Preparation method of high-coating-rate nickel-coated graphite composite powder material

A nickel-coated graphite and composite powder technology, which is applied in the field of preparation of high-coverage nickel-coated graphite composite powder materials, can solve problems such as low production efficiency and environmental pollution, and achieve convenient processing, high wrapping rate, and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

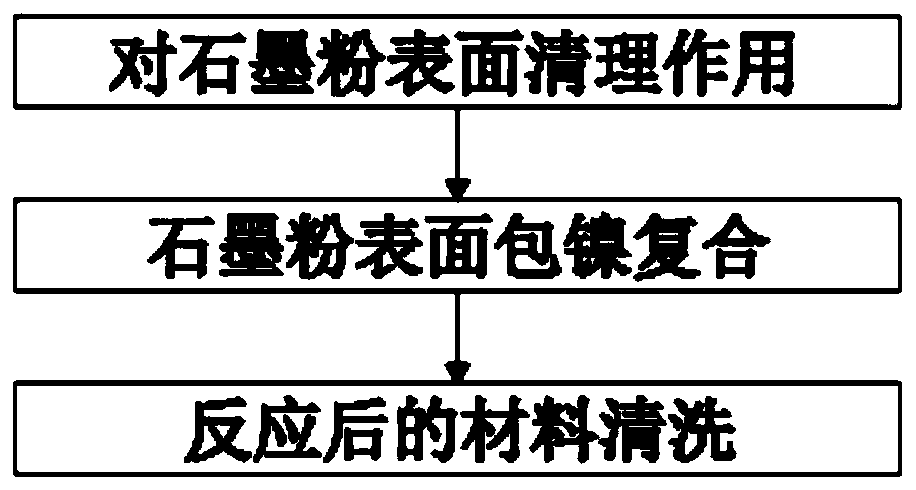

[0026] see figure 1 The present invention provides a technical solution: a method for preparing a high-coverage nickel-coated graphite composite powder material. The specific preparation steps of the high-coverage nickel-coated graphite composite powder material are as follows:

[0027] S1 cleaning effect on the surface of graphite powder: use sodium hydroxide solution with a mass concentration of 80-90g / L to treat the surface of graphite powder with cleaning oil;

[0028] Put the graphite powder after cleaning oil treatment into SnCl with a mass concentration of 3-5g / L 2 Carry out sensitization treatment in middle, the sensitization treatment time is 15-17min;

[0029] Put the sensitized graphite powder in PdCl 2 Activated in the solution, the activated pH is 1-2, and the temperature is 35-39 degrees Celsius;

[0030] Graphite powder is stored after cleaning oil treatment, sensitization treatment and activation treatment;

[0031] S2: Nickel-coated composite on the surfac...

Embodiment 1

[0041] The specific preparation steps of the preparation method of the high-coverage nickel-coated graphite composite powder material are as follows:

[0042] The particle size of graphite powder is 10μm;

[0043] S1 cleans the surface of graphite powder: use sodium hydroxide solution with a mass concentration of 80g / L to clean the surface of graphite powder with oil;

[0044] Put the graphite powder after the cleaning oil treatment into the SnCl with a mass concentration of 3g / L 2 Carry out sensitization treatment in sensitization treatment, the sensitization treatment time is 15min, the pH range of sensitization treatment is 1, and temperature is 25 degrees Celsius, during sensitization treatment, graphite powder is constantly stirred, and stirring speed is 20r / min;

[0045] Put the sensitized graphite powder in PdCl 2 Activated in solution, PdCl 2 The mass concentration of the solution is 0.03g / L, the activated pH is 1, and the temperature is 35 degrees Celsius;

[0046...

Embodiment 2

[0051] The specific preparation steps of the preparation method of the high-coverage nickel-coated graphite composite powder material are as follows:

[0052] The particle size of graphite powder is 15μm;

[0053] S1 cleans the surface of graphite powder: use sodium hydroxide solution with a mass concentration of 85g / L to clean the surface of graphite powder with oil;

[0054] The graphite powder after cleaning oil treatment is placed in the SnCl that mass concentration is 4g / L 2 Carry out sensitization treatment in middle, sensitization treatment time is 16min, and the pH range of sensitization treatment is 1.5, and temperature is 30 degrees Celsius, during sensitization treatment, graphite powder is stirred constantly, and stirring speed is 20r / min;

[0055] Put the sensitized graphite powder in PdCl 2 Activated in solution, PdCl 2 The mass concentration of the solution is 0.04g / L, the activated pH is 1.5, and the temperature is 37 degrees Celsius;

[0056] Graphite powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com