Ceramic spray coating composite and preparation method thereof

A composition and ceramic technology, which is applied in the field of architectural ceramic decoration, can solve the problems of insufficient penetration depth, affecting the decorative effect of pattern texture, impure color development of penetrating ink, etc., and achieve high resolution, strong three-dimensional effect and pure color development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

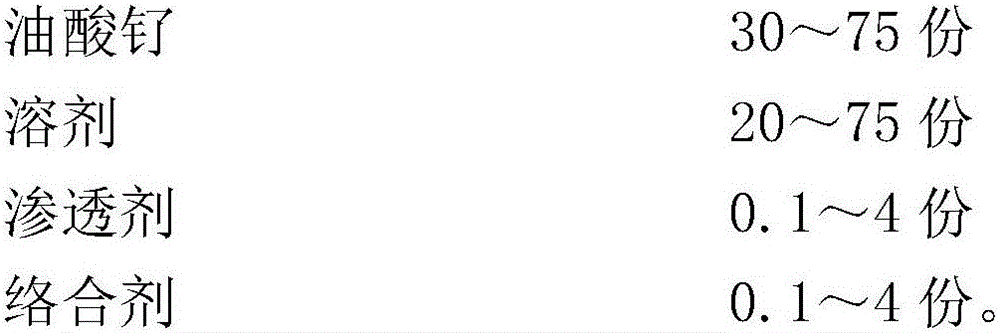

Method used

Image

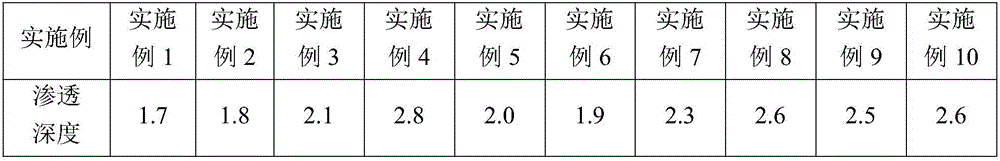

Examples

Embodiment 1

[0021] Mix ruthenium trichloride and oleic acid in a molar ratio of 1:3, stir and react at a temperature of 120±5°C to prepare ruthenium oleate;

[0022] After stirring 61.4 parts of n-hexane, 1.5 parts of fatty alcohol polyoxyethylene ether and 1.1 parts of triethanolamine at high speed, slowly add 36 parts of ruthenium oleate and stir at high speed to obtain a mixed solution;

[0023] The obtained mixture was subjected to ball milling and sand milling to prepare a black ceramic spraying composition.

Embodiment 2

[0025] Mix ruthenium trichloride and oleic acid in a molar ratio of 1:3, stir and react at a temperature of 120±5°C to prepare ruthenium oleate;

[0026] After stirring 41.7 parts of n-hexane, 1.8 parts of fatty alcohol polyoxyethylene ether and 1.5 parts of triethanolamine at high speed, slowly add 55 parts of ruthenium oleate and stir at high speed to obtain a mixed solution;

[0027] The obtained mixture was subjected to ball milling and sand milling to prepare a black ceramic spraying composition.

Embodiment 3

[0029] Mix ruthenium acetate and oleic acid in a molar ratio of 1:2.5, stir and react at a temperature of 110±5°C to prepare ruthenium oleate;

[0030] After stirring 20 parts of dichloromethane, 1.8 parts of nonylphenol polyoxyethylene ether and 0.1 part of diethanolamine at high speed, slowly add 30 parts of ruthenium oleate, and stir at high speed to obtain a mixed solution;

[0031] The obtained mixture was subjected to ball milling and sand milling to prepare a black ceramic spraying composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com