Patents

Literature

32results about How to "Pure hair color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

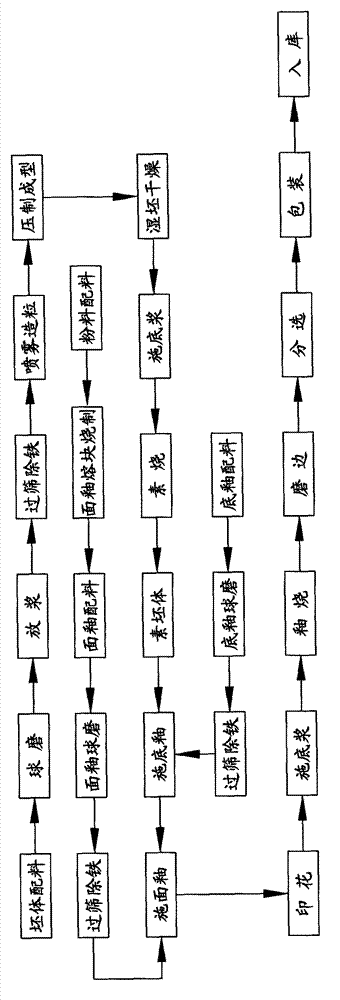

Formula and preparation method of national flag bright red glazed brick

The invention relates to a formula and preparation method of a national flag bright red glazed brick. On the basis of not changing the existing glazed brick production technique too much, the invention mainly adjusts and optimizes the composition of blank materials, the composition of base / cover coating fused blocks, the preference and proportion of the fused blocks having different properties in base / cover coating, the processing technique of the cover coating, the formula composition of the base coating, the water absorptivity of a biscuit, the firing temperature and the like, thereby ensuring that the fired national flag bright red glazed brick has a dazzlingly beautiful glaze color, is bright like a reflective mirror, and has a high decorative effect and an artistic aesthetic effect; and the color is as pure as the color of a national flag and is glossy and bright, so that the national flag bright red glazed brick can shine like the rising sun. Meanwhile, the technology has high universality, and is readily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +1

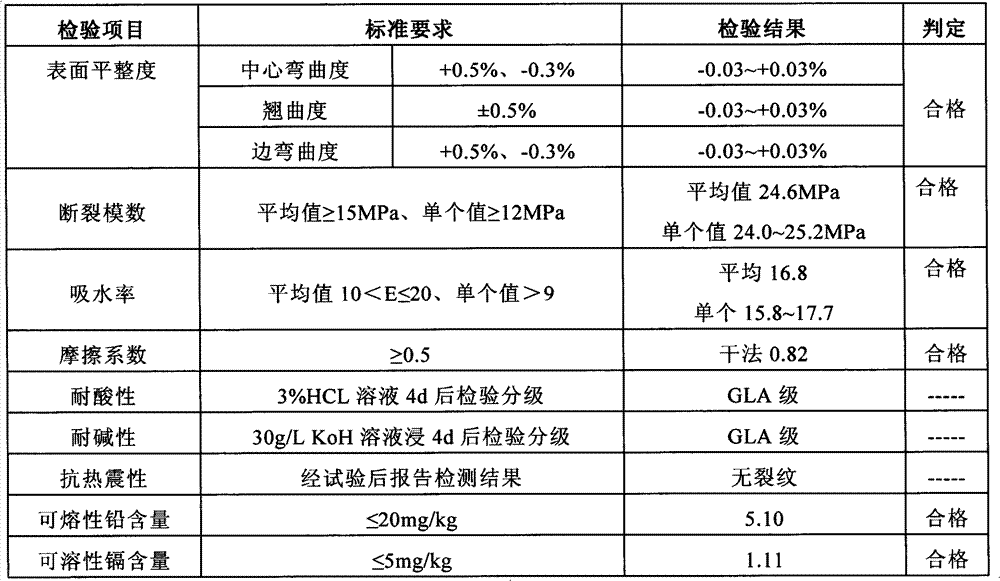

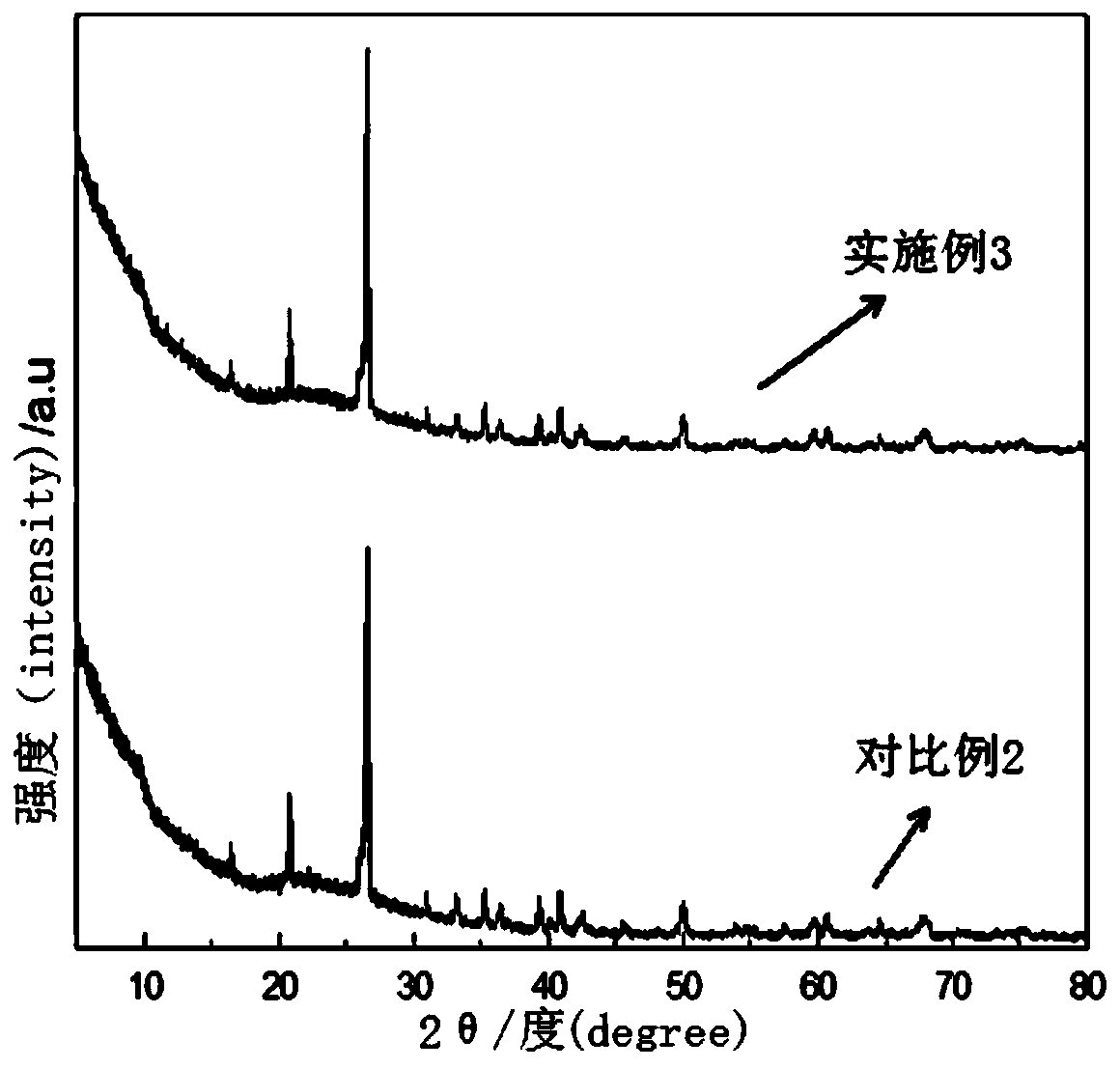

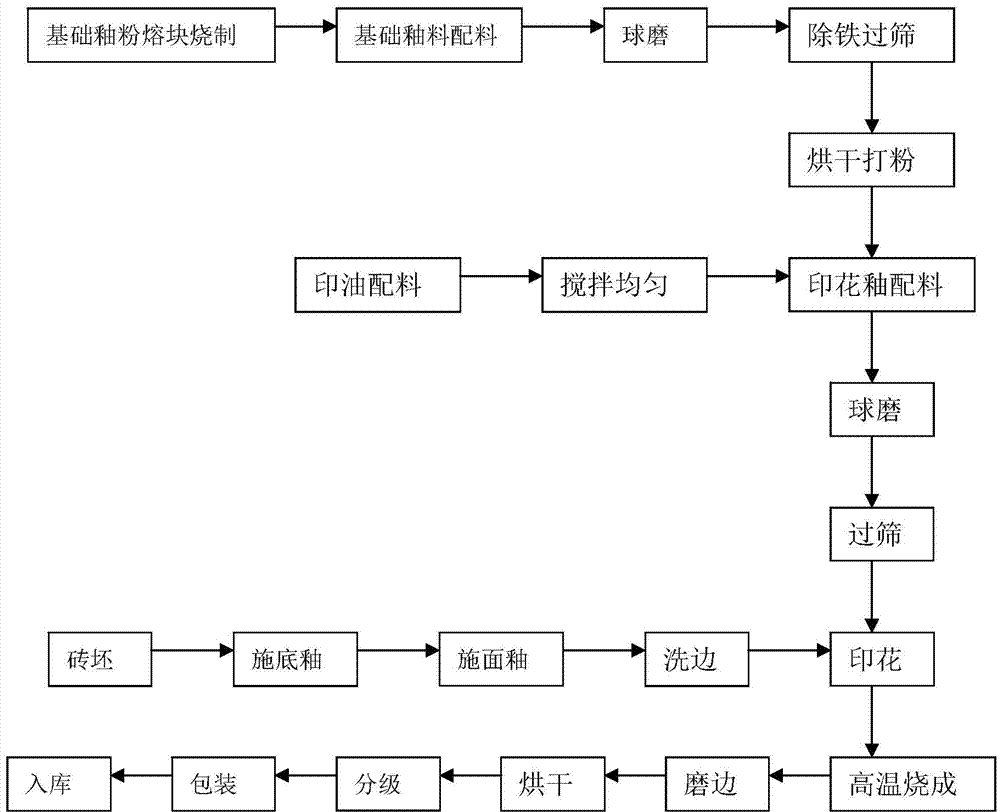

High-temperature bright-red printing glaze, preparation method and preparation method of glazed tile

The invention relates to high-temperature bright-red printing glaze, its preparation method and a preparation method of a glazed tile. On the basis of not making big changes on a present glazed tile production technology, emphasis is put on adjustment and optimization of composition of printing basic glaze powder, composition of frit in the printing basic glaze powder, optimization and ratio of frits with different properties, composition of stamp-pad ink, processing technology of printing glaze, engraving mode of a rubber covered roller, mesh number of a screen printing plate and the like. Thus, the color of the surface of a high-temperature sintered glazed tile imprinted with the single printing glaze is bright, pure, glossy and shiny and is typical bright red. When the printing glaze is alternately printed with a printing glaze of other colors, the color on the surface is bright, pure, wide in color gamut and colorful, can be compared favorably with colors in the fields of fabrics, wallpaper, advertisement design, and has strong decorative effect and aesthetic feeling. Meanwhile, the technology has high universality and is easy to popularize in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

High-temperature domestic porcelain metallic bright glaze and product decorated by same

The invention relates to a high-temperature domestic porcelain metallic bright glaze and a product decorated by the same. The bright glaze produced by using natural mineral raw materials and industrial pure raw materials comprises the following materials by weight percent: 10-25 percent of potassium feldspar, 10-30 percent of albite, 0-35 percent of quartz, 0-10 percent of barium carbonate, 0-10 percent of wollastonite, 0-10 percent of kaolin, 0-5 percent of zinc oxide, 1-10 percent of aluminum oxide, 1-10 percent of bone ash, 1-5 percent of purple clay and 10-35 percent of ferric phosphate, and the glaze is obtained by mixing, ball-milling and screening the raw materials. The fabrication technology of the glaze is basically the same as the common porcelain glaze, the cost is low, not only can the pure color be guaranteed through redesigning of the formula of the glaze, but also the burning temperature of the glaze is increased to 1380 DGE C, so that the decoration effect of domestic porcelain is greatly enriched, and the high-temperature domestic porcelain metallic bright glaze has wide application prospect.

Owner:HUNAN KARPERY INDAL +1

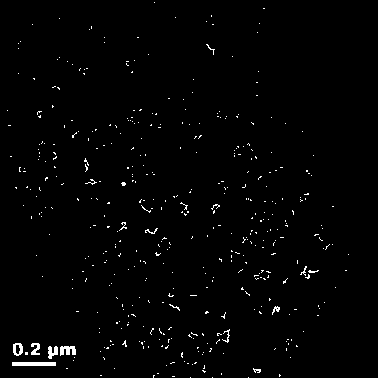

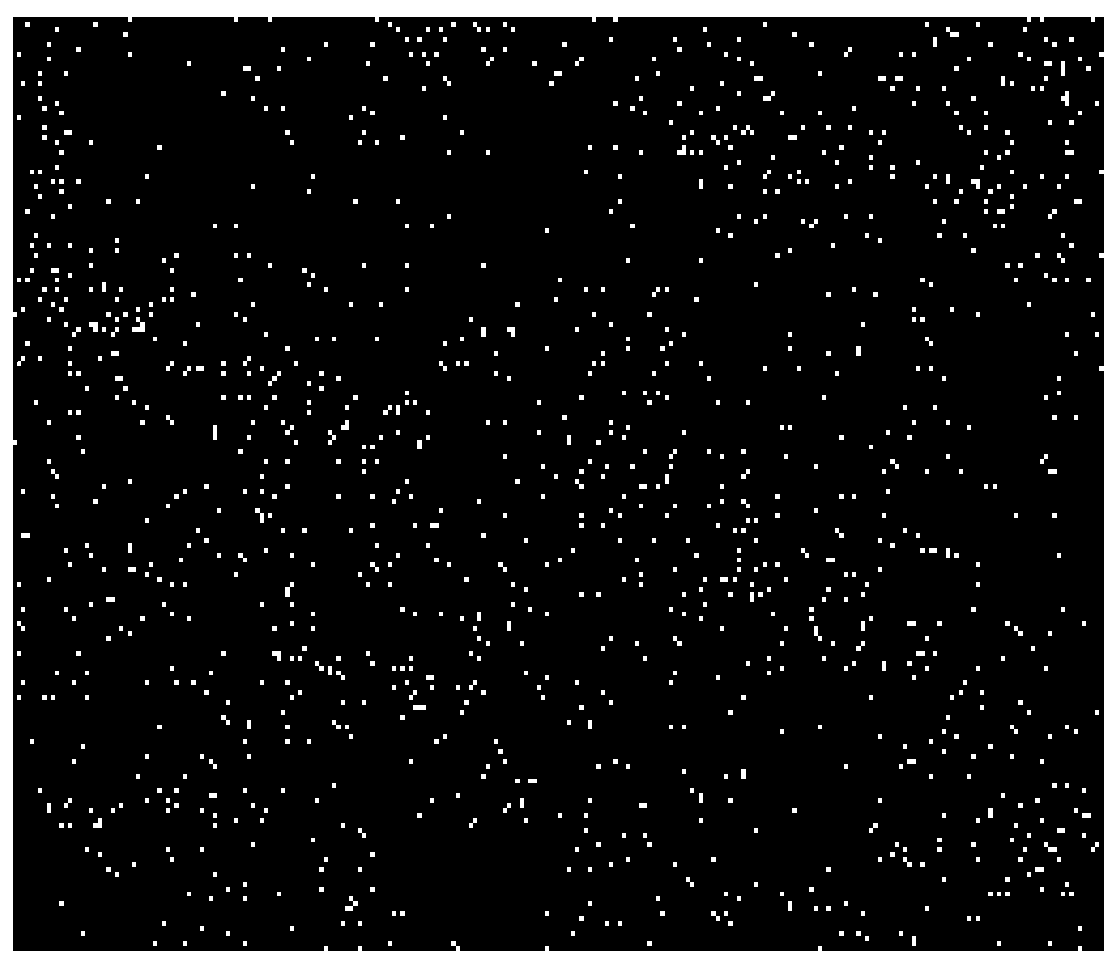

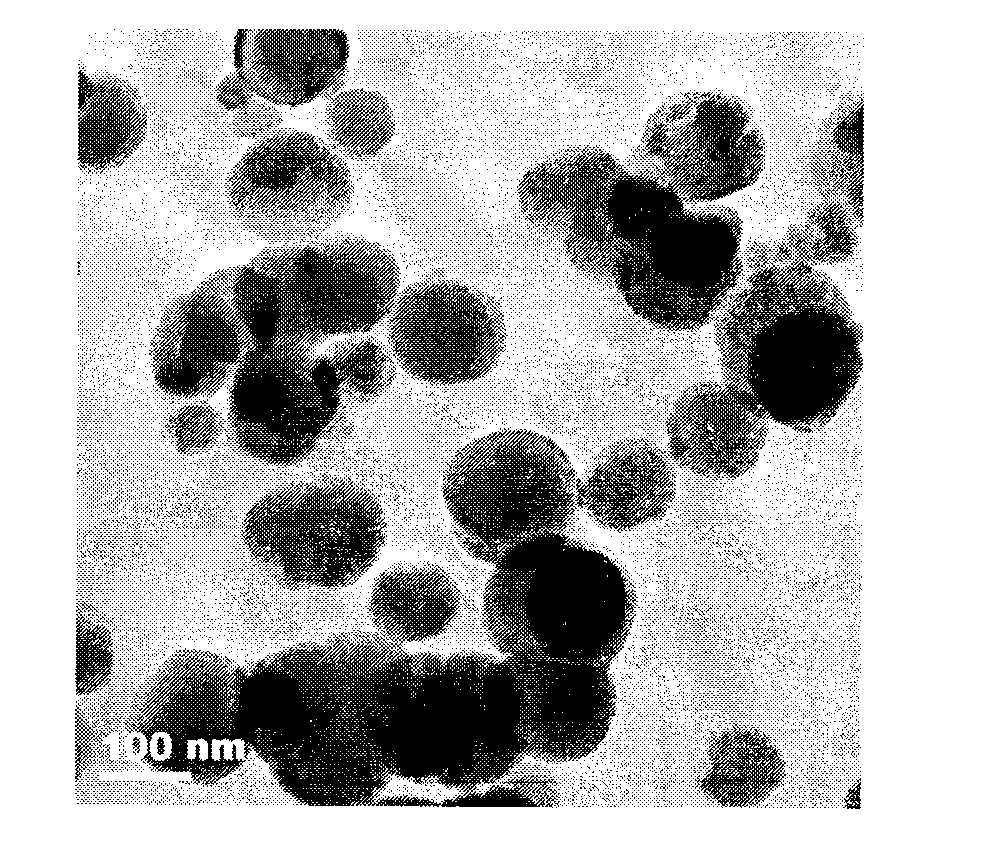

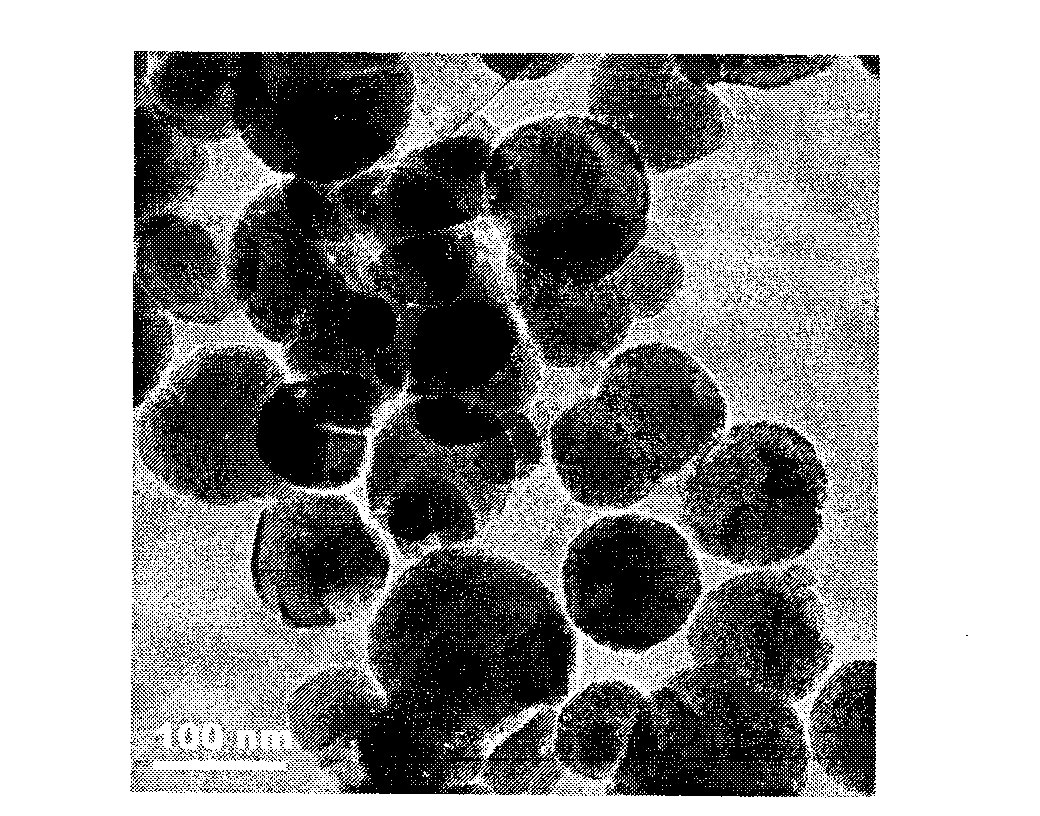

Process for preparing spherical nanometer spinel zaffre by hydrothermal method

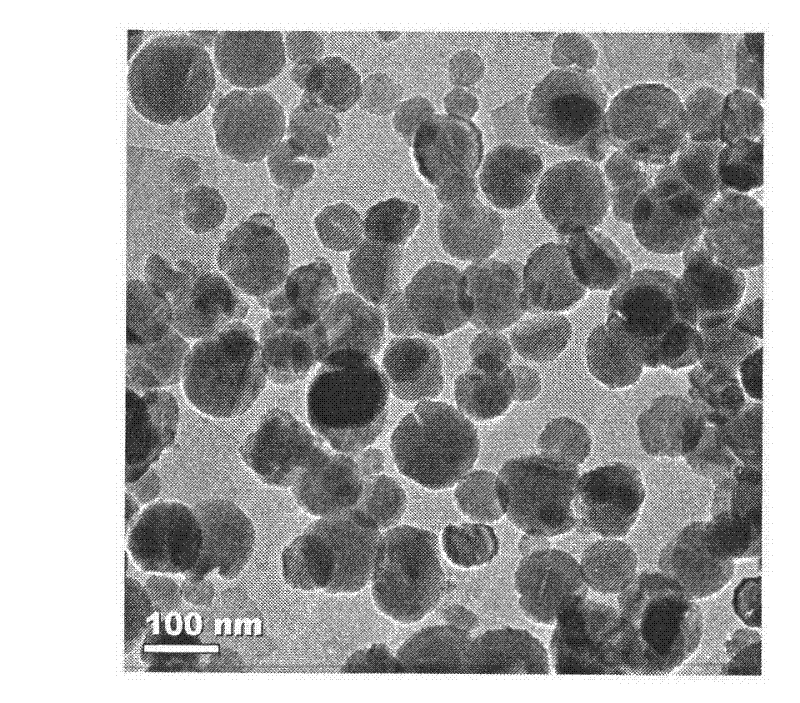

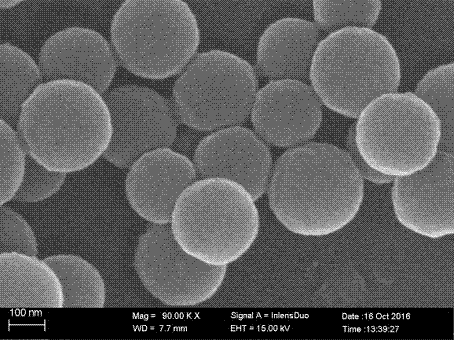

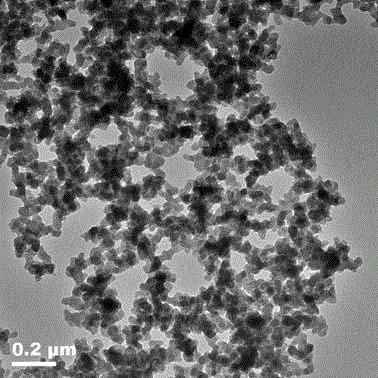

The invention discloses a process for preparing spherical nanometer spinel zaffre by the hydrothermal method. The process comprises the following steps: weighing and putting cobalt chloride and aluminum chloride according to a mol ratio of Co<2+> : Al <3+> = 1:2, putting the materials into a beaker, adding a proper amount of deionized water and carrying out uniform stirring on a magnetic stirrer;adding a sodium hydroxide solution drop by drop until the pH value of the mixture in the beaker is 13 and continuing stirring; adding mixed liquor of triethanolamine and glycerol with a volume fraction of 6 to 18% and resuming stirring; carrying out hydrothermal cultivation on the mixed solution at a temperature of 245 DEG C for 20 to 40 hours and taking the mixed solution out for natural coolingat room temperature; repeatedly rinsing the hydrothermal cultivation resultant material in liquid phase until the pH value equals 7 and putting the resultant material into a baking oven for drying attemperature of 60 DEG C so as to obtain spherical products with particle size less than 100 nm. The advantages of the invention are as follows: liquid phase hydrothermal cultivation is employed and composite organic matters are added; therefore, nanometer spherical powder is formed directly without calcining, energy consumption is relatively low, and no environmental pollution is generated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

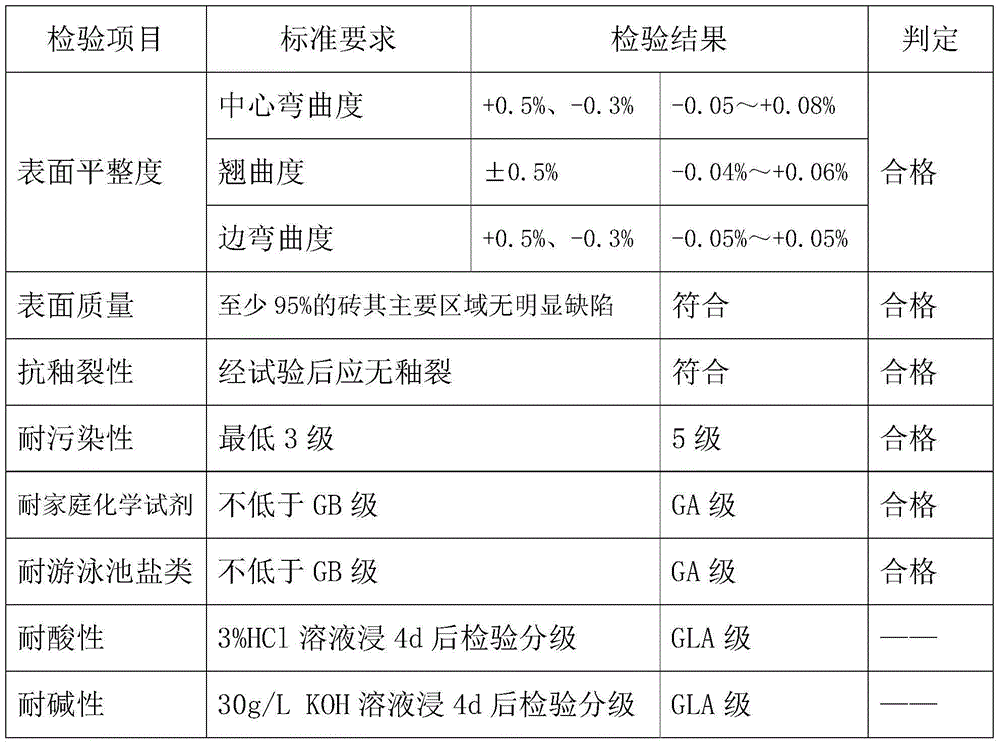

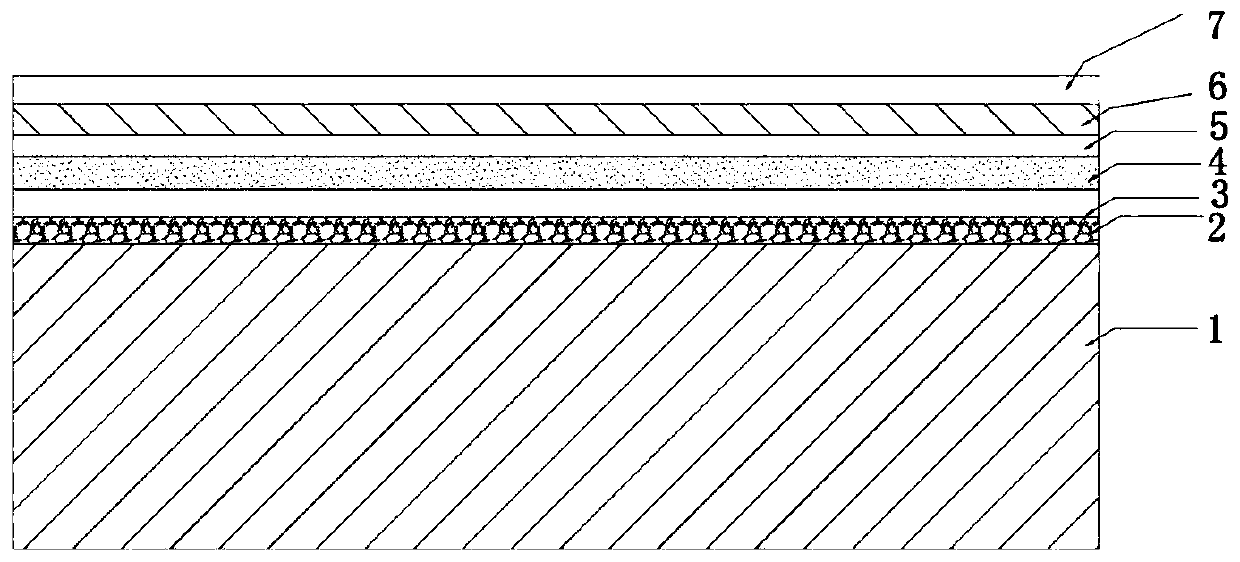

Luxurious stone glaze ceramic tile and production method thereof

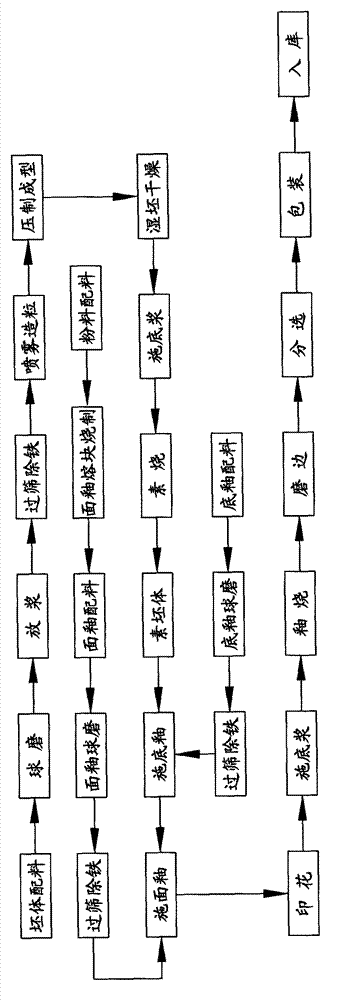

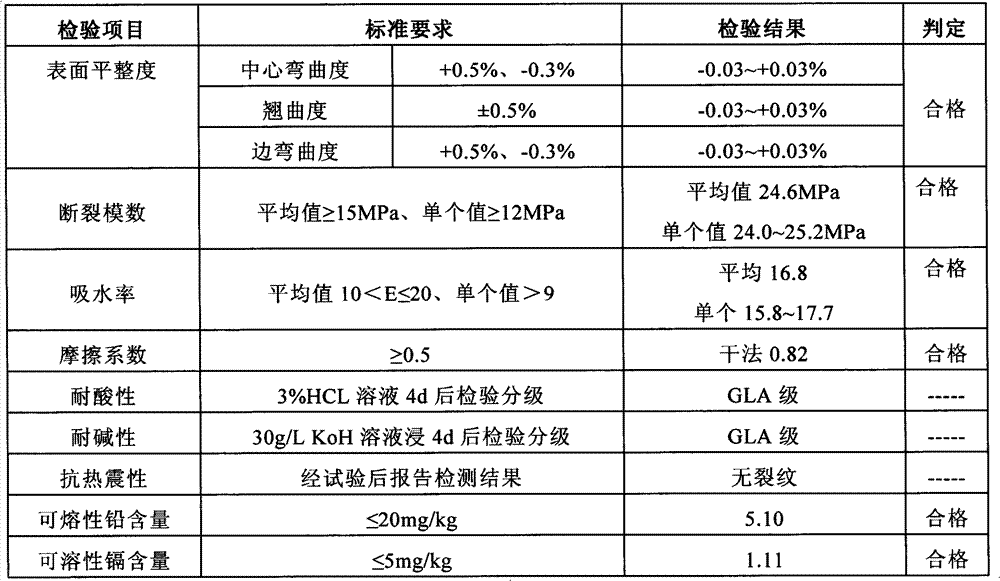

The invention relates to a luxurious stone glaze ceramic tile and a production method thereof. The method comprises the steps that engobe, ground glaze, ink permeation resistant oil, a pattern layer,an isolation layer and a protective glaze layer are sprayed to the surface of a green body layer in sequence, then the ceramic tile obtained in the above steps is subjected to high-temperature firingto prepare the luxurious stone glaze ceramic tile, wherein the thickness of the glaze layer in the stone glaze ceramic tile is 0.5-1.0 mm; in the ceramic tile, permeation and diffusion of ink are controlled through a special glaze formula in combination with the ink permeation-resistant layer and the isolation layer, which have an isolation effect, so that a fine and high-definition glazed ceramictile is obtained, and the smooth texture and effect are introduced into a ceramic tile product. The luxurious ceramic tile is smooth and fine in glaze surface, is pure in color development, has clearlines, has antifouling and wear-resisting properties, and is a ceramic tile product with great practical value.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

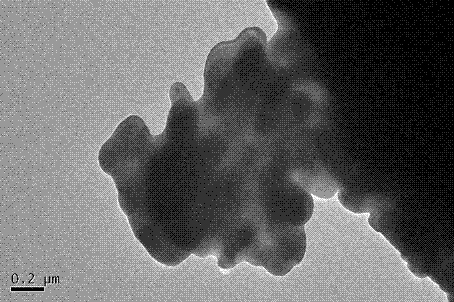

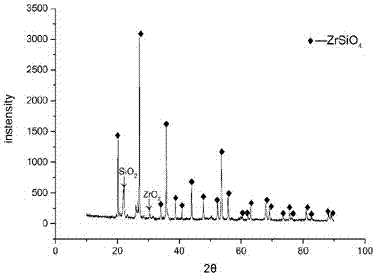

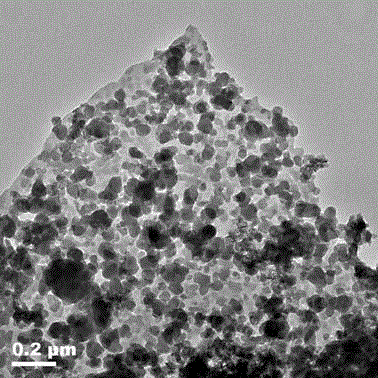

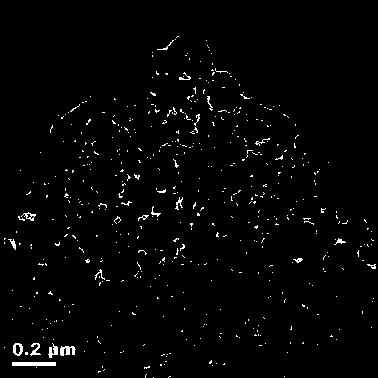

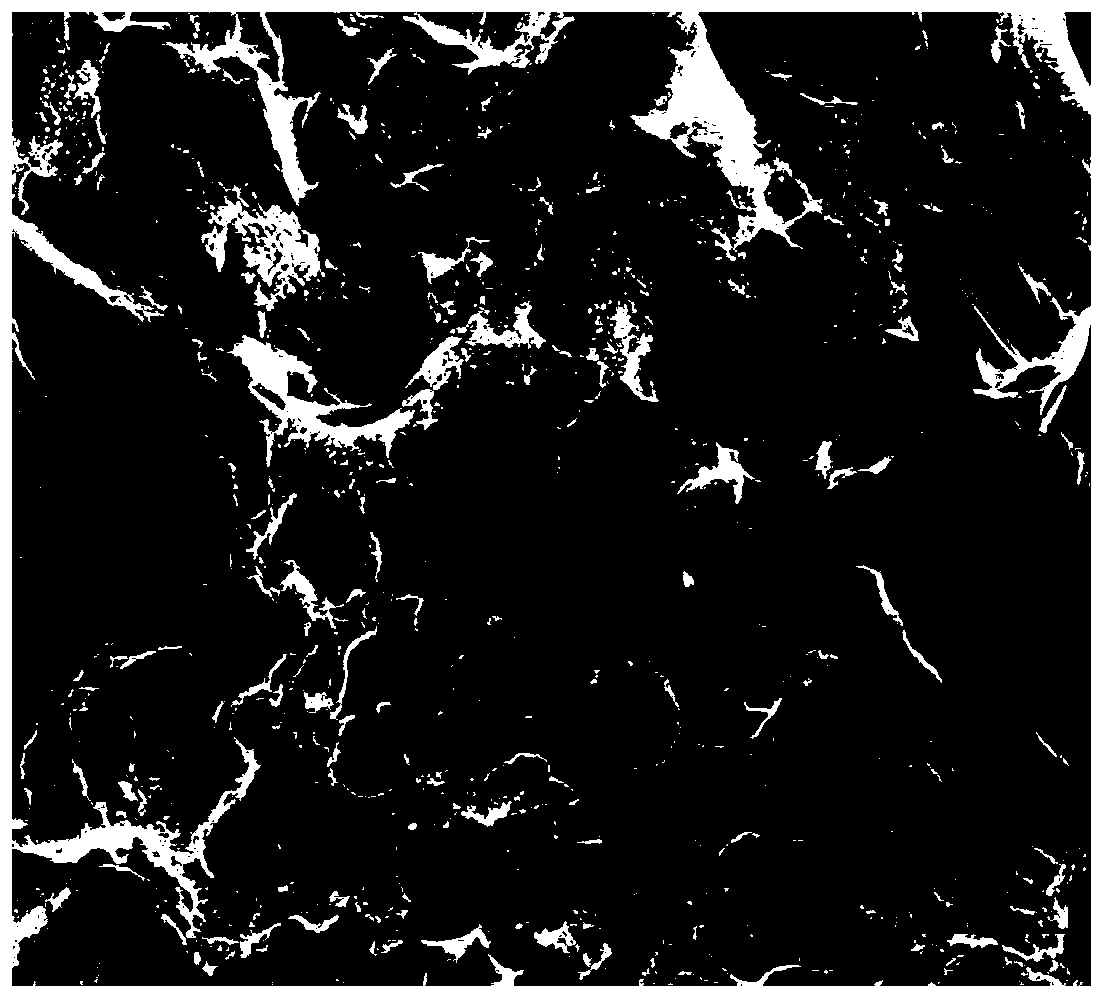

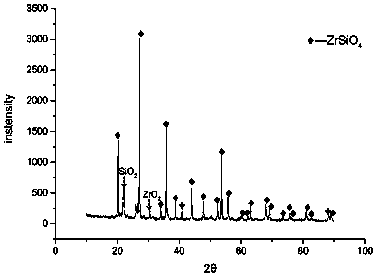

Method for preparing zirconium silicate coated carbon nanosphere ceramic black pigment

The invention discloses a method for preparing a zirconium silicate coated carbon nanosphere ceramic black pigment. The method is characterized in that carbon nanospheres prepared from a biomass raw material by a hydrothermal method replace a traditional carbon source, the hydrophilicity is improved by use of rich oxygen-containing functional groups on the surfaces of the carbon nanospheres and the negative potential state, and the dispersity of the carbon source is enhanced; the thickness of wrappers of the carbon nanospheres and the electrostatic adsorption capability are adjusted and controlled to enable a zirconium silicate precursor to tightly wrap the carbon nanospheres; and under the action of a mineralizer, the ceramic black pigment in which zirconium silicate wraps the carbon nanospheres is prepared after high-temperature calcination. In the experiment process, through optimization and control of such conditions as the addition of glucose, the hydrothermal temperature, the hydrothermal time, the silicon-zirconium ratio, the stirring time of the precursor, type and consumption selection of the mineralizer and a firing system, the synthesized black pigment is pure in color, uniform in particle size and stable in performance, can be used in various high-temperature ceramic glazes, and has a high economical value.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Preparation method for colorful flame candle

The invention discloses a preparing method of candle with colored flame, including steps: a. preparing burning core of candle; b. preparing colored core of candle; c. making main igniting agent of candle; d. forming candle. The invention using polyglycol (molecular weight is 20000) as forming modifier of candle to reduce preparing cost and not reduce anticipating effect of candle. The invention using alkali as degreaser to degrease to increase amount of colour fixatives absorbed on cotton, getting more pure colour.

Owner:SHANGHAI INST OF TECH

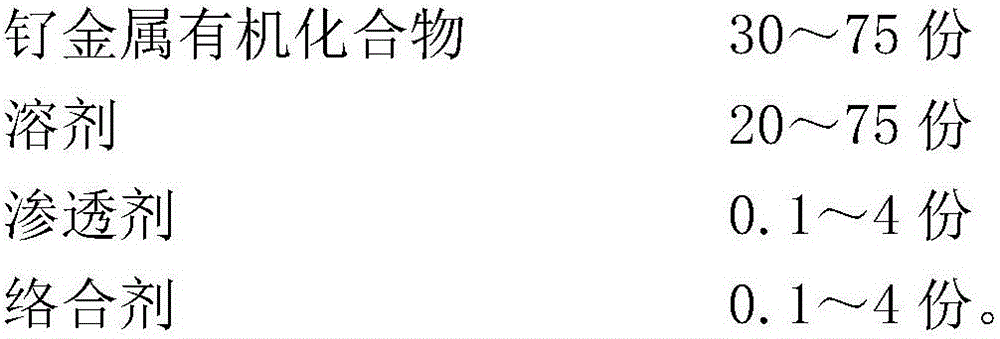

Ink for color-penetrated ceramics and preparation method of ink for color-penetrated ceramics

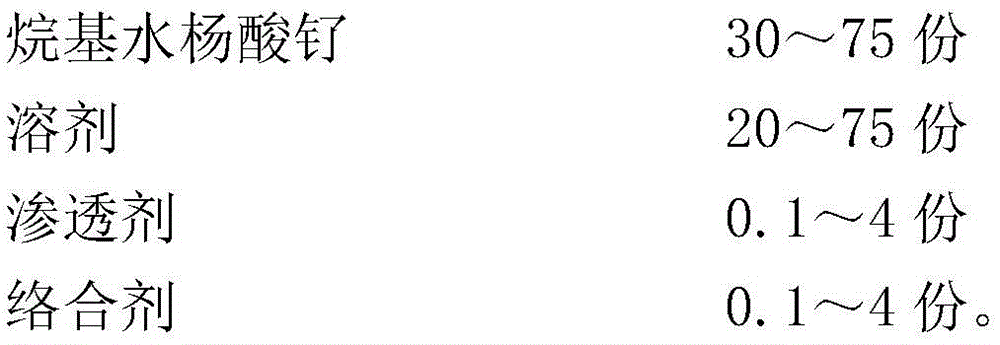

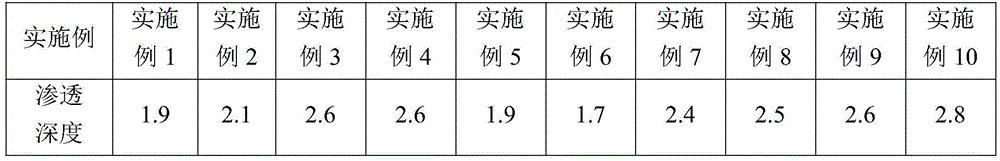

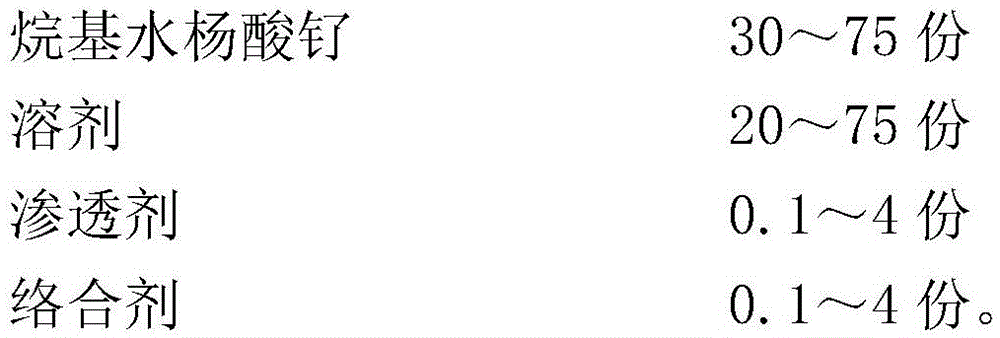

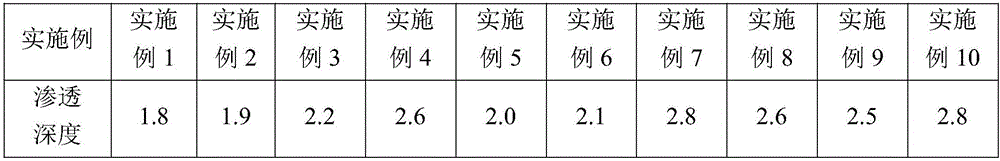

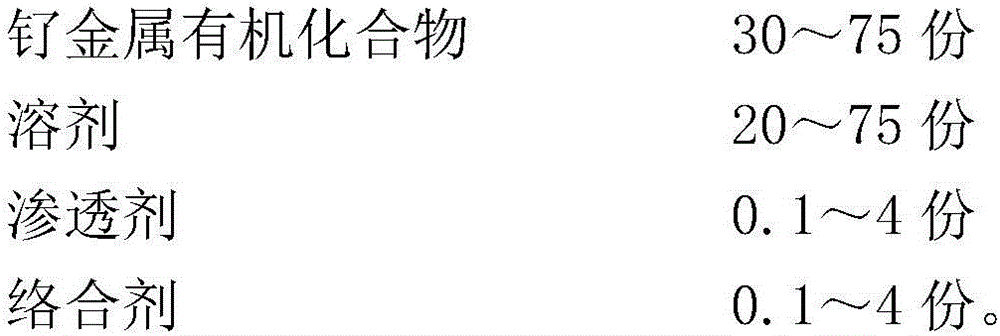

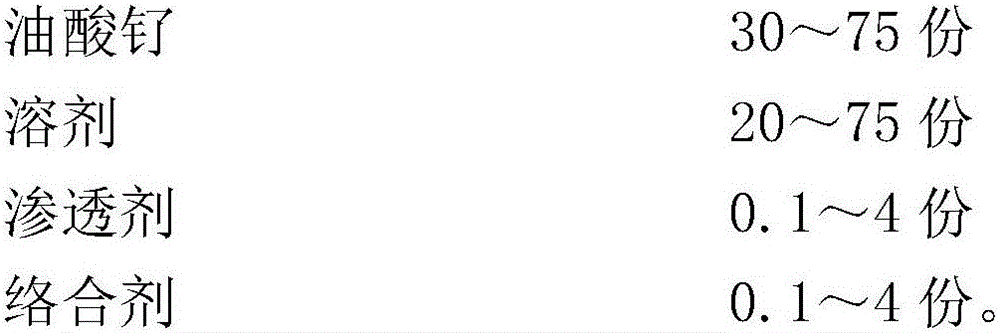

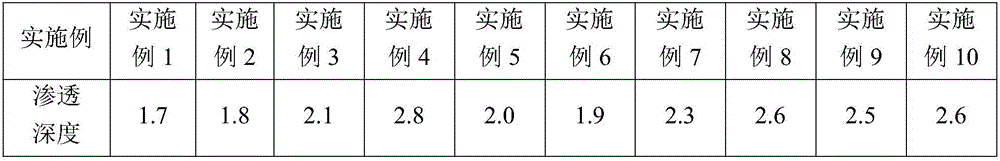

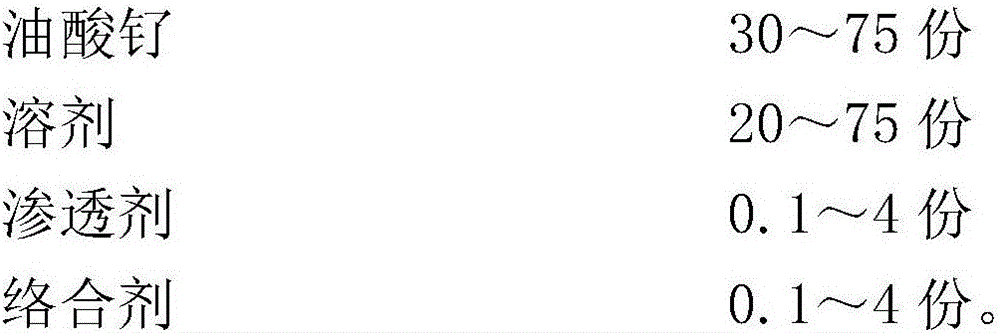

The invention discloses a bleed ceramic ink and a preparation method thereof, and relates to the technical field of architectural ceramic decoration. The bleeding ceramic ink consists of 30-75 parts of ruthenium alkyl salicylate, 20-75 parts of solvent, 0.1-4 parts of penetrating agent and 0.1-4 parts of complexing agent in parts by weight. The bleed ceramic ink prepared by the preparation method of the present invention can be directly sprayed onto the ceramic surface by an inkjet printer, the color is pure, the bleed depth can reach 1.7-2.8mm, and it shows bleed with high resolution and strong three-dimensional effect. Flower decoration effect.

Owner:FOSHAN CAIGUI NEW MATERIAL CO LTD

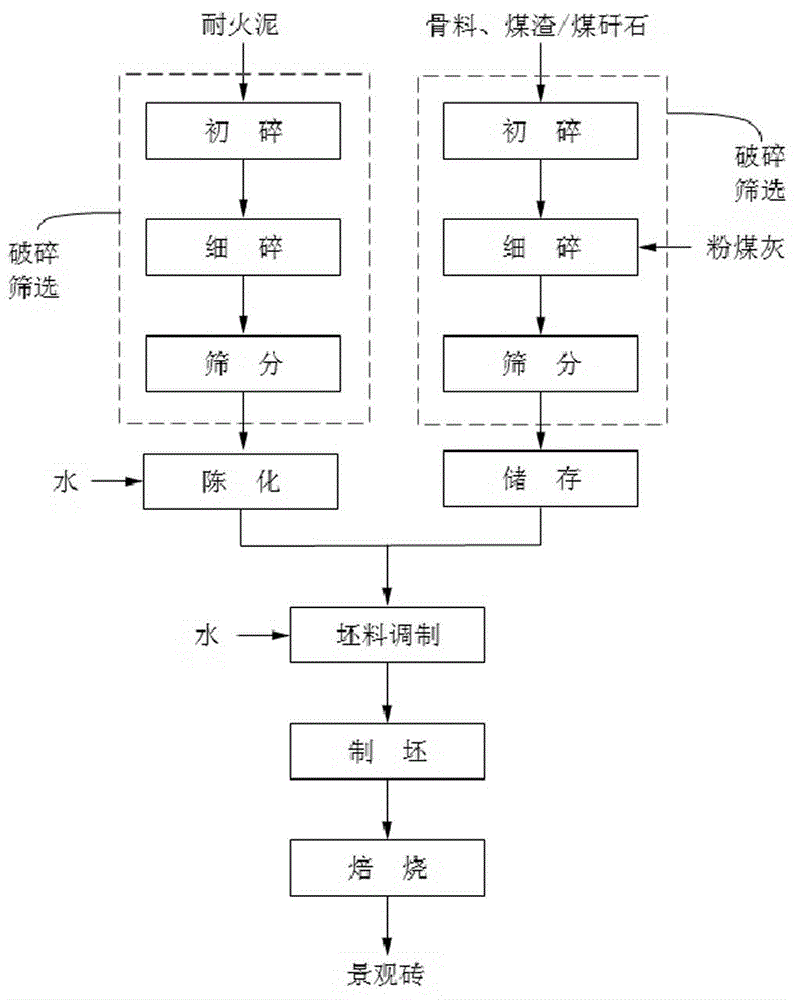

Yellow sintered landscape brick and production method thereof

InactiveCN104556962AImprove firing performanceReduce deformation of finished productFire clayHigh pressure

The invention discloses a yellow sintered landscape brick and a production method thereof. The yellow sintered landscape brick comprises 30 to 50 percent of fire clay and 50 to 70 percent of aggregate, wherein the sum of mass percent of all raw materials is not more than 100 percent. The production method comprises the steps of crushing, screening, blank mixing, blank preparation and roasting. According to the yellow landscape brick, aggregate is adopted as a main material, fire clay is adopted as an auxiliary material, and particularly hard fire clay and / or half-hard fire clay is adopted, so that the plasticity of the aggregate can be realized, and the blank is good in moldability; meanwhile, the raw materials are sintered at a high temperature of a specific range, the fire clay is thermally decomposed and toughened and covers and is bonded to the aggregate to present in faint yellow color and yellow color effects, so that the landscape brick has the characteristics of pure yellow color, relatively high pressure resistance and bending resistance and small deformation. The production method is pure in color, simple in process and stable in product quality.

Owner:楚雄诚鑫工贸有限公司

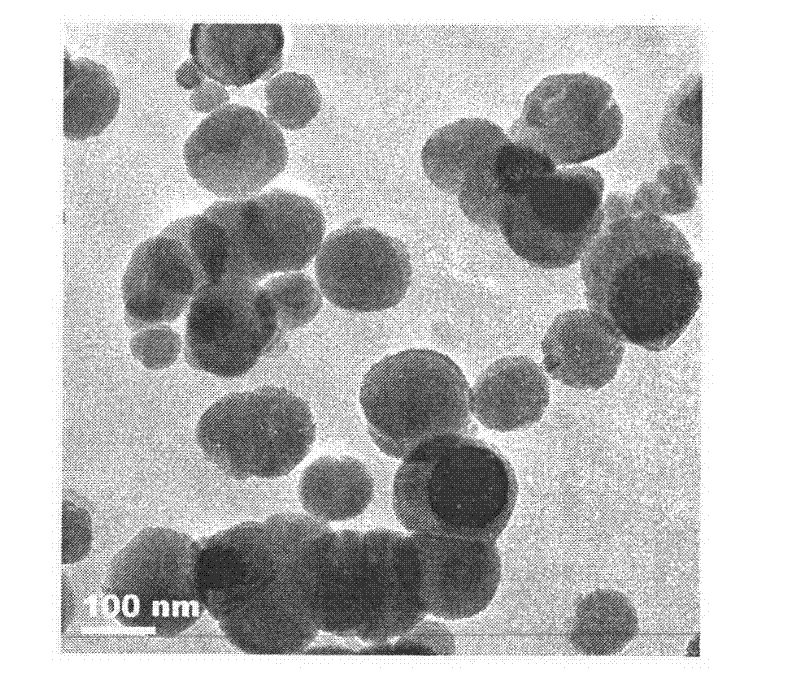

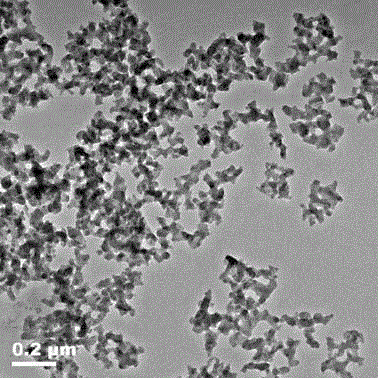

Method for preparing nanospherical ferrosilicon red-coated pigment by microwave hydrothermal method

The invention discloses a method for preparing a nanospherical ferrosilicon red-coated pigment by a microwave hydrothermal method, wherein the method comprises: firstly measuring a certain amount of deionized water into a beaker, adding iron chloride, enabling the iron chloride to be completely dissolved, adding borax into the solution of the previous step, and continuously stirring for 10min; dropping ethyl orthosilicate into the previous solution, then dropping 3mol / L of NaOH solution to regulate a pH value to a needed value, setting the temperature of a magnetic stirrer to be 40 DEG C, and continuously stirring for 120min; and moving the obtained mixed solution into a microwave hydrothermal reaction vessel for reaction at 180-210 DEG C, collecting the products after reaction, washing the products with deionized water until being neutral, and drying with a drying box to prepared the ferrosilicon red-coated pigment with 30-80nm of diameters and pure color. The method has prominent advantages of low preparation temperature, simple technology, and cheap and easily available raw material, so the method has a wide market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Permeable ink applicable to ceramic surface printing

The invention discloses permeable ink applicable to ceramic surface printing and relates to the technical field of architectural ceramic decoration. The permeable ink applicable to ceramic surface printing consists of the following components in parts by weight: 30-75 parts of ruthenium metal organic compound, 20-75 parts of solvent, 0.1-4 parts of penetrant and 0.1-4 parts of complexing agent. The permeable ink applicable to ceramic surface printing disclosed by the invention can be directly sprayed to the ceramic surface by an inkjet printer, the ink has pure color, the permeation depth can reach 1.7-2.8mm, and a glaze penetrating decoration effect with high resolution and strong stereoscopic impression is realized.

Owner:FOSHAN CAIGUI NEW MATERIAL CO LTD

Formula and preparation method of national flag bright red glazed brick

The invention relates to a formula and preparation method of a national flag bright red glazed brick. On the basis of not changing the existing glazed brick production technique too much, the invention mainly adjusts and optimizes the composition of blank materials, the composition of base / cover coating fused blocks, the preference and proportion of the fused blocks having different properties in base / cover coating, the processing technique of the cover coating, the formula composition of the base coating, the water absorptivity of a biscuit, the firing temperature and the like, thereby ensuring that the fired national flag bright red glazed brick has a dazzlingly beautiful glaze color, is bright like a reflective mirror, and has a high decorative effect and an artistic aesthetic effect; and the color is as pure as the color of a national flag and is glossy and bright, so that the national flag bright red glazed brick can shine like the rising sun. Meanwhile, the technology has high universality, and is readily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +1

Preparation method for colorful flame candle

The invention discloses a preparation method of a colored flame candle, which comprises the following steps: a. making a candle burning core; b. making a candle color core; c. preparing a candle main burner; d. forming a candle. The present invention adopts polyethylene glycol (molecular weight is 20000) as the molding improver of the candle, which can reduce the expected effect of the candle while reducing the cost of making the candle. The invention uses dilute alkali as the degreasing agent to degrease the candle wick, so that the amount of the color developing agent absorbed by the cotton thread is greatly increased, and the hair color is also purer.

Owner:SHANGHAI INST OF TECH

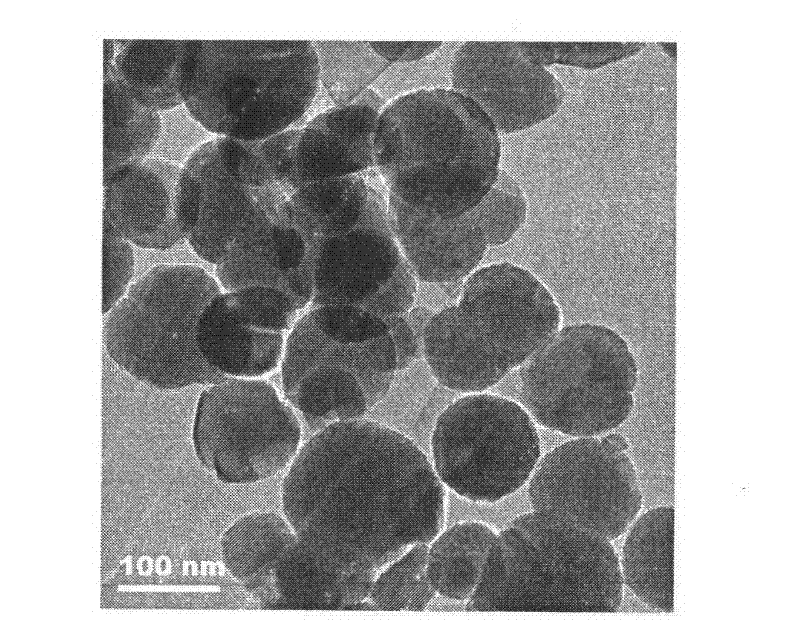

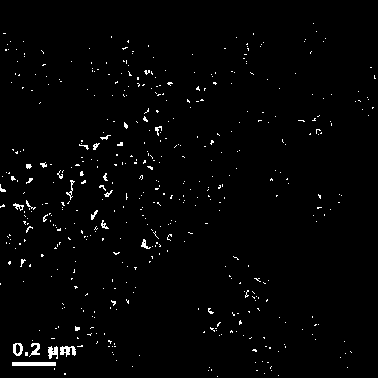

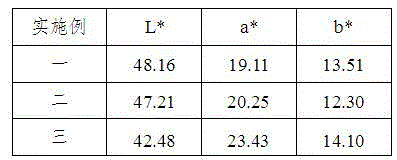

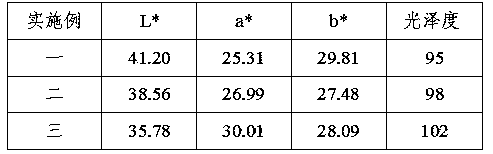

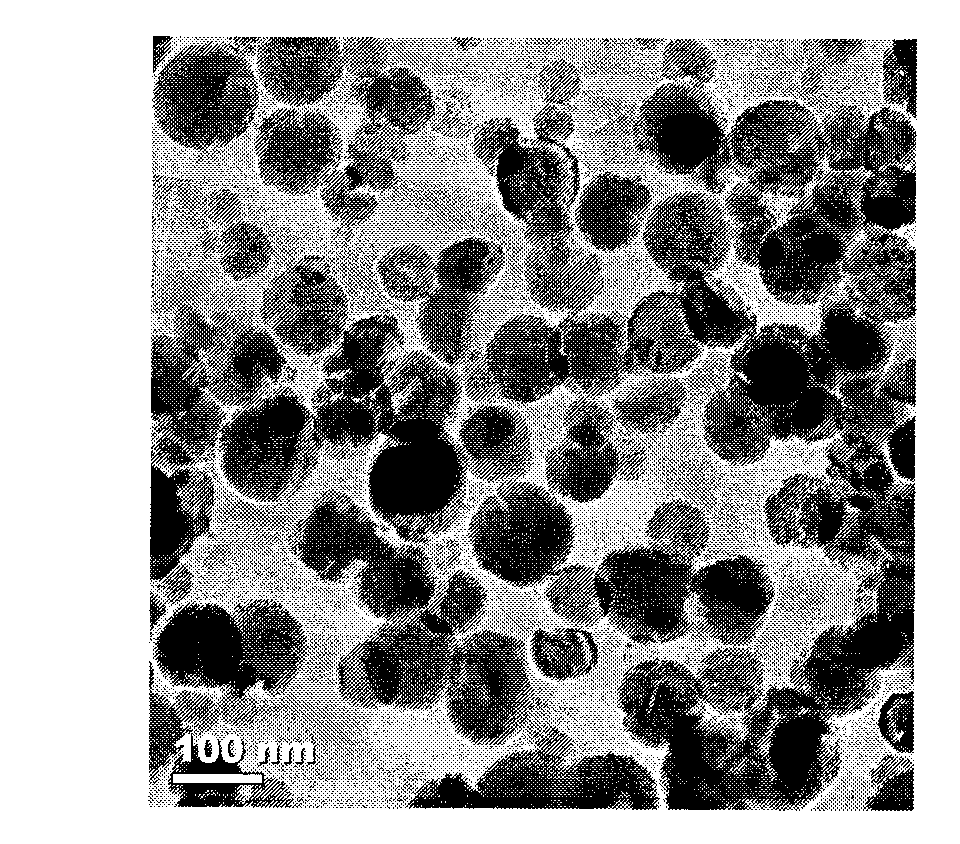

Preparation method of nano spherical ferrosilicon red pigment with high dispersity and high encapsulation rate

InactiveCN107987561AHigh parcel rateHigh economic valuePigment treatment with macromolecular organic compoundsDispersityParticle stability

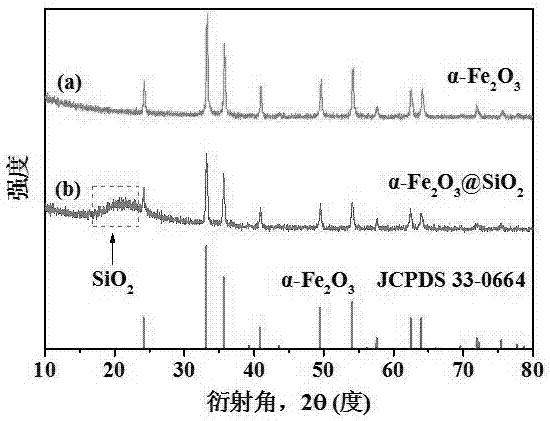

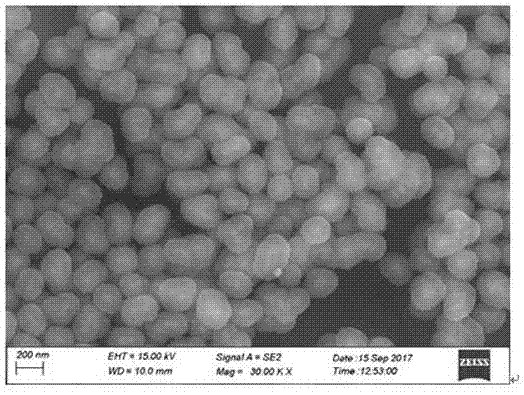

The invention discloses a preparation method of a nano spherical ferrosilicon red pigment with high dispersity and a high encapsulation rate. Fe2O3 with a particle size of 40nm is prepared by virtue of a hydrothermal method, and PVP (polyvinylpyrrolidone) is used for modifying the Fe2O3. The PVP is adsorbed on the surface of the Fe2O3 to form a layer of macromolecular protection membrane and a steric hindrance layer, so that the repelling force and the particle stability can be improved, and the dispersity is improved. Then the surfaces of the Fe2O3 surface particles are uniformly coated witha layer of SiO2 to form Fe2O3@SiO2 having a core-shell structure by adopting a simple St-ber method. By virtue of high-temperature calcinations, the nano spherical ferrosilicon red pigment with high encapsulation rate and high dispersity can be obtained, the synthesized red pigment is pure in color, uniform in particle size and stable in performance, can be used in various glaze bodies and has higher economic value.

Owner:JINGDEZHEN CERAMIC INSTITUTE

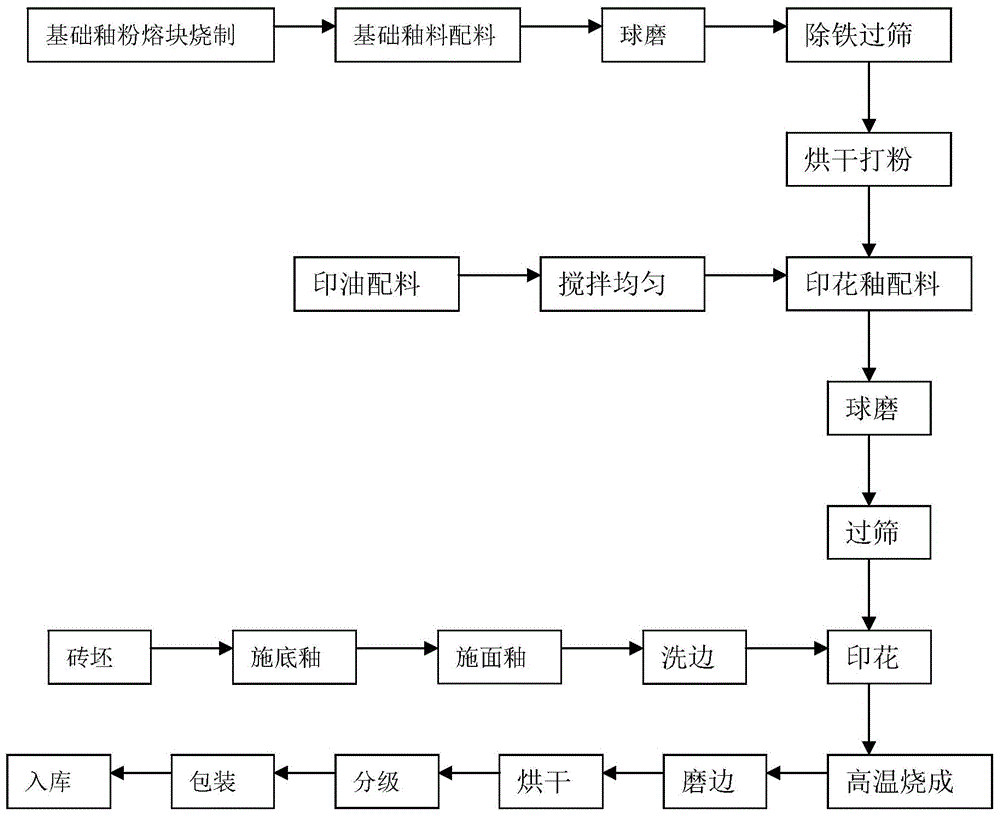

Ink-jet brick and production process thereof

The invention discloses and provides an ink-jet brick with a smooth glaze surface and a good ink pattern effect and a production process of the ink-jet brick. The ink-jet brick comprises a green brickbody, wherein a surface glaze and a pattern layer are sequentially sprayed outside the green brick body. The surface glaze comprises, by percentage, 25%-40% of albite, 5%-10% of calcite, 1%-6% of quartz, 10%-20% of barium carbonate, 1%-5% of zinc oxide, 10%-15% of kaolin, 5%-10% of aluminum oxide, 5%-10% of zirconium silicate, 5%-10% of black mud powder and 1%-3% of calcined talc. The method is suitable for the field of production and manufacturing of ink-jet bricks.

Owner:珠海市白兔陶瓷有限公司

Ceramic spray coating composite and preparation method thereof

The invention discloses a ceramic spraying composition and a preparation method thereof, and relates to the technical field of architectural ceramic decoration. The ceramic spraying composition is composed of 30-75 parts of ruthenium oleate, 20-75 parts of solvent, 0.1-4 parts of penetrating agent and 0.1-4 parts of complexing agent in parts by weight. The ceramic spraying composition prepared by the preparation method of the present invention can be directly sprayed onto the surface of the ceramic by an inkjet printer, the color is pure, the penetration depth can reach 1.7-2.8mm, and it exhibits high resolution and strong three-dimensional effect. Bleeding decorative effect.

Owner:FOSHAN CAIGUI NEW MATERIAL CO LTD

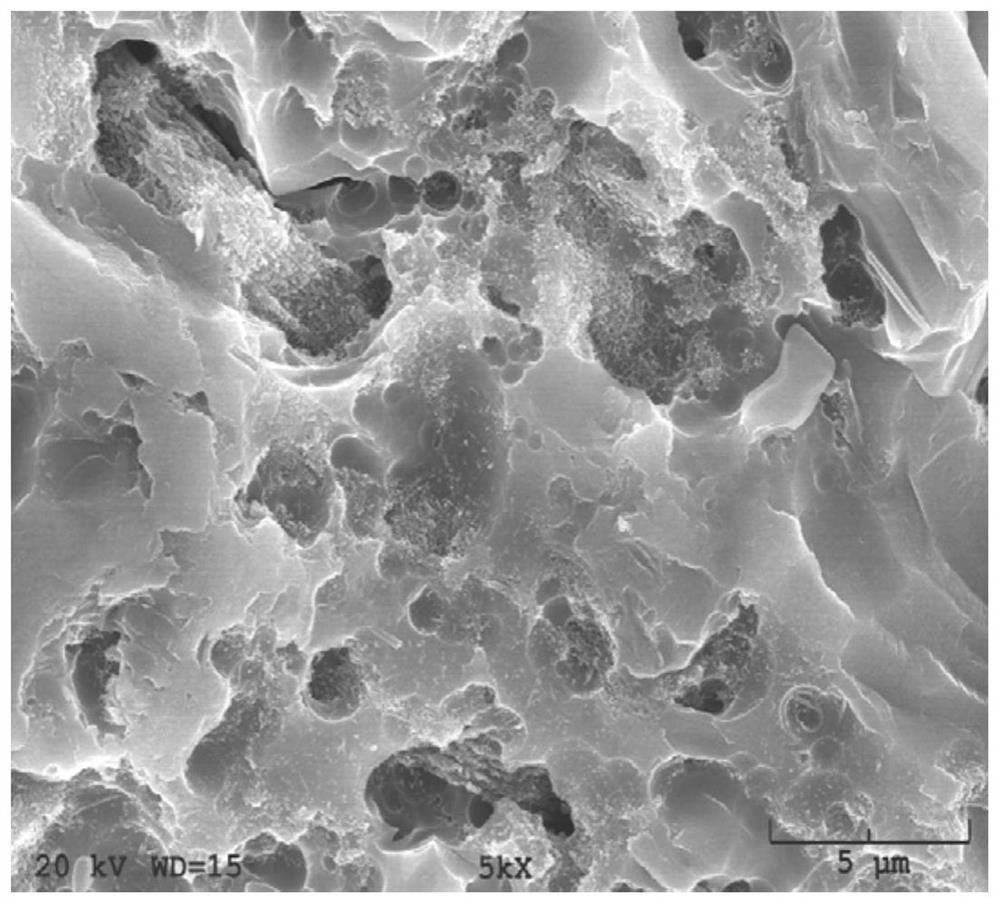

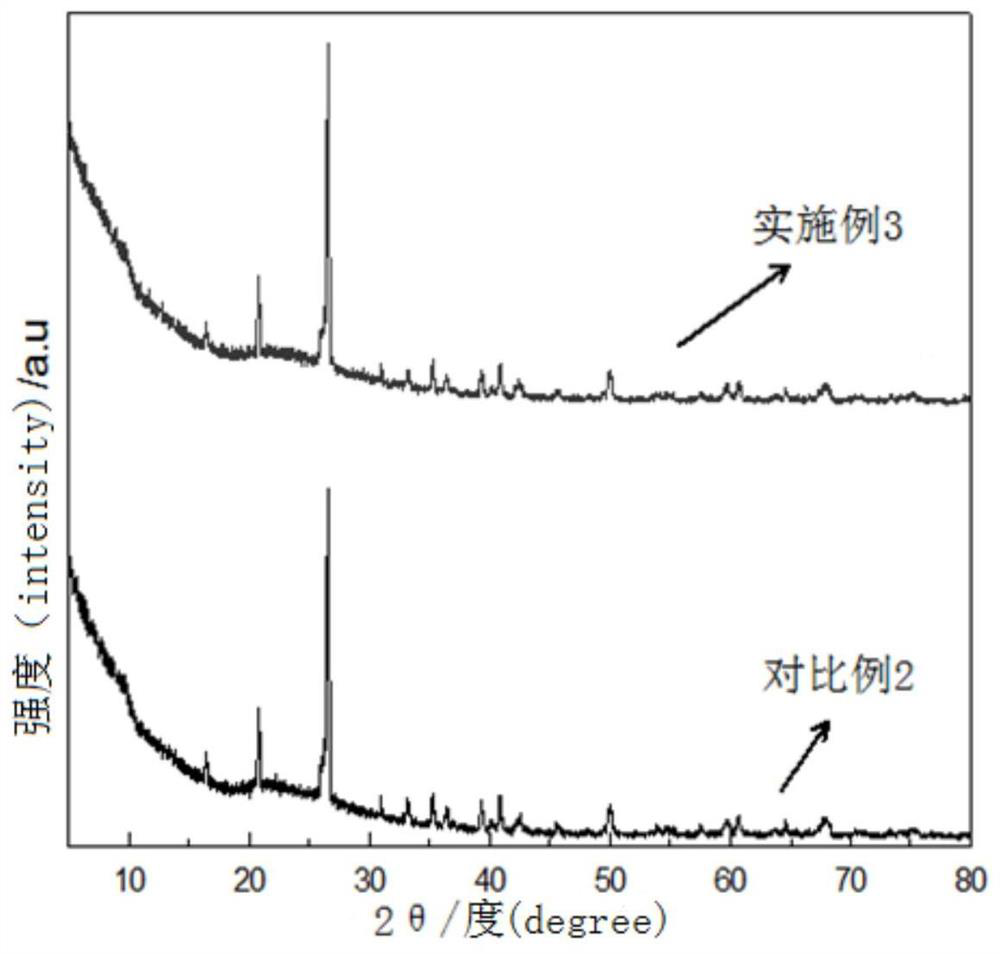

A kind of black ceramic and preparation method thereof

The invention relates to the technical field of ceramic materials, in particular to a black ceramic and a preparation method thereof. The method for preparing black ceramics provided by the invention comprises the following steps: sintering a ceramic body and carbon black in a closed environment to obtain the black ceramics. The preparation method of black ceramics provided by the present invention is simple in process, easy in operation and easy to control, does not need to add any black high-temperature pigments or colored metal oxides before blank making, does not change the basic formula of ceramic blanks, and does not change the kiln structure And the firing atmosphere, only changing the firing process of the ceramics, can achieve the firing of black ceramics with pure color and high density. The black ceramics prepared by it are uniform without black spots and high in blackness. After refiring, the black hair color is stable and does not fade.

Owner:浙江古婺窑火陶瓷文化有限公司

Ceramic ferrosilicon red material prepared with red-bed mudstones as main raw material

The invention discloses a ceramic ferrosilicon red material prepared with red-bed mudstones as a main raw material. The ceramic ferrosilicon red material is prepared by the following steps: with red-bed mudstones and ferric oxide as raw materials, adding a mineralizer, and carrying out coarse crushing, burdening, mixing, sieving, mechanochemistry ball milling and roasting to obtain a product. By adopting the preparation method of the ceramic ferrosilicon red material, with cheap red-bed mudstones as the main raw material, only a small quantity of Fe2O3 chemical material needs to be added, and the ceramic ferrosilicon red material with good color generation is prepared by combining a mechanochemistry method; and compared with the traditional preparation method of a ferrosilicon red material, the preparation method of the ceramic ferrosilicon red material has the advantages of simpleness in process, no pollution to the environment, high yield, little energy consumption, lower cost, pure color development and the like and has a wide market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing nanospherical ferrosilicon red-coated pigment by microwave hydrothermal method

The invention discloses a method for preparing a nanospherical ferrosilicon red-coated pigment by a microwave hydrothermal method, wherein the method comprises: firstly measuring a certain amount of deionized water into a beaker, adding iron chloride, enabling the iron chloride to be completely dissolved, adding borax into the solution of the previous step, and continuously stirring for 10min; dropping ethyl orthosilicate into the previous solution, then dropping 3mol / L of NaOH solution to regulate a pH value to a needed value, setting the temperature of a magnetic stirrer to be 40 DEG C, and continuously stirring for 120min; and moving the obtained mixed solution into a microwave hydrothermal reaction vessel for reaction at 180-210 DEG C, collecting the products after reaction, washing the products with deionized water until being neutral, and drying with a drying box to prepared the ferrosilicon red-coated pigment with 30-80nm of diameters and pure color. The method has prominent advantages of low preparation temperature, simple technology, and cheap and easily available raw material, so the method has a wide market prospect.

Owner:JINGDEZHEN CERAMIC UNIV

Black ceramic and preparation method thereof

The invention relates to the technical field of ceramic materials, in particular to black ceramic and a preparation method thereof. The preparation method comprises the following step: sintering a ceramic green body and carbon black in a closed environment to obtain the black ceramic. The preparation method is simple in process, easy to operate and easy to control. Any black high-temperature pigment or colored metal oxide does not need to be added before green body making; the black ceramic with pure color and high density can be obtained through firing by only changing the firing process of the ceramic without changing the basic formula of the ceramic green body, a kiln structure and the firing atmosphere. The prepared black ceramic is uniform, free of black spots and high in blackness, and the black color is stable and does not fade after re-firing at the temperature of 900 DEG C or below.

Owner:浙江古婺窑火陶瓷文化有限公司

Non-toxic famille rose pigment and preparation method thereof

The invention relates to a non-toxic famille rose pigment and a preparation method thereof. The pigment adopts natural raw mineral materials and industrial chemical raw materials, and comprises the following components in percentage by weight: 25 to 40 percent of quartz, 10 to 20 percent of feldspar, 20 to 30 percent of boric acid, 5 to 15 percent of alumina, 2 to 6 percent of lithium carbonate, 5 to 15 percent of light calcium carbonate, 0 to 3 percent of talc, 2 to 8 percent of zirconite, 3 to 6 percent of tin oxide, 0 to 3 percent of titanium oxide, 0 to 2 percent of cerium oxide, 0 to 5 percent of barium carbonate, 0 to 3 percent of magnesium carbonate, 0 to 5 percent of potassium nitrate, and 0 to 5 percent of sodium fluoride; and 0.5 to 2 percent of coloring metal oxide or 10 to 20 percent of nontoxic ceramic pigment are additionally or directly added into the components to prepare the product. The method well solves the problems that the famille rose is not white, famille or tender, has high expansion coefficient and the like after lead and arsenic are not added by adopting composite opacifier and controlling the proportion of flux components so as to prepare the non-toxic famille rose pigment with traditional famille rose decorating effect of Jingdezhen.

Owner:JINGDEZHEN CERAMIC UNIV

High-temperature bright-red printing glaze, preparation method and preparation method of glazed tile

Owner:GUANGDONG WINTO CERAMICS +3

A kind of preparation method of zirconium silicate wrapped nano-carbon sphere ceramic black material

The invention discloses a method for preparing a zirconium silicate coated carbon nanosphere ceramic black pigment. The method is characterized in that carbon nanospheres prepared from a biomass raw material by a hydrothermal method replace a traditional carbon source, the hydrophilicity is improved by use of rich oxygen-containing functional groups on the surfaces of the carbon nanospheres and the negative potential state, and the dispersity of the carbon source is enhanced; the thickness of wrappers of the carbon nanospheres and the electrostatic adsorption capability are adjusted and controlled to enable a zirconium silicate precursor to tightly wrap the carbon nanospheres; and under the action of a mineralizer, the ceramic black pigment in which zirconium silicate wraps the carbon nanospheres is prepared after high-temperature calcination. In the experiment process, through optimization and control of such conditions as the addition of glucose, the hydrothermal temperature, the hydrothermal time, the silicon-zirconium ratio, the stirring time of the precursor, type and consumption selection of the mineralizer and a firing system, the synthesized black pigment is pure in color, uniform in particle size and stable in performance, can be used in various high-temperature ceramic glazes, and has a high economical value.

Owner:JINGDEZHEN CERAMIC UNIV

Ceramic silicon iron red pigment mainly prepared from laterite

The invention discloses a ceramic silicon iron red pigment mainly prepared from laterite. Laterite and ferric oxide used as raw materials and an additional mineralizer are proportioned, mixed, screened, subjected to mechanochemical ball milling, and roasted to obtain the product. The cheap laterite used as the main raw material and a small amount of Fe2O3 chemical raw material are combined with the mechanochemical process to prepare the favorable-coloration ceramic silicon iron red pigment. Compared with the existing preparation method of the silicon iron red pigment, the method disclosed by the invention has the advantages of simple technique, no environment pollution, high yield, low energy consumption, low cost, pure color development and the like, and thus, has broad market prospects.

Owner:JINGDEZHEN CERAMIC UNIV

Polychrome painting pigment prepared by taking red mudstone as coloring agent

Owner:JINGDEZHEN CERAMIC UNIV

A preparation method of nano-spherical ferrosilicon red material with high dispersion and high encapsulation rate

InactiveCN107987561BHigh parcel rateHigh economic valuePigment treatment with macromolecular organic compoundsMetallurgyGlaze

The invention discloses a preparation method of a nano spherical ferrosilicon red pigment with high dispersity and a high encapsulation rate. Fe2O3 with a particle size of 40nm is prepared by virtue of a hydrothermal method, and PVP (polyvinylpyrrolidone) is used for modifying the Fe2O3. The PVP is adsorbed on the surface of the Fe2O3 to form a layer of macromolecular protection membrane and a steric hindrance layer, so that the repelling force and the particle stability can be improved, and the dispersity is improved. Then the surfaces of the Fe2O3 surface particles are uniformly coated witha layer of SiO2 to form Fe2O3@SiO2 having a core-shell structure by adopting a simple St-ber method. By virtue of high-temperature calcinations, the nano spherical ferrosilicon red pigment with high encapsulation rate and high dispersity can be obtained, the synthesized red pigment is pure in color, uniform in particle size and stable in performance, can be used in various glaze bodies and has higher economic value.

Owner:JINGDEZHEN CERAMIC UNIV

Metal flower glaze and fully glazed ceramic tile with metal effect and its production process

The invention discloses a metallic patterned glaze, a full-glazed ceramic brick with metallic effects and a production process thereof. Polished glaze layer, the metal patterned glaze layer is composed of metal patterned glazes of the same or different colors by screen printing with effect nets, and the full-polished glaze layer is made of cross-printed multi-channel full-polished glazed layers with full-pass nets and effect nets composed of glaze. Adopting the adjustment of the ratio of transparent glazes with different refractoriness in the present invention can promote the pure color of the introduced metal particles in the firing process, and can be effectively matched and combined with non-metallic raw materials, so that the color of the metal particles is stable and shows an excellent and textured metal Effect, improve the decorative effect of the product on the building.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

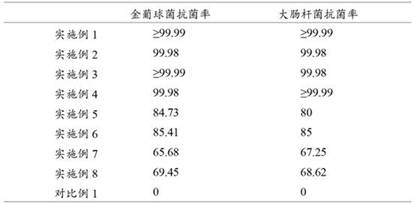

A kind of glass-ceramic antibacterial powder and its preparation method and application

The invention discloses a glass ceramic antibacterial powder and a preparation method and application thereof. The invention relates to the technical field of antibacterial materials, in particular to a glass ceramic antibacterial powder and a preparation method and application thereof. The method includes: weighing and mixing raw materials to obtain a first mixture; mixing the first mixture with a dispersion liquid to obtain a first slurry; grinding, drying, and powdering the first slurry to obtain a first powder ; The first powder is melted at high temperature to obtain a first glass body; the first glass body is heated and crystallized, and then crushed, ground, and sieved to obtain a finished product. The preparation method has the advantages of simple process, low cost and large output, and the obtained powder particles have no agglomeration and good filling performance. Correspondingly, the prepared glass-ceramic antibacterial powder has good high temperature resistance and stable antibacterial performance, and can be added to ceramic glazes as an antibacterial agent.

Owner:FOSHAN SANSHUI CREATE TIDE

Process for preparing spherical nanometer spinel zaffre by hydrothermal method

The invention discloses a process for preparing spherical nanometer spinel zaffre by the hydrothermal method. The process comprises the following steps: weighing and putting cobalt chloride and aluminum chloride according to a mol ratio of Co<2+> : Al <3+> = 1:2, putting the materials into a beaker, adding a proper amount of deionized water and carrying out uniform stirring on a magnetic stirrer;adding a sodium hydroxide solution drop by drop until the pH value of the mixture in the beaker is 13 and continuing stirring; adding mixed liquor of triethanolamine and glycerol with a volume fraction of 6 to 18% and resuming stirring; carrying out hydrothermal cultivation on the mixed solution at a temperature of 245 DEG C for 20 to 40 hours and taking the mixed solution out for natural coolingat room temperature; repeatedly rinsing the hydrothermal cultivation resultant material in liquid phase until the pH value equals 7 and putting the resultant material into a baking oven for drying attemperature of 60 DEG C so as to obtain spherical products with particle size less than 100 nm. The advantages of the invention are as follows: liquid phase hydrothermal cultivation is employed and composite organic matters are added; therefore, nanometer spherical powder is formed directly without calcining, energy consumption is relatively low, and no environmental pollution is generated.

Owner:JINGDEZHEN CERAMIC UNIV

High-temperature domestic porcelain metallic bright glaze and product decorated by same

The invention relates to a high-temperature domestic porcelain metallic bright glaze and a product decorated by the same. The bright glaze produced by using natural mineral raw materials and industrial pure raw materials comprises the following materials by weight percent: 10-25 percent of potassium feldspar, 10-30 percent of albite, 0-35 percent of quartz, 0-10 percent of barium carbonate, 0-10 percent of wollastonite, 0-10 percent of kaolin, 0-5 percent of zinc oxide, 1-10 percent of aluminum oxide, 1-10 percent of bone ash, 1-5 percent of purple clay and 10-35 percent of ferric phosphate, and the glaze is obtained by mixing, ball-milling and screening the raw materials. The fabrication technology of the glaze is basically the same as the common porcelain glaze, the cost is low, not only can the pure color be guaranteed through redesigning of the formula of the glaze, but also the burning temperature of the glaze is increased to 1380 DGE C, so that the decoration effect of domestic porcelain is greatly enriched, and the high-temperature domestic porcelain metallic bright glaze has wide application prospect.

Owner:HUNAN KARPERY INDAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com