Patents

Literature

53results about How to "Product Quality Impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

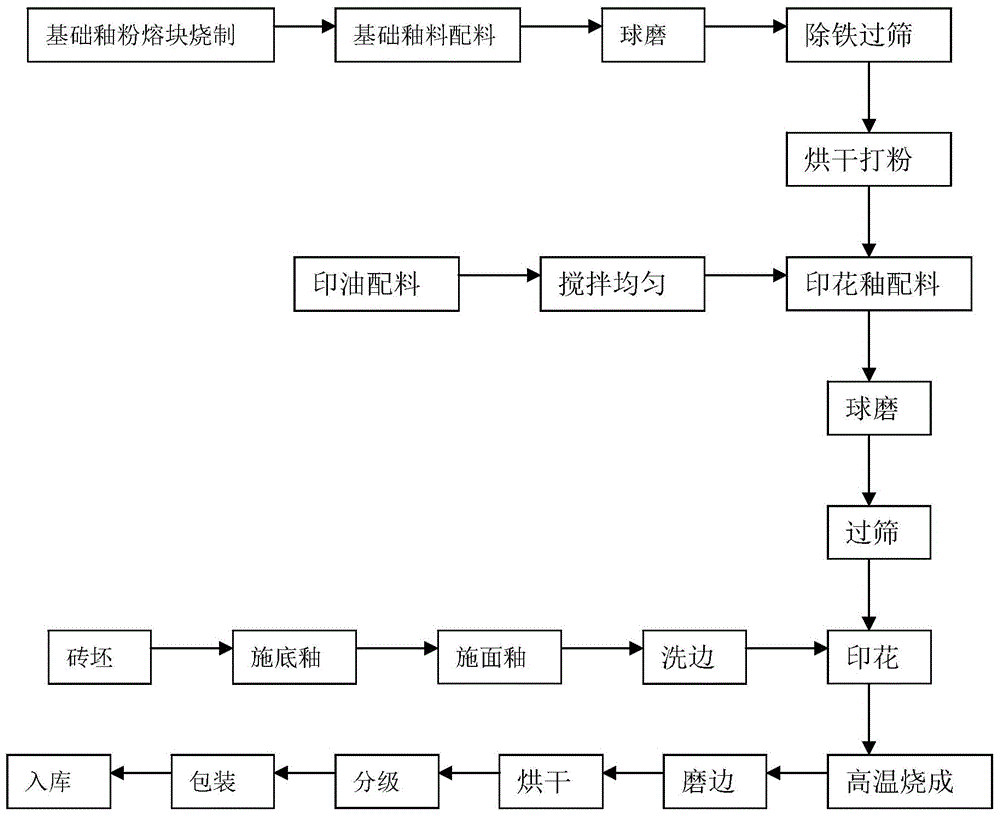

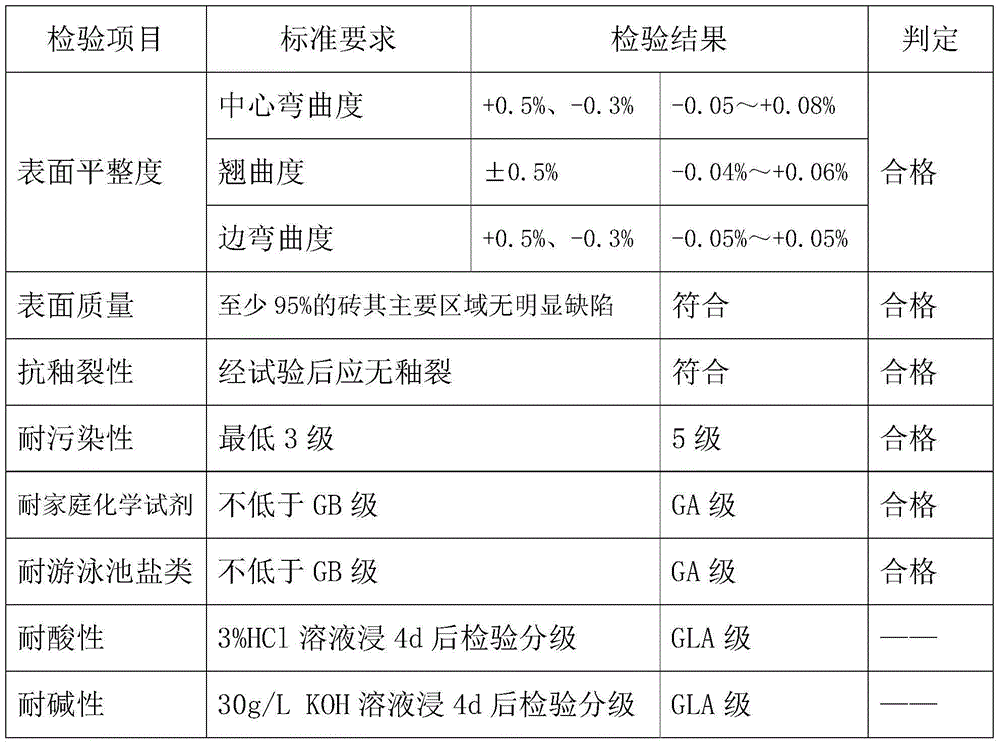

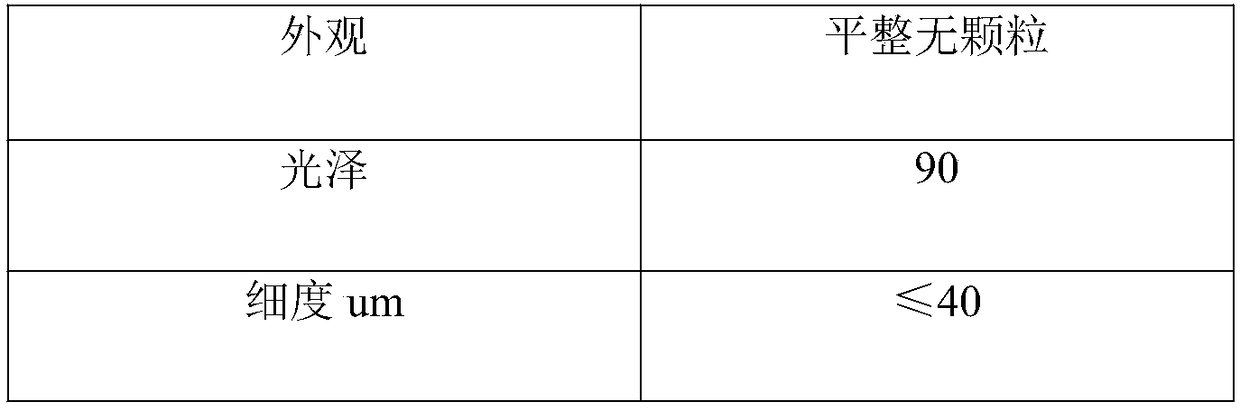

High-temperature bright-red printing glaze, preparation method and preparation method of glazed tile

The invention relates to high-temperature bright-red printing glaze, its preparation method and a preparation method of a glazed tile. On the basis of not making big changes on a present glazed tile production technology, emphasis is put on adjustment and optimization of composition of printing basic glaze powder, composition of frit in the printing basic glaze powder, optimization and ratio of frits with different properties, composition of stamp-pad ink, processing technology of printing glaze, engraving mode of a rubber covered roller, mesh number of a screen printing plate and the like. Thus, the color of the surface of a high-temperature sintered glazed tile imprinted with the single printing glaze is bright, pure, glossy and shiny and is typical bright red. When the printing glaze is alternately printed with a printing glaze of other colors, the color on the surface is bright, pure, wide in color gamut and colorful, can be compared favorably with colors in the fields of fabrics, wallpaper, advertisement design, and has strong decorative effect and aesthetic feeling. Meanwhile, the technology has high universality and is easy to popularize in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

Process for preparation of ultrapure hydrogen peroxide

ActiveCN1919724AGood securityStable qualityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesIon exchangePre treatment

The invention discloses a making method of ultrapure hydrogen peroxide, which comprises the following steps: adopting industrial hydrogen peroxide as raw material; predisposing through ionic exchanging method or distilling method to reach agent grade standard; adopting large-hole adsorbing resin to remove organic carbon; removing impurity ion through two-segment of ionic exchanging column; gathering the dust particle from film filter to obtain the object.

Owner:SHANGAI HUAYI MICROELECTRONICS MATERIAL

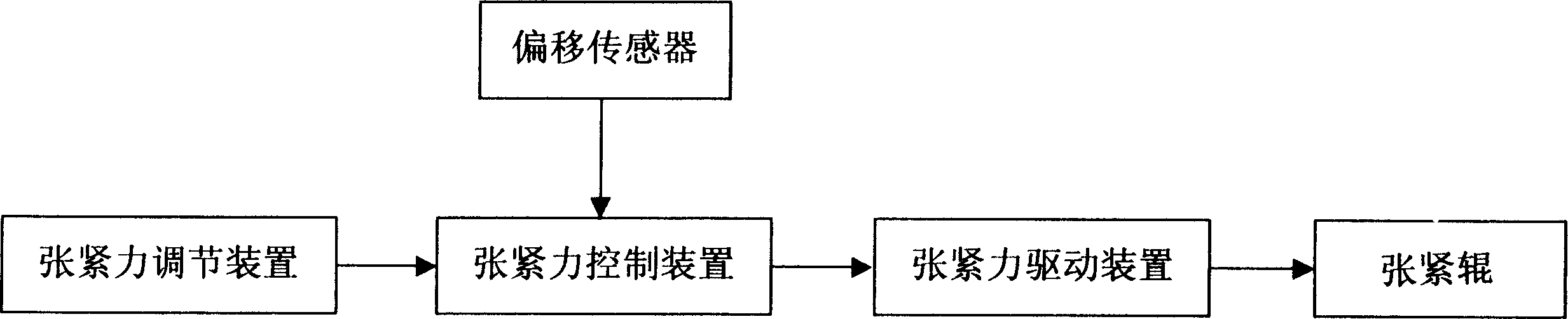

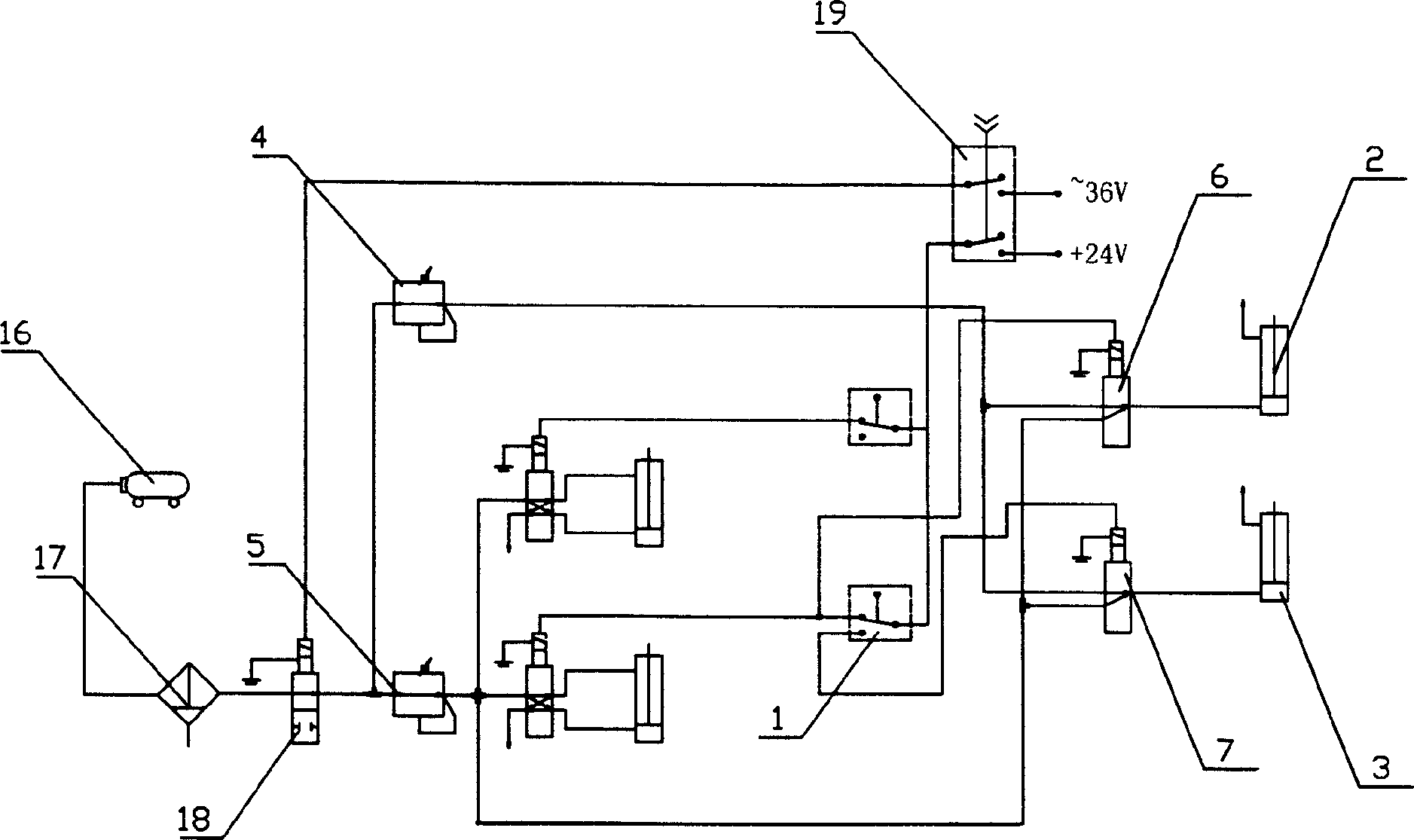

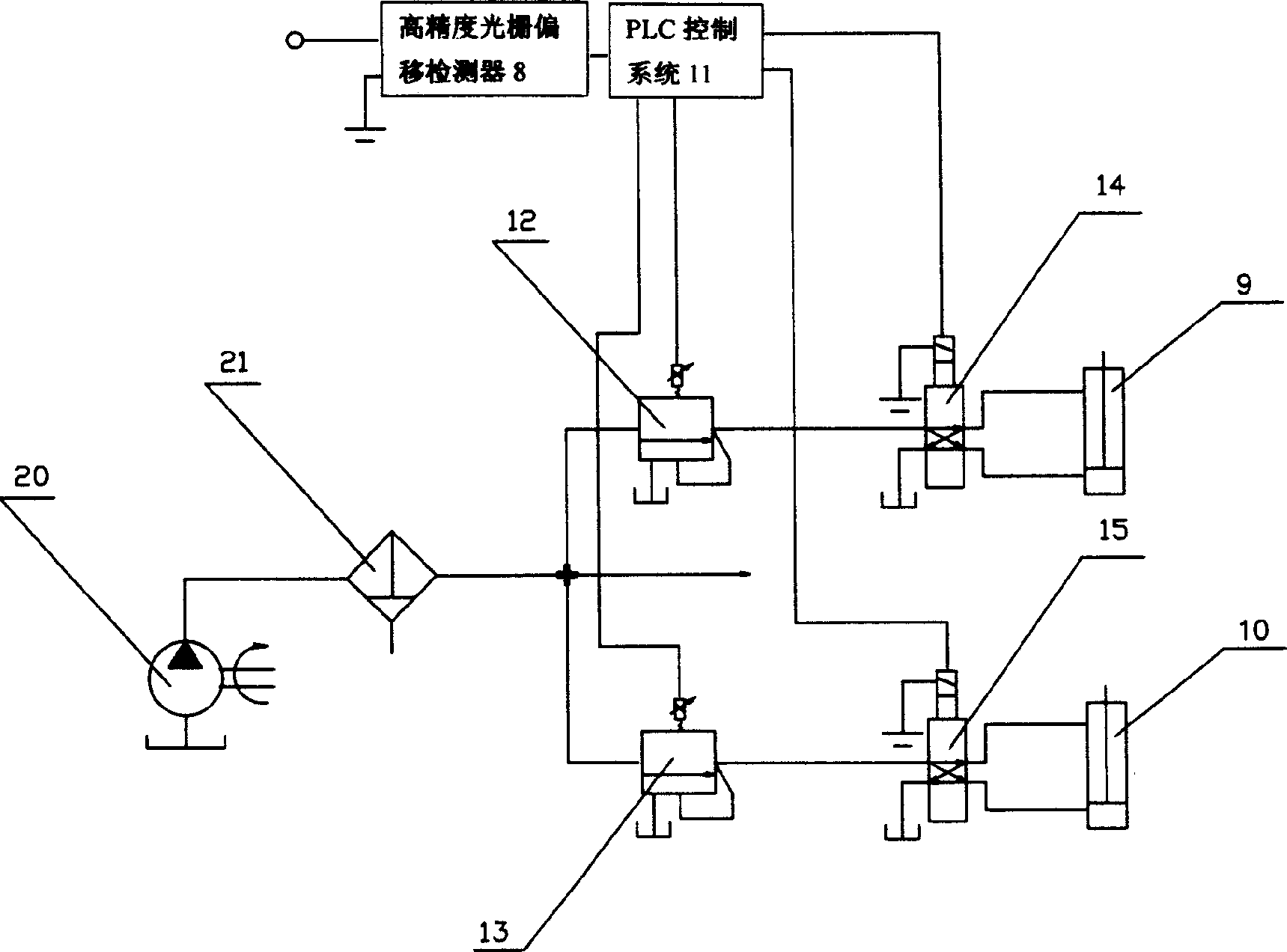

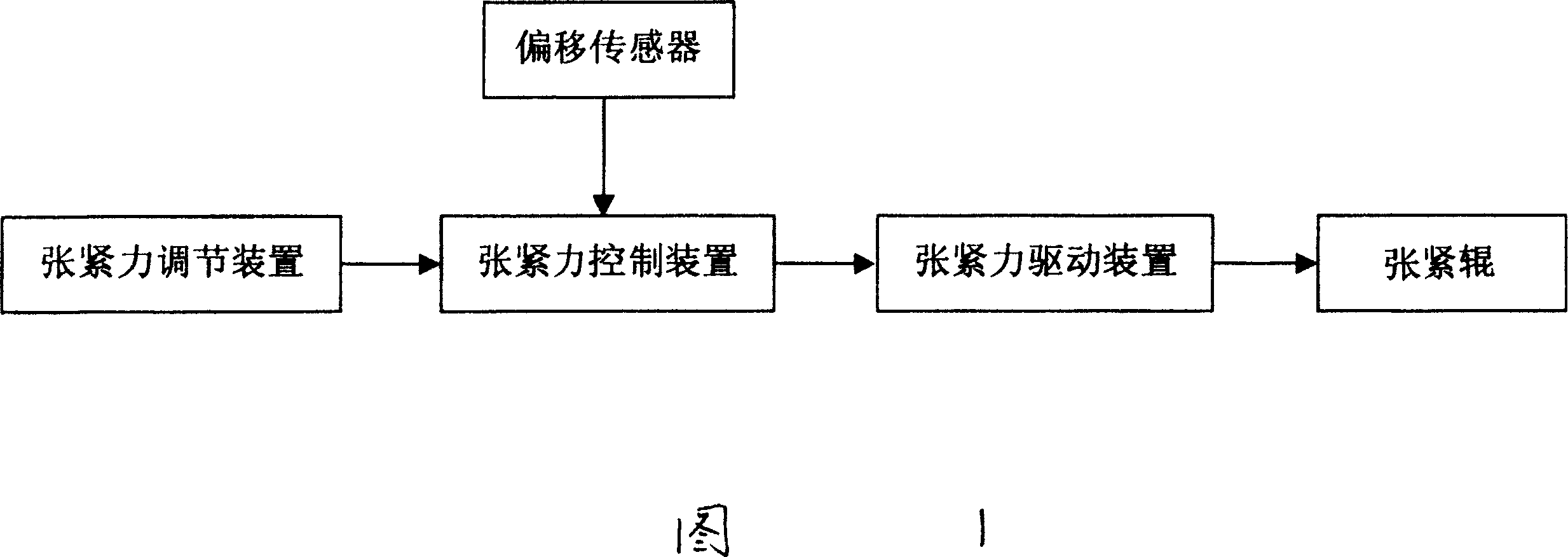

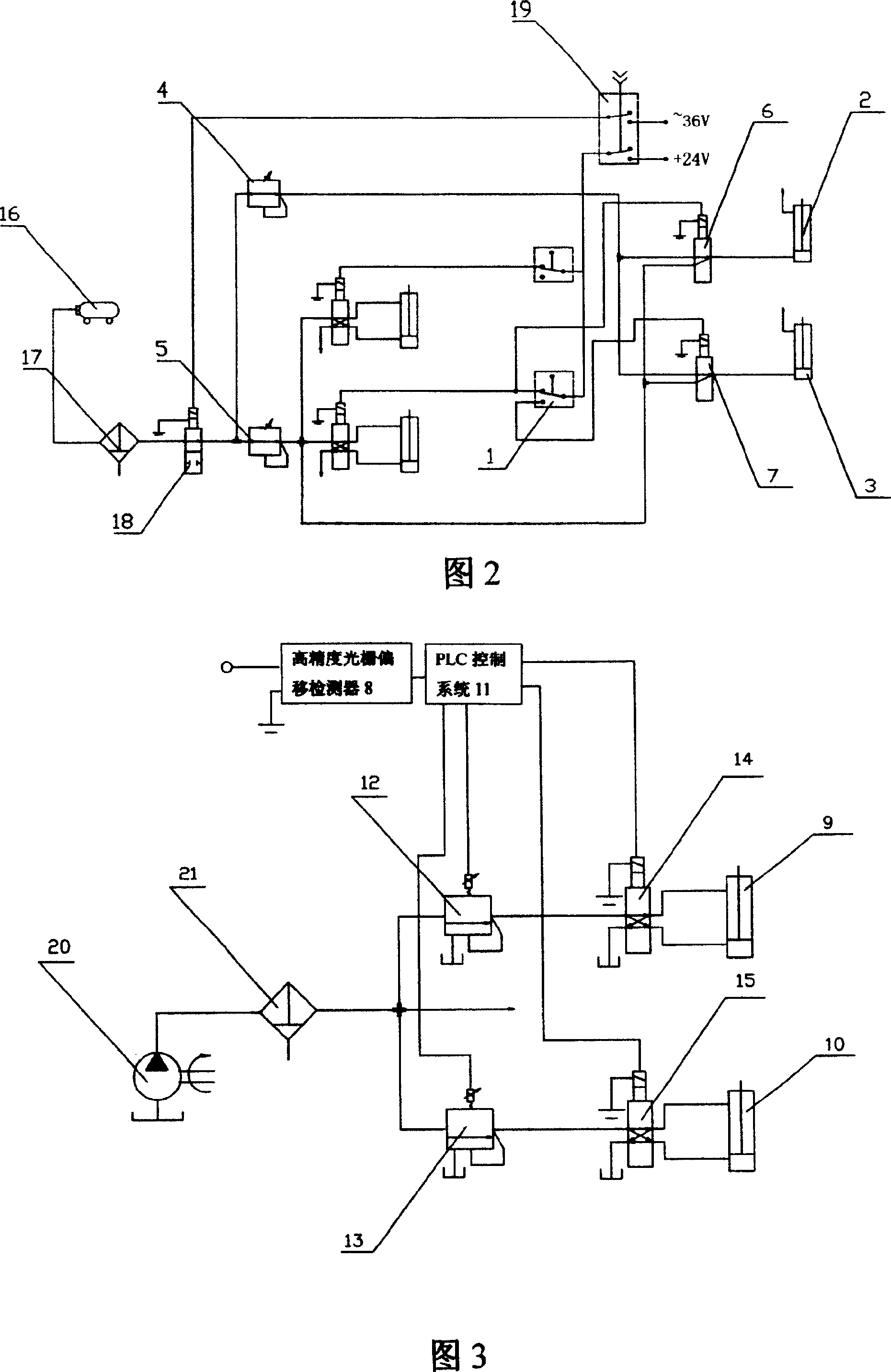

Belt-shape moving body tension differential adjusting and correction method and device therefor

Owner:大连经济技术开发区排水管理有限公司

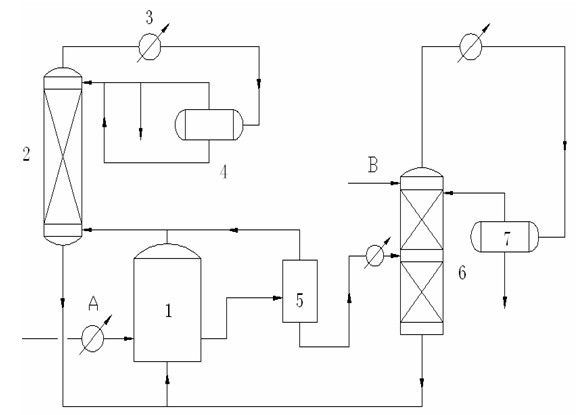

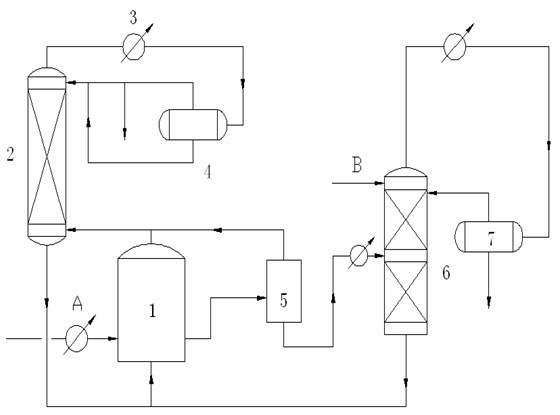

Energy-saving and yield-improving production method of ethyl acetate

ActiveCN102675094AReduce back flowReduce operating loadOrganic compound preparationCarboxylic acid esters preparationEthylic acidOil phase

The invention discloses an energy-saving and yield-improving production method of ethyl acetate. The production method comprises the following steps of: heating and gasifying raw material acetic acid and ethanol and then feeding into a reaction kettle to react; recovering a bottom material in the reaction kettle according to a certain proportion with the total amount of fed materials to an evaporator to perform flash evaporation, wherein most of ester and alcohol in the bottom material which is subjected to flash evaporation are returned to the bottom of an esterification tower, and the ester phase of the rest bottom material is a large amount of acid and a part of water and is discharged through a pump from the bottom of the evaporator; conveying the treated bottom material to a heat exchanger through the pump for heating and then directly feeding into a dehydration tower to perform dehydration treatment; performing azeotropic distillation and recovering azeotrope formed by water and a dehydrant from the top of the esterification tower; condensing to split phase; discharging the water phase to a recovery tower for treatment; reflowing the oil phase to a dehydration tower; and newly returning acid which is discharged from the bottom of the dehydration tower to the reaction kettle to participate in esterification reaction. After the process is implemented, the water in the kettle is effectively reduced to further reduce the corrosion condition of the equipment, the energy of an esterification section is saved by 5-10 percent, the capacity can be increased by 10-20 percent, and the economic benefit is obvious.

Owner:JINJIANG TAIXING CHEM IND CO LTD

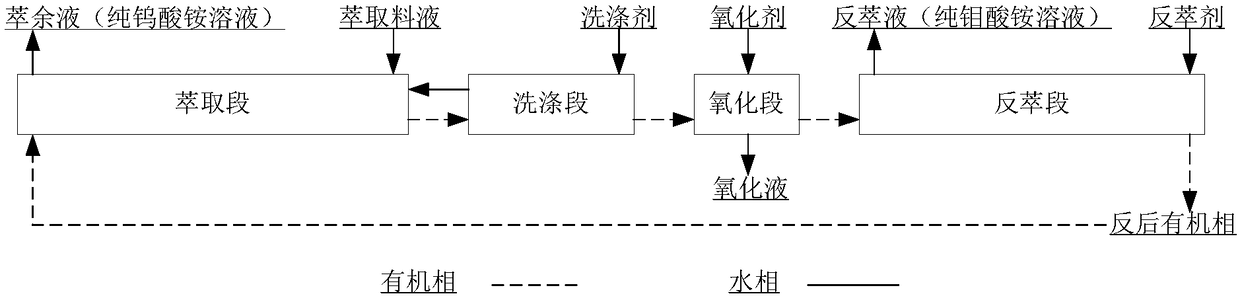

Method for extracting and separating tungsten and molybdenum from molybdenum-contained ammonium tungstate solution

ActiveCN108342573AWeak corrosiveProduct Quality ImpactProcess efficiency improvementDiammonium carbonateTungsten

The invention discloses a method for extracting and separating tungsten and molybdenum from a molybdenum-contained ammonium tungstate solution. The method comprises the steps that bicarbonate containing trialkyl methyl ammonium and an organic phase of a carbonate composite extractant of the bicarbonate are used for making contact with molybdenum-contained ammonium tungstate feed liquid subjected to vulcanization and an ammonium bicarbonate-ammonium carbonate mixed detergent correspondingly for performing fractional extraction, the molybdenum is made to enter the organic phase, the tungsten remains in a water phase, and a high-purity ammonium tungstate aqueous solution and an organic phase loaded with pure molybdenum are obtained; and then, the organic phase loaded with the pure molybdenumis oxidized through a hydrogen peroxide solution, reextraction is performed by adopting an ammonium bicarbonate-ammonium carbonate mixed solution, a high-purity ammonium molybdate solution is obtained, and an organic phase after reextraction can directly return back to extraction for repeated use without needing treatment. The method has the characteristics that the tungsten and molybdenum mutualseparation depth is high, no detrimental impurity is introduced, and high-purity tungsten and molybdenum product liquid can be obtained simultaneously.

Owner:CENT SOUTH UNIV

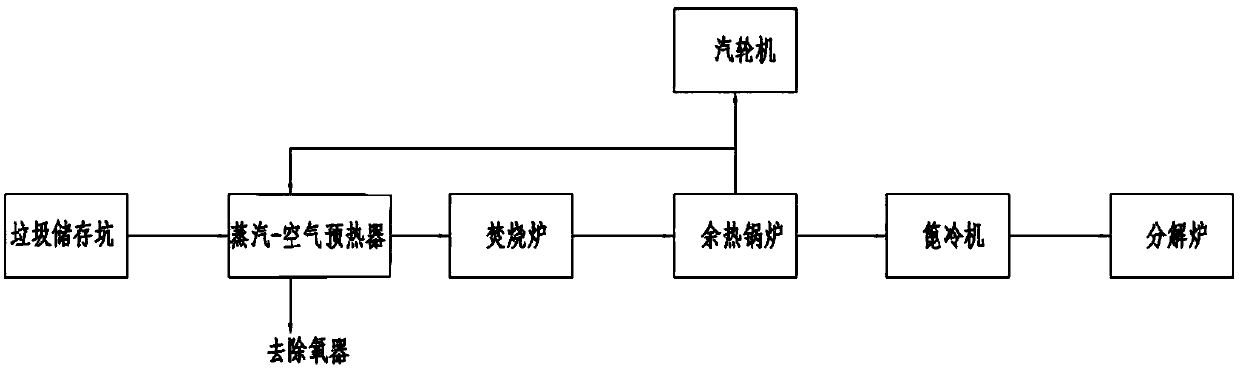

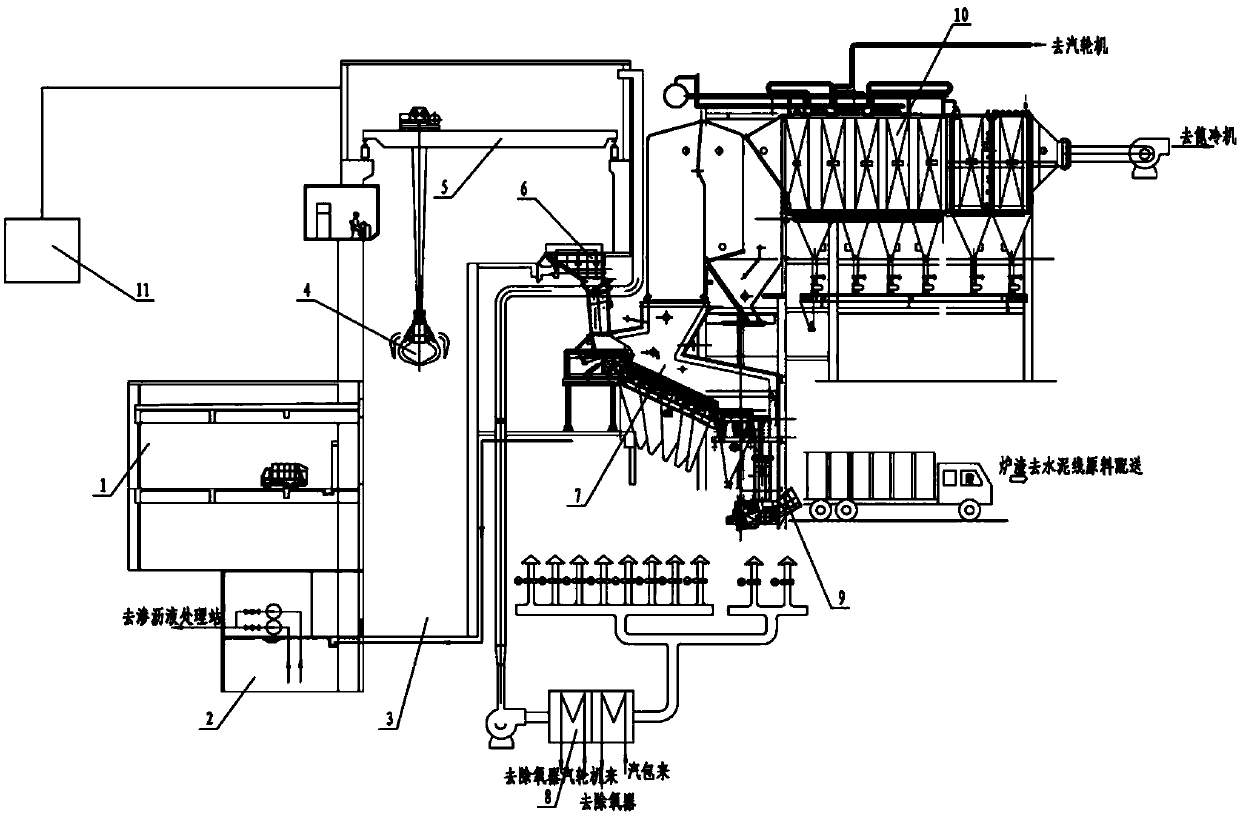

Cement kiln cooperative processing domestic garbage power generation system and method

InactiveCN108679614AReduce the impactSimple and fast operationMachines/enginesIncinerator apparatusFlue gasEnvironmental engineering

The invention discloses a cement kiln cooperative processing domestic garbage power generation system and method. The power generation system comprises a garbage receiving and storage system, an incineration system, a filtered liquid treatment system, an odor treatment system, an afterheat boiler system, a steamer power generation system and a flue gas purification system. The cement kiln cooperative processing domestic garbage power generation system combines three process technologies, namely, cement production, garbage treatment and garbage power generation, and adopts a brand new garbage treatment technology which carries out harmless treatment on waste gases and ash residues generated by garbage incineration and the garbage filtered liquid and effectively utilizes the waste gases, ashresidues and the garbage filtered liquid. The technology solves the difficult problem of treating dioxin and garbage ash residues very well in addition to the advantages of a traditional garbage incineration method.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

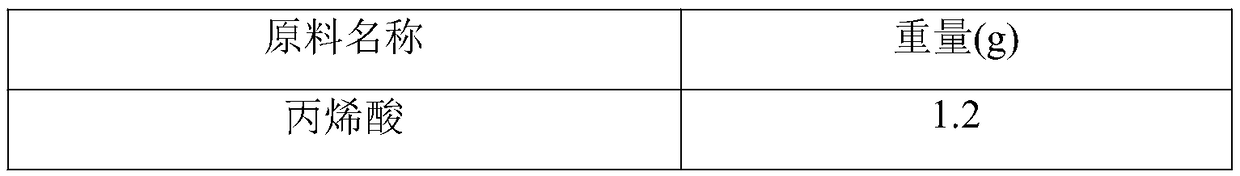

Epoxy resin modified acrylic resin for road marking paints and preparation method thereof

The invention discloses epoxy resin modified acrylic resin for road marking paints and a preparation method thereof. The epoxy resin modified acrylic resin is synthesized with, by weight, 5-10% of epoxy resin, 0.1-0.5% of acrylic acid, 10-20% of styrene, 10-25% of methyl methacrylate, 8-16% of methyl acrylate, 6-15% of a hydroxy acrylic monomer, 1-5% of an initiator, and 20-40% of methylbenzene. The optimal material composition and ratio are attained by screening through massive experiments; the synthetic process and the optimal usage ratio of the materials are optimized by massive experiments; modifying is performed on the acrylic resin via the epoxy resin under the optimal conditions so that good adhesion and wear resistance are attained; excellent water resistance, weatherability and gloss can also be retained; excellent advantages are gained.

Owner:江苏三木化工股份有限公司 +1

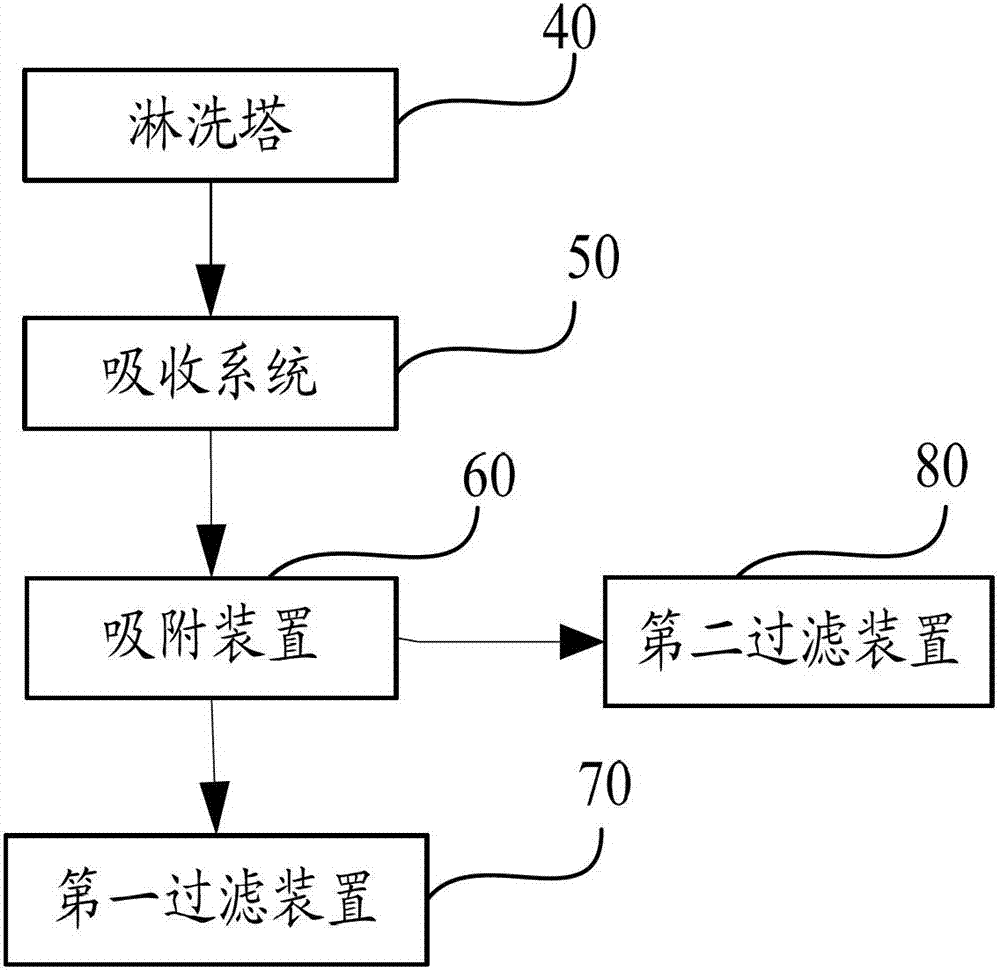

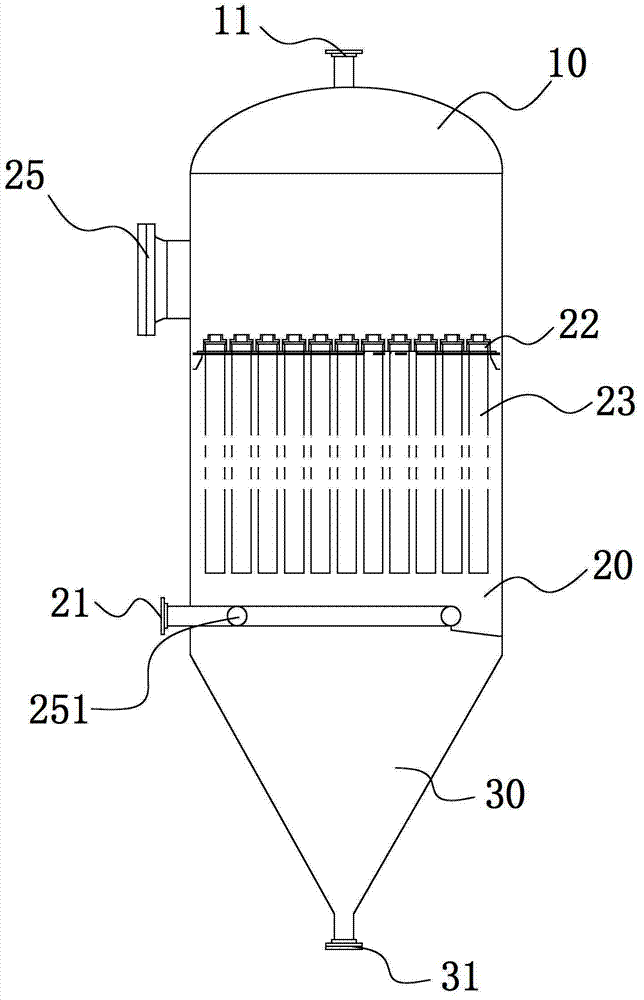

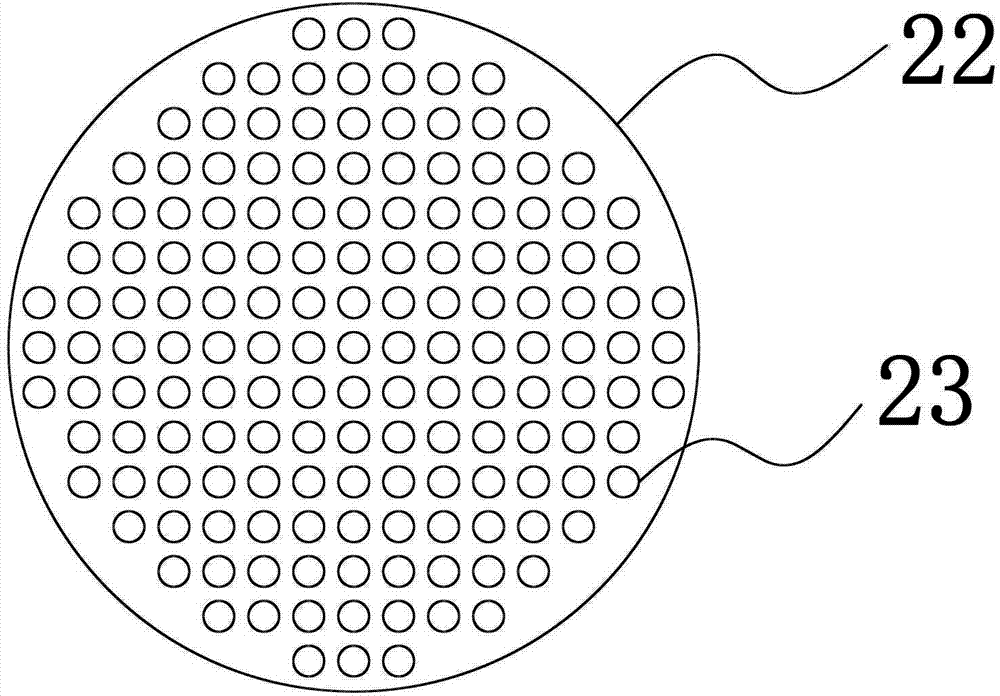

Dry recovery system and method of reduction tail gas produced in polysilicon production process

ActiveCN102815670AProduct Quality ImpactEasy to shapeHydrogen separation using solid contactHydrogen separation using liquid contactRecovery methodHydrogen

The invention discloses a dry recovery system and a dry recovery method of reduction tail gas produced in a polysilicon production process. The system comprises a leaching tower, an absorption system, an absorption device, and a first filtering device. The absorption system is used for carrying out an absorption treatment upon leached reduction tail gas, such that chlorosilane and hydrogen chloride in the leached reduction tail gas can be removed, and hydrogen can be obtained. An adsorbentused for carrying out an absorption treatment upon the hydrogen is arranged in the absorption device, such that residual chlorosilane and hydrogen chloride in hydrogen can be further removed by adsorption. The first filtering device is used for filtering the hydrogen processed through the absorption treatment, such that high-purity hydrogen is obtained. A ceramic filter core is arranged in the first filtering device. According to the dry recovery system provided by the invention, a gas filtering device provided with the ceramic filter core is adopted. The filtering device has excellent properties of high-temperature resistance and corrosion resistance. Therefore, no influence is caused upon polysilicon product quality.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for reducing organic acid content of fruit wine

InactiveCN104152309AReduce organic acid contentFood safetyMicroorganism based processesWine preparationOrganic acidFlavor

The invention discloses a method for reducing organic acid content of a fruit wine by adopting fungal hyphae. The method comprises the following steps: adding the fungal hyphae in a vegetative growth stage into the fruit wine in a production process, standing under the condition that the wine temperature is kept at 10-30 DEG C, and intermittently stirring so as to achieve the aim of reducing organic acid. The method disclosed by the invention can be used for reducing the specific organic acid content of the fruit wine by adopting the absorption, decomposition and transformation capacities of the fungal hyphae on the premise that the edible safety is ensured and the flavor can not be influenced, and can achieve a significant effect on reducing the organic acid.

Owner:HUBEI UNIV OF TECH

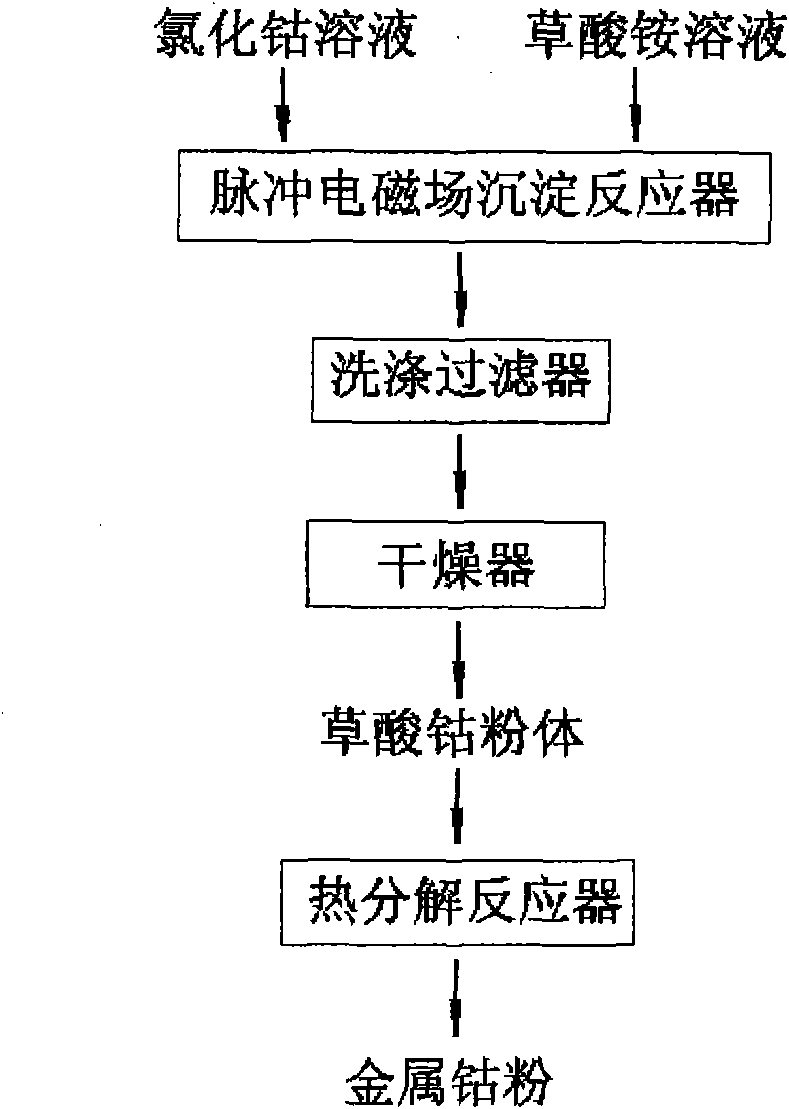

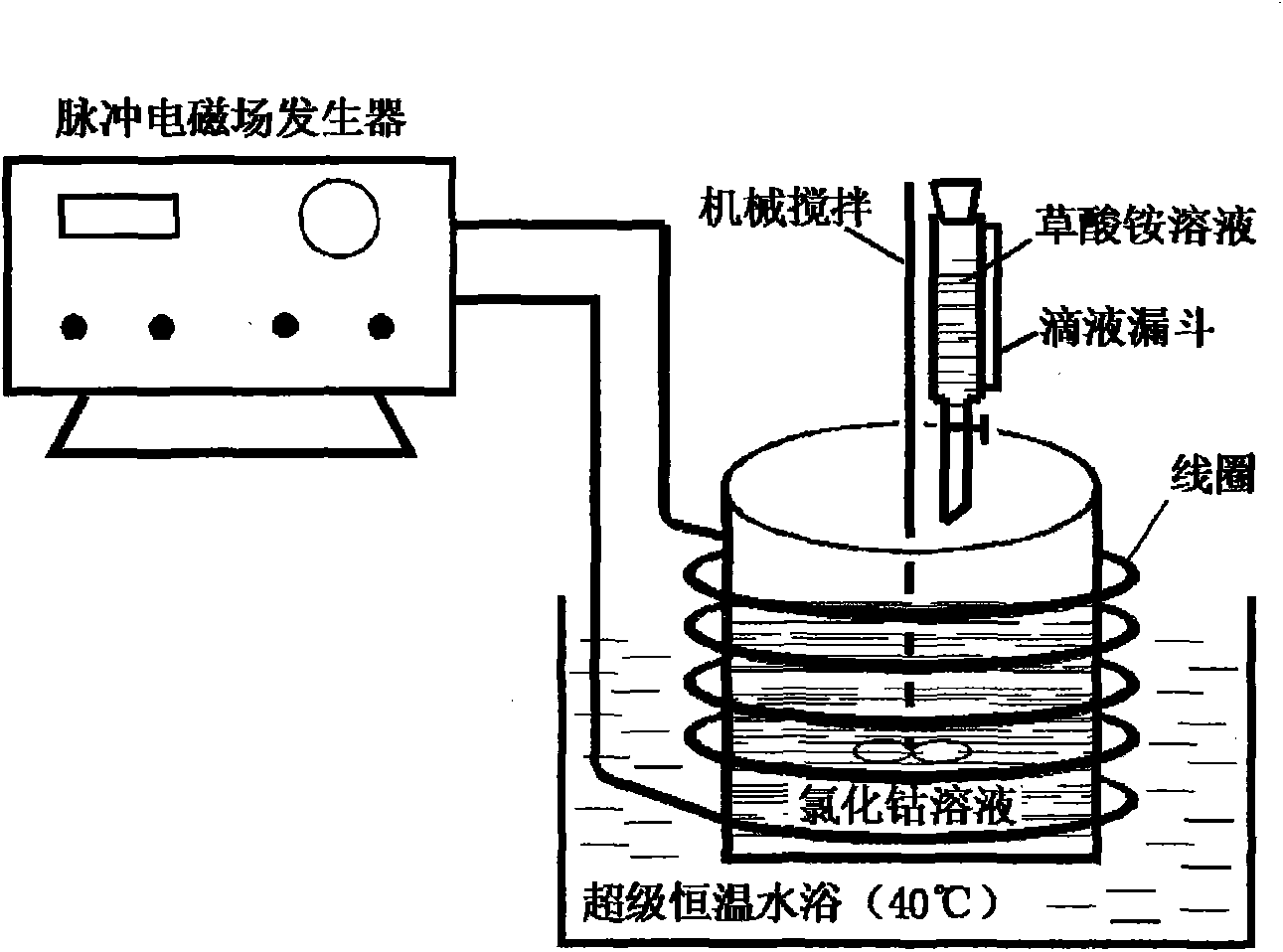

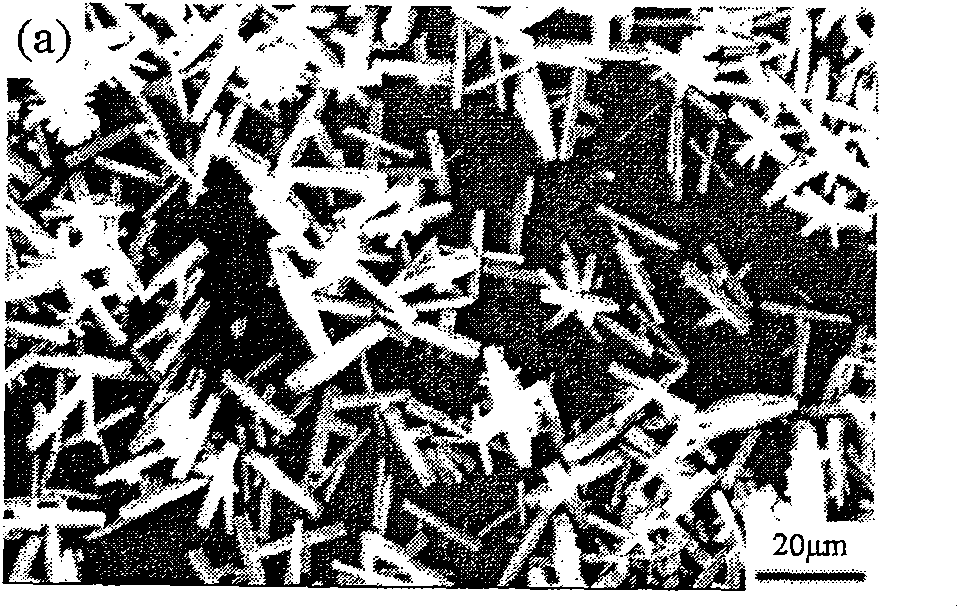

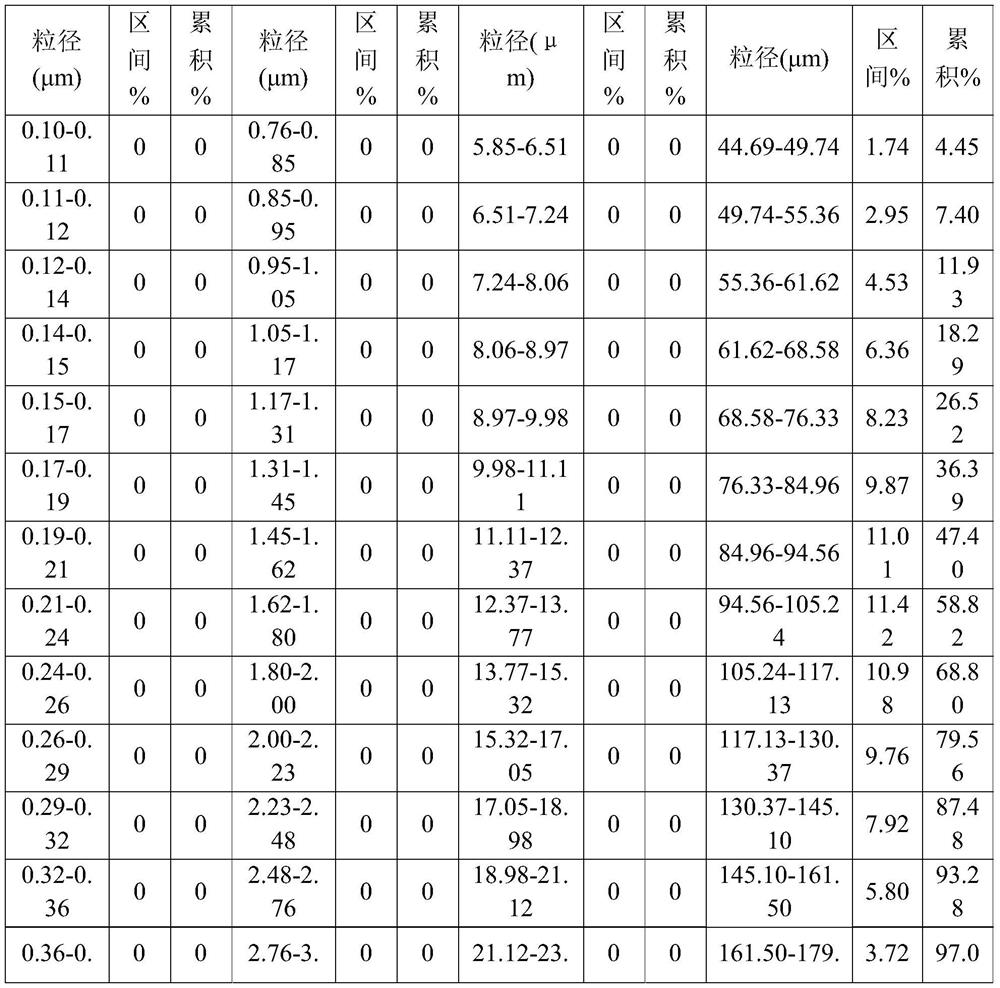

Method for preparing cobalt oxalate by pulse electromagnetic field

InactiveCN101612669AEasy to separateProduct Quality ImpactCarboxylic acid salt preparationFiltrationCobalt

The invention relates to a method for preparing cobalt oxalate by a pulse electromagnetic field, which solves the problems in the prior cobalt powder manufacture of complex process, high cost and large particle size and irregular shape of cobalt powder. The method comprises the following steps: acidulating (NH4)2C2O4 solution and controlling the pH value of the (NH4)2C2O4 solution at 4-6; dripping the acidulated (NH4)2C2O4 solution into CoCl2 solution, wherein the mol ration of (NH4)2C2O4 solution to CoCl2 solution is 1:1-2:1, and the dripping speed is controlled to be 100-200 ml / min; reacting in thermostatic water-circulator bath at 20-45 DEG C; mechanically stirring during reaction; processing the reaction system by a pulse electromagnetic field, wherein the pulse voltage is 1-1000V, and the pulse frequency is 1-100Hz; carrying out filtration, washing, vacuum drying at normal temperature after the reaction is completed to obtain a cobalt oxalate sample; and putting the cobalt oxalate sample into a tube-type resistance furnace to perform thermolysis reaction, cooling to room temperature in the furnace to obtain cobalt powder as a thermolysis product of cobalt oxalate. The invention has the advantages of simple process, low production cost, good quality, no pollution to treated objects or surrounding environment and wide application range, and can obtain products with different shapes and particle sizes.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

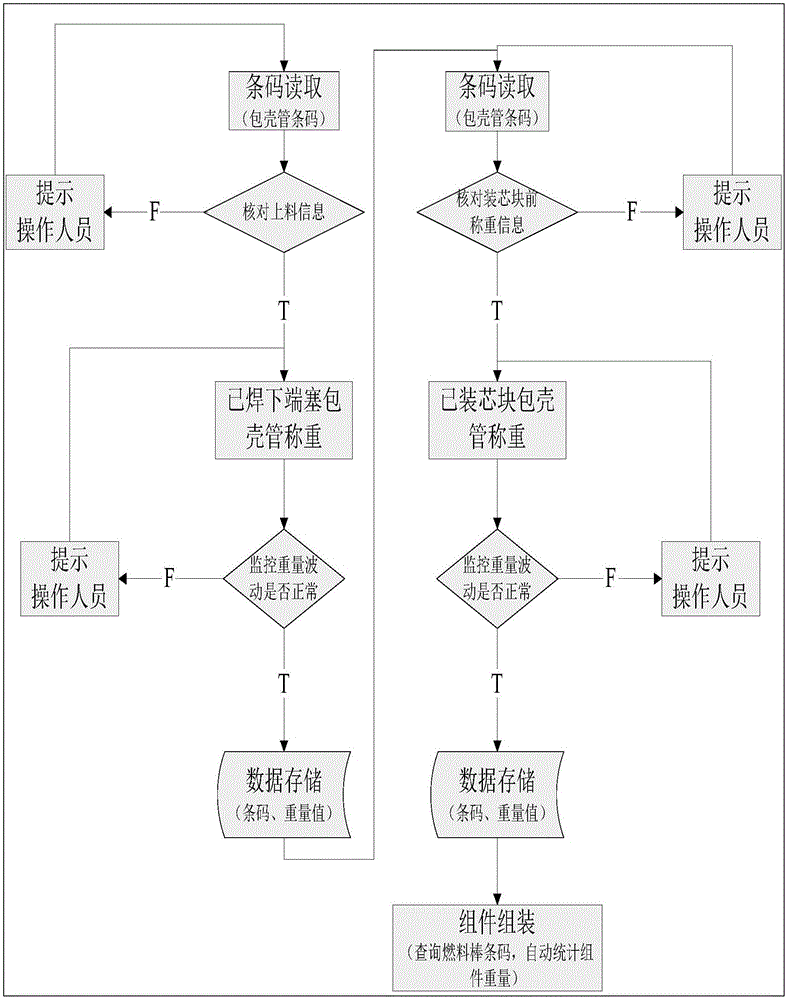

Method of measuring and monitoring weight of UO2 pellets in single fuel rod in real time

ActiveCN106782706AImprove the degree of weighing informationRealize data traceabilityNuclear energy generationNuclear monitoringMonitor weightBarcode

The invention provides a method of measuring and monitoring weight of UO2 pellets in a single fuel rod in real time. The method comprises the following steps: (1) automatically reading, by a barcode reading device, a barcode on a cladding tube, and then comparing the barcode with welding information in a database to determine whether the cladding tube is already welded; (2) automatically weighing the determined welded cladding tube by means of a weighing system; (3) conveying the cladding tube already loaded with pellets to a weighing position again, automatically reading, by the barcode reading device, the barcode on the cladding tube, and then comparing the barcode with weighing information in the database; (4) automatically weighing the cladding tube determined as being filled with pellets by means of the weighing system; and (5) assembling a fuel assembly, inquiring about the barcodes on the cladding tubes, and automatically reading and counting up the weight of the loaded UO2 pellets. The method in the invention increases the level of informationization of fuel rod weighing, achieves data tracing in weight data storage, and can achieve immediate obtaining of the weight of UO2 pellets in a single fuel rod and real-time monitoring on consumption fluctuation of UO2 pellets during the production of the fuel rods.

Owner:CHINA NORTH NUCLEAR FUEL

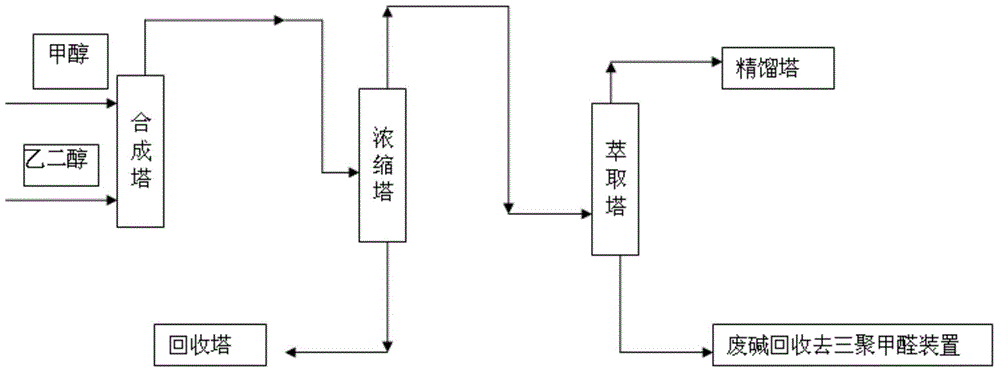

Method for recycling waste alkali liquor in polyformaldehyde device

InactiveCN103554079AProduct Quality ImpactDoes not affect product qualityOrganic chemistryGas phaseTower

The invention discloses a method for recycling waste alkali liquor in a polyformaldehyde device. The method comprises the following steps: (1) respectively delivering formaldehyde and ethanol into a dioxolane synthesizing tower; (2) delivering a gas phase material at the top of the dioxolane synthesizing tower into a dioxolane concentrating tower so as to remove ethylene glycol and the majority of formaldehyde in dioxolane; (3) cooling and delivering a gas phase discharged material at the top of the dioxolane synthesizing tower into an extraction tower, and extracting by adopting sodium hydroxide with mass percentage of greater than 45%; (4) delivering the dioxolane, with mass percentage of greater than 98%, obtained from the top of the extraction tower into a rectifying tower for purifying; and transporting the waste sodium hydroxide alkali liquor, with mass percentage of 30-35%, obtained from the bottom of the extraction tower to the polyformaldehyde device to prepare a sodium hydroxide solution with mass percentage of 10% below so as to be used for producing trioxymethylene. Any influence on the quality of trioxymethylene products can not be caused by adopting the method.

Owner:TIANJIN BOHUA YONGLI CHEM IND

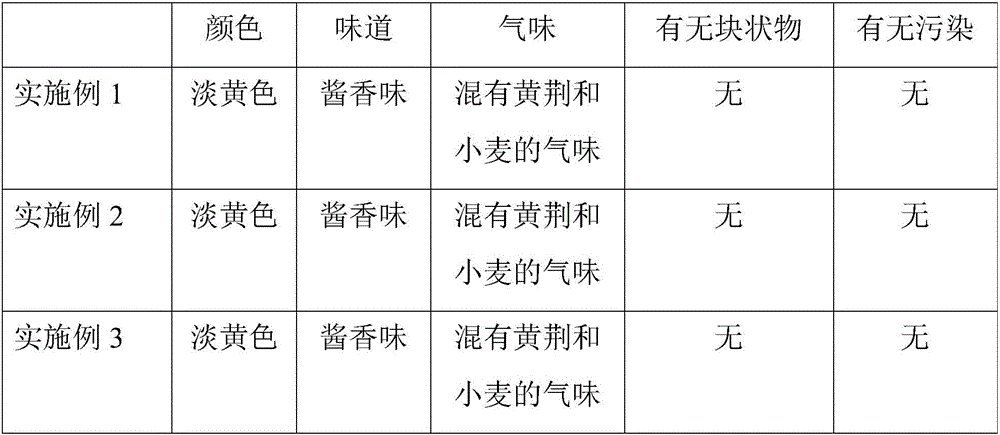

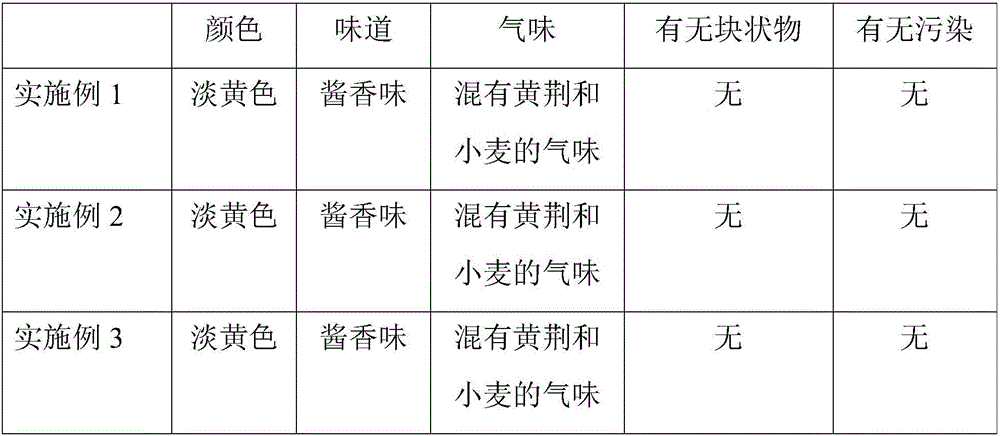

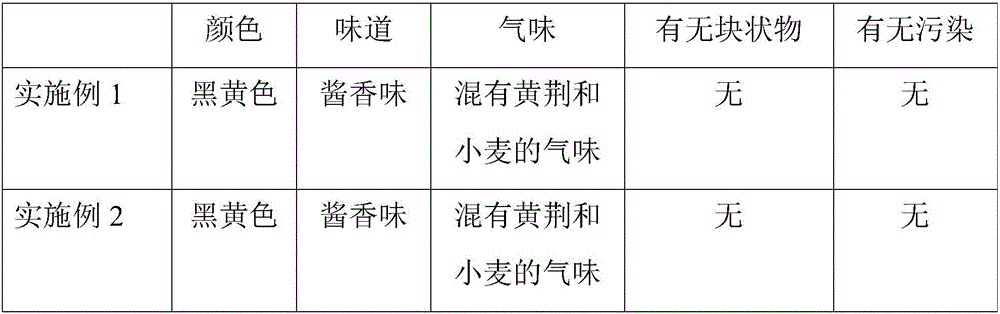

Plant Vitex negundo Linn paste and manufacturing method thereof

The invention discloses a plant Vitex negundo Linn paste. The manufacturing method comprises the following steps: (1) picking Vitex negundo Linn leaves, cleaning, and airing; (2) selecting full wheat, mixing the wheat with pure water, soaking, boiling the wheat, and finally, cooling; (3) spreading the cooled wheat on the Vitex negundo Linn leaves, covering the Vitex negundo Linn leaves on the wheat, and fermenting in a wood container at room temperature for 10-12 days; (4) taking out the fermented wheat, airing for 3-4 days, and grinding into powder; and (5) mixing the powder obtained in the step (4) with pure water and table salt according to the weight ratio of (1-2):(3-4):(0.05-0.1) to obtain the paste, and sealing in a jar for preservation. The product has the advantages of unique flavor, bright color, longer preservation time and low pollution tendency, and can be directly eaten after being taken out of the jar.

Owner:成都尚碧净家政服务有限公司

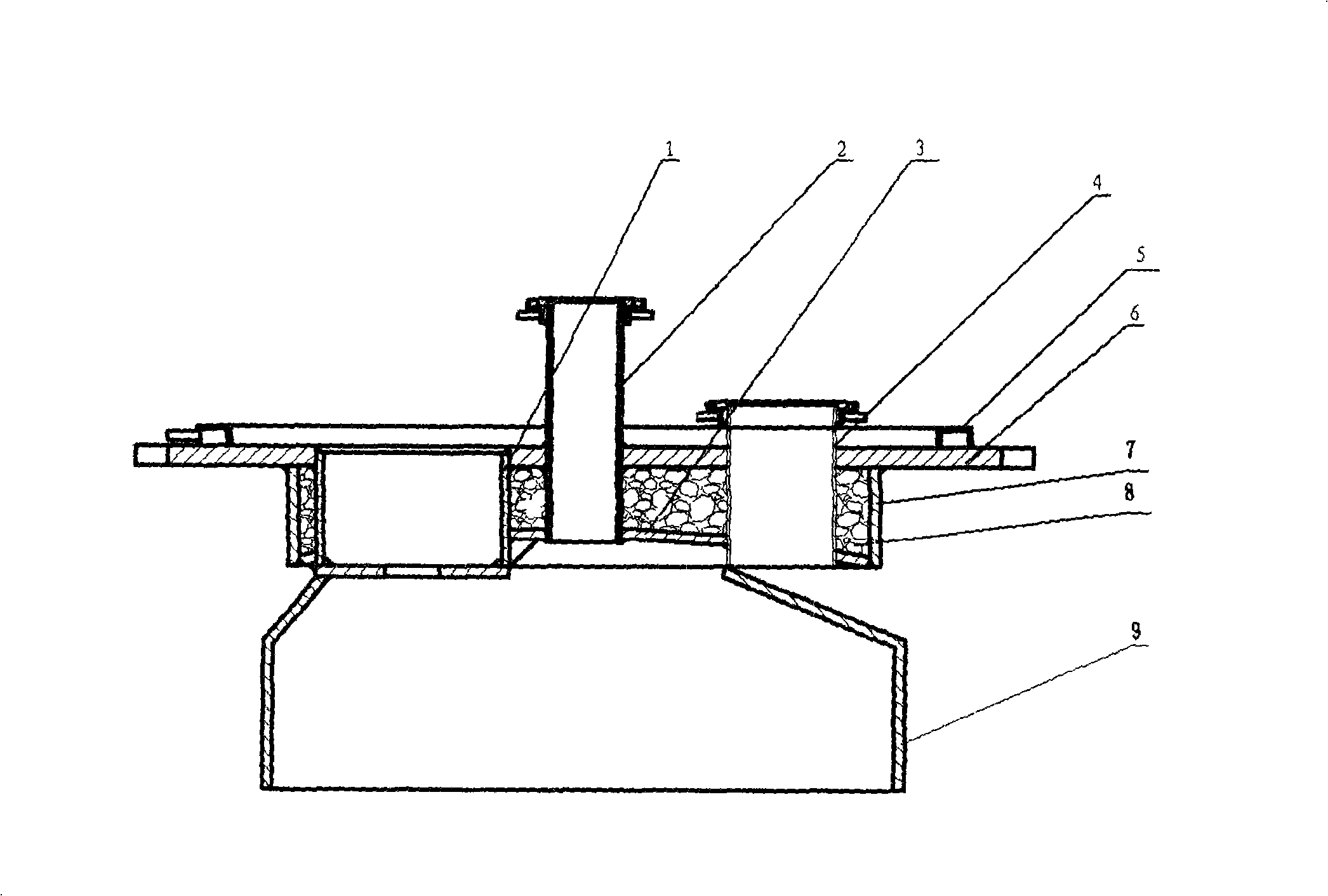

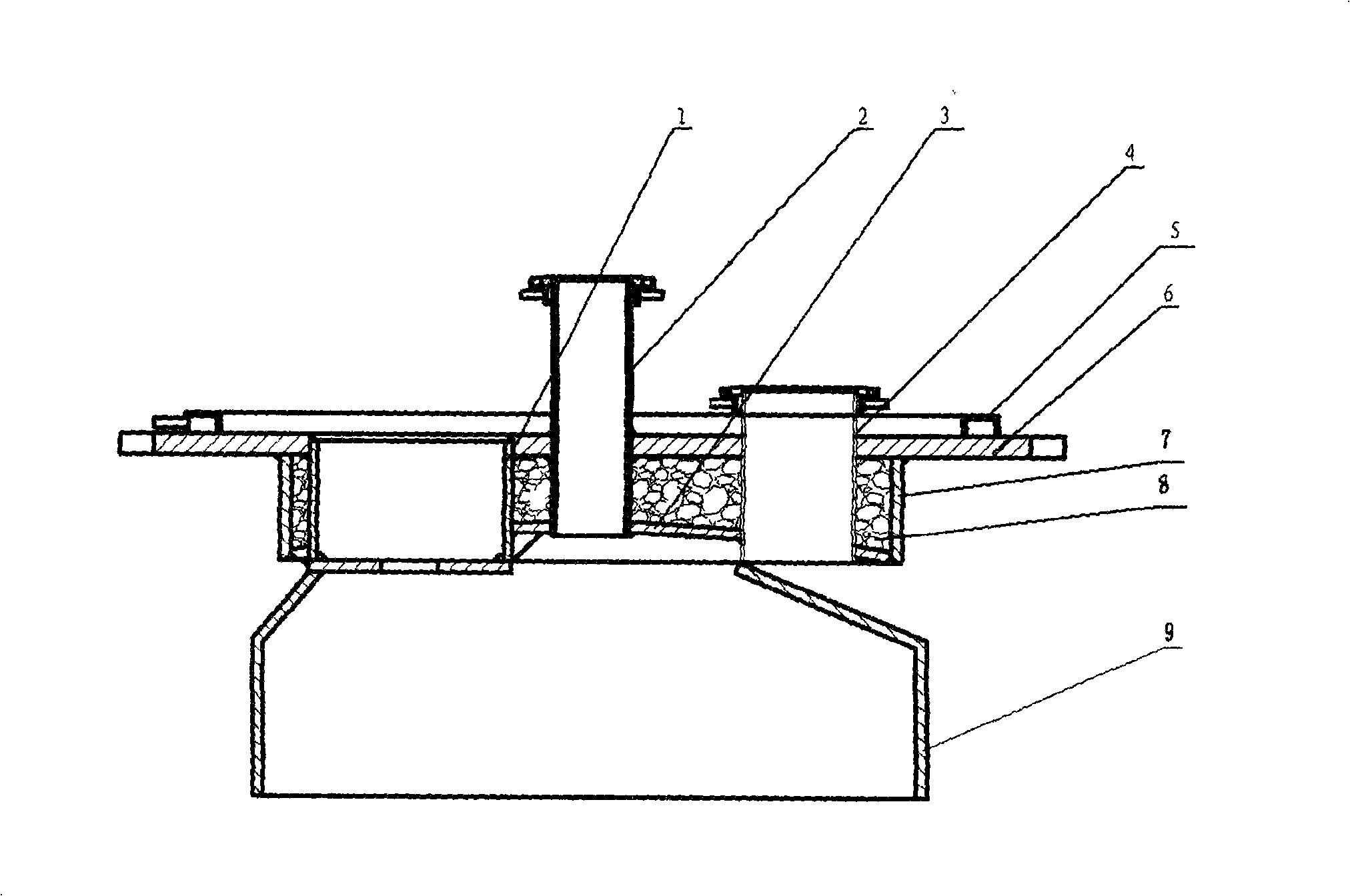

Furnace lid for manufacturing titanium sponge

The invention discloses a furnace cover for producing sponge titanium, which comprises a cylinder, a panel arranged on the cylinder, and a bottom plate under the cylinder, wherein, the furnace cover is provided with an aisle bushing, a feeder bushing and a vacuum pipeline bushing. The furnace cover is characterized in that: a sleeve is arranged below the bottom plate of the furnace cover to ensure that the aisle bushing and the feeder bushing are arranged inside the sleeve, the vacuum pipeline bushing is positioned outside the sleeve, the bottom plate of the furnace cover is of an upward vaulted spherical shape, and a heat insulating material, namely sayla cotton containing zirconium is filled in a cavity enclosed by the panel, the bottom plate and the cylinder. The furnace cover can effectively prevent distilled materials from being directly pumped by a vacuum unit, and does not affect the production of reduction reaction at the same time; the vaulted bottom plate has large anti-deformation ability, which solves the problems of furnace cover deformation, threatening weld craters, short service life and so on. The furnace cover has universal interchange function, avoids distillates from contacting the air to be polluted, and assures the steady operation of the production.

Owner:CITIC JINZHOU METAL

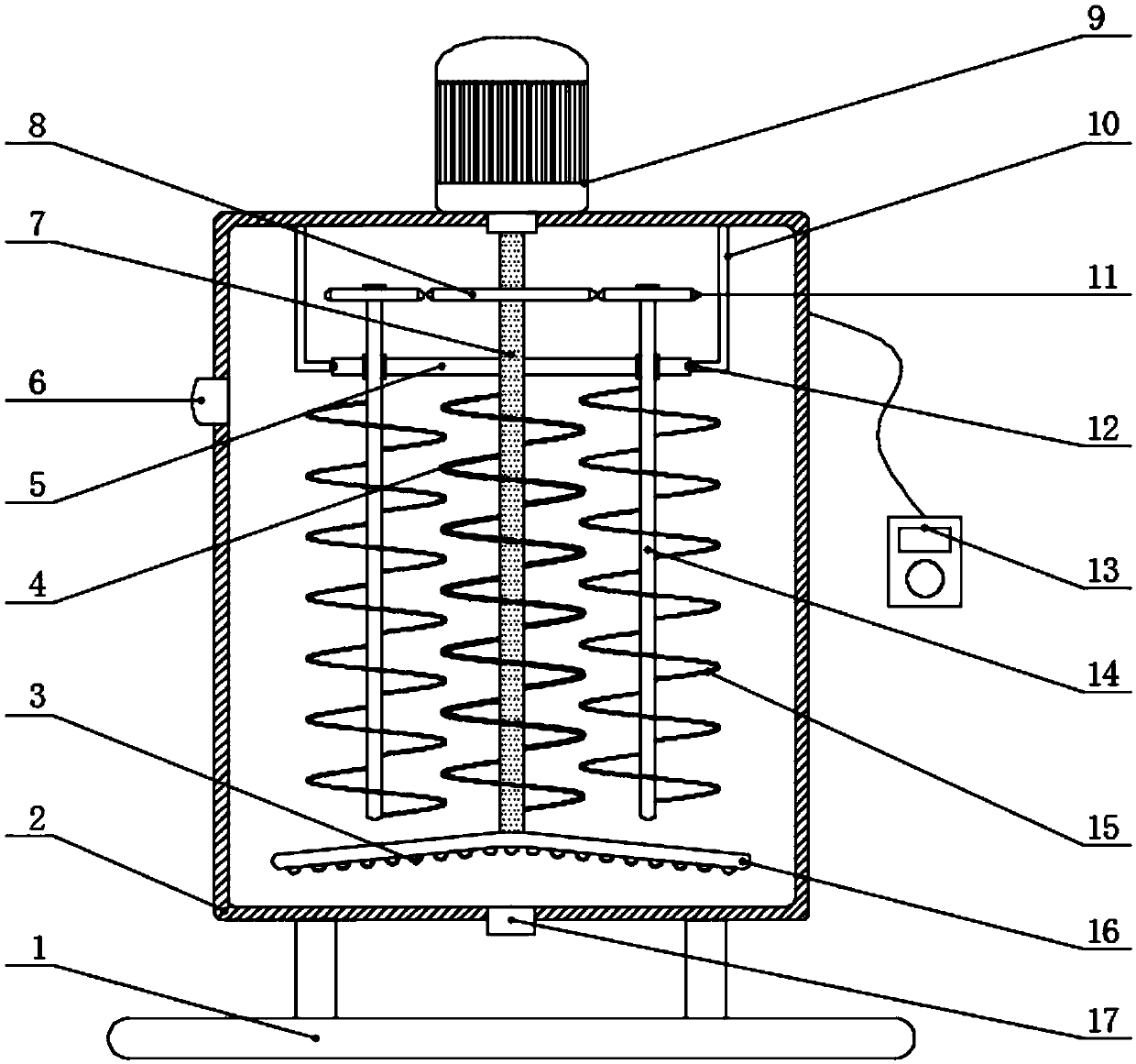

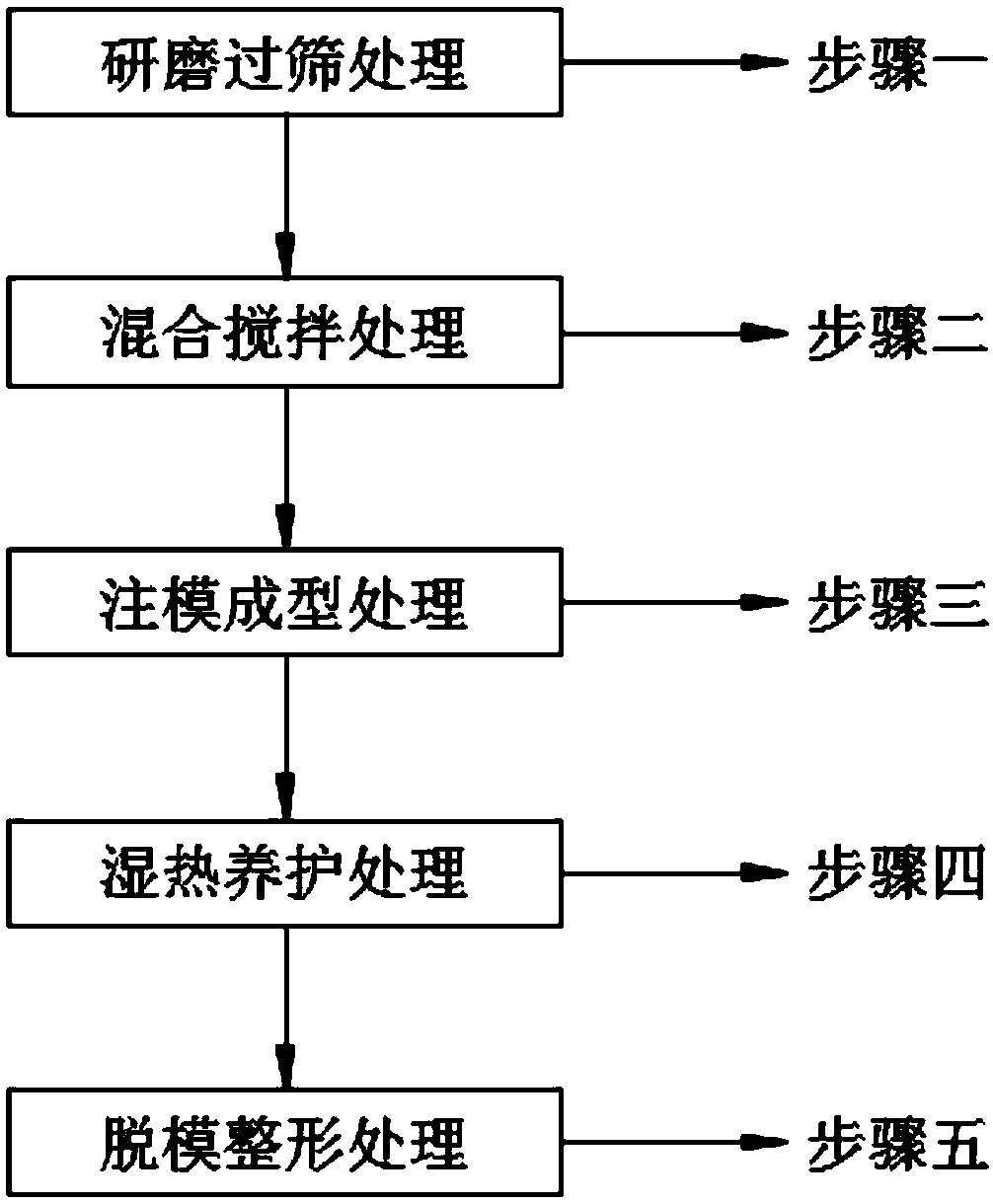

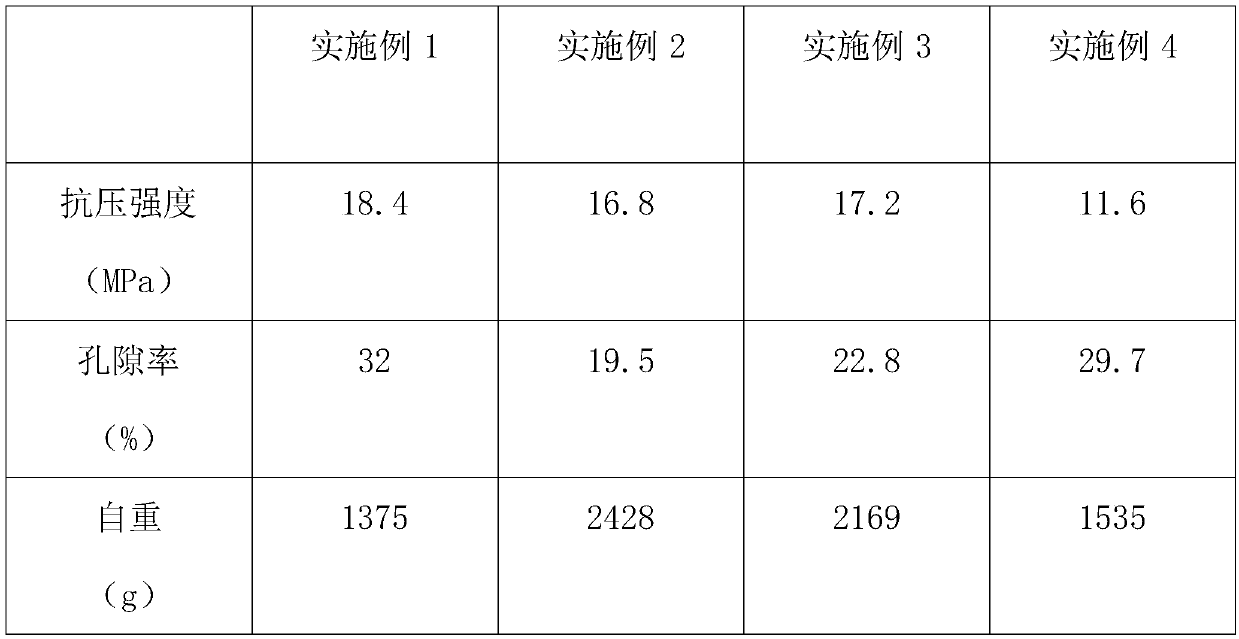

Light environmental-friendly brick based on building waste and production process of light environmental-friendly brick

ActiveCN109516735AImprove structural strengthAffect the normal service lifeCement mixing apparatusCeramicwareBrickSlag

The invention discloses a light environmental-friendly brick based on building wastes and a production process of the light environmental-friendly brick. The light environmental-friendly brick comprises the following raw materials in percentage by weight: 30-50% of water, 15-25% of Portland cement, 5-15% of a ceramic waste, 5-15% of a brick waste, 6-8% of river sand, 3-7% of bits of wood, 3-7% offurnace cinder and 2-4% of modified foaming aids. Due to adoption of the ceramic waste, the brick waste, the bits of wood and the furnace cinder in the raw materials, building wastes and slag materials can be reasonably recycled, environment influence caused by casual treatment can be avoided, the production cost can be reduced, and meanwhile the environment protection is greatly improved; and dueto adoption of the modified foaming aids, under coactions of final products, namely calcium dodecyl benzene sulfonate and sodium dodecyl benzene sulfonate generated in mutual reactions of raw materials in the modified foaming aids, and under the synergetic effect of a silicon resin polyether emulsion, a foaming effect is improved, and the consequence that bricks have unequal and too large self weights since air pores are unequal in size and non-uniform in distribution can be avoided.

Owner:湖南钰龙建材有限公司

Reactor cap for manufacturing titanium sponge

The invention provides a cover of a reactor used for producing sponge titanium. The cover comprises a barrel, a panel arranged on the upper part of the barrel, a bottom plate arranged on the lower part of the barrel; and a channel sleeve, a feeder sleeve and a vacuum piping sleeve are arranged on the cover of the reactor. The cover is characterized in that a cavity enclosed by the panel, the bottom plate and the barrel is filled with a heat insulating material-serra cotton containing zirconium, the bottom plate of the cover of the reactor is arched spherical, a sleeve barrel is arranged below the bottom plate of the reactor cover, the channel sleeve and the feeder sleeve are arranged inside the sleeve barrel, the vacuum piping sleeve is arranged outside the sleeve barrel. The reactor cover has the advantages of simple structure, easy manufacturing, light weight, safety and reliability and hard deformation, and can effectively avoid distilled materials from being directly pumped out by a vacuumizer and simultaneously does not affect the completion of the reduction reaction. The reactor cover has the functions of universal interchangeability, and can ensure the normal operation of production, and the product quality is not threatened, so that the main equipment problem of producing the sponge titanium by the combined method is radically solved.

Owner:CITIC JINZHOU METAL

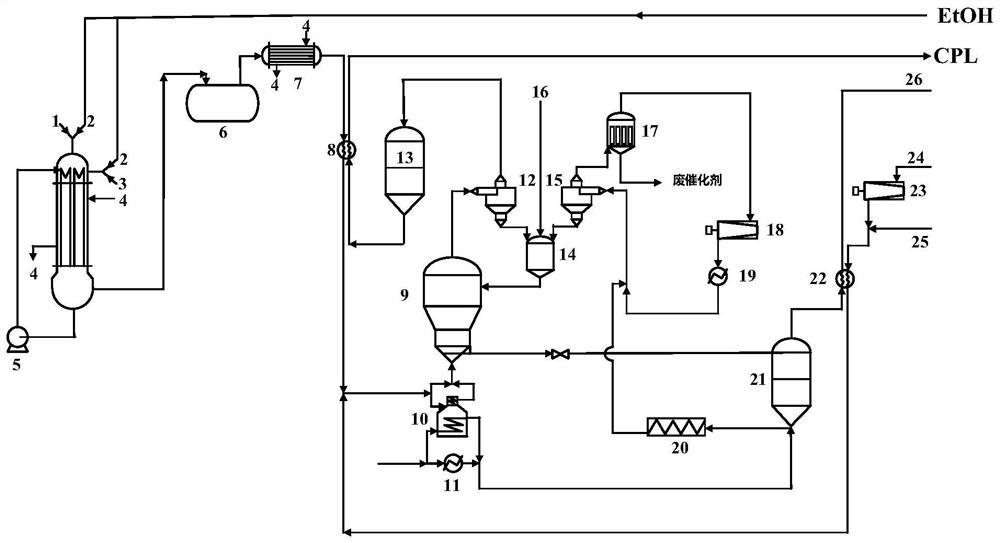

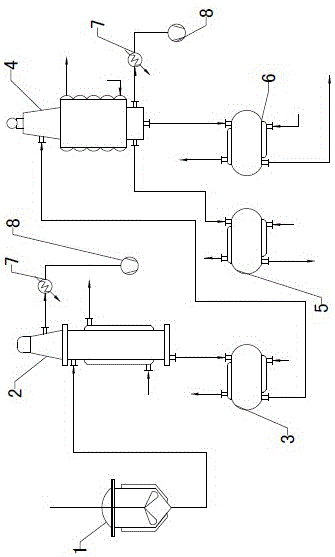

Production device and production method of caprolactam

PendingCN112079759AEfficient evaporationHigh Efficiency in Evaporation and GasificationLactams preparationLactams separation/purificationPtru catalystFluidized bed

The invention relates to the field of caprolactam production, in particular to a caprolactam production device and method, and the device comprises a cyclohexanone-oxime evaporation and gasification system, a mist separation system, a fluidized bed reaction system and a moving bed reaction system which are connected in series; the device further comprises a reaction solvent recycling system and acarrier gas recycling system. The method comprises the following steps: (1) evaporating and gasifying carrier gas, ethanol and cyclohexanone-oxime in a cyclohexanone-oxime evaporation and gasificationsystem; (2) feeding a gas-phase material flow obtained in the step (1) into a mist separation device to gasify cyclohexanone-oxime which is not completely gasified in a cyclohexanone-oxime evaporation and gasification system; (3) feeding the material flow obtained in the step (2) into a fluidized bed reaction system and a moving bed reaction system in sequence for gas-phase Beckmann rearrangementreaction; and (4) recovering ethanol and carrier gas in the material flow obtained in the step (3). By adopting the device and the method, the high conversion rate of cyclohexanone-oxime can be obtained, the problem of catalyst discharge is avoided, and the production is not interrupted.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

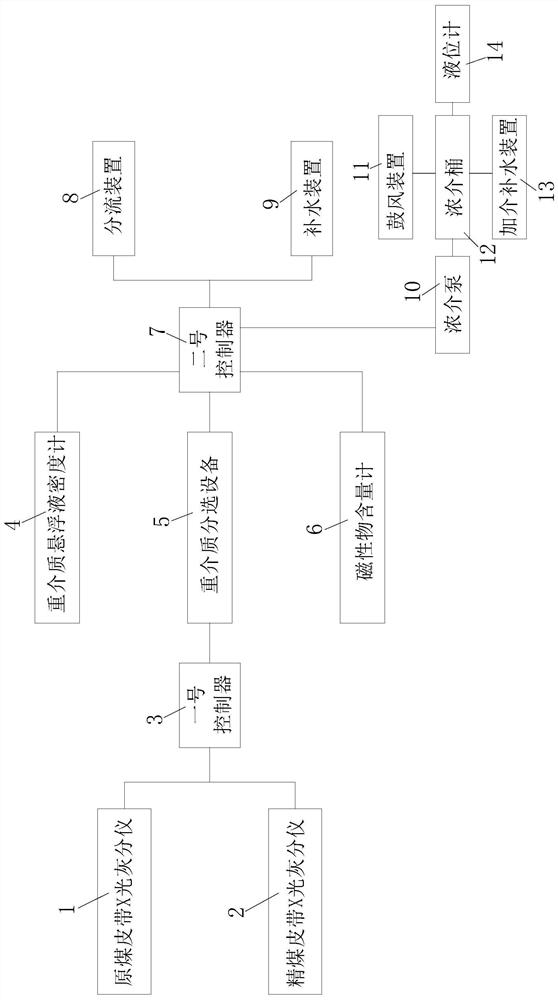

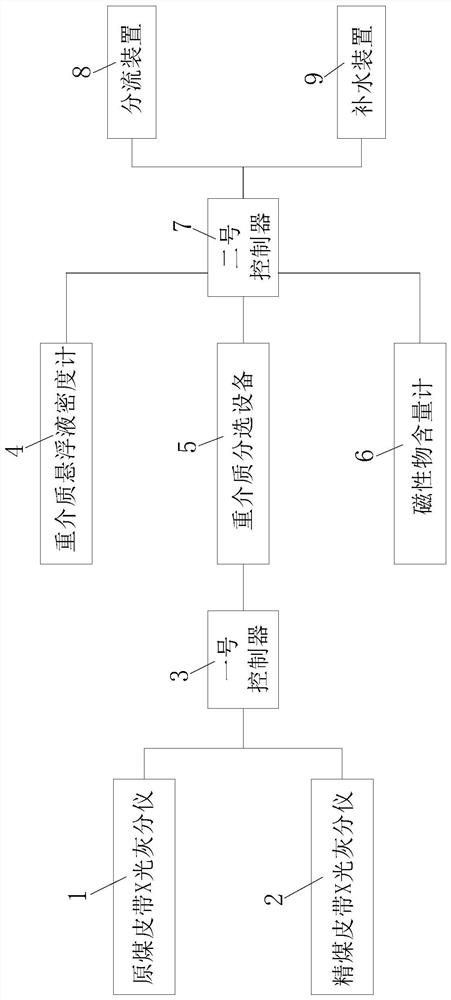

Intelligent dense medium separation system and working method thereof

InactiveCN113210119AEasy to adjustImplement automatic additionWet separationThermodynamicsProcess engineering

The invention relates to an intelligent dense medium separation system and a working method thereof, and belongs to the technical field of coal washing. The system comprises a raw coal belt X-ray ash content testing system, a clean coal belt X-ray ash content testing system, a first controller, a dense medium suspension densimeter, dense medium separation equipment, a magnetic substance content meter, a second controller, a flow dividing device and a water supplementing device, wherein the raw coal belt X-ray ash content testing system and the clean coal belt X-ray ash content testing system are both connected with the first controller, the first controller is connected with the dense medium suspension densimeter, the dense medium separation equipment and the magnetic substance content meter, the dense medium suspension densimeter, the dense medium separation equipment and the magnetic substance content meter are all connected with the second controller, and the second controller is connected with the flow dividing device and the water supplementing device.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

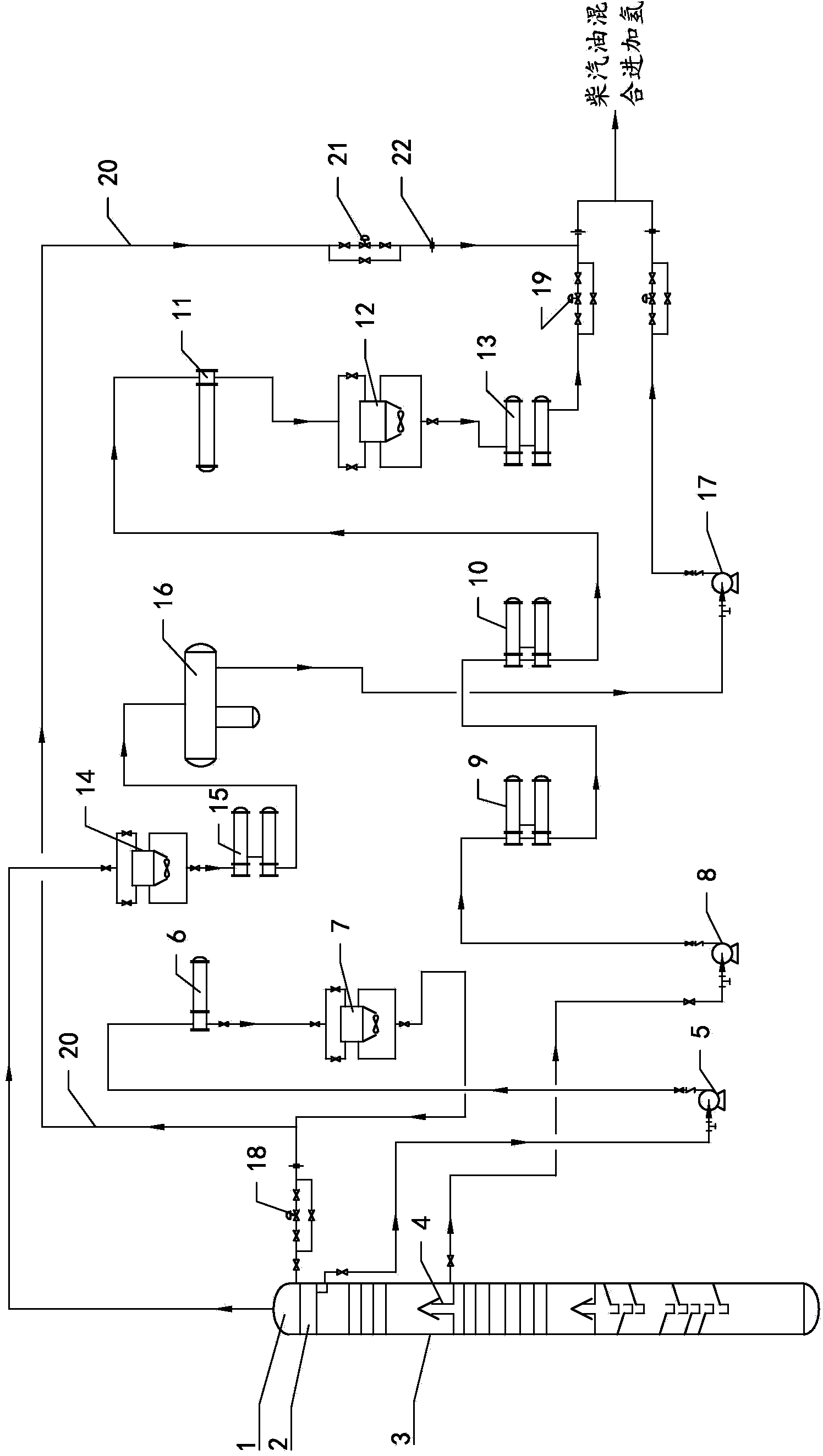

Process device for treatment of salt coagulation of fractionating column top circulation system

InactiveCN103952182AProduct Quality ImpactPrevent salt formationTreatment apparatus corrosion/fouling inhibitionRefluxGasoline

The invention relates to a process for delaying coking and in particular relates to a process device for treatment of salt coagulation of a fractionating column top circulation system. The technical key points are as follows: a top cycle oil series diesel pipeline is further arranged on a connecting pipeline between a fractionating column top reflux air cooler and a first column tray to a diesel and gasoline hydrogenation device and a top cycle oil series diesel regulating valve and a top cycle oil series diesel flowmeter are connected on the top cycle oil series diesel pipeline in series. The process device provided by the invention can break the balance of circulation of top circulation in the system, reduce accumulation of salt coagulation and achieve the purpose of preventing column top salt coagulation through the newly increased top cycle oil series diesel regulating valve and the newly increased top cycle oil series diesel flowmeter under the situation of not changing the reflux quantity of top cycle oil and not affecting the fractionating column top temperature.

Owner:SHANDONG JINCHENG HEAVY OIL RES INST OFCHEM TECH

Rapid-granulating and curing process of natural rubber

The invention provides a method for quickly granulating and solidifying natural rubber latex. The invention is characterized in that the method comprises the steps as follows: the natural rubber latex is dropped into an alcoholic solution containing polyvinyl alcohol and calcium ions at room temperature; the latex surface is solidified and is automatically granulated and sedimentated in the alcoholic solution; latex particles are separated; and the separated latex particles are dried. The method can quickly acquire rubber particles with smooth, round and non-adhesive surfaces, has no pollution during the whole production process, and ensures that the production quality meets rubber processing requirements, thereby the method is the latest domestic natural rubber solidification technology.

Owner:刘结平

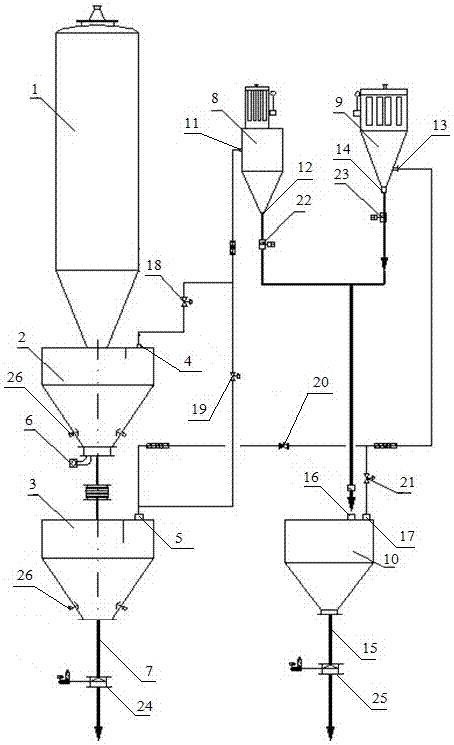

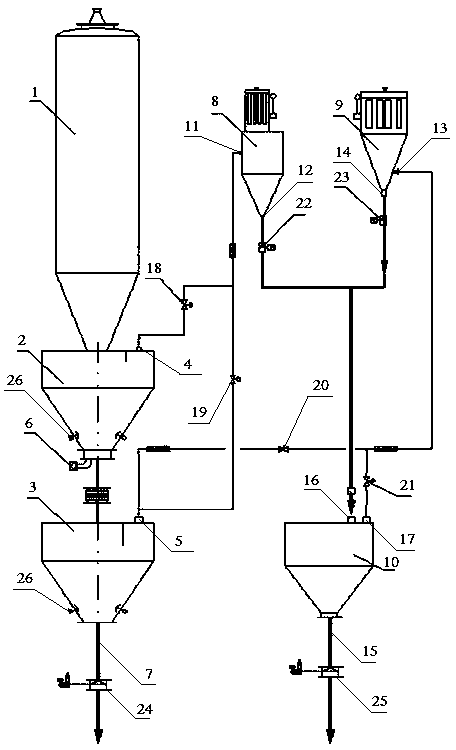

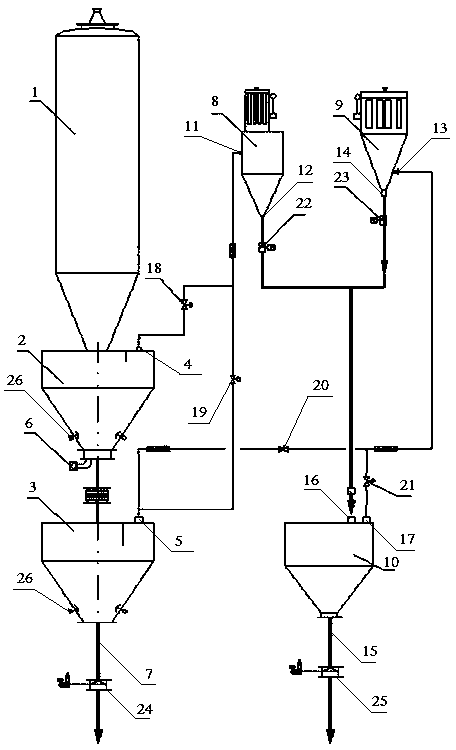

Anti-blocking powder discharging device and method for low-loose-density metal powder products

The invention discloses an anti-blocking powder discharging device and method for low-loose-density metal powder products. The device comprises a decomposer, a middle bin and a produced powder material bin, and the decomposer, the middle bin and the produced powder material bin are sequentially connected from top to bottom; the tops of the middle bin and the produced powder material bin are each provided with an exhausting port; the bottom of the middle bin is provided with a discharging valve; the device further comprises a decomposed gas dust remover, a disinfecting replacement gas dust remover and a dust collecting powder material bin; an inlet of the decomposed gas dust remover is connected with the exhausting port of the middle bin and the exhausting port of the produced powder material bin through pipelines; the top of the dust collecting powder material bin is provided with a dust collecting port and a disinfecting port; an inlet of the disinfecting replacement gas dust remover is connected with the exhausting port of the produced powder material bin and the disinfecting port through pipelines; and the dust collecting port is connected with an outlet of the decomposed gas dust remover and an outlet of the disinfecting replacement gas dust remover through pipelines. The device and method are good in powder discharging smoothness and high in powder product quality.

Owner:JINCHUAN GROUP LIMITED

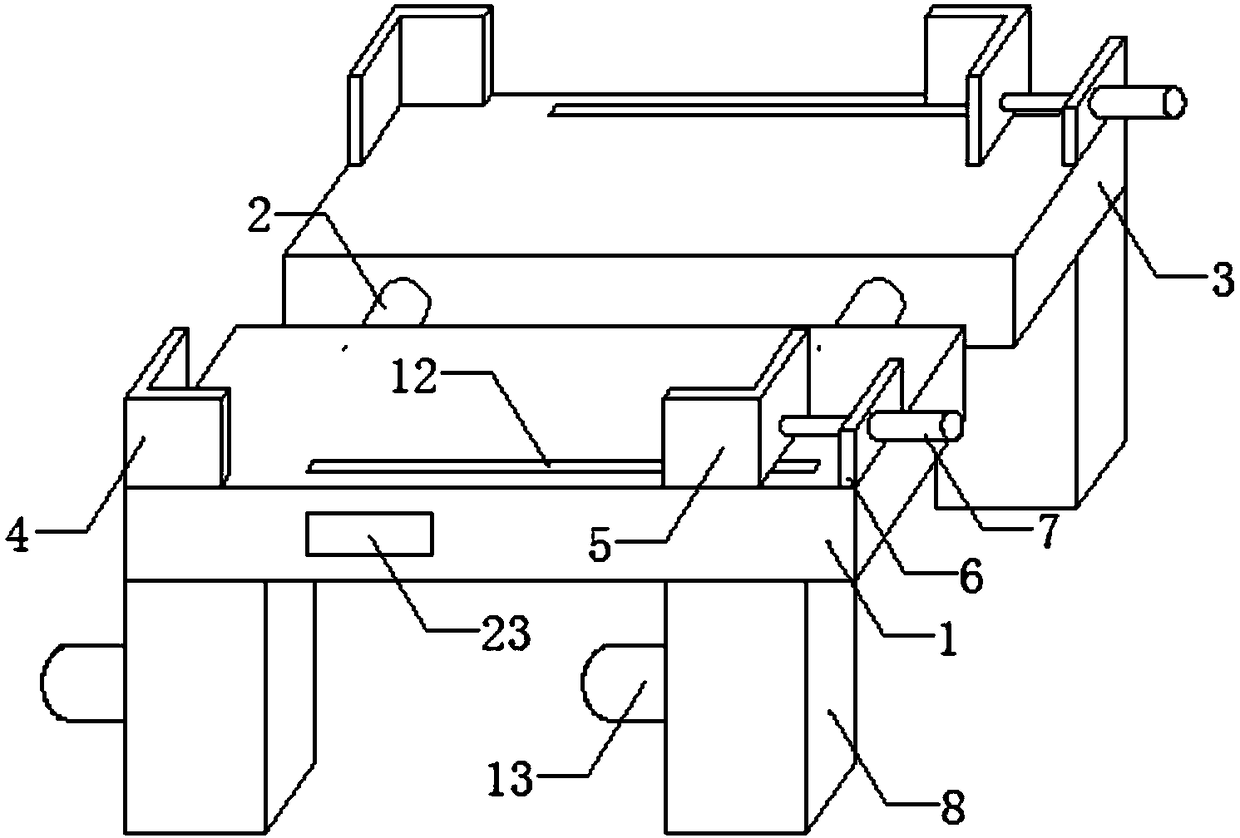

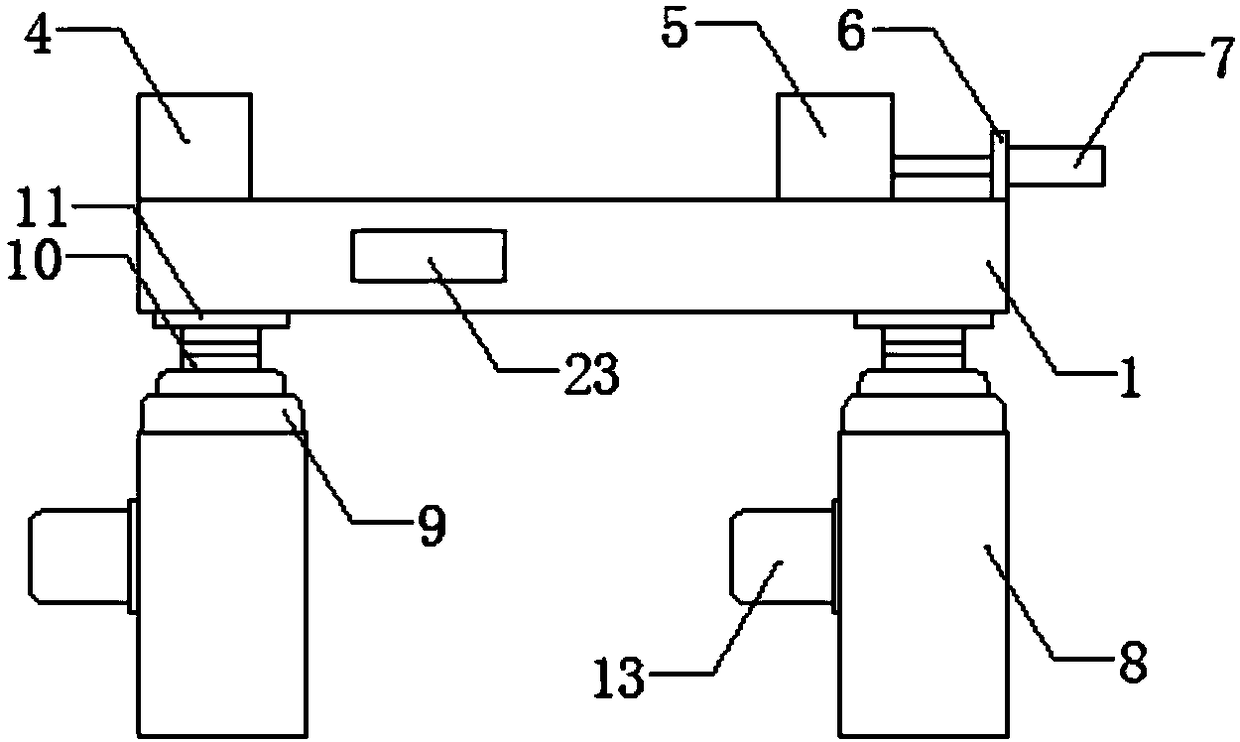

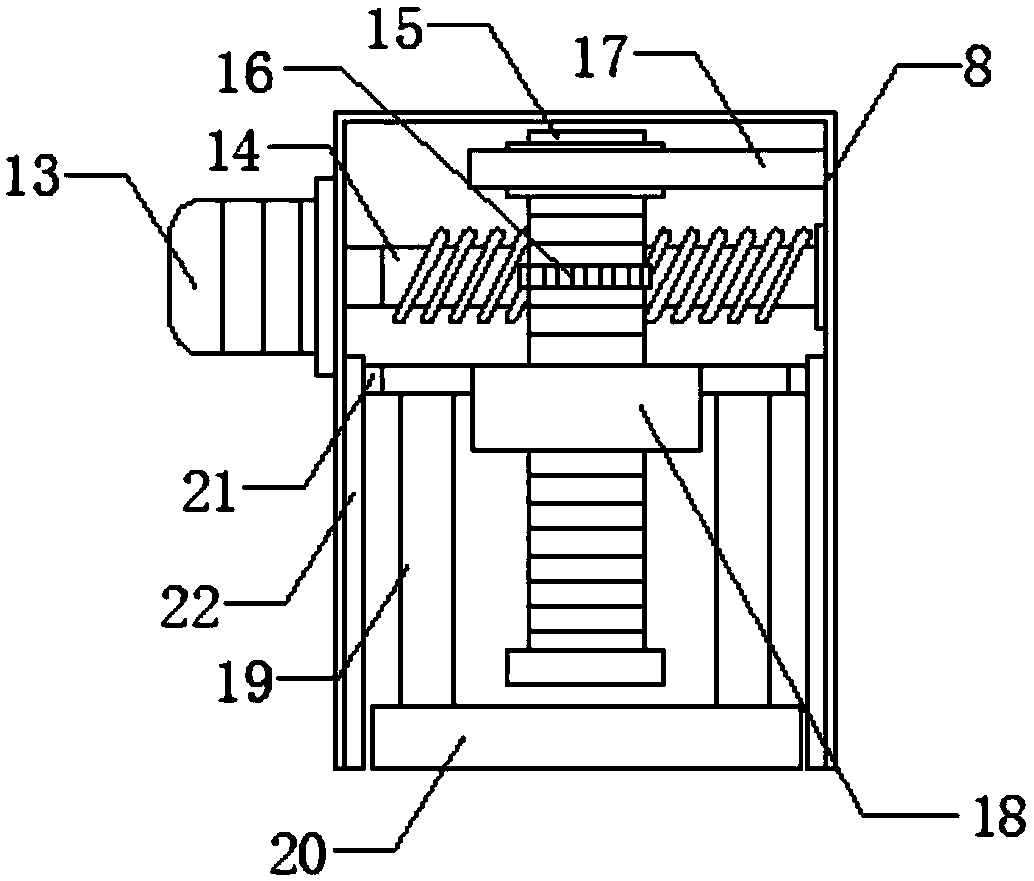

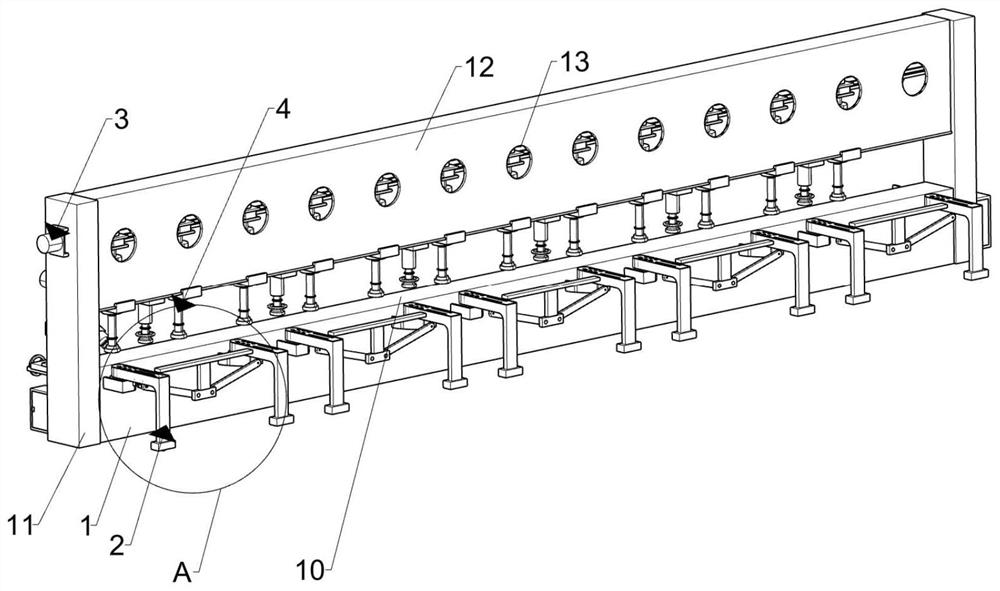

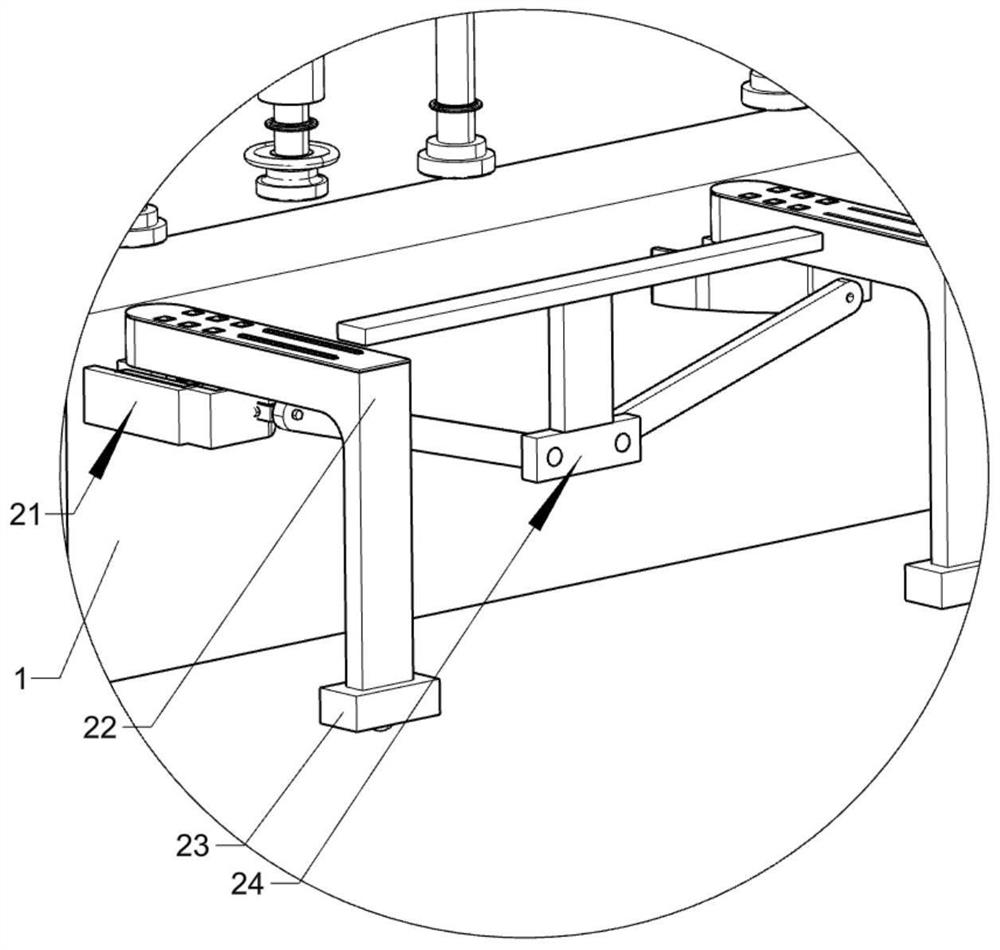

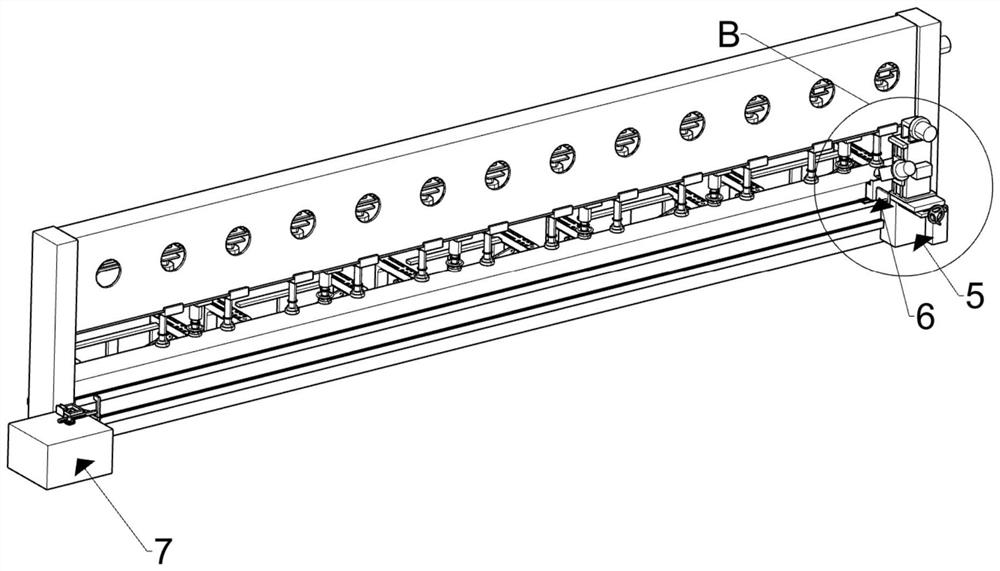

Rack for textile machine

PendingCN108396413AEasy to fixReduce economic costsLoomsContinuous wound-up machinesCost (economic)Industrial engineering

The invention discloses a rack for a textile machine. The rack comprises a first supporting plate and a second supporting plate, one side of the first supporting plate is fixedly connected with one side of the second supporting plate through two first electric telescopic rods, the top of the first supporting plate and the top of the second supporting plate are both provided with a fixing mechanism, and the bottom of the first supporting plate and the bottom of the second supporting plate are both fixedly connected with the top of a fixing base through damping mechanisms; a lifting mechanism isarranged in the fixing base, and a control panel is arranged on one side of the first supporting plate. According to the scheme, textile machines in different sizes can be fixed through the fixing mechanisms and the first electric telescopic rods, so that the application range of the rack is wide, and the economic cost is reduced; the height of the first supporting plate and the height of the second supporting plate can be adjusted through the lifting mechanism so that workers with different heights can conveniently operate the textile machine on the rack, and the working efficiency is improved.

Owner:浙江开创智库科技有限公司

A method for preparing needle coke

InactiveCN104479707BHigh softening pointControl cut volumeWorking-up pitch/asphalt/bitumen by distillationCoking carbonaceous materialsAsphaltDegasification

The invention discloses a method and a device of preparing a needle coke, and belongs to the technical field of needle coke preparation. The method disclosed by the invention is characterized by comprising the following steps: separating an asphalt raw material by virtue of a degasification column and a molecular distillation column, preheating the asphalt raw material, pumping the asphalt raw material in the degasification column and carrying out degasification treatment at a degasification temperature of 250-330 DEG C under an in-column pressure of 100-1000Pa, then pumping the degasified materials to the molecular distillation column, controlling a distillation temperature in the molecular distillation column to 300-400 DEG C and controlling a pressure to 0.01-100Pa, separating the materials into a light-phase component and a heavy-phase component in the molecular distillation column through a short-path distillation action, carrying out delayed coking on the light-phase component to obtain green coke, and calcining the green coke to obtain the needle coke. The method disclosed by the invention is capable of stably and accurately controlling the cutting amounts of the raw material components, thus flexibly adjusting the product quality, and furthest reserving ideal components. Moreover, the method is low in treatment temperature, rapid in material separation, and free from forming secondary quinoline undissolved substances.

Owner:乔光明

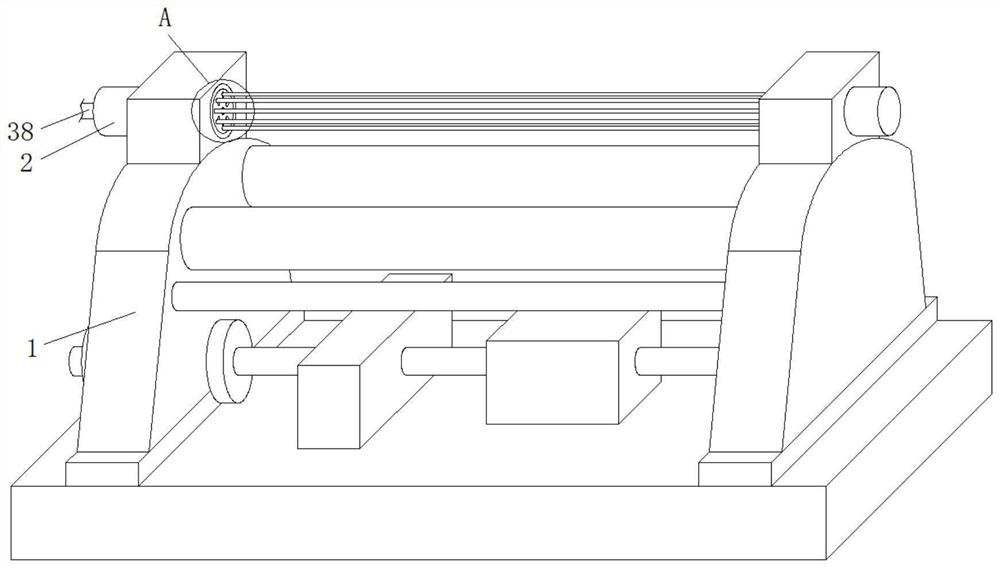

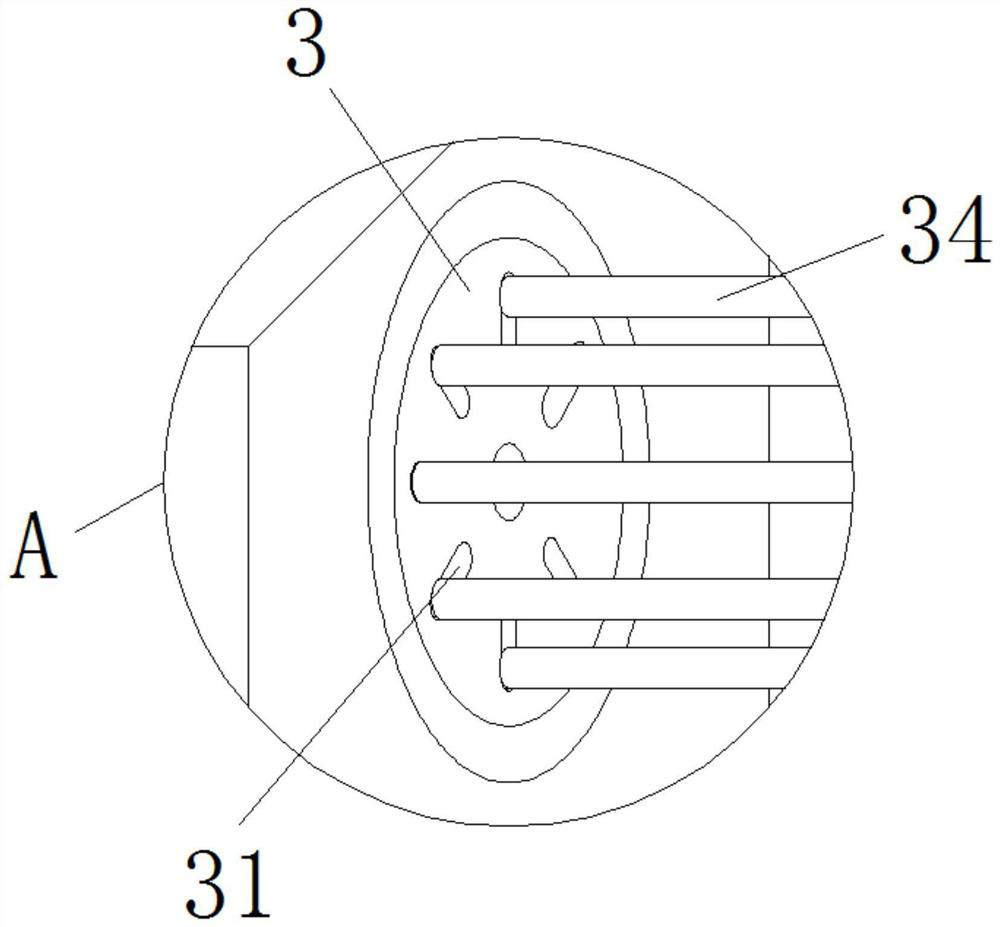

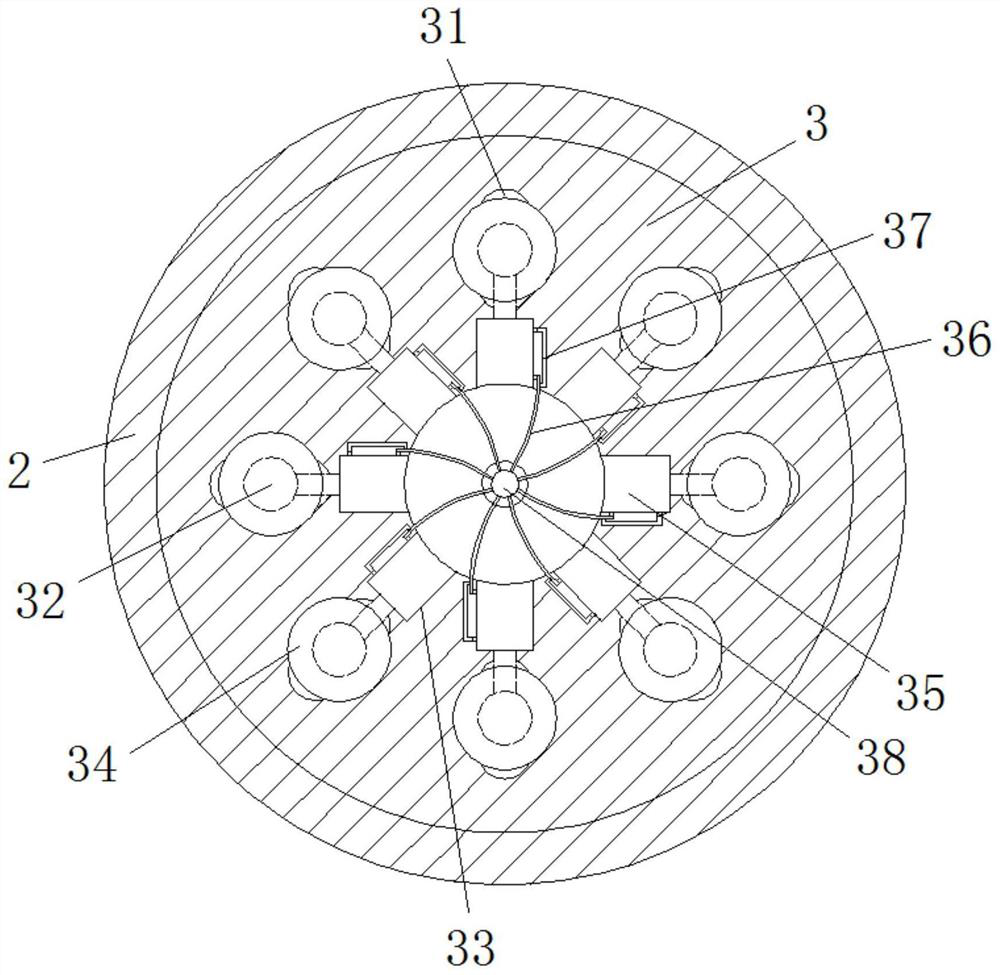

Thin-wall veneer reeling machine with adjustable roll shaft diameter

The invention belongs to the technical field of veneer reeling machines, and particularly relates to a thin-wall veneer reeling machine with an adjustable roll shaft diameter. The machine comprises aveneer reeling machine body, the veneer reeling machine body comprises an end shaft, a diameter-adjustable mechanism is arranged on the inner wall of the end shaft, the diameter-adjustable mechanism comprises a disc, and the inner wall of the end shaft is fixedly sleeved with the outer surface of the disc. According to the thin-wall veneer reeling machine with the adjustable roll shaft diameter, when two specifications of veneer reeling plates with the same veneer reeling diameter but different wall thicknesses are required, the distance between an upper roll shaft and two lower roll shafts onthe veneer reeling machine body is automatically adjusted, the action of adjusting while veneer reeling during veneer reeling is achieved, meanwhile, The differential connection mode that an oil inlet pipe and an oil outlet pipe of a hydraulic cylinder are communicated is adopted, the outward extending movement speed of a piston rod of the hydraulic cylinder can be conveniently achieved on the premise that the flow of a hydraulic pump is not increased, and the effect that the quality of plate products after veneer reeling is affected is avoided.

Owner:NANTONG CHAOLI ROLLING MACHINE PRODUCING

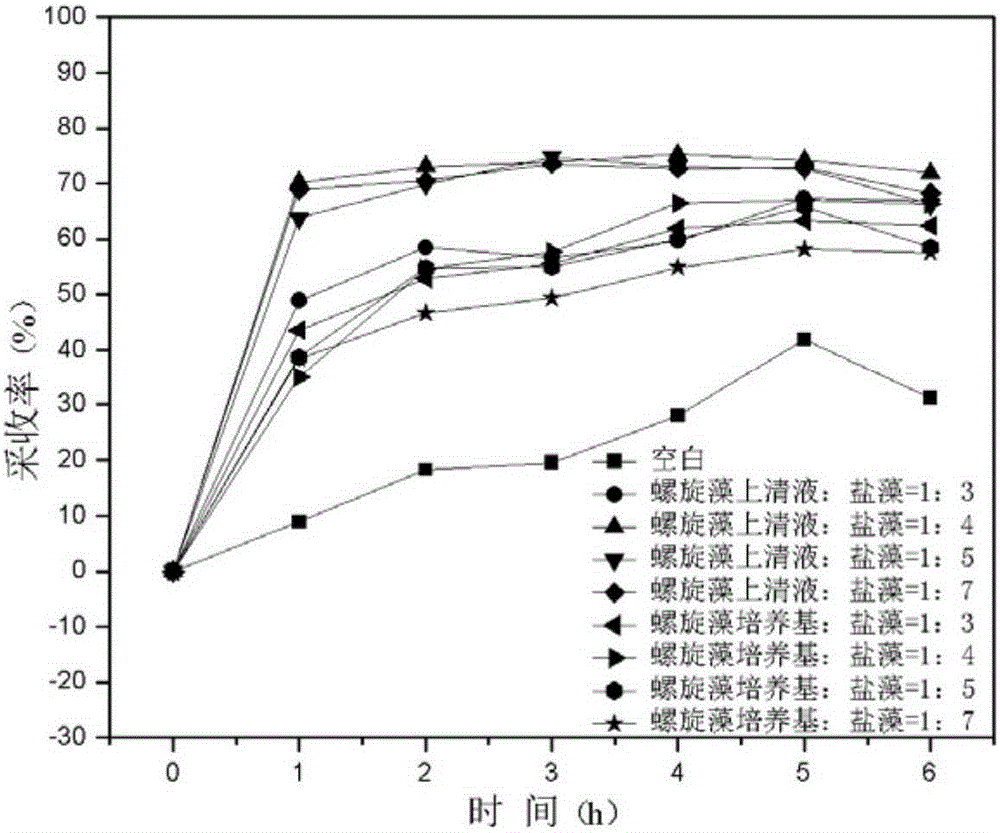

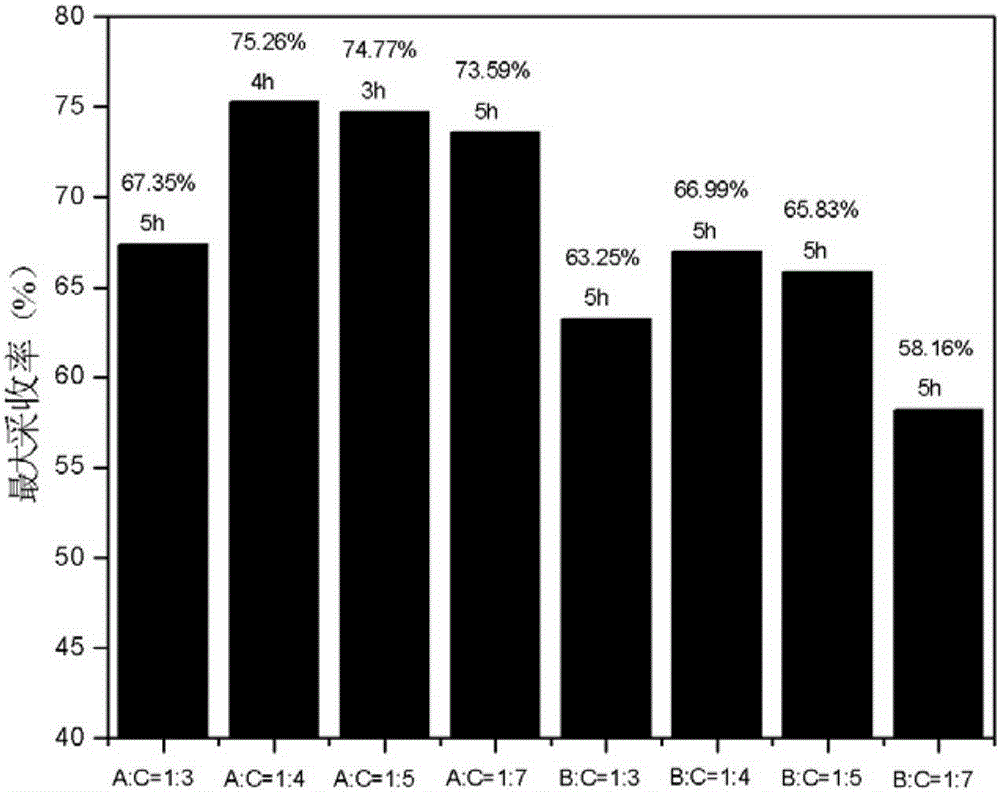

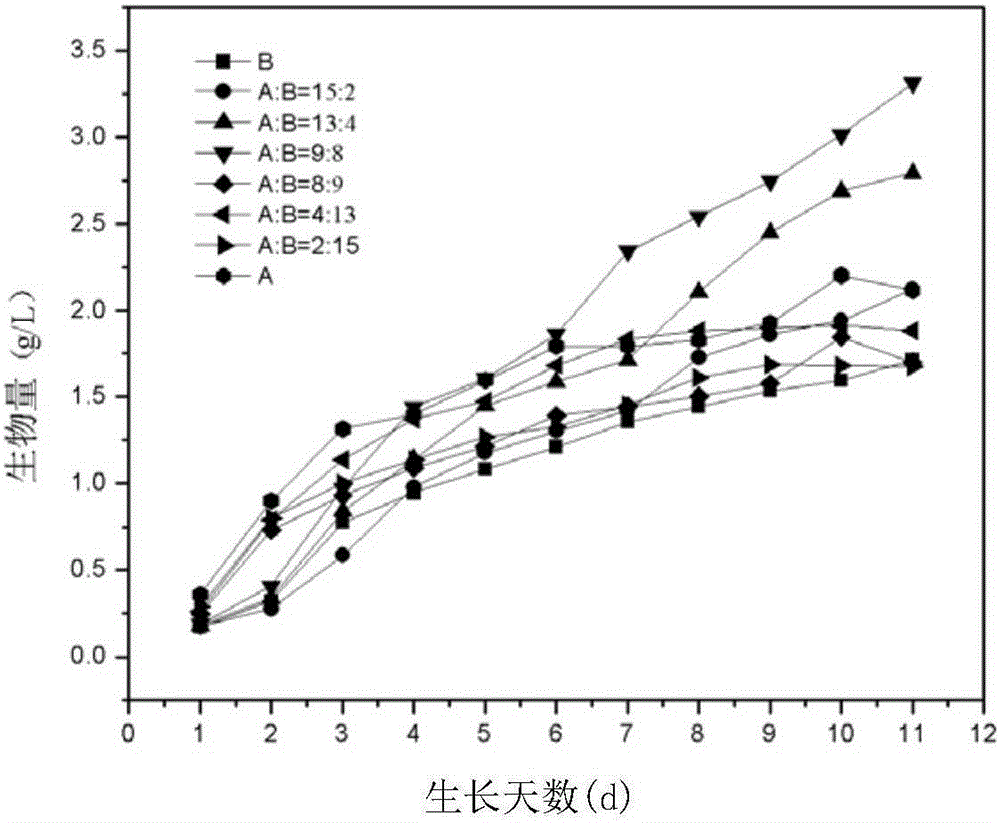

Method for harvesting dunaliella salina by using waste spirulina culture liquid

InactiveCN105176827ATake advantage ofReduce manufacturing costUnicellular algaeMicroorganism based processesDunaliella salinaTest agent

The invention discloses a method for harvesting dunaliella salina by using a waste spirulina culture liquid, and relates to a dunaliella salina harvesting method. The method comprises the following steps: 1) collecting supernate after spirulina is harvested, and testing the pH value; 2) adding the supernate collected in the step 1) into dunaliella salina, leaving to stand, and testing the harvesting rate; and 3) mixing the supernate obtained in the step 2) with a dunaliella salina culture medium, inoculating dunaliella salina cells, performing circulation culture, and testing the growth curve of dunaliella salina. By making full use of characteristics that the pH of the culture liquid used in the growth process of spirulina is alkali and dunaliella salina can be automatically flocculated under a high pH value, the supernate of spirulina can be sufficiently utilized, the supernate obtained after dunaliella salina is harvested can be continuously adopted for dunaliella salina culture, and the production cost is low. The harvested dunaliella salina is free of organic test agent or toxic or harmful substance, influence to the quality of an algae paste product in the harvesting process can be avoided, the waste supernate can be sufficiently utilized, and secondary pollution can be prevented.

Owner:XIAMEN UNIV

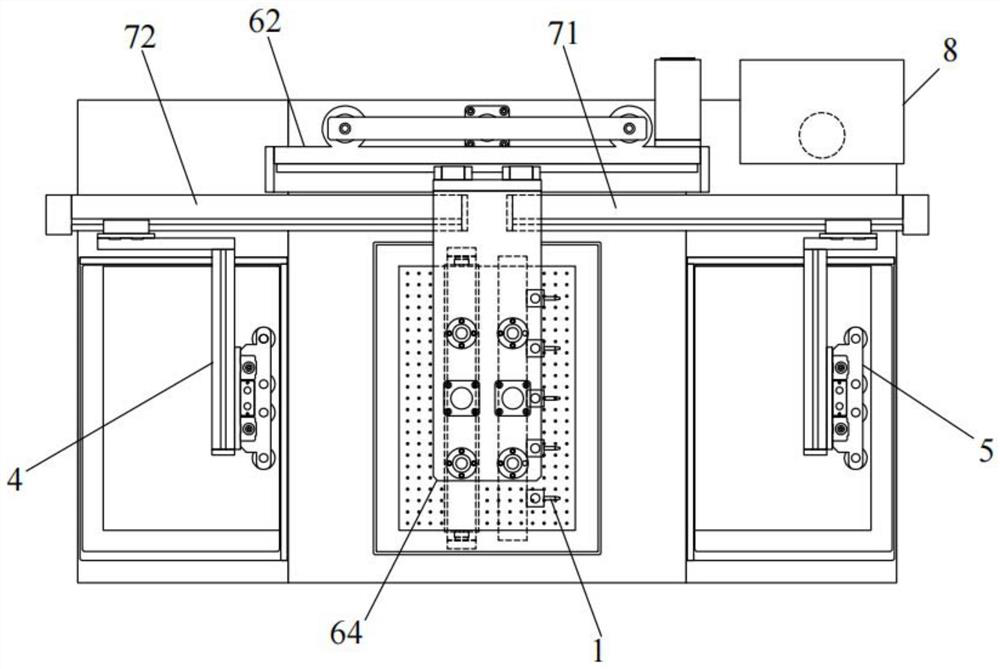

Automatic film tearing machine

The invention relates to the technical field of film tearing machines, in particular to an automatic film tearing machine. The automatic film tearing machine comprises an air blowing mechanism, a waste suction pipe, a hot pressing mechanism, an automatic feeding mechanism, an automatic discharging mechanism, a fixing mechanism and a machine frame, the air blowing mechanism, the hot pressing mechanism and the waste suction pipe are arranged on the fixing mechanism in a sleeving mode through fixing plates, the air blowing mechanism is located on one side of the hot pressing mechanism, the waste suction pipe is located on one side of the air blowing mechanism, the automatic feeding mechanism is arranged on one side of the machine frame, and the automatic discharging mechanism is arranged on the other side of the machine frame. According to the film tearing machine, the air blowing mechanism, the waste suction pipe and the hot pressing mechanism are arranged on the machine frame and matched with one another for film tearing, the product quality is not affected due to the fact that products are not in contact, the film tearing machine can achieve automatic feeding and discharging due to the arrangement of the automatic feeding mechanism and the automatic discharging mechanism, the film tearing machine can work automatically after the automatic feeding mechanism is full of label paper, and the film tearing machine automatically works in the whole process, does not need manual operation, and is high in working efficiency, simple and clear to operate and stable in running performance.

Owner:深圳市恒兴安实业有限公司

Anti-clogging powder feeding device and method for low bulk ratio metal powder products

The invention discloses an anti-blocking powder discharging device and method for low-loose-density metal powder products. The device comprises a decomposer, a middle bin and a produced powder material bin, and the decomposer, the middle bin and the produced powder material bin are sequentially connected from top to bottom; the tops of the middle bin and the produced powder material bin are each provided with an exhausting port; the bottom of the middle bin is provided with a discharging valve; the device further comprises a decomposed gas dust remover, a disinfecting replacement gas dust remover and a dust collecting powder material bin; an inlet of the decomposed gas dust remover is connected with the exhausting port of the middle bin and the exhausting port of the produced powder material bin through pipelines; the top of the dust collecting powder material bin is provided with a dust collecting port and a disinfecting port; an inlet of the disinfecting replacement gas dust remover is connected with the exhausting port of the produced powder material bin and the disinfecting port through pipelines; and the dust collecting port is connected with an outlet of the decomposed gas dust remover and an outlet of the disinfecting replacement gas dust remover through pipelines. The device and method are good in powder discharging smoothness and high in powder product quality.

Owner:JINCHUAN GROUP LIMITED

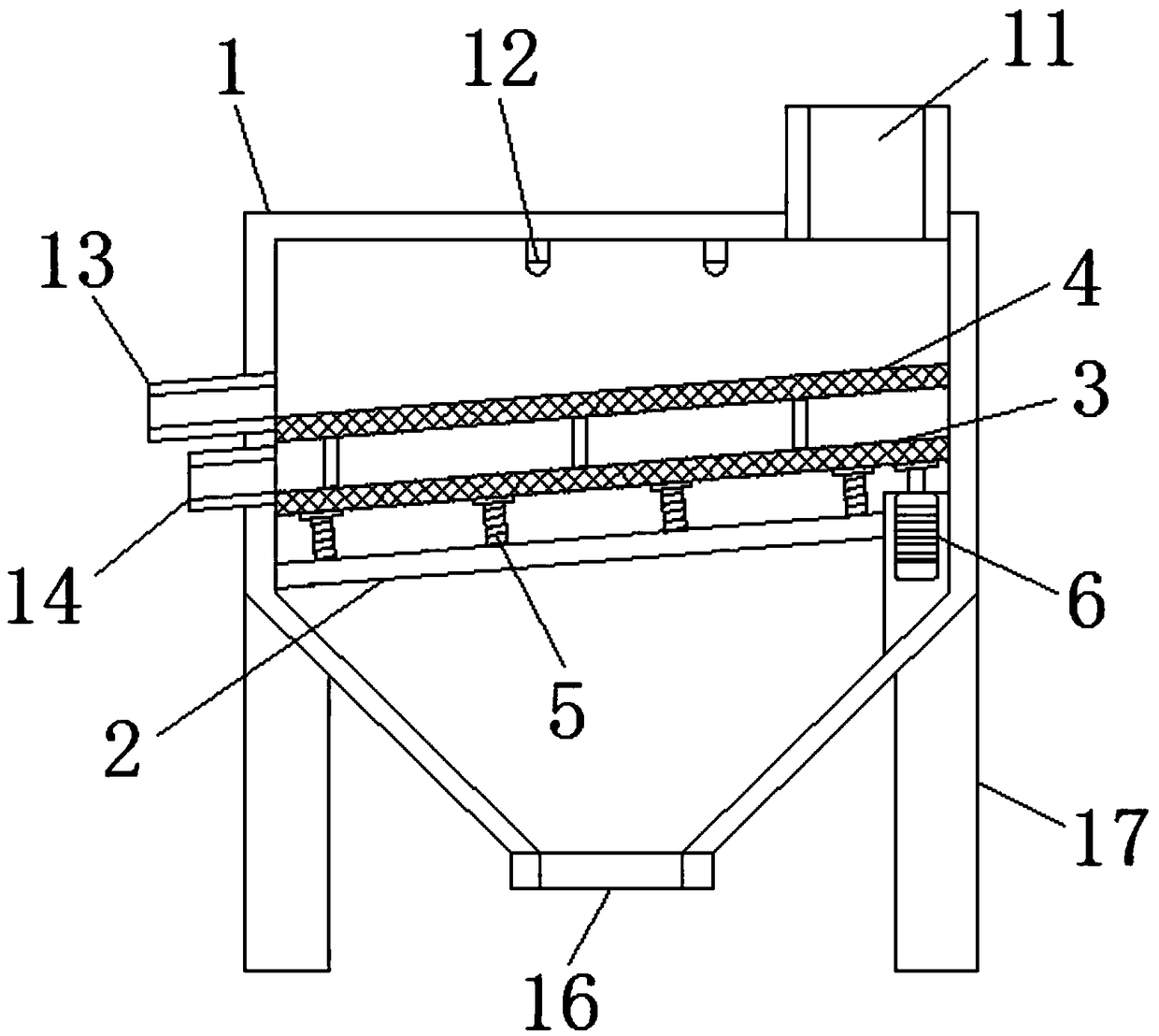

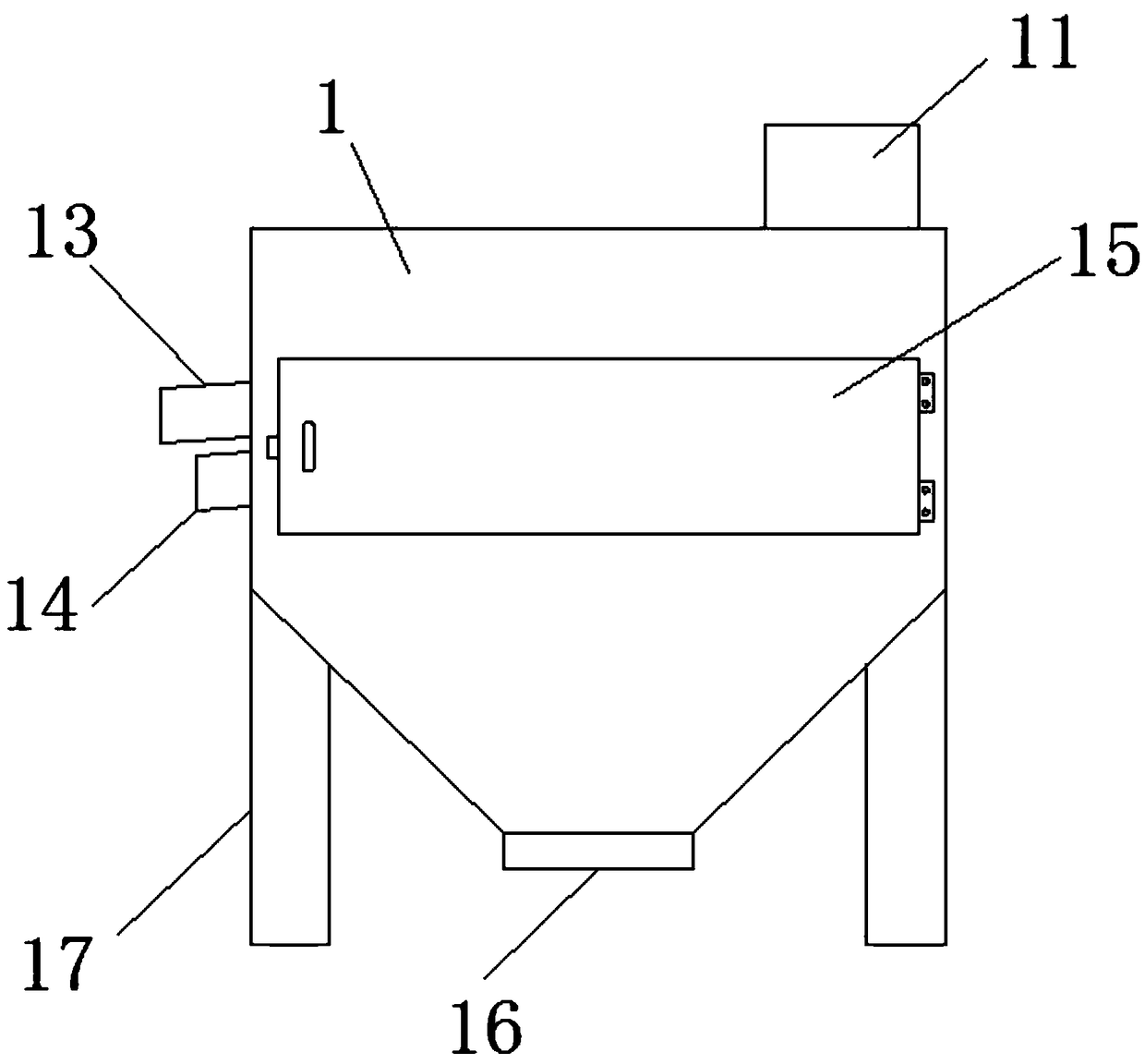

Raw material sieving machine for production of calculus bovis factitius

InactiveCN108311376AEasy to cleanEasy to assemble and disassembleSievingScreeningElectric machineryPulp and paper industry

The invention discloses a raw material sieving machine for production of calculus bovis factitius. The raw material sieving machine comprises a sieving machine main body, a feeding inlet is formed inthe upper end of the sieving machine main body, and two sets of symmetrical supporting plates are arranged in the sieving machine main body; springs are arranged above the two sets of supporting plates correspondingly and fixedly connected with a first sieving plate through connecting blocks; the upper side of the first sieving plate is fixedly connected with the lower side of a second sieving plate through connecting rods; and a vibrating motor is arranged on the lower portion of one end of the first sieving plate, and one end of an output shaft of the vibrating motor is fixedly connected with the lower portion of one end of the first sieving plate through a connecting block. According to the raw material sieving machine for production of the calculus bovis factitius, the vibrating motoris utilized to provide vibration force for the two sieving plates, sieving operation of raw materials is achieved, the first sieving plate and the connecting block are fixed by adopting a clamping connection mode, and an operator can conveniently dismount and mount the sieving plates for clearing the sieving plates through the position of a mounting door; and a spraying head is arranged in the sieving machine, and the interior of the sieving machine is flushed through the spraying head.

Owner:武汉百草园生化药业有限公司

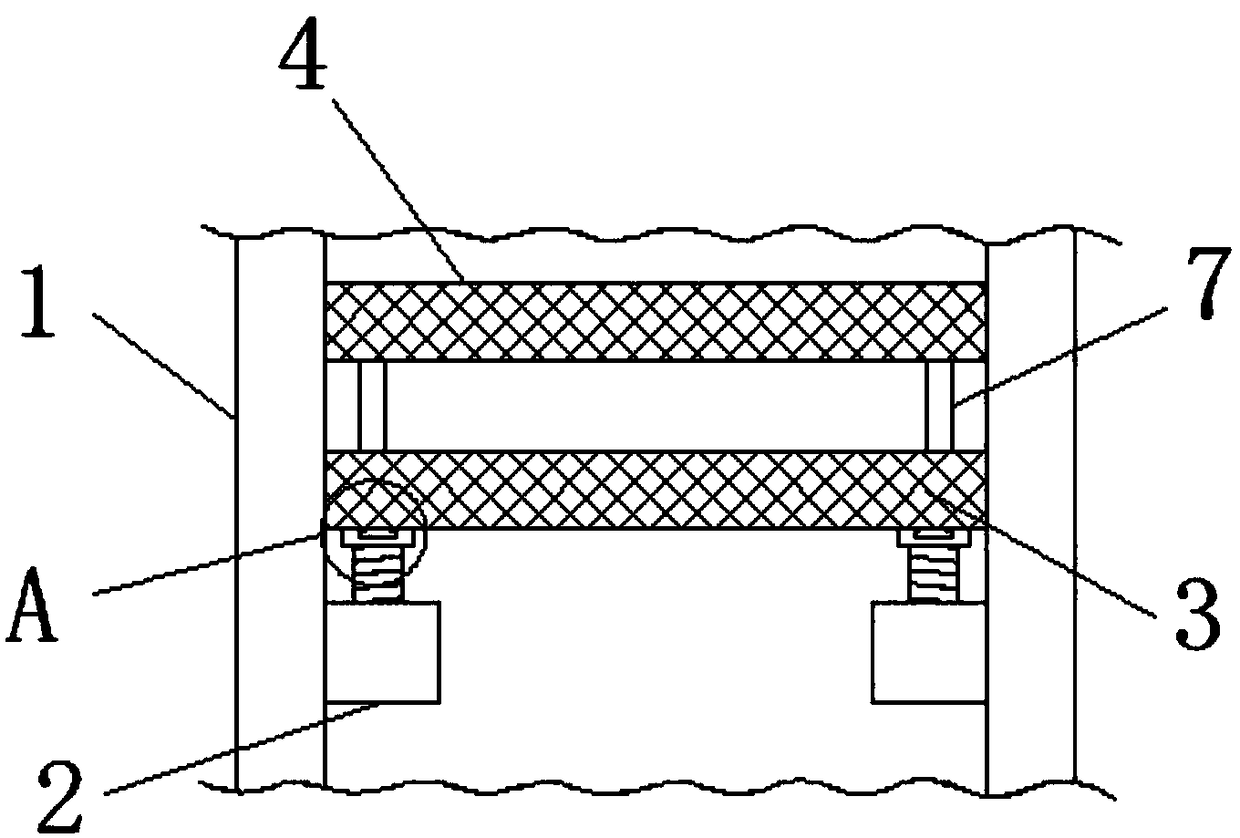

Belt-shape moving body tension differential adjusting and correction method and device therefor

InactiveCN100366517CAdjust the tensioning pressure in timeTo achieve the purpose of correctingWebs handlingState of artBand shape

Owner:大连经济技术开发区排水管理有限公司

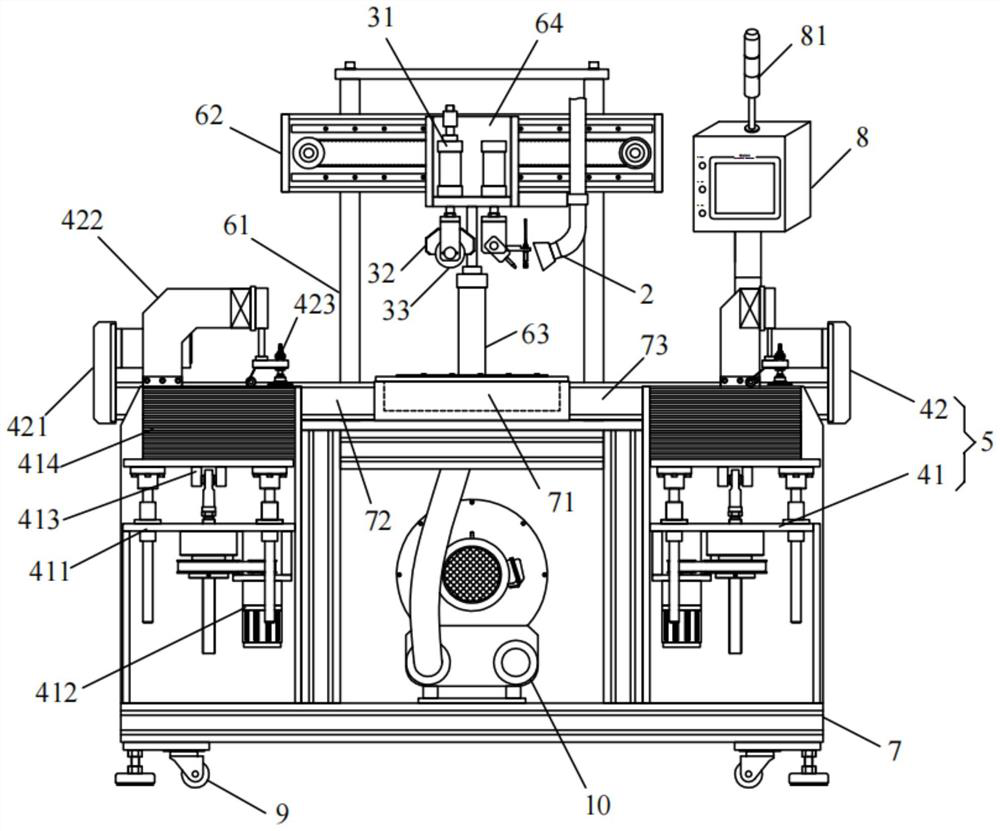

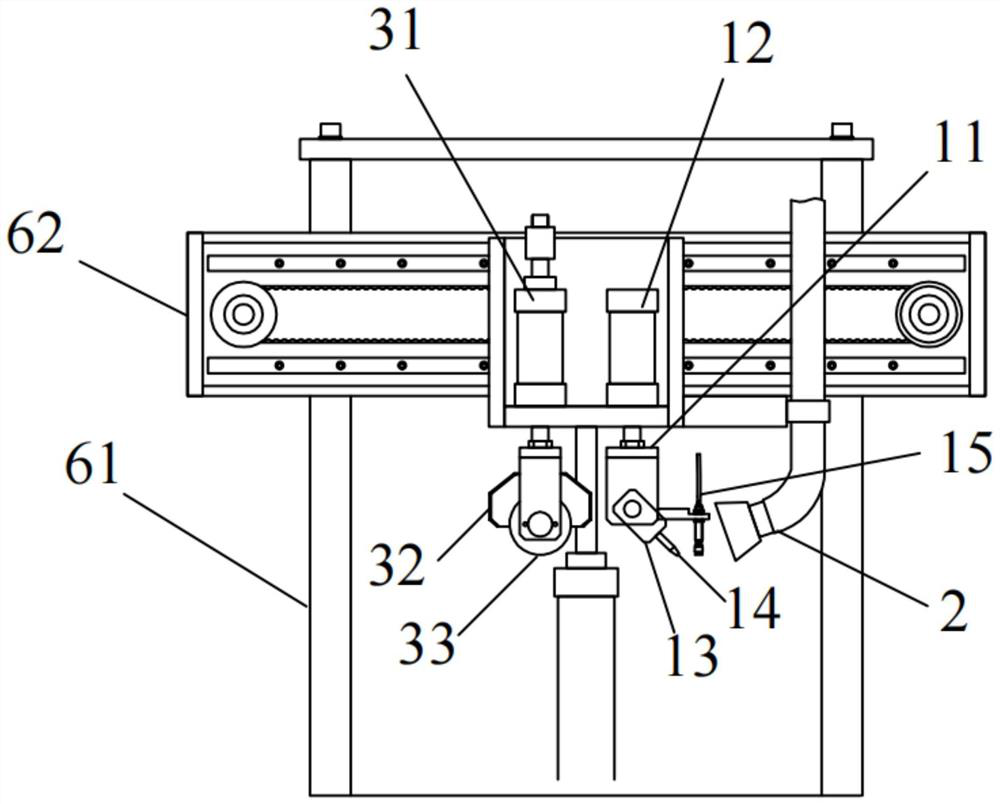

An automatic cutting system

ActiveCN113458820BEasy to collectSave spacePositioning apparatusMaintainance and safety accessoriesHydraulic cylinderWaste collection

The invention discloses an automatic cutting system, which comprises a workbench, a hydraulic cylinder, a supporting device arranged on one side of the workbench and in contact with the ground, and a support device arranged on the other side of the workbench and capable of sliding on the workbench The driving device, the first waste collecting device connected to the driving device, the second waste collecting device set at the limit position when the driving device slides and fixed on the workbench; the hydraulic cylinder includes an adjustable preload assembly; by setting The support device can support parts of different sizes; the first waste collection device and the second waste collection device are set up to collect waste and discard them regularly during collection to keep collecting waste The inside of the first collection box is clean, which makes the collection of waste chips better. The present invention improves the degree of automation by automatically realizing the collection and cleaning of waste chips.

Owner:绍兴上虞舜宏化工设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com