Ternary positive electrode material doped with Er and Zr metal ions and preparation method thereof

A positive electrode material and metal ion technology, applied in the field of Zr metal ion mixed doping ternary positive electrode material and its preparation, Er, to achieve the effect of reducing polarization, reducing cation mixing, and stabilizing the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

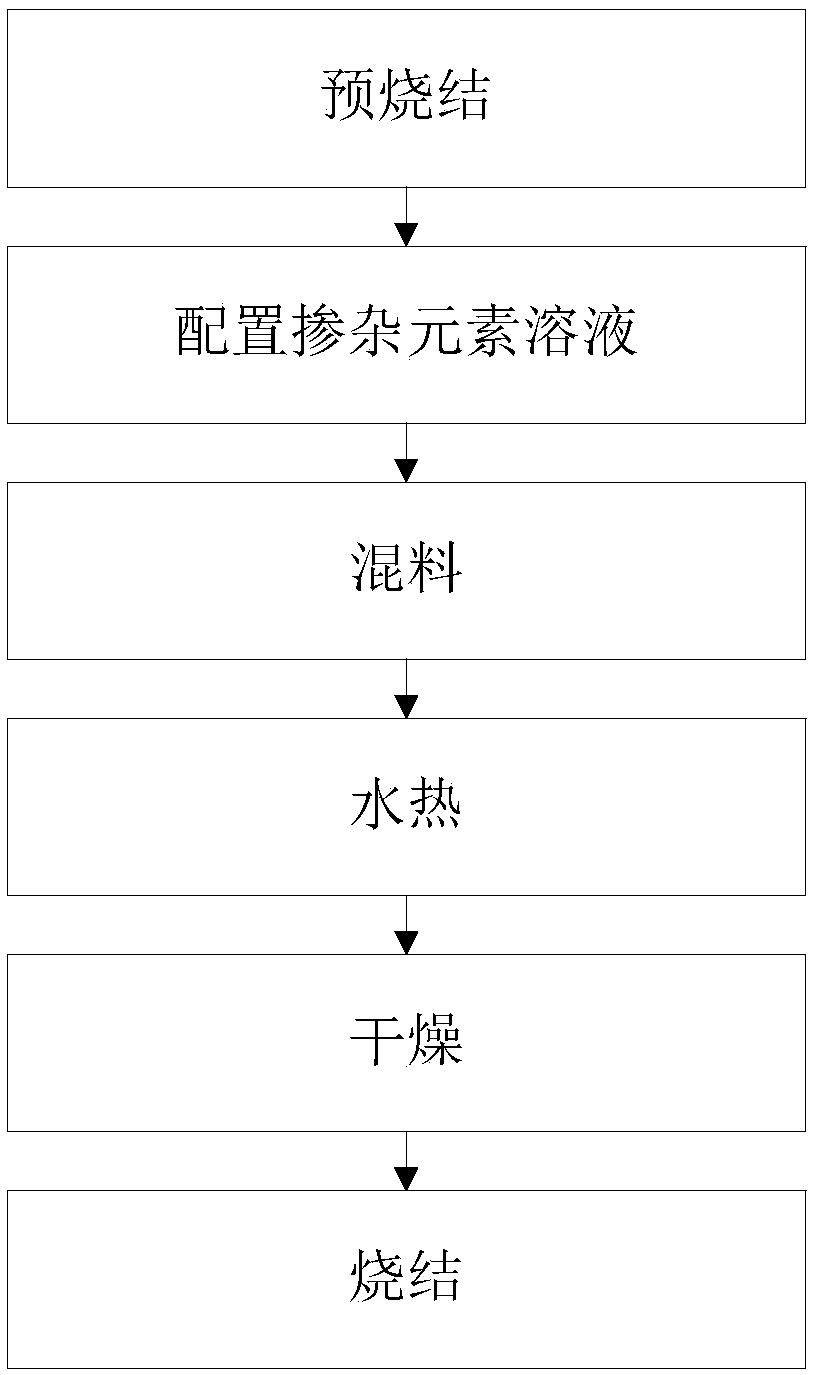

[0018] Such as figure 1 As shown, the preparation method of Er, Zr metal ion mixed doping ternary cathode material provided by the present invention comprises the following steps:

[0019] S1. Pre-sintering step.

[0020] Weigh the nickel-cobalt-lithium-aluminate precursor, spray it with high-purity water, mix it evenly, and transfer it to a sintering furnace for pre-sintering. Here, the mass ratio of spraying high-purity water mixed with the nickel-cobalt-lithium-aluminate precursor is 1%-10%, the pre-sintering temperature is 300-700°C, and the time is 2-10h.

[0021] S2. The step of configuring a doping element solution.

[0022] A certain mass ratio of Er source and Zr source is selected and added into deionized water for stirring, and ultrasound is performed while stirring to obtain a mixed solution of Er and Zr. The molar ratio of the Er source and the Zr source selected here is 1:1, the quality of the added deionized water is 3-10 times of the total mass of the Er sou...

Embodiment

[0035] 1) Weigh 200g of nickel-cobalt-lithium-aluminate precursor, spray 5% high-purity water, mix evenly, and put it in a sintering furnace for pre-sintering, at a ventilation rate of 5m 2 / h, the temperature is 500 ℃, sintering 5h.

[0036] 2) Weigh 44.3g of erbium nitrate and 42.9g of zirconium nitrate and put them into a flask, add 872mL of water, and use ultrasound and a stirrer to sonicate for 3h while stirring.

[0037] 3) Weigh 100g of pre-calcined NCA precursor, put it into a flask, add 58.7g of lithium source, and then add 650mL of deionized water, using ultrasonic and While stirring with the stirrer for 3h, add 12mL of the mixed solution of Er and Zr dropwise while stirring ultrasonically.

[0038] 4) Put the mixed materials into the reaction kettle with built-in polytetrafluoroethylene lining, tighten the lid of the reaction kettle, and then put it in the oven, set it at 180°C and 15h.

[0039] 5) The material after hydroheating is subjected to rotary evaporation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com