Method and device of preparing needle coke

A needle coke and delayed coking technology, applied in the processing of tar pitch/petroleum pitch/natural pitch, coke oven, coking carbonaceous materials, etc., can solve the problems of harsh process conditions, strict requirements on filter materials, and expensive filter materials. , to achieve the effect of wide range of raw materials, low thermal expansion coefficient and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

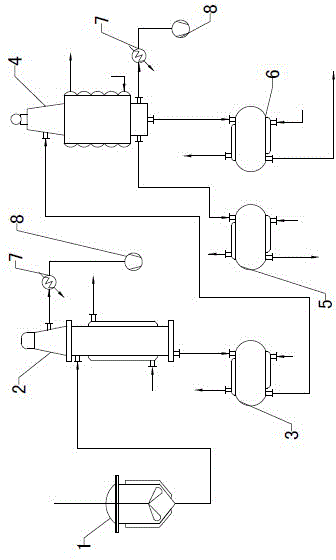

Embodiment 1

[0027] The softening point is 75°C, and the medium-temperature coal tar pitch with 4.8% quinoline insoluble matter is preheated to 200°C in the raw material preheating kettle 1 at a stirring speed of 70 rpm, and then pumped into the degassing column 2. The temperature is 280°C and the pressure is 300Pa for degassing treatment. The degassed material enters the raw material receiving tank 3 for buffering and heat preservation, and then pumps it to the molecular distillation column 4 for molecular distillation treatment. The distillation temperature is 390°C and the pressure is 0.01Pa. The material after molecular distillation is divided into 85% light phase and 15% heavy phase. The light phase component is refined pitch and enters the light phase receiving tank 6 as raw material for needle coke; the heavy phase component enters the heavy phase receiving tank 5 as high Softening point high carbon residue bitumen is used as binder bitumen. The obtained refined pitch enters the del...

Embodiment 2

[0029] The medium temperature coal tar pitch with a softening point of 75°C and quinoline insolubles of 4.8% is preheated to 200°C in the raw material preheating kettle 1 at a stirring speed of 80 rpm, and then pumped into the degassing column 2. The temperature is 270°C and the pressure is 600Pa for degassing treatment. The degassed material enters the raw material receiving tank 3 for buffering and heat preservation, and then pumps it to the molecular distillation column 4 for molecular distillation treatment. The distillation temperature is 390°C and the pressure is 1Pa. The material after molecular distillation is divided into 50% light phase and 50% heavy phase. The light phase component is refined pitch and enters the light phase receiving tank 6 as raw material for needle coke; the heavy phase component enters the heavy phase receiving tank 5 as high Softening point high carbon residue bitumen is used as binder bitumen. The obtained refined pitch enters the delayed coki...

Embodiment 3

[0031] The medium temperature coal tar pitch with a softening point of 75°C and quinoline insolubles of 4.8% is preheated to 180°C in the raw material preheating kettle 1 at a stirring speed of 100 rpm, and then pumped into the degassing column 2. The temperature is 260°C and the pressure is 600Pa for degassing treatment. The degassed material enters the raw material receiving tank 3 for buffering and heat preservation, and then pumps it to the molecular distillation column 4 for molecular distillation treatment. The distillation temperature is 350°C and the pressure is 100Pa. The material after molecular distillation is divided into 30% light phase and 70% heavy phase. The light phase component is refined pitch and enters the light phase receiving tank 6 as raw material for needle coke; the heavy phase component enters the heavy phase receiving tank 5 as high Softening point high carbon residue bitumen is used as binder bitumen. The obtained refined pitch enters the delayed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com