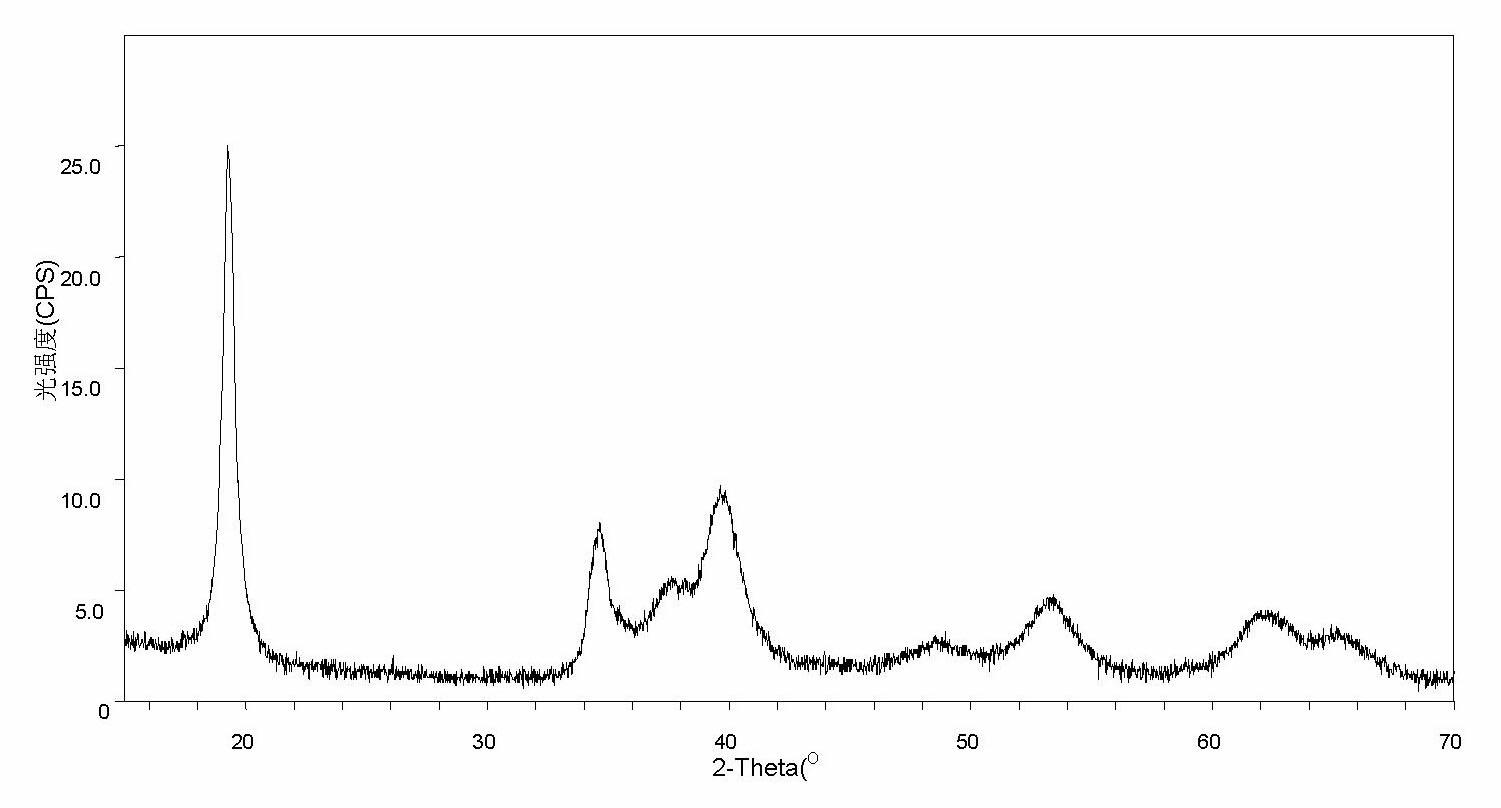

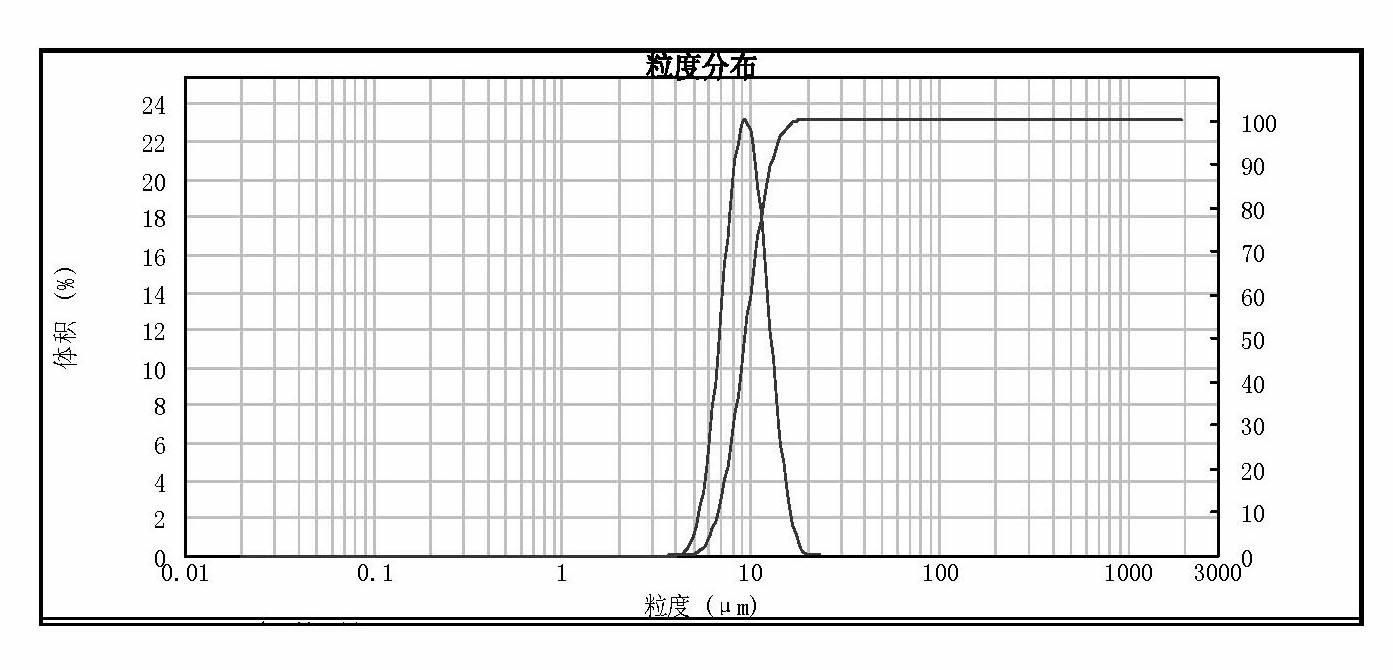

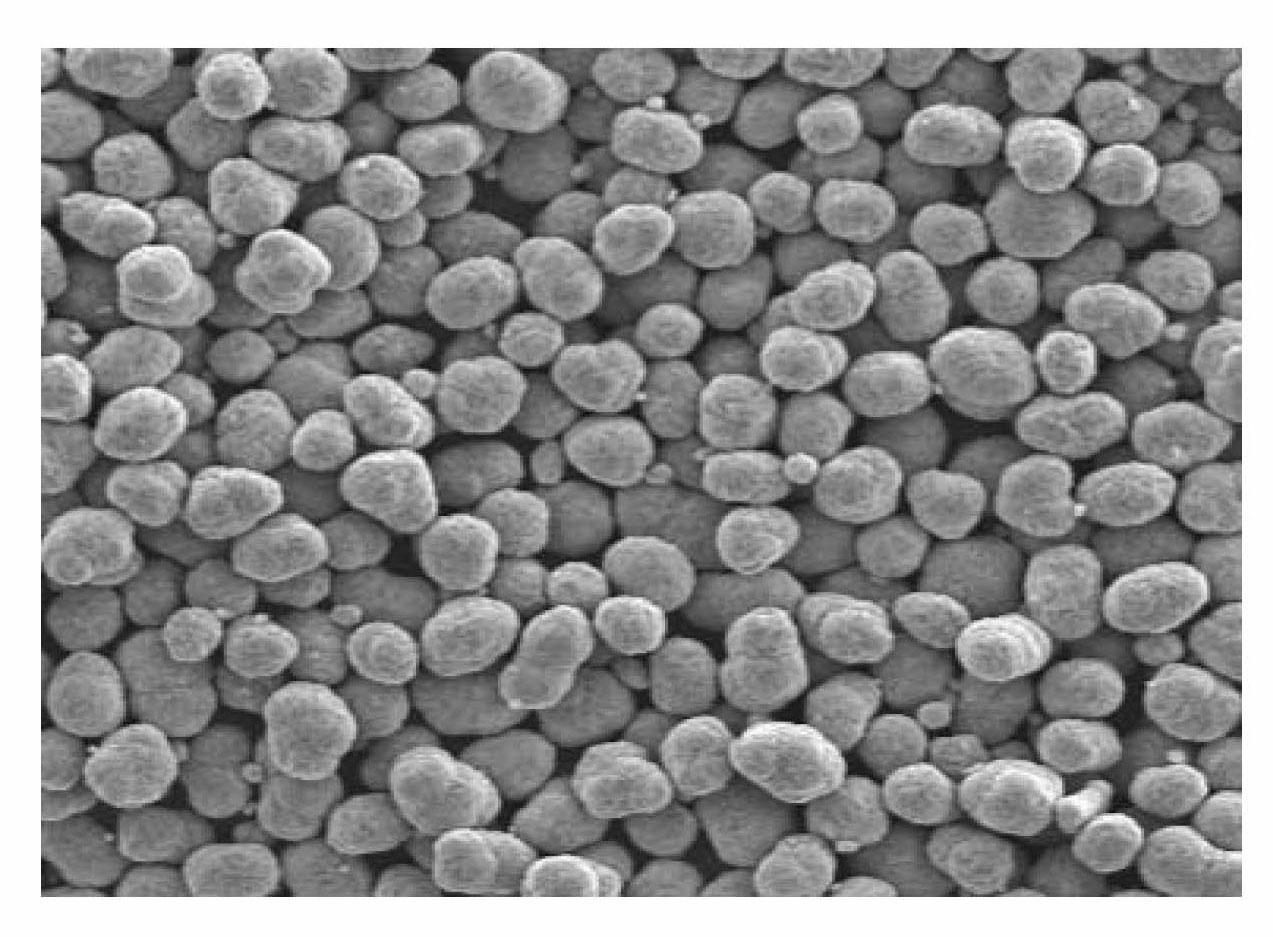

Preparation method of high-tap spherical ternary cathode material precursor

A cathode material and precursor technology, applied in the field of new energy material preparation, can solve the problems of low bulk density and achieve the effect of improving high temperature performance, excellent physical and electrochemical performance, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] NiSO 4 , MnSO 4 , CoSO 4 According to the molar ratio of Ni: Mn: Co = 5:3:2, the nickel-manganese-cobalt mixed aqueous solution is prepared, the total concentration is 3.0 mol / liter, and the sodium hydroxide solution is prepared at 10.0 mol / liter, and the concentration is 6.0 mol / liter. Ammonia solution, use a metering pump to respectively input nickel-cobalt-manganese salt solution, sodium hydroxide solution, and ammonia solution into the pre-filled 6m 3 The volume of the reactor is carried out in the reactor. Under the protection of argon, the temperature of the reactor is controlled to be 50°C, the pH value is 11.5, the stirring speed is 180r / min, the flow rate of ammonia water is controlled, the nickel content in the mother liquor is controlled to be 200mg / L, and the liquid-solid content in the reactor is controlled to be 400g / L, the feed liquid in the reactor is discharged naturally, the feed is continuously fed for 60 hours, the feed is stopped, the material i...

Embodiment 2

[0027] Ni(NO 3 ) 2 , Mn(NO 3 ) 2 , Co(NO 3 ) 2 According to the molar ratio of Ni: Mn: Co = 8:1:1, the nickel-manganese-cobalt mixed aqueous solution is prepared, the total concentration is 2.0 mol / liter, and the potassium hydroxide solution is prepared at 5 mol / liter, and the concentration is 4 mol / liter. Mixed solution of ammonia water and 2 mol / liter ammonium bicarbonate, input the mixed solution of nickel cobalt manganese salt solution, sodium hydroxide solution, ammonia water and ammonium bicarbonate into the pre-filled 6m 3 The volume of the reactor is carried out in the reactor. Under the condition of nitrogen protection, the temperature of the reactor is controlled at 55°C, the pH value is 11.0, and the stirring speed is 240r / min. The solid content of the feed liquid is 300g / L, the feed liquid of the reactor is naturally discharged, the feed is continuously fed for 50 hours, the feeding is stopped, the material in the reactor is transferred to the aging tank, the...

Embodiment 3

[0029] NiCl 2 , MnCl 2, CoCl 2 According to the molar ratio of Ni: Mn: Co = 7:2:1, the nickel-manganese-cobalt mixed aqueous solution is prepared, the total concentration is 2.5 mol / liter, and the sodium hydroxide solution is prepared at 4 mol / liter, and the concentration is 4 mol / liter. Ammonia and 0.5 mol / liter disodium edetate mixed complexing agent solution, nickel cobalt manganese salt solution, sodium hydroxide solution, ammonia and disodium edetate mixed solution are input into Pre-filled 6m 3 The volume of the reactor is carried out in the reactor. Under nitrogen or other inert and other protective conditions, control the temperature of the reactor to 45°C, the pH value to 10.5, and the stirring speed to 150r / min, and control the flow rate of the mixed complexing agent so that the content of the mother liquor in the reactor is 100mg / L. The liquid-solid content of the medium feed is 500g / L, the feed liquid in the reactor is naturally discharged, the feed is continuo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com