A kind of glass-ceramic antibacterial powder and its preparation method and application

A glass ceramic and antibacterial powder technology, applied in the field of antibacterial materials, can solve the problems of complex preparation process of antibacterial powder, restricting the development of antibacterial ceramic tiles, and being unsuitable for antibacterial ceramic tiles, etc., and achieves improved high temperature antibacterial stability, narrow particle size distribution, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

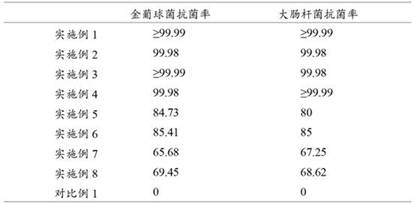

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of glass-ceramic antibacterial powder, comprises the following steps:

[0033] S1, weighing and mixing the raw materials to obtain the first mixture;

[0034] S2. The first mixture is mixed with the dispersion liquid to obtain the first slurry;

[0035] S3. Grinding, drying, and powdering the first slurry to obtain a first powder;

[0036] S4. Obtaining a first glass body after melting the first powder at high temperature;

[0037] S5. After heating and crystallizing the first glass body, crushing, grinding, and sieving to obtain a finished product;

[0038] The chemical composition of the prepared described glass-ceramic antibacterial powder comprises by mass percentage:

[0039] SiO 2 41~51%, ZrO 2 1~2%,Al 2 o 3 10~20%, B 2 o 3 2~5%, ZnO 10~20%, MgO 1~4%, CaO 4~8%, Na 2 O 1~7%, K 2 O 3~4%.

[0040] The preparation method of the glass-ceramic antibacterial powder has simple process, low cost and large ...

Embodiment 1

[0071] A preparation method of glass-ceramic antibacterial powder, comprising the following steps:

[0072] S1, weighing and mixing the raw materials to obtain the first mixture;

[0073] S2. The first mixture is mixed with the dispersion liquid to obtain the first slurry;

[0074] For every 100 parts by weight of the first mixture, 30 parts by weight of dispersion liquid should be added. The dispersion liquid includes by mass percentage: 80% water, 19% ethylene glycol, and 1% sodium polyacrylate.

[0075] S3. Grinding, drying, and powdering the first slurry to obtain a first powder;

[0076] The first slurry is wet ground by ball milling, the ball milling speed is 450 r / min, and the ball milling time is 1 h;

[0077] The drying condition is: keep warm at 100° C. for 3.5 hours.

[0078] S4. Obtaining a first glass body after melting the first powder at high temperature;

[0079] The high-temperature melting condition of the first powder is as follows: heat preservation at...

Embodiment 2

[0087] A preparation method of glass-ceramic antibacterial powder, comprising the following steps:

[0088] S1, weighing and mixing the raw materials to obtain the first mixture;

[0089] S2. The first mixture is mixed with the dispersion liquid to obtain the first slurry;

[0090] For every 100 parts by weight of the first mixture, 50 parts by weight of dispersion liquid should be added. The dispersion liquid includes by mass percentage: 80% water, 15% ethylene glycol, and 5% sodium polyacrylate.

[0091] S3. Grinding, drying, and powdering the first slurry to obtain a first powder;

[0092] The first slurry is wet ground by ball milling, the ball milling speed is 50 r / min, and the ball milling time is 3h;

[0093] The drying condition is: keep warm at 250° C. for 2 hours.

[0094] S4. Obtaining a first glass body after melting the first powder at high temperature;

[0095] The high-temperature melting condition of the first powder is: heat preservation at 1380° C. for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com