Lithium nickel and cobalt aluminate anode material and preparation method and lithium ion battery thereof

A technology of lithium nickel cobalt aluminate and cathode material, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that the cycle performance of cathode materials needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the above nickel-cobalt-lithium-aluminate cathode material, comprising the following steps:

[0044] S1) Mix nickel salt, cobalt salt, aluminum salt, the first complexing agent and the first precipitant, heat for precipitation reaction, and obtain a suspension of nickel cobalt aluminum hydroxide; mix the manganese salt, the second complexing agent, the first The second precipitating agent is mixed with the nickel-cobalt-aluminum hydroxide suspension, and after the heating reaction, the first intermediate product is obtained; the mol ratio of the nickel ion in the nickel salt, the cobalt ion in the cobalt salt and the aluminum ion in the aluminum salt is (1- x-y): x:y; 0.00<x≤0.30, 0.00<y≤0.10;

[0045] S2) heat-treating the first intermediate product to obtain a second intermediate product;

[0046] S3) mixing and sintering the second intermediate product and lithium compound to obtain a third intermediate prod...

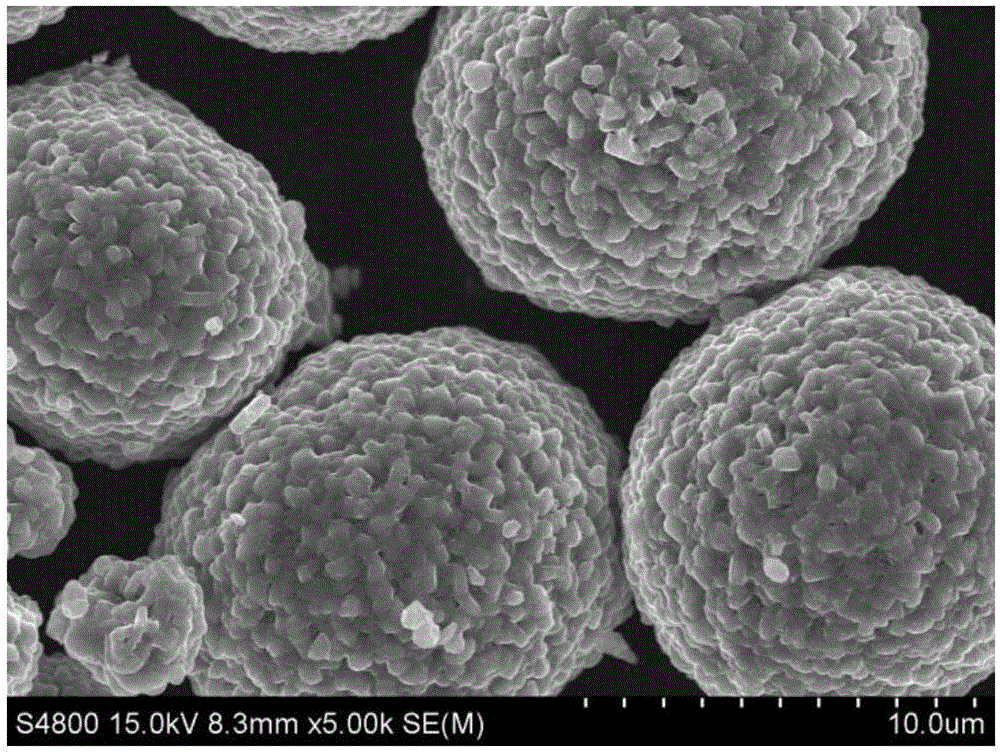

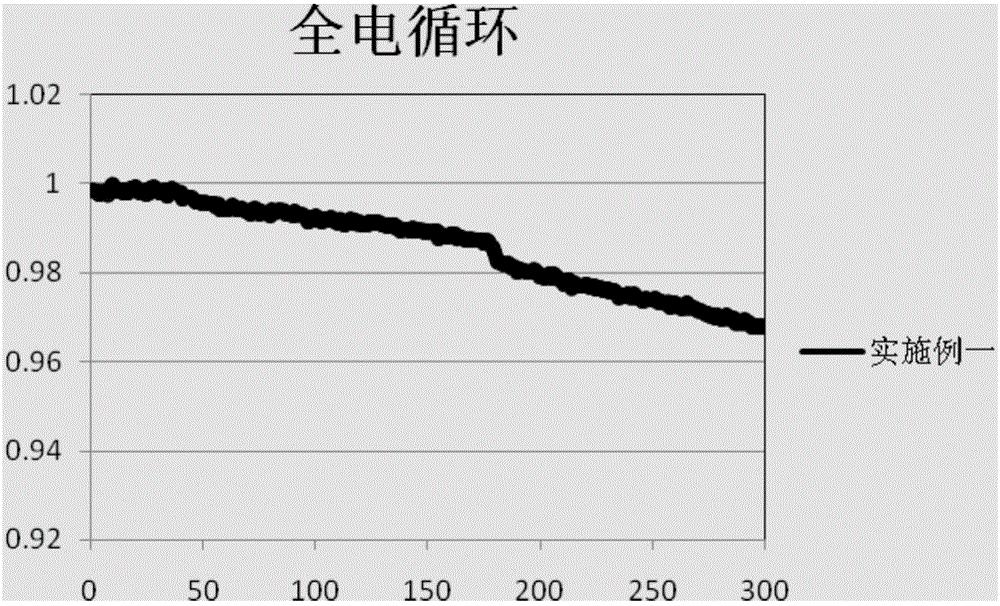

Embodiment 1

[0064]1.1 Preparation of nickel-cobalt-aluminum hydroxide: dissolving nickel sulfate and cobalt sulfate with deionized water to form the first mixed solution with a metal ion concentration of 1.5 mol / L, and the Ni:Co atoms in the first mixed solution The ratio is 0.90:0.10; the aluminum sulfate solution and glycine are made into the second mixed solution with an aluminum ion concentration of 0.5mol / L in a molar ratio of 1:3; the manganese sulfate solution and glycine are made in a molar ratio of 1:3 Manganese ion concentration is the 3rd mixed solution of 0.05mol / L; The sodium hydroxide solution of the ammoniacal liquor of described first mixed solution, the second mixed solution, 10mol / L and 5mol / L is added in the reactor by peristaltic pump, Continuous co-precipitation reaction was carried out at 50°C and a stirring speed of 300 rpm, and the ammonia value during the precipitation process was controlled to be 18g / L, and the pH value was 12. After fully reacting for 10 hours, n...

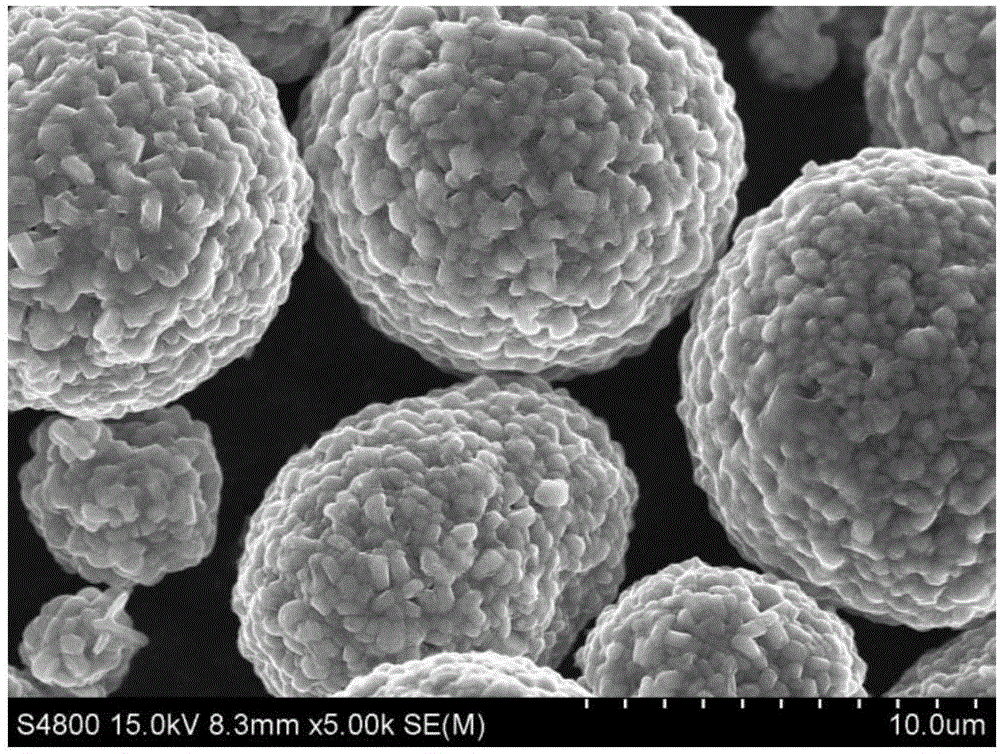

Embodiment 2

[0073] 2.1 Preparation of nickel-cobalt-aluminum hydroxide: the nickel sulfate solution, cobalt sulfate solution, and aluminum sulfate solution with an atomic ratio of Ni:Co:Al of 0.85:0.12:0.03 are uniformly mixed in deionized water, and the metal in the mixed solution is The ion concentration is 2mol / L; then, 8mol / L ammonia water, 5mol / L sodium hydroxide solution and the above-mentioned mixed metal solution flow into the reactor with a peristaltic pump. Continuous co-precipitation reaction was carried out at 45°C and a stirring speed of 320 rpm. The ammonia value during the precipitation process was controlled to be 15g / L and the pH value was 11.8. After the reaction was complete for 12 hours, nickel-cobalt lithium aluminate was obtained. Hydroxide suspension; mix manganese sulfate solution and glycine at a molar ratio of 1:3 to form a solution with a manganese ion concentration of 0.06mol / L and add it to the nickel-cobalt lithium aluminate hydroxide suspension with a perista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com