Ceramic silicon iron red pigment mainly prepared from laterite

A main raw material, ceramic silicon technology, applied in the field of ceramic ferrosilicon red material, can solve the problems of only being used for ceramic blanks and low iron content, and achieve the effects of low cost, pure color development and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

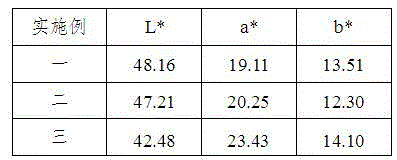

Examples

Embodiment 1

[0017] Formula: 93.7% red clay, 6.3% iron oxide, plus 3% borax as a mineralizer

[0018] (1) Weigh the ingredients according to the formula, mix them and pass through an 80-mesh sieve;

[0019] (2) The ball is a zirconia ball with a diameter of 5 mm, the mass ratio of the ball to material is 20:1, the speed of the ball mill is 300 rpm, and the ball is dry-milled with a high-energy ball mill for 10 hours;

[0020] (3) Take out the powder obtained in (2), put it into a corundum crucible, and put it into an electric furnace for roasting. The initial temperature is room temperature, and the temperature is raised to 1150°C in 6 hours, kept for 2 hours, and cooled naturally to obtain a powdered color product.

Embodiment 2

[0022] Formula: 93.7% red clay, 6.3% iron oxide, plus 3% CaF 2 as a mineralizer

[0023] (1) Weigh the ingredients according to the formula, mix them and pass through an 80-mesh sieve;

[0024] (2) The ball is a zirconia ball with a diameter of 3 mm, the mass ratio of the ball to material is 30:1, the speed of the ball mill is 400 rpm, and the ball is dry-milled with a high-energy ball mill for 20 hours;

[0025] (3) Take out the powder obtained in (2), put it into a corundum crucible, and put it into an electric furnace for roasting. The initial temperature is room temperature, and the temperature is raised to 1150°C in 6 hours, kept for 2 hours, and naturally cooled to obtain a powdered color product.

Embodiment 3

[0027] Formula: 93.7% red clay, 6.3% iron oxide, plus 3% NaF as a mineralizer

[0028] (1) Weigh the ingredients according to the formula, mix them and pass through an 80-mesh sieve;

[0029] (2) The ball is a zirconia ball with a diameter of 1 mm, the mass ratio of the ball to material is 40:1, the speed of the ball mill is 450 rpm, and the ball is dry-milled with a high-energy ball mill for 30 hours;

[0030] (3) Take out the powder obtained in (2), put it into a corundum crucible, and put it into an electric furnace for roasting. The initial temperature is room temperature, and the temperature is raised to 1150°C in 6 hours, kept for 2 hours, and cooled naturally to obtain a powdered color product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com