Patents

Literature

184 results about "Cobalt aluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

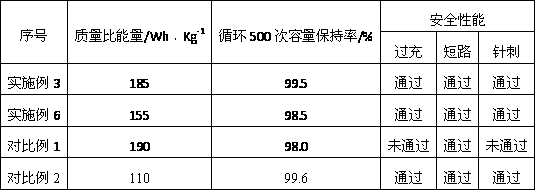

Highly stable lithium nickel cobalt aluminate positive electrode material and its preparation method

ActiveCN104218243AFacilitate conductionImprove side effectsCell electrodesSecondary cellsBattery chargeHigh energy

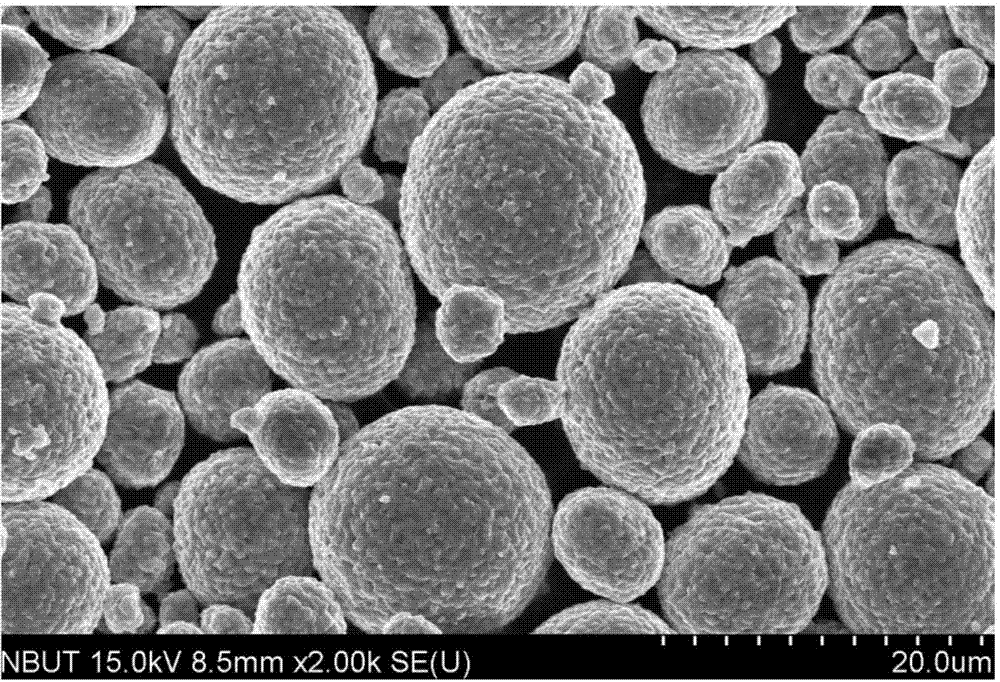

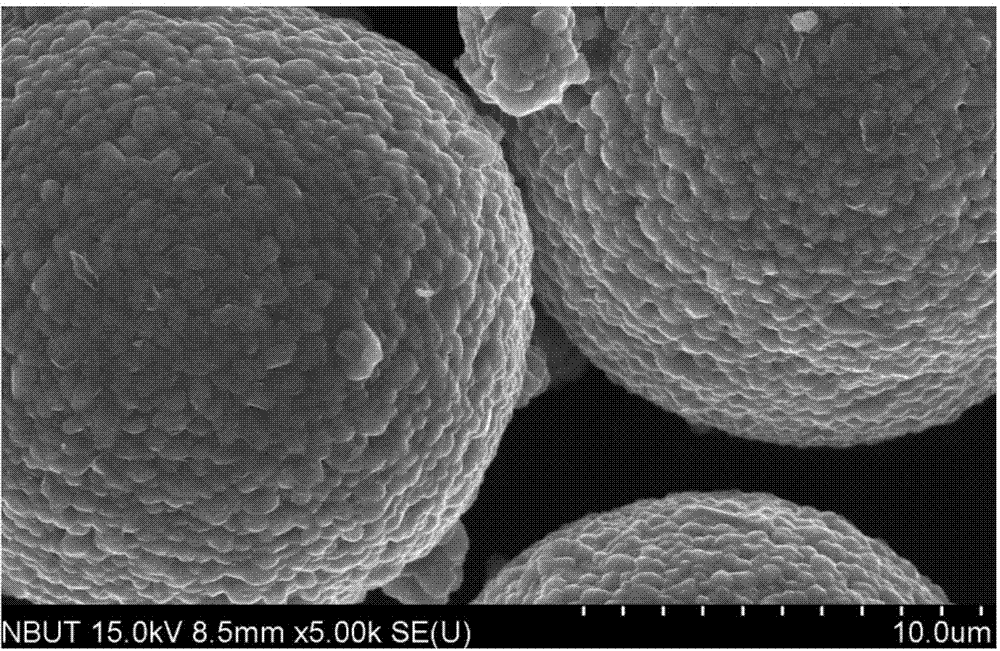

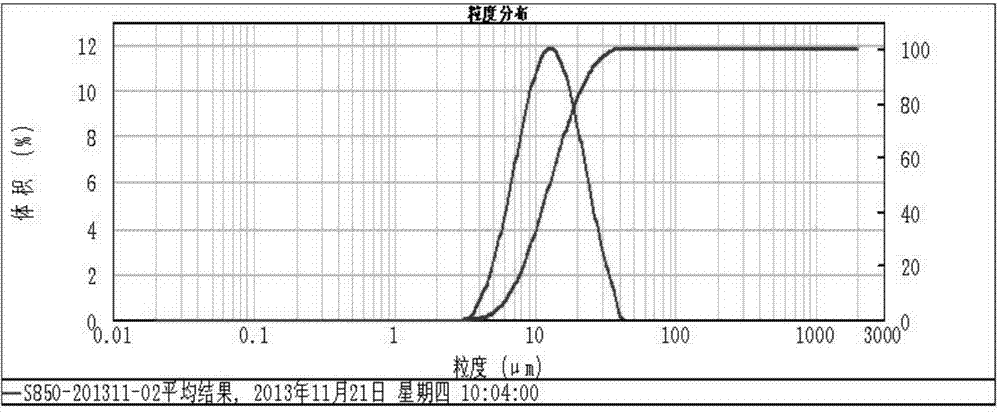

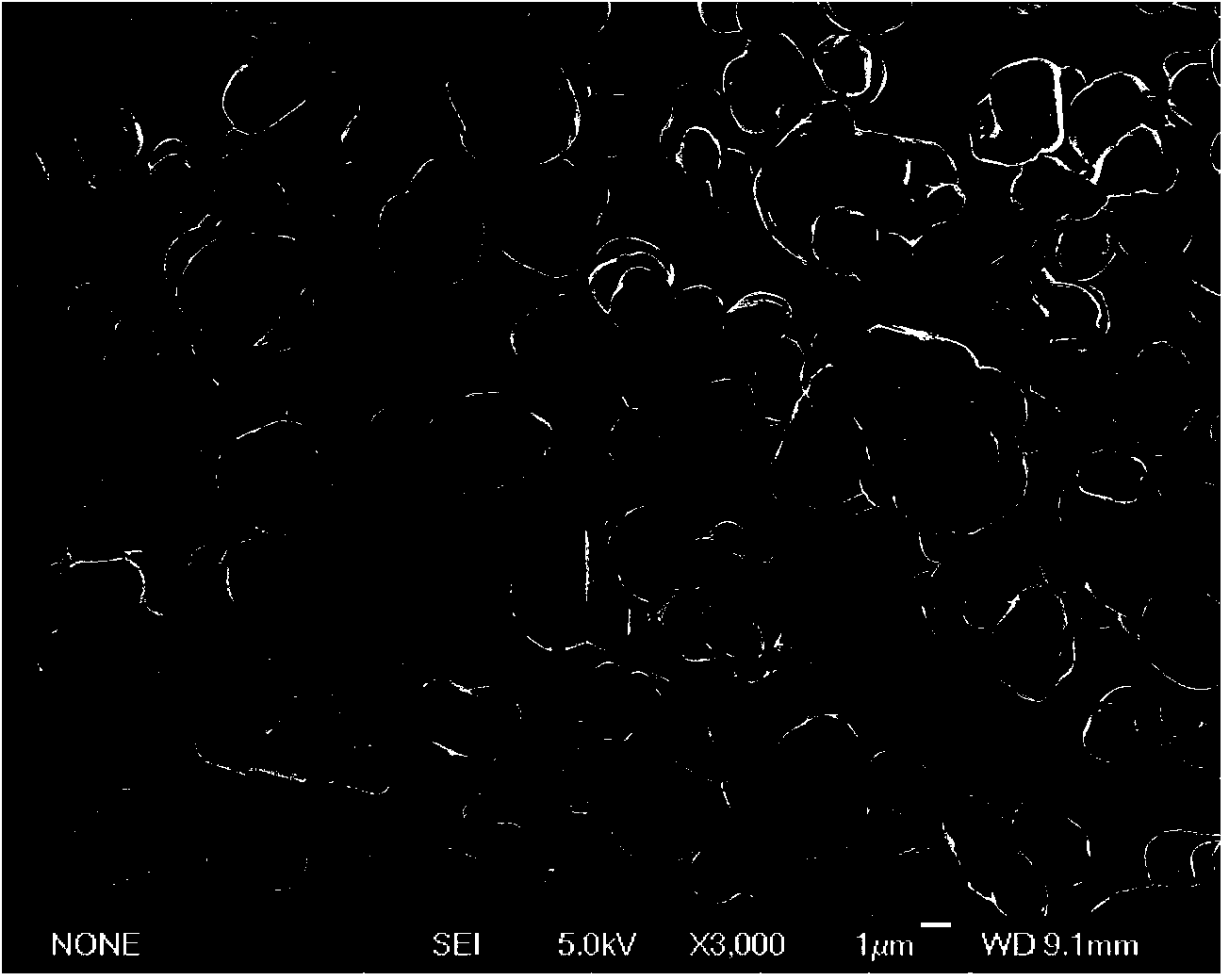

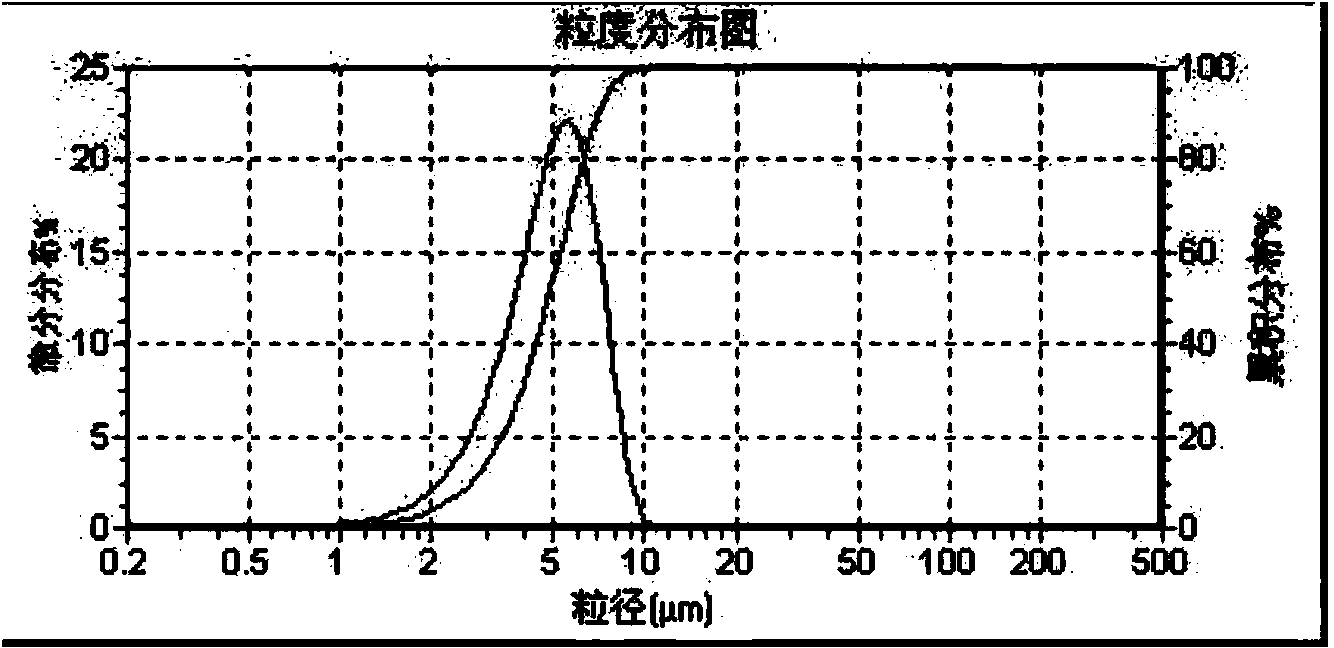

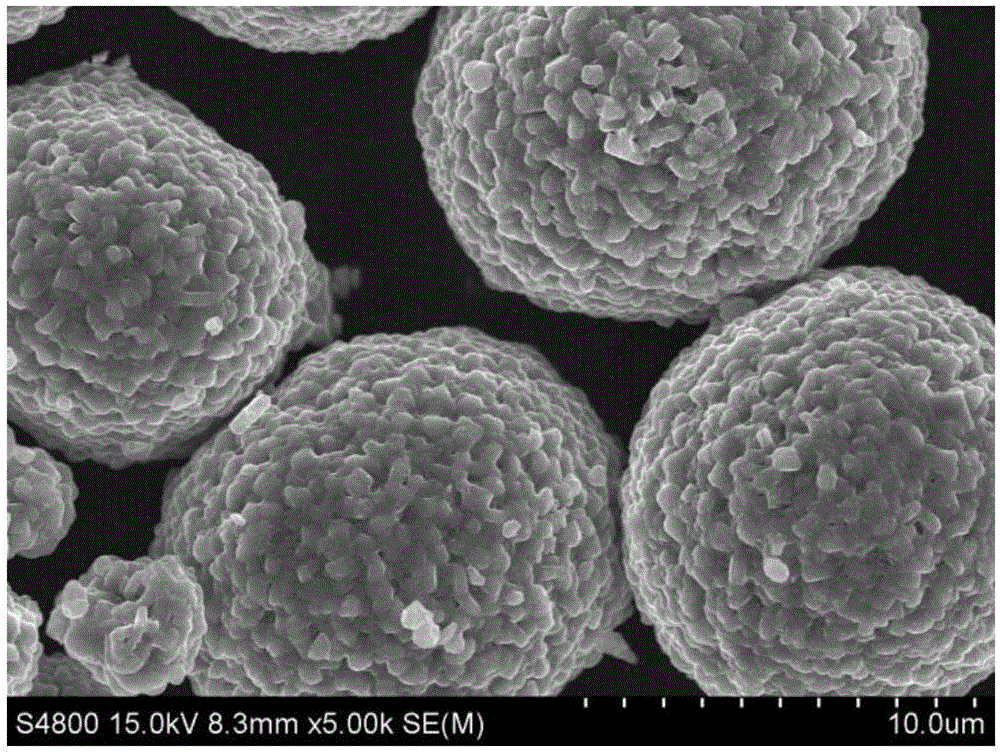

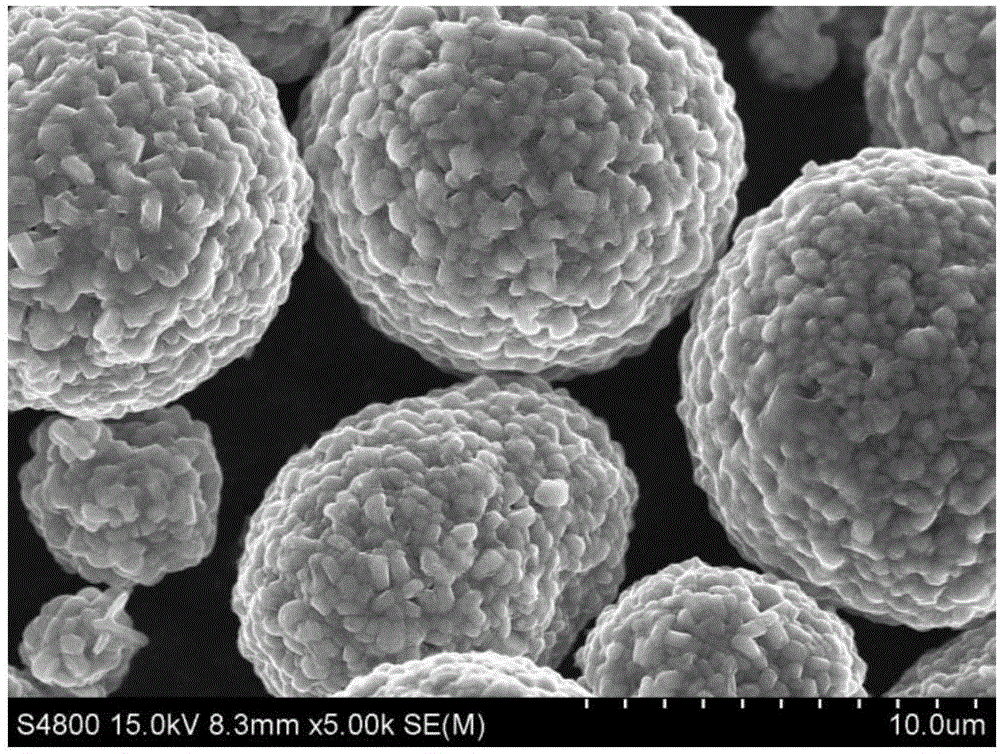

The invention provides a highly stable lithium nickel cobalt aluminate positive electrode material and its preparation method. The characteristic chemical formula of the lithium nickel cobalt aluminate material is LinNi1-x-yCoxAlyO2.mLiMaOb, wherein n is not less than 0.95 and not more than 1.15, x is more than 0.00 and less than 0.30, y is not less than 0.01 and not more than 0.10, m is more than 0.00 and less than 0.05, a is more than 0.0 and less than 3.0, b is a valence matching coefficient, and b is (M valence * a +1) / 2. The morphology of the material is a spheroidic secondary particle structure formed by a primary particle, the average particle size of the primary particle is 0.10-2.5mum, and the average particle size of the secondary particle is 3.0-20.0mum. LiMaOb is a composite oxide lithium ion conductor coating and is uniformly distributed on the surface of the primary and secondary particle, so the removal and embedding of lithium ions in the battery charge and discharge process are promoted, and the side reactions of the lithium nickel cobalt aluminate material and an electrolyte can be inhibited. The above lithium ion battery positive electrode material has the advantages of high energy, high safety and long cycle life.

Owner:HUBEI RONGBAI LITHIUM BATTERY MATERIAL CO LTD

High-temperature resistant coating for refining crystal grains of casting and preparation method of high-temperature resistant coating

InactiveCN103100661AGuaranteed high temperature performanceGrain refinementFoundry mouldsFoundry coresAverage sizeCobalt aluminate

The invention relates to a high-temperature resistant coating for refining crystal grains of a casting. The high-temperature resistant coating comprises silica sol and white fused alumina powder as main components. The high-temperature resistant coating is characterized by also comprising cobalt aluminate as the main component, wherein the addition proportion of the cobalt aluminate to the silica sol to the white fused alumina powder is (0.07-0.15):1: (2.4-2.6). The high-temperature resistant coating provided by the invention has the advantages that fine grains of a casting crystal grain refiner are uniformly inlaid in the inner surface of a shell in the shell making process to play a role of catalyzing the formation of a condensation nucleus in the casting pouring, solidification and formation processes, so that the average size of the crystal grains of the casting can be up to 0.4-0.8mm, the grain size can be up to the first-level or third-level, and then, the aim of more conveniently and reliably refining the crystal grains is achieved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Surface modification technology of cathode material for lithium ion battery

ActiveCN103972486AImprove storage effectCell electrodesSecondary cellsMetallic materialsSodium-ion battery

The invention belongs to the field of inorganic nonmetallic materials and relates to a surface modification technology of a cathode material for a lithium ion battery. The surface modification technology comprises the following steps: the cathode material for the lithium ion battery, mainly including ternary materials of lithium cobalt oxide, lithium manganese oxide, lithium nickel-cobalt-manganese oxide, nickel and cobalt aluminate, layered rich lithium high manganese and other solid solution materials, is sintered at a high temperature, and put into an organic solvent to be fully stirred; then a solid-liquid mixture is filtered; a filter cake is heated to obtain a final product. The surface modification technology of the anode material for the lithium ion battery has the benefits that through the cathode material for the lithium ion battery modified by the surface modification technology, the pH value and the impurity lithium content of the material can be effectively reduced, and the high temperature cycle and the storage performance of the material can be improved, so that the material has excellent cycle performance and high-temperature performance; the surface modification technology can be widely used in the cathode material for the lithium ion battery and particularly is applied to a power type lithium ion battery.

Owner:QINGDAO LNCM

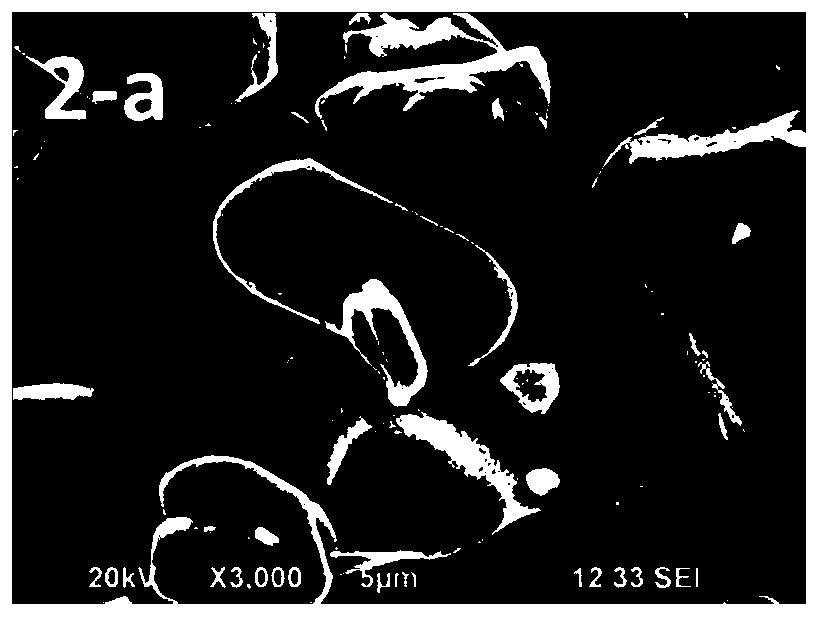

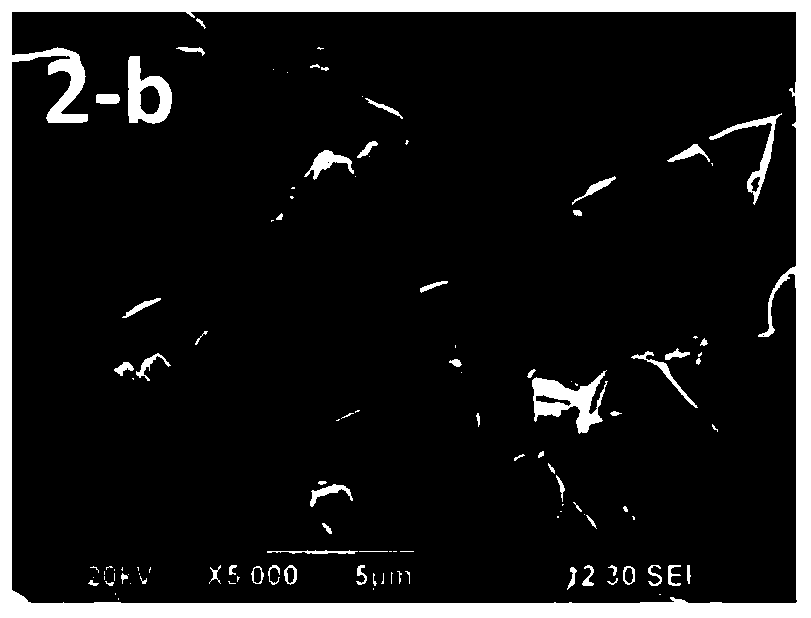

Lithium nickel and cobalt aluminate anode material and preparation method and lithium ion battery thereof

InactiveCN106532038ASurface low in alkalinityAlkaline compounds decreaseCell electrodesSecondary cellsNickel saltLithium compound

The invention provides a preparation method of a lithium nickel and cobalt aluminate anode material. The preparation method comprises the following steps that nickel salt, cobalt salt, aluminum salt, a first complexing agent and a first precipitant are mixed and are heated, precipitation reaction is performed to obtain aluminum nickel and cobalt hydroxide suspension liquid, the suspension liquid is mixed with manganese salt, a second complexing agent and a second precipitant, a first intermediate product is obtained after heating reaction, thermal treatment is performed to obtain a second intermediate product, the second intermediate product is mixed and sintered with a lithium compound to obtain a third intermediate product, the third intermediate product is mixed with a coating agent, and thermal treatment is performed to obtain the lithium nickel and cobalt aluminate anode material. Compared with the prior art, manganese hydroxide coating is conducted on the surface of aluminum nickel and cobalt hydroxide, and direct contact between surface nickel ions and air is effectively avoided in follow-up treatment, so that the alkali compound content of the lithium nickel and cobalt aluminate anode material is remarkably reduced. In addition, the material can react with residual lithium on the surface of a sintering product through the follow-up coated coating agent, and the alkalinity and moisture of the lithium nickel and cobalt aluminate anode material are reduced.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

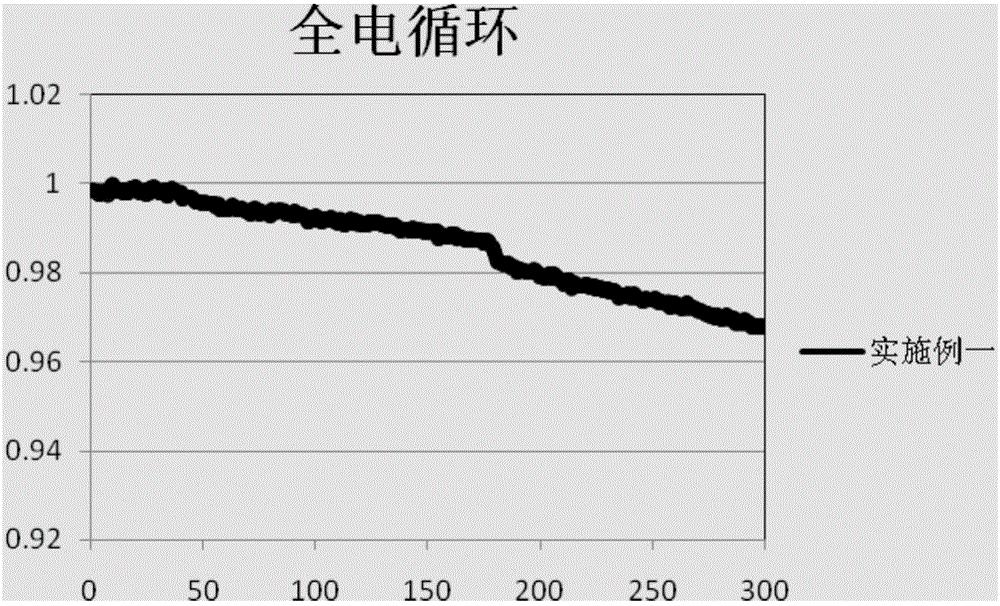

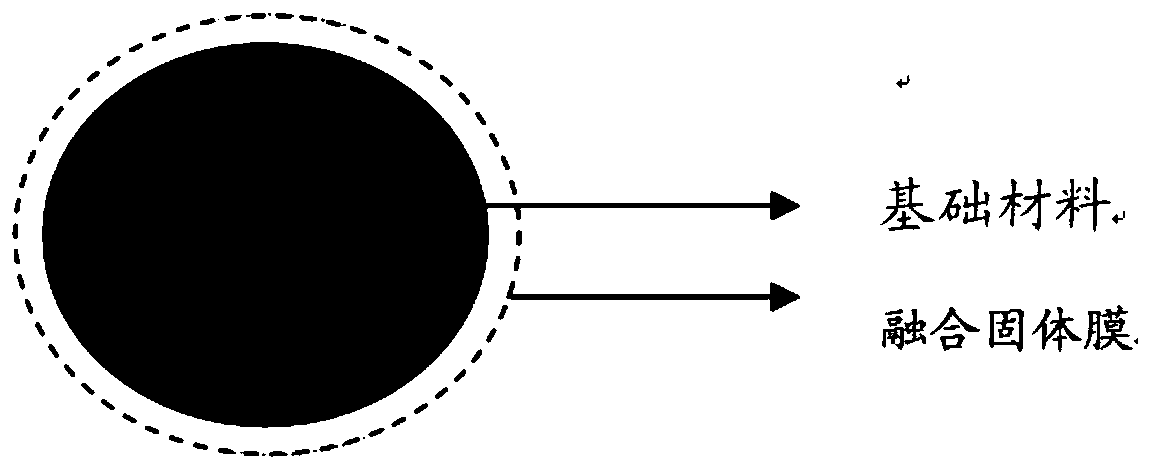

Positive electrode material of lithium ion battery as well as preparation method and application of positive electrode material

PendingCN109888208AImprove interfacial ionic conductivityReduce exposureCell electrodesSecondary cellsElectrical conductorComposite oxide

The invention relates to a positive electrode material of a lithium ion battery. The positive electrode material comprises a basic material and a fast ion conductor coating layer, wherein the coatinglayer is selected from a lithium-titanium composite oxide, a lithium-zirconium composite oxide or a lithium-phosphorus composite compound, wherein the basic material is selected from one or more thantwo of lithium cobalt oxide, lithium nickel cobalt aluminate, lithium nickel cobalt manganate, lithium manganate, lithium iron phosphate, lithium nickel manganate or lithium nickel cobalt oxide; the preparation method comprises the following stepsof preparing the raw materials containing elements in the fast-ion conductor into a precursor, and then carrying out surface fusion with the basic material, and the solid coating film is formed by sintering, so that the ion migration capacity is improved, and the decomposition reaction of the transition element to the electrolyte is reduced, the cyclelife of the prepared lithium ion battery is prolonged, the safety is improved, and the positive electrode material has a wide application prospect.

Owner:高点(深圳)科技有限公司 +1

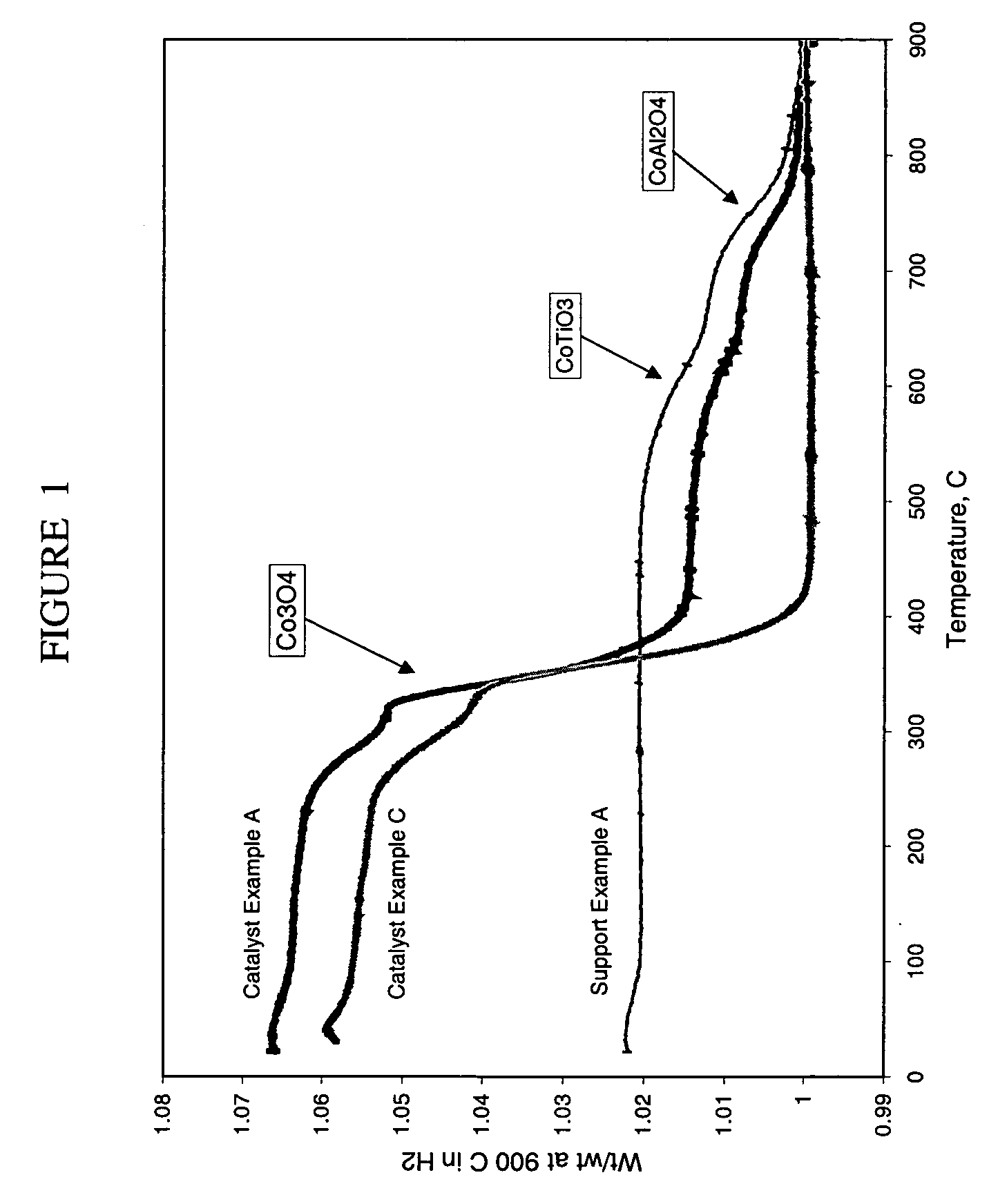

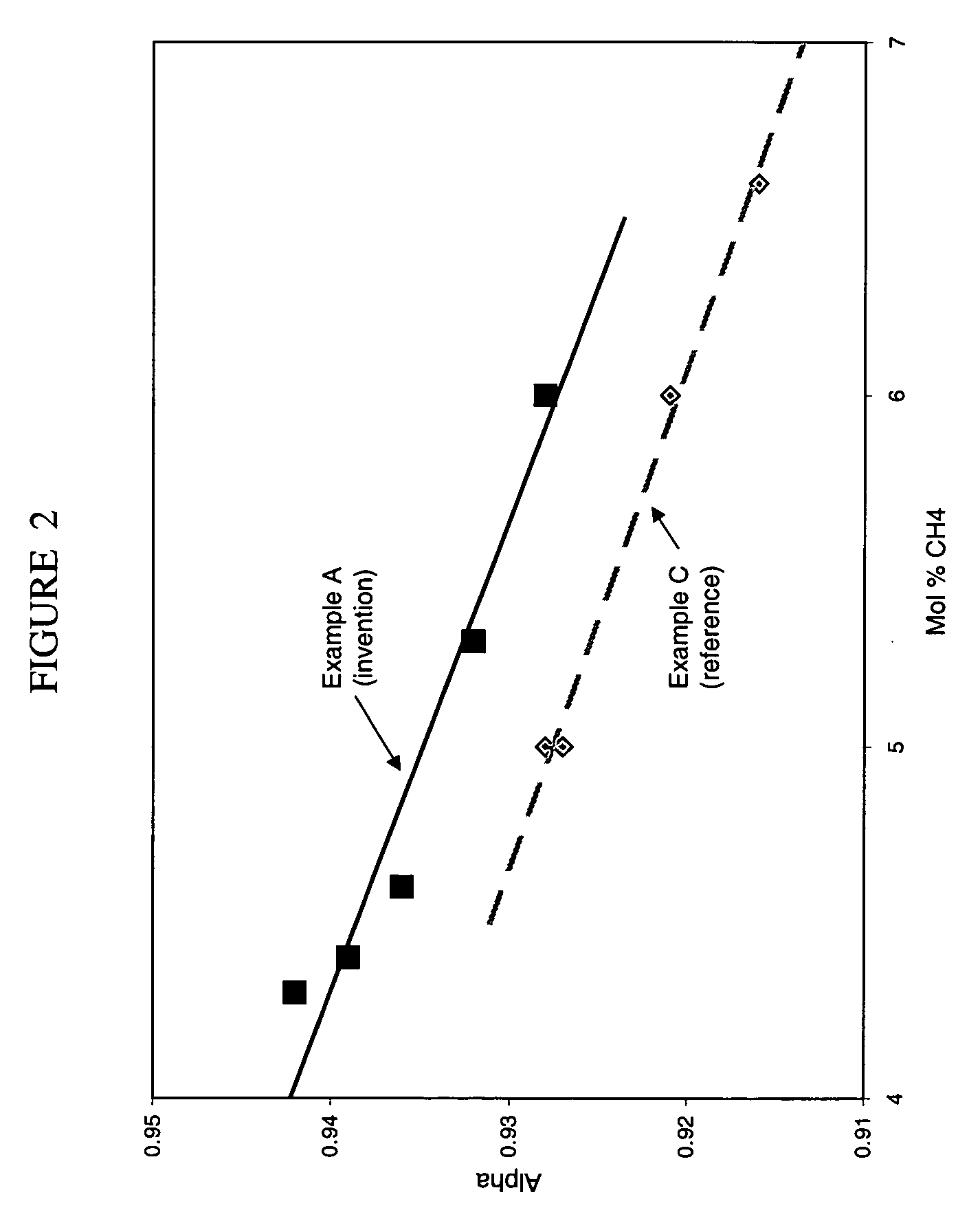

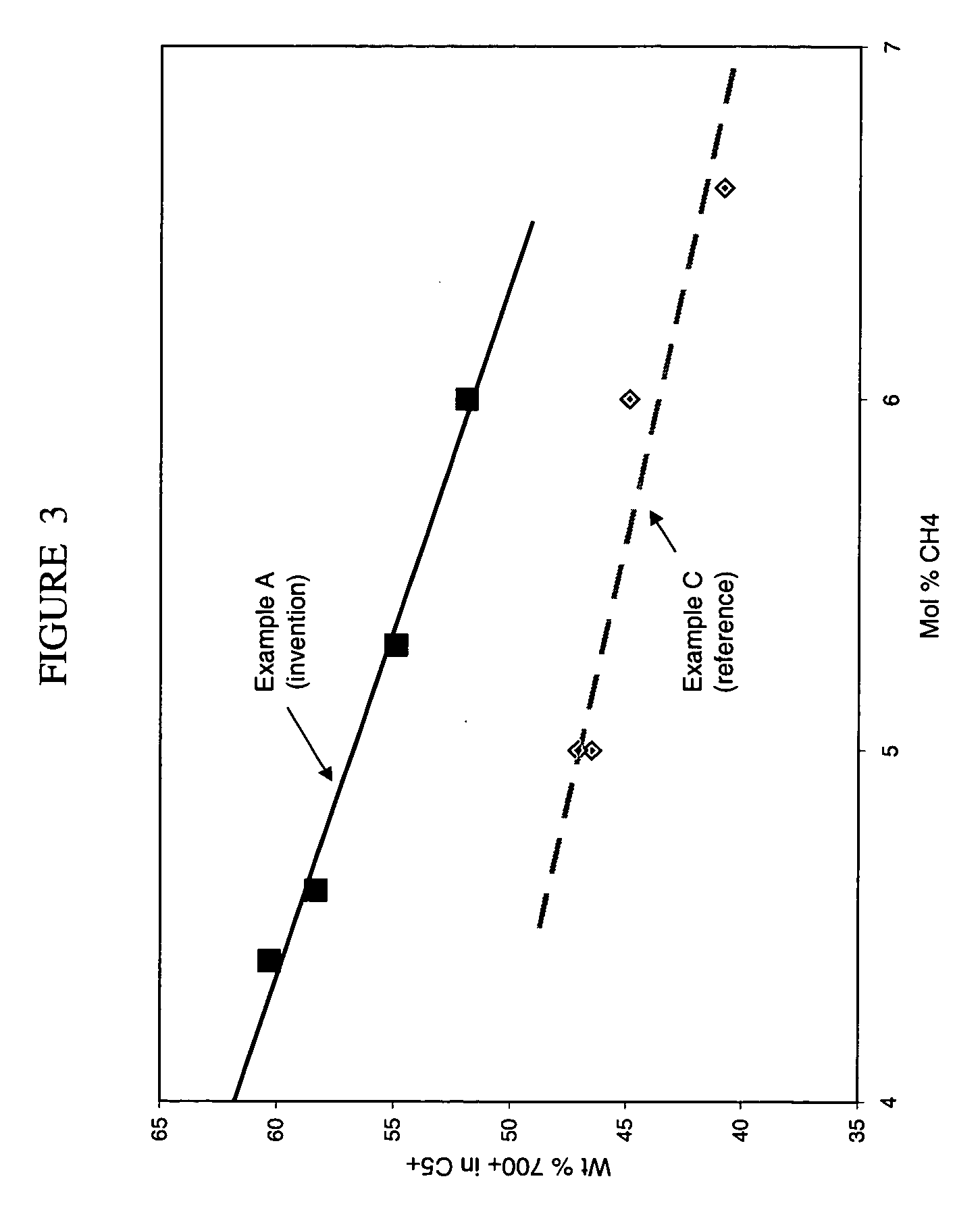

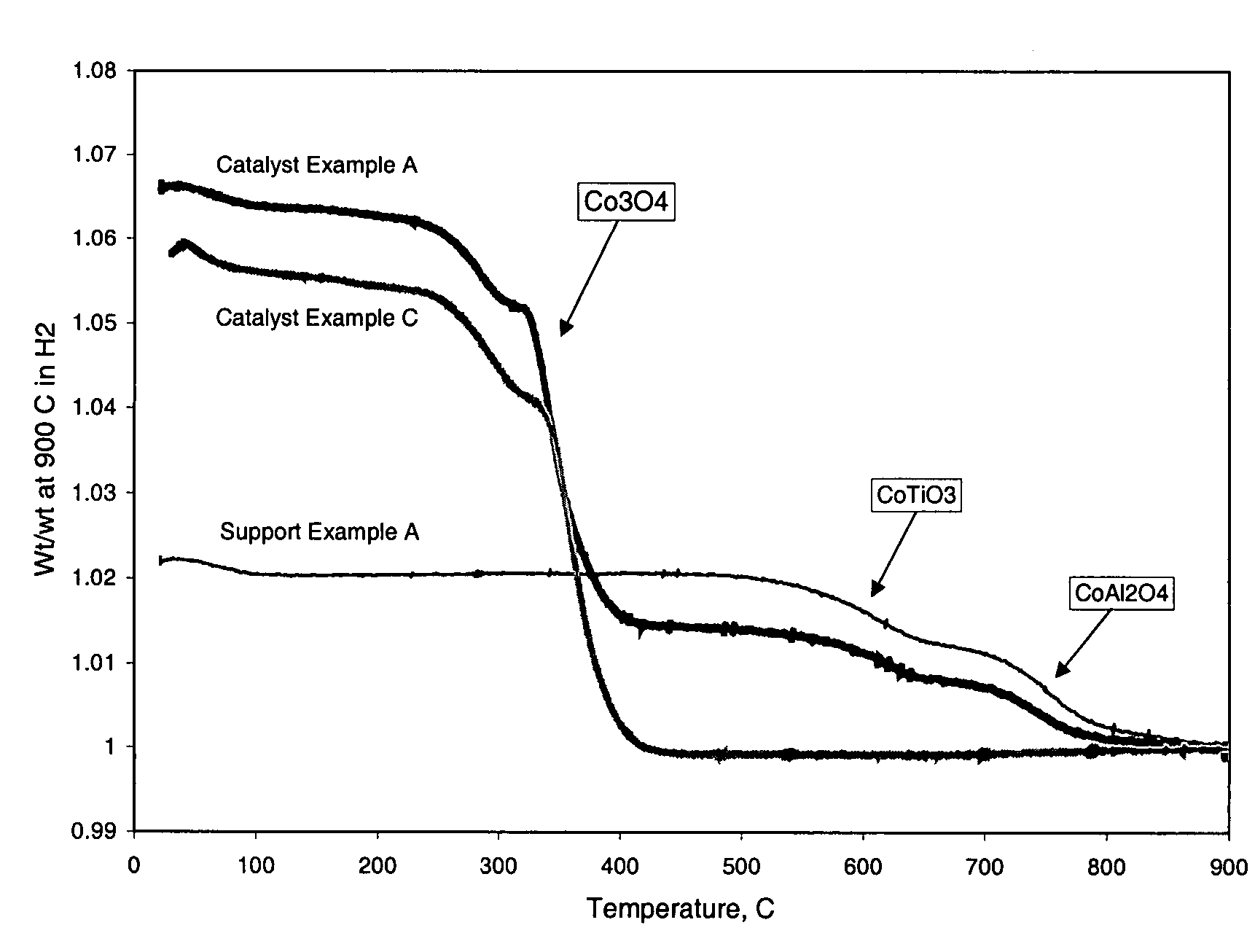

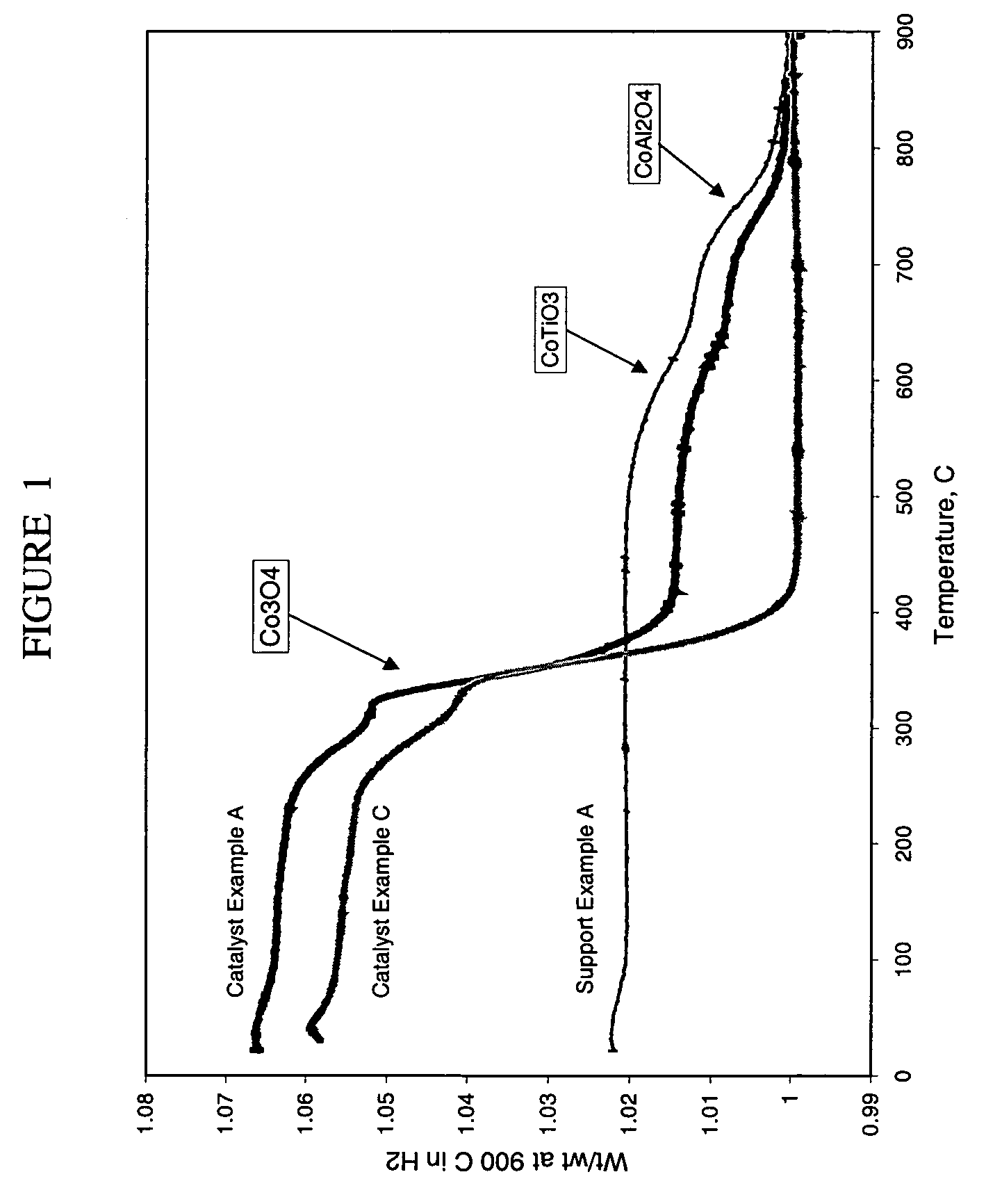

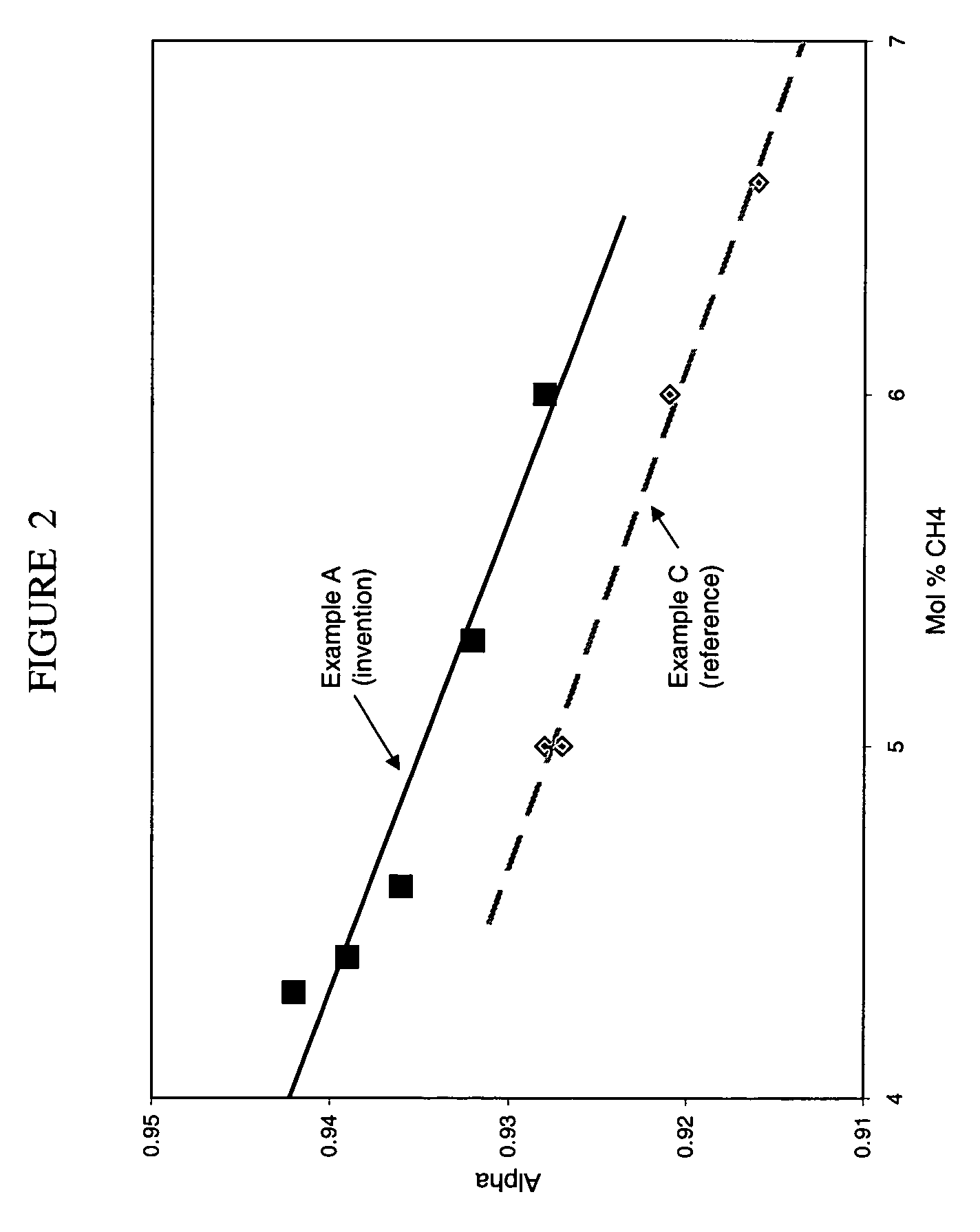

Preparation of titania and cobalt aluminate catalyst supports and their use in Fischer-Tropsch synthesis

ActiveUS20040204506A1Add supportOther chemical processesOrganic compound preparationSilicon dioxideCobalt aluminate

Supports for Fischer-Tropsch catalysts are formed by forming a particulate material from titania, alumina and optionally silica. A cobalt compound is incorporated into the particulate material which then is calcined to convert at least part of the alumina to cobalt aluminate.

Owner:EXXON RES & ENG CO

Preparation method of dark-blue zirconia ceramic

The invention provides a preparation method of dark-blue zirconia ceramic. The method comprises following steps: step one, taking zirconia powder as the base material, adding at least one component from following components: cobalt ferrite, cobalt oxide and cobalt aluminate in the zirconia powder as the coloring agent, and adding polyvinyl alcohol water solution in the zirconia powder as the binder; step two, putting the mixture of the ceramic raw materials prepared in the step one into a ball-grinding bottle to grind until the mixture is homogenously mixed, pouring out the suspending liquid in the ball-grinding bottle, drying the suspending liquid to remove the water, and obtaining ceramic powder; step three, pressing the ceramic powder obtained in the step two into required ceramic bodies through the dry pressing technology or the isostatic pressing technology; step four, putting the ceramic bodies obtained in the step three into a high-temperature sintering furnace after slow glue discharging to sinter into products. The preparation method produces a dark-blue zirconia ceramic, and the ceramic contains a coloring material. The coloring material can stably exist at the temperature of 1500 DEG C, furthermore, the coloring material not only can guarantee that zirconia is sintered into a completely compact state, but also makes the zirconia ceramic have a dark-blue appearance.

Owner:无锡特科精细陶瓷有限公司

Preparation of titania and cobalt aluminate catalyst supports and their use in Fischer-Tropsch synthesis

ActiveUS7253136B2Organic compound preparationOther chemical processesSilicon dioxideCobalt aluminate

Supports for Fischer-Tropsch catalysts are formed by forming a particulate material from titania, alumina and optionally silica. A cobalt compound is incorporated into the particulate material which then is calcined to convert at least part of the alumina to cobalt aluminate.

Owner:EXXON RES & ENG CO

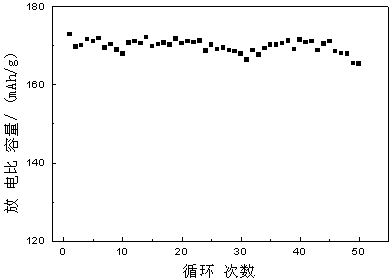

Method for preparing ternary high-nickel positive electrode material by employing sol-gel self-propagating combustion method

ActiveCN107403903AParticles are highly dispersed at the nanoscaleIncreased dispersionElectrode thermal treatmentCombustionSodium fluoride

The invention relates to a method for preparing a ternary high-nickel positive electrode material by employing a sol-gel self-propagating combustion method. The ternary high-nickel positive electrode material is LiNi<1-x-y>CoxAlyO2 (1-x-y is greater than 0.5, x is smaller than 1 and greater than 0 and y is smaller than 1 and greater than 0). The method comprises the steps of mixing and dissolving a lithium source, a nickel source, a cobalt source and an aluminum source into deionized water, adding glutamic acid and sodium fluoride to obtain a mixed solution; preparing dry gel from the mixed solution; carrying out heating and heat preservation, and carrying out complete self-propagating combustion on the dry gel to generate fluffy powder; and carrying out heat treatment on the powder to prepare lithium nickel cobalt aluminate positive electrode material. Sol-gel self-propagating combustion is carried out to prepare the lithium nickel cobalt aluminate by employing a glutamic acid as water-soluble gel and sodium fluoride as a catalyst. According to the method, the rate capability of the material can be improved, the cycling stability of the material is improved and the first cycling specific discharge capacity reaches 270-320mAh / g; and meanwhile, the requirements on heat treatment equipment can be reduced and the method has a good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Precision casting process of high-temperature alloy turbine

InactiveCN110181001ALow shrinkageSolve Oxidation ProblemsFoundry mouldsFoundry coresPorosityAviation

The invention belongs to the technical field of aviation precision casting, and particularly relates to a precision casting process of a high-temperature alloy turbine. The precision casting process of the high-temperature alloy turbine comprises the following steps of designing and manufacturing a part mold, preparing a ceramic core, preparation of a shell slurry, preparation of a part shell, dewaxing of a shell, pre-roasting of the shell and casting of the part, wherein the part mold is designed to ensure the integral punching of a wax mold by adopting a bottom injection type design. An inner cavity of the part is filled with the ceramic core, the ceramic core is an aluminum-based ceramic coated with cobalt aluminate on the surface, the surface of the inner cavity of the part can be effectively reduced by coating the surface of the ceramic core with cobalt aluminate, so that the problems of oxidation and shrinkage in the inner cavity of a traditional casting process casting are successfully solved, and meanwhile, the high porosity can ensure that the ceramic core can be removed by a high-pressure water gun after being poured.

Owner:鹰普航空科技有限公司

Aqueous boron nitride coating capable of binding at low temperature and being used at high temperature

ActiveCN109021628AGood adhesionImprove stabilityCoatingsEnvironmental resistanceHexagonal boron nitride

The invention discloses an aqueous boron nitride coating capable of binding at a low temperature and being used at a high temperature. The coating is prepared from 15-60 wt% of hexagonal boron nitride, 2-15 wt% of a composite high temperature binder, 1 wt% of carboxymethyl cellulose, 0.5 wt% of a thickener, 1 wt% of cobalt aluminate, 0.2 wt% of isooctanol, and the balance is demineralized water. Apreparation method of the coating comprises the following steps: mixing and stirring carboxymethyl cellulose used as a dispersant, the high-temperature binder, the thickener, cobalt aluminate used asa high-temperature pigment and demineralized water at a normal temperature to form a uniform solution, adding the hexagonal boron nitride and isooctanol used as a defoamer to the solution, and performing stirring until a uniform system is formed. The coating adopts an aqueous system, has no harmful substance volatilization during use, is clean and environmentally friendly, has good adhesion, anddoes not crack or spall in order to effectively block direct contact between a metal melt and the surface of a refractory material. Additionally, the coating has excellent stability and suspension capacity, and the stability and the suspension capacity do not change under high dilution.

Owner:SHANGQIU NORMAL UNIVERSITY

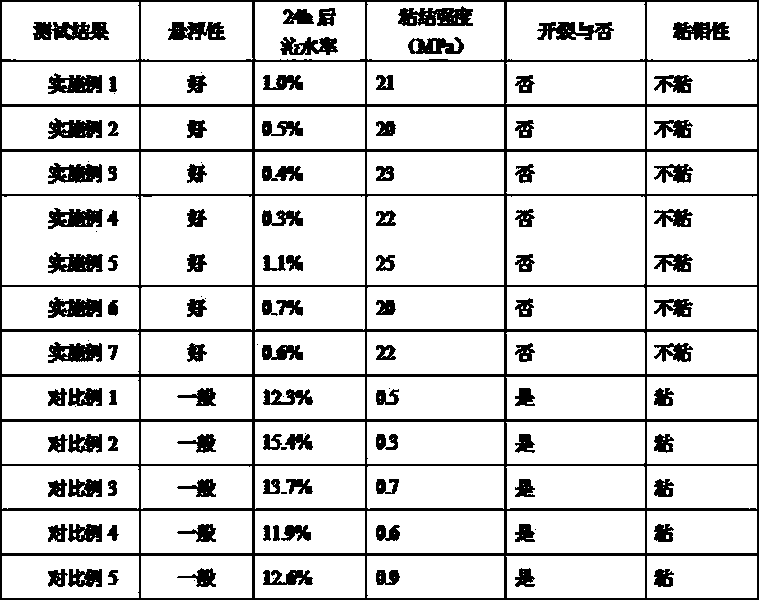

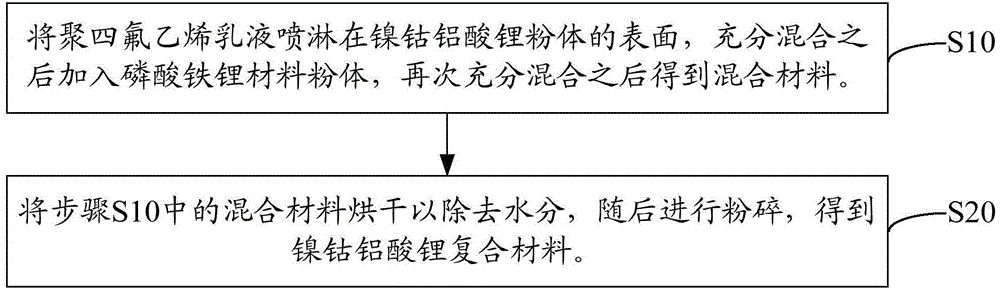

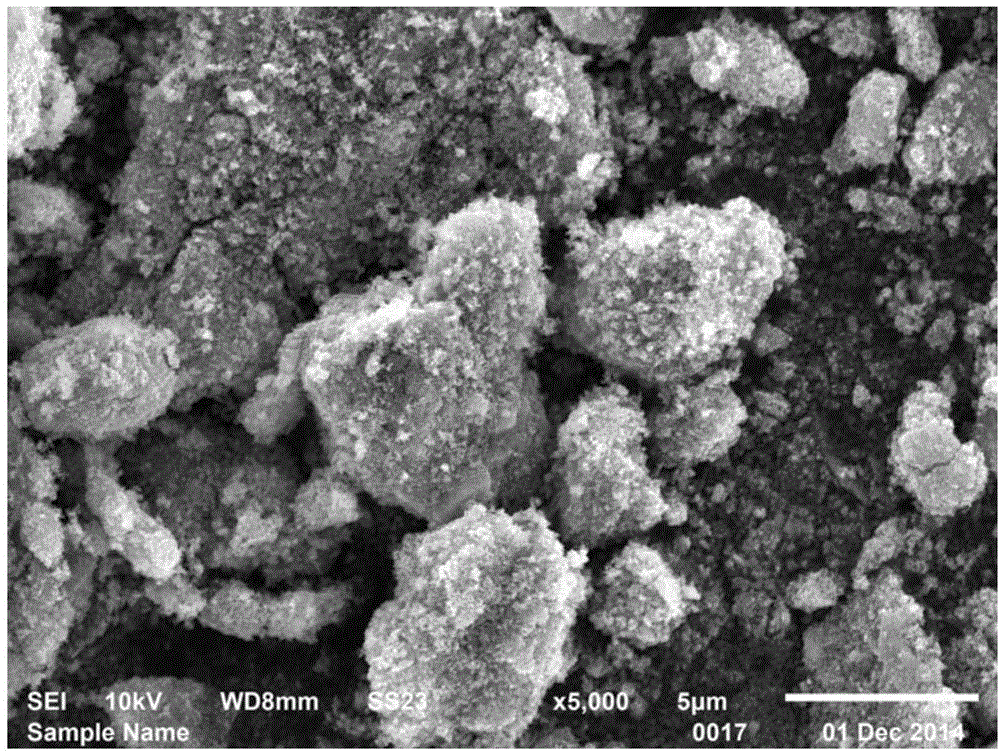

Lithium nickel cobalt aluminate composite material and preparation method and application thereof

InactiveCN106299353AAvoid ability to declineImprove gas problemCell electrodesMixed materialsLithium-ion battery

The invention relates to a lithium nickel cobalt aluminate composite material and a preparation method and application thereof. The lithium nickel cobalt aluminate composite material comprises lithium nickel cobalt aluminate and a lithium iron phosphate material coating the surface of the lithium nickel cobalt aluminate, wherein lithium ferric manganese phosphate and the lithium nickel cobalt aluminate are glued together through polytetrafluoroethylene. By the lithium nickel cobalt aluminate composite material, the problem of battery bulging can be solved. The preparation method of the lithium nickel cobalt aluminate composite material comprises the following steps of spraying a polytetrafluoroethylene emulsion on the surface of lithium nickel cobalt aluminate powder, fully mixing, adding lithium iron phosphate powder and fully mixing again to obtain a mixed material; and drying the mixed material to remove moisture, and then carrying out crushing to obtain the lithium nickel cobalt aluminate composite material. By the method, secondary sintering on the material is not needed, the problem of performance reduction of the lithium nickel cobalt aluminate composite material caused by sintering is solved and application is facilitated. Furthermore, the invention further provides a positive pole piece comprising the composite material and a lithium-ion battery comprising the positive pole piece.

Owner:LONG POWER SYST SUZHOU

Preparation method for ammonium fluoride modified nickel-cobalt-aluminum ternary positive electrode material

InactiveCN106602016ASimple processEasy to operateCell electrodesSecondary cellsLithiumMuffle furnace

The invention relates to the field of the battery material science, and particularly discloses a preparation method for an ammonium fluoride modified nickel-cobalt-aluminum ternary positive electrode material. The preparation method comprises the steps of putting ammonium fluoride granules and lithium nickel cobalt aluminate powder into an agate mortar at a normal temperature, and grinding and mixing uniformly; putting the grinded mixture into a muffle furnace, and performing heating, heat preservation and sintering; and after the obtained product is grinded, sieving by a 400-mesh sieve to obtain a final product. The preparation method disclosed by the invention is simple in process, convenient to operate, easy to realize large-scale production, low in energy consumption, and remarkable in energy-saving effect.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

High-capacity lithium ion battery cathode material and preparation method thereof

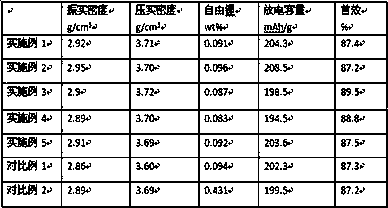

InactiveCN104201374AHigh specific capacityIncrease compaction densityCell electrodesSecondary cellsCobalt aluminateMaterials science

The invention relates to a high-capacity lithium ion battery cathode material and a preparation method thereof. The material consists of two active substances, namely LiNi<1-a-b>CoaAlbO2 and lithium cobalt oxide, as well as Al2O3 coating layers coating the surfaces of the active substances, wherein a is larger than 0.1 and smaller than 0.3, b is larger than 0.01 and smaller than 0.2, and 1-a-b is larger than 0 and smaller than 1; a lithium nickel and cobalt aluminate material accounts for 10-90 percent of the mass sum of the lithium nickel and cobalt aluminate material and the lithium cobalt oxide; the mass ratio of the Al2O3 coating layers to the active substances is (0.001-0.05):1. The preparation method comprises the following steps: uniformly mixing the two active substances, namely the LiNi1-a-bCoaAlbO2 and the lithium cobalt oxide according to the certain proportion; adding the mixture into a trivalent aluminum source solution and stirring to form a solid-liquid mixture; enabling the trivalent aluminum source solution to uniformly coat the surfaces of active substance particles; drying and calcining to obtain the high-capacity lithium ion battery cathode material. The specific capacity of the material disclosed by the invention is greatly improved compared with that of the lithium cobalt oxide; the compaction density, the conductivity and a voltage platform of the material are greatly improved compared with those of the lithium nickel and cobalt aluminate material; the material has better rate performance and cycle performance.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

Ether-ester composite electrolyte solution for stabilizing lithium metal battery

ActiveCN108336397AImprove uniformityImprove stabilityFinal product manufactureElectrolyte accumulators manufactureComposite electrolyteLithium metal

The invention discloses an ether-ester composite electrolyte solution for stabilizing a lithium metal battery, and belongs to the technical field of charging and discharging high-specific-energy secondary battery. The composite electrolyte solution contains an ether-ester mixed solvent, an electrolyte and lithium nitrate, wherein the electrolyte molar concentration is 0.5-4 mol / L, and the mass fraction of lithium nitrate is 0.01-10% of the ether-ester compound electrolyte solution. The composite electrolyte solution is prepared by introducing lithium nitrate as an additive into the ether-estermixed solvent containing the electrolyte. A metal lithium negative electrode can be effectively protected and is matched in a lithium metal battery with lithium iron phosphate, lithium nickel cobaltmanganate, lithium nickel cobalt aluminate and lithium cobaltate as a positive electrode, the battery cycle life can be improved obviously, good high and low temperature performance is achieved, and the ether-ester composite electrolyte solution is an electrolyte solution with great research value and industrialization potential.

Owner:TSINGHUA UNIV

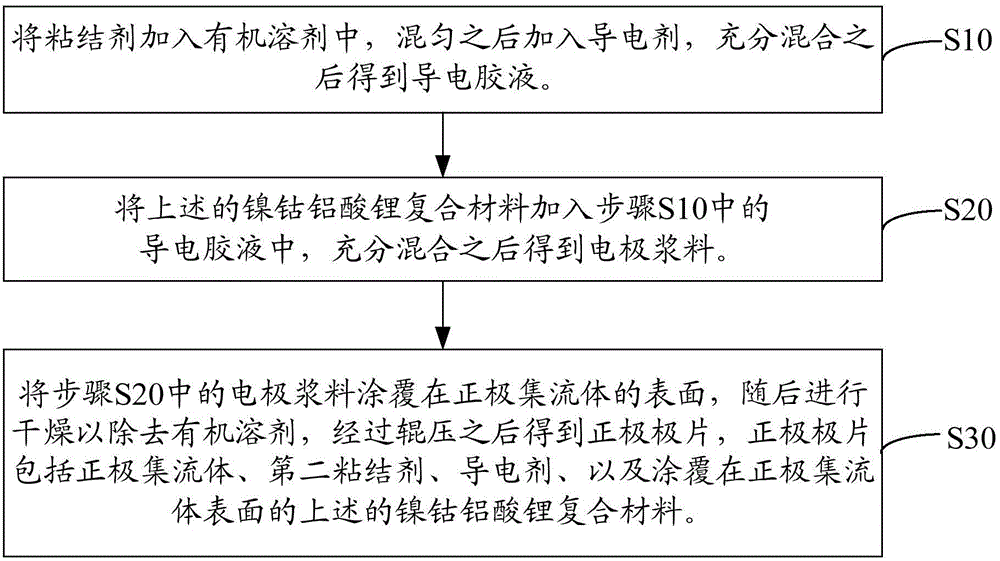

High-safety long-service-life lithium ion storage battery positive plate and preparation method and application thereof

InactiveCN107644968ASolve the problem of low specific capacityWork lessSecondary cellsNon-aqueous electrolyte accumulator electrodesSolventCobalt aluminate

The invention discloses a preparation method of a high-safety long-service-life lithium ion storage battery positive plate. The method includes: step 1, adding an adhesive into solvent to dissolve, and adding a conductive agent to obtain conductive adhesive; step 2, adding lithium iron phosphate and lithium nickel cobalt aluminate into the conductive adhesive obtained in the step 1, and well mixing to obtain lithium iron phosphate positive pole paste and lithium nickel cobalt aluminate positive pole paste; step 3, coating upper and lower surfaces of a metal foil current collector with the lithium iron phosphate positive pole paste and lithium nickel cobalt aluminate positive pole paste sequentially, drying, rolling, and slicing to obtain the high-safety long-service-life lithium ion storage battery positive plate. By adoption of the method for preparing the positive plate, an active substance coating with lithium nickel cobalt aluminate is applied to lithium iron phosphate, and accordingly the cycle life of a battery is prolonged, safety of the battery is improved, and specific capacity of the battery is increased.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

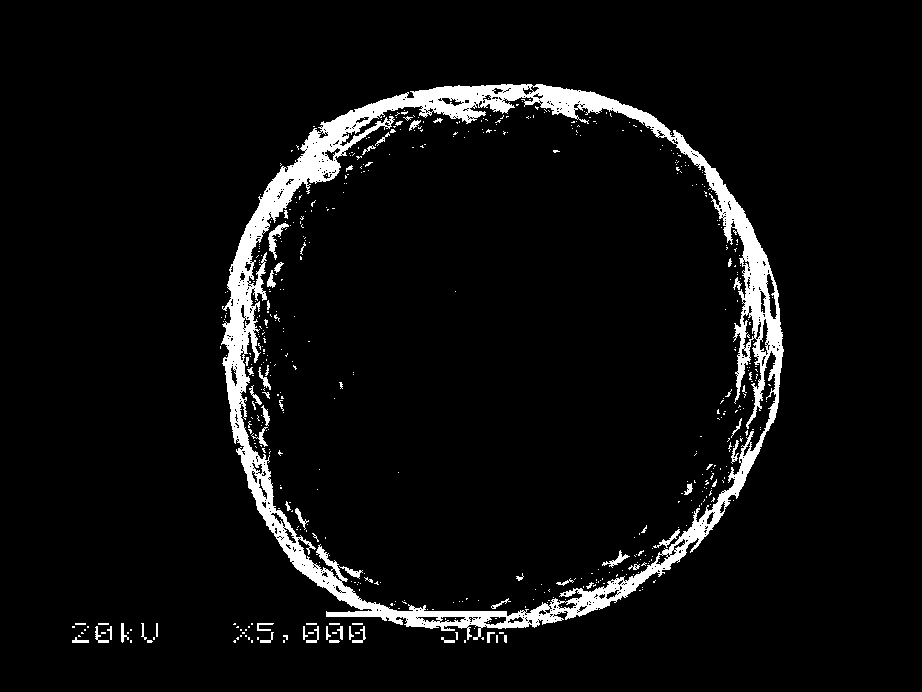

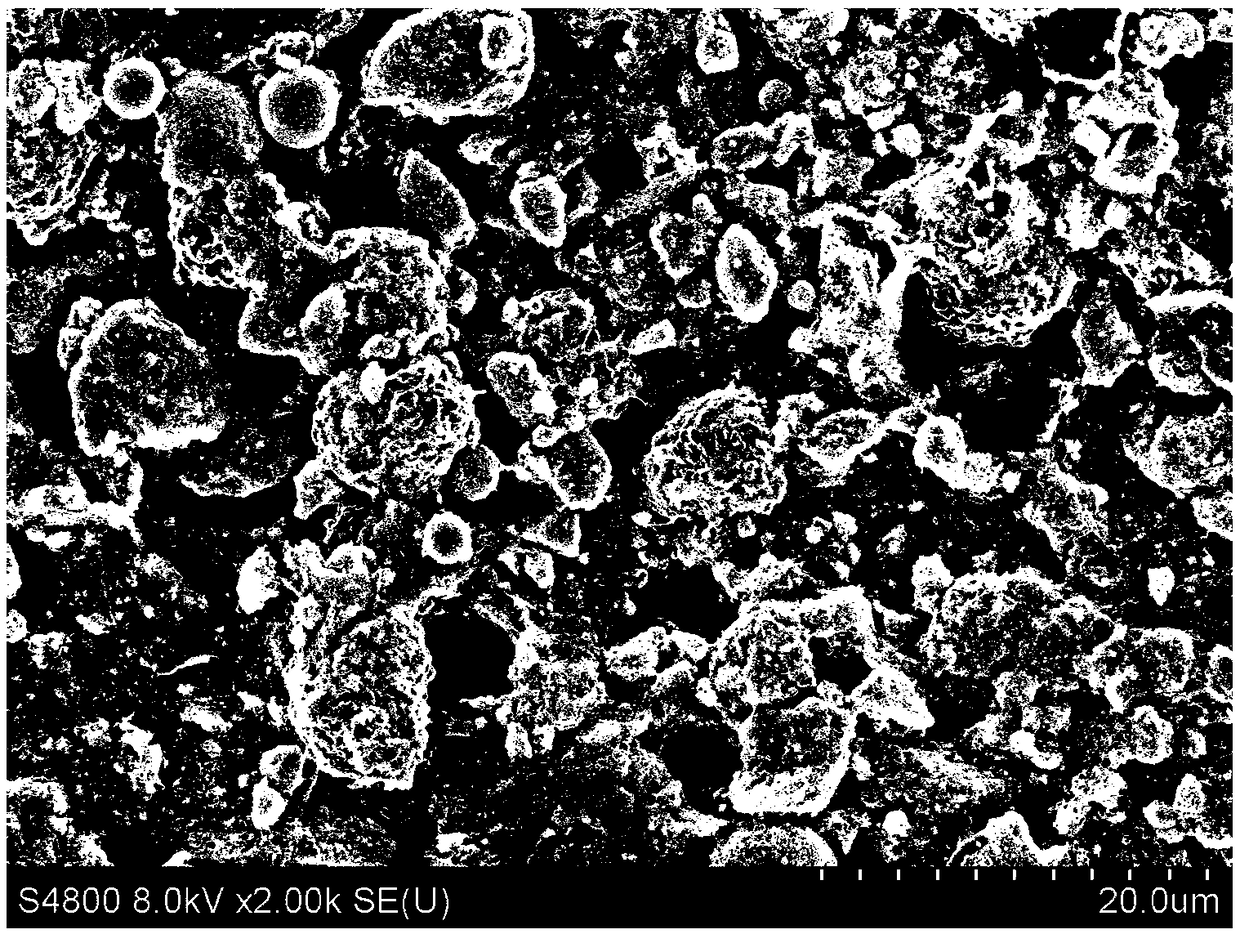

Lithium zirconium phosphate fast ionic conductor coated lithium nickel cobalt aluminate positive electrode material and preparation method thereof

ActiveCN109192956AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsElectrical conductorMaterials science

The invention relates to a lithium zirconium phosphate fast ionic conductor coat lithium nickel cobalt aluminate positive electrode material and a preparation method thereof, wherein that mass of thelithium zirconium phosphate fast ionic conductor is 0. 1-10wt%, and the lithium zirconium phosphate fast ionic conductor form a coating layer with a thickness of 5-30nm and is coated on the lithium nickel cobalt aluminate. The positive electrode material is spherical particles with a particle diameter of 5 to 15 mum. The preparation method comprises the following steps: (1) preparing a solution containing phosphorus source and zirconium source, adding zirconium source solution into an organic solvent or water, adding phosphorus source solution, stirring, adding lithium nickel cobalt aluminate,heating and stirring, slowly evaporating and drying, and placing the obtained powder in an oven for drying; (2) placing the powder obtained in the step (1) in a tubular furnace for low-temperature rapid sintering. The positive electrode material of the invention has good cycle stability and rate discharge performance; as that method of the invention can effectively reduce the problem of low circulation stability of the surface residual lithium and ternary materials dure conventional coating, the process cost is low, the process is simple, and the method is suitable for large-scale industrialproduction.

Owner:CENT SOUTH UNIV

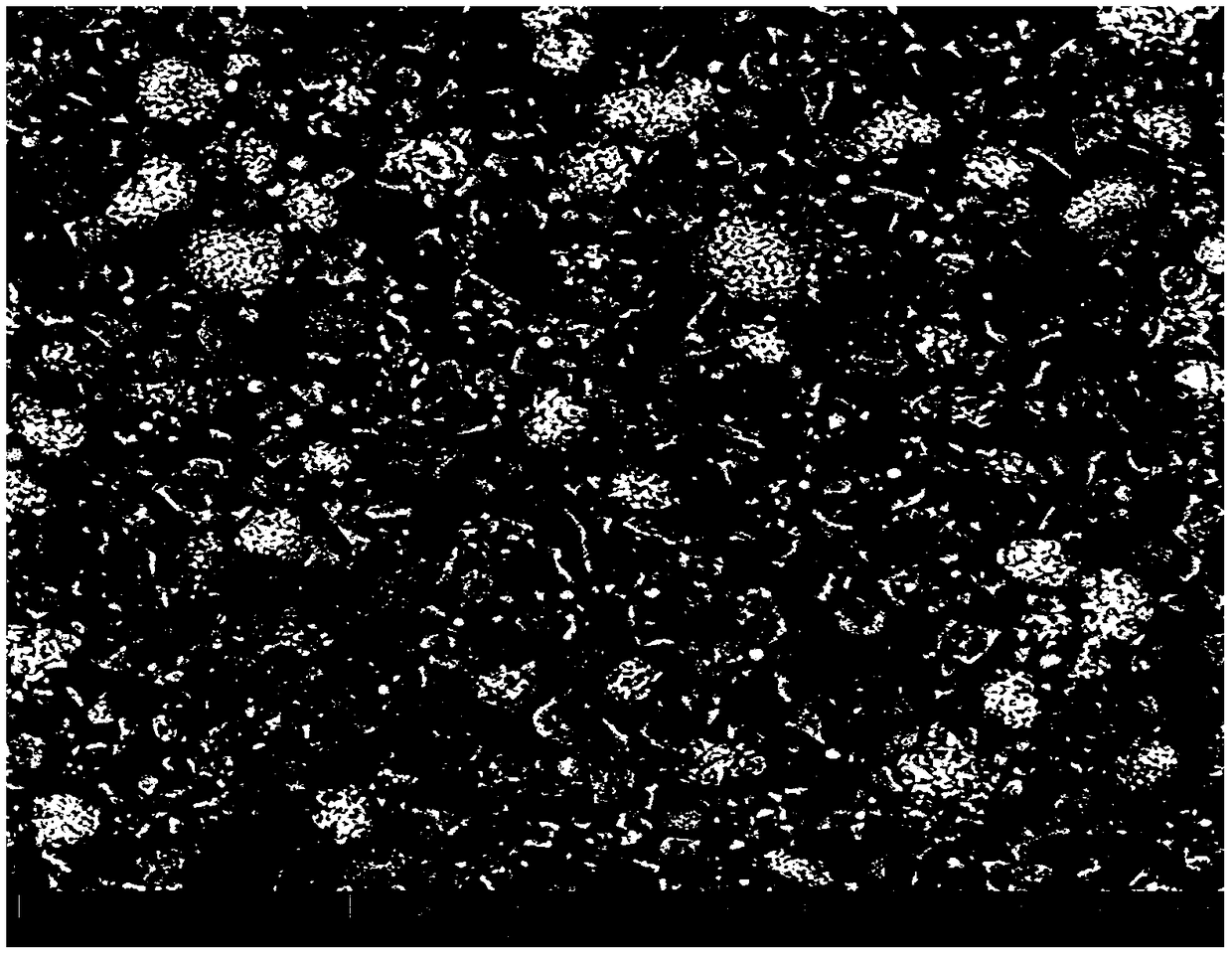

Positive material, positive plate and lithium ion battery

InactiveCN108777298ASmall heat releaseImprove securityCell electrodesSecondary cellsManganateIron phosphate

The invention provides a positive material, which is prepared from lithium manganese iron phosphate and a ternary material, wherein lithium manganese iron phosphate is LiMnzFe1-zPO4, and wherein z ismore than or equal to 0.6 and less than or equal to 0.9; the ternary material is lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate; the D50 of lithium manganese iron phosphate is3.6-6.5mu m; the D50 of lithium nickel cobalt manganate is 8.5-11.0mu m; the D50 of lithium nickel cobalt aluminate is 10.0-14.0mu m; the D50 of the ternary material is 1.5-2.5 times that of lithium manganese iron phosphate. The ternary material is surrounded by the lithium manganese iron phosphate material, so that the heat release amount of the positive material is reduced, the ignition point ofthe positive material is increased, and the safety performance of a battery can be improved; furthermore, the cycle performance of the battery is improved. The invention also provides a positive plate and a lithium ion battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Titanium chrome alloy lost-foam casting flame retardant coatings

InactiveCN101450369AReduce manufacturing costHigh refractorinessFireproof paintsFoundry mouldsPhosphateSuspending Agents

The invention provides a Ti-Cr alloy disappearance casting flame retardant coating, which is characterized in that weight contents of various composition of the flame retardant coating are: 46 to 58 percent of swell soil, 10 to 13 percent of binder, 13 to 22 percent of suspending agent, 12 to 17 percent of flame retardant agent and 3 to 9 percent of silica solution. The binder consists of 35 to 45 percent of corn starch; 3 to 5 percent of poly water-soluble cellulose ether, 0.5 to 4.5 percent of vinyl ethanol, 15 to 25 percent of solid organic acid, the residual water or 45 to 55 percent of phosphoric acid, 33 to 45 percent of aluminum dehydrogenate phosphate, 5 to 15 percent of boric acid and 6 to 12 percent of citric acid monohydrate. The suspending agent consists of 50 to 60 percent of artificial mica, 8 to 12 percent of sodium borate, 5 to 8 percent of phosphoric acid and the balance being water ethyl acetate. The flame retardant agent consists of 35 to 45 percent of cobalt aluminate, 28 to 36 percent of magnesium chloride and 24 to 29 percent of potassium chloride. The casting flame retardant coating can improve the surface quality of casting products effectively and the finish of the casting products, and has cohesive property and heat preservation property.

Owner:大连核心铸造技术工程研究所

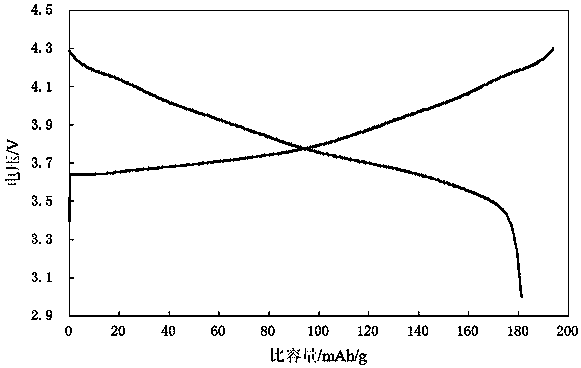

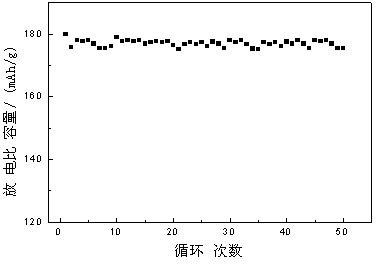

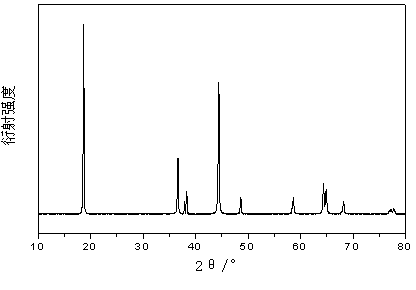

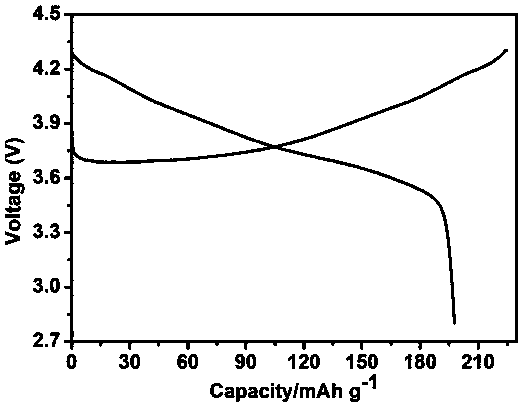

Preparation method of high-capacity lithium nickel cobalt aluminate

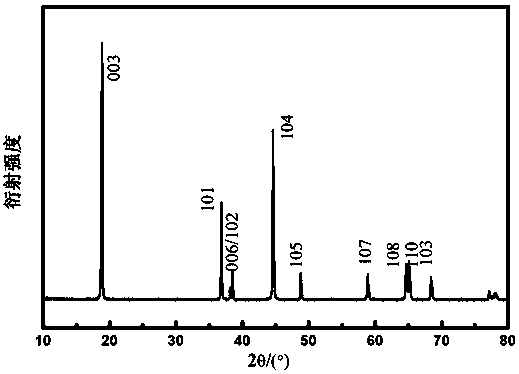

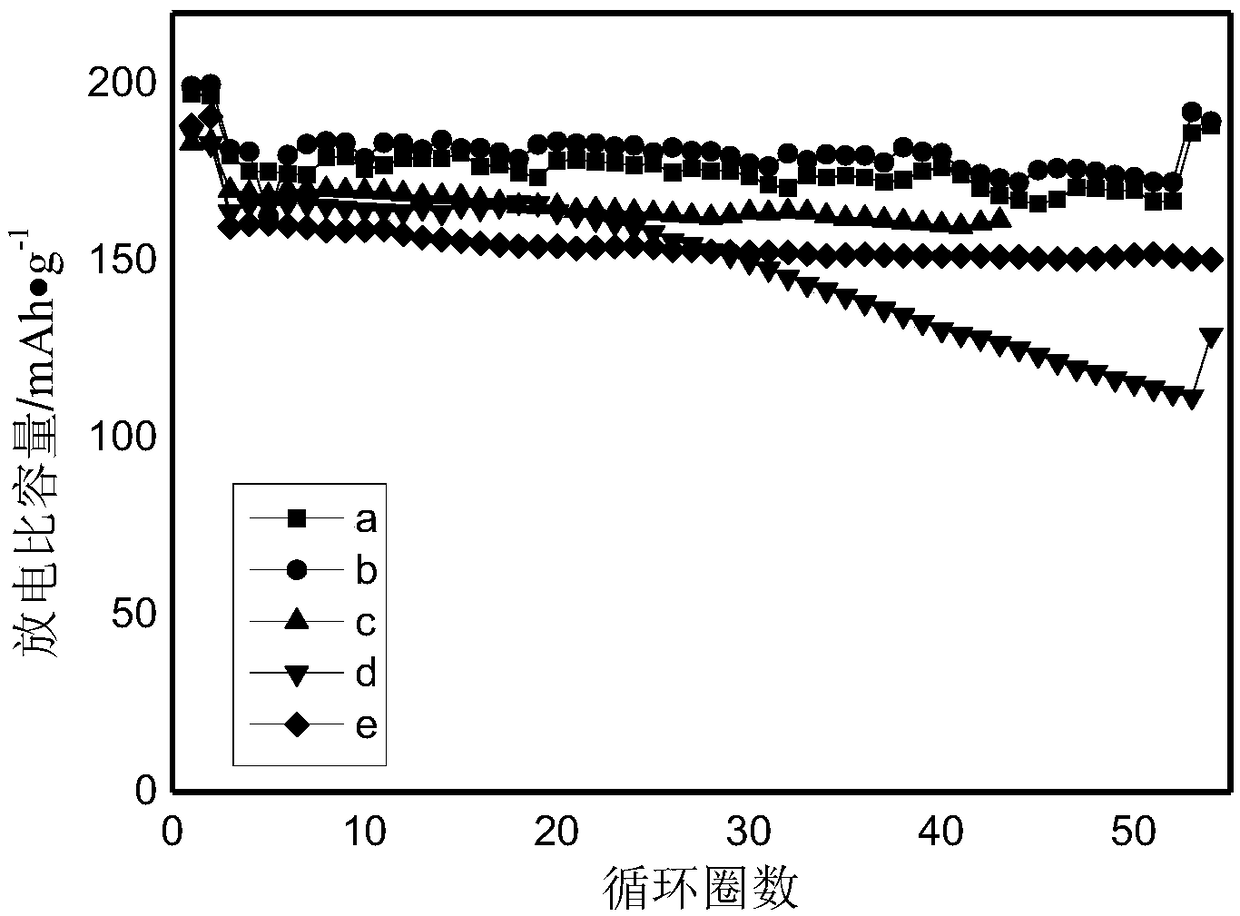

ActiveCN104795556AHomogeneous material phaseMorphological rulesCell electrodesSecondary cellsAluminiumLithium electrode

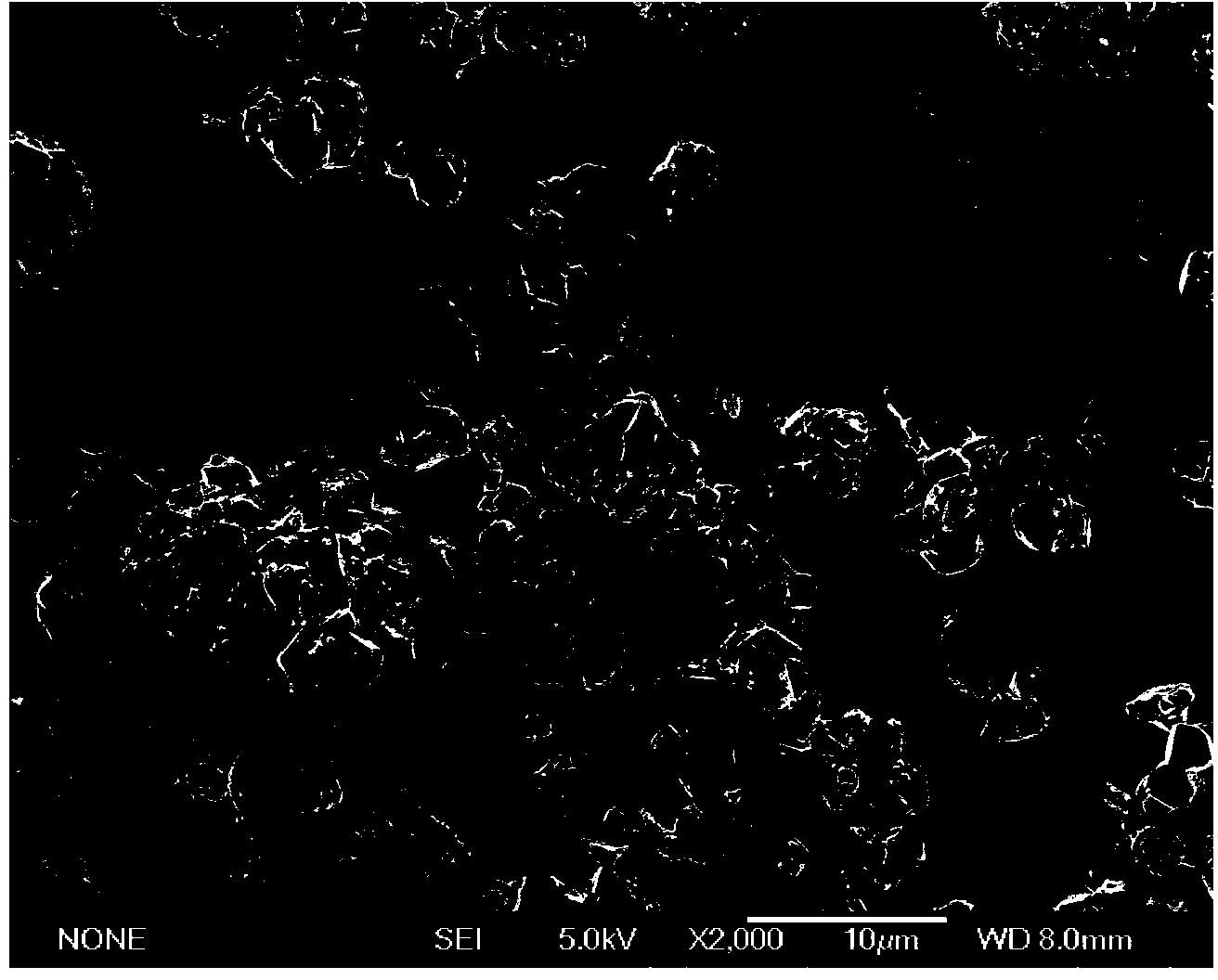

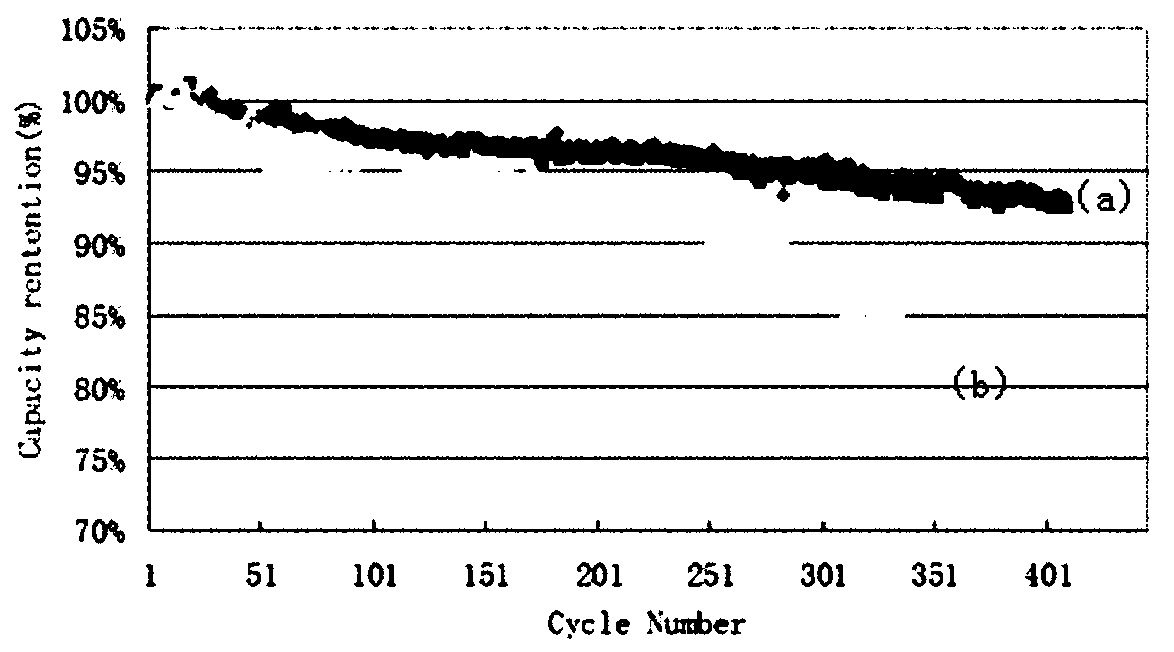

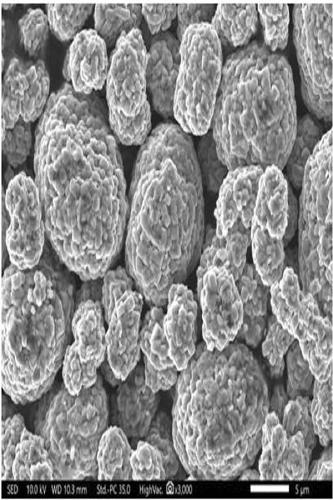

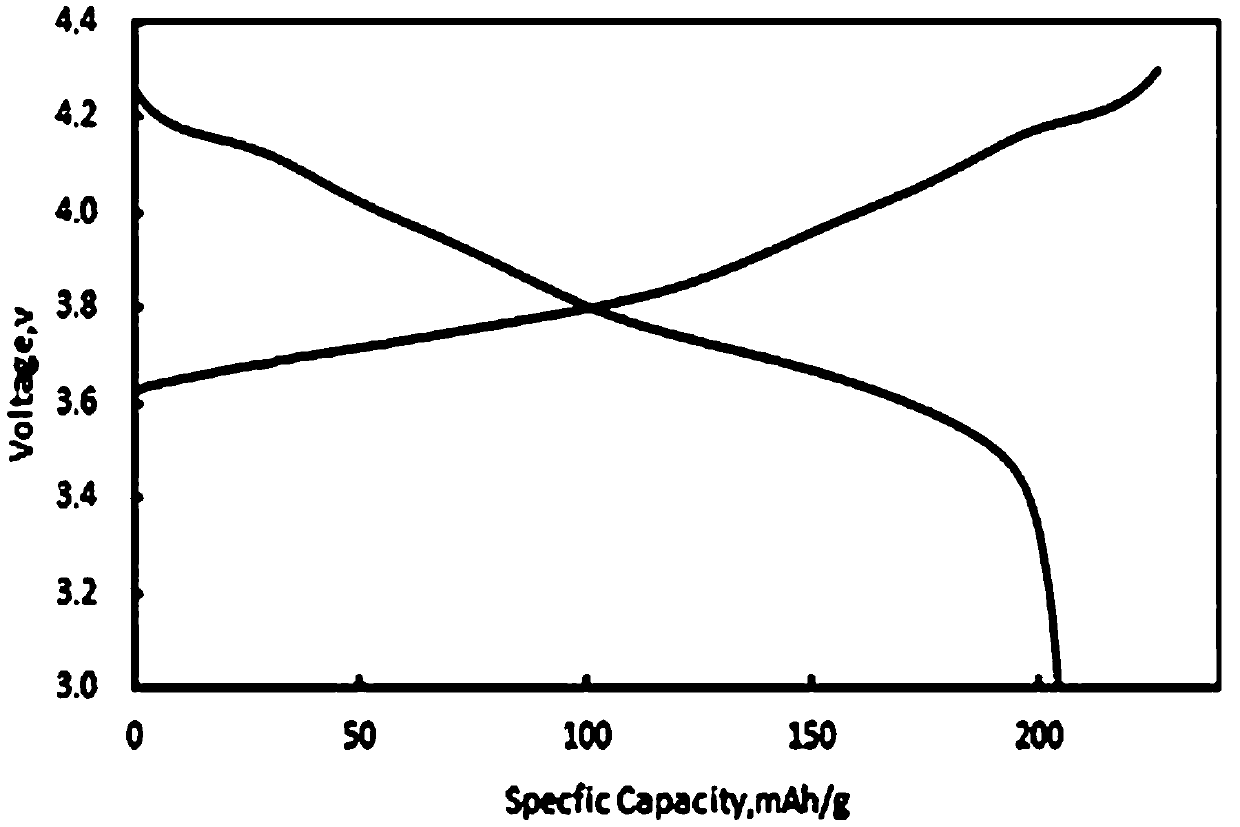

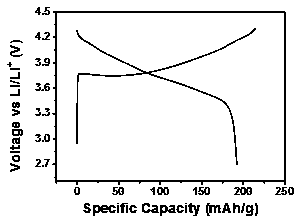

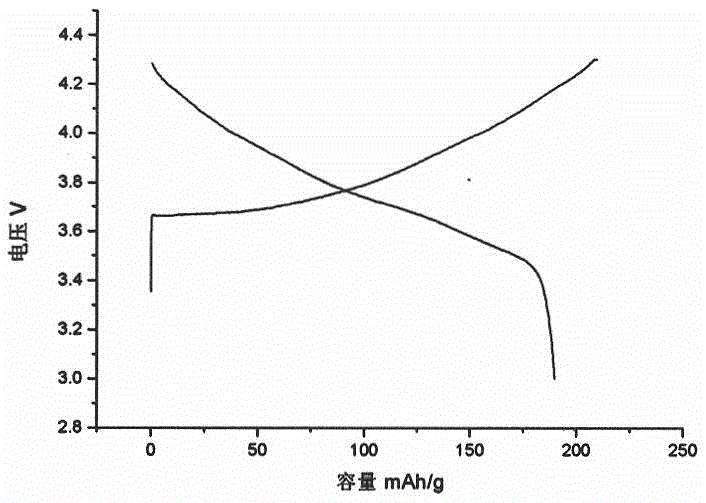

The invention relates to a preparation method of a high-capacity lithium ion battery cathode material of lithium nickel cobalt aluminate. The preparation method comprises: adding a nickel-containing compound, a cobalt-containing compound, a lithium-containing compound, and an aluminium-containing compound into a high temperature-resistant ball-milling tank and performing uniform mixing; putting the tank into a mechanical device capable of heating and rotating; performing ball milling at a room temperature; performing mixing for 5-20h; sintering the reactants in the ball-milling tank in the presence of air flow or oxygen flow at two temperature segments while keeping ball milling, wherein firstly, elevating the temperature to 400-600 DEG C in the presence of air flow or oxygen flow and performing sintering for 2-10h, and elevating the temperature to 700-900 DEG C in the presence of air flow or oxygen flow and performing sintering for 5-30h; performing cooling while performing ball milling till the temperature is relatively low; and opening the device to obtain cathode material powder of lithium nickel cobalt aluminate. The method is simple in technology, and raw materials can be completely mixed through high-temperature ball milling to obtain the cathode material of lithium nickel cobalt aluminate. In a voltage range of 3.0-4.2V and under a rate of 0.2C, the cathode material has an initial discharge specific capacity higher than 180mAH / g and has excellent cycle performance.

Owner:湖南秒冲新能源科技有限责任公司

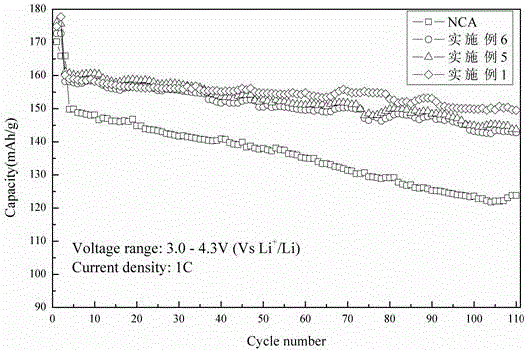

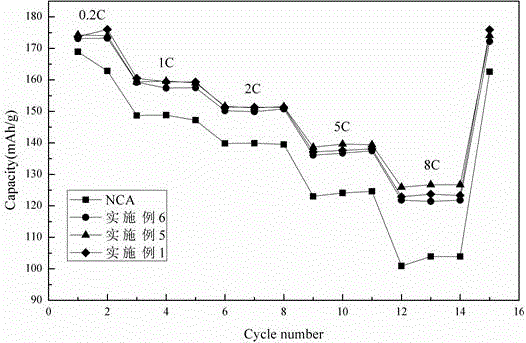

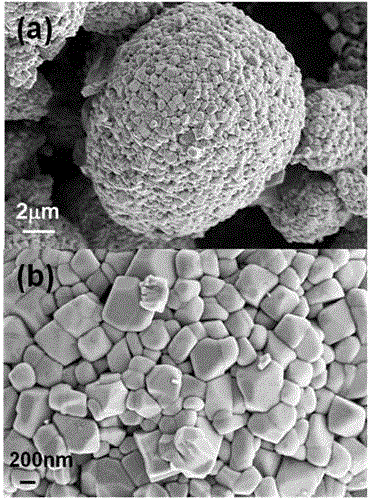

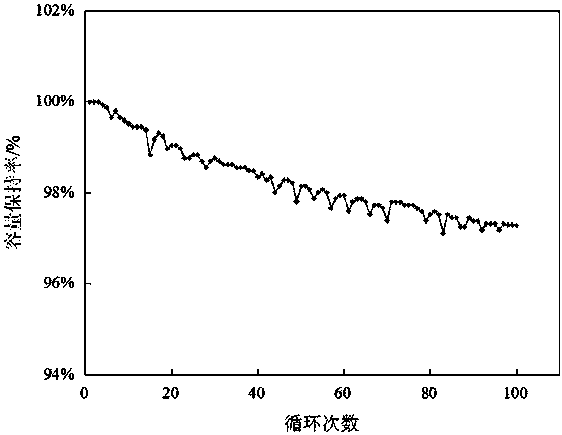

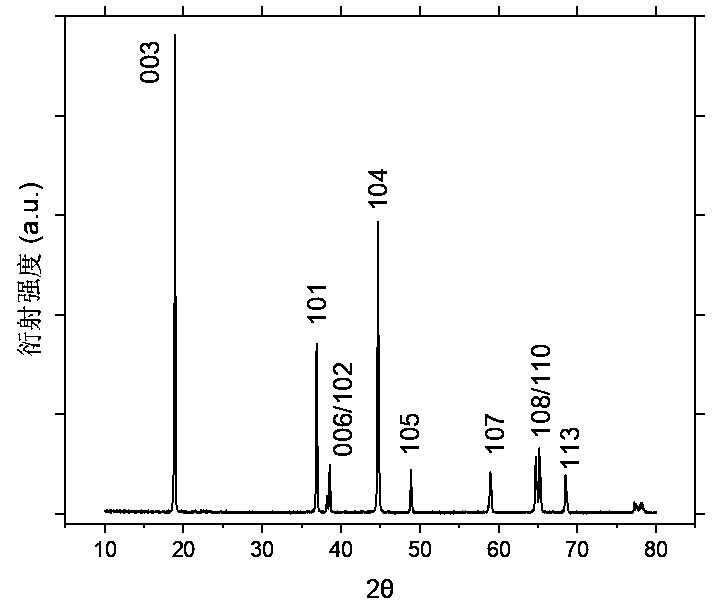

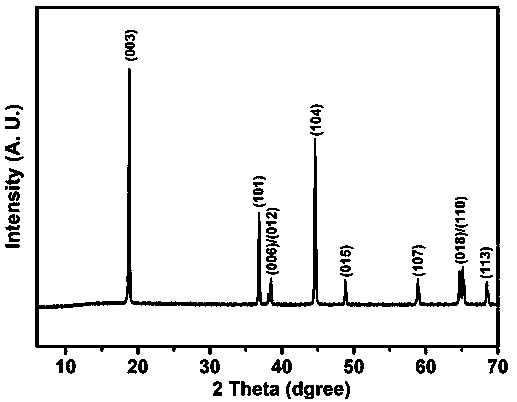

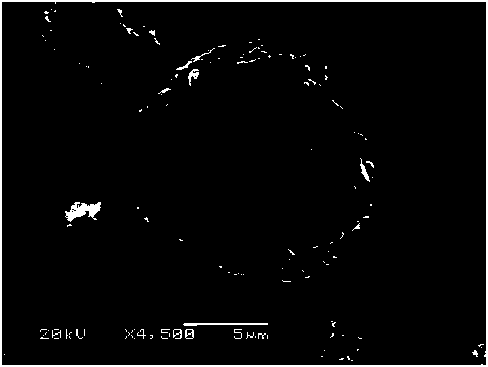

High-capacity monocrystal-like lithium nickel cobalt aluminate positive electrode material and preparation method thereof

InactiveCN109449391ALow melting pointReduce residual alkali contentCell electrodesSecondary cellsSingle crystalLithium compound

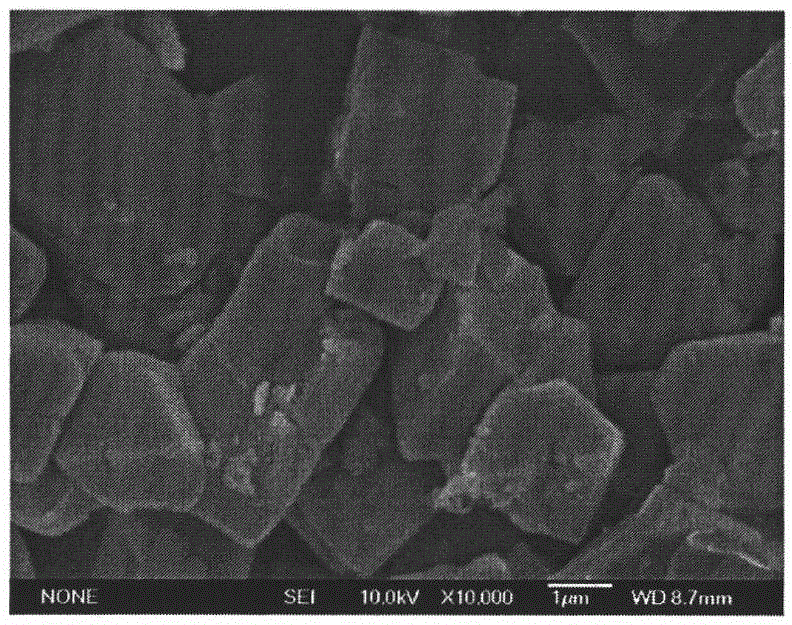

The invention discloses a high-capacity monocrystal-like lithium nickel cobalt aluminate positive electrode material and a preparation method thereof; the preparation method comprises the following steps of 1) preparing a monocrystal-like lithium nickel cobalt aluminate precursor; 2) preparing a monocrystal-like lithium nickel cobalt aluminate positive electrode material; and 3) performing coatingmodification on the monocrystal-like lithium nickel cobalt aluminate positive electrode material. According to the invention, a large-particle spherical precursor is utilized, and an additive is added in a lithium distribution calcination stage, so that the melting point of the material is reduced, and the crystal grain starts to grow and develop at a relatively low temperature, the positive electrode material with the small particle monocrystal morphology is finally generated, and the calcining temperature and time of the monocrystal ternary material in the preparation process are reduced, so that the generation cost is lowered; and the lithium-containing compound coating modification is carried out on the monocrystal-like lithium nickel cobalt aluminate positive electrode material, so that the residual alkali content on the surface of the material is reduced, erosion of an electrolyte to the material is prevented, the side effects are effectively inhibited, and the purpose of improving the performance of the material is achieved.

Owner:郑州中科新兴产业技术研究院 +1

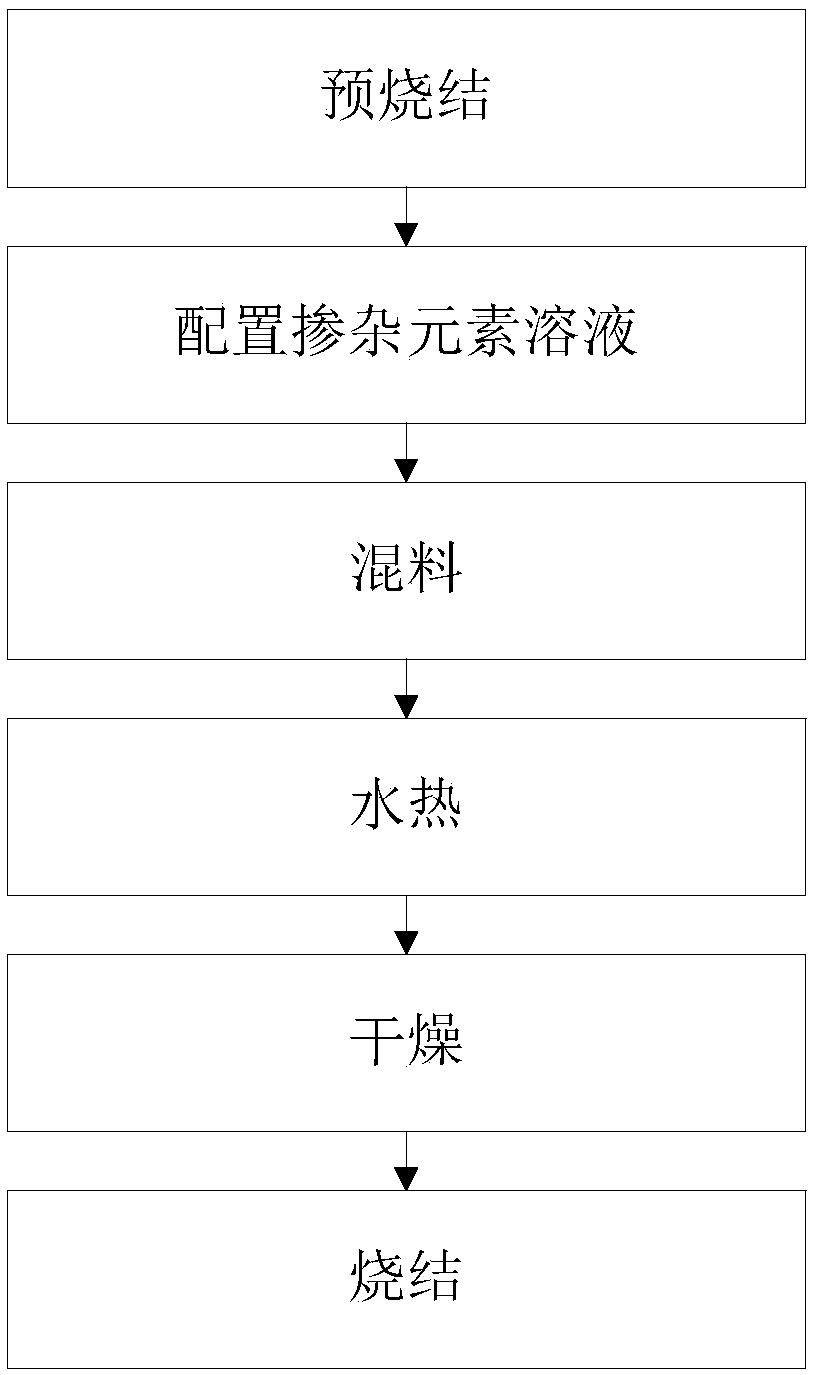

Ternary positive electrode material doped with Er and Zr metal ions and preparation method thereof

ActiveCN107732234AReduce shufflingReduce polarizationCell electrodesElectrochemical responseHigh pressure

The invention is applicable to the technical field of lithium batteries and provides a preparation method of a ternary positive electrode material doped with Er and Zr metal ions. The preparation method includes a step of pre-sintering, a step of preparing a doping element solution, a step of mixing, a step of hydrothermal treatment, and a step of drying, and a step of sintering. The preparation method pre-sinters a NCA precursor into a porous honeycomb-shaped spheroidal pre-sintered precursor by a pre-sintering method, then prepares a solution with Er and Zr sources in proportions, mixes thesolution with the pre-sintered precursor under a water condition, effectively introduces the Er and Zr solution into the positive electrode material substrate through honeycomb-shaped holes, then addslithium, melts the Er and Zr sources, the substrate, and the lithium source under hydrothermal and high temperature and high pressure conditions for sufficient and effective reaction, finally sintersthe material at a high temperature, and crystallizes the finished product to obtain a doped nickel-cobalt-aluminate positive electrode material. Zr4<+> can reduce cation mixing, and Er3<+> can reducepolarization and enhance electrochemical performance, so that Er3<+> / Zr4<+>, during charging, does not undergo electrochemical reaction, has no change in valence, and can play a role in stabilizing the crystal structure.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

Lithium cobalt oxide-coated lithium nickel cobalt aluminate positive electrode material and preparation method thereof

ActiveCN107946578AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsHigh rateCobalt hydroxide

Disclosed are a lithium cobalt oxide-coated lithium nickel cobalt aluminate positive electrode material and a preparation method thereof. Lithium cobalt oxide accounts for 1-10wt% of the material based on mass percentage composition; lithium cobalt oxide forms a coating layer with thickness of 5-30nm to coat lithium nickel cobalt aluminate; and the positive electrode material is spherical particles with the grain diameter of 5-15[mu]m. The preparation method comprises the following steps of (1) dissolving a water soluble surfactant into water, and heating to perform an ultrasonic stirring reaction; (2) adding aluminum nickel cobalt hydroxide, soluble cobalt salt and soluble lithium salt synchronously, and heating to perform an ultrasonic stirring reaction; (3) performing spraying and drying while ultrasonic stirring; and (4) putting the product into a tubular furnace and performing two-stage sintering in oxidizing atmosphere. The positive electrode material disclosed in the invention has relatively high cycle stability and high-rate discharging performance; by virtue of the method, the problem of surface residue existing the conventional coating can be lowered effectively; and themethod is low in cost, simple in process and suitable for massive industrial production.

Owner:安徽维晶新材料科技有限公司

Lithium nickel cobalt manganate/lithium nickel cobalt aluminate battery and functional diaphragm for lithium nickel cobalt manganite/lithium nickel cobalt aluminate battery as well as production technology of diaphragm

ActiveCN109411675AEasy to useInhibition of dissolution throughSecondary cellsCell component detailsEthylenediamineAdhesive

The invention discloses a lithium nickel cobalt manganate / lithium nickel cobalt aluminate battery and a functional diaphragm for the lithium nickel cobalt manganite / lithium nickel cobalt aluminate battery as well as a production technology of the diaphragm and belongs to the technical field of battery diaphragms. The lithium nickel cobalt manganite / lithium nickel cobalt aluminate battery disclosedby the invention comprises a porous diaphragm base material and a functional coating layer which coats the surface of the base material; coating of the functional coating layer comprises a filling agent, an adhesive, a thickening agent, a dispersant and a stabilizer, wherein the stabilizer is selected from one or more of a combination of triethylenetetramine hexaacetic acid, diethylenetriamine pentaacetic acid, 1,3-diamino-2-hydroxypropane-N,N,N',N'-tetracetic acid, N,N-bi(2-hydroxyphenyl)ethylenediamine-N,N-diethylamine hydrochloride and dihydroxyethylglycine. By adopting the technical scheme provided by the invention, the shuttling of nickel, cobalt, manganese and aluminum metal elements can be effectively inhibited, so that the circulating performance of lithium nickel cobalt manganiteand lithium nickel cobalt aluminate ternary batteries is improved.

Owner:安徽金力新能源有限公司

Low-surface-alkalinity lithium nickel cobalt aluminate positive electrode material and preparation method thereof

InactiveCN108417796ALow structural firmnessSmall latticeCell electrodesSecondary cellsPhosphatePyrophosphate

The invention discloses a low-surface-alkalinity lithium nickel cobalt aluminate positive electrode material and a preparation method thereof. The lithium nickel cobalt aluminate positive electrode material is obtained by performing calcining on metal hydrogen phosphate and a lithium nickel cobalt aluminate positive electrode active material in oxygen flow. By adoption of metal hydrogen phosphatewhich is decomposed into pyrophosphate in calcining, reactant activity is improved, and a reaction with the residual alkali in the lithium nickel cobalt aluminate positive electrode active material ispromoted to generate a Li<3>PO<4> coating layer; compared with phosphate, hydrogen phosphate is lower in structural firmness, lower in lattice energy and easier in reaction, so that the calcining temperature can be obviously lowered; dry method coating of the lithium nickel cobalt aluminate positive electrode active material is converted from high temperature solid phase reaction (700 DEG C) in the prior art into a medium temperature solid phase reaction (400-600 DEG C), so that reaction difficulty is greatly lowered; and in addition, simple process, low cost and high production efficiency are achieved, so that realization of large-scale industrial production can be facilitated.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

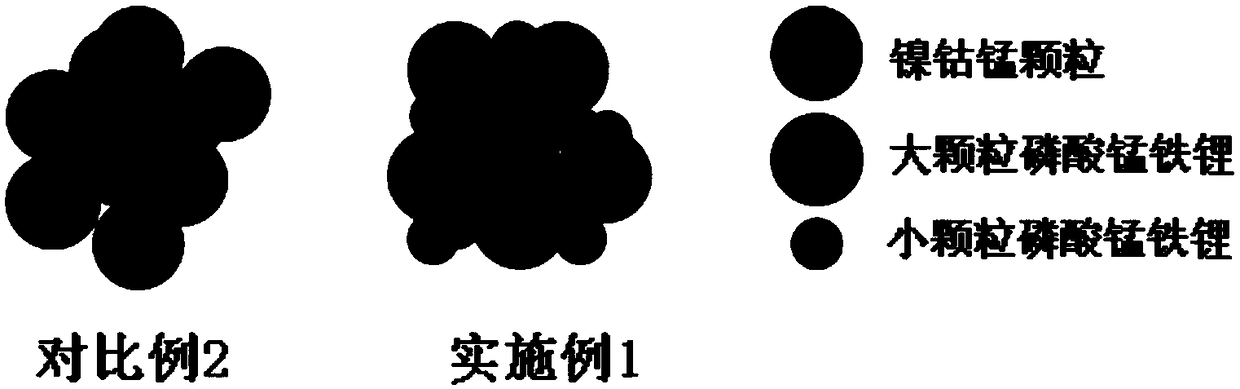

Preparation method of mixed lithium nickel cobalt aluminate positive electrode material

InactiveCN111525118AIncrease compaction densityImproved magnification performanceSecondary cellsPositive electrodesPhysical chemistryLithium aluminate

The invention discloses a preparation method of a mixed lithium nickel cobalt aluminate positive electrode material. The preparation method of the mixed lithium nickel cobalt aluminate positive electrode material is obtained by uniformly mixing a large-particle lithium nickel cobalt aluminate positive electrode material and a small-particle lithium nickel cobalt aluminate positive electrode material in a mass ratio of (1-8): 1, the particle size range of the large-particle-size lithium nickel cobalt aluminate positive electrode material is D50 = 10-20 [mu] m, and the particle size range of thesmall-particle-size lithium nickel cobalt aluminate positive electrode material is D50 = 2-7 [mu] m. The chemical formula of the mixed lithium nickel cobalt aluminate cathode material is LiNixCoyAlzMaO2, wherein x + y + z + a = 1, x is more than 0.8 and less than 1, y is more than 0.01 and less than 0.2, z is more than 0.01 and less than 0.1, and a is more than 0.001 and less than 0.01. Accordingto the present invention, the bulk phase doping, the water washing and the surface coating are respectively performed on the large-particle size lithium nickel cobalt aluminate particles and the small-particle size lithium nickel cobalt aluminate particles, and then the mixing is performed, such that the residual alkali on the surface of the lithium nickel cobalt aluminate is reduced, the consistency and the processability of the material are improved, and the compaction density and the rate performance of the positive electrode material are improved.

Owner:陕西红马科技有限公司

Preparation method of semiconductor oxide coated lithium nickel-cobalt aluminate ternary material

The invention discloses a semiconductor oxide coated lithium nickel-cobalt aluminate ternary material and a preparation method thereof. The method comprises the following steps: a semiconductor oxideis used as a modifier for coating the surface of a lithium nickel-cobalt aluminate material; the semiconductor oxide is dispersed in an organic solvent, the lithium nickel-cobalt aluminate ternary material is added to the mixed solution, and spray drying is performed after uniform mixing; the semiconductor oxide is one or more of tin oxide, indium oxide, tin antimony oxide and indium tin oxide. The method is simple, and the prepared material has good thermal stability, reduced sensitivity to moisture and increased charge and discharge capacity and cycle stability.

Owner:SHAANXI COAL & CHEM TECH INST

High-energy-density lithium-ion battery and preparation method thereof

PendingCN107394202AImprove securityReduce residual alkaliCell seperators/membranes/diaphragms/spacersCell electrodesHigh energyCarbon nanotube

The invention discloses a high-energy-density lithium-ion battery and a preparation method thereof. A positive electrode is prepared from lithium nickel cobalt aluminate, lithium ferric manganese phosphate, a single-walled carbon nanotube and polyvinylidene fluoride at a certain ratio; and a negative electrode is prepared from nanometer silicon, synthetic graphite, the single-walled carbon nanotube and polypropylene. The lithium-ion battery prepared through the method is high in energy density and long in cycle life.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

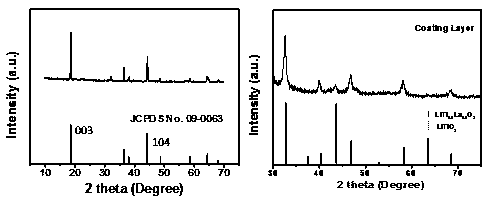

Lithium lanthanum titanate-lithium titanate coated lithium nickel cobalt aluminate cathode material and preparation method thereof

ActiveCN109119621AReduce alkalinityImprove ion conduction abilitySecondary cellsPositive electrodesOrganic solventTitanium

The invention relates to a lithium lanthanum titanate-lithium titanate coated lithium nickel cobalt aluminate cathode material and preparation method thereof. The preparation method comprises the following steps: S1, dissolving an organic titanium source and a lanthanum source in an organic solvent, and stirring to obtain a mixed solution; 2, adding lithium nickel cobalt aluminate and a surfactantinto the mixed solution, and stirring at 60-80 DEG C to obtain a suspension; 3, adding water drop by drop under the stirring condition, continuing stirring until the organic solvent volatilizes completely, and drying to obtain the coating material; S4, calcining the coating material at 450-650 DEG C for 5-10 hours to obtain the lanthanum lithium titanate-lithium titanate coated lithium nickel cobalt aluminate cathode material. The preparation method provided by the invention is simple in operation and easy to industrialize, and is suitable for popularizing and using in the field. The preparedlithium titanate-lithium lanthanum titanate coated lithium nickel cobalt aluminate cathode material has excellent electrochemical performance and cycle stability.

Owner:乳源东阳光新能源材料有限公司 +1

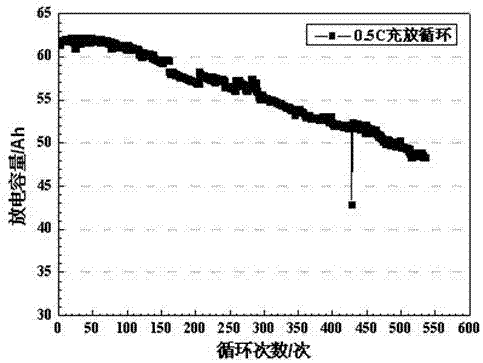

Preparation method of primary large-particle lithium nickel cobalt aluminate anode material

InactiveCN104979552AHigh discharge specific capacity performanceHigh specific energy densityCell electrodesLithiumThree stage

The invention relates to a preparation method of a primary large-particle lithium nickel cobalt aluminate anode material. The method is characterized by preparing a spherical nickel cobalt aluminium precursor by using a liquid phase method, then carrying out roasting by using a three-stage method, adding a certain amount of specific flux during second roasting, carrying out high-temperature roasting after uniformly mixing the materials, then washing away the flux and carrying out third roasting, thus obtaining the product after roasting, namely primary large-particle lithium nickel cobalt aluminate. The primary large-particle lithium nickel cobalt aluminate material has higher tap density and compaction density, the cycle life of the material is greatly prolonged under the conditions of high-temperature cycle and high voltage, and ballooning is obviously weakened after the material is used for preparing soft-package batteries. The process is simple and practicable and can be used for large-scale industrial production.

Owner:张联齐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com