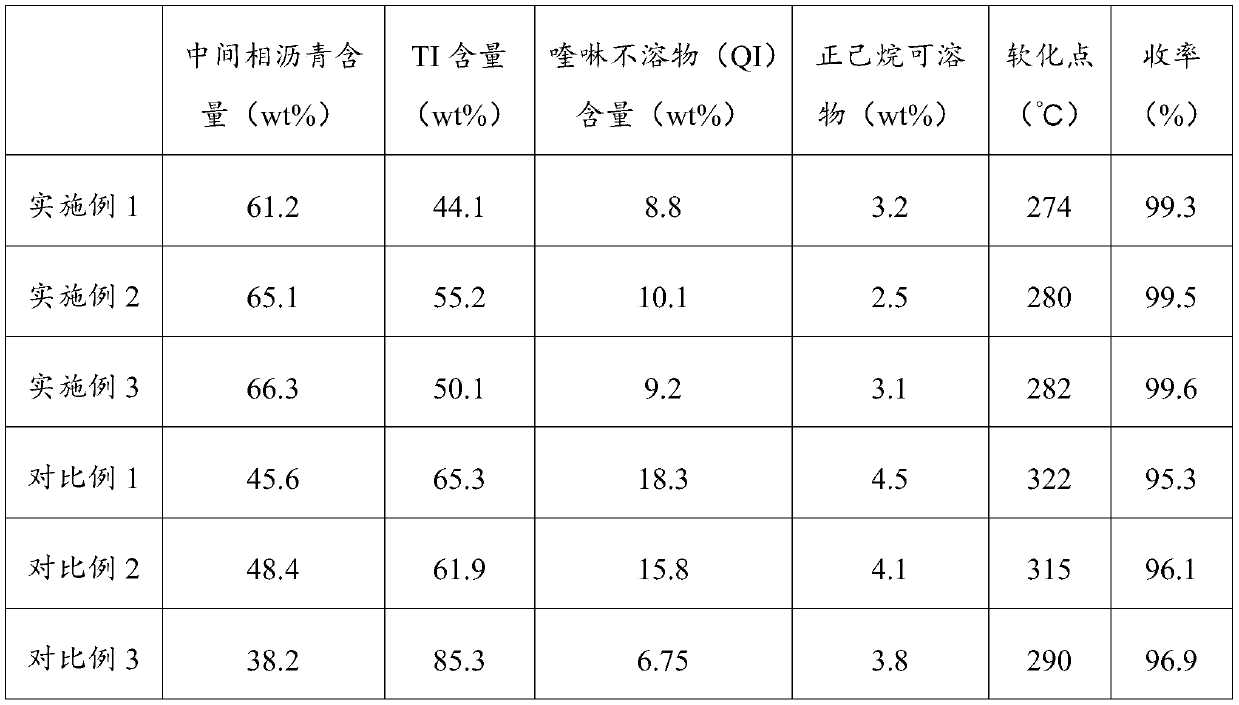

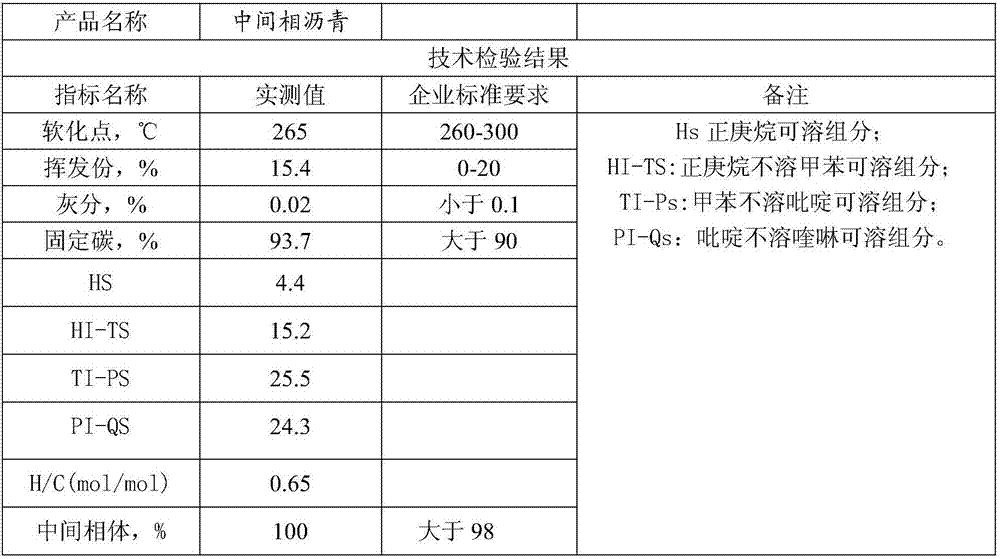

Process for Producing Mesophase Pitch by Hydrogenation of High-temperature Coal Tar

ActiveUS20150076031A1Increase H/C ratioHigh content of mesophase pitchWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixtures productionBoiling pointCoal tar

A process for producing mesophase pitch from high-temperature coal tar comprises: removing salts and quinoline insoluble fraction from a high-temperature coal tar to obtain a decant oil; using the decant oil as a hydrogenation feedstock, or pre-distilling the decant oil to obtain a residue with a boiling point higher than 230 and formulating the residue into a hydrogenation feedstock; catalytic hydrorefining the hydrogenation feedstock to obtain a hydrofined oil; distilling the hydrofined oil to obtain hydrogenated pitch; and subjecting the hydrogenated pitch to the thermal polymerization to obtain the mesophase pitch. The process has features such as an easily controllable degree of hydrogenation, complete removal of impurities, good raw material flowability, not tending to form the carbon deposition and the coking during the process, and not tending to jam the reactor. The product has a high content of mesophase pitch, a low softening point and a low impurity content.

Owner:ECO CARBON MATERIALS HLDG (SHENZHEN) CO LTD +1

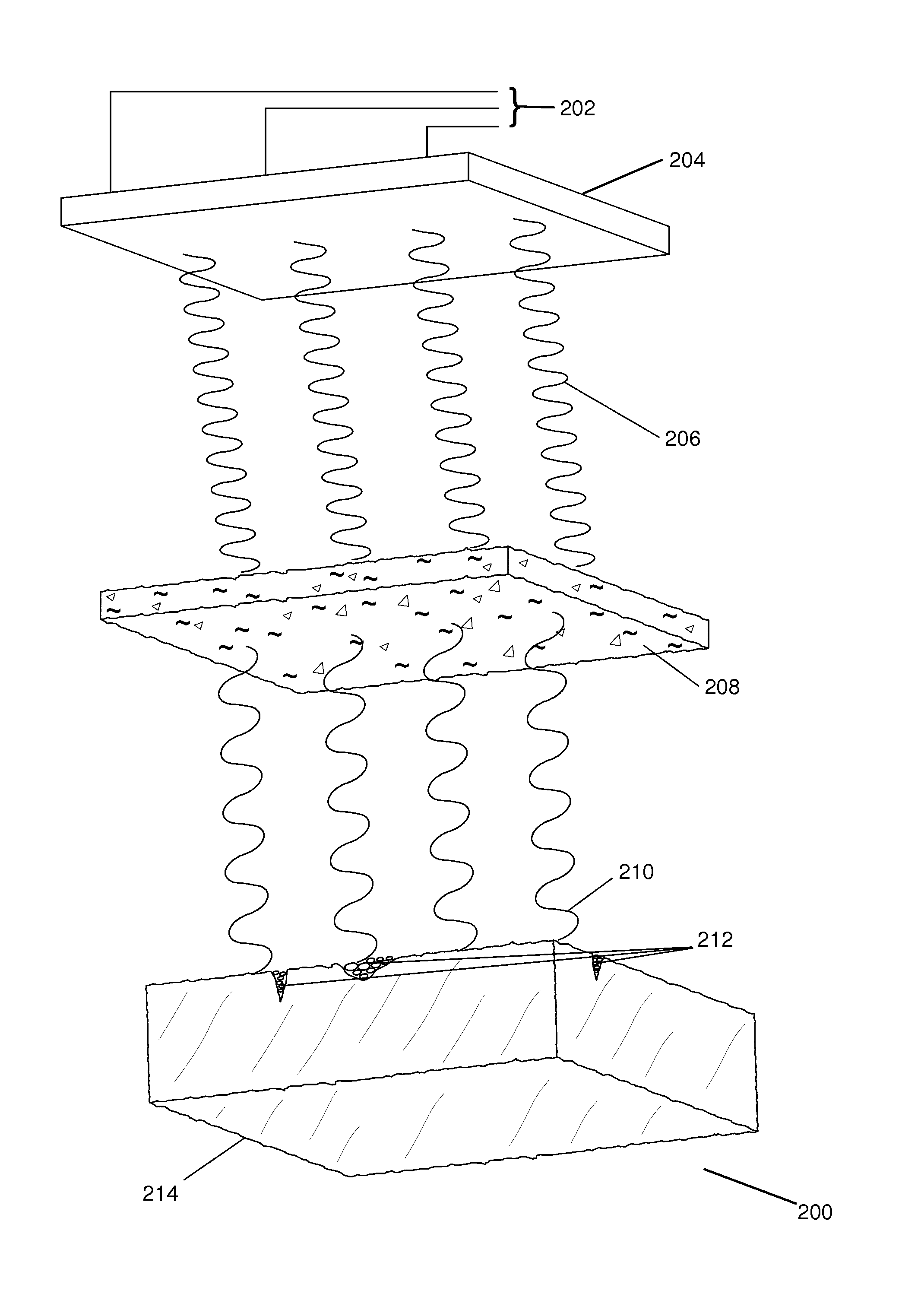

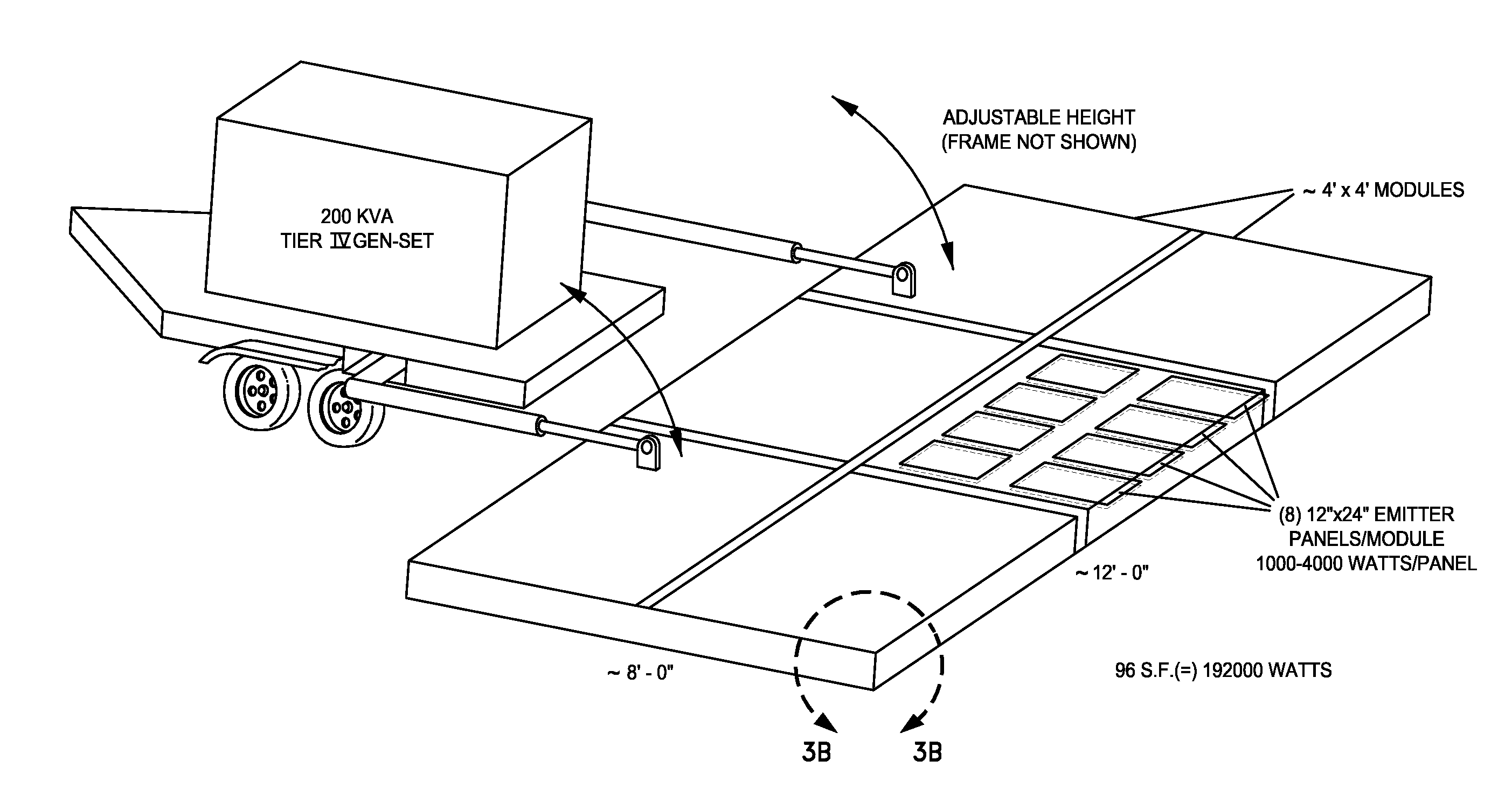

Pavement repair system utilizing solid phase autoregenerative cohesion

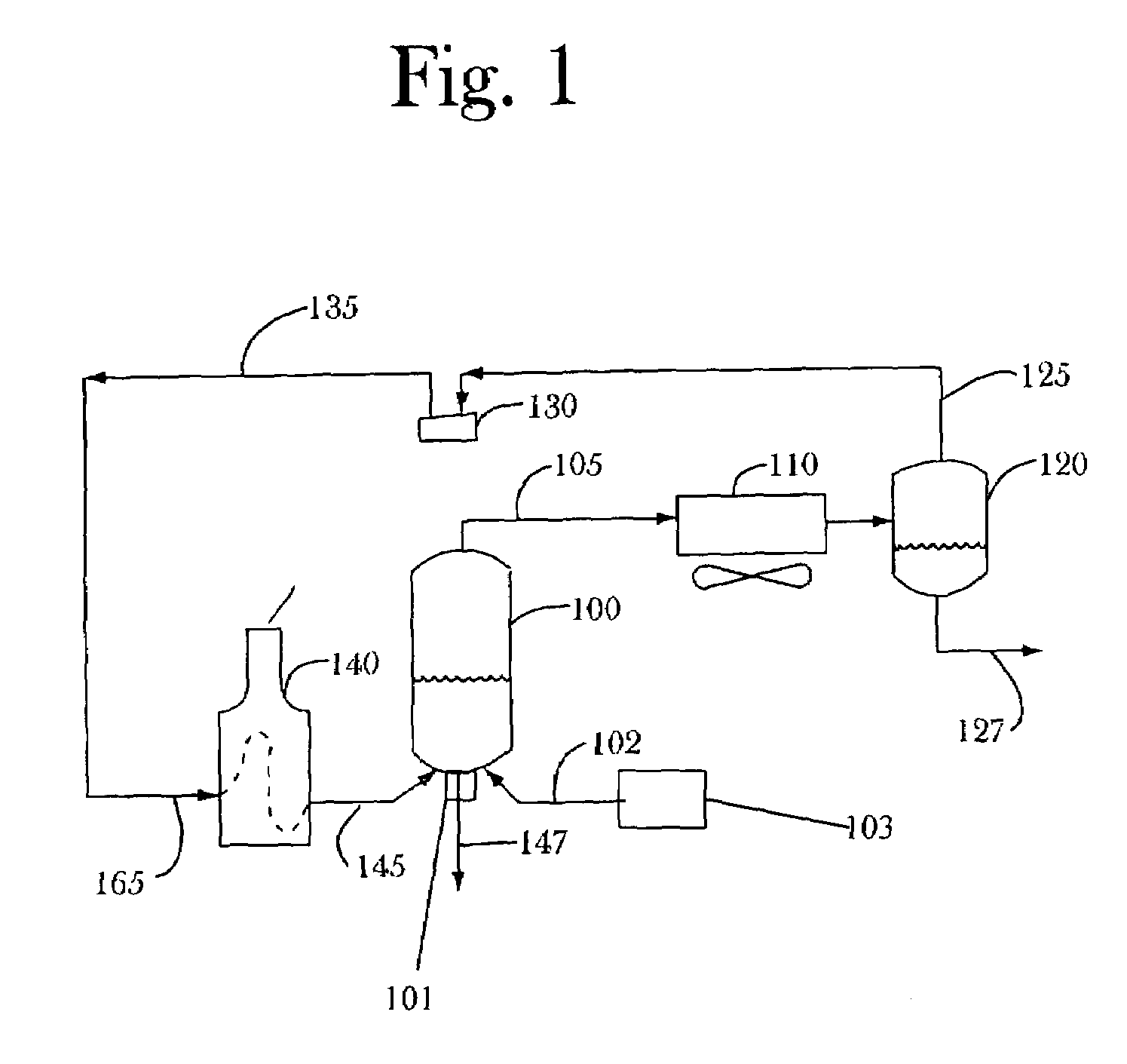

ActiveUS20140270955A1Long and longer useful lifePaving propertyPaving reinforcementsIn situ pavingsRoad surfaceLiquid phase

A pavement repair system is provided utilizing Solid Phase Auto Regenerative Cohesion (SPARC) Homogenization by Liquid Asphalt Oligopolymerization (HALO) technologies. The SPARC-HALO system is suitable for use in repairing asphalt pavement, including pavement exhibiting a high degree of deterioration (as manifested in the presence of potholes, cracks, ruts, or the like) as well as pavement that has been subject to previous repair and may comprise a substantial amount of dirt and other debris (e.g., chipped road paint or other damaged or disturbed surfacing materials). The HALO system is suitable for rejuvenating aged asphalt, thereby improving properties of the paving material.

Owner:COE WILLIAM B

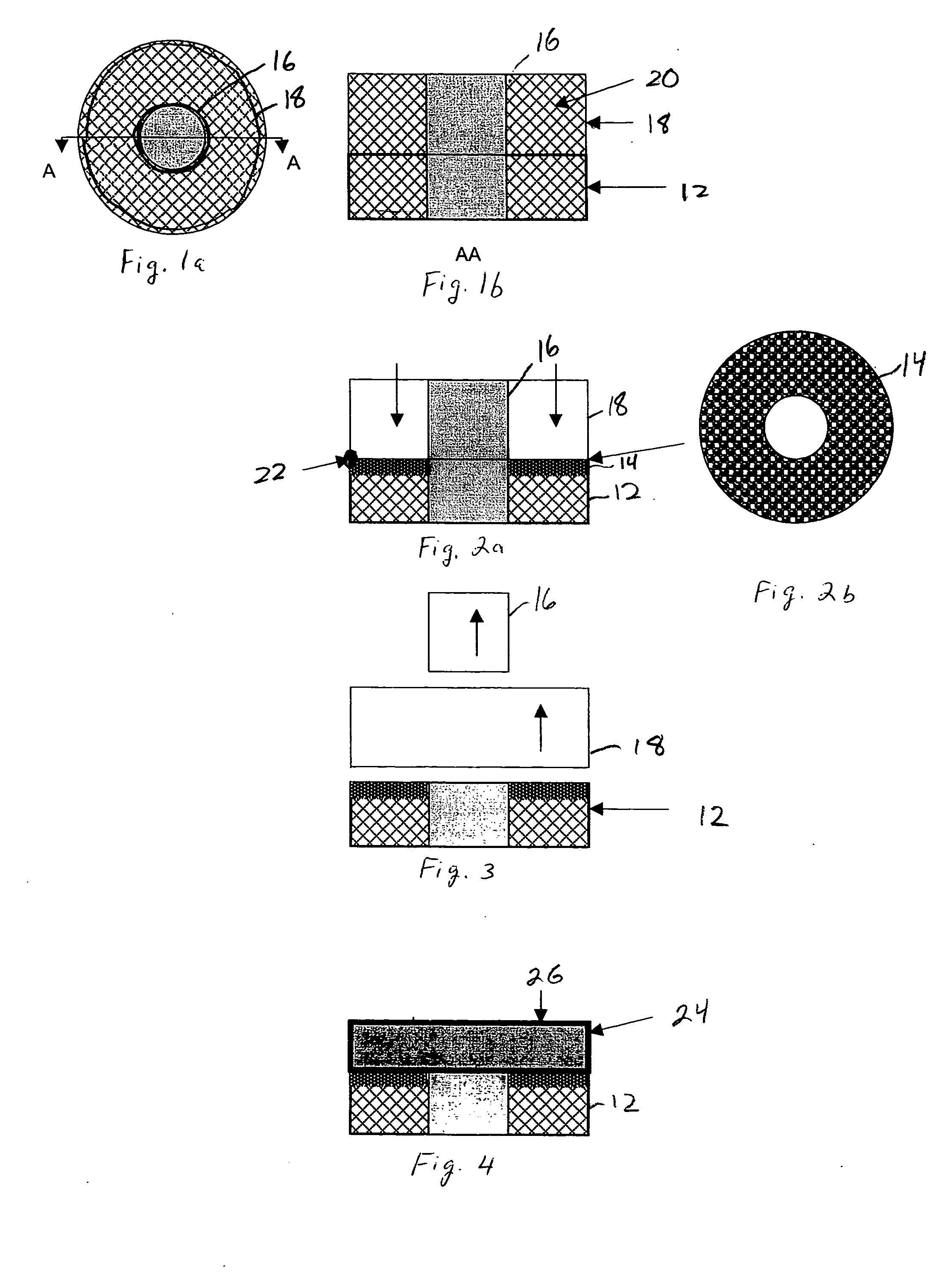

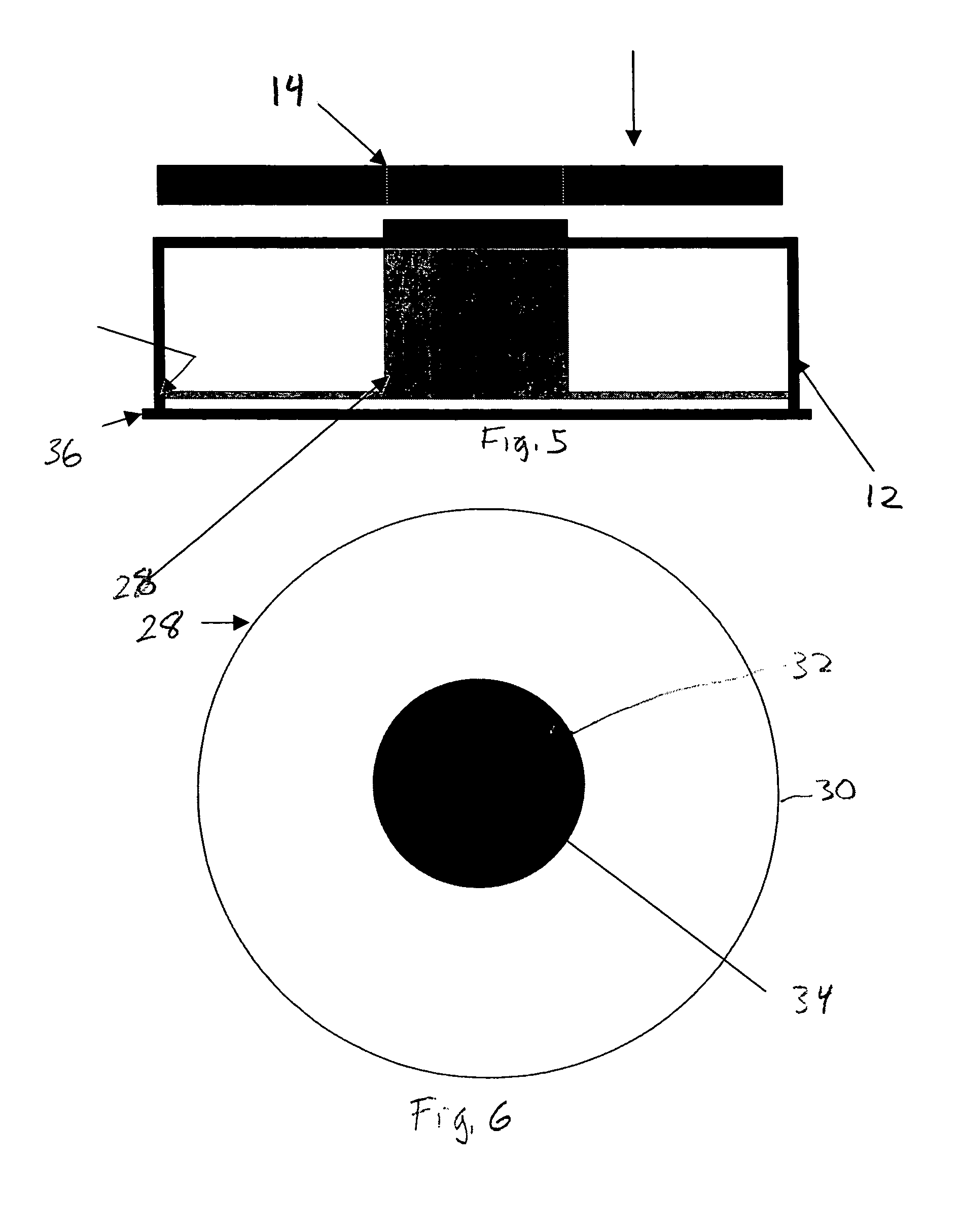

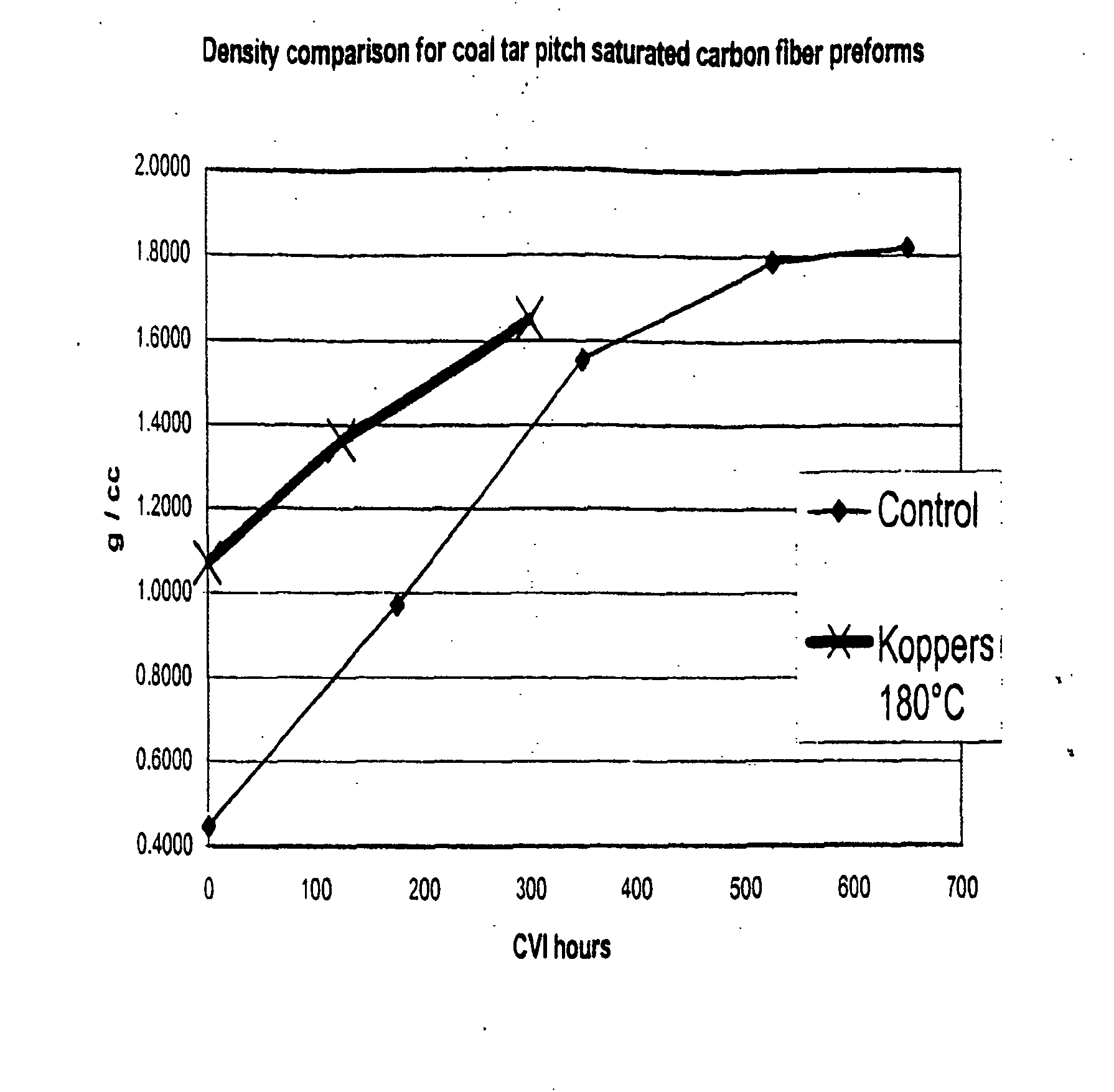

Chopped carbon fiber preform processing method using coal tar pitch binder

InactiveUS20050081752A1High densityExcellent propertyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

Owner:KOPPERS DELAWARE INC

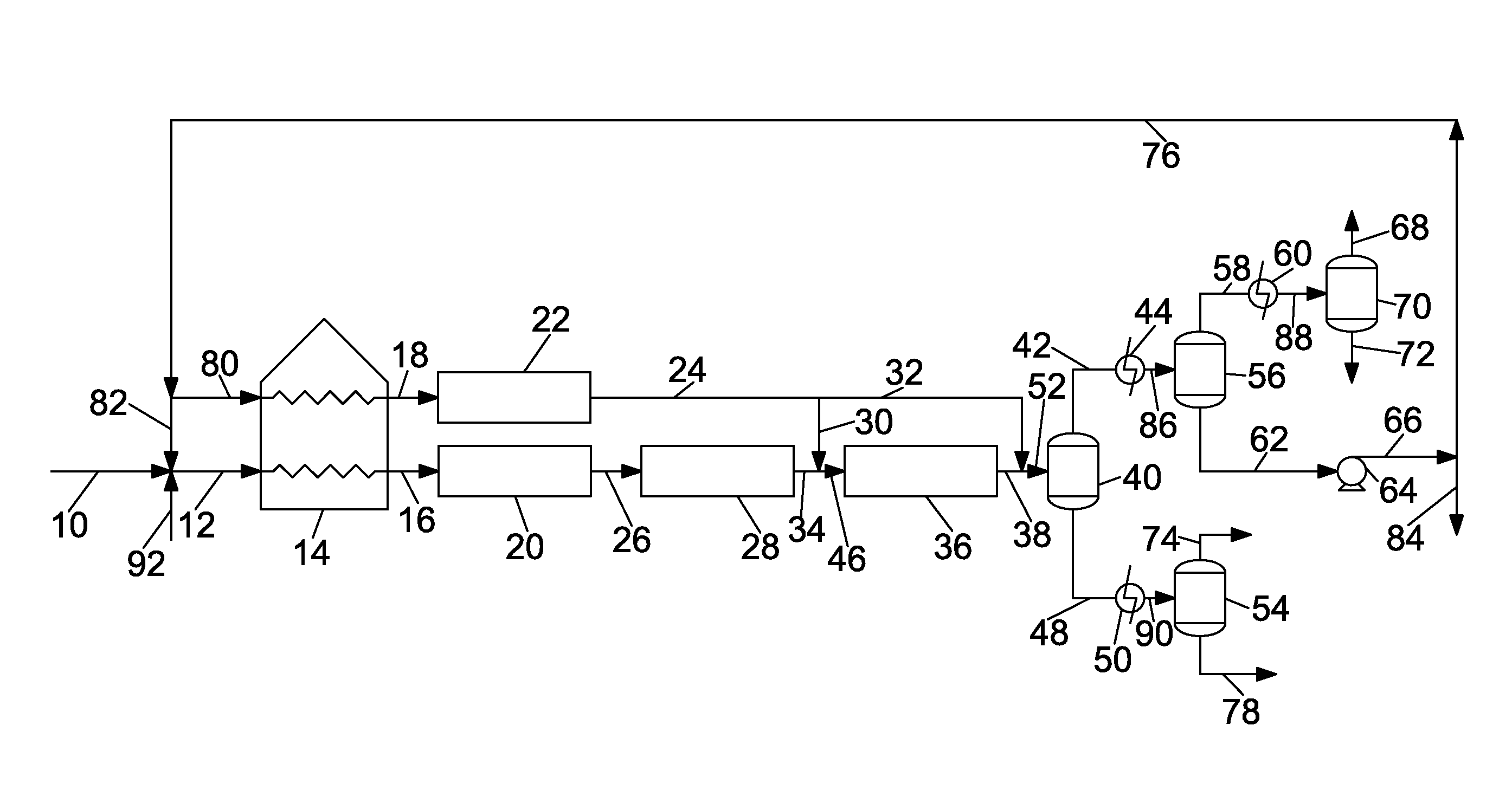

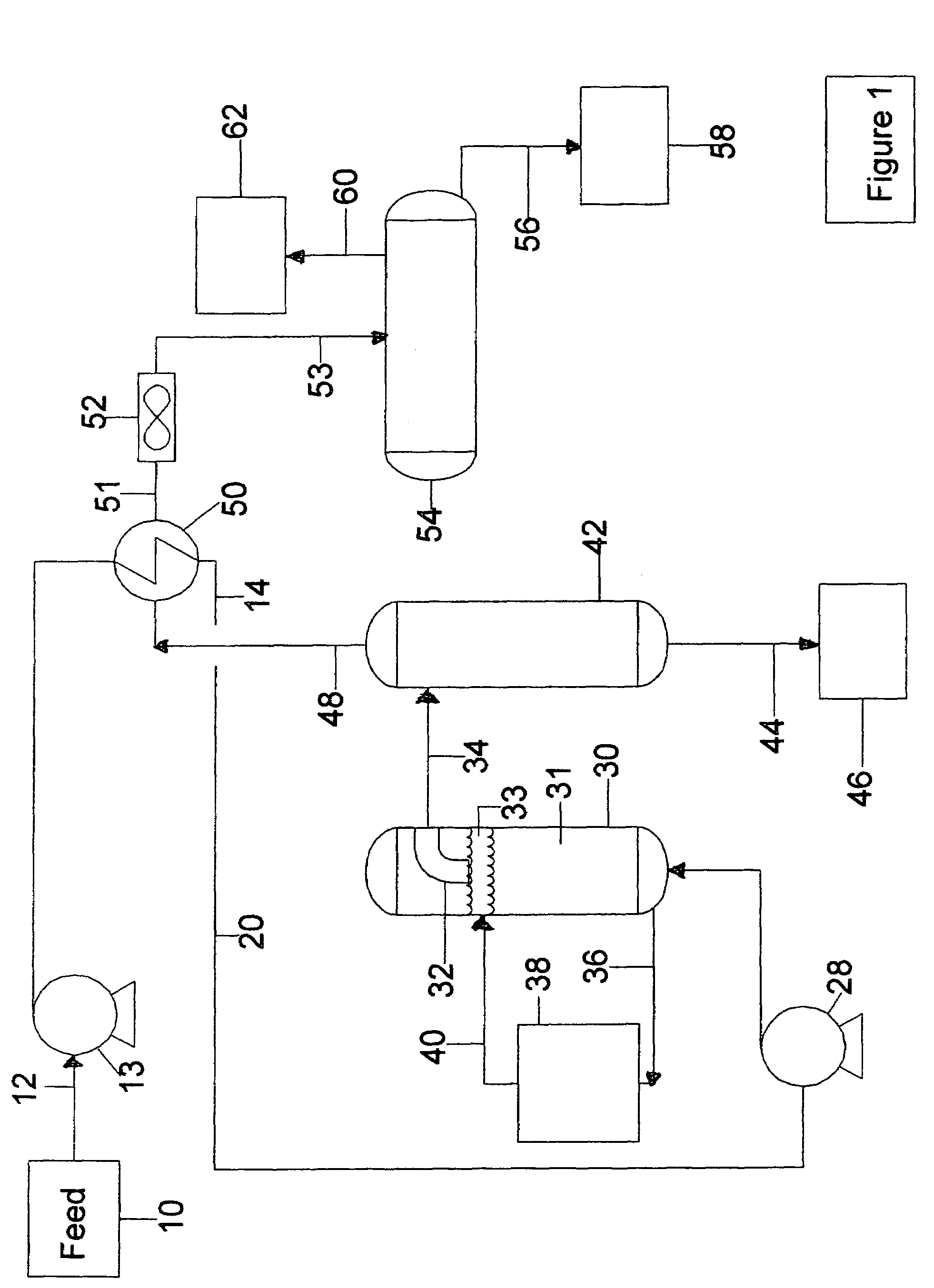

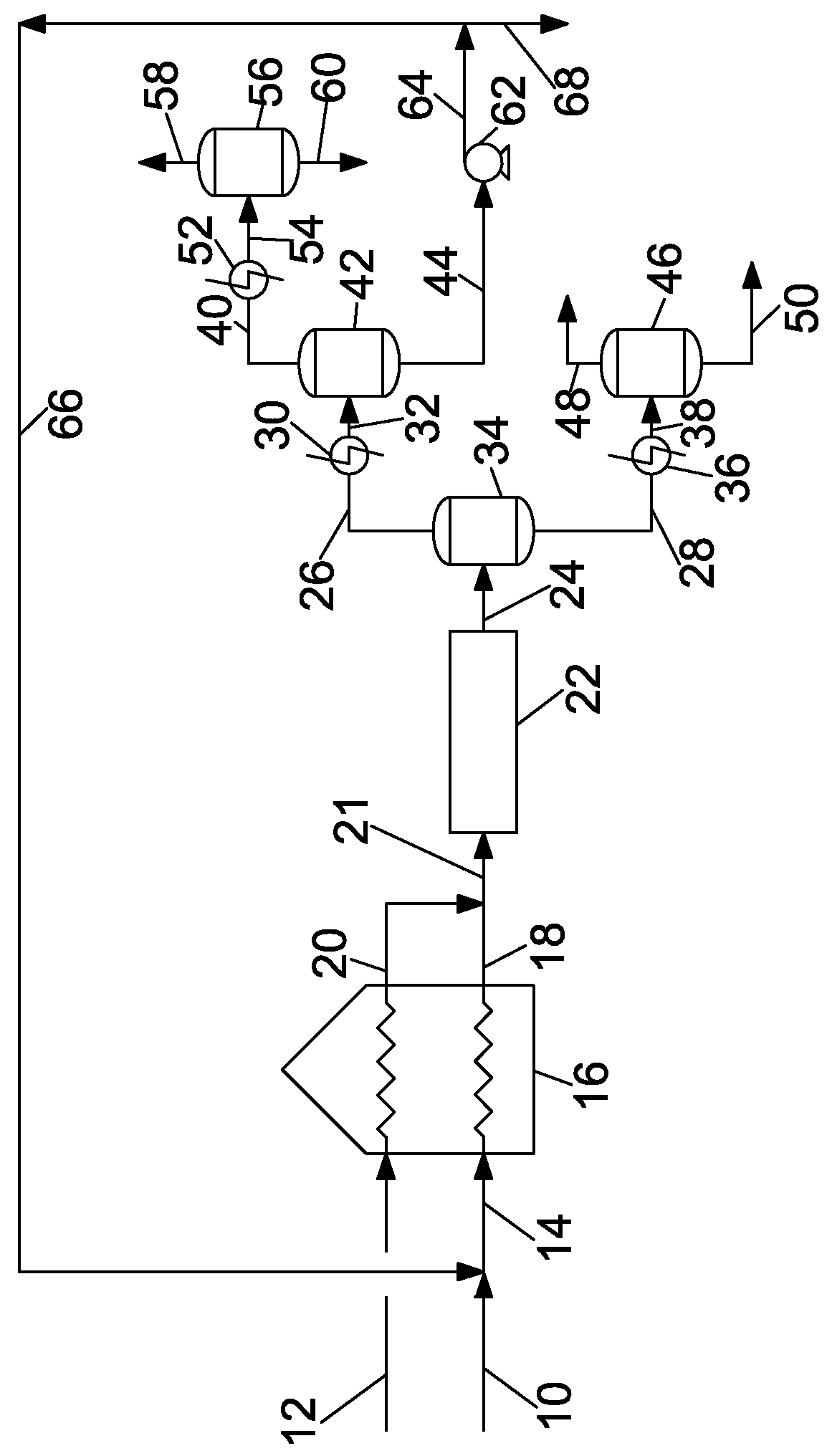

Single stage pitch process and product

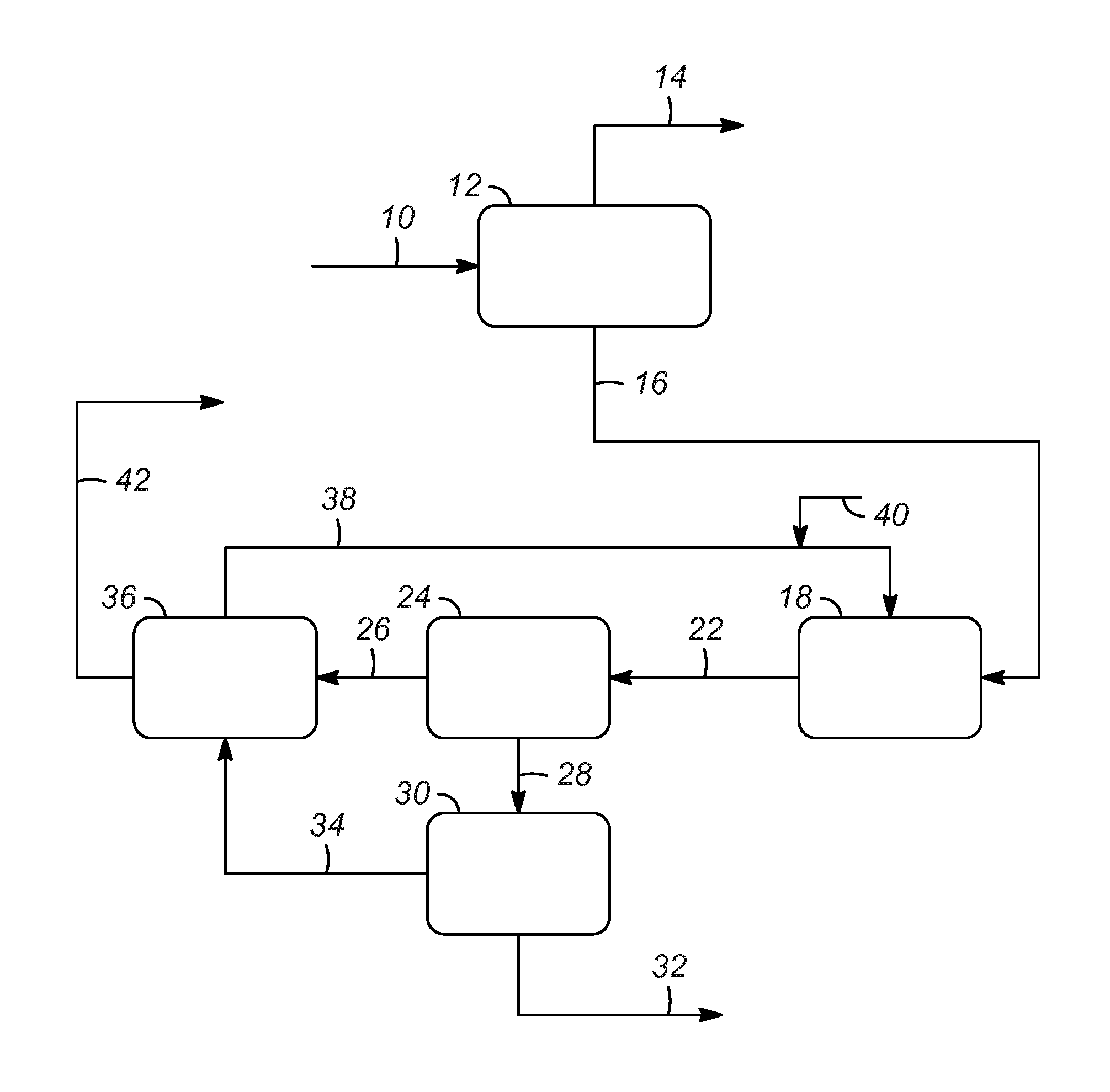

ActiveUS9222027B1Suppress mesophase formationSimple materialThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansEngineeringHigh pressure

A process and apparatus for making isotropic pitch are disclosed. A tubular reactor operating at high velocity and pressure converts aromatic rich liquid feed to pitch within minutes. Reactor is heated by electric resistance or inductance, a salt or molten metal bath, or fired heater. Reactor effluent flashes and isotropic pitch recovered from the flash drum. Softening point is affected by flash drum pressure or stripping steam. Unconverted feed may be recycled. Process makes little gasoline, simple condensation of flash drum vapor may produce gas oil and gasoline fractions. Isotropic pitch is made in a single step with a coking value of 50 to 55 wt %. Time and temperature in the reactor convert at least 20 wt % of feed and any recycle material present to isotropic pitch. Pressure is preferably above 500 psig, to suppress mesophase formation and produce isotropic pitch with less than 0.5 wt % mesophase.

Owner:ACP TECH LLC

Noah's pitch process

A process for producing pitch from pitch precursors, such as wood tar, coal tar or petroleum fractions is disclosed. Direct contact heat exchange of the pitch precursor with molten metal, preferably maintained as a metal continuous bath, heats the pitch precursor to a temperature sufficient to induce thermal polymerization reactions and produce a pitch product.

Owner:DTX TECH

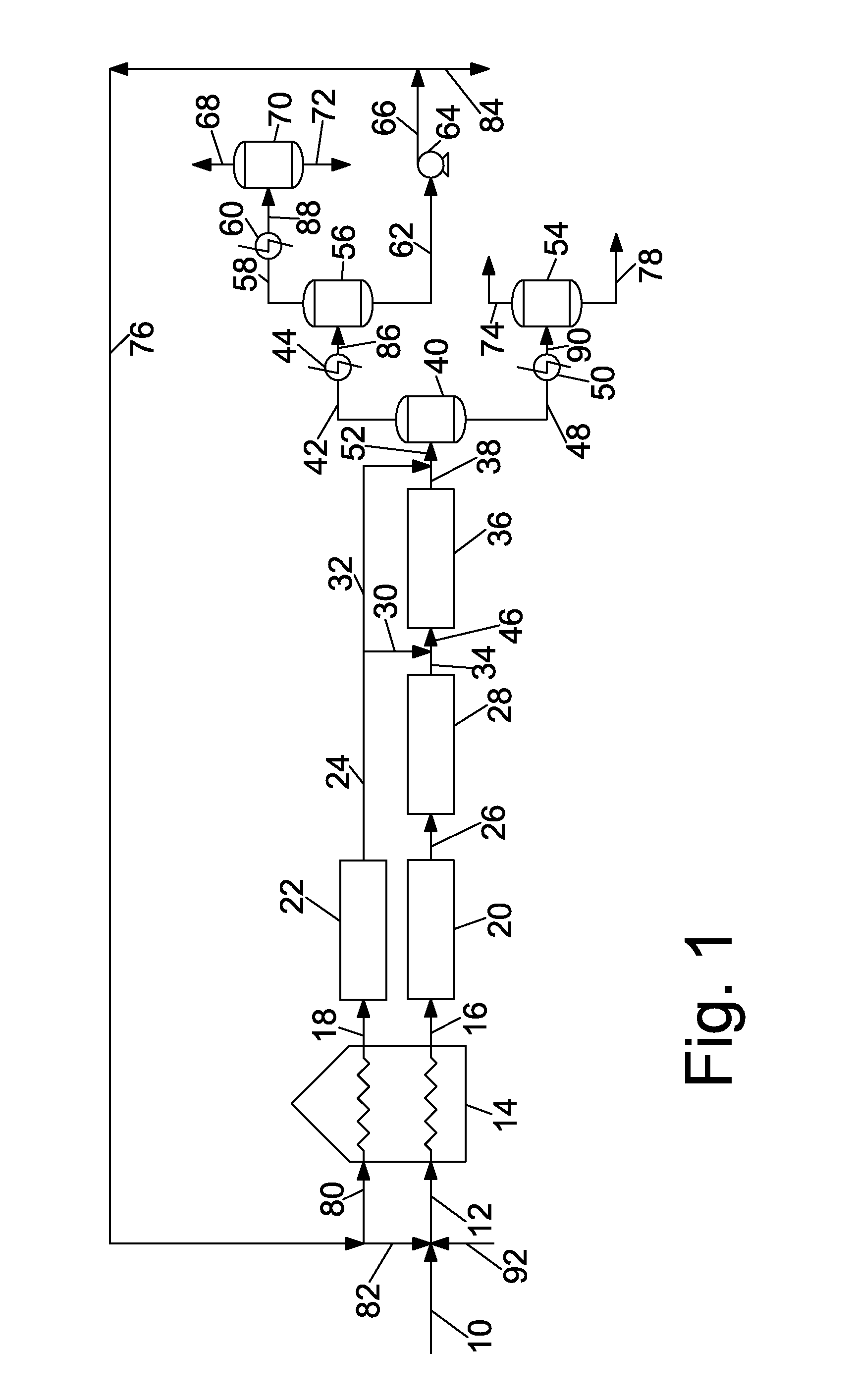

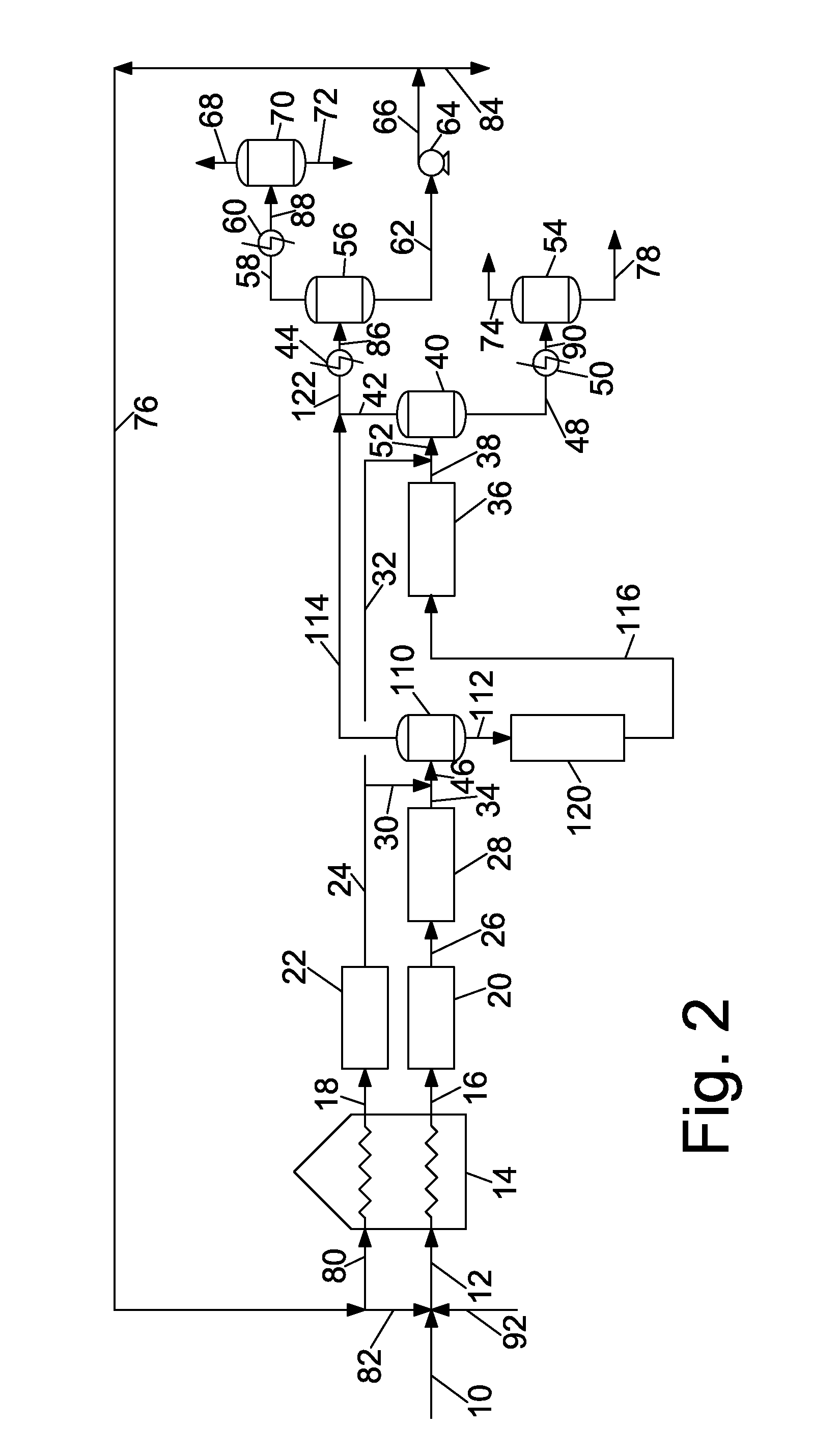

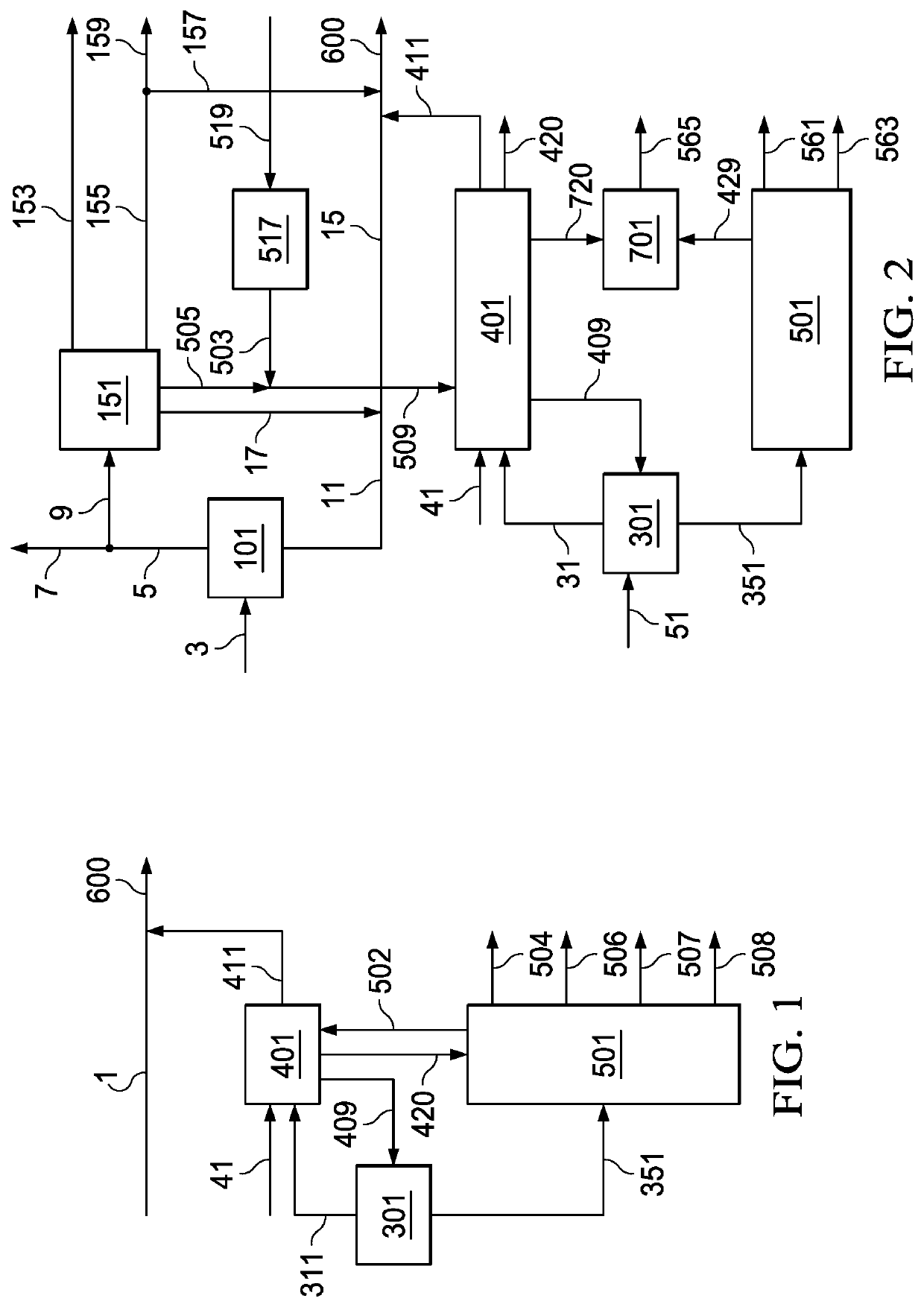

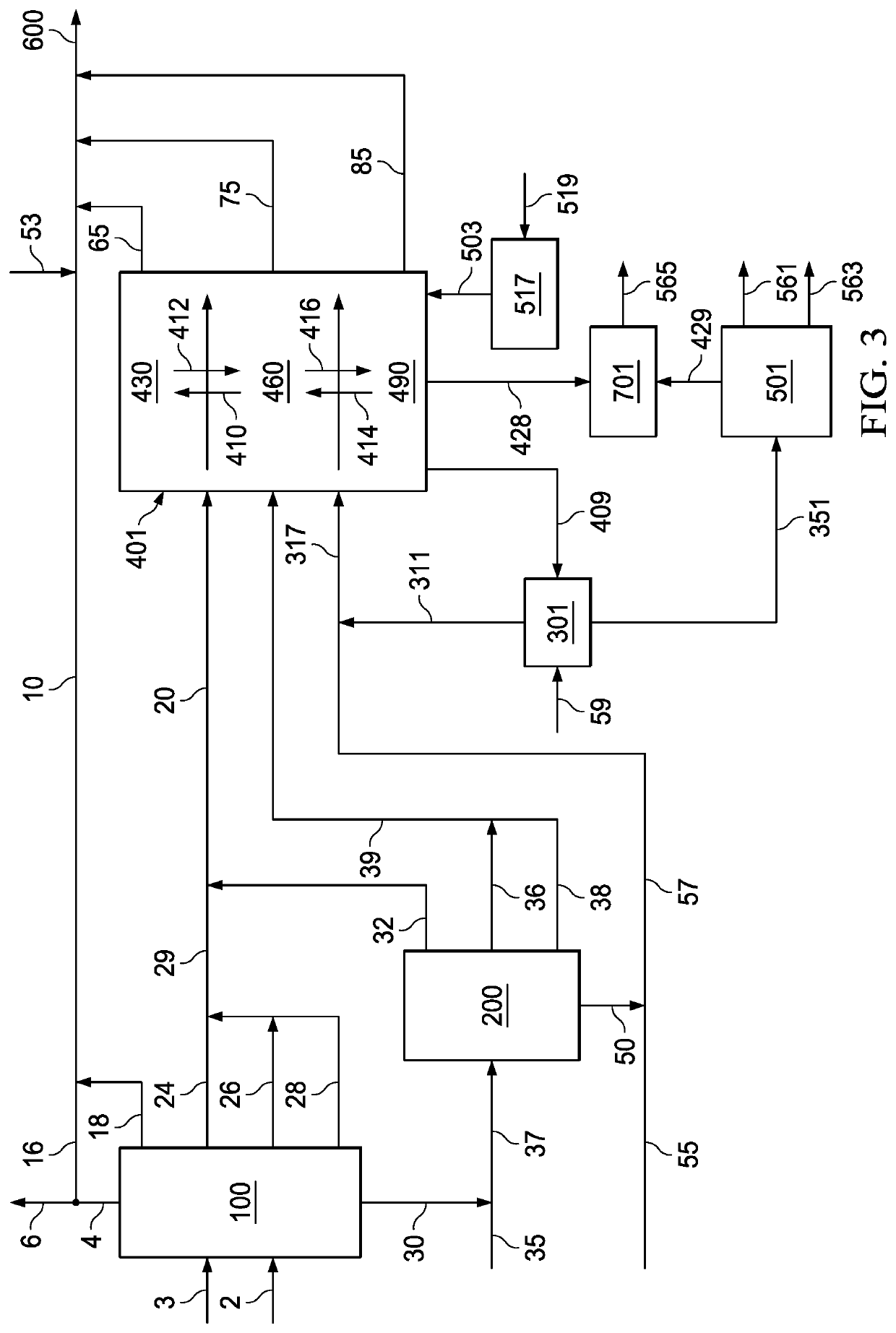

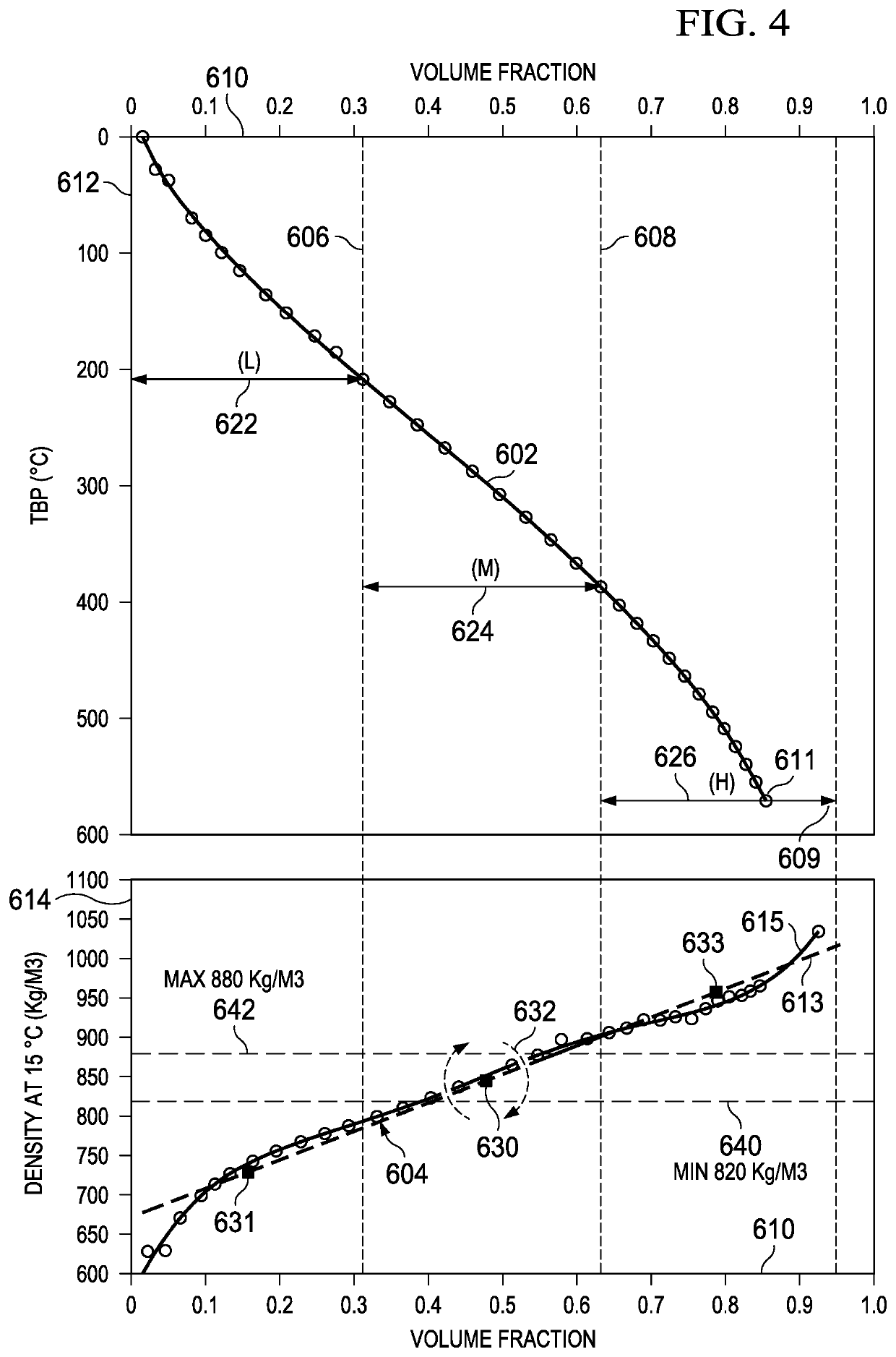

Fuel compositions from light tight oils and high sulfur fuel oils

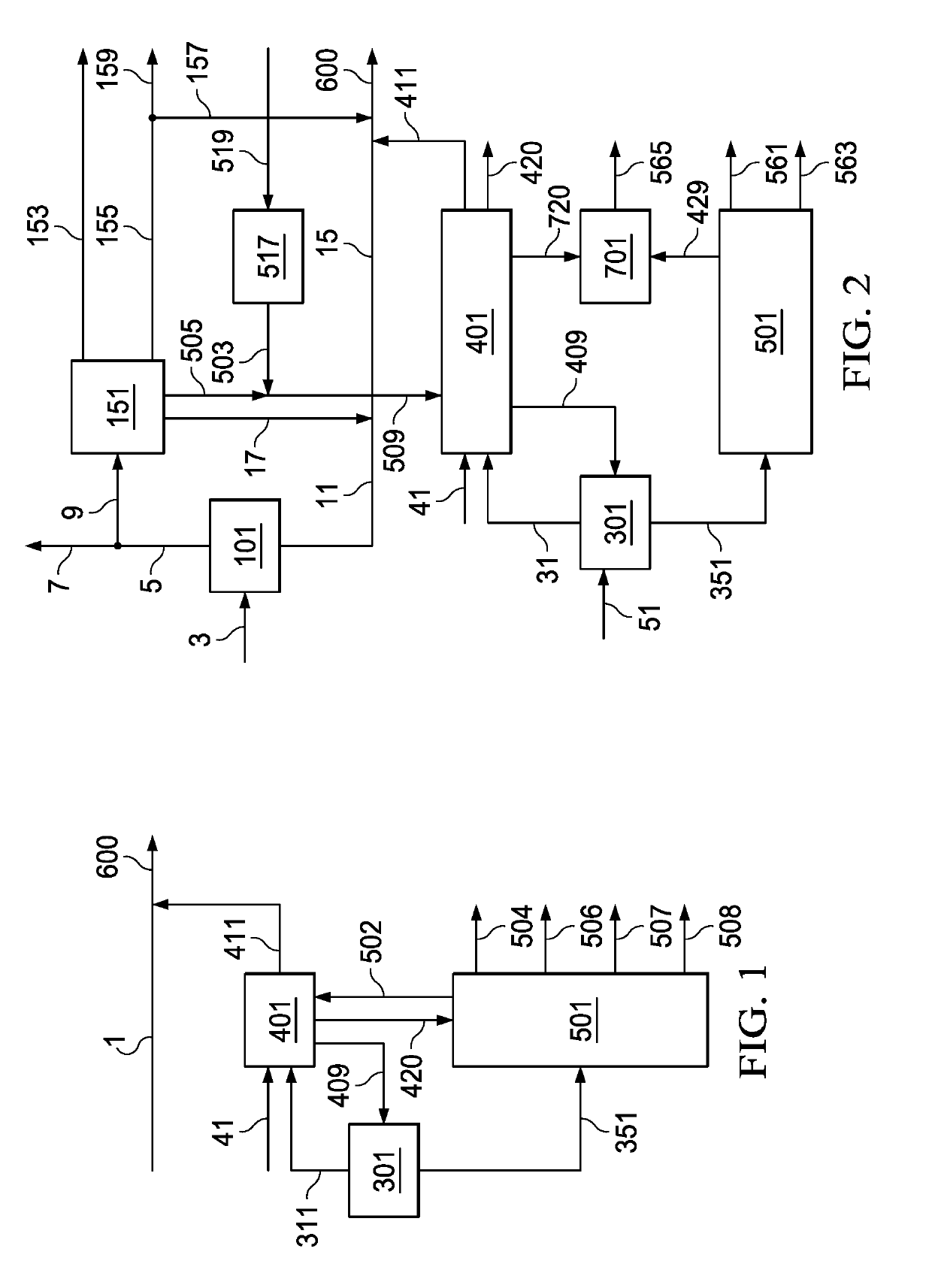

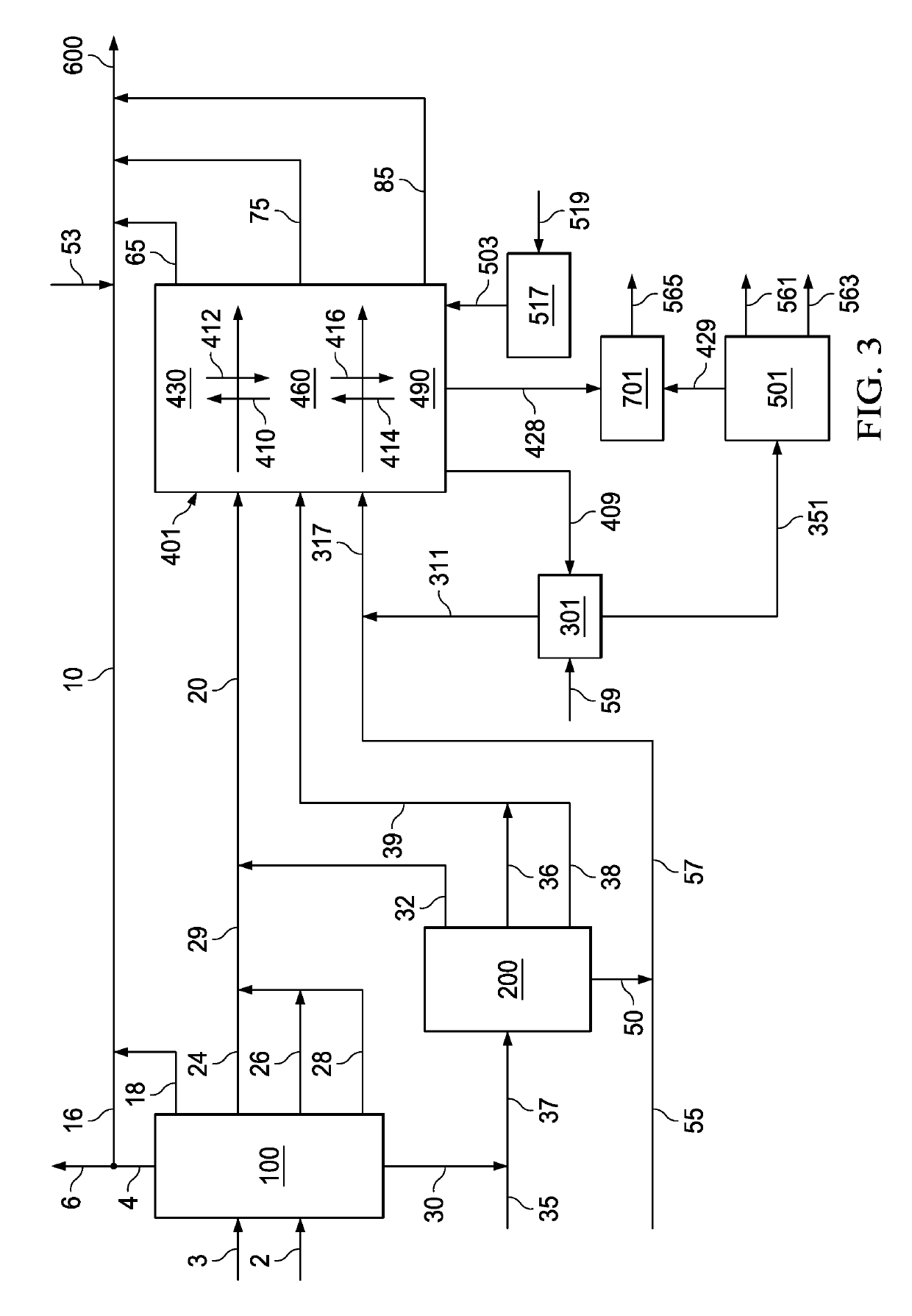

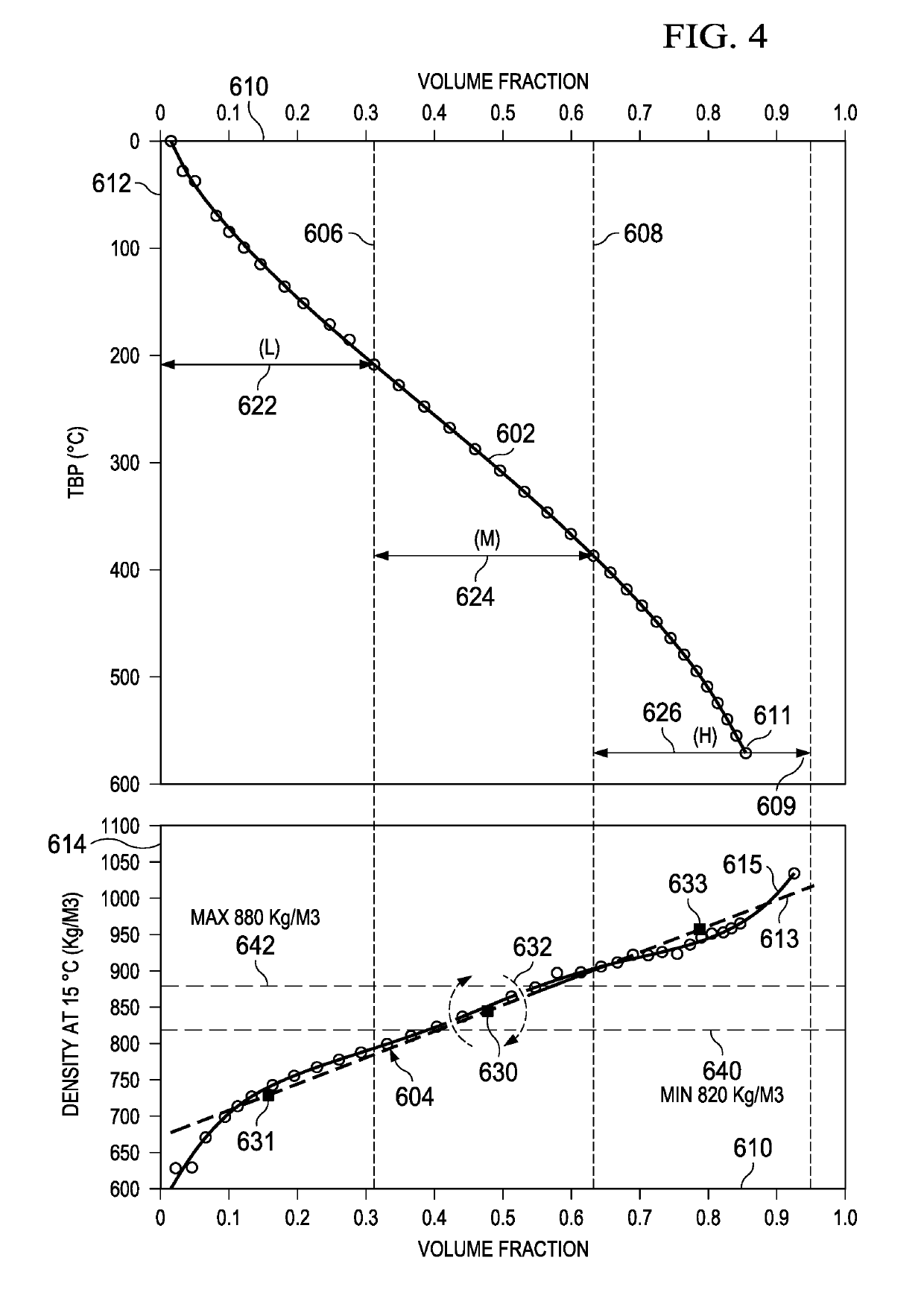

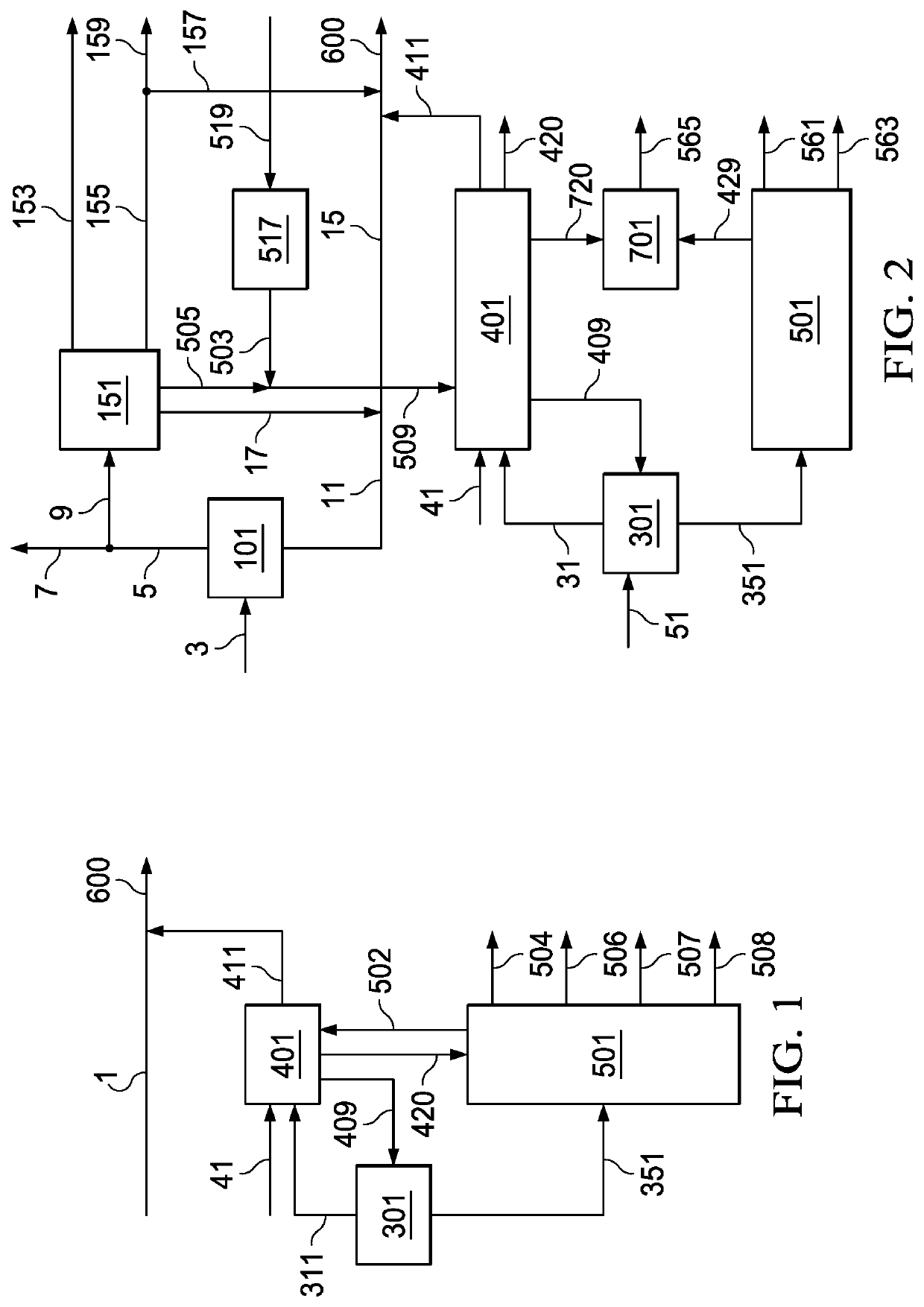

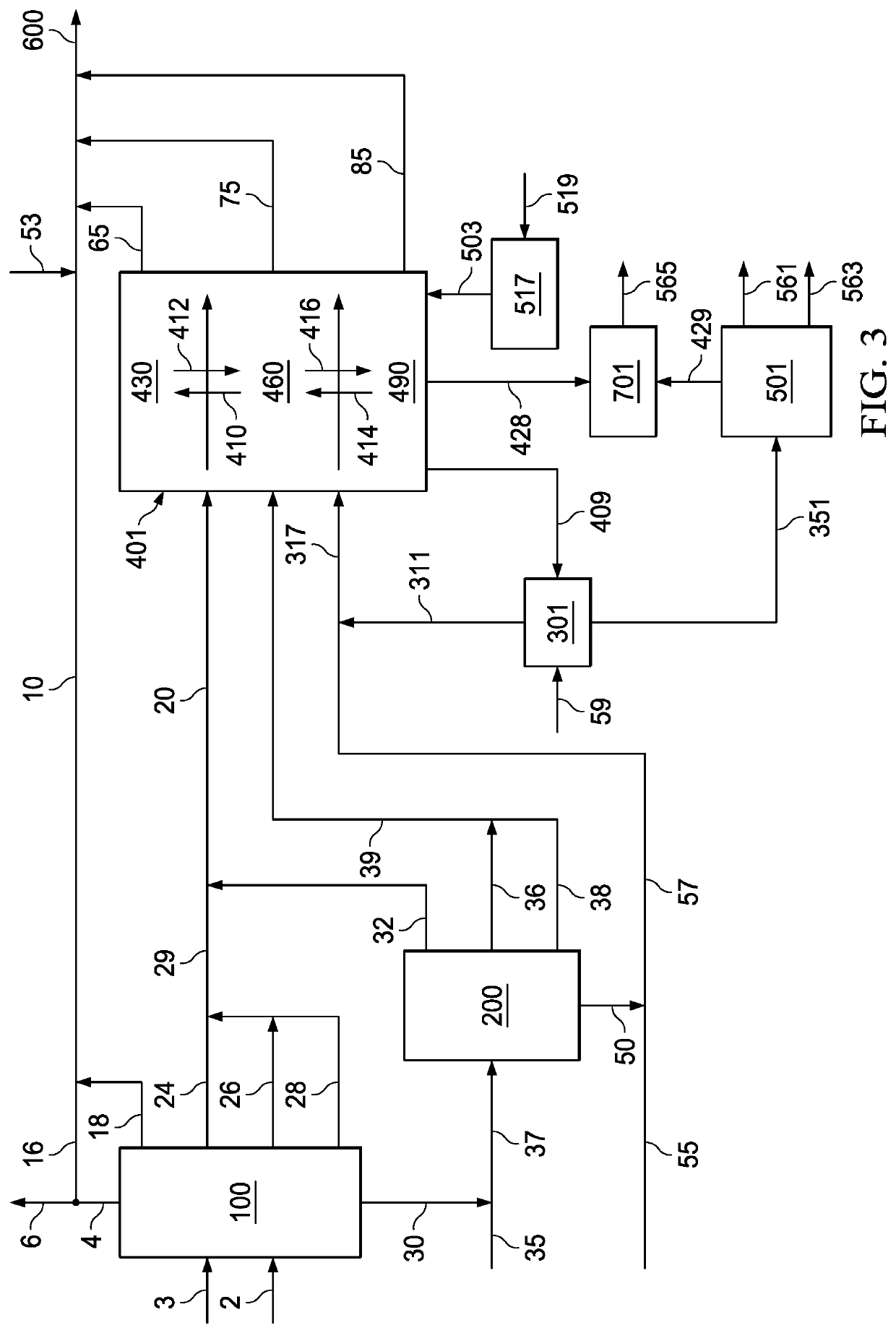

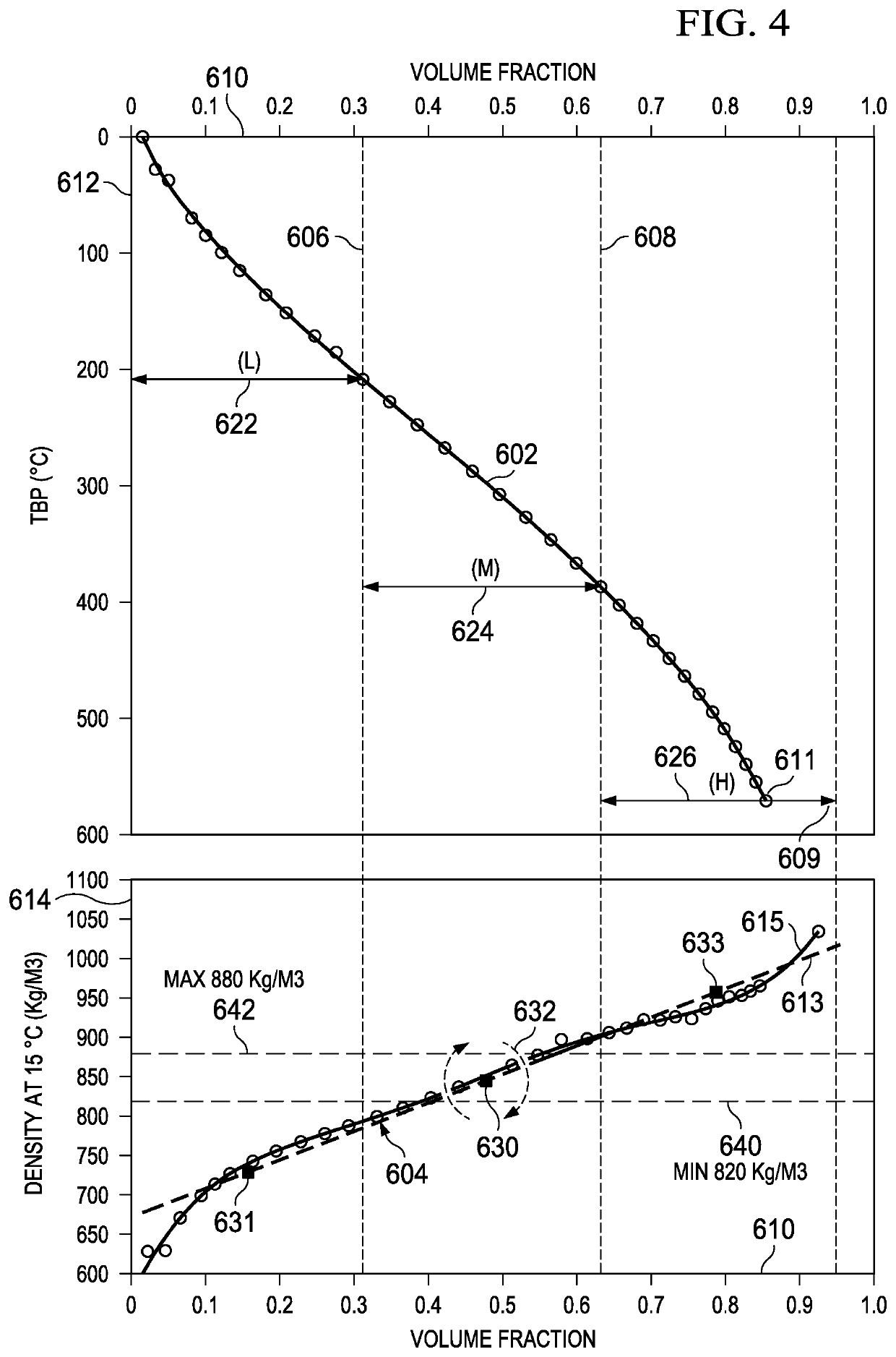

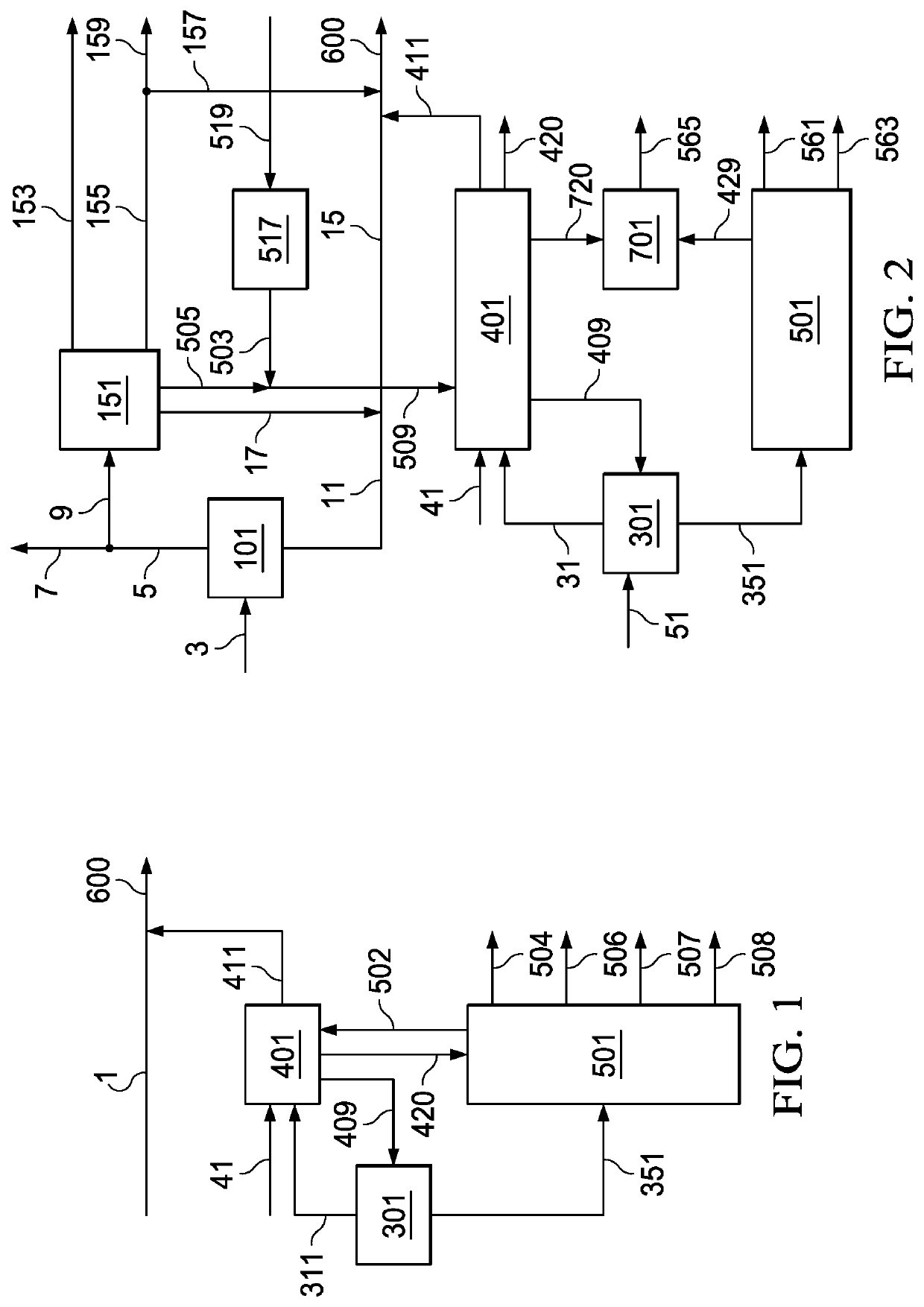

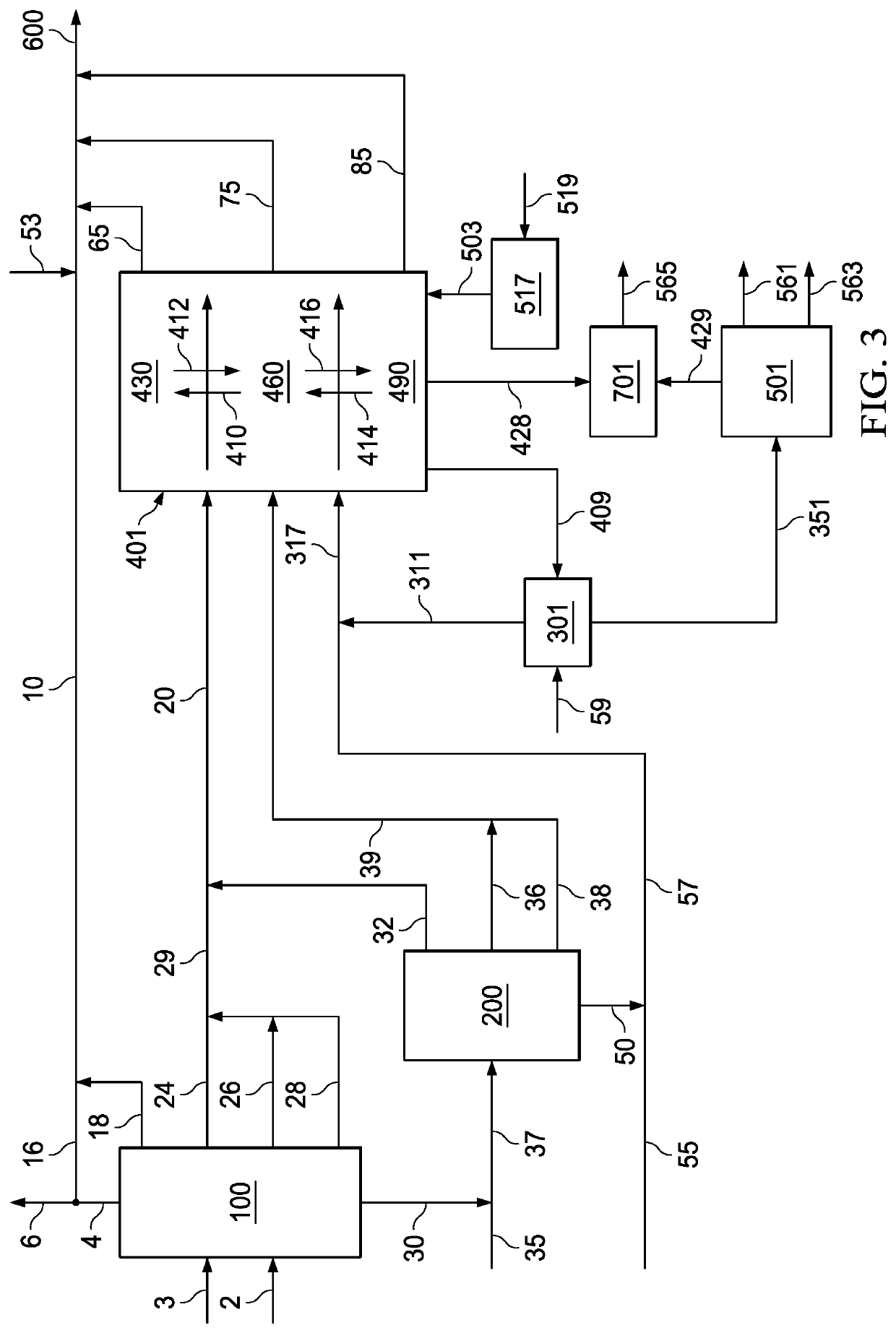

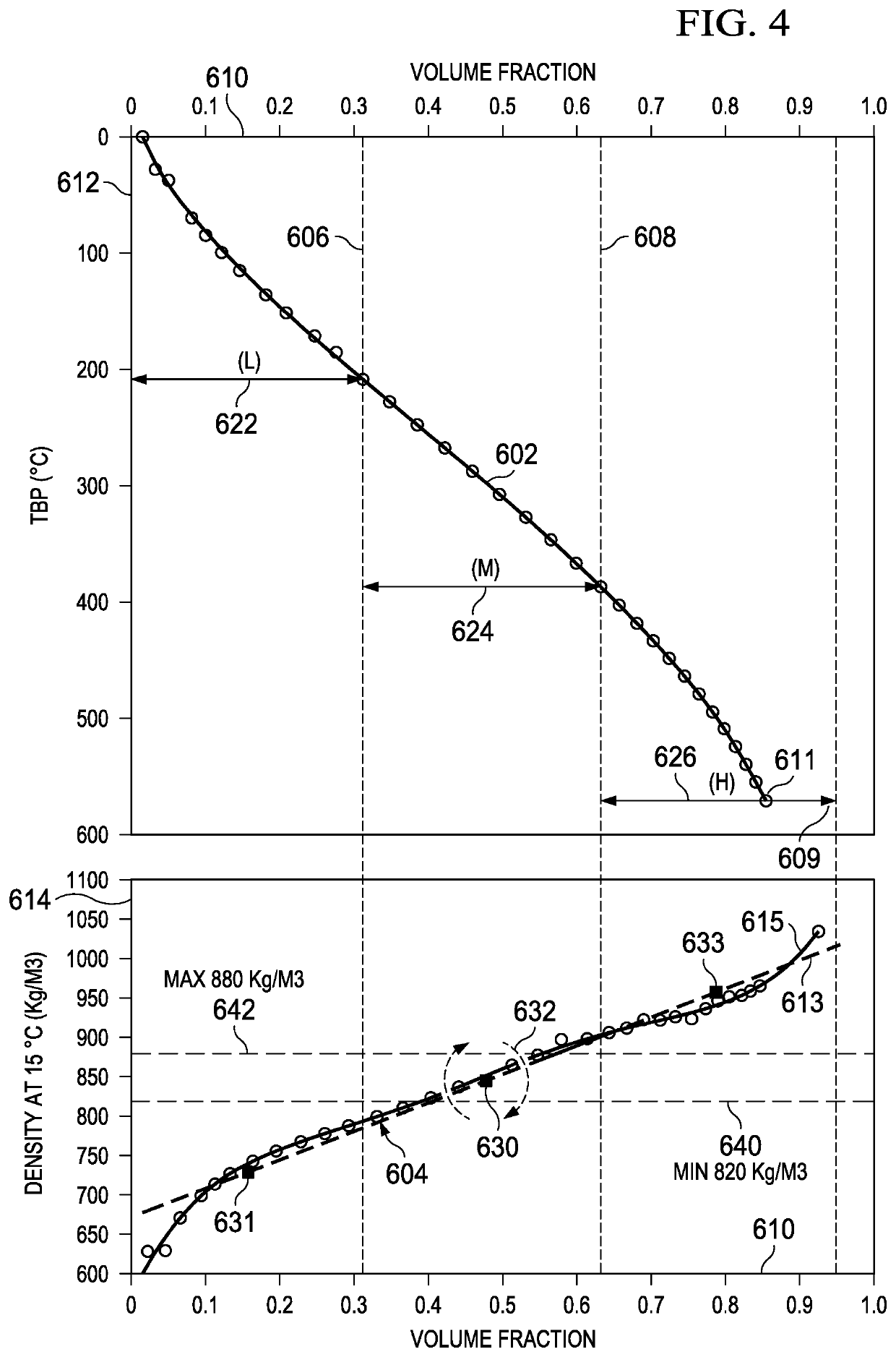

ActiveUS10883056B2Low costEmission reductionPump componentsTreatment with hydrotreatment processesCombustionHydrocotyle bowlesioides

Methods are provided to prepare a low sulfur fuel from hydrocarbon sources, such as light tight oil and high sulfur fuel oil, often less desired by conventional refiners, who split crude into a wide range of differing products and may prefer presence of wide ranges (C3 or C5 to C20 or higher) of hydrocarbons. These fuels can be produced by separating feeds into untreated and treated streams, and then recombining them. Such fuels can also be formulated by combinations of light, middle and heavy range constituents in a selected manner as claimed. Not only low in sulfur, the fuels of this invention are also low in nitrogen and essentially metals free. Fuel use applications include on-board large marine transport vessels but also on-shore for large land based combustion gas turbines, boilers, fired heaters and transport vehicles and trains.

Owner:MAWETAL LLC

Fuel compositions from light tight oils and high sulfur fuel oils

ActiveUS20190136144A1Low costEmission reductionPump componentsTreatment with hydrotreatment processesOn boardFuel oil

Methods are provided to prepare a low sulfur fuel from hydrocarbon sources, such as light tight oil and high sulfur fuel oil, often less desired by conventional refiners, who split crude into a wide range of differing products and may prefer presence of wide ranges (C3 or C5 to C20 or higher) of hydrocarbons. These fuels can be produced by separating feeds into untreated and treated streams, and then recombining them. Such fuels can also be formulated by combinations of light, middle and heavy range constituents in a selected manner as claimed. Not only low in sulfur, the fuels of this invention are also low in nitrogen and essentially metals free. Fuel use applications include on-board large marine transport vessels but also on-shore for large land based combustion gas turbines, boilers, fired heaters and transport vehicles and trains.

Owner:MAWETAL LLC

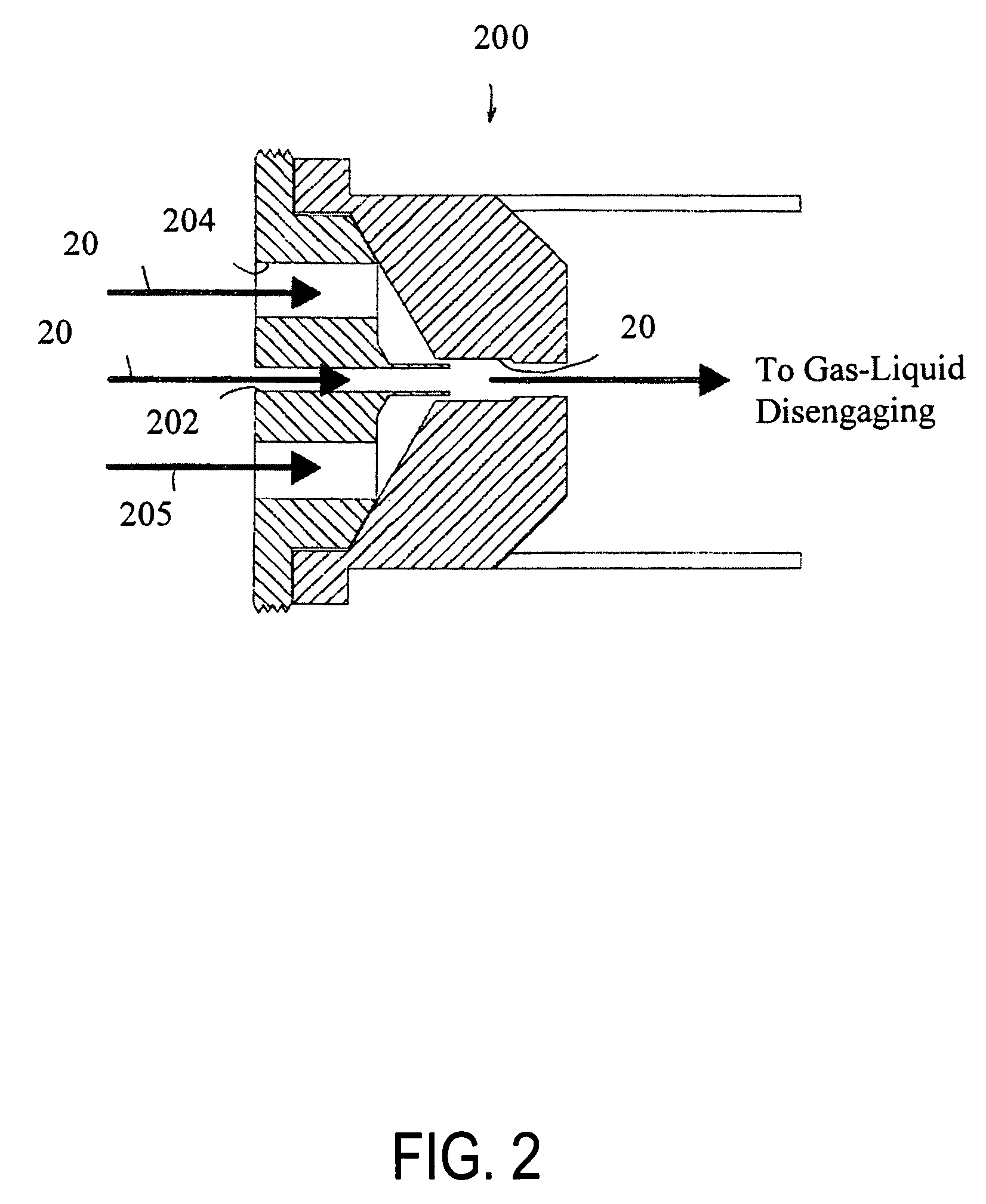

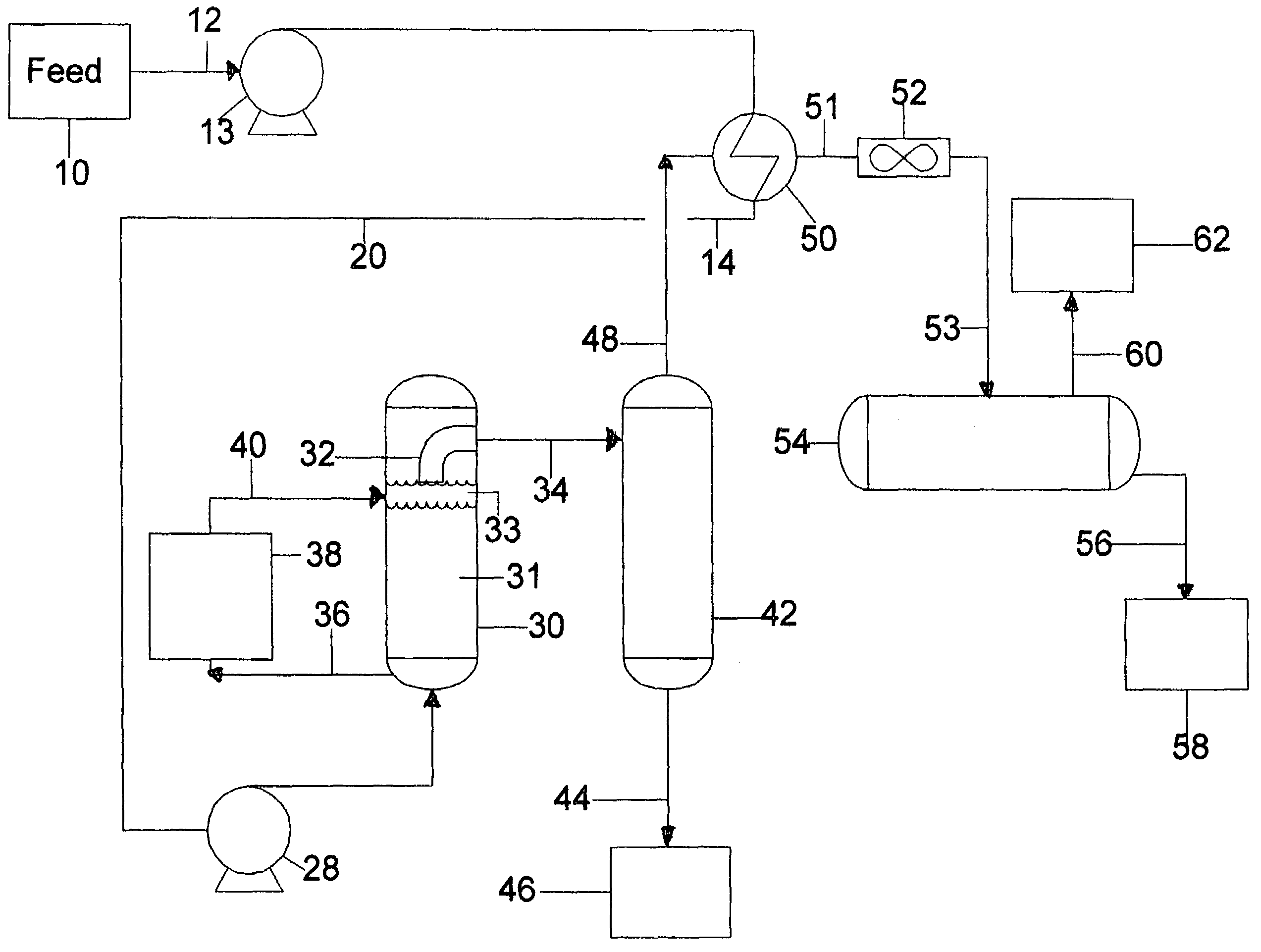

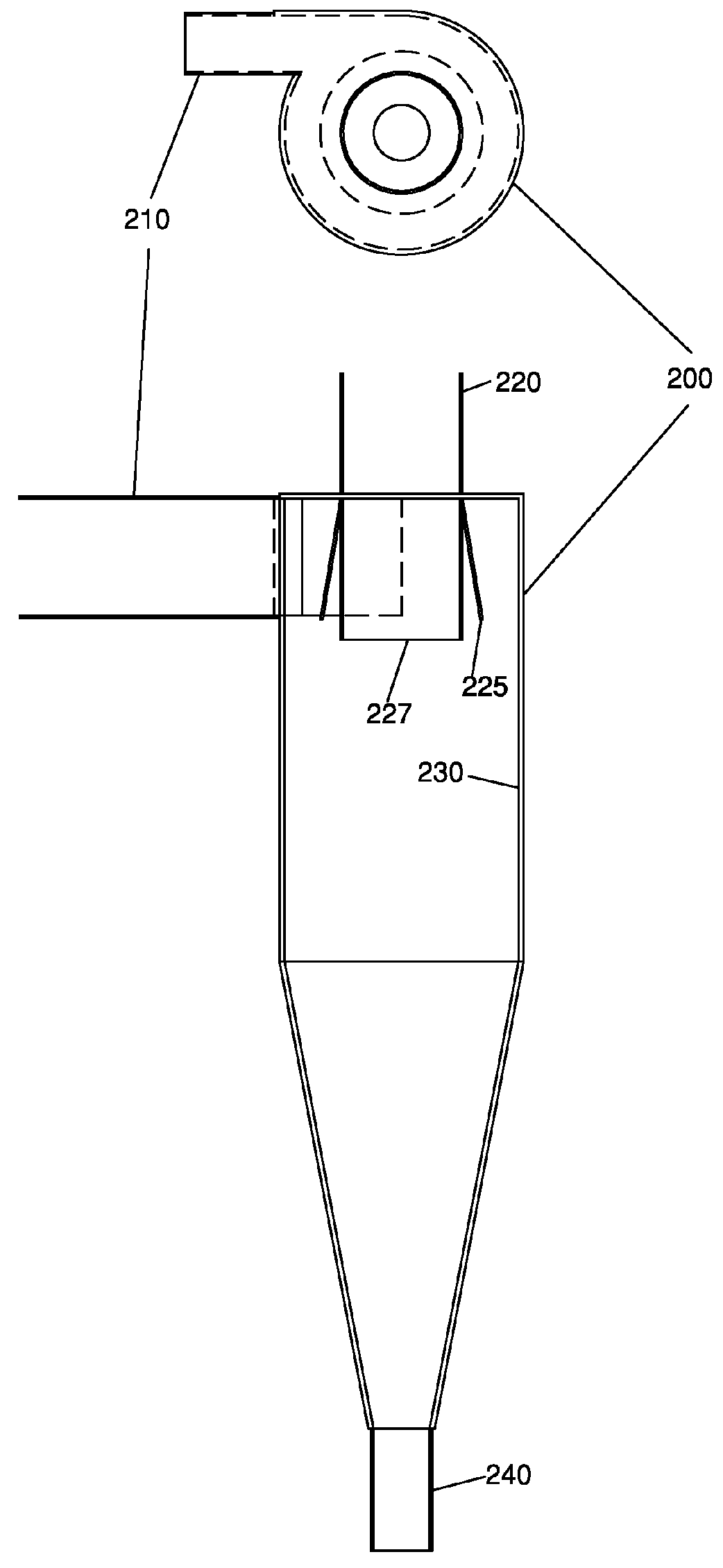

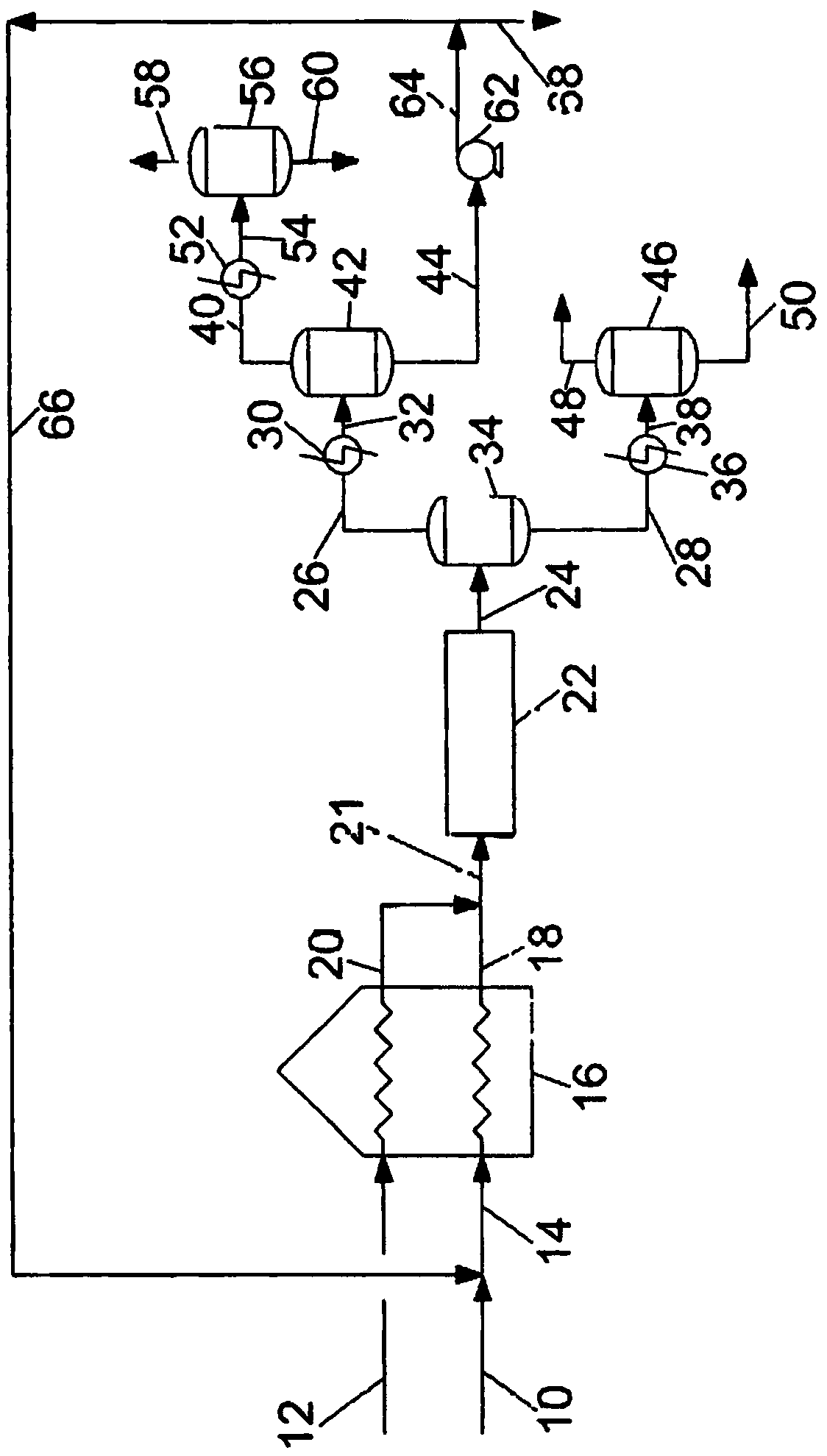

Turbulent mesophase pitch process and products

ActiveUS9376626B1Reduce and prevent formationWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by thermal meansFully developedEngineering

A process for producing mesophase pitch using a long tube reactor is disclosed. An aromatic rich feed, preferably a petroleum pitch having a softening point above 100° C., is preheated to a temperature above its softening point and mixed with a vapor, preferably steam, in a long tubular reactor under intense mixing conditions, preferably fully developed turbulent flow such as mist annular flow, with a residence time at least an order of magnitude less than prior art processes and preferably less than 10 seconds. Preferably the reactor is heated by electric resistance or induction heating or by immersion in a heated fluid or in a fired heater. Mesophase pitch with a high coking value and a surprisingly low quinolone insoluble content is produced. The byproducts of thermal polymerization and thermal dealkylation have less than 50% as much olefin and diene content as compared to similar byproducts from prior art processes.

Owner:ACP TECH LLC

Method for preparing mesophase asphalt and carbon fibers through flash pyrolysis pretreatment-catalytic condensation polymerization of heavy oil

PendingCN108728147ALow softening pointLow optical textureWorking-up pitch/asphalt/bitumen by chemical meansFibre chemical featuresWide areaFiber

The invention provides a method for preparing mesophase asphalt and carbon fibers through flash pyrolysis pretreatment-catalytic condensation polymerization of heavy oil. The method comprises the following steps: carrying out short-time high-temperatrure pyrolysis pretreatment on the raw materials, so as to obtain the modified raw materials; and mixing the modified raw materials with a catalyst, so as to prepare mesophase asphalt, wherein raw material oil is FCC oil slurry heavy fraction, naphthene base decompression distillate oil or naphthene base hydrogenation tail oil; and preparing high-modulus the high-strength carbon fibers from the obtained mesophase asphalt. The method has the beneficial effects that the process flow is simple, and the adopted catalyst does not corrode equipment and does not have harsh requirements on the equipment; the prepared mesophase asphalt is low in softening point (230-250 DEG C), the content of an intermediate phase reaches 98% or above, and the mesophase asphalt has a large-wide area streamline optical anisotropy structure and good spinnability; and by carrying out pre-oxidation, carbonization and graphitization on the spun raw yarns, the high-modulus and high-strength asphalt-based carbon fibers can be obtained.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of high-modulus carbon fibers and precursor mesophase pitch thereof

ActiveCN111575037AHigh modulusHigh tensile strengthWorking-up pitch/asphalt/bitumen by selective extractionTreatment with plural serial stages onlyChromatographic separationPolymer science

The invention provides a preparation method of high-modulus carbon fibers and precursor mesophase pitch thereof. According to the method, with heavy oil adopted as a raw material, components with molecular weight distribution of 400-1000 are separated out by volume exclusion chromatography; acidic components and alkaline components in the heavy oil are respectively removed through ion exchange chromatography and by means of large-aperture cation exchange resin and anion exchange resin in sequence, so that modified raw oil can be obtained; thermal polycondensation carbonization is performed onthe modified raw oil to obtain the high-quality mesophase pitch with good spinnability; the high-quality mesophase pitch has the advantages of high mesophase content, low softening point, low viscosity, meltability and good spinnability, and is a high-quality raw material for preparing high-modulus carbon fibers; and after melt spinning, pre-oxidation, carbonization and graphitization treatment are carried out, the high-modulus mesophase pitch-based carbon fibers can be obtained.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

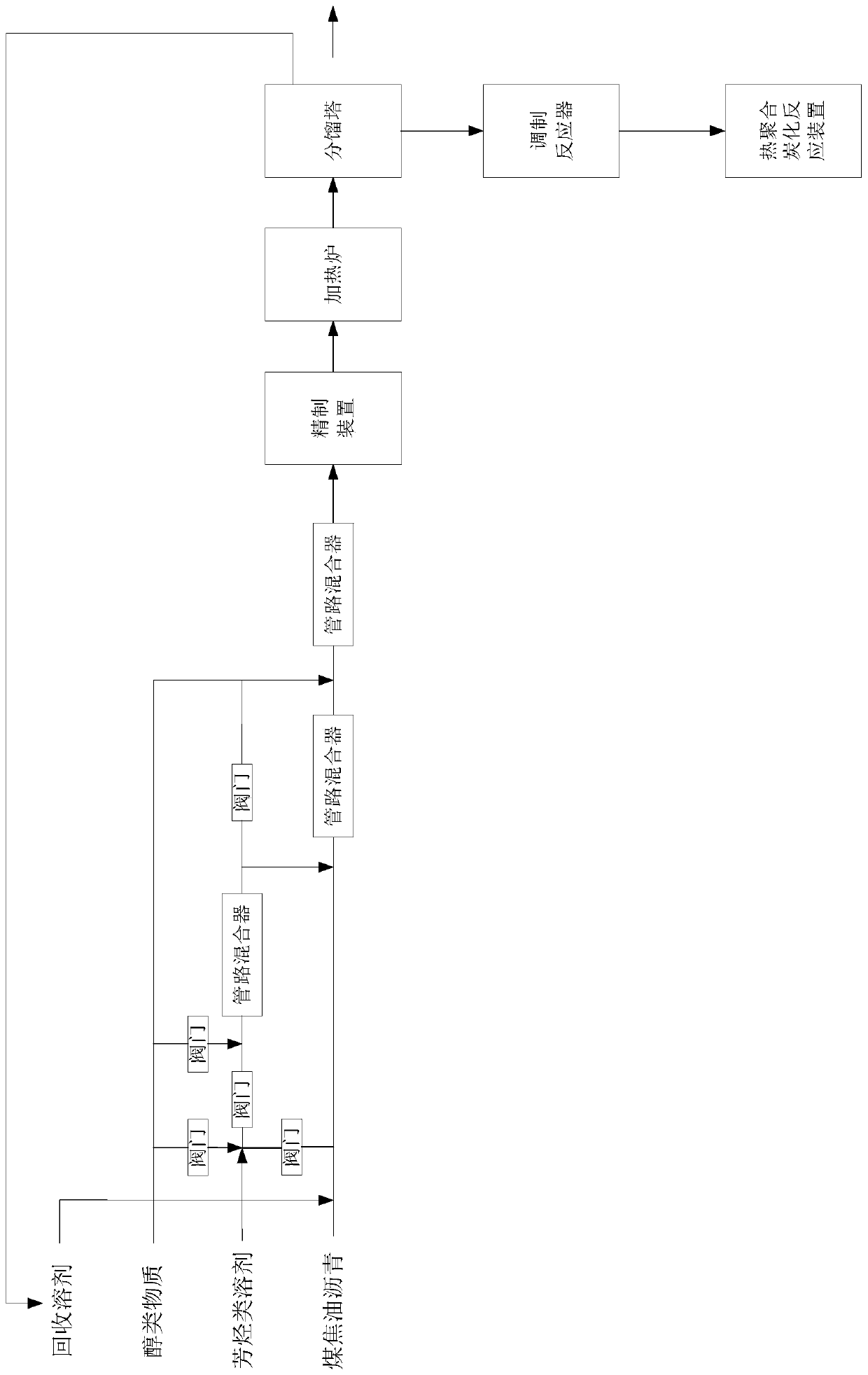

Mesophase pitch coke preparation method, mesophase pitch coke, negative electrode material and lithium battery

ActiveCN110437862AHigh yieldHigh recovery rateWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCarbonizationPhysical chemistry

The invention provides a mesophase pitch coke preparation method, which comprises: (1) adding an alcohol substance and an aromatic hydrocarbon solvent to coal tar pitch, pre-treating, and removing quinoline insoluble matter to obtain refined asphalt; (2) adding a viscosity adjusting agent to the refined asphalt obtained in the step (1), and adjusting the viscosity to obtain adjusted asphalt; (3) heating the adjusted asphalt obtained in the step (2), and carrying out a thermal polymerization reaction to obtain mesophase asphalt; and (4) carrying out carbonization treatment on the mesophase asphalt obtained in the step (3) to obtain mesophase pitch coke. According to the present invention, the mesophase pitch coke obtained by the preparation method has an ash content of less than or equal to0.1%, a true density of more than or equal to 1.9 and an anisotropy degree of more than or equal to 95%, and the graphitization degree after graphitization can be above 98%. The invention further provides a mesophase pitch coke, a negative electrode material and a lithium battery.

Owner:BEIJING RISUN TECH CO LTD

Mesophase pitch and preparation method thereof

ActiveCN110041952AEasy to changePromote aromatizationWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansHeat sensitizationDistillation

The invention provides an application of a heavy product with a boiling point at 350-410 DEG C prepared through a lignite thermal melting catalysis technology as a raw material in preparing a mesophase pitch and a preparation method of the mesophase pitch. The preparation method comprises the following steps: taking the heavy product with the boiling point at 350-410 DEG C prepared through the lignite thermal melting catalysis technology as the raw material, and then performing thermal polycondensation, reduced pressure distillation, hydrogenation reaction, flashing and heat sensitization, thereby acquiring the mesophase pitch. The content of raw quinoline insolubles in the mesophase pitch product can be extremely reduced; the conversion of hydrogenated pitch into the mesophase pitch can be boosted; the loss of high-value components in the reaction process can be obviously reduced; the yield and quality stability of high-quality mesophase pitch product can be promoted; light componentsare removed by flashing, so that all hydrogen-donor solvent can be recycled; continuous production can be realized; lastly, the high-quality mesophase pitch product with mesophase pitch content not less than 61.2%, softening point at 274-282 DEG C and yield not less than 99.3% can be prepared.

Owner:广东煤基碳材料研究有限公司

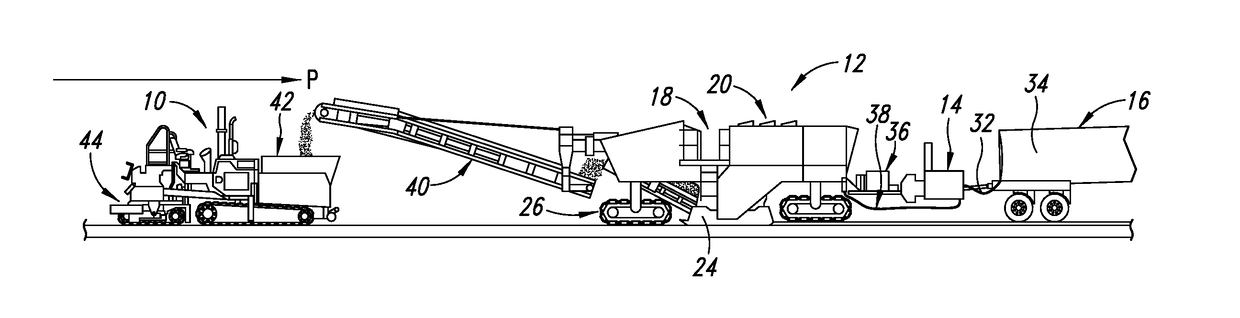

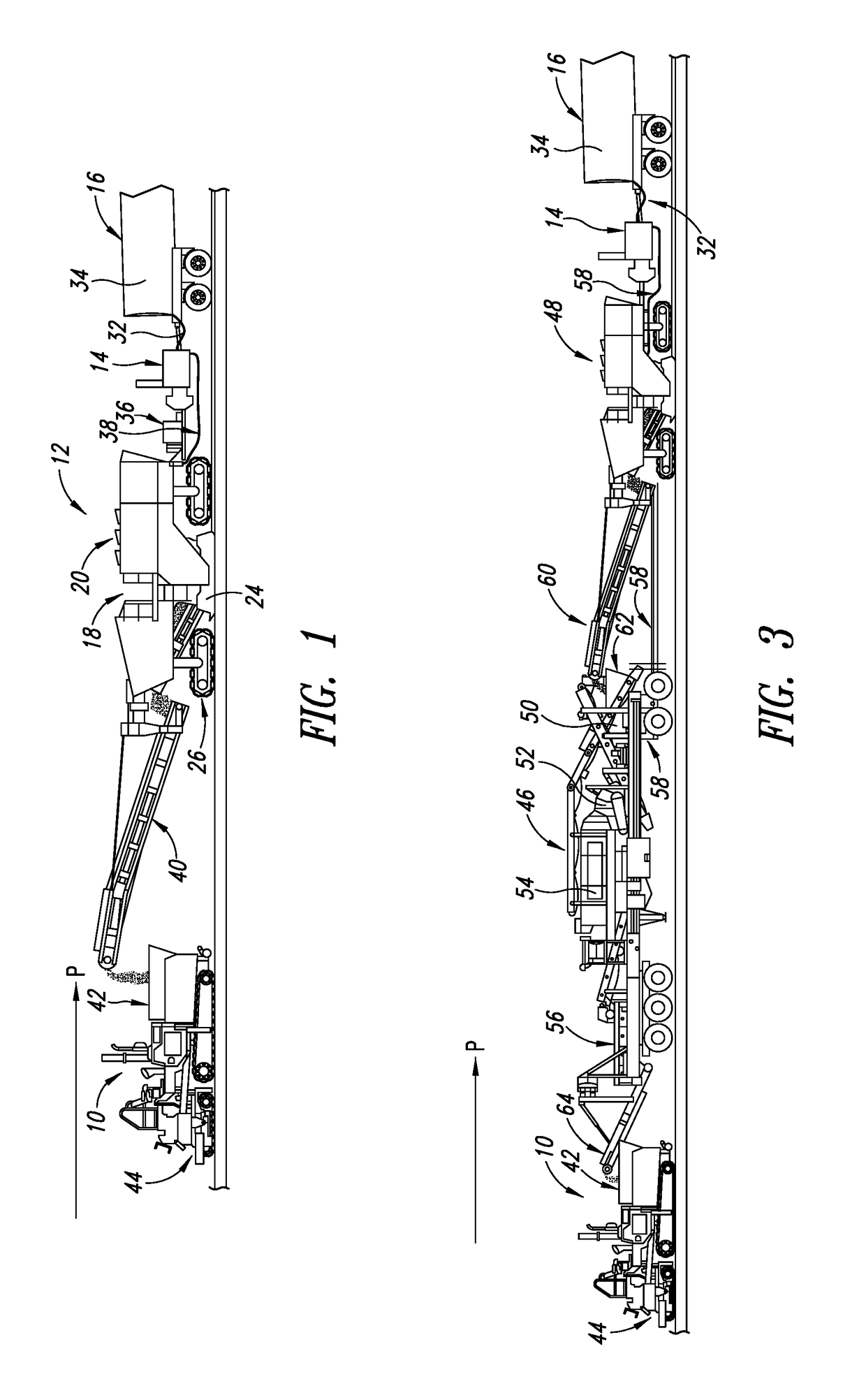

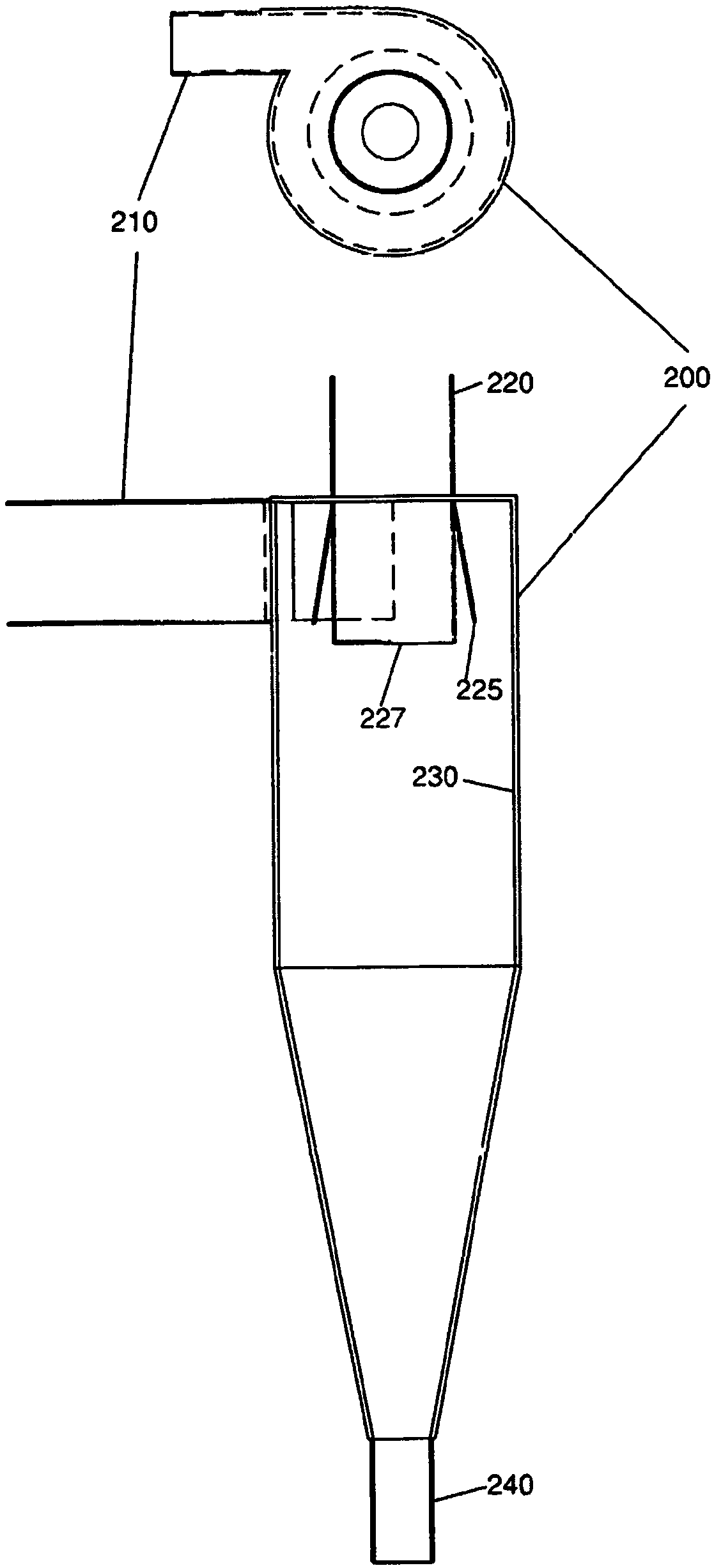

Cold in-place recycling with in-line heater for asphalt cement

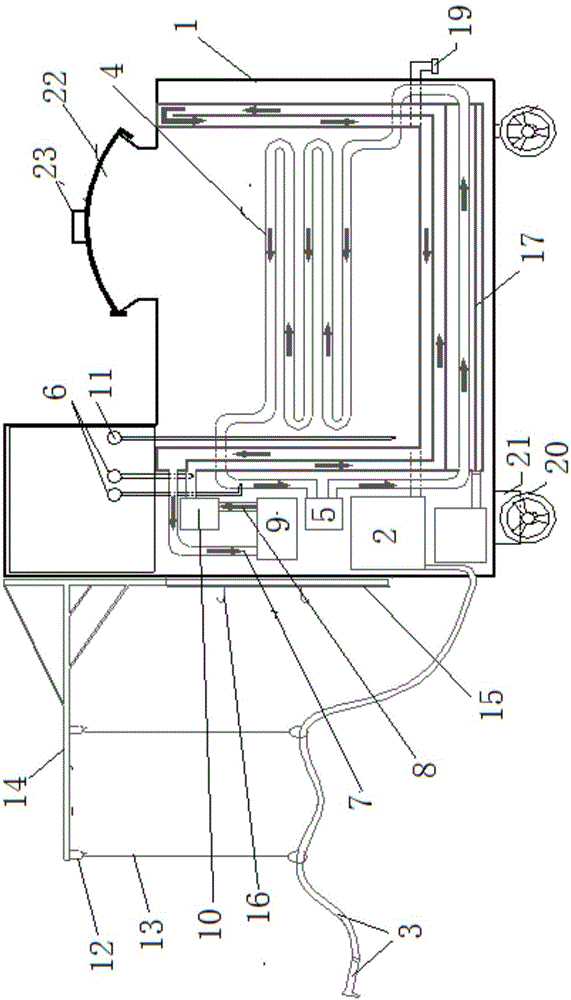

ActiveUS20180187384A1Convenient lightingWorking-up pitch/asphalt/bitumen by chemical meansPaving detailsRoad surfaceEngineering

A CIR train that is adapted to traverse a roadway of asphalt pavement in order to recycle and repair the asphalt pavement includes a milling machine for removing asphalt paving material from the roadway. The CIR train also includes an asphalt cement supply tank and a mechanism for dispensing asphalt cement onto asphalt paving material that has been removed from the roadway. A heater is in fluid communication with the asphalt cement supply tank and the mechanism for dispensing asphalt cement on the asphalt paving material that has been removed from the roadway. The heater is adapted to heat the asphalt cement from the asphalt cement supply tank prior to said asphalt cement being dispensed on the asphalt paving material that has been removed from the roadway.

Owner:ROADTEC

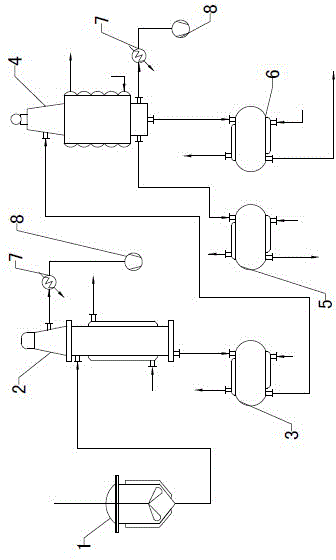

Method and device of preparing needle coke

InactiveCN104479707AControl cut volumeReduce energy consumptionWorking-up pitch/asphalt/bitumen by distillationCoking carbonaceous materialsAsphaltDegasification

The invention discloses a method and a device of preparing a needle coke, and belongs to the technical field of needle coke preparation. The method disclosed by the invention is characterized by comprising the following steps: separating an asphalt raw material by virtue of a degasification column and a molecular distillation column, preheating the asphalt raw material, pumping the asphalt raw material in the degasification column and carrying out degasification treatment at a degasification temperature of 250-330 DEG C under an in-column pressure of 100-1000Pa, then pumping the degasified materials to the molecular distillation column, controlling a distillation temperature in the molecular distillation column to 300-400 DEG C and controlling a pressure to 0.01-100Pa, separating the materials into a light-phase component and a heavy-phase component in the molecular distillation column through a short-path distillation action, carrying out delayed coking on the light-phase component to obtain green coke, and calcining the green coke to obtain the needle coke. The method disclosed by the invention is capable of stably and accurately controlling the cutting amounts of the raw material components, thus flexibly adjusting the product quality, and furthest reserving ideal components. Moreover, the method is low in treatment temperature, rapid in material separation, and free from forming secondary quinoline undissolved substances.

Owner:乔光明

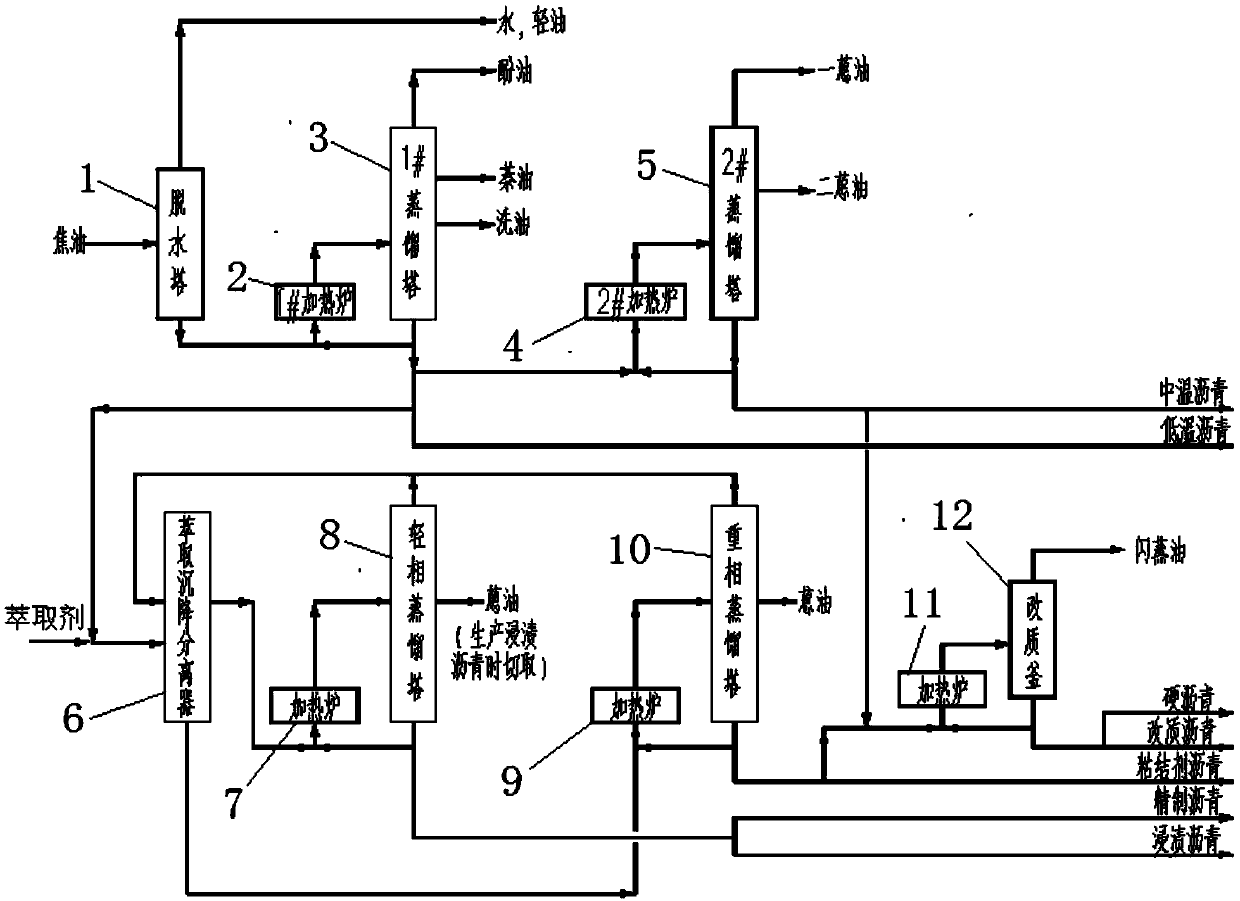

Process and device for producing various asphalt products by combining distillation and extraction

PendingCN109517614AMeet needsSolve the problem of low single added valueWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionDistillationTar

The invention relates to a process and a device for producing various asphalt products by combining distillation and extraction. The device comprises a dehydration tower, a distillation system, an extraction system and an asphalt modification system. Coal tar is used as a raw material to produce low-temperature asphalt, medium-temperature asphalt, modified asphalt, low-quinoline insoluble refinedasphalt, impregnated asphalt, hard asphalt, binder asphalt and other products by using a combined production process of distillation, extraction and asphalt modification. A variety of high value-addedasphalt products can be produced simultaneously with a set of production device, the utilization of the device is maximized, and the process and the device are adaptive to the needs of large-scale tar processing.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

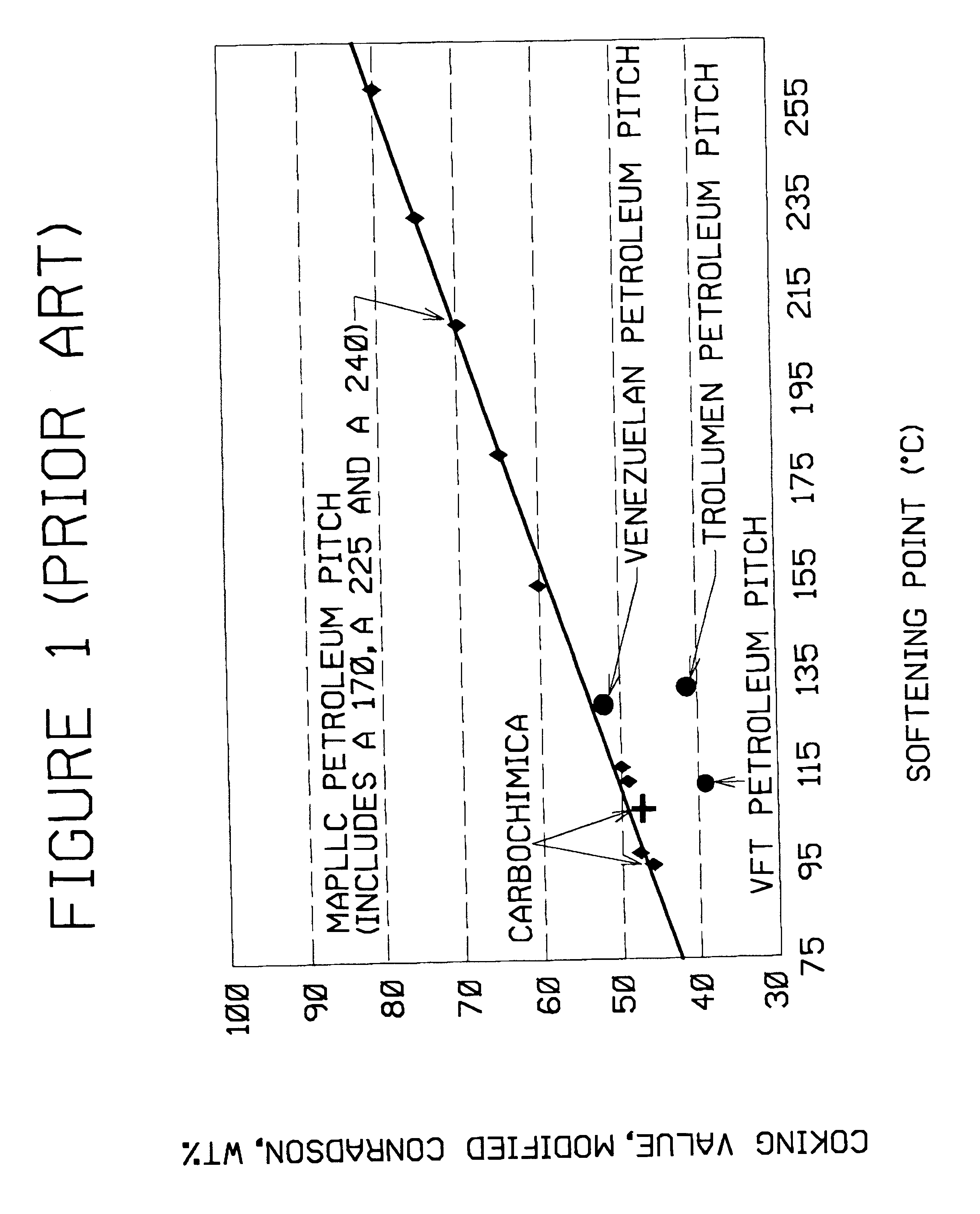

High coking value pitch

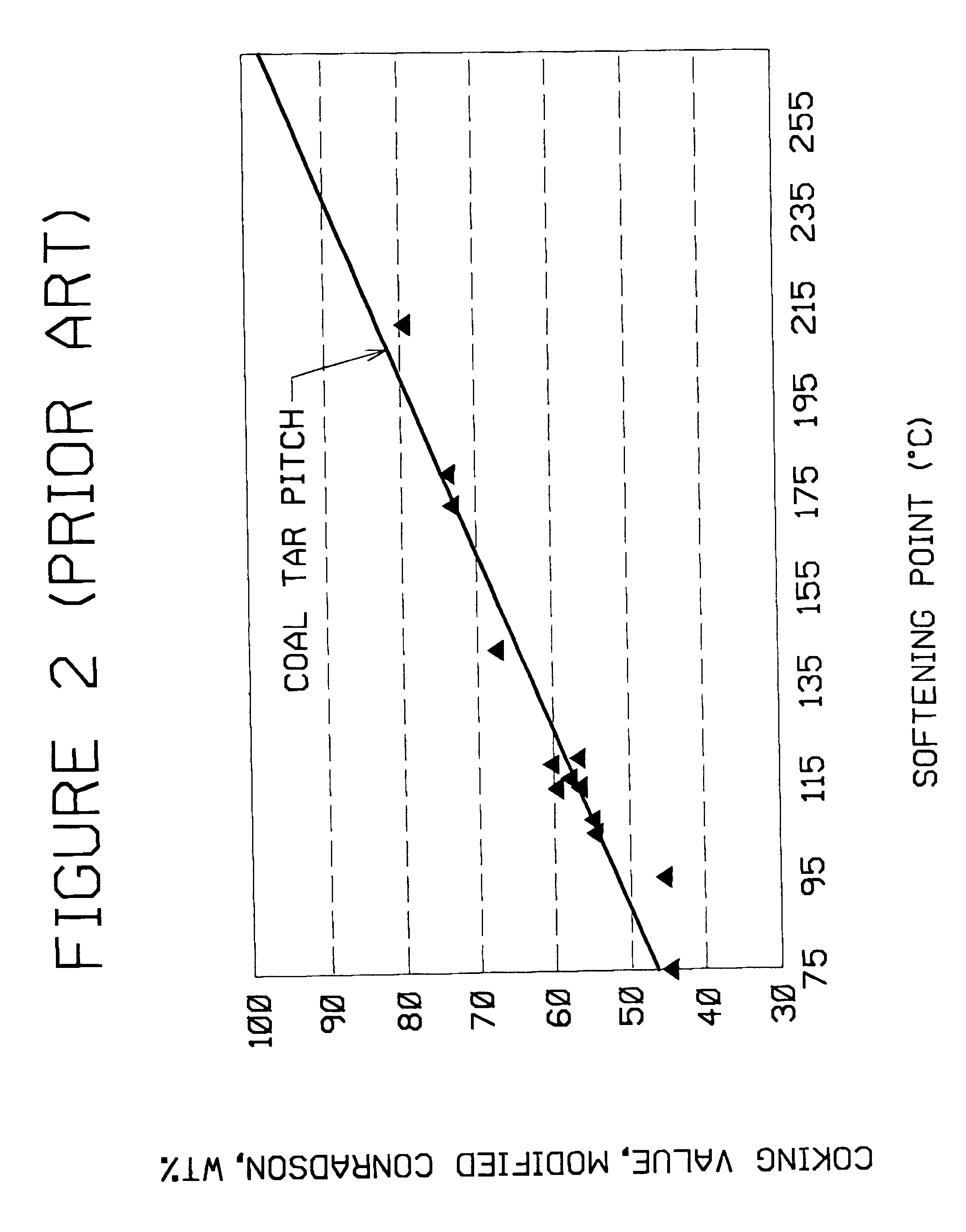

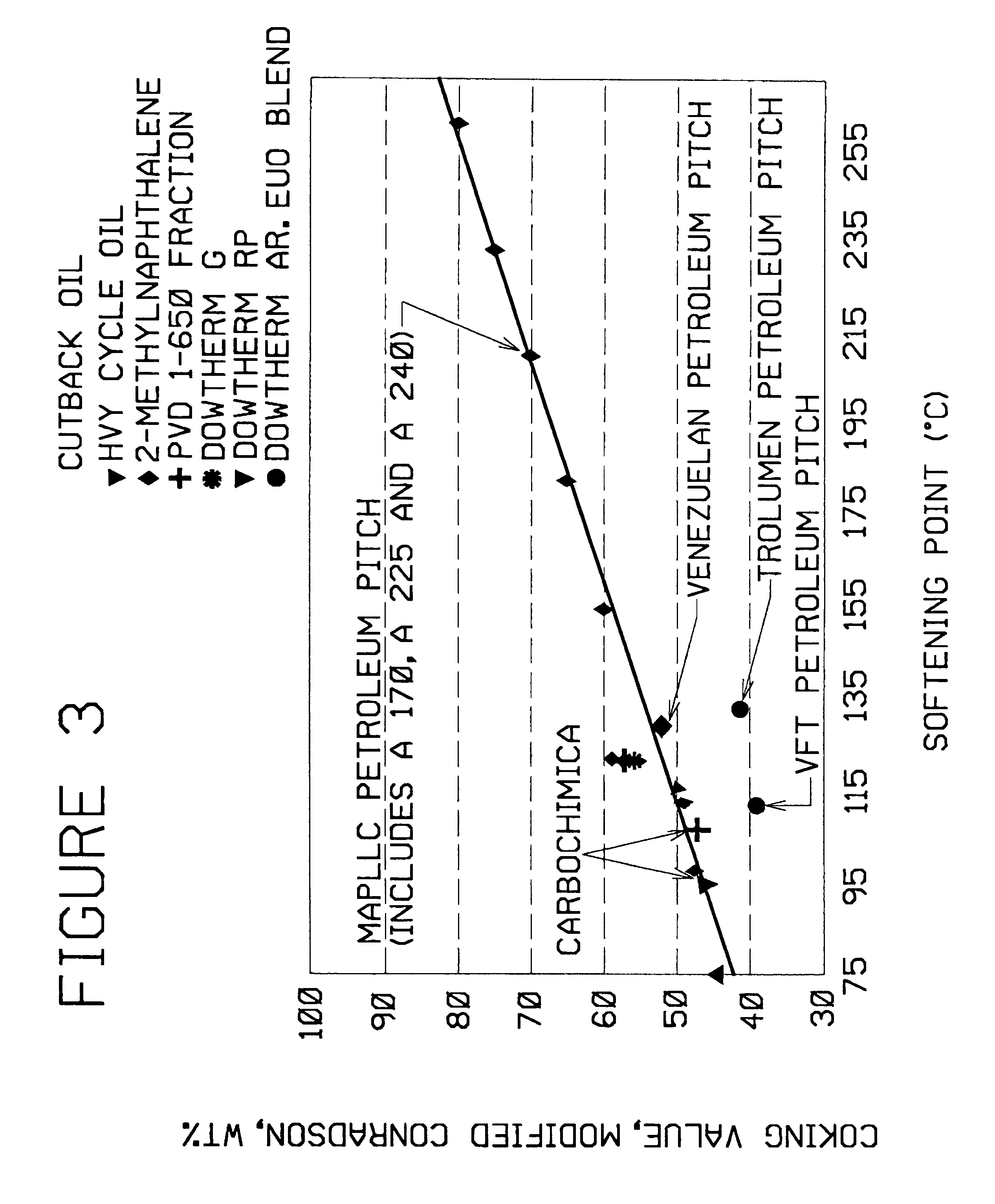

InactiveUS6352637B1Increase valueImprove workabilityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by mixing fractionsBoiling pointLiquid hydrocarbons

A high coking value pitch with a relatively low softening point is disclosed. A pitch is distilled or thermally processed to produce an intermediate pitch with an increased coking value and relatively high softening point, then blended with a cutter solvent of a liquid hydrocarbon stream to form a product pitch. The process may be used to increase the coking value of either petroleum or coal tar pitch. Preferably the cutter solvent is methylnaphthalene, or a highly aromatic, low viscosity oil or similar aromatic rich stream having a substantially lower boiling point than the intermediate pitch product.

Owner:MARATHON PETROLEUM

Binder for metallurgical coke and a process for making same

ActiveUS20150368745A1Working-up pitch/asphalt/bitumen by selective extractionCoke ovensSolventBituminous coal

A binder for making metallurgical coke and a process for making the binder. The binder is thermally hydrocracked pitch which has been de-ashed. The binder may be mixed with low rank bituminous coal, heated to make coke which is acceptable as a metallurgical coke. The thermally hydrocracked pitch may be de-ashed by mixing with a solvent, and separating the insoluble portions from the soluble portions using a centrifuge. The soluble portions may be separated from the solvent, for example, in a fractionating section, and used as the binder with poor coking coal to make metallurgical coke.

Owner:UOP LLC

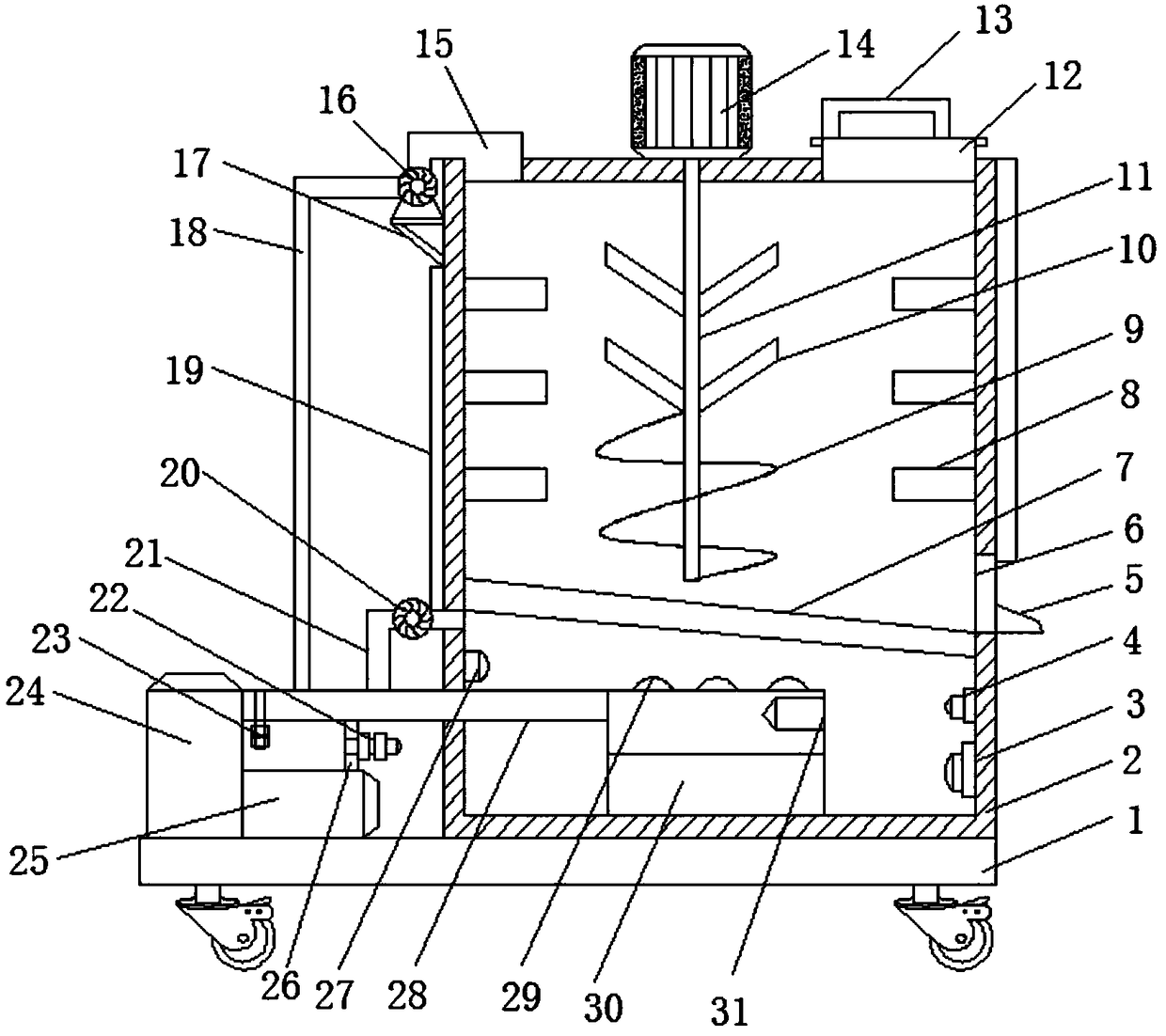

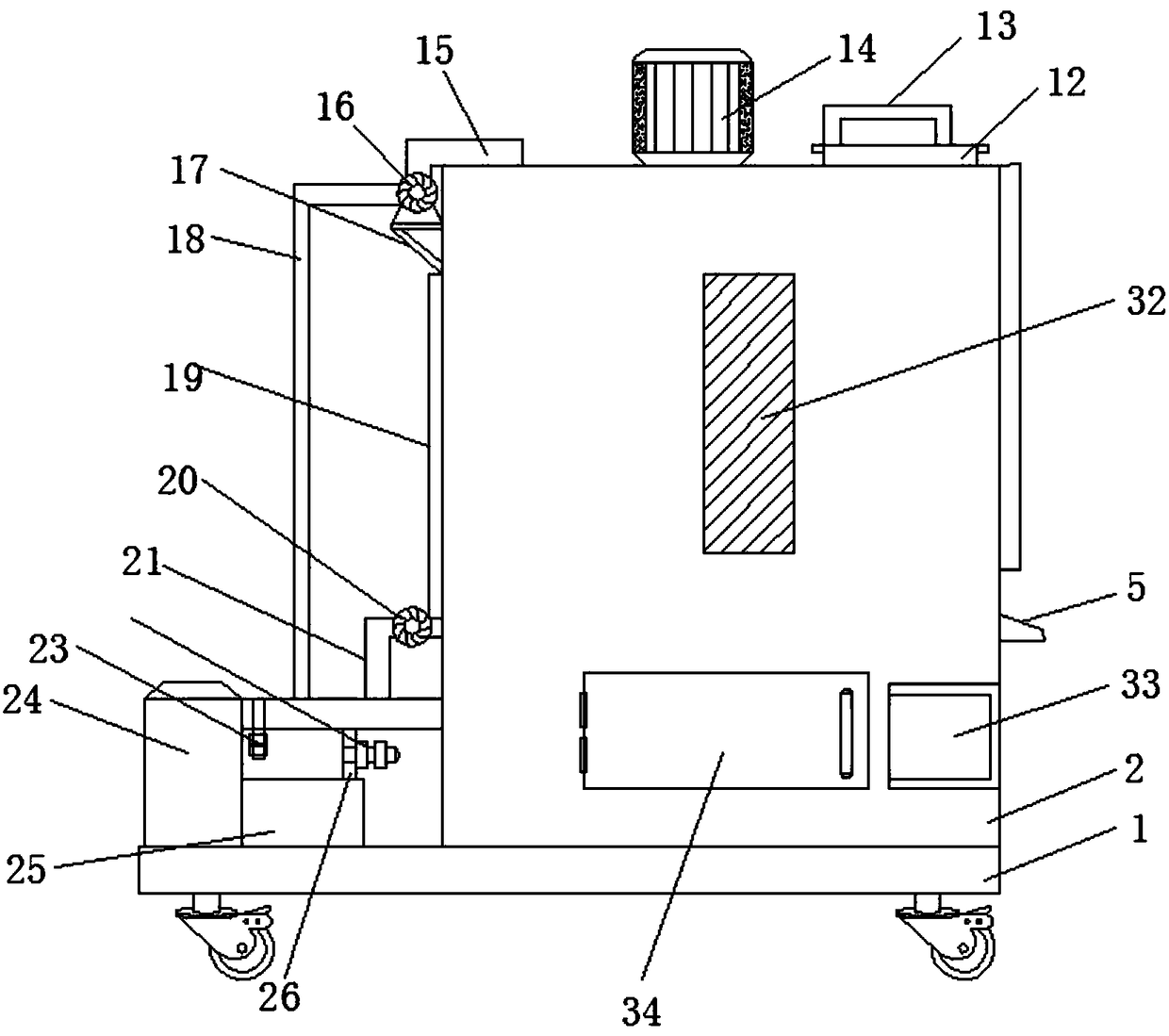

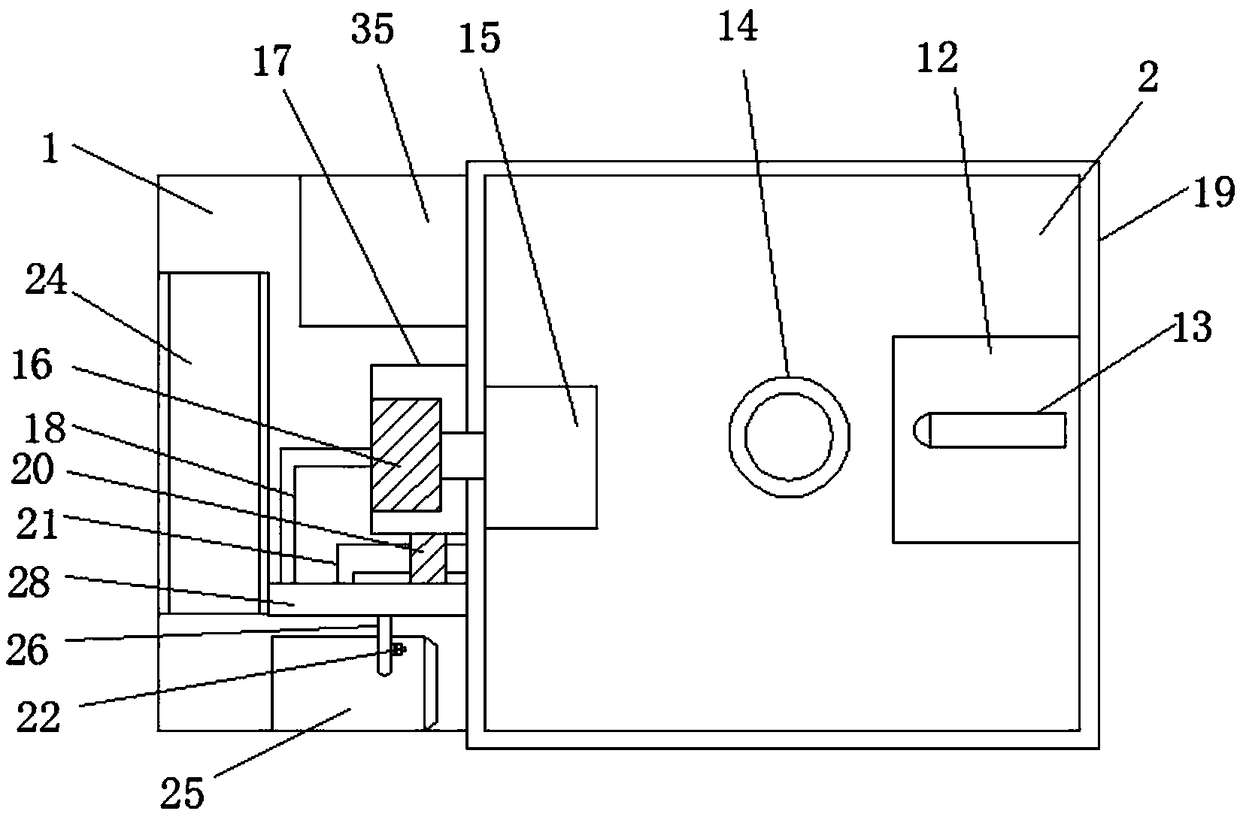

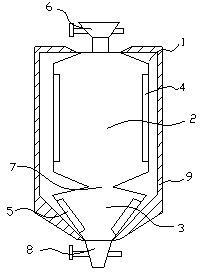

Environment-friendly asphalt melting furnace for road repairing

PendingCN108359488ABurn fullySpeed up meltingWorking-up pitch/asphalt/bitumen by meltingRoads maintainenceSpiral bladeHeat conducting

The invention belongs to the technical field of road repairing equipment and in particular relates to an environment-friendly asphalt melting furnace for road repairing. Aiming at the technical problems that a general asphalt heating furnace is simple in design structure, single in function, inconvenient to use and poor in environment friendliness, the following scheme is provided. The environment-friendly asphalt melting furnace comprises a bottom plate, wherein a box body is welded on one side of an outer wall of the top of the bottom plate; a motor is fixed in the center of an outer wall onthe top of the box body by virtue of bolts; an output shaft of the motor penetrates through the box body to be welded with a transmission shaft; stirring rods in annular distribution in equal distance are welded on the outer wall, which is close to one side of the motor, of the transmission shaft; spiral blades are welded at one end, which is far away from the motor, of the transmission shaft; the same heat-conducting plate is welded on the inner walls on two opposite sides of the box body; a rectangular through hole is formed in a position, which is close to the heat-conducting plate, of theinner wall on one side of the box body. The environment-friendly asphalt melting furnace disclosed by the invention is practical and novel, melting of asphalt can be accelerated, and the working efficiency is improved. Moreover, asphalt fume produced by molten asphalt and waste heat produced by gas burning can be fully utilized, and the asphalt melting furnace is energy-saving and environmentallyfriendly.

Owner:求佳飞

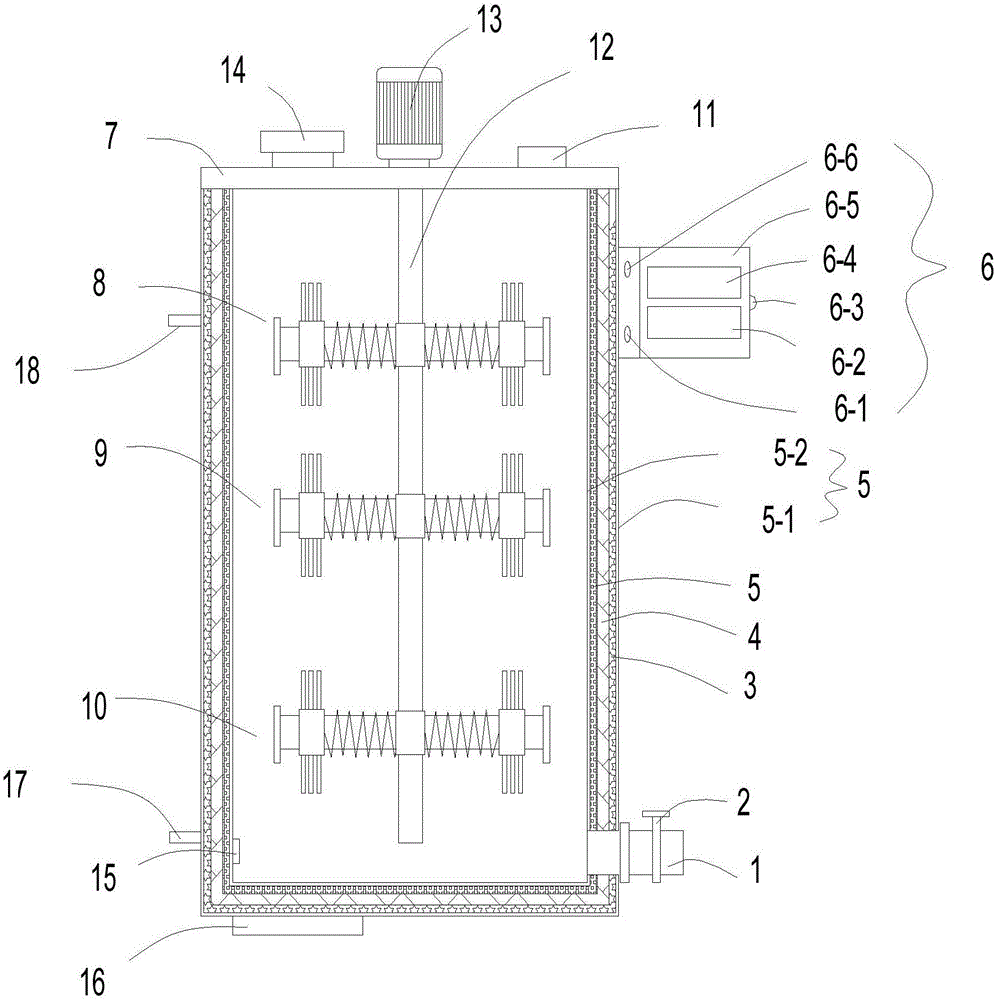

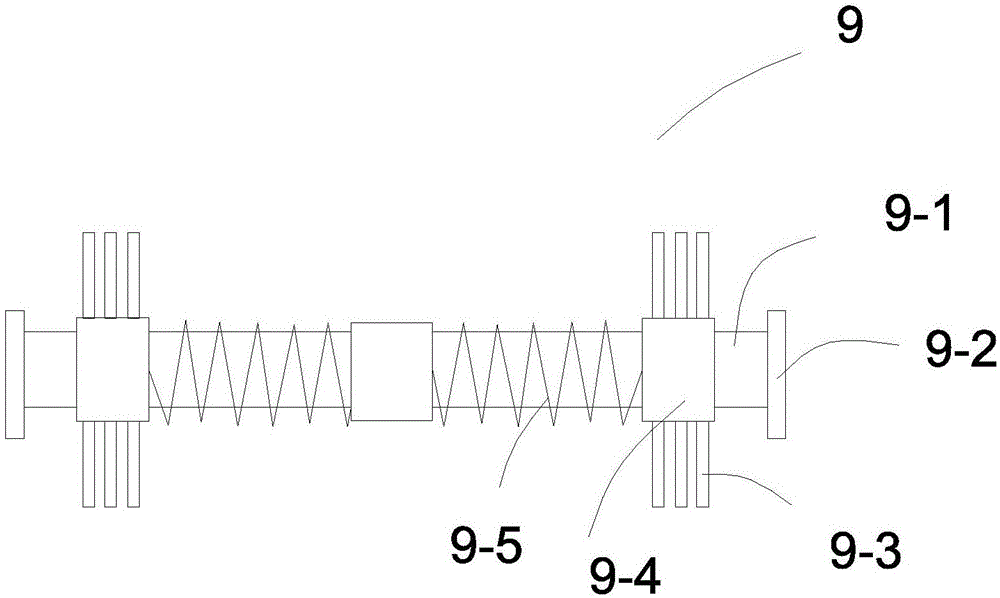

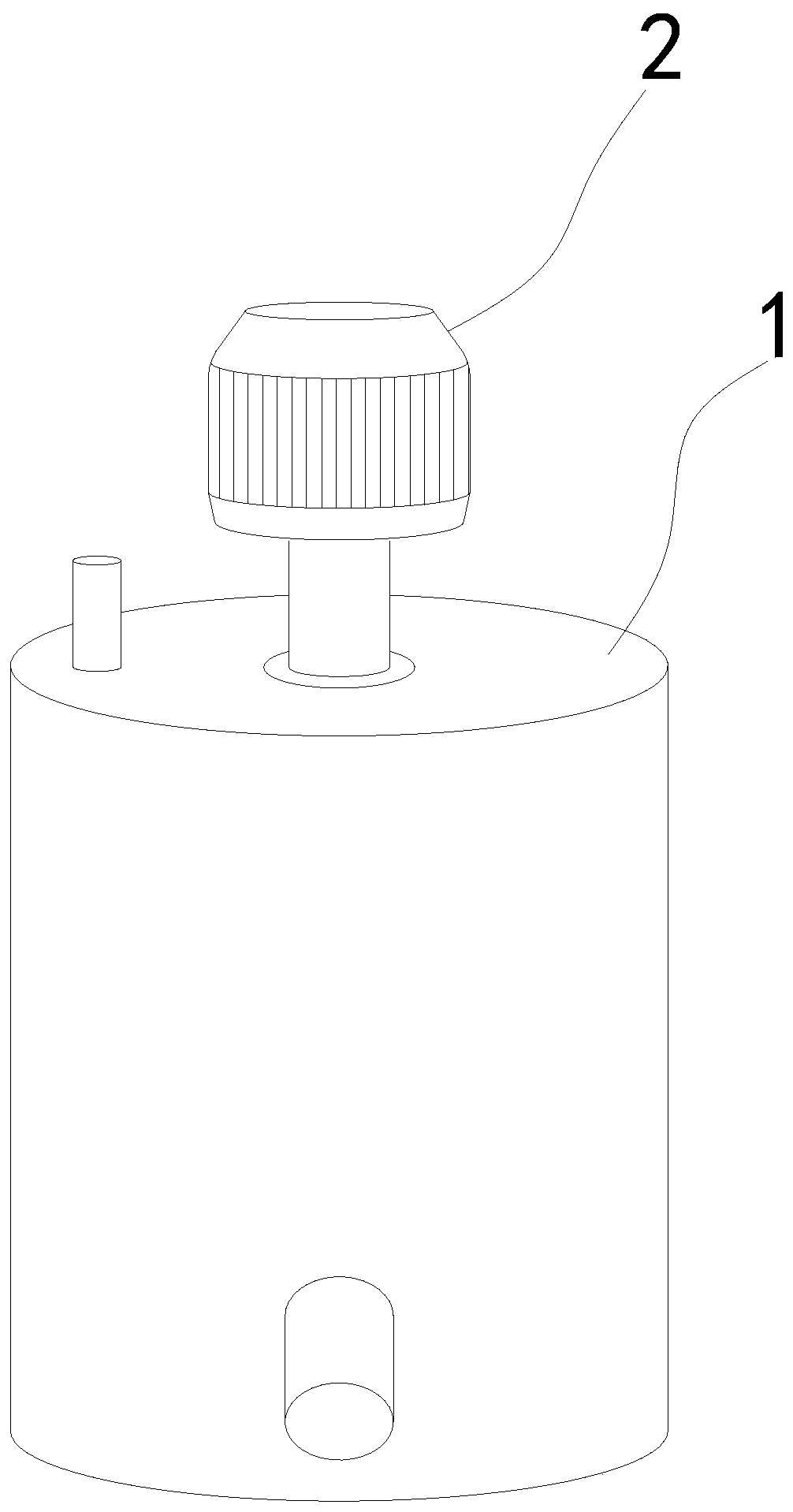

Agitation device

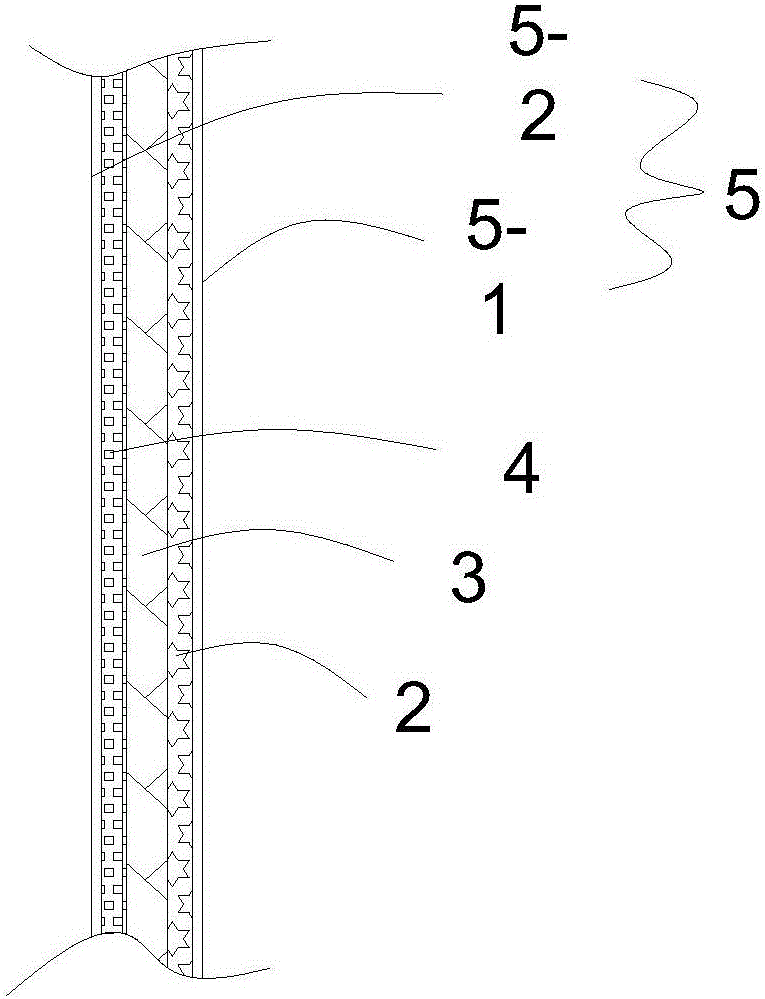

InactiveCN106268415AImprove uniformityImprove modification efficiencyRotary stirring mixersTransportation and packagingInsulation layerHeat conducting

The invention relates to the technical field of an asphalt agitation and discloses an agitation device. The agitation device comprises a tank and a seal cover, the seal cover for sealing the tank is provided with a feeding port communicated with the interior of the tank, and one side of the bottom end of the tank is provided with a discharging port. An agitation shaft is arranged below the seal cover and in the tank and provided with an agitation component A, an agitation component B and an agitation component C sequentially from top to bottom. The tank comprises an inner shell and an outer shell, the inner shell and the outer shell form a cavity structure which is provided with a heat insulation layer, an isolation layer and a heating layer sequentially from outside to inside, the heating layer comprises a heat conducting oil spiral pipe which is spirally wound on the inner shell, the outer shell is provided with a heat conducting oil outlet and a heat conducting oil inlet, and the heat conducting oil outlet and the heat conducting oil inlet are communicated with two ends of the heat conducting oil spiral pipe respectively. The agitation device has advantages of simple structure, high operation efficiency, freeness of dead corners in agitation and high practicality.

Owner:赵黎

Construction equipment for spraying non-curing rubber asphalt

ActiveCN105863218AConducive to low temperature constructionNo damageWorking-up pitch/asphalt/bitumen by meltingBuilding constructionsMechanical indexEngineering

The invention relates to construction equipment for heating and spraying non-curing rubber asphalt. The construction equipment comprises a storage tank; the storage tank serves as an important component part of the equipment and a zone for conducting heating and temperature adjusting and preserving on asphalt paint and divided into two areas, the upper portion is a heating area, and the lower portion is a temperature lowering and preserving area. A first conduction oil heating system is placed in the heating area and used for heating and melting the non-curing asphalt paint, after being heated, the paint enters the temperature lowering and preserving area, and a second heating system is mounted in the temperature preserving area and used for conducting temperature adjusting and preserving treatment on the heated and molten paint; a paint spraying machine is connected with the temperature lowering and preserving area and used for implementing spraying operation. According to the construction equipment, temperature adjusting and control are conducted on the paint in the temperature lowering and preserving area, so that the paint is constructed in the low temperature state, it is guaranteed that mechanical indexes of a material are not damaged, the situation that a coating layer has the pinhole phenomenon due to high temperature of the paint is avoided, or the phenomenon that when the pain is in the high temperature state, smoke occurs in the site construction process is avoided.

Owner:中科建通工程技术有限公司

Turbulent mesophase pitch process and products

ActiveCN109328215AReduce depositionWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsPolymer scienceQuinolone

A process for producing mesophase pitch using a long tube reactor is disclosed. An aromatic rich feed, preferably a petroleum pitch having a softening point above 100 DEG C, is preheated to a temperature above its softening point and mixed with a vapor, preferably steam, in a long tubular reactor under intense mixing conditions, preferably fully developed turbulent flow such as mist annular flow,with a residence time at least an order of magnitude less than prior art processes and preferably less than 10 seconds. Preferably the reactor is heated by electric resistance or induction heating orby immersion in a heated fluid or in a fired heater. Mesophase pitch with a high coking value and a surprisingly low quinolone insoluble content is produced. The byproducts of thermal polymerization and thermal dealkylation have less than 50 % as much olefin and diene content as compared to similar byproducts from prior art processes.

Owner:エーシーピーテクノロジーズエルエルシー

Energy-saving asphalt melting device

InactiveCN104294741AReduce consumptionDoes not affect the melting effectWorking-up pitch/asphalt/bitumen by meltingRoads maintainenceAsphaltMaterials science

The invention discloses an energy-saving asphalt melting device. The energy-saving asphalt melting device comprises a cylinder, wherein a first heating cavity is formed at the upper part of the cylinder, a second heating cavity is formed at the lower part of the cylinder, a feed inlet is formed in the top of the first heating cavity, a channel connected to the second heating cavity is formed at the bottom of the first heating cavity, a discharge outlet is formed in the bottom of the first heating cavity, a first heating component is arranged in the first heating cavity, a second heating component is arranged in the second heating cavity, and the first heating component and the second heating component are controlled independently respectively. The energy-saving asphalt melting device disclosed by the invention adopts a way that preheating is matched with centralized heating, thereby effectively reducing the consumption of energy on the premise of not affecting melting effect and achieving the purpose of saving energy.

Owner:ZHONGSHAN TOPWARE ELECTRONICS TECH

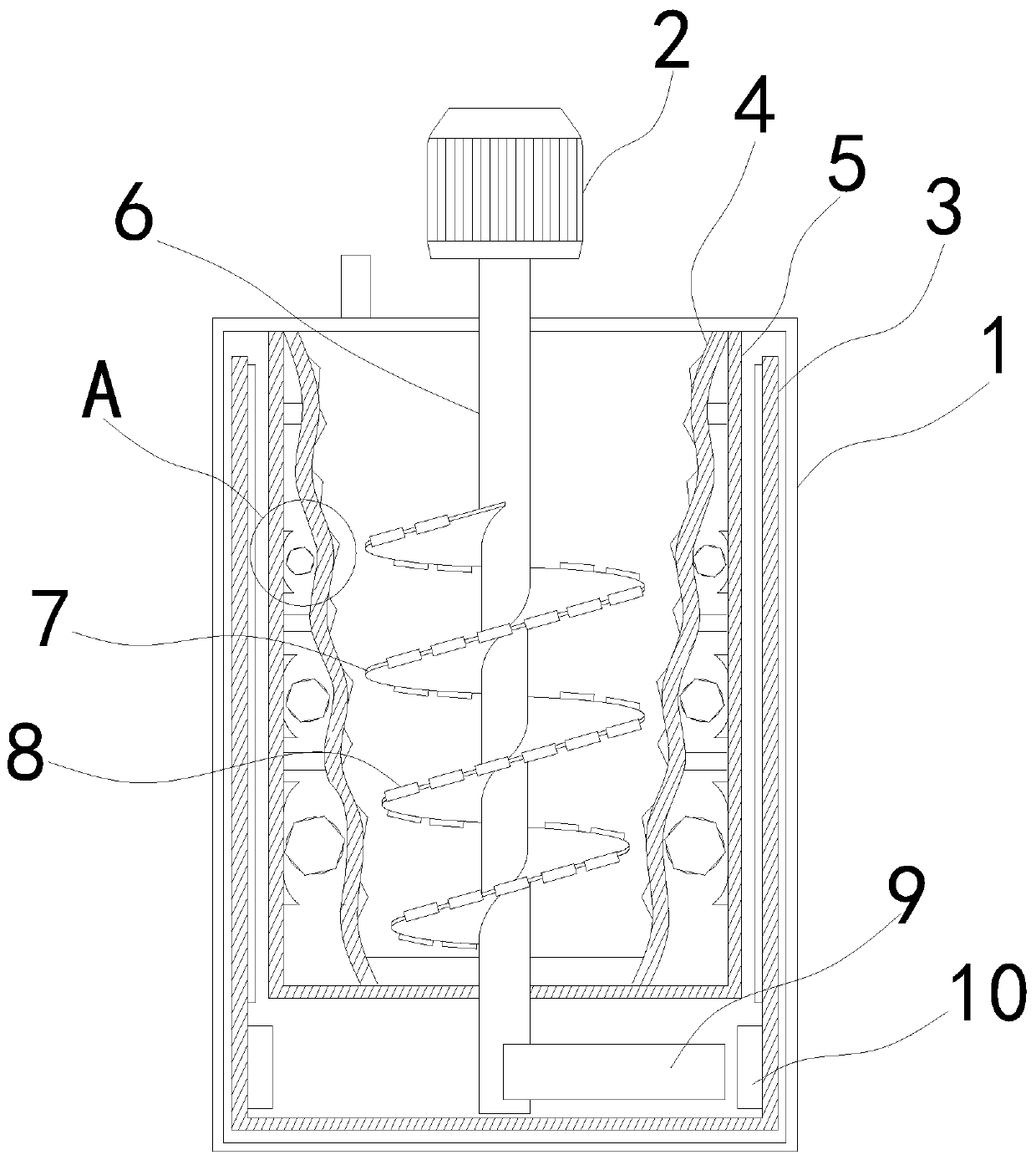

Asphalt high-efficiency stirring device capable of preventing adhesion on inner wall

ActiveCN110252195AIncrease contact areaImprove rotation efficiencyShaking/oscillating/vibrating mixersFlow mixersHeating timeAsphalt

The invention relates to the field of asphalt production, and particularly relates to an asphalt high-efficiency stirring device capable of preventing adhesion on an inner wall. The device comprises a device main body and a heating wall; a vibrating wall is fixedly arranged in the device main body; the inner side of the vibration wall is fixedly provided with a vibration guide wall; and the inner side of the vibration guide wall is fixedly provided with a heating wall. The heating wall is arranged in a mode of a bent curve, so that the contact area between asphalt and the heating wall is larger and heating efficiency is higher. When a rotating piece rotates to drive the asphalt to move upwards, the asphalt can roll and overflow from the edge of the rotating piece, flows downwards from the gap between the heating wall and the rotating piece for carrying out heating at a fixed time, then falls on to the bottom end, and then is driven upwards by the rotating piece for forming a circulation, so that the heating time of the asphalt is uniformly controlled. Inclined blocks are arranged inside stirring wheels at the edge of the rotating piece, and when stirring rods on the inclined blocks rotate around the inclined blocks, the stirring rods at the upper end are retracted and the stirring rods at the lower end extend outwards, so that when the asphalt overflows from the edge of the rotating piece, the stirring wheels can be driven to rotate to further stir the asphalt on the rotating piece.

Owner:广东金泉道路建筑新材料实业有限公司

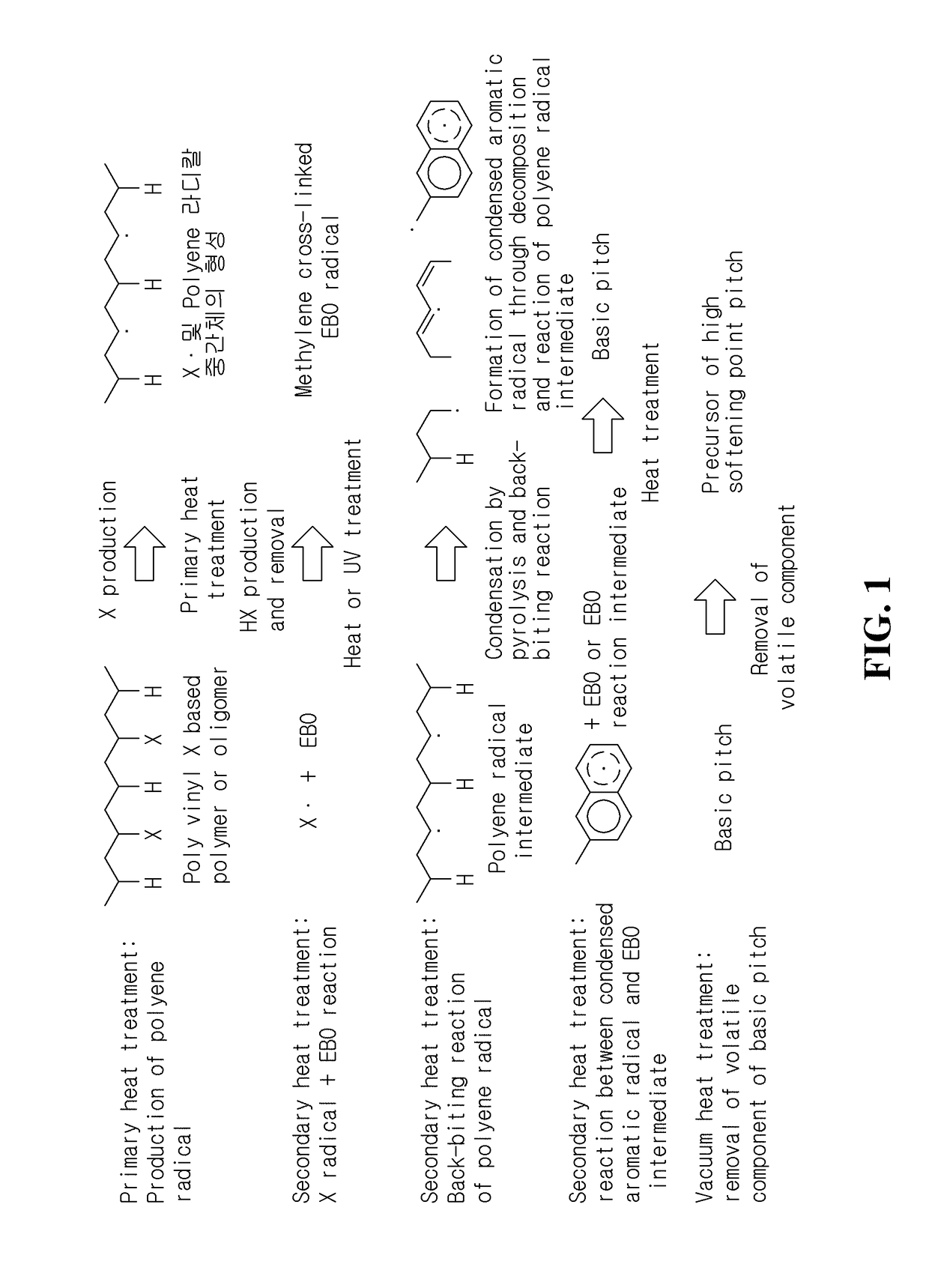

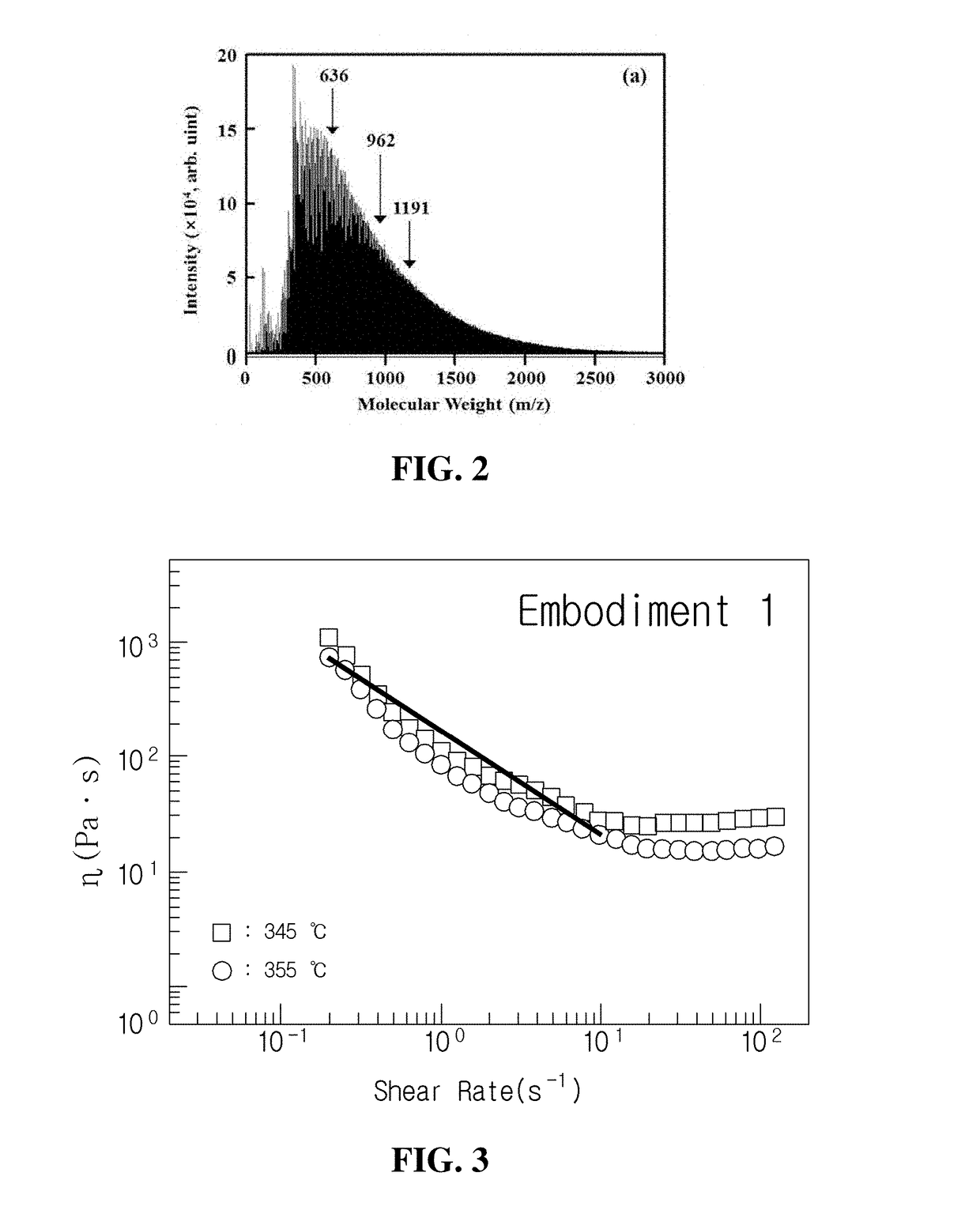

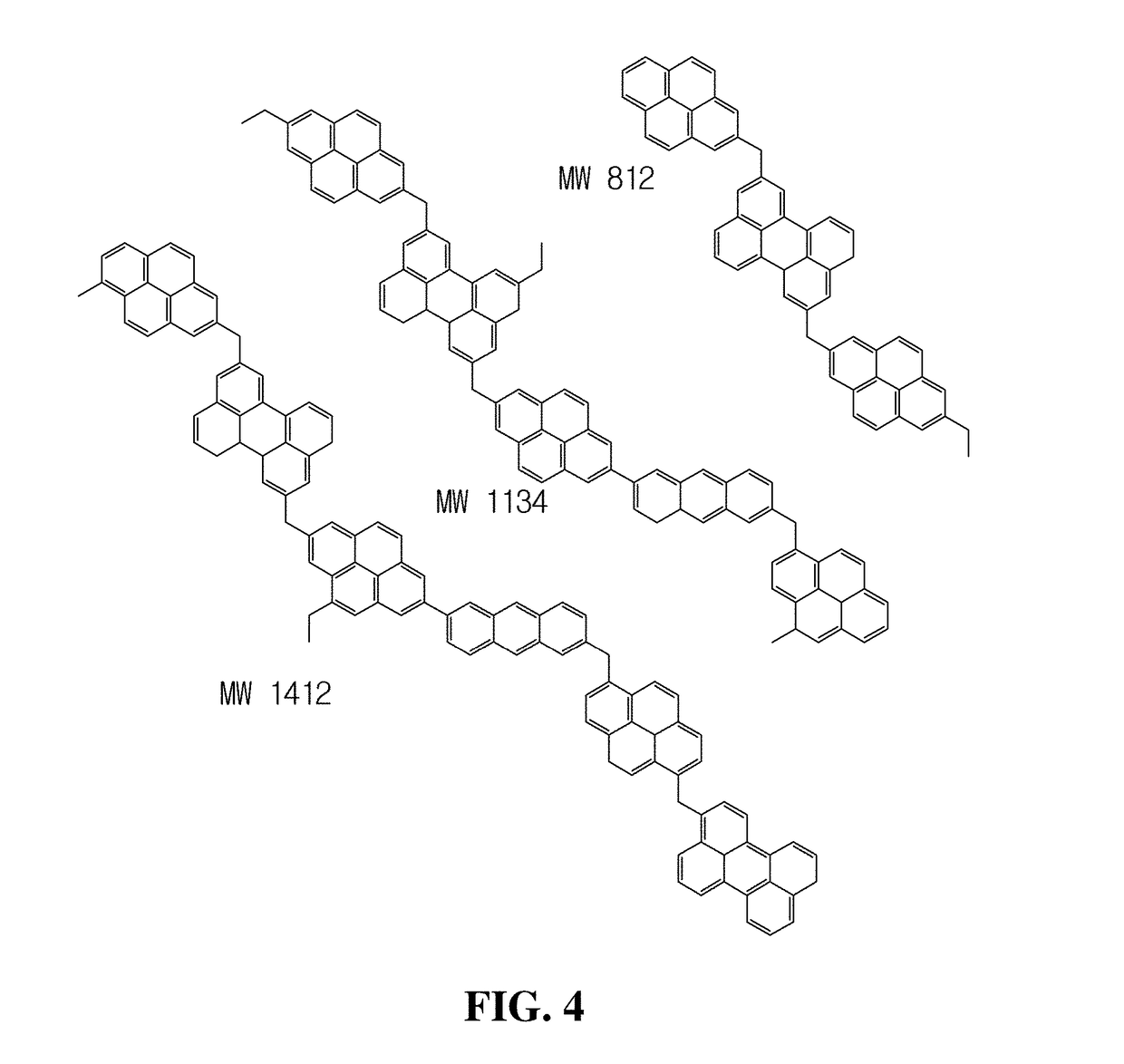

Method of preparing high softening point pitch and high softening point pitch prepared thereby

InactiveUS20170175001A1Improve yieldHigh molecular weightCell electrodesWorking-up pitch/asphalt/bitumen by chemical meansHeat treatedPhotochemistry

Provided are a method of preparing a high softening point pitch and the high softening point pitch prepared thereby, in which a polyene radical intermediate is formed, and an alkylaromatic radial material is linearly linked to the polyene radical intermediate in a benzyl or methylene form to be polymerized. The method includes performing heat treatment by adding a compound, which is able to a polyene radical intermediate, to 1- to 4-ring alkylaromatic condensates to produce a basic pitch, and performing vacuum heat treatment for the basic pitch.

Owner:YUSUNG TELECOM

Fuel compositions from light tight oils and high sulfur fuel oils

ActiveUS20210017460A1Low costEmission reductionPump componentsTreatment with hydrotreatment processesCombustionHydrocotyle bowlesioides

Methods are provided to prepare a low sulfur fuel from hydro-carbon sources, such as light tight oil and high sulfur fuel oil, often less desired by conventional refiners, who split crude into a wide range of differing products and may prefer presence of wide ranges (C3 or C5 to C20 or higher) of hydrocarbons. These fuels can be produced by separating feeds into untreated and treated streams, and then recombining them. Such fuels can also be formulated by combinations of light, middle and heavy range constituents in a selected manner as claimed. Not only low in sulfur, the fuels of this invention are also low in nitrogen and essentially metals free. Fuel use applications include on-board large marine transport vessels but also on-shore for large land based combustion gas turbines, boilers, fired heaters and transport vehicles and trains.

Owner:MAWETAL LLC

Fuel compositions from light tight oils and high sulfur fuel oils

ActiveUS20210017459A1Low costEmission reductionPump componentsTreatment with hydrotreatment processesCombustionHydrocotyle bowlesioides

Methods are provided to prepare a low sulfur fuel from hydrocarbon sources, such as light tight oil and high sulfur fuel oil, often less desired by conventional refiners, who split crude into a wide range of differing products and may prefer presence of wide ranges (C3 or C5 to C20 or higher) of hydrocarbons. These fuels can be produced by separating feeds into untreated and treated streams, and then recombining them. Such fuels can also be formulated by combinations of light, middle and heavy range constituents in a selected manner as claimed. Not only low in sulfur, the fuels of this invention are also low in nitrogen and essentially metals free. Fuel use applications include on-board large marine transport vessels but also on-shore for large land based combustion gas turbines, boilers, fired heaters and transport vehicles and trains.

Owner:MAWETAL LLC

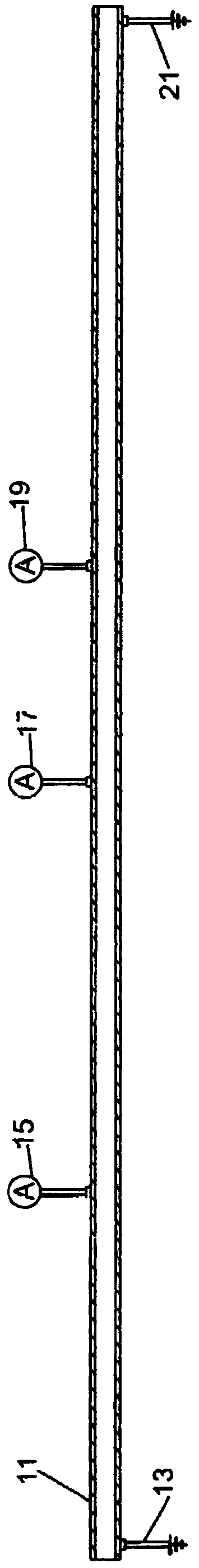

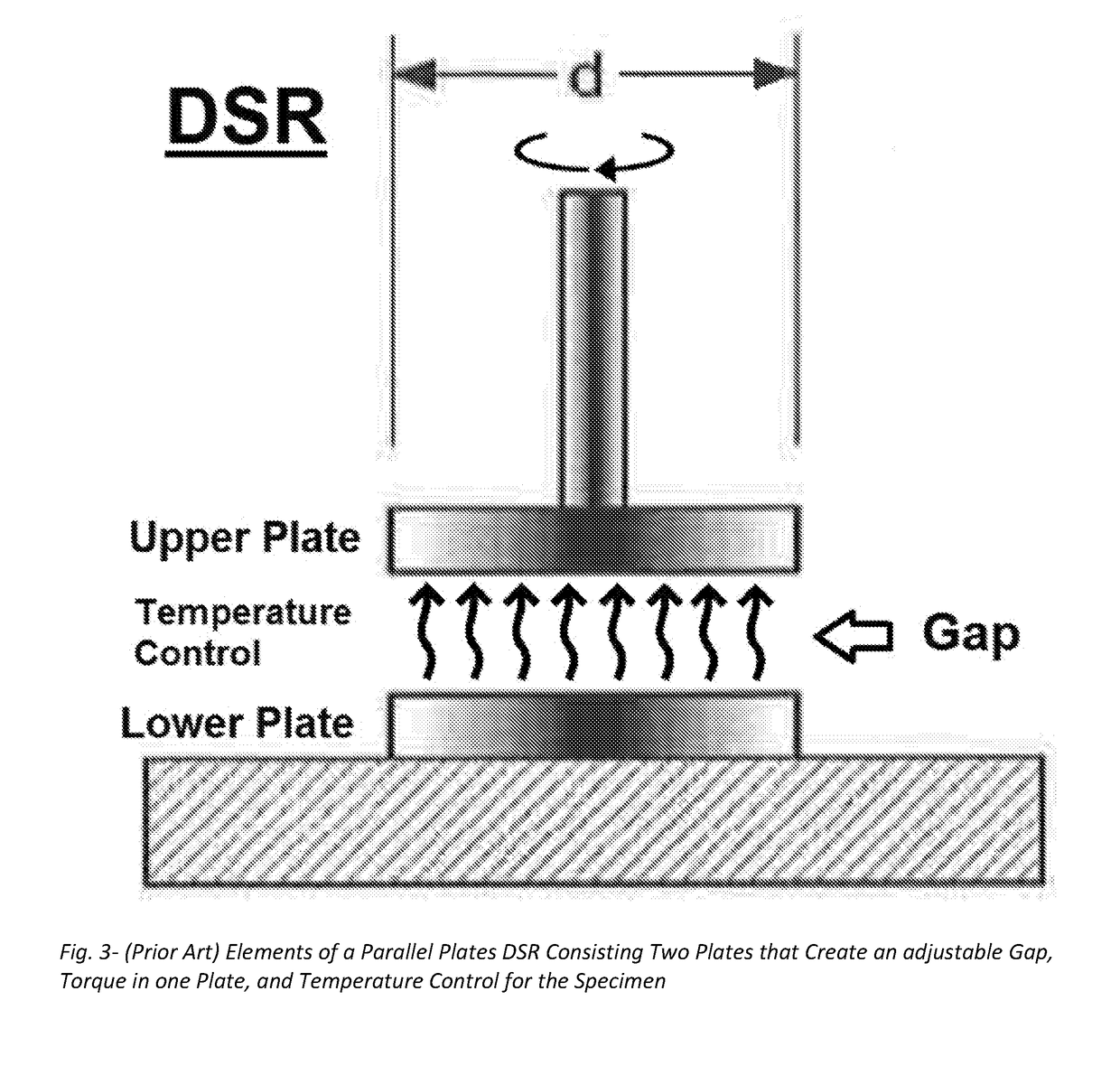

Unified performance test for viscoelastic materials

ActiveUS20180372606A1Easy to optimizePerfect geometrySamplingFlow propertiesRecovery methodDynamic shear rheometer

The use of recycled materials can have significant economic value. With the increasing quantity of recycled material used in viscoelastic materials, especially asphalt mixture, understanding how they interact with original materials to produce a mixture that performs successfully, becomes critical. Currently, the technology to determine the effect of additives on the performance of asphalt mixture is lacking. The present invention relates to a new unified methodology for mechanical testing of asphalt mixture and other viscoelastic materials that improves the current practice in speed, convenience, and accuracy. A new improved specimen mounting method on Dynamic Shear Rheometer (DSR), a new recovery method for fine portion of asphalt mixture, and three new tests for the performance of recovered material using DSR is disclosed. The new methods provide performance grading of asphalt mixtures that is new to the industry and provide necessary tools for determining the effect of recycled materials on performance.

Owner:MOHSENI ALAEDDIN

Method for catalytic synthesis of high quality intermediate phase carbon material with pure aromatic hydrocarbon

ActiveCN106967450AImprove performanceLarge specific surface areaWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionAnthraceneDistillation

The invention relates to a method for catalytic synthesis of a high quality intermediate phase carbon material with pure aromatic hydrocarbon. The method includes the steps of: (1) taking one or two of fraction naphthalene and anthracene in coal tar as the raw material, conducting blending and adding the raw material into a raw material tank, performing mixing and heating, then adding a catalyst and conducting full stirring; (2) adding the liquid mixture of step (1) into a microwave heating reactor through a metering pump; (3) controlling the temperature of a liquid outlet of the microwave heating reactor at 195DEG C; (4) cooling a mixed compound left by distillation at the bottom of a distillation kettle to 160DEG C, and performing full stirring till stratification; (5) heating a lower separated liquid X2 obtained by step (4) to 180-200DEG C, then passing the liquid through a fractionating tower to obtain a distilled liquid S3; (6) transferring high purity asphalt Z obtained in step (5) into a growth furnace, and performing stirring, at the same time introducing nitrogen, and conducting heat preservation for 6h to generate an intermediate phase carbon material, i.e. intermediate phase asphalt; and (7) taking the product obtained by cooling in step (6) out rapidly, and loading the product into a nitrogen protected sealed barrel. The method provided by the invention improves the content of the intermediate phase, and the preparation method is simple and is convenient for popularization and use.

Owner:亚太中碳(山西)新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com