Process for preparing spherical nanometer spinel zaffre by hydrothermal method

A nano-spinel and spinel-type technology is applied in the field of preparing spherical nano-spinel-type cobalt blue materials by a hydrothermal method, which can solve the problems of limited use range, complex synthesis process, high price, etc. Single, simple process, no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

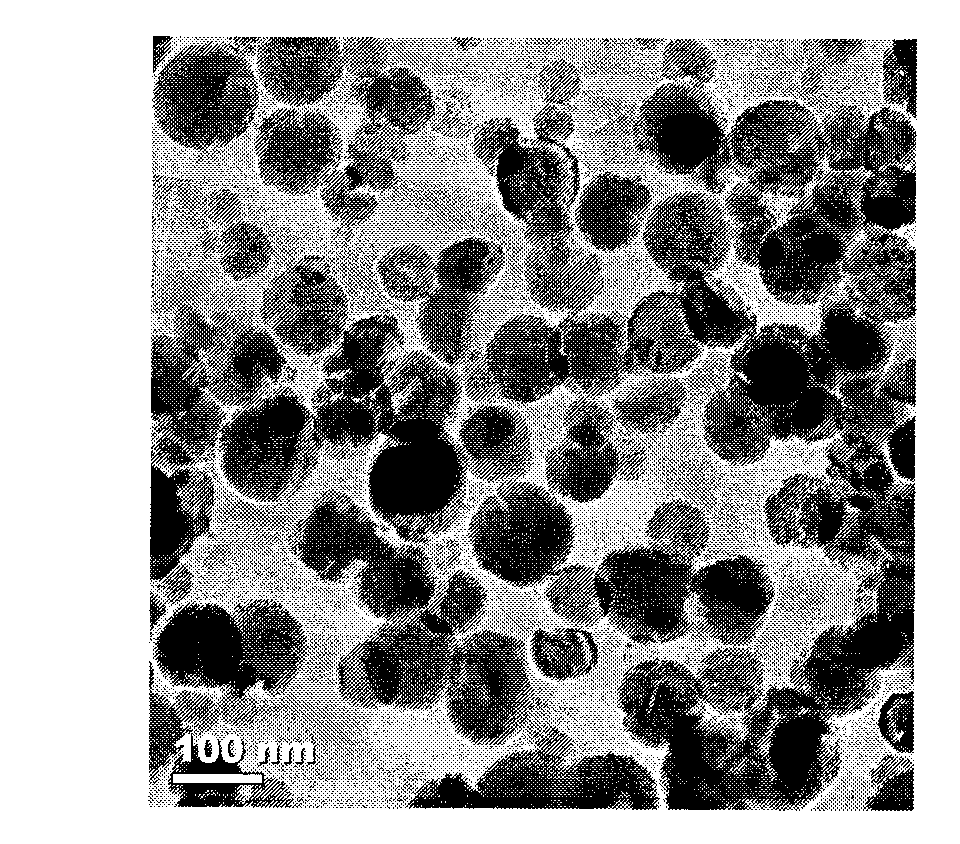

Embodiment 1

[0032] (1) With cobalt chloride and aluminum chloride as raw materials, 0.15mol Co 2+ , 0.3mol Al 3+ Weigh it into a beaker, add deionized water, and then put the beaker on a magnetic stirrer and stir evenly;

[0033] (2) Slowly drop 3 mol / L NaOH solution into the uniformly stirred mixed solution, and continue stirring at a constant temperature of 20°C for 30 minutes until the pH of the solution is 13;

[0034] (3) Take a small amount of the supernatant of the above solution and add dropwise a few drops of 3mol / L NaOH solution to observe whether there is precipitation or not. If there is no precipitation, the reaction is complete;

[0035] (4) In the above-mentioned fully reacted solution, add a triethanolamine liquid with a volume fraction of 4% and a glycerol liquid with a volume fraction of 2%, and continue stirring for 30 minutes;

[0036] (5) Put the above-mentioned uniformly stirred mixed solution into a 100mL reactor with a filling degree of 70%, and incubate it under...

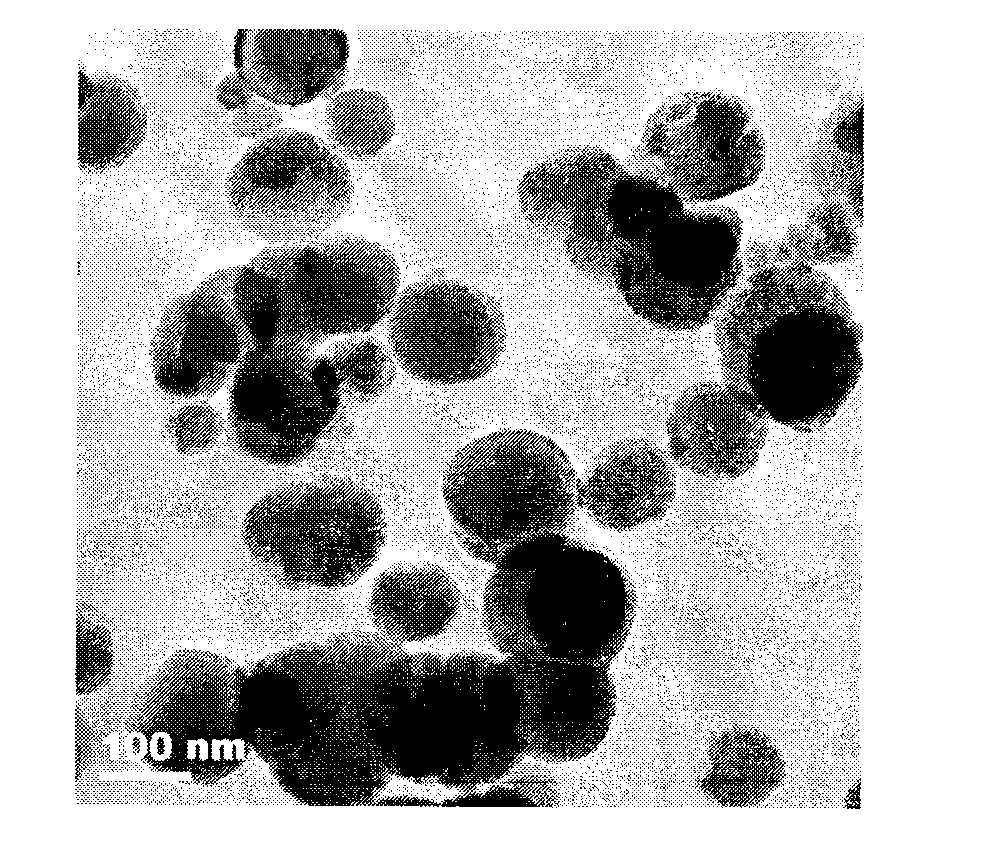

Embodiment 2

[0039] (1) With cobalt chloride and aluminum chloride as raw materials, 0.12mol Co 2+ , 0.24mol Al 3+ Add to the beaker, add deionized water, then put the beaker on a magnetic stirrer and stir evenly;

[0040] (2) Slowly drop 3 mol / L NaOH solution into the uniformly stirred mixed solution, and continue stirring at a constant temperature of 20°C for 30 minutes until the pH of the solution is 13;

[0041] (3) Take a small amount of the supernatant of the above solution and add dropwise a few drops of 3mol / L NaOH solution to observe whether precipitation is generated, if there is no precipitation, the reaction is complete;

[0042] (4) In the above-mentioned fully reacted solution, add a triethanolamine liquid with a volume fraction of 8% and a glycerol liquid with a volume fraction of 4%, and continue stirring for 30 min;

[0043] (5) Put the above-mentioned uniformly stirred mixed solution into a 100mL reactor at a filling degree of 70%, and incubate it under hydrothermal hea...

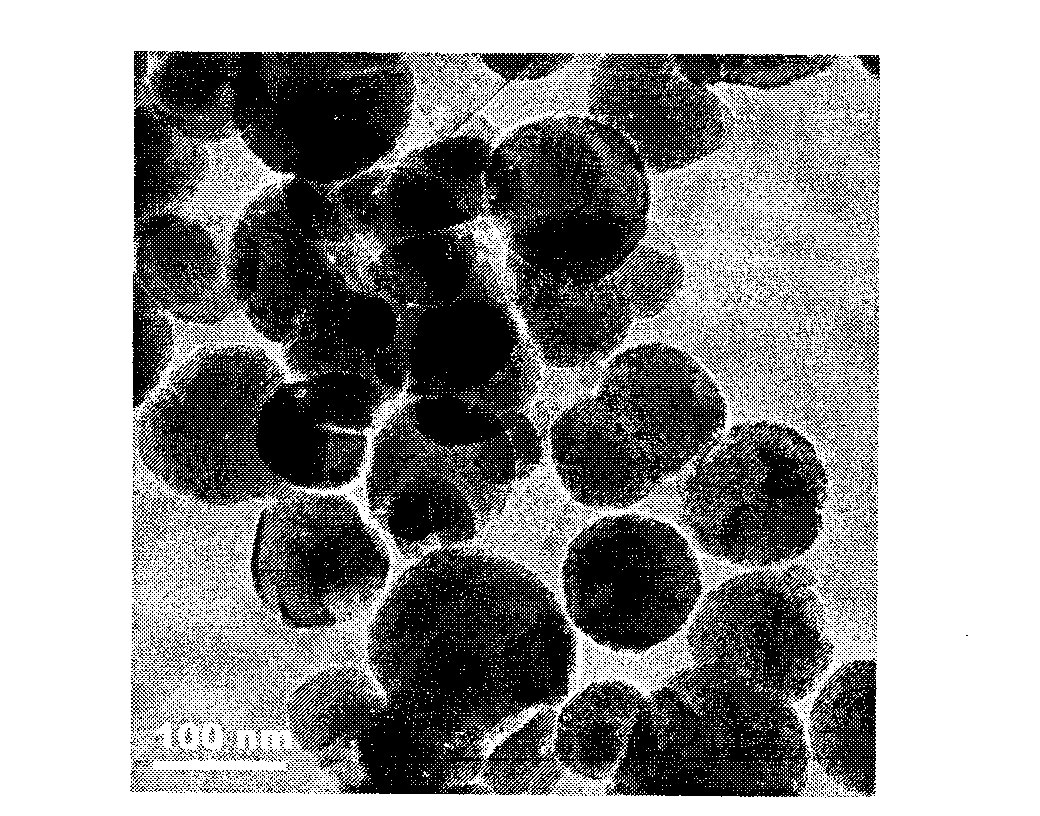

Embodiment 3

[0046] (1) With cobalt chloride and aluminum chloride as raw materials, 0.18mol Co 2+ , 0.36mol Al 3+ Add to the beaker, add deionized water, then put the beaker on a magnetic stirrer and stir evenly;

[0047] (2) Slowly drop 3 mol / L NaOH solution into the uniformly stirred mixed solution, and continue stirring at a constant temperature of 20°C for 30 minutes until the pH of the solution is 13;

[0048] (3) Take a small amount of the supernatant of the above solution and add dropwise a few drops of 3mol / L NaOH solution to observe whether there is precipitation or not. If there is no precipitation, the reaction is complete;

[0049] (4) In the above-mentioned fully reacted solution, add a triethanolamine liquid with a volume fraction of 12% and a glycerol liquid with a volume fraction of 6%, and continue stirring for 30 min;

[0050] (5) Put the above-mentioned uniformly stirred mixed solution into a 100mL reactor with a filling degree of 70%, and incubate it with hydrotherma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com