Mesophase pitch coke preparation method, mesophase pitch coke, negative electrode material and lithium battery

A mesophase pitch and pitch technology, which is applied in the field of negative electrode materials and lithium batteries, mesophase pitch coke, and mesophase pitch coke, can solve the problem of loss of effective components, low coking value, and low yield of mesophase pitch coke raw materials and other problems, to achieve the effect of improving yield, large operating space, and regular microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

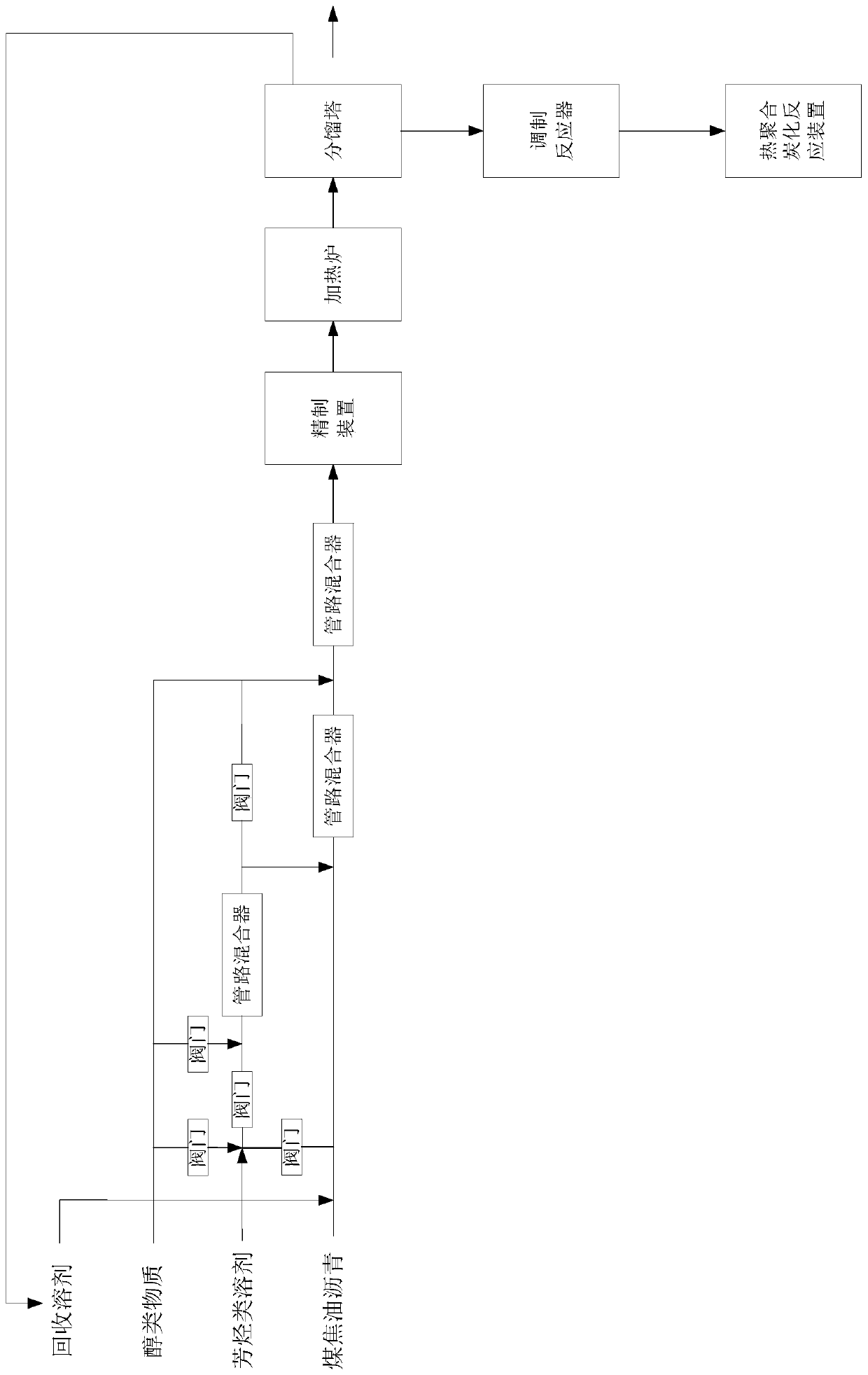

Method used

Image

Examples

Embodiment 1

[0045] Choose coal tar medium-temperature pitch with a softening point of 85°C as the raw material, preheat the medium-temperature pitch, glycerol monomethyl ether, and methyl naphthalene oil to 85°C, and mix 100 parts by weight of medium-temperature pitch and 60 parts by weight of methylnaphthalene oil After 30 minutes, the mixed oil of medium temperature asphalt and methyl naphthalene oil was obtained, and then 10 parts by weight of glycerol monomethyl ether was further mixed with the mixed oil of medium temperature asphalt and methyl naphthalene oil in a static mixer, and was heated to 120 ° C, after that Enter the static settling device, and carry out settling and separation under this device. The heavy oil rich in quinoline insolubles is extracted from the bottom, and the refined oil is obtained from the upper part. After heating, the refined bitumen is obtained by distillation. The yield is 94%, and the mixed solvent is obtained. Removal and recovery, the solvent recovery...

Embodiment 2

[0052]Choose coal tar soft asphalt with a softening point of 35°C as the raw material, preheat the soft asphalt, dipropylene glycol (295°C), and dephenolized phenolic oil to 80°C, soft asphalt, dephenolized phenolic oil, and dipropylene glycol The weight ratio of 100:40:8 was stirred and mixed for 30 minutes, heated to 110°C, and the filtrate and filter residue were obtained through a filtration device. After the filtrate was heated, refined pitch was obtained by distillation. The yield was 92%, and the mixed solvent was removed. With recovery, the solvent recovery rate is 99.5%.

[0053] Add ethylene tar to the refined bitumen obtained in the upper part to adjust the kinematic viscosity of the bitumen at 100°C to 800mPa·S. The viscosity-adjusted asphalt is added to the thermal reactor, nitrogen gas is passed through the lower part, preferably the lower part, the reaction pressure is 0.3Mpa, and the temperature is 400 °C for thermal polymerization reaction, and the thermal pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com