Agitation device

A stirring device and stirring shaft technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of low mixing efficiency, long mixing time, and slow mixing speed of asphalt, so as to improve the uniformity and modification efficiency, increase stirring efficiency, and improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

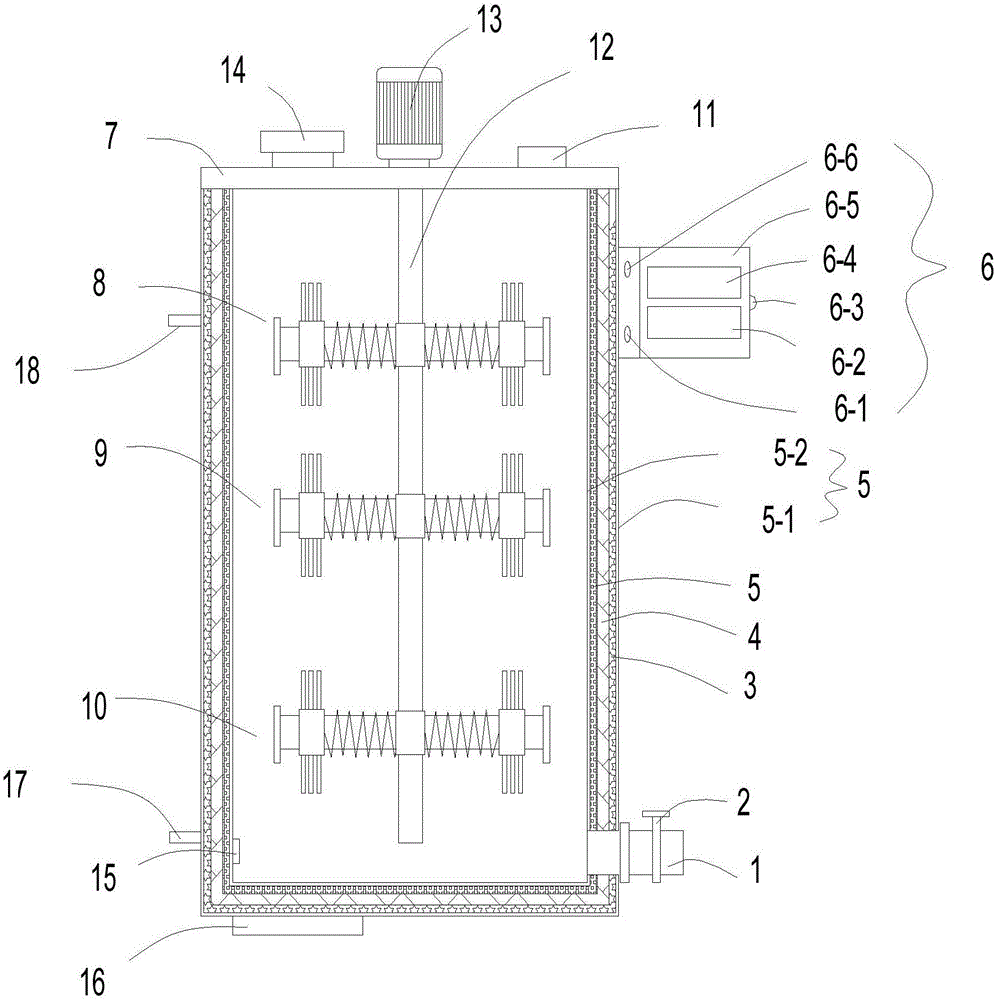

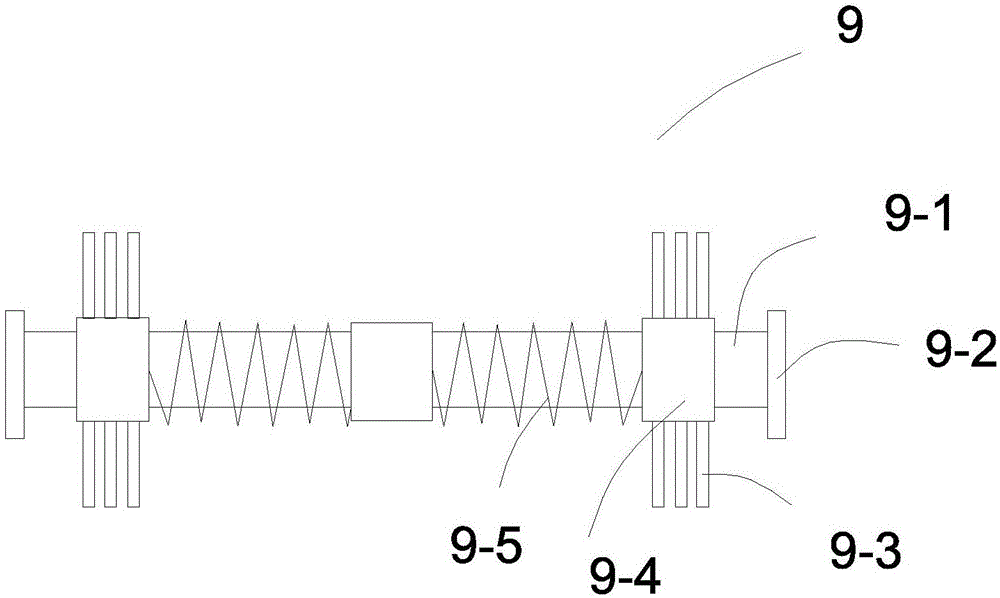

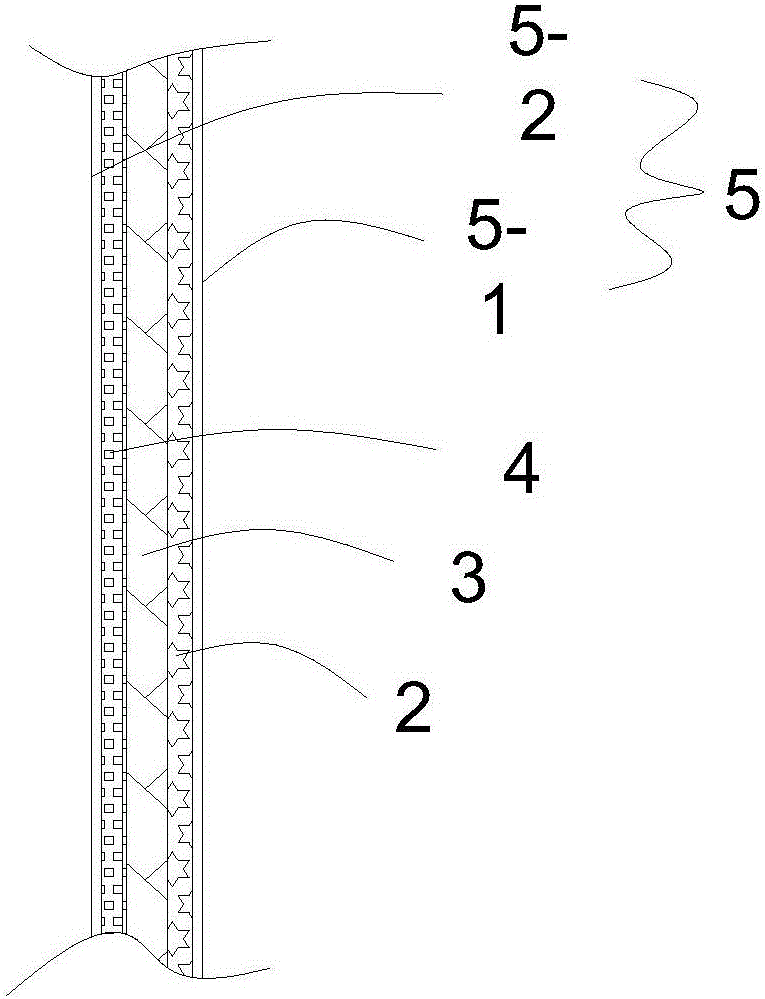

[0024] like Figures 1 to 4 As shown, the present embodiment provides a stirring device, which includes a tank body 5 and a cover 7 for sealing the tank body 5 . , the bottom side of the tank body 1 is provided with a discharge port 1, and a stirring shaft 12 located inside the tank body 5 is provided under the cover 7. The stirring shaft 12 is sequentially provided with stirring components A8, stirring components B9 and stirring components from top to bottom. Assembly C10, the tank body 5 includes an inner shell 5-2 and an outer shell 5-1, the inner shell 5-2 and the outer shell 5-1 form a cavity structure, and the cavity structure extends from the inside to the outside A thermal insulation layer 4, an isolation layer 3 and a heating layer 2 are arranged in sequence, and the heating layer 2 includes a spiral heat-conducting oil coil 19 wound on the inner casing 5-2, and the outer casing 5-1 is provided with The heat transfer oil outlet 18 and the heat transfer oil inlet 17 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com