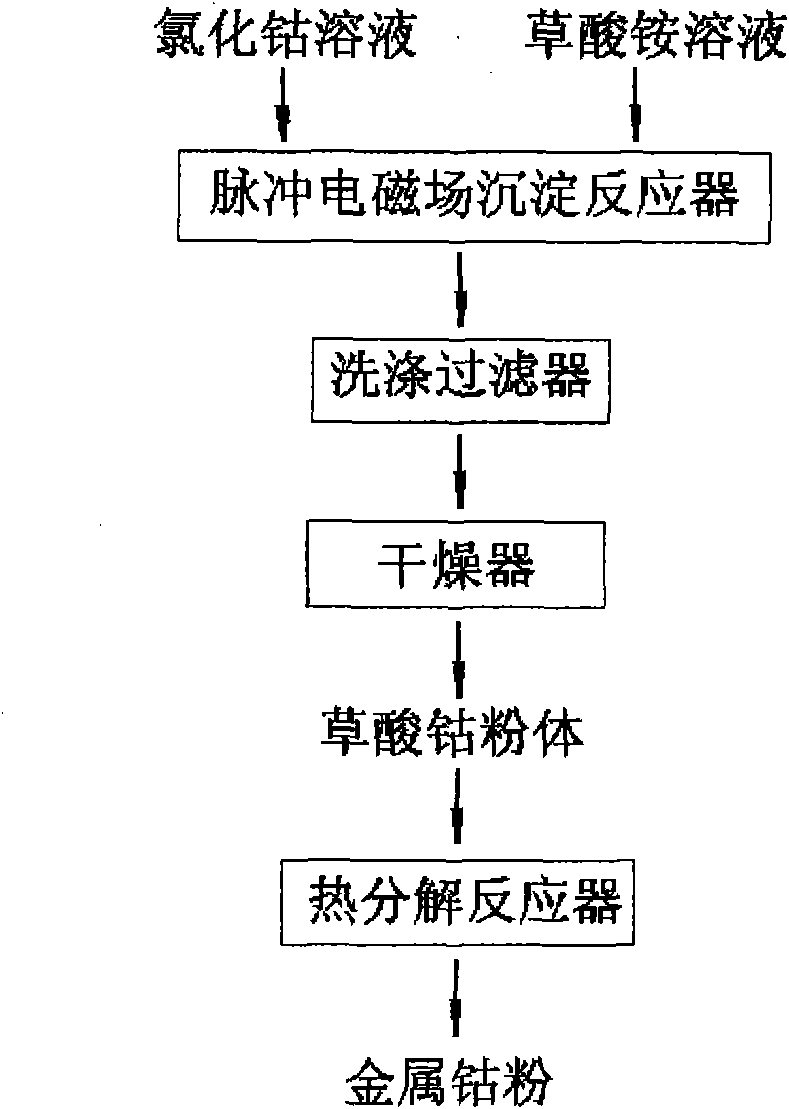

Method for preparing cobalt oxalate by pulse electromagnetic field

A pulsed electromagnetic field, cobalt oxalate technology, applied in the preparation of carboxylate, organic chemistry and other directions, can solve the problems of irregular morphology, low yield, high cost, reduce material flow and wastewater treatment volume, reduce production costs, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

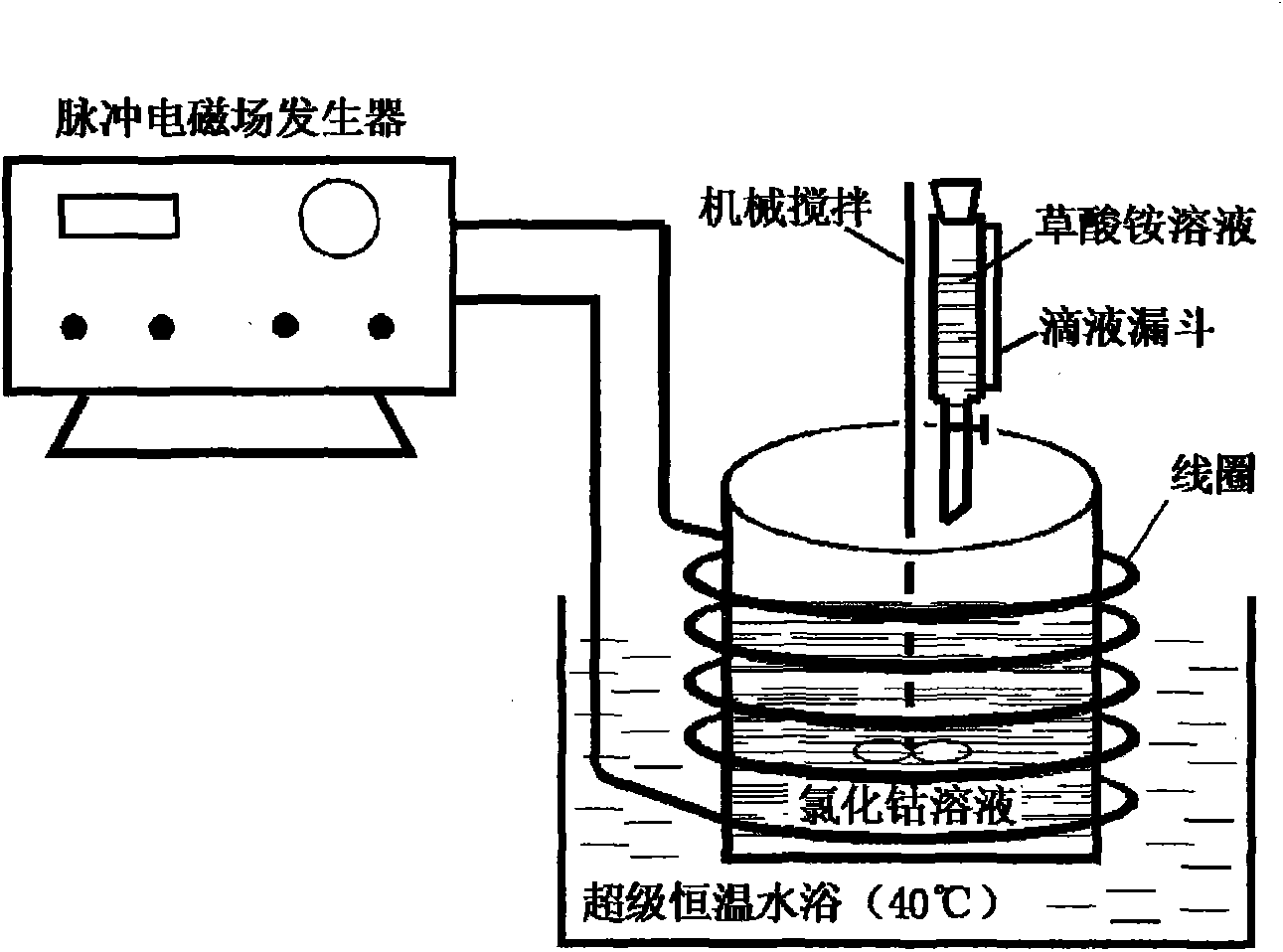

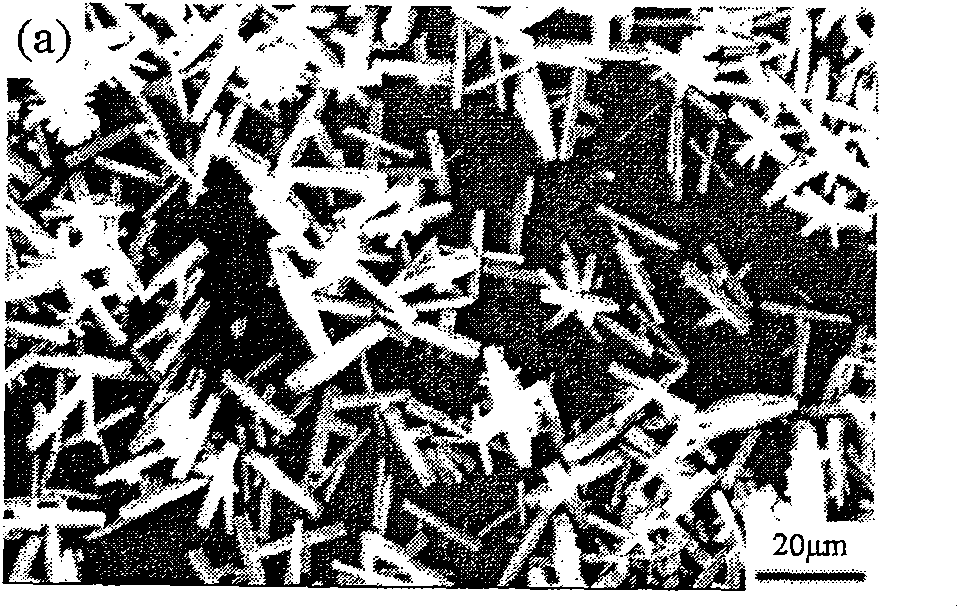

Embodiment 1

[0027] Use a dropping funnel to acidify (pH=5) (NH 4 ) 2 C 2 O 4 Add CoCl to the solution 2 In solution, (NH 4 ) 2 C 2 O 4 With CoCl 2 The molar ratio is 1.5:1, and the dropping rate is controlled at 150ml / min. The reaction is carried out in a super constant temperature water bath at 35℃. During the reaction, mechanical stirring is applied and pulse electromagnetic field treatment is applied to the reaction system at the same time. The specific operation is to cover the coil outside the reaction vessel and connect both ends of the coil to the output terminal of the pulse electromagnetic field generator. , The pulse voltage is 600-800v, the pulse frequency is 1-10Hz, and the pulse current is passed into the coil. After the reaction is completed, the precipitate is filtered, washed with deionized water, and dried under vacuum at room temperature for 26 hours to obtain a sample of cobalt oxalate. Weigh 6g of cobalt oxalate sample and place it in a tubular resistance furnace, heat i...

Embodiment 2

[0029] Use a dropping funnel to acidify (pH=4) (NH 4 ) 2 C 2 O 4 Add CoCl to the solution 2 In solution, (NH 4 ) 2 C 2 O 4 With CoCl 2 The molar ratio of is 1:1, and the dropping rate is controlled at 100ml / min. The reaction is carried out in a super constant temperature water bath at 20°C. During the reaction, mechanical stirring is applied and pulse electromagnetic field treatment is applied to the reaction system at the same time. The specific operation is to cover the coil outside the reaction vessel and connect both ends of the coil to the output terminal of the pulse electromagnetic field generator. , The pulse voltage is 1v, the pulse frequency is 1Hz, and the pulse current is passed into the coil. After the reaction is completed, the precipitate is filtered, washed with deionized water, and dried under vacuum at room temperature for 30 hours to obtain a sample of cobalt oxalate. Weigh 6g of cobalt oxalate sample and place it in a tubular resistance furnace, heat it to 430℃...

Embodiment 3

[0031] Use a dropping funnel to acidify (pH=6) (NH 4 ) 2 C 2 O 4 Add CoCl to the solution 2 In solution, (NH 4 ) 2 C 2 O 4 With CoCl 2 The molar ratio is 2:1, and the dropping rate is controlled at 200ml / min. The reaction is carried out in a super constant temperature water bath at 40℃. During the reaction, mechanical stirring is applied and pulse electromagnetic field treatment is applied to the reaction system at the same time. The specific operation is to put the coil outside the reaction vessel and connect the two ends of the coil to the output terminal of the pulse electromagnetic field generator. , The pulse voltage is 1000v, the pulse frequency is 100Hz, and the pulse current is passed into the coil. Pulse voltage: 1000v; pulse frequency: 100Hz. After the reaction is completed, the precipitate is filtered, washed with deionized water, and dried under vacuum at room temperature for 24 hours to obtain a sample of cobalt oxalate. Weigh 6g of cobalt oxalate sample and place it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com