Furnace lid for manufacturing titanium sponge

A technology of sponge titanium and furnace cover, which is applied in the field of furnace cover for the production of sponge titanium, can solve the problems of cumbersome manufacturing methods, poor heat insulation effect, poor deformation ability, etc., so that the product quality is not threatened, the temperature is lowered, and pollution is avoided Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

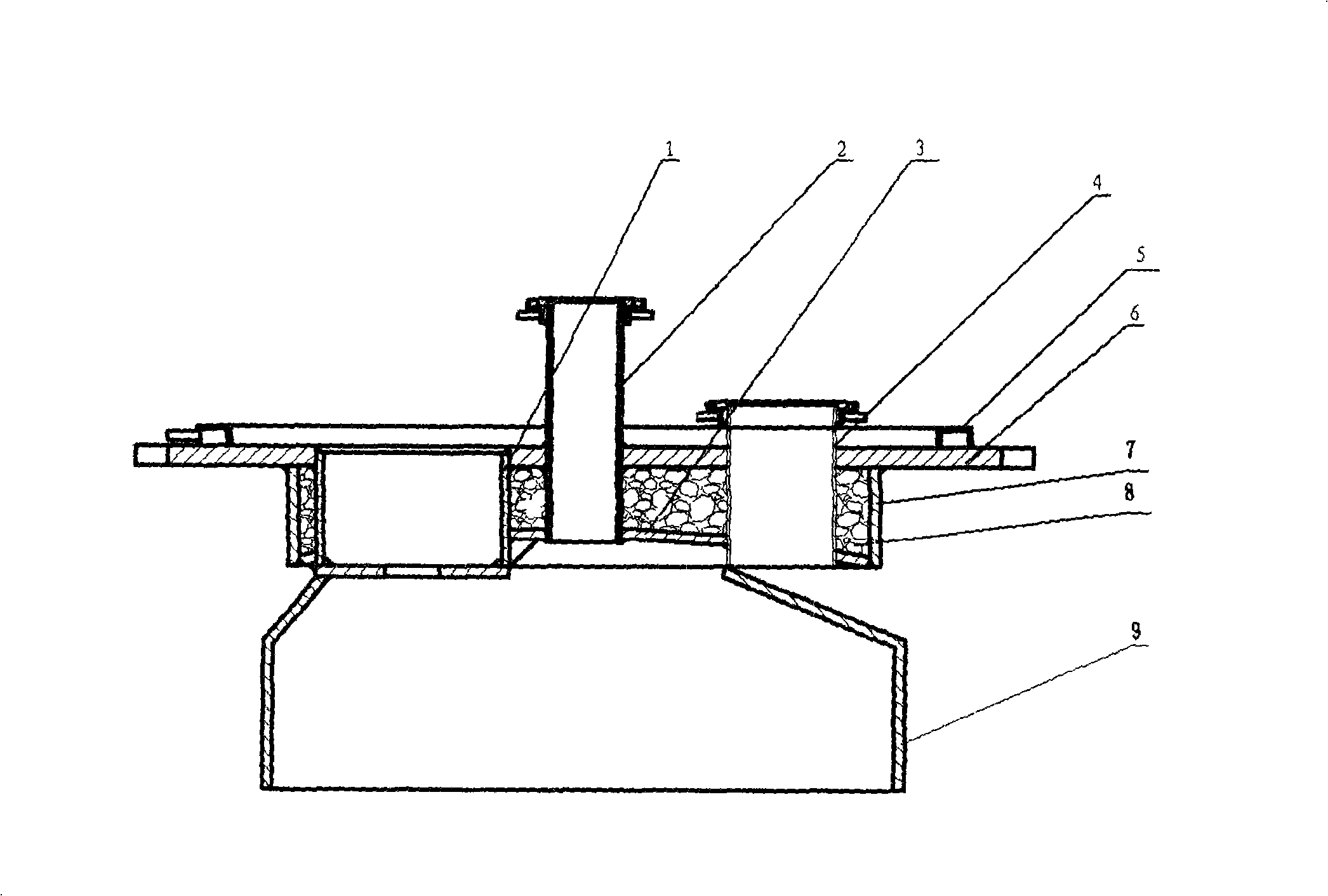

[0013] A furnace cover for producing titanium sponge, which comprises a cylinder body 7, a panel 6 installed on the cylinder body 7, a bottom plate 3 below the cylinder body 7, a cooling water ring 5 is installed on the top of the panel 6, and on the furnace cover The aisle casing 1, the feeder casing 2 and the vacuum pipeline casing 4 are installed, which penetrate through the panel 6 and the bottom plate 3 of the furnace cover, and the cavity enclosed by the panel 6, the bottom plate 3 and the cylinder 7 is filled with thermal insulation material 8 ——Zirconium-containing plug cotton (also known as zirconium-containing ceramic cotton), the bottom plate 3 of the furnace cover is in the shape of an upwardly arched spherical surface, and a sleeve 9 is installed under the bottom plate 3 of the above-mentioned furnace cover, so that the aisle casing 1 and feeding The device sleeve 2 is placed inside the sleeve 9 , and the vacuum line sleeve 4 is placed outside the sleeve 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com