Preparation method of Janus-structure composite emulsion particle

A composite latex and particle technology, which is applied in the synthesis of asymmetric non-spherical composite colloidal particles, can solve the problems of poor fluidity of highly cross-linked Janus particles, inability to distinguish newborn polymer protrusions from the matrix, and complex synthesis processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] Example 1 Preparation of PVDF / PS Composite Particles with Janus Structure

[0031] Component Mass

[0032] PVDF emulsion 10.5g

[0033] Deionized water 60.0g

[0034] Styrene 6.0g

[0035] Initiator 0.042g

[0036] In a 250ml beaker, 10.5g of PVDF seed emulsion (industrial product) with a solid content of 10.4% and an average particle diameter of 180nm was added, followed by 60.0g of deionized water, and ultrasonically dispersed for 1 hour. The ultrasonically dispersed emulsion was poured into a four-necked reaction flask equipped with a condenser tube, magnetic stirring, and nitrogen gas introduction tube, the stirring was started and nitrogen gas was introduced, and the stirring rate was set at 400 rpm. After 15 minutes, start to heat up the reaction system, add 6.0g styrene to the reaction bottle simultaneously, and open the cooling water of the reflux condenser. When the temperature of the system was raised to 75°C, 5 ml of an aqueous solution containing 0.042 ...

Embodiment example 2-4

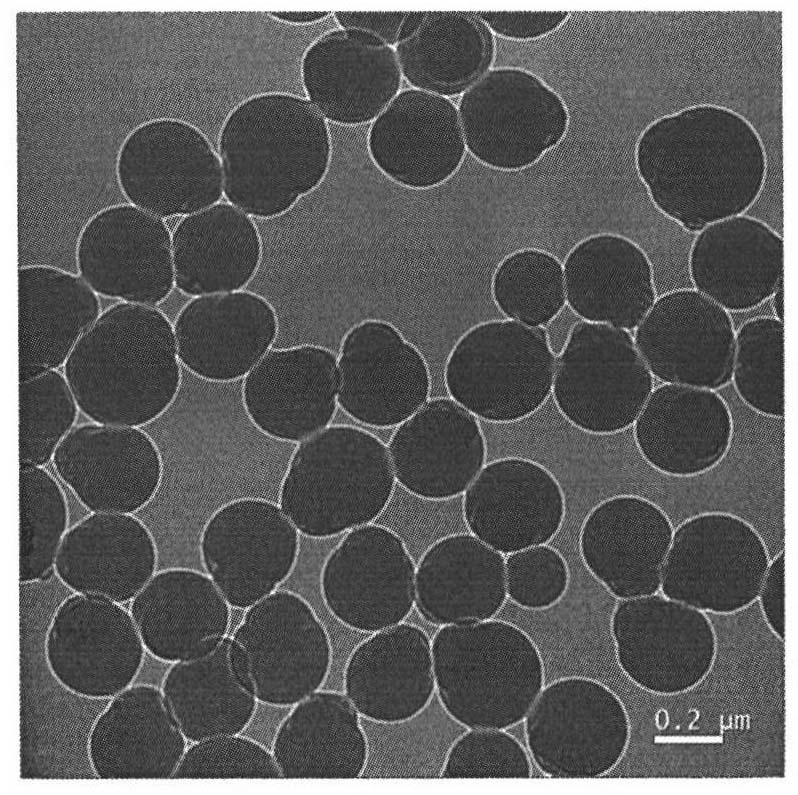

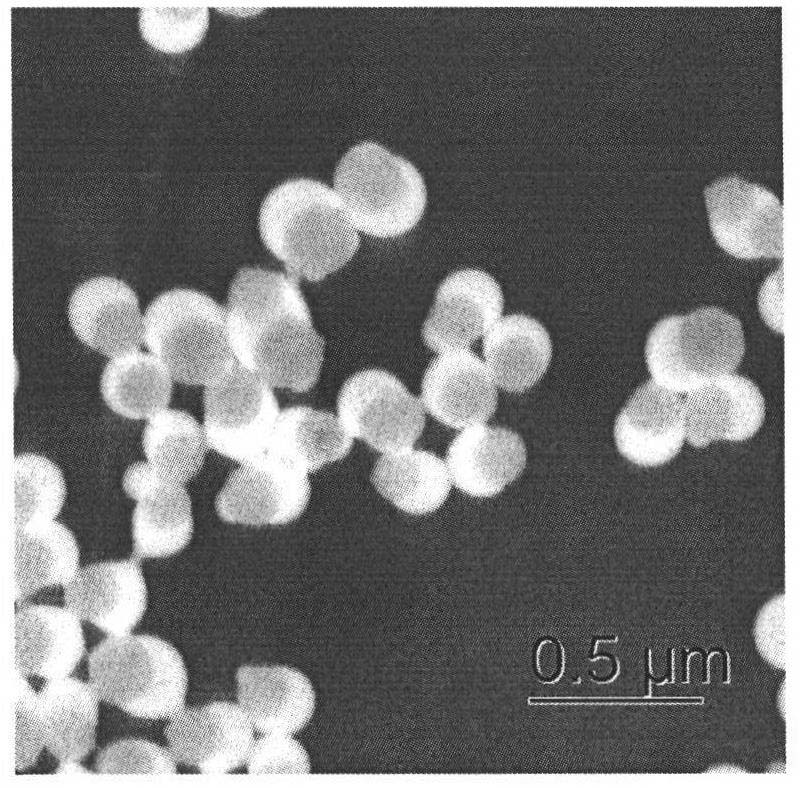

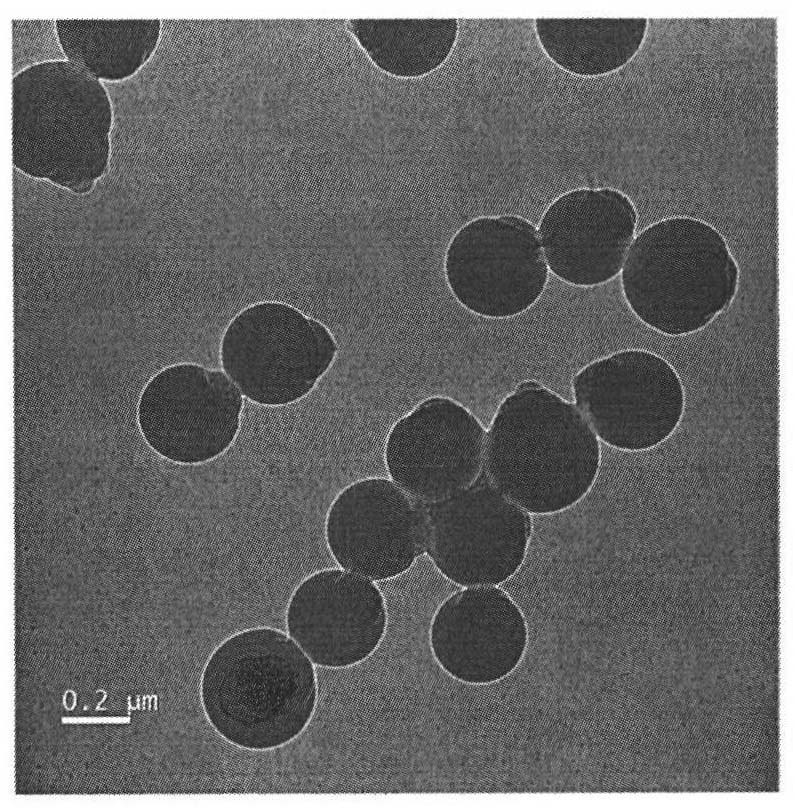

[0040] The polymerization reaction time of implementation case 2-4 is respectively 1 hour, 3 hours, 4 hours, and all the other implementation processes are the same as implementation case 1, and the morphological TEM photos of the composite particles prepared by implementation case 2-4 are shown in the attached document respectively. Figure 2-4 . figure 2 The TEM pictures shown are taken by electron energy filtering technology, according to the characteristics of fluorine compounds showing the maximum loss peak at a certain electron energy. From figure 2 In the photo, we can clearly distinguish the two phases of PVDF and PS, as well as the morphology and growth of composite particles. The black part is the PVDF seed, and the white part is the newly grown PS polymer protrusion. Then, compared to the photos taken without electronic energy filtering technology figure 1 From the photos, it is not easy for us to distinguish the two phases of PVDF and PS.

[0041] Depend on ...

Embodiment example 5

[0043] In Example 5, the polymerization temperature was 65° C., the amount of styrene monomer added was 8.0 g, the amount of initiator potassium persulfate was 0.08 g, and the rest of the operating steps were the same as in Example 1. The TEM photo of the composite particle form prepared by embodiment case 5 is shown in the appendix Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com