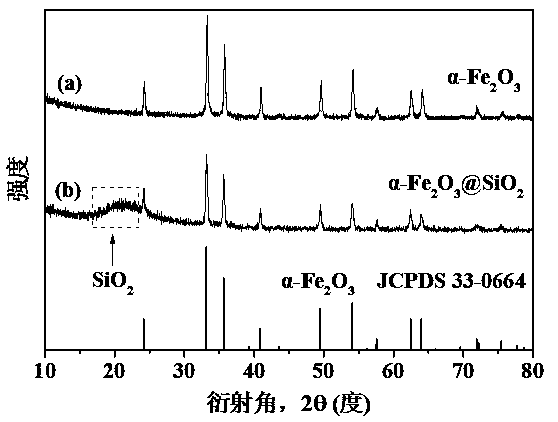

A preparation method of nano-spherical ferrosilicon red material with high dispersion and high encapsulation rate

A technology with high dispersion and encapsulation rate, which is applied in chemical instruments and methods, fibrous fillers, dyed polymer organic compound treatment, etc., can solve the problems of low encapsulation rate and poor monodispersity of ferrosilicon red

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 2.89g of ferric chloride and 3.39g of sodium carbonate in 80ml of deionized water, stir evenly, and pour the solution into a 100ml reaction kettle. Then place it in an oven at 180°C for 6 hours. The reacted solution was suction filtered, washed three times with absolute ethanol and deionized water, and dried to obtain nano-Fe 2 o 3 particles. Take the prepared nano-Fe 2 o 3 Add 0.1g and 0.8g of PVP powder into 200ml of deionized water, stir for 12 hours after ultrasonic dispersion, and then centrifuge to obtain PVP modified Fe 2 o 3 . Weigh 0.1g of PVP modified Fe 2 o 3 Disperse in 160ml of ethanol, add 10ml of ammonia water with a mass fraction of 25% in stirring, to obtain Fe 2 o 3 dispersion solution. Subsequently, 1 ml of tetraethyl orthosilicate was dissolved in ethanol with a volume ratio of 1:4, and Fe was added dropwise at a constant speed of 40 s / ml. 2 o 3 In the dispersion, stir continuously for 16h. Finally, Fe can be obtained by centri...

Embodiment 2

[0029] Dissolve 3.38g of ferric chloride and 4.23g of sodium dihydrogen phosphate in 80ml of deionized water, stir evenly, and pour the solution into a 100ml reaction kettle. Then put it in an oven at 190°C for 8 hours. The reacted solution was suction filtered, washed three times with absolute ethanol and deionized water, and dried to obtain nano-Fe 2 o 3 particles. Take the prepared nano-Fe 2 o 3 Add 0.35g and 2.8g of PVP powder into 200ml deionized water, stir for 16 hours after ultrasonic dispersion, and then centrifuge to obtain PVP modified Fe 2 o 3 . Weigh 0.35g of PVP modified Fe 2 o 3 Be dispersed in the ethanol of 250ml, add 24ml mass fraction in stirring and be the ammoniacal liquor of 25%, obtain Fe 2 o 3 dispersion solution. Subsequently, 3.5 ml of tetraethyl orthosilicate was dissolved in ethanol with a volume ratio of 1:6, and was dropped into Fe at a constant speed of 100 s / ml. 2 o 3 In the dispersion, stir continuously for 20h. Finally, Fe can be...

Embodiment 3

[0032] Dissolve 4.56g of ferric perchlorate and 5.73g of sodium carbonate in 80ml of deionized water, stir evenly, and pour the solution into a 100ml reaction kettle. Then place it in an oven at 200°C for 10 hours. The reacted solution was suction filtered, washed three times with absolute ethanol and deionized water, and dried to obtain nano-Fe 2 o 3 particles. Take the prepared nano-Fe 2 o 3 Powder 0.48g and 3.84g PVP were added to 200ml deionized water, stirred for 24 hours after ultrasonic dispersion, and then centrifuged to obtain PVP modified Fe 2 o 3 . Weigh 0.48g of PVP modified Fe 2 o 3 Disperse in 500ml of ethanol, add 42ml of ammonia water with a mass fraction of 25% in stirring, to obtain Fe 2 o 3 dispersion solution. Subsequently, 6.8 ml of silicon chloride was dissolved in ethanol with a volume ratio of 1:10, and Fe was added dropwise at a constant speed of 120 s / ml. 2 o 3 In the dispersion, stir continuously for 24h. Finally, Fe can be obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com