High-safety long-service-life lithium ion storage battery positive plate and preparation method and application thereof

A high-safety, long-life technology, used in non-aqueous electrolyte battery electrodes, battery electrodes, secondary batteries, etc., can solve the problems of poor cycle life and safety, low specific capacity of lithium iron phosphate batteries, etc., and achieve good charge and discharge. performance, the effect of improving the rate of delithiation and intercalation, good liquid absorption and liquid retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A method for preparing a high-safety and long-life lithium-ion battery positive plate, the method comprising:

[0061] Step 1: Add NMP (the amount of NMP added to completely dissolve PVDF) into the mixing tank, add PVDF, stir until PVDF is completely dissolved, add conductive carbon black in different weight ratios, and obtain conductive colloid and nickel iron phosphate respectively The conductive colloid of lithium cobalt aluminate, wherein the weight of conductive carbon black added to the conductive colloid of lithium iron phosphate is 0.5 times of the weight of PVDF, and the weight of conductive carbon black added to the conductive colloid of nickel cobalt aluminate lithium is 0.5 times of the weight of PVDF. 2 / 3 times;

[0062] Step 2: Add lithium iron phosphate and lithium nickel cobalt aluminate respectively to the conductive colloid in step 1, mix evenly, and obtain lithium iron phosphate positive electrode slurry and lithium nickel cobalt aluminate positive el...

Embodiment 2

[0065] A high-safety and long-life lithium-ion battery positive electrode sheet prepared in Example 1, the positive electrode sheet includes: an aluminum foil current collector and a double-layer active material coating coated on its surface. The double-layer active material coating is: a lithium iron phosphate coating, and a nickel cobalt lithium aluminate coating coated on the lithium iron phosphate coating. The coating surface density of lithium iron phosphate coating is 50g / m 2 , the coating surface density of nickel cobalt lithium aluminate coating is 300g / m 2 .

[0066] The lithium iron phosphate coating contains the following components in weight percentage: 94% lithium iron phosphate, 4% PVDF and 2% conductive carbon black.

[0067] The nickel-cobalt-lithium-aluminate coating contains the following components by weight percentage: 95% nickel-cobalt-lithium aluminate, 4% PVDF and 3% conductive carbon black.

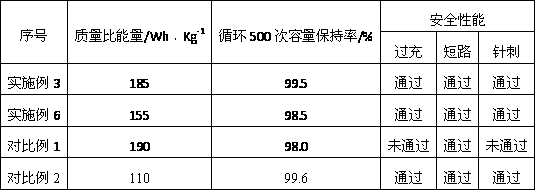

Embodiment 3

[0069] A high-safety and long-life lithium-ion storage battery comprises: a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte and a casing. The positive electrode sheet is the high-safety and long-life lithium-ion battery positive electrode sheet of Example 2, and the preparation process of the negative electrode sheet, diaphragm, electrolyte, and the battery is the same as that of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com