Preparation method of mixed lithium nickel cobalt aluminate positive electrode material

A technology of lithium nickel cobalt aluminate and positive electrode materials, which is applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of product performance degradation, poor material electrical properties and processing performance, and low compaction density, and achieve improvement Consistency, improving compaction density and rate performance, reducing the effect of surface residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

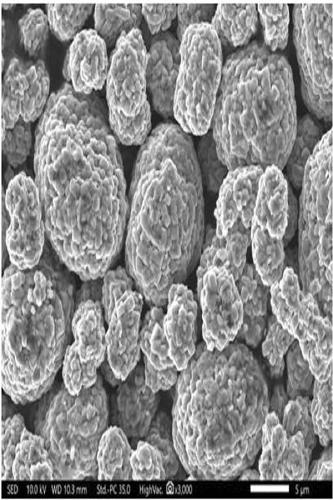

Image

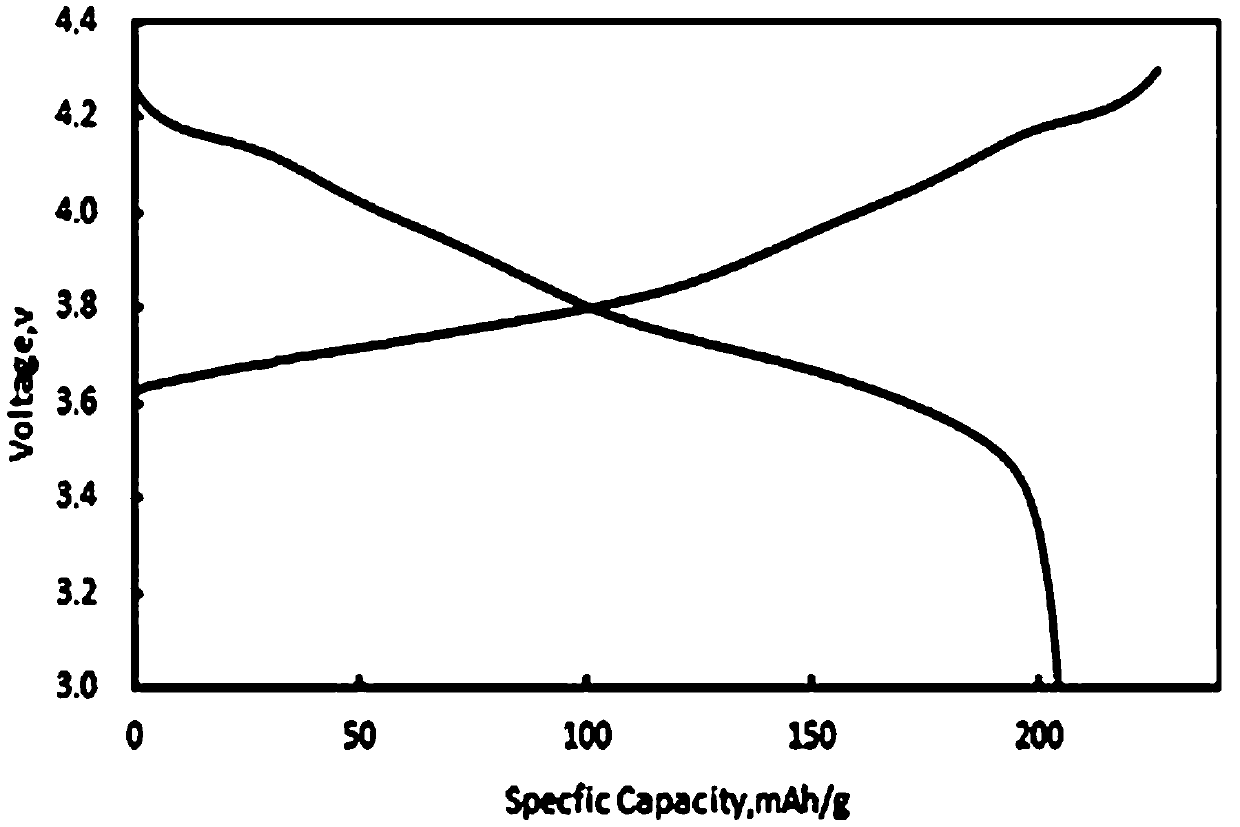

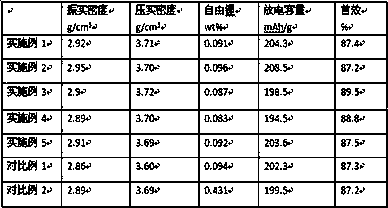

Examples

Embodiment 1

[0032] 1. The specific preparation steps of the large-grain nickel-cobalt-lithium-aluminate cathode material are as follows:

[0033] (1) Weigh Ni with D50=16μm 0.88 co 0.10 Al 0.02 (OH) 2 Precursor A 2000g, weigh lithium hydroxide 992g according to the molar ratio of lithium salt to precursor A as 1.1, weigh 1.844g of strontium oxide according to the molar ratio of doping compound and precursor A as 0.0008, and weigh 2000g of D50= 16μm Ni 0.88 co 0.10 Al 0.02 (OH) 2 The precursor A was mixed with 992g of lithium hydroxide and 1.844g of strontium oxide, and oxygen with a purity of 90% was introduced. First, the temperature was raised to 550°C at 3°C / min, kept for 4 hours, and then raised to 750°C at 2°C / min. ℃, heat preservation for 9 hours, then naturally cool down to room temperature, pulverize, and sieve to obtain the primary nickel-cobalt-lithium-aluminate positive electrode material;

[0034] (2) According to the initial nickel-cobalt-lithium-aluminate positive el...

Embodiment 2

[0044] 1. The specific preparation steps of the large-grain nickel-cobalt-lithium-aluminate cathode material are as follows:

[0045] (1) Weigh Ni with D50=20μm 0.92 co 0.06 Al 0.02 (OH) 2 Precursor A 2000g, weigh lithium hydroxide 970g according to the molar ratio of lithium salt to precursor A as 1.074, weigh magnesium carbonate 5.583g according to the molar ratio of doping compound and precursor A as 0.0027, and take 2000g of D50= 20μm Ni 0.92 co 0.06 Al 0.02 (OH) 2 The precursor A was mixed with 970g of lithium hydroxide and 5.583g of magnesium carbonate, and oxygen with a purity of 97% was introduced. First, the temperature was raised to 500°C at 3°C / min, kept for 4 hours, and then raised to 730°C at 2°C / min. ℃, heat preservation for 12 hours, then naturally cool down to room temperature, crush, and sieve to obtain the primary nickel-cobalt-lithium-aluminate positive electrode material;

[0046] (2) According to the initial nickel-cobalt-lithium-aluminate positive...

Embodiment 3

[0055] 1. The specific preparation steps of the large-grain nickel-cobalt-lithium-aluminate cathode material are as follows:

[0056] (1) Weigh Ni with D50=10μm 0.83 co 0.155 Al 0.025 (OH) 2 Precursor A 2000g, weigh lithium hydroxide 903g according to the molar ratio of lithium salt and precursor A as 1.0, weigh 2.461g of yttrium oxide according to the molar ratio of doping compound and precursor A as 0.0005, and weigh 2000g of D50= 10μm Ni 0.83 co 0.155 Al 0.025 (OH) 2 Precursor A was mixed with 903g of lithium hydroxide and 2.461g of yttrium oxide, and oxygen with a purity of 99.9% was introduced. First, the temperature was raised to 590°C at 3°C / min, kept for 4 hours, and then raised to 780°C at 2°C / min. , heat preservation for 20 hours, then naturally cool down to room temperature, crush, and sieve to obtain the initial nickel-cobalt-lithium-aluminate positive electrode material;

[0057] (2) Mix the initial nickel-cobalt-lithium-aluminate cathode material with pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com