Polychrome painting pigment prepared by taking red mudstone as coloring agent

A technology of red bed mudstone and ceramic glaze, which is applied in the field of inorganic non-metallic materials (ceramics), can solve problems such as no research reports on ceramic materials, and achieve the effects of high yield, no pollution to the environment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

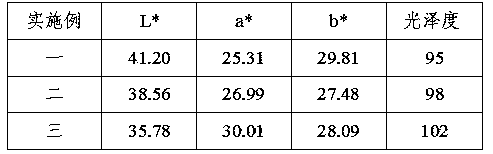

Examples

Embodiment 1

[0019] (1) Coarsely crush the red mudstone and pass through a 180-mesh sieve;

[0020] (2) Perform mechanical chemical ball milling on the powder obtained in step (1). The process parameters are: the ball is a zirconia ball with a diameter of 5mm, the ball-to-material mass ratio is 20:1, and the speed of the ball mill is 300 rpm. Dry ball milling with high-energy ball mill for 5 hours;

[0021] (3). Mix the powder and flux obtained in step (2) uniformly according to a certain proportion of ingredients to make Xi Chi pigment, where the mass percentage of powder and flux is 52:48;

[0022] (4) Add water and mix thoroughly the Xichi pigment obtained in step (3), apply it flat on the surface of the porcelain body, and bake it at 780℃ to obtain an on-glaze Xichi decoration product. The mass ratio of Xichi pigment to water is 2: 1.

Embodiment 2

[0024] (1) Coarsely crush the red mudstone and pass through a 180-mesh sieve;

[0025] (2) Perform mechanical chemical ball milling on the powder obtained in step (1). The process parameters are as follows: the balls are zirconia balls with a diameter of 3mm, the mass ratio of the balls is 40:1, and the speed of the ball mill is 400 rpm. High-energy ball mill dry ball milling for 10 hours;

[0026] (3). Mix the powder and flux obtained in step (2) uniformly according to a certain proportion of ingredients to make Xi Chi pigment, where the mass percentage of powder and flux is 59:41;

[0027] (4) Add water and mix thoroughly the Xichi pigment obtained in step (3), apply it flat on the surface of the porcelain body, and bake at 800℃ to obtain an on-glaze Xichi decoration product. The mass ratio of Xichi pigment to water is 2: 1.

Embodiment 3

[0029] (1) Coarsely crush the red mudstone and pass through a 180-mesh sieve;

[0030] (2) Perform mechanical chemical ball milling on the powder obtained in step (1). The process parameters are as follows: the balls are zirconia balls with a diameter of 1 mm, the mass ratio of the balls is 60:1, and the speed of the ball mill is 450 rpm. High-energy ball mill dry ball milling for 15 hours;

[0031] (3). Mix the powder and flux obtained in step (2) uniformly according to a certain proportion of ingredients to make Xi Chi pigment, in which the mass percentage of red clay and flux is 62:38;

[0032] (4) Add water and mix thoroughly the Xichi pigment obtained in step (3), apply it flat on the surface of the porcelain body, and bake it at 850℃ to obtain an on-glaze Xichi decoration product. The mass ratio of Xichi pigment to water is 2: 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com