Patents

Literature

31results about How to "Low specific capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-capacity silicon-carbon composited anode material, preparation method and application thereof

InactiveCN102637872AOvercoming the low capacity of lithium deintercalationPromote circulationCell electrodesSecondary cellsCarbon compositesPyrolytic carbon

The invention relates to a high-capacity silicon-carbon composited anode material, a preparation method and application thereof, wherein the silicon-carbon composited anode material comprises the following compositions in parts by weight: 1-30 parts of silicon materials, 30-120 parts of carbon materials, and 10-80 parts of pyrolytic carbon. The silicon materials in the silicon-carbon composited anode material disclosed by the invention are uniformly adhered to the surfaces of carbon material particles, and then the outer layers of the carbon material particles are wrapped with the pyrolytic carbon, therefore, the silicon-carbon composited anode material disclosed by the invention has the advantages of lower first irreversible specific capacity, higher specific capacity, excellent cycle performance, low preparation cost and the like; and the first discharge capacity of the silicon-carbon composited anode material is greater than 450 mAh.g<-1> under a 0.2 C discharge ratio, and the retention rate of capacity after 50 cycles is more than 80%.

Owner:天津市贝特瑞新能源材料有限责任公司

Lithium titanate/titanium black anode material and preparation method thereof

ActiveCN102496704AImproved magnification performanceImprove cycle performanceCell electrodesTitanium compoundsElectrical batteryTitanium oxide

The invention relates to a lithium titanate / titanium black anode material and a preparation method thereof belonging to the technical field of lithium ion batteries. The lithium titanate / titanium black anode material has a chemical formula of (1-0.8x)Li4Ti5O12-xTi4O7, wherein x is more than 0,03 and is not more than 0.30. The lithium titanate / titanium black anode material can be synthesized by adopting two methods, the first method is as follows: lithium titanate is carbonized in vacuum, a compact titanium black high-conductive membrane is formed on the surface of the lithium titanate through controlling temperature, reaction time and pressure to have higher multiplying power performance; and the second method is as follows: Ti4O7 is directly added in the lithium titanate, and the lithium titanate / titanium black anode material is synthesized under an inert atmosphere at high temperature. The lithium titanate / titanium black anode material has a simple manufacture process and is beneficial to industrialized production. Compared with the current marketized anode material, the lithium titanate / titanium black anode material has higher electrical conductivity and corrosion resistance and higher large-current discharge cycling performance; and multiplying power charge and discharge performances and cycling performance of a lithium ion power battery can be further improved.

Owner:北京盟固利新材料科技有限公司

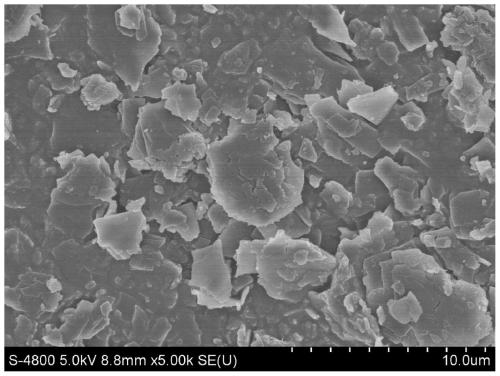

Lithium nickel manganese oxide material and preparation method thereof and lithium ion battery containing lithium nickel manganese oxide material

ActiveCN102664255AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsSodium-ion batteryManganese oxide

The invention provides a lithium nickel manganese oxide material and a preparation method thereof and a lithium ion battery containing the lithium nickel manganese oxide material, relates to the technical field of lithium ion batteries, and can solve the problems that the first coulomb efficiency or specific capacity of an existing lithium nickel manganese oxide material and a lithium ion battery prepared with the same is low and the cycle performance is poor. The lithium nickel manganese oxide material preparation method includes the following steps of precipitation to prepare a nickel manganese precursor, pretreatment of the precursor and solid phase synthesis. Proper process parameters are selected to obtain the lithium nickel manganese oxide material with good performance, so that the first coulomb efficiency, specific capacity and cycle performance of the lithium nickel manganese oxide material and the lithium ion battery prepared with the same are high. The lithium nickel manganese oxide material is prepared by the preparation method. The lithium ion battery comprises the lithium nickel manganese oxide material.

Owner:CHERY AUTOMOBILE CO LTD

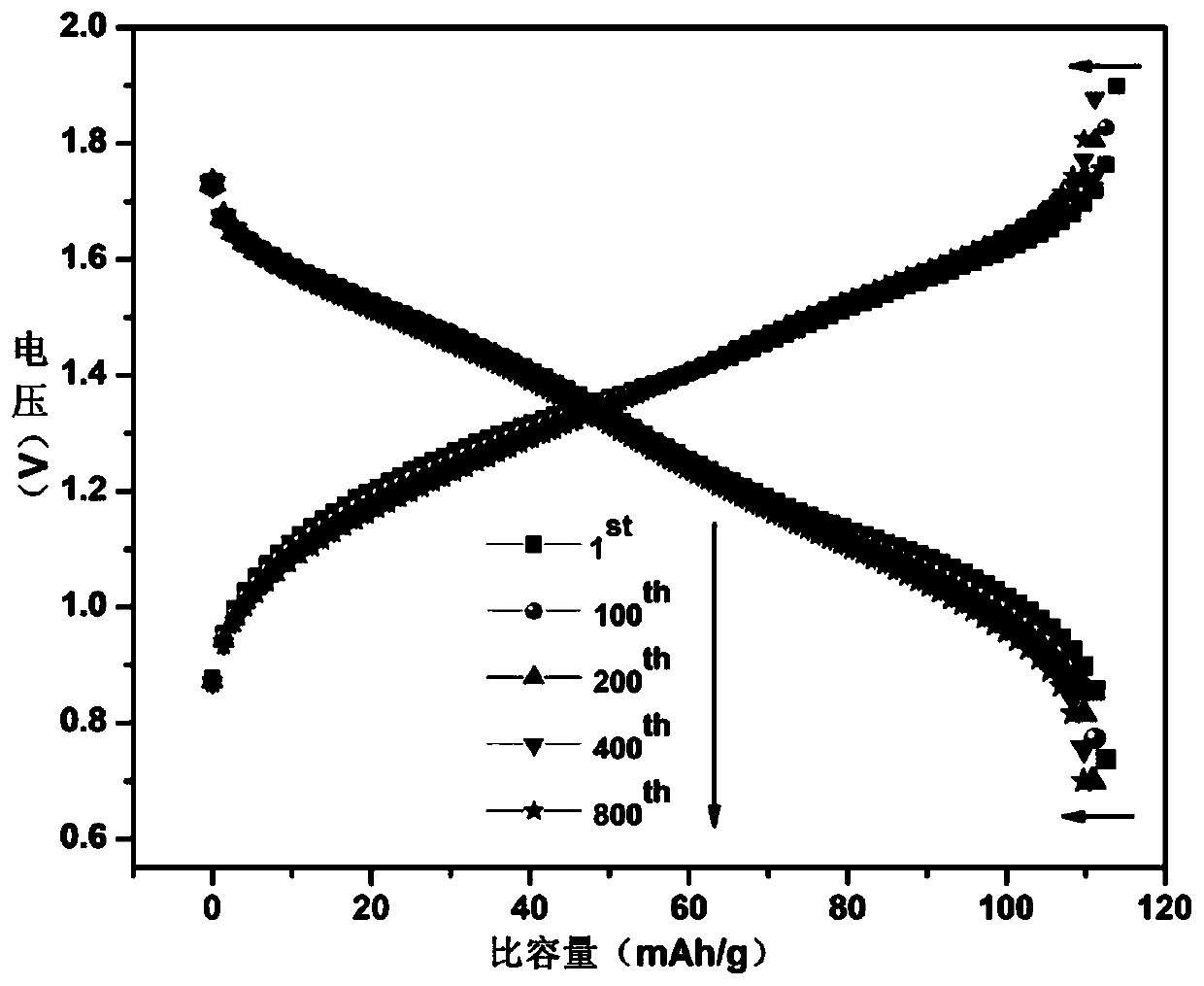

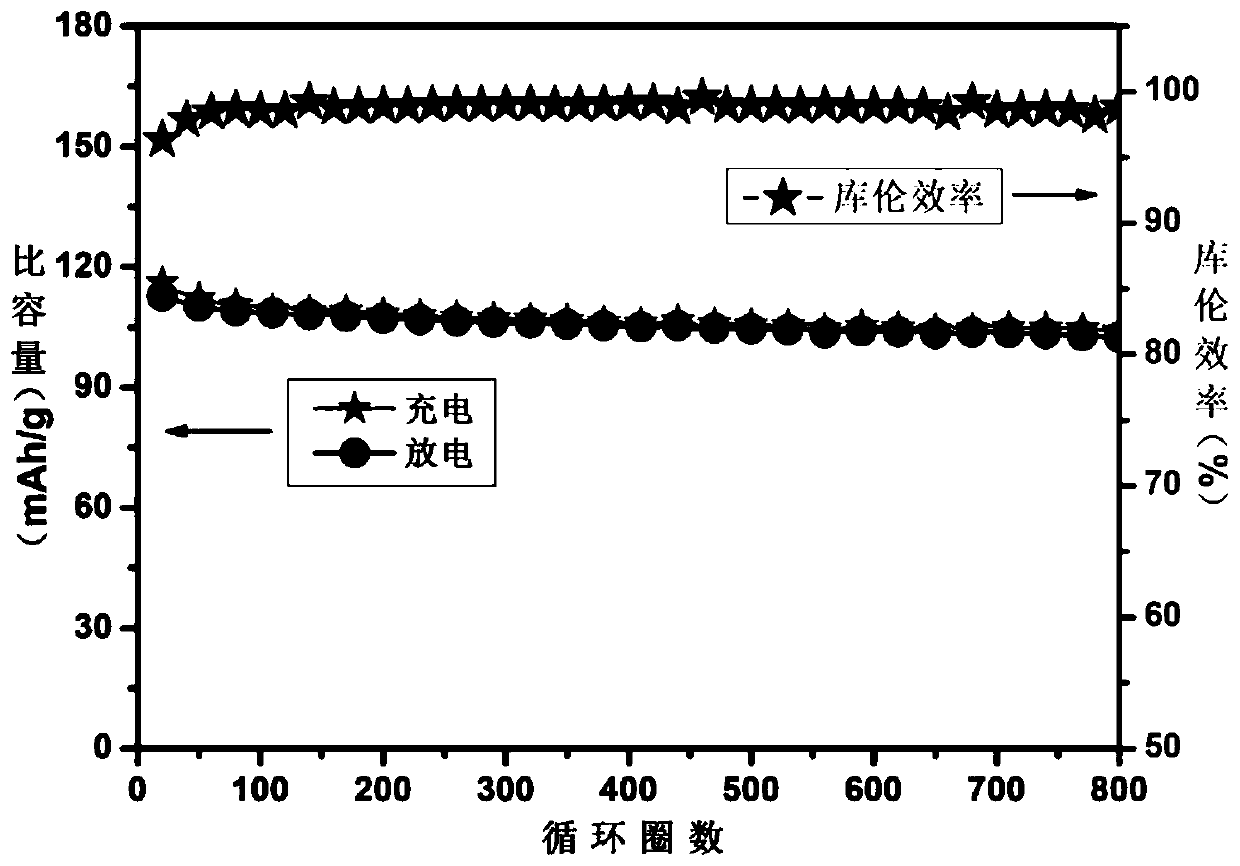

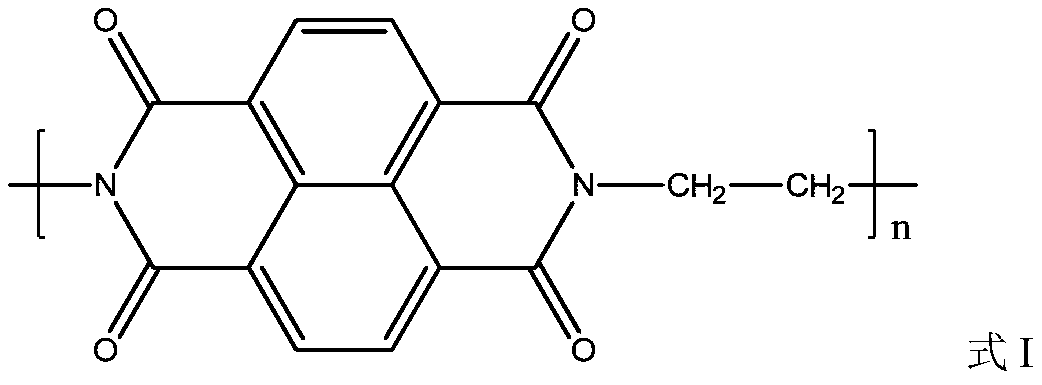

Aqueous ion battery and application thereof

ActiveCN110993944ALow cycle lifeLow specific capacitySecondary cellsNegative electrodesElectrolytic agentElectrical battery

The application discloses an aqueous ion battery. The aqueous ion battery comprises: an electrolyte which is an aqueous solution containing an electrolyte; a negative electrode containing a negative electrode active material; a negative electrode active material which includes polyimide containing a naphthalene ring; and a positive electrode, wherein a positive electrode comprises a positive electrode active material comprising a sodium-embedded material. The problems that the cycle life of the battery is short and the specific capacity of the battery is low due to poor matching (such as the mass ratio of positive and negative electrode material, process parameters of electrode preparation and a potential voltage window) of an existing negative electrode material and a positive electrode sodium-embedded material are solved; and moreover, the electrode preparation of the existing negative electrode material and battery assembly processes are complex, the condition requirements on an operation workshop are high, and the material preparation cost is high, so that the production and manufacturing cost of the whole battery is increased.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST

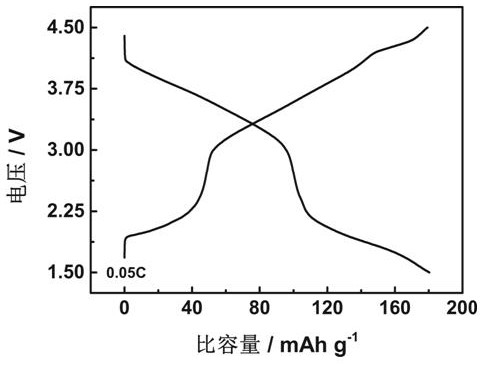

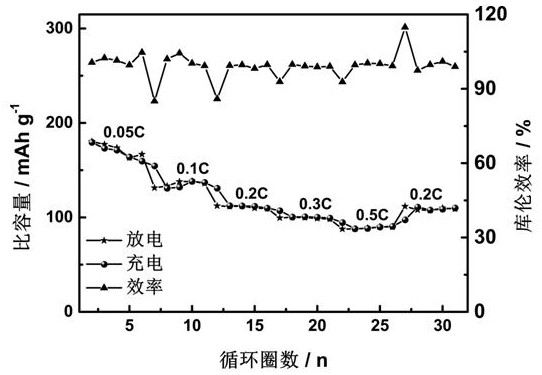

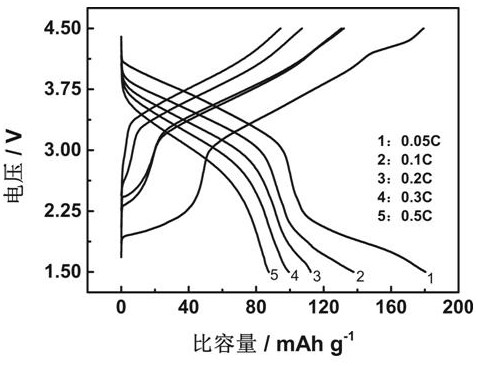

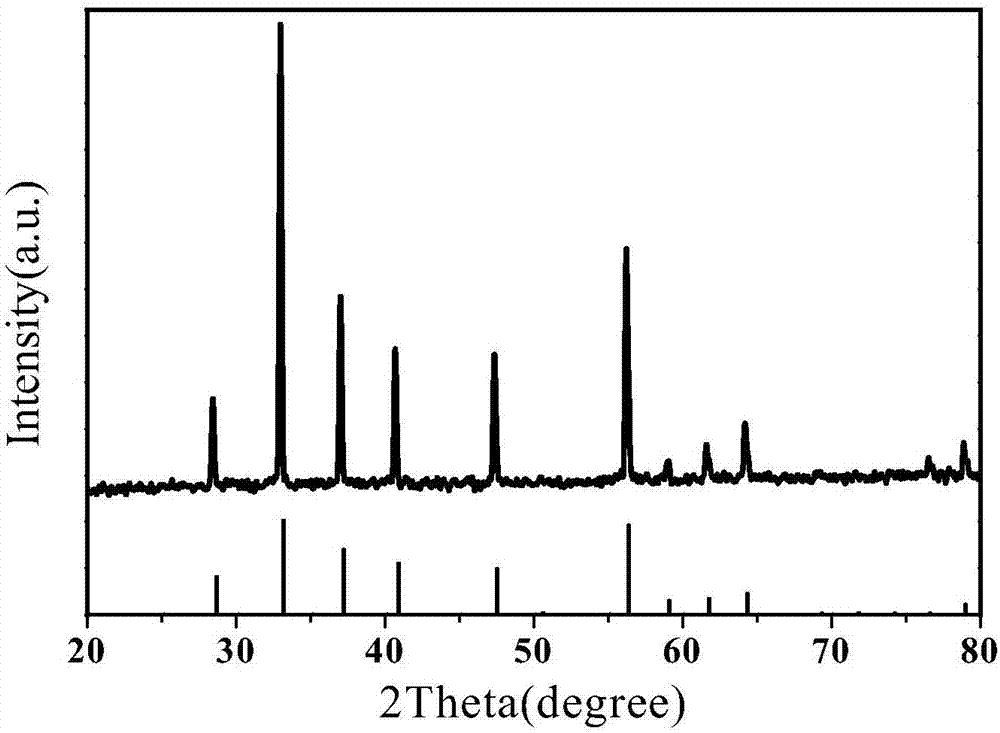

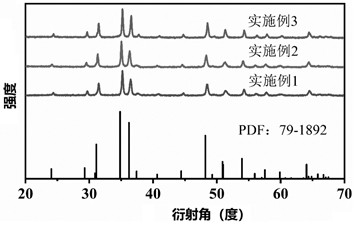

P2-type sodium ion battery layered positive electrode material as well as preparation method and application thereof

ActiveCN112490398ASuppressed vacancy orderingInhibition of irreversible phase transitionsElectrode thermal treatmentSecondary cellsElectrolytic agentHigh energy

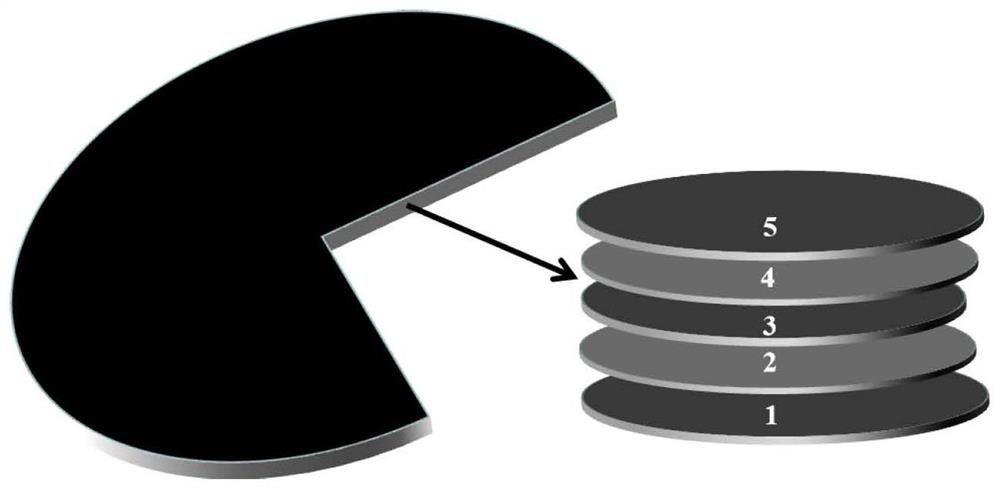

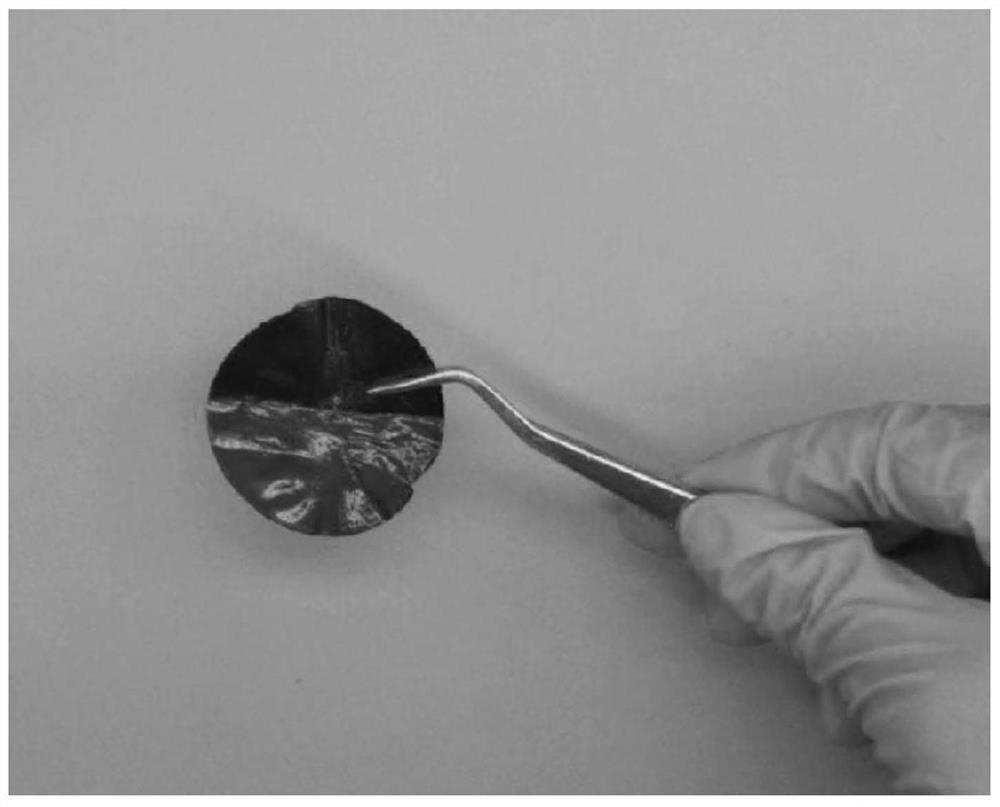

The invention relates to a P2-type sodium ion battery layered positive electrode material as well as a preparation method and application thereof. The positive electrode material is Na0.67NixMnyAZO2,wherein A is one of Ti, Mg, Sn or Bi, x is greater than or equal to 0 and less than or equal to 0.5, y is greater than or equal to 0 and less than or equal to 1, and z is greater than or equal to 0 and less than or equal to 0.5. The preparation method comprises the steps of weighing raw materials according to a stoichiometric ratio by adopting a high-temperature solid-phase method, grinding, pressing into a ceramic chip, calcining in air at high temperature, and cooling to room temperature. The application comprises the steps of uniformly mixing the positive electrode material, conductive carbon black and polyvinylidene fluoride according to a mass ratio ranging from 8: 1: 1 to 6: 3: 1, coating a thin sheet by using an aluminum foil as a current collector, and drying in a vacuum drying oven to form a positive plate; and assembling the sodium ion battery in a glove box filled with argon by taking metal sodium as a negative electrode, GF / D as a diaphragm and a sodium perchlorate electrolyte. The positive electrode material prepared by the invention has a simple phase change process, high energy density and good stability; and the method is simple, easily available in raw materials, low in price, environment-friendly and suitable for large-scale production.

Owner:江西省钒电新能源有限公司

Lithium titanate/titanium black anode material and preparation method thereof

ActiveCN102496704BGood chemical stabilityImprove cycle performanceCell electrodesTitanium compoundsSolid-phase synthesisLithium electrode

The invention relates to a lithium titanate / titanium black anode material and a preparation method thereof belonging to the technical field of lithium ion batteries. The lithium titanate / titanium black anode material has a chemical formula of (1-0.8x)Li4Ti5O12-xTi4O7, wherein x is more than 0,03 and is not more than 0.30. The lithium titanate / titanium black anode material can be synthesized by adopting two methods, the first method is as follows: lithium titanate is carbonized in vacuum, a compact titanium black high-conductive membrane is formed on the surface of the lithium titanate through controlling temperature, reaction time and pressure to have higher multiplying power performance; and the second method is as follows: Ti4O7 is directly added in the lithium titanate, and the lithium titanate / titanium black anode material is synthesized under an inert atmosphere at high temperature. The lithium titanate / titanium black anode material has a simple manufacture process and is beneficial to industrialized production. Compared with the current marketized anode material, the lithium titanate / titanium black anode material has higher electrical conductivity and corrosion resistance and higher large-current discharge cycling performance; and multiplying power charge and discharge performances and cycling performance of a lithium ion power battery can be further improved.

Owner:北京盟固利新材料科技有限公司

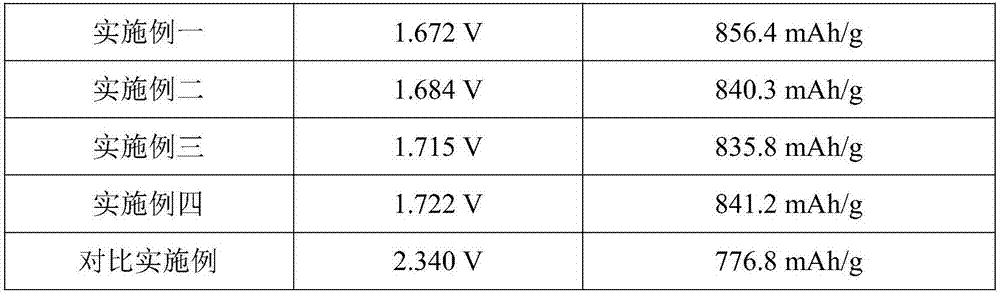

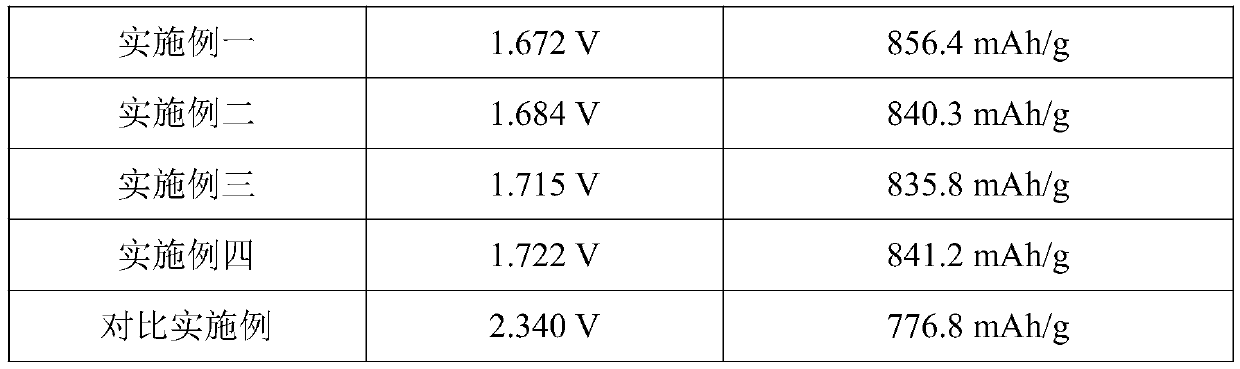

Synthesis method of FeS2 composite positive electrode material, and battery

ActiveCN107482185AHigh purityWell mixedNon-aqueous electrolyte cellsCell electrodesSynthesis methodsThiourea

The invention discloses a synthesis method of a FeS2 composite positive electrode material, and a battery. The method comprises the following steps: dispersing a ferrous salt of an organic acid, thiourea, PVP and a chelating agent in a solvent, carrying out a polymerization reaction to form sol, further generating gel, carrying out heat treatment and grinding to prepare FeS2 powder, adding metal powder with the mass percentage of 0.1-2%, and carrying out surface coating in order to obtain the FeS2 composite positive electrode material. The battery comprises the composite positive electrode material synthesized through the method. The synthesized composite positive electrode material has the characteristics of high purity, small particle size, fast ion diffusion rate and high specific capacity, and effectively controls the open circuit voltage of the produced battery to be lower than 1.83 V; and the metal powder is used to coat iron disulfide, so the electric conductivity of the positive electrode material is enhanced, the rate performances are improved, the erosion of an electrolyte to the material is alleviated, the life of the battery is prolonged, and the discharge performance of the battery at a heavy current is effectively improved.

Owner:东莞市天球实业有限公司 +1

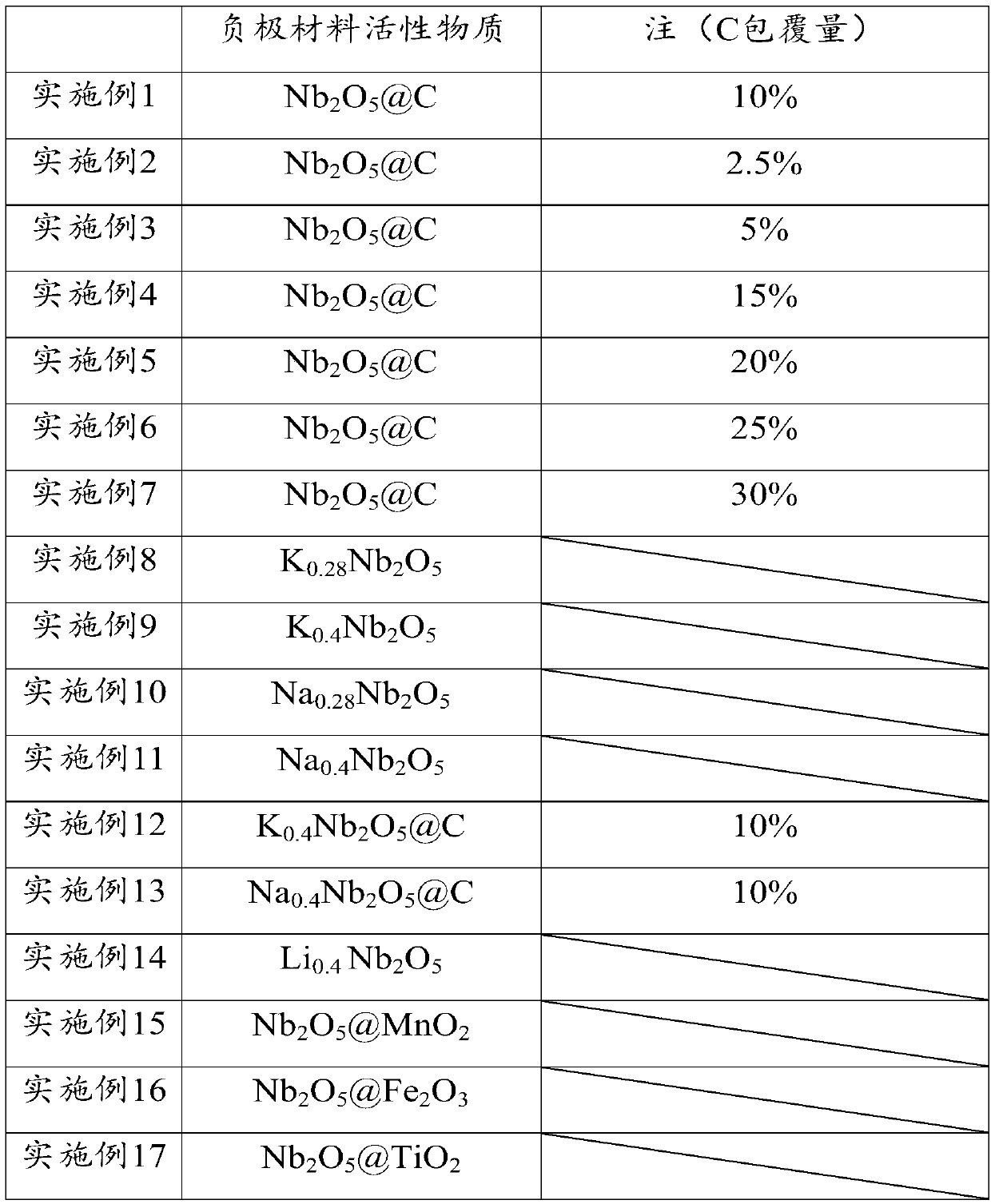

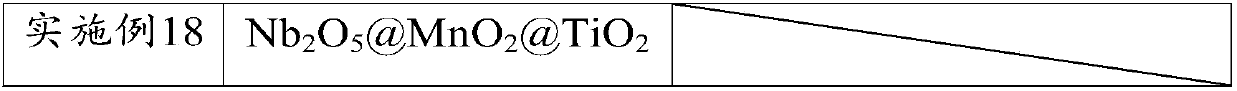

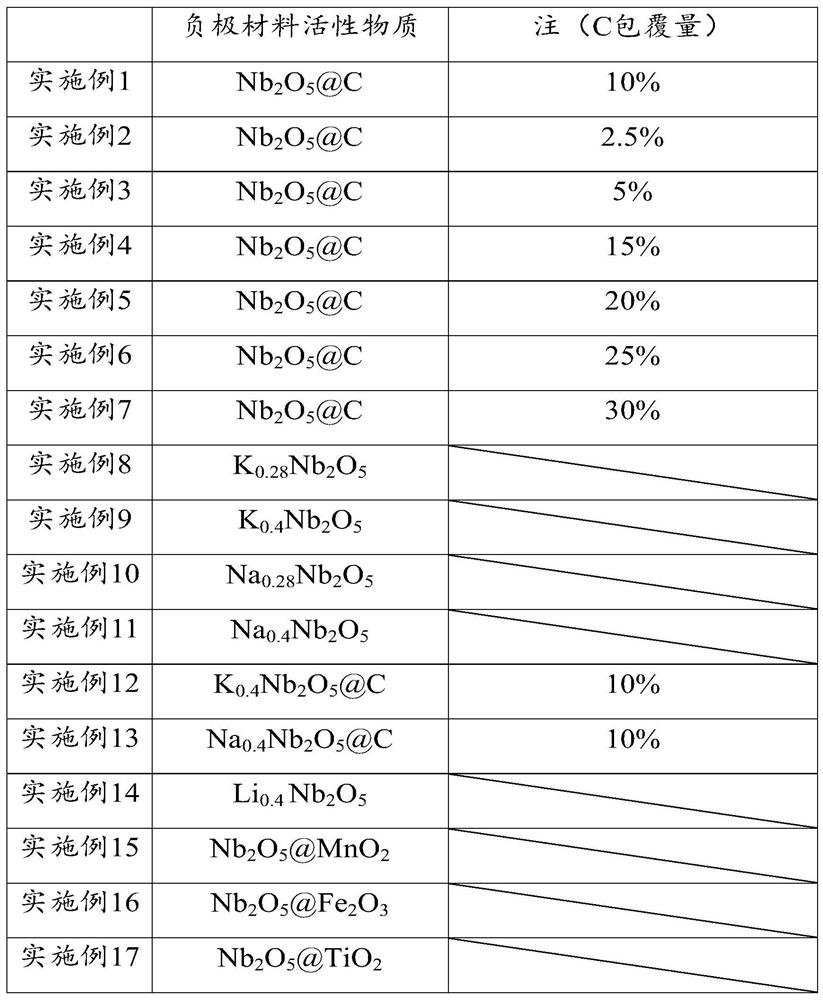

Potassium ion battery negative electrode active material, potassium ion battery negative electrode material, potassium ion battery negative electrode, potassium ion battery and application thereof

ActiveCN109659528AImprove cycle lifeHigh specific capacityNegative electrodesSecondary cellsCapacitanceAlloy

The invention provides a potassium ion battery negative electrode active material, a potassium ion battery negative electrode material, a potassium ion battery negative electrode, a potassium ion battery and an application thereof, belonging to the technical field of potassium ion batteries. The potassium ion battery negative electrode active material provided by the invention comprises a ruthenium pentoxide composite material, wherein the ruthenium pentoxide composite material comprises a ruthenium pentoxide composite material containing a doping ions and / or a coating layer. The ruthenium pentoxide composite material has excellent potassium ion transport channels, can realize rapid insertion and de-intercalation of potassium ions, has stable crystal structure, adopts the reaction mechanism of intercalation and pseudocapacitance dual mechanism, prepares the potassium ion battery with the advantages of long cycle life, high specific capacity and low cost, can solve the problem of priceincrease caused by insufficient lithium resources, avoids the problems of expansion and pulverization of the alloy-type negative electrode of the potassium ion battery, slow dynamics of the intercalated carbon material and the like, and can be widely applied to electric tools, electronic equipment, electric vehicles or energy storage equipment.

Owner:SHENZHEN INST OF ADVANCED TECH

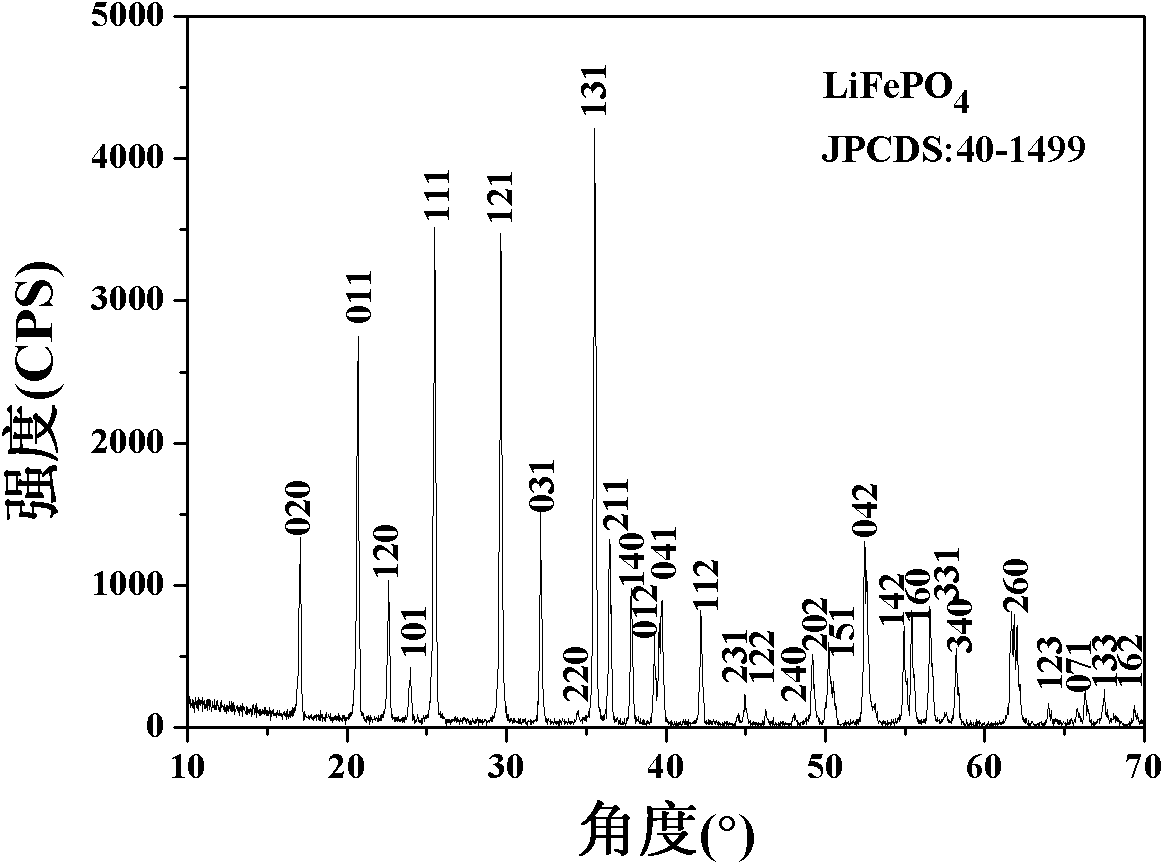

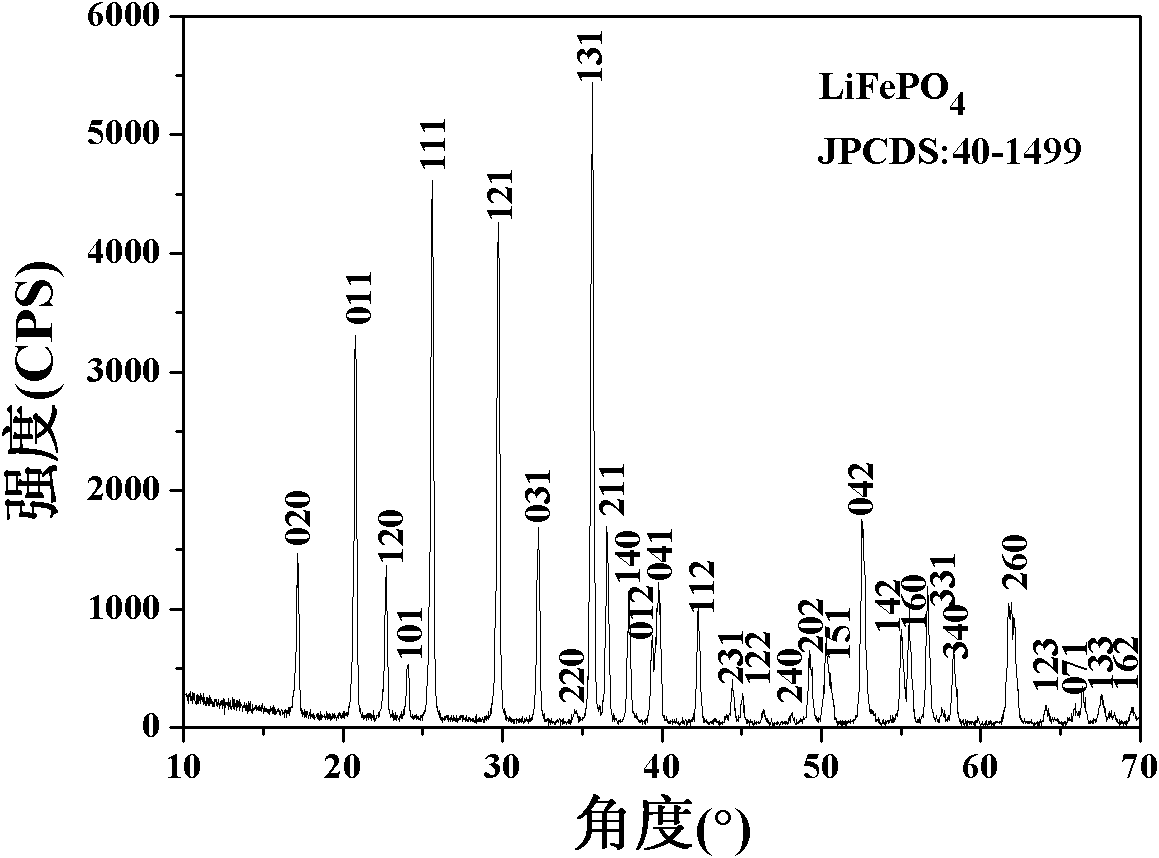

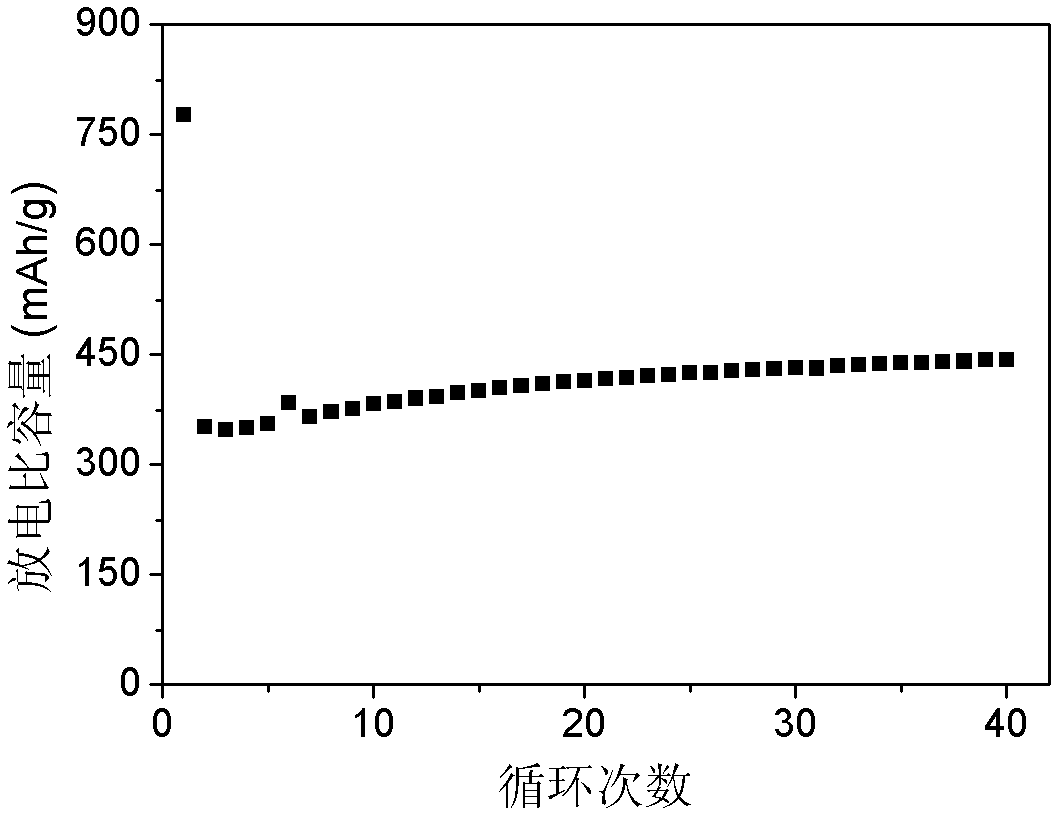

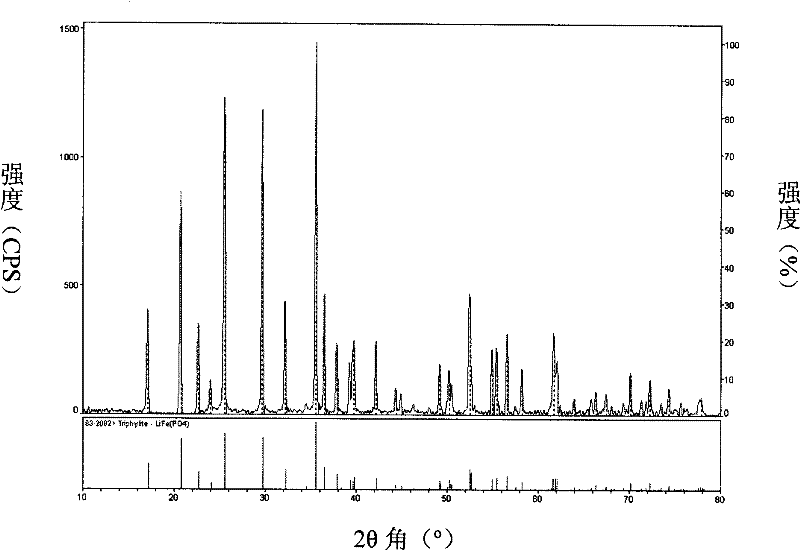

Method for repair and regeneration of waste lithium iron phosphate battery cathode material

ActiveCN102208707BComparative Electrochemical PerformanceReduce pollutionSolid waste disposalWaste accumulators reclaimingLithium iron phosphateEngineering

The invention discloses a method for repair and regeneration of waste lithium iron phosphate battery cathode materials, which allows a lithium-source solution or a suspension to react with a recovered waste lithium iron phosphate battery material by a hydrothermal reaction or a solvent-thermal reaction, or allows the recovered waste lithium iron phosphate battery material to be processed by solid-phase ball-milling and calcination with the lithium source, performs liquid-phase or solid-phase direct lithium-supplementing repair of delithiated waste lithium iron phosphate, and then performs pertinent repair and regeneration by coating conductive agents or coating conductive agents and doping metal ions. The invention adopts a direct repair and regeneration method; the repaired waste lithium iron phosphate battery cathode material has excellent performance, and the specific capacity can reach above 90% of the specific capacity before discard; the method not only can effectively reduce environmental pollution of waste batteries, but also can make full use of waste resources and changes waste into valuables.

Owner:HEFEI UNIV OF TECH

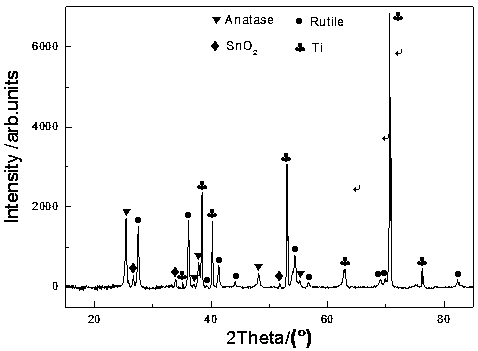

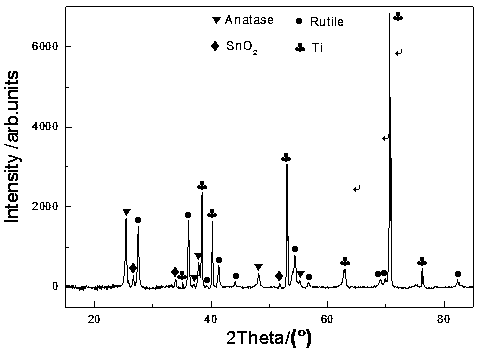

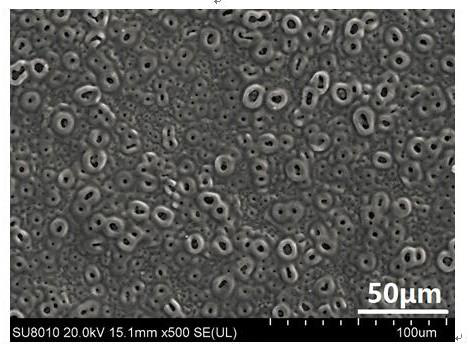

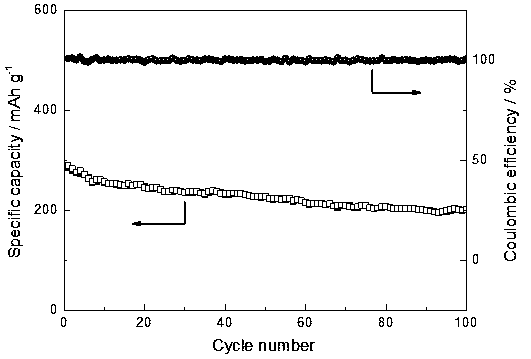

Preparation method for titanium oxide/tin oxide composite membrane for sodium ion battery cathode

ActiveCN109537021AHigh specific capacityGood cycle stabilityCell electrodesSurface reaction electrolytic coatingIonSodium silicate

The invention provides a method of preparing a TiO2 / SnO2 cathode material of a sodium ion battery by using a plasma electrolytic oxidation technique. An electrolyte is prepared from 1-10 ml / l phosphoric acid (85wt.%), 1-10 g / L sodium silicate, 5-30 g / L sodium stannate and 5-30 ml / L glycerol separately. The method comprises the following steps: by taking foamed titanium as an anode and stainless steel as a cathode, immersing the anode and the cathode into a special electrolyte solution containing phosphoric acid, sodium silicate, sodium stannate, glycerol and deionized water; applying a bipolarpulse voltage between the two electrodes at constant temperature and constant pressure, wherein plasma discharge happens on the surface of the foamed titanium; turning off a power supply after discharge for a period of time to prepare the TiO2 / SnO2 composite membrane on the surface of the foamed titanium. The composite membrane can be used as a cathode material of the sodium ion battery. The TiO2 / SnO2 cathode material makes full use of a high capacity characteristic and high cyclic stability of TiO2. The method is simple in preparation process, low in production cost and suitable for industrial production.

Owner:TIANJIN NORMAL UNIVERSITY

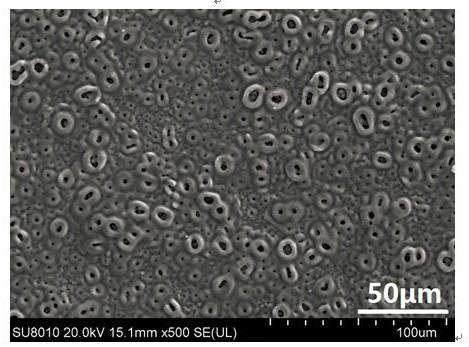

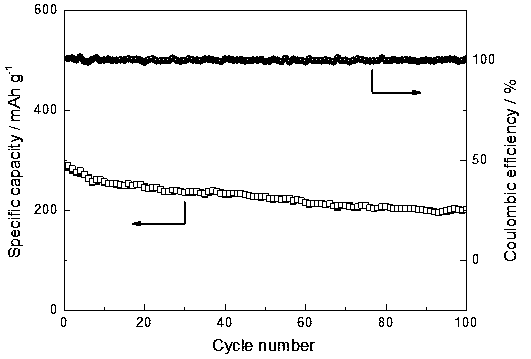

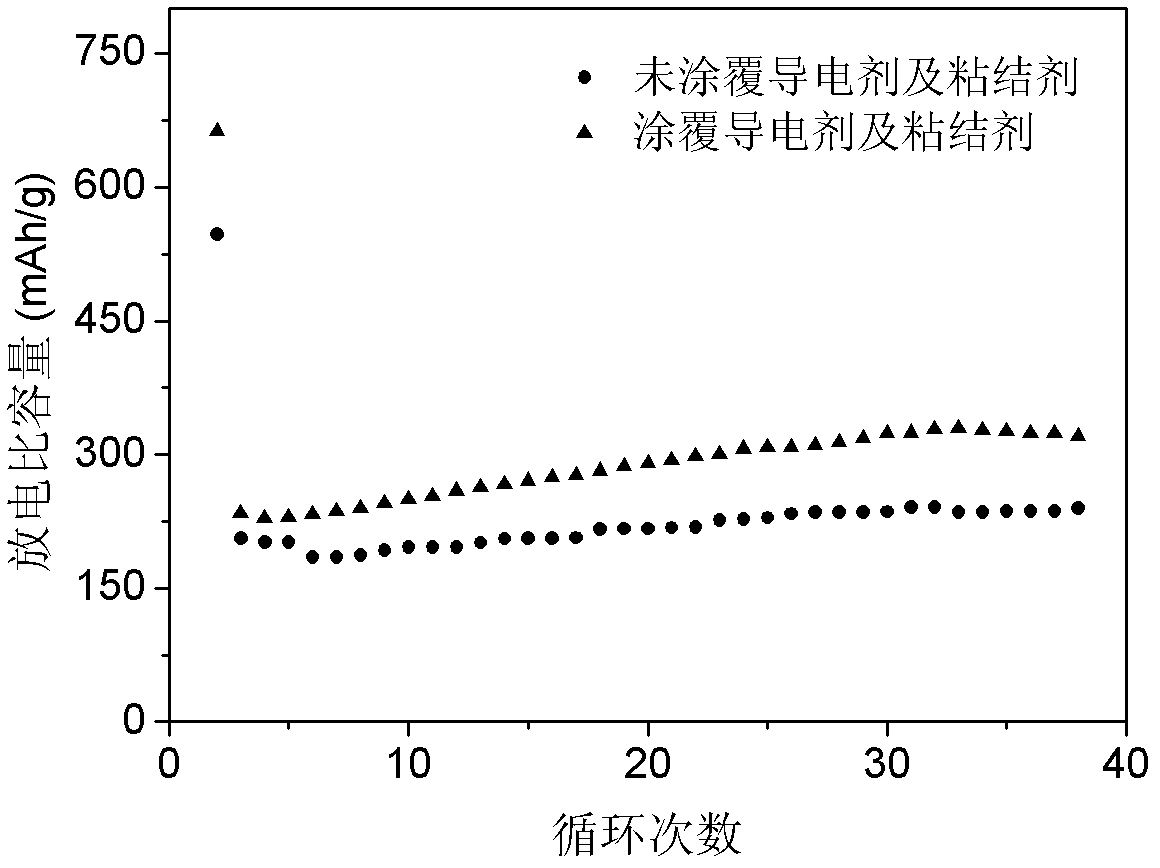

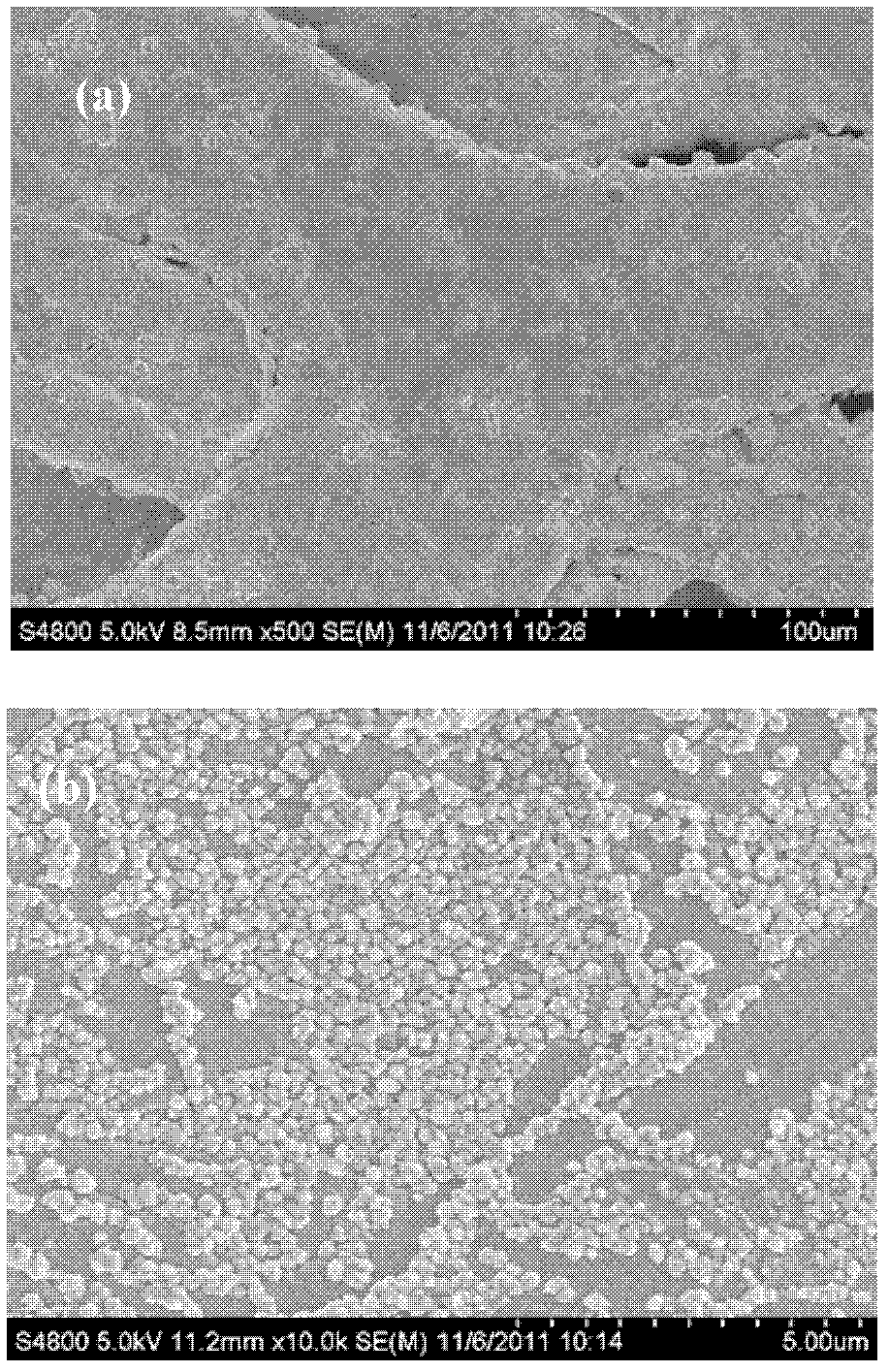

Foamy copper oxide/copper lithium ion battery anode and preparation method thereof

InactiveCN102394305BImprove contact strengthHigh bonding strengthElectrode carriers/collectorsElectrical batteryCopper oxide

The invention discloses a negative electrode of a foamed copper oxide / copper lithium ion battery and a preparation process thereof, comprising the following steps: carrying out pickling treatment on the surface of the foamed copper, washing and drying it with water, and compacting it; The surface is oxidized in an air atmosphere heat treatment furnace to obtain a layer of copper oxide (CuO, Cu2O or a mixture of the two) on the surface; then the slurry obtained by mixing carbon-based conductive agent, binder and solvent Coating on the surface of the foamed copper oxide / copper composite material, drying and pressing. The three-dimensional structure copper oxide / copper material coated with a conductive agent and a binder on the surface can be directly used as a negative electrode of a lithium-ion battery, without the need for mixing active materials with a binder and a conductive agent in the traditional preparation of a negative electrode of a lithium-ion battery The process of making a slurry and coating it on a current collector. The coated conductive agent and binder can increase the electrical contact of the copper oxide active material during charging and discharging, and increase the electronic conductivity and the utilization rate of the active material. The negative electrode of the lithium ion battery of the invention has high specific capacity, good cycle performance, and the preparation method of the electrode is simple and easy to control, and is very suitable for the industrial application of the lithium ion battery.

Owner:ZHEJIANG UNIV

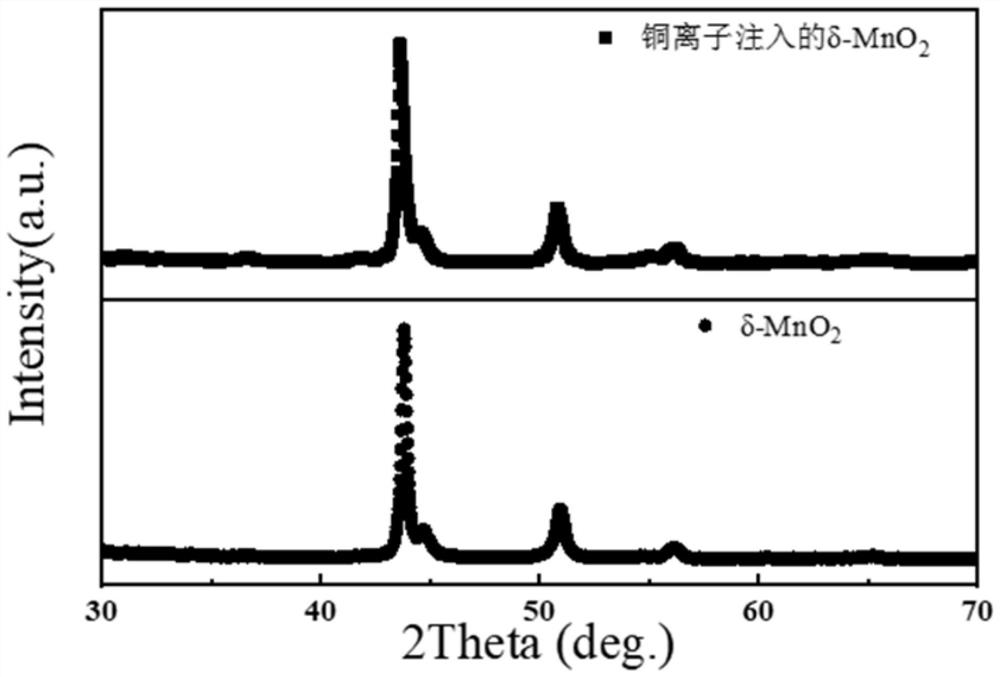

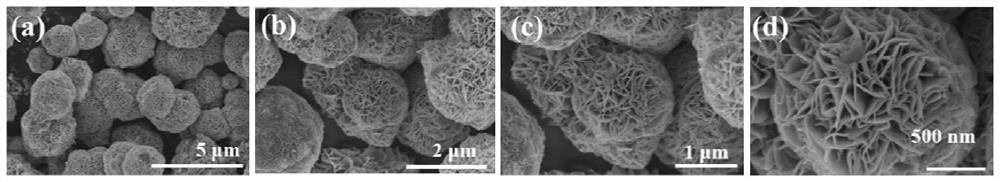

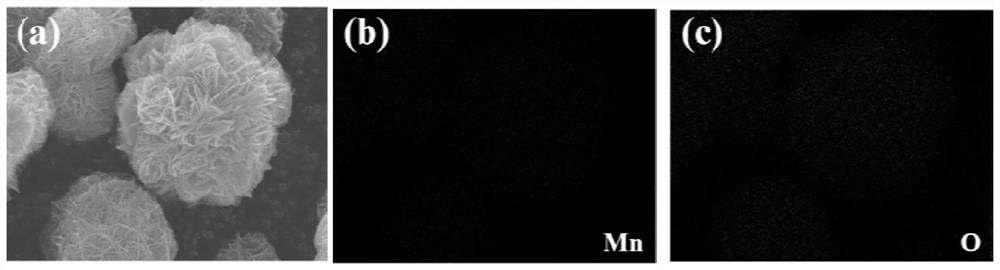

Modification method of copper ion implanted zinc battery positive electrode material delta-manganese dioxide

ActiveCN114314670AWide variety of sourcesPollution advantageCell electrodesEnergy inputElectrical batteryPhysical chemistry

The invention discloses a modification method of a copper ion implanted zinc battery positive electrode material delta-manganese dioxide, and relates to a preparation method of a battery positive electrode material. The invention aims to solve the problems that the traditional lithium ion battery is toxic and inflammable, needs a water-free operation environment and consumes a large amount of lithium resources. The method comprises the following steps: 1, preparing delta-manganese dioxide powder; 2, preparing viscous electrode slurry; and 3, copper ion implantation. Compared with the performance of an aqueous zinc ion battery assembled by a delta-manganese dioxide-loaded electrode plate without copper ion implantation, the performance of the aqueous zinc ion battery assembled by the copper ion-implanted delta-manganese dioxide electrode plate prepared by the invention has the high specific capacity of 519.4 mAhg <-1 > at 0.1 Ag <-1 >, and the specific capacity of the aqueous zinc ion battery assembled by the copper ion-implanted delta-manganese dioxide electrode plate is 519.4 mAhg <-1 > at 0.1 Ag <-1 >. And the capacity of an aqueous zinc ion battery assembled by the electrode plate loaded with the delta-manganese dioxide is only 209.7 mAhg <-1 > under the same current density.

Owner:NORTHWEST UNIV(CN)

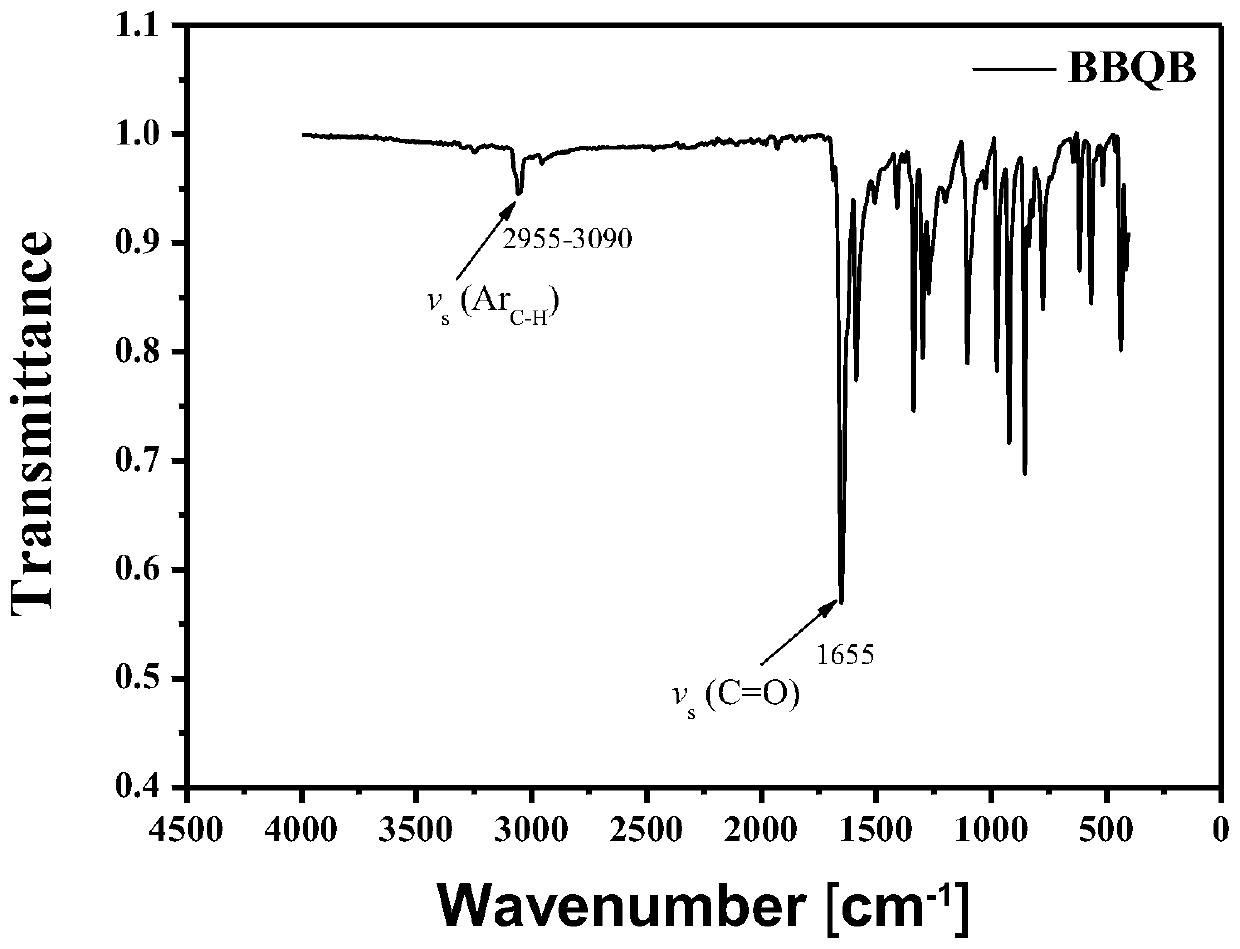

Compound for positive electrode material of lithium ion battery, and preparation method and application

ActiveCN111211327AEasy to synthesizeHigh reaction yieldSecondary cellsPositive electrodesCarbon compositesElectrical battery

The invention relates to a compound for the positive electrode material of a lithium ion battery, a preparation method and application. The compound is 1, 4-dibenzoquinonyl benzene. A precursor is obtained from 1, 4-dibromobenzene and 2, 5-dimethoxyphenylboronic acid under the catalytic action of tetrakis (triphenylphosphine) palladium; and the precursor compound is oxidized with ceric ammonium nitrate, so that a target product can be obtained. The raw materials in the reactions of the above two steps are cheap and easily available, and simple to synthesize; the yield of the compound is greater than 60%. The carbon composite electrode of the compound is used as the positive electrode of the lithium battery; under the current density of 0.1 C, the initial discharge capacity of the lithium battery reaches a theoretical value (370mAh / g), after 100 cycles, the actual specific capacity of the lithium battery is still 300mAh / g or above, and the retention rate of the lithium battery is about83.0%; the average discharge voltage of the lithium battery is 60 V; under the current density of 1C, the specific capacity of the lithium battery can reach 260mAh / g. Compared with that of a lithium battery with the capacity of 0.1 C, the retention rate of the lithium battery is about 70.3%.

Owner:TIANJIN UNIV

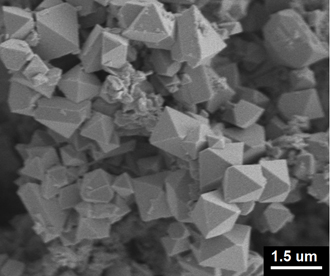

Iron-copper-tin ternary selenide nano material for sodium-ion battery and preparation method of iron-copper-tin ternary selenide nano material

ActiveCN114671414AHigh specific capacityIncrease capacitySecondary cellsPositive electrodesElectrical batteryNanoparticle

The invention discloses an iron-copper-tin ternary selenide nano material for a sodium ion battery, which takes FeSe2 as a matrix and has a FeSe2 type phase structure. Two transition metal elements of Cu and Sn are uniformly dispersed in FeSe2; the microcosmic shape is a nano-polyhedron stacked shape, and fine nano-particles are attached to the surfaces of part of nano-polyhedrons. The invention also discloses a preparation method of the nano material, which comprises the following steps: taking dichloride as a transition metal source, taking water as a solvent, adding citric acid, and continuously stirring to homogenize a precursor solution; adding a selenium source sodium selenite and selenium powder, dropwise adding hydrazine hydrate, and then carrying out hydrothermal reaction to obtain the nano material. According to the invention, multi-component compounding of the selenide is realized, and the multi-component metal selenide with uniformly distributed transition metal elements is formed. The iron-copper-tin ternary selenide nano material is used as an electrode material to assemble a sodium ion battery, and the sodium ion battery has the advantages of ultra-long cycle life, ultra-fast charge characteristic and ultra-wide temperature range working characteristic.

Owner:ZHEJIANG UNIV

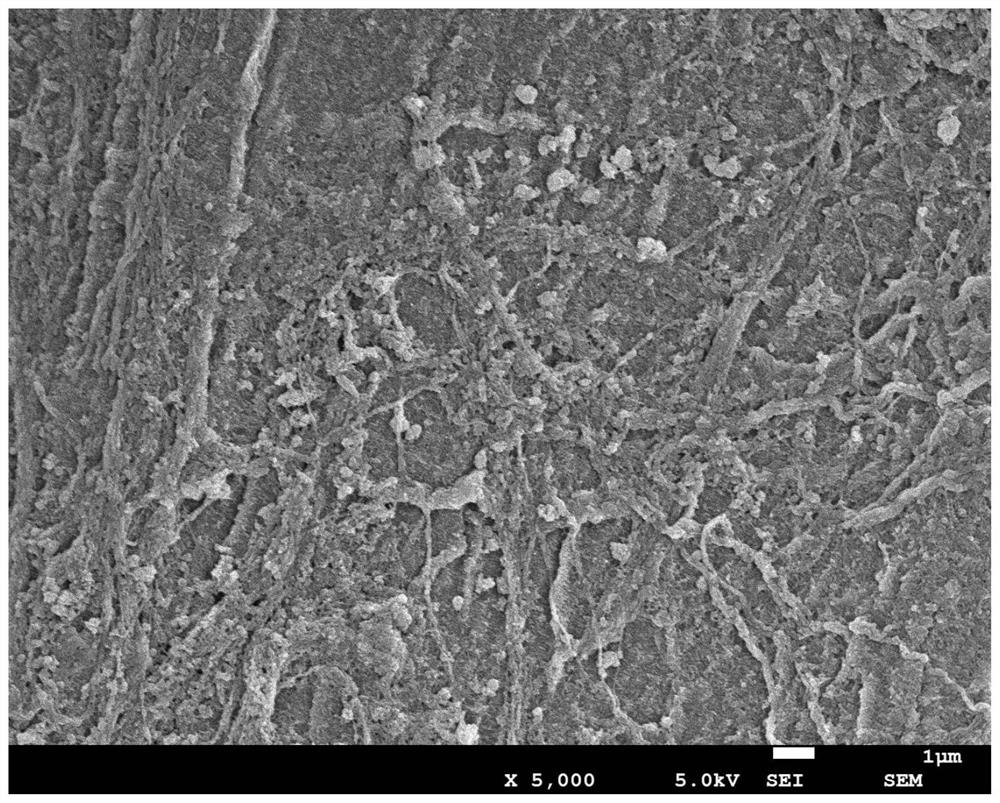

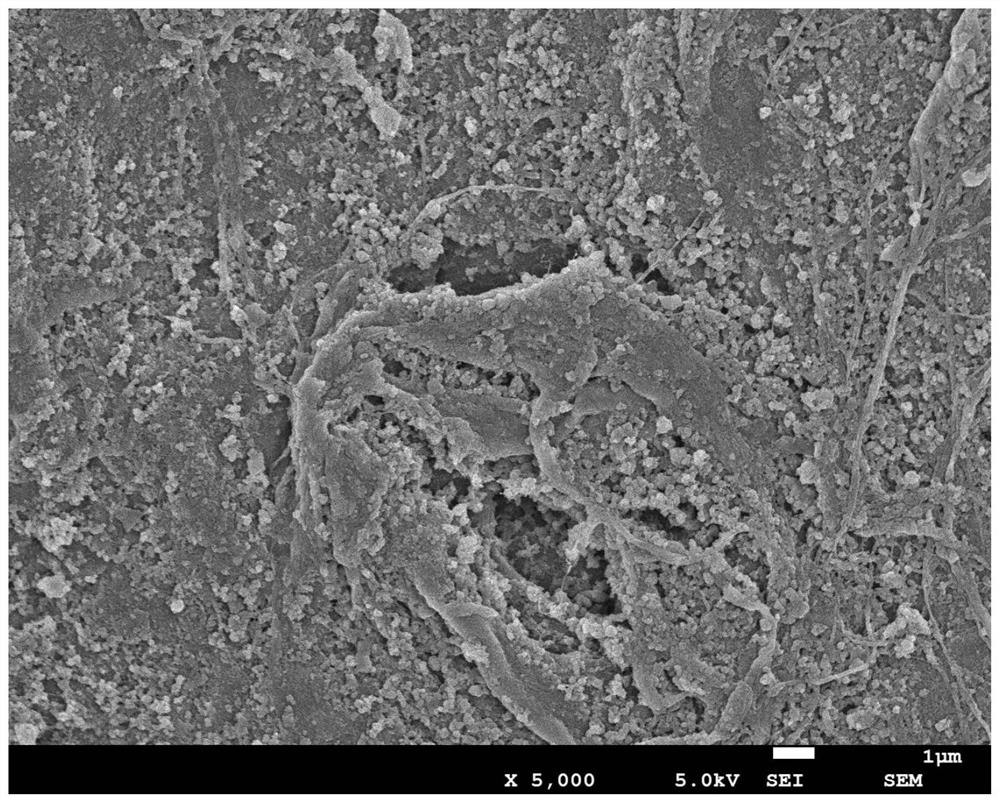

Hybrid doped polypyrrole paper-based flexible electrode material and preparation method thereof

The invention discloses a hybrid doped polypyrrole paper-based flexible electrode material, which is prepared by the following steps: simultaneously dissolving a certain amount of lignosulfonate and anthraquinone-2-sodium sulfonate in a certain amount of distilled water to obtain a hybrid doped solution; dispersing a certain amount of cellulose fibers in a hybrid doping solution, placing in an ice-water bath, mechanically dispersing, adding a certain amount of pyrrole monomer, mechanically stirring for a certain time, and dropwise adding a ferric trichloride oxidant solution to initiate polymerization; and after polymerizing for a certain time, filtering, washing and drying a product to obtain the hybrid doped polypyrrole paper-based flexible electrode material. The method has the advantages that the process is simple, the raw materials are easy to obtain, and the method is suitable for large-scale industrial production; and the prepared hybrid doped polypyrrole paper-based flexible electrode material has the characteristics of low cost and high specific capacity.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

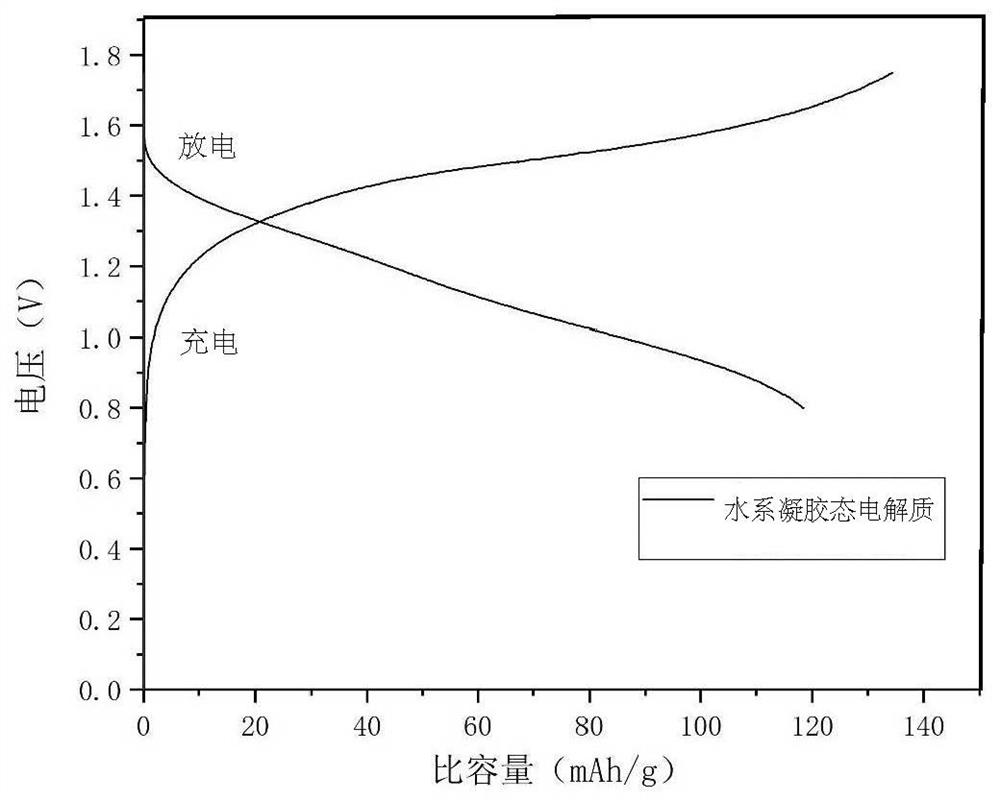

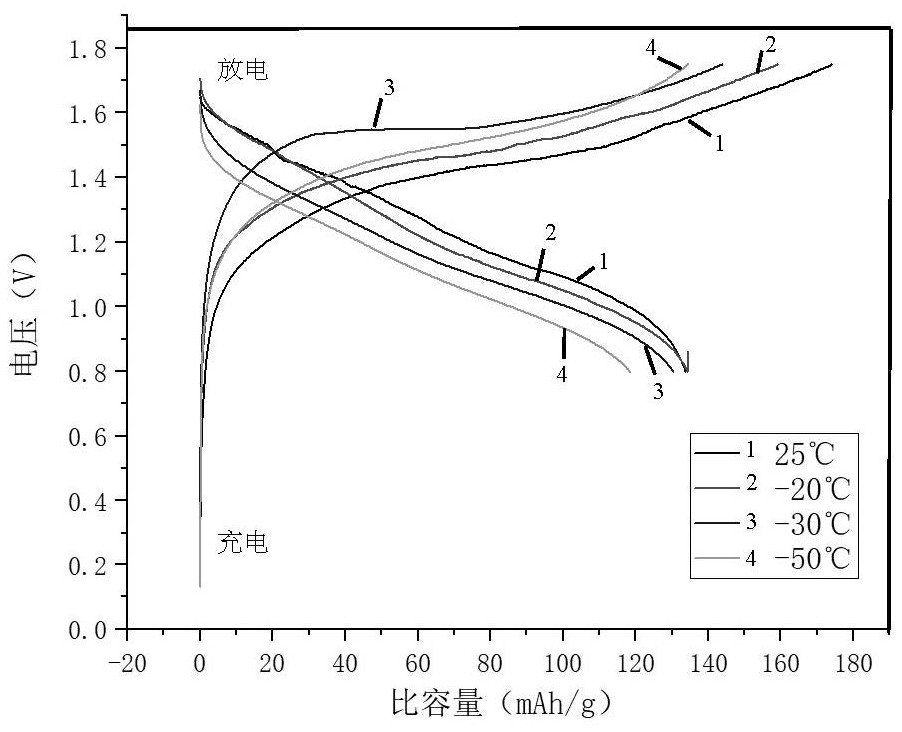

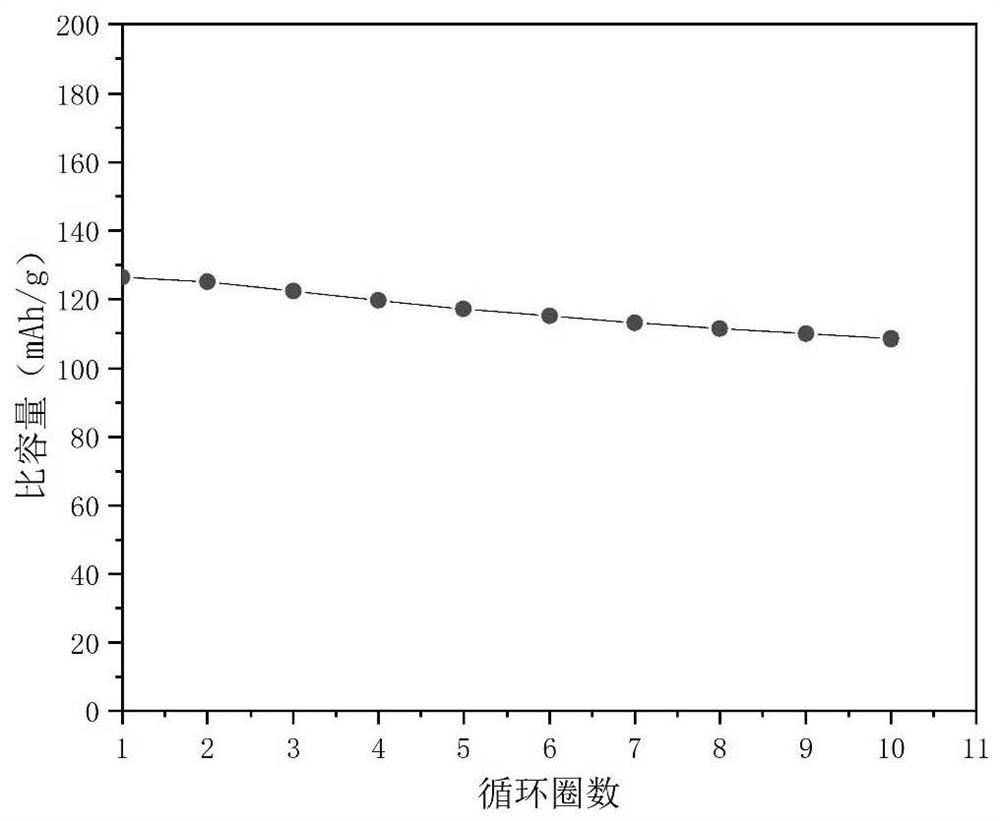

Aqueous gel-state electrolytes, electrode additives and solid-state sodium-ion batteries with low-temperature operating characteristics

ActiveCN111403829BSimple manufacturing methodLow costCell electrodesSecondary cellsElectrolytic agentSulfate radicals

The invention discloses a water-based gel-state electrolyte, a pole piece additive and a solid-state sodium-ion battery with low-temperature working characteristics. The water-based gel-state electrolyte includes fumed silicon dioxide with a gel-conducting ion effect and a sulfate electrolyte loaded on it, and the preparation method of the water-based gel-state electrolyte includes: adding gas-phase silicon dioxide to the sulfate-based electrolyte Silica and methyl alcohol obtain gel state electrolyte; Wherein, the concentration of sulfate in the said sulfate salt system electrolytic solution is 0.5-3mol / L, the mole of the sulfate radical in the described fumed silicon dioxide and sulfate salt system electrolyte The ratio is (1-5):1, preferably: (1.5-2.5):1; the volume ratio of the sulfate-based electrolyte to methanol is (1-10):1, preferably (1-2):1.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

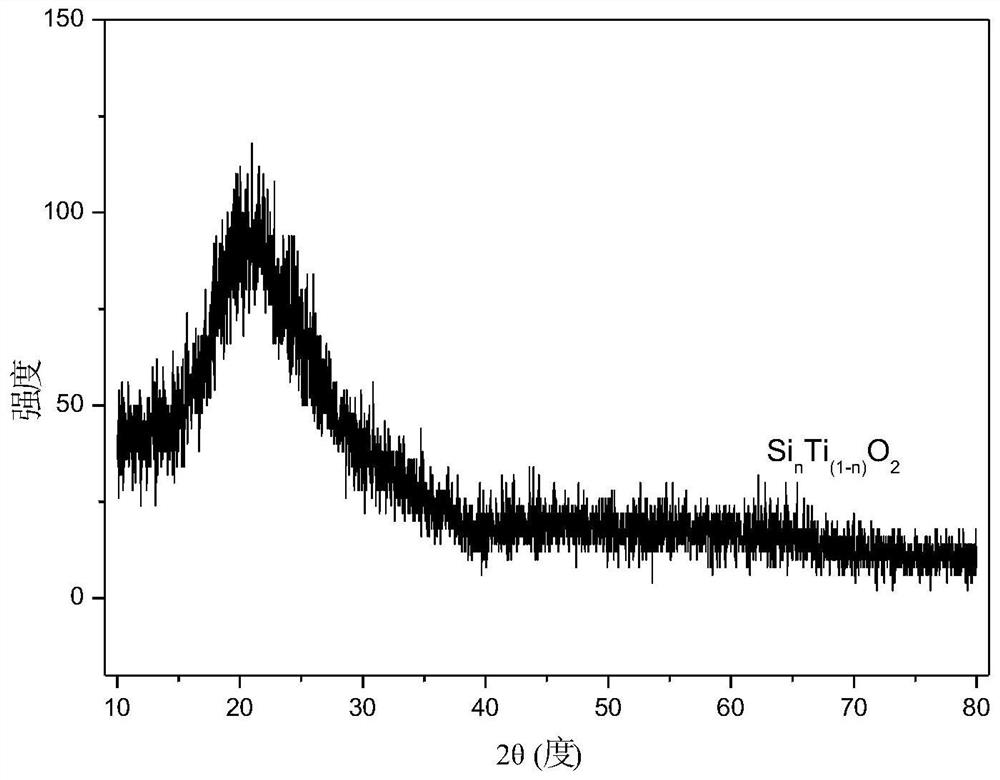

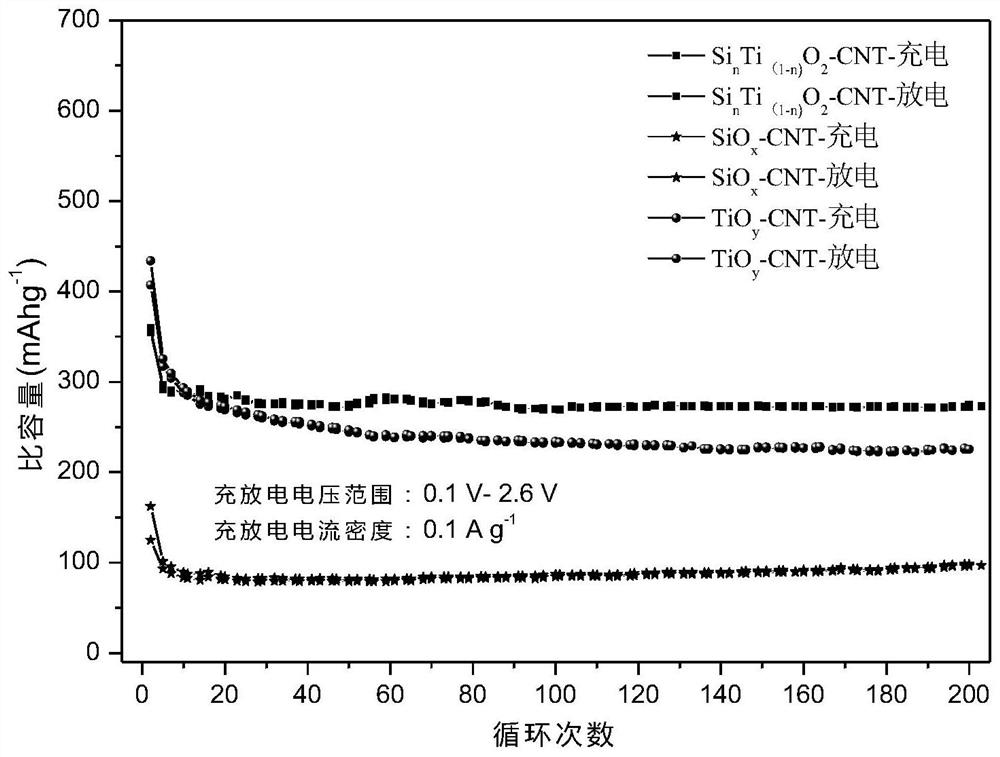

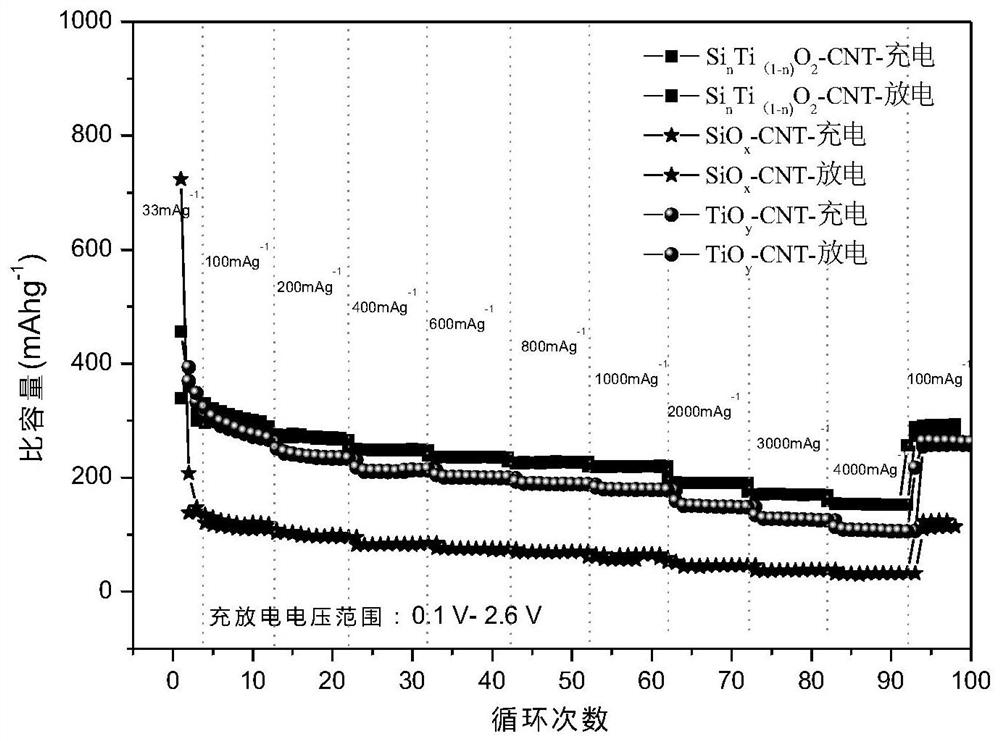

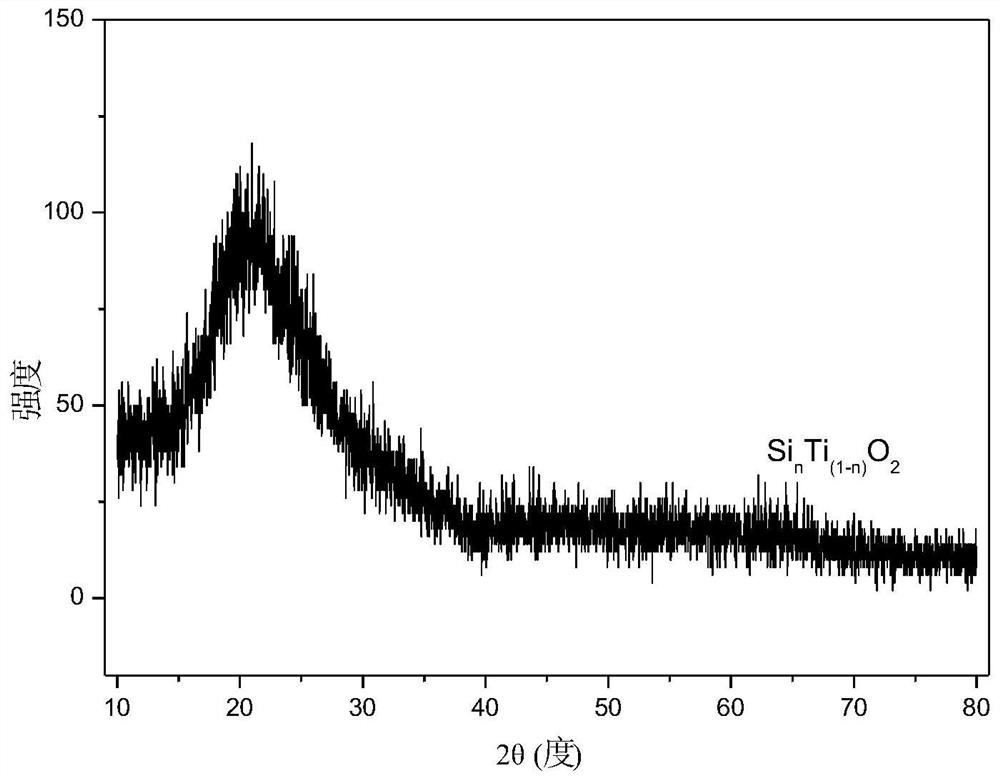

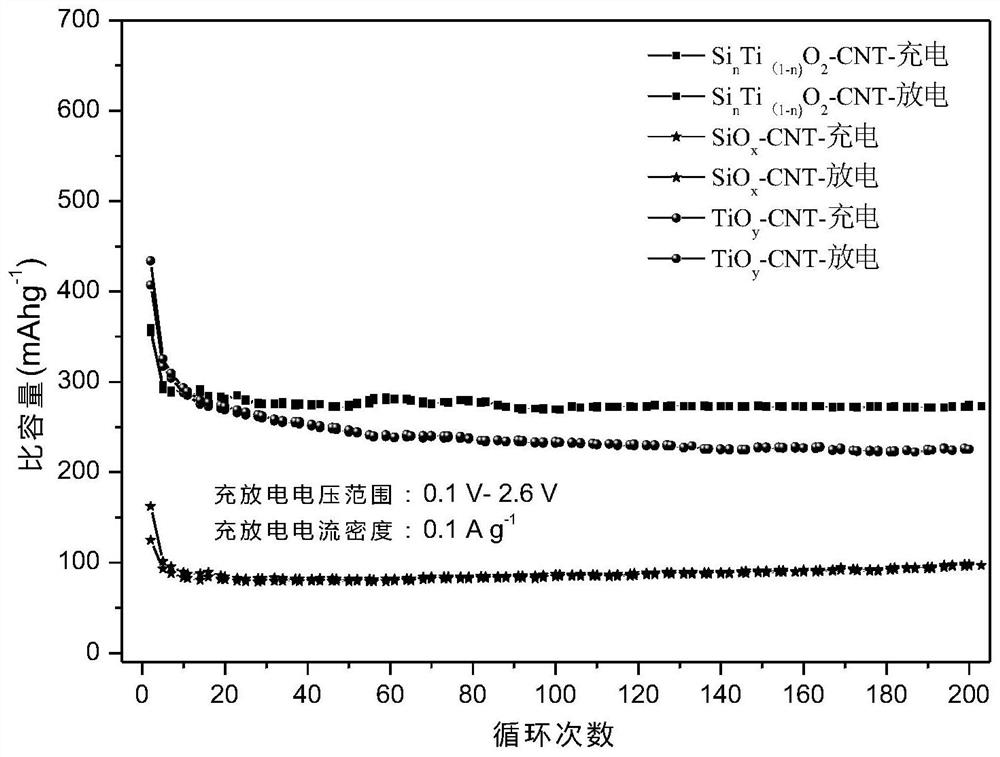

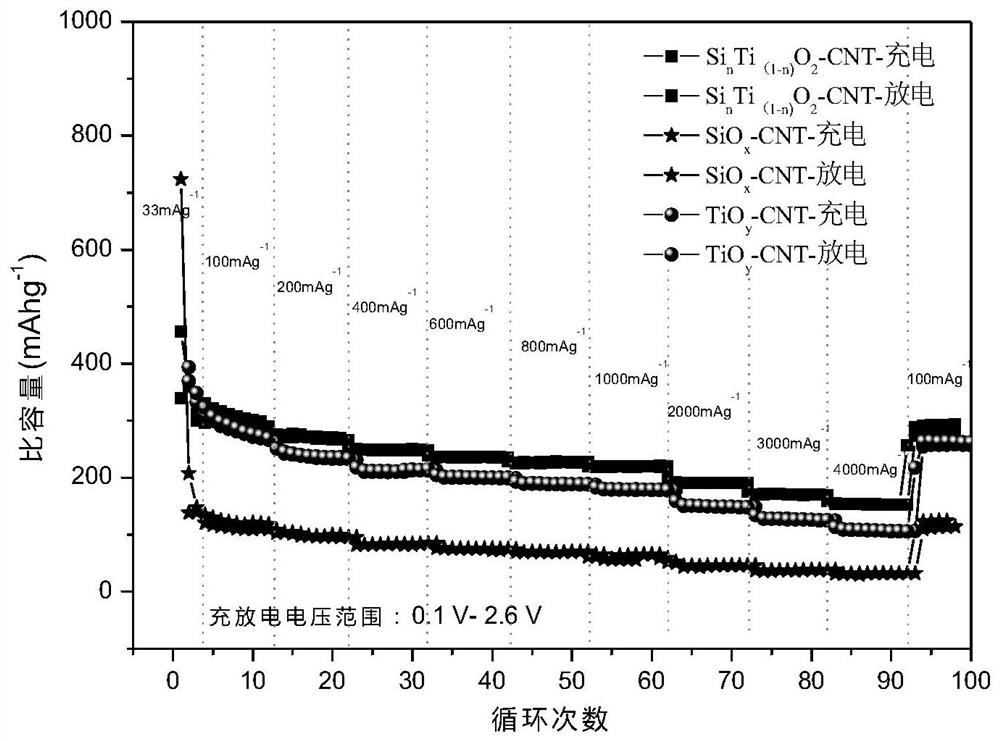

A method for preparing titanium-silicon polymer oxide composite lithium-ion battery negative electrode material by thermal decomposition of organic titanium-silicon polymer

ActiveCN111916685BSmall volume changeImprove electrochemical performanceNegative electrodesSecondary cellsPtru catalystCarbon nanotube

The invention discloses a method for preparing a negative electrode material of a titanium-silicon polymer oxide composite lithium ion battery by thermal decomposition of an organic titanium-silicon polymer, which comprises the following steps: (1) carbon nanotubes (CNT), a solvent, an organic binary After mixing alcohol, silicon orthoester and titanium orthoester, organic amine is added as a catalyst to fully stir to obtain a mixed slurry M; (2) the mixed slurry M is put into a reaction kettle and fully reacted at a certain temperature, and then solidified. Liquid separation, take the solid, and then dry the obtained solid to obtain the precursor S; (3) calcine the precursor S under the protection of inert gas to obtain Ti n Si (1‑n) O 2 ‑CNT composite lithium-ion battery anode material. Ti prepared by the method of the present invention n Si (1‑n) O 2 ‑CNT composite lithium-ion battery anode material has the characteristics of good rate performance, high cycle stability and high specific capacity.

Owner:ZHEJIANG FOLTA TECH CO LTD

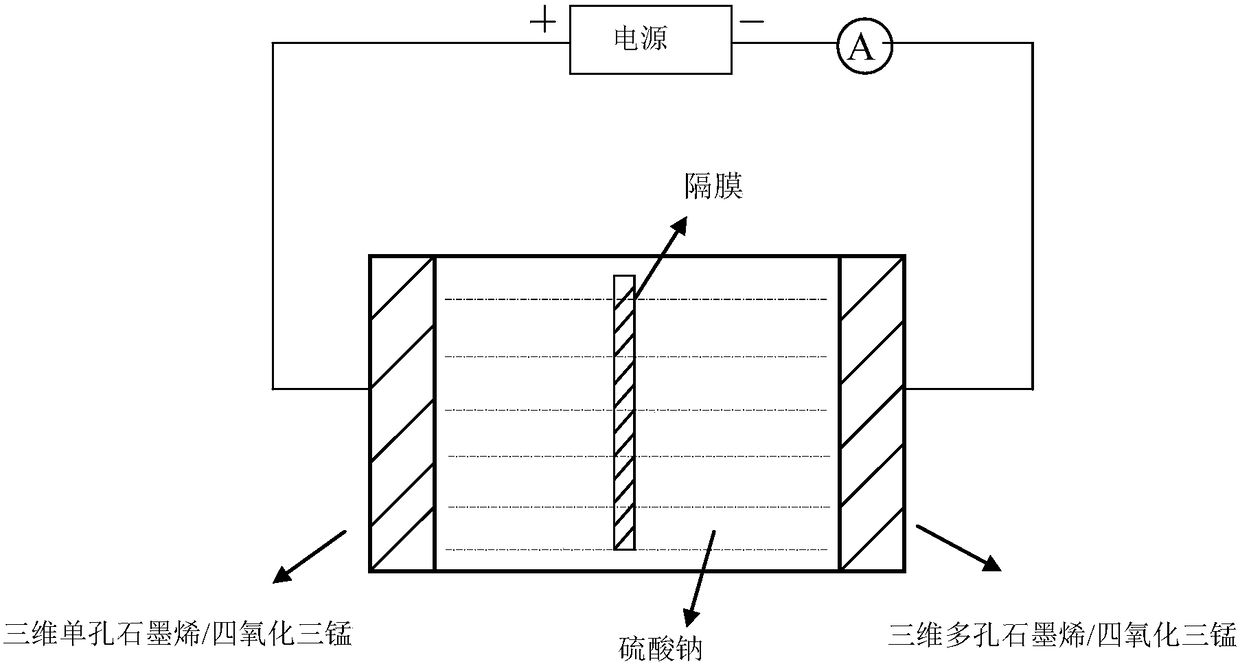

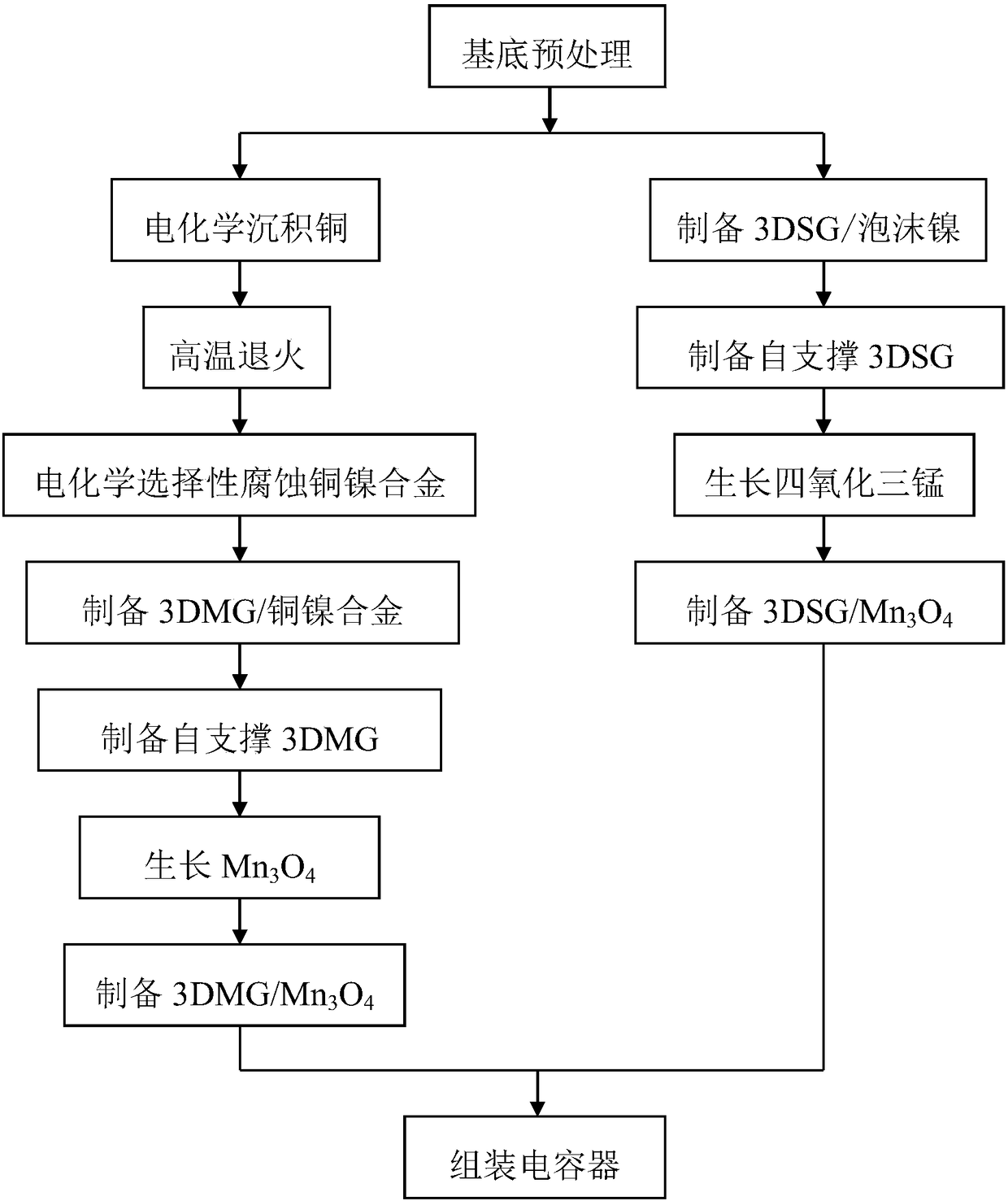

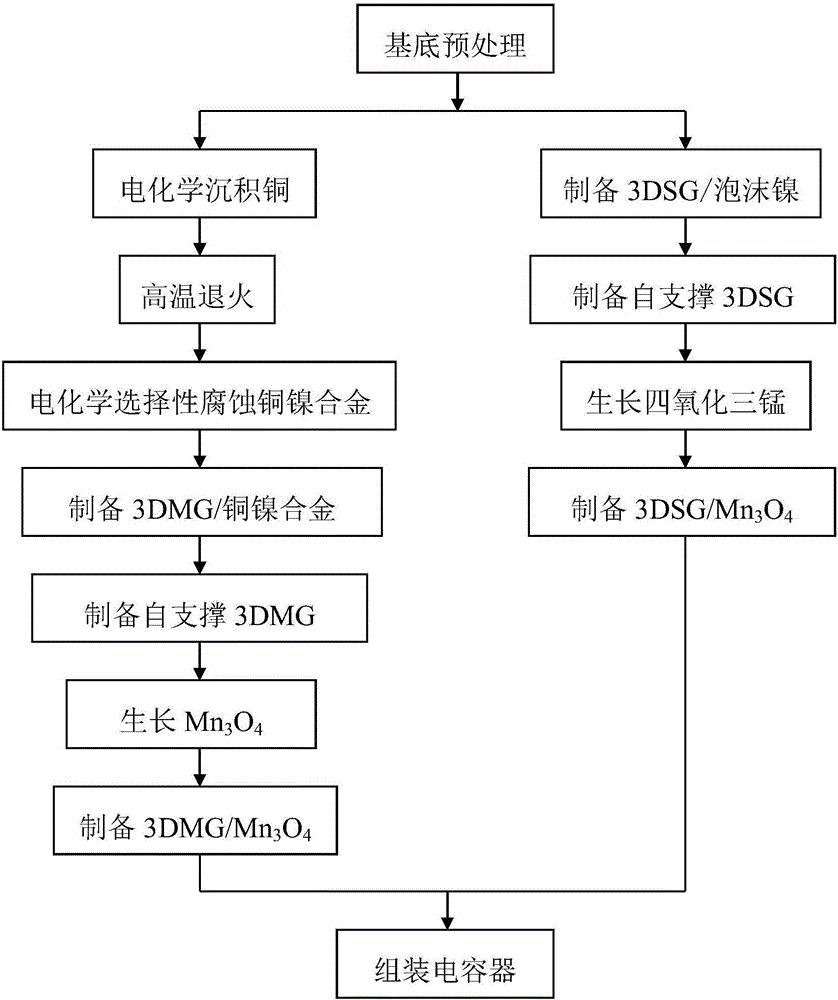

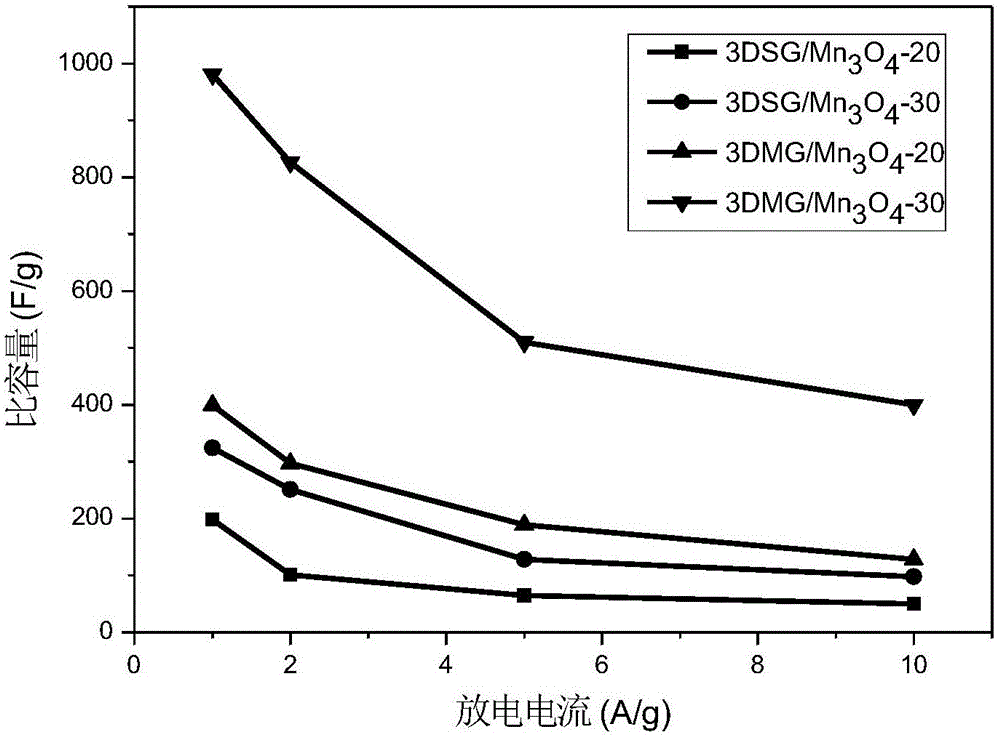

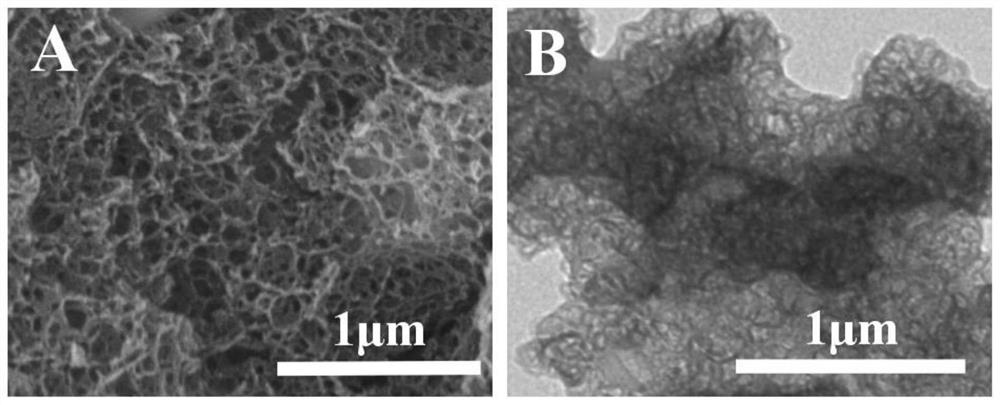

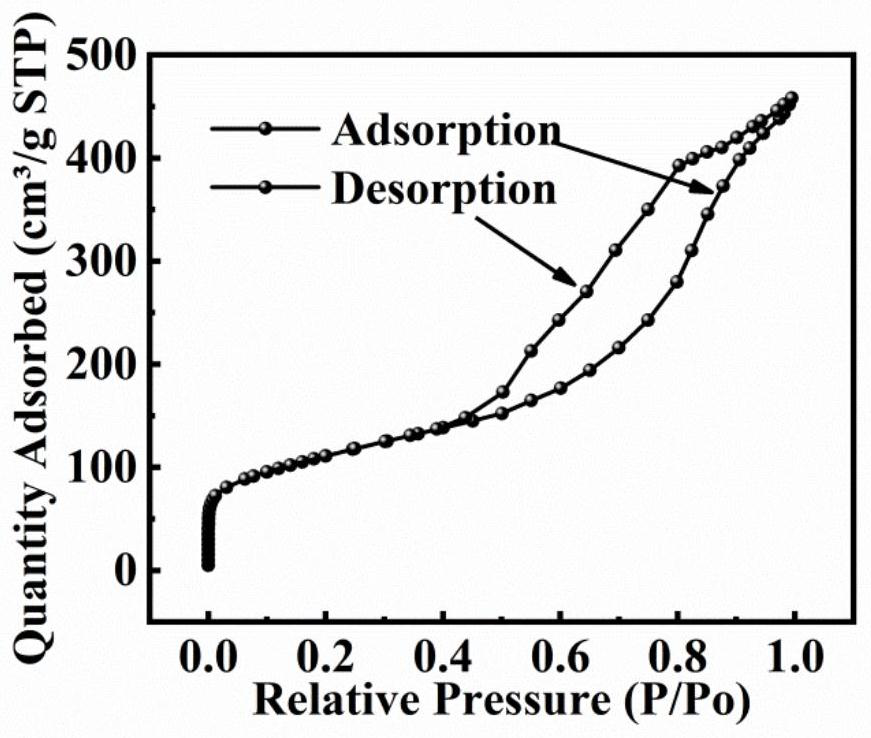

3dsg/mn3o4/3dmg-based asymmetric supercapacitor and preparation method

ActiveCN105845452BTo overcome the deficiency of the electrode specific surface area is not highLarge specific surface areaHybrid capacitor electrolytesHybrid capacitor electrodesMaterials scienceElectrolyte

Owner:泰州巨纳新能源有限公司

A hybrid doped polypyrrole paper-based flexible electrode material and its preparation method

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Solid solution material and preparation method thereof as well as lithium ion battery containing material

ActiveCN102659184APromote circulationImprove the first Coulombic efficiencyCell electrodesSecondary cellsPhysical chemistrySodium-ion battery

The invention provides a solid solution material and a preparation method thereof as well as a lithium ion battery containing the material, belongs to the technical method of the lithium ion battery, and solves the problems of low first coulomb efficiency or low specific capacity and poor circulating performance of the existing 0.5LiNi0.5Mn1.5O4*0.5Li2MnO3*0.5LiNi0.5Mn0.5O2 material and the lithium ion battery prepared from the material. The preparation method of the solid solution material disclosed by the invention comprises a step of nickel-manganese precursor preparation based on a co-precipitation method, a step of precursor pre-treatment and a step of solid phase synthesizing. The solid solution material with a good performance can be obtained through selecting suitable technical parameters so that the material and the lithium ion battery prepared from the material have high first coulomb efficiency, high specific capacity and good circulating performance.. The solid solution material prepared by the invention is prepared by the preparation method. The lithium ion battery disclosed by the invention comprises the solid solution material.

Owner:CHERY AUTOMOBILE CO LTD

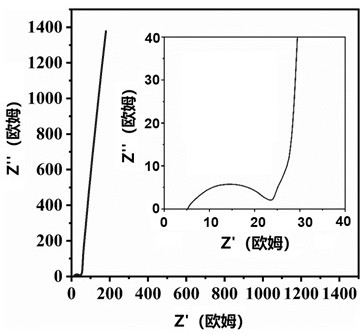

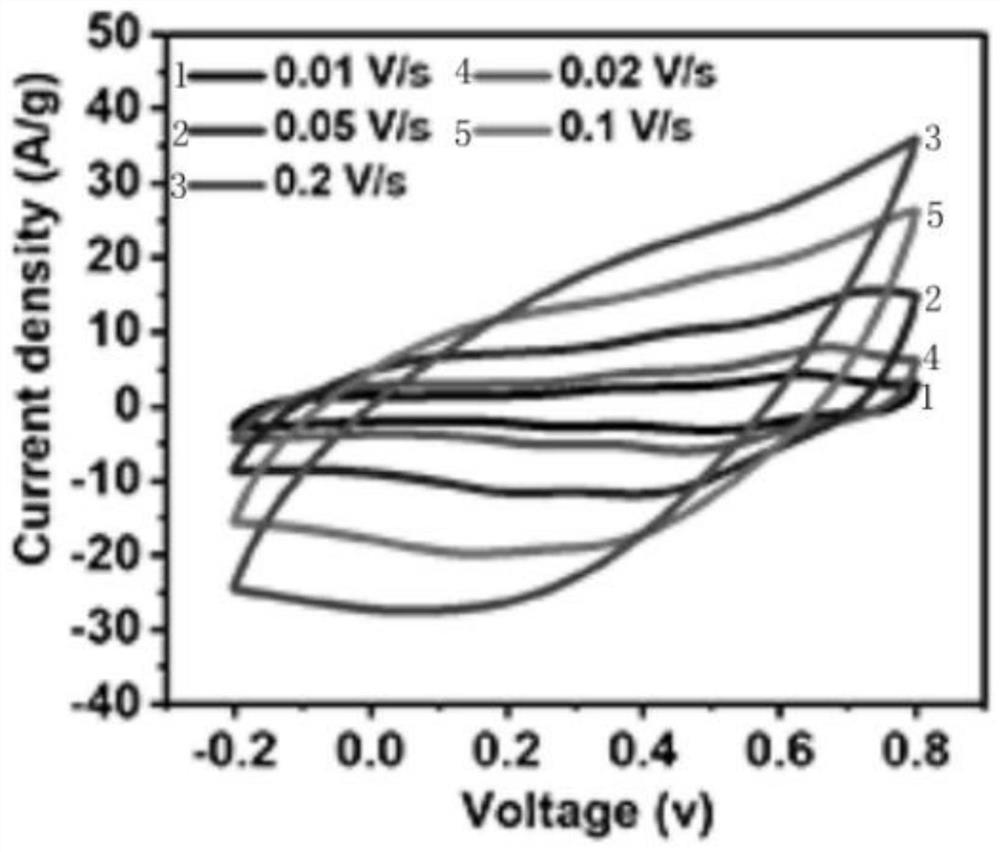

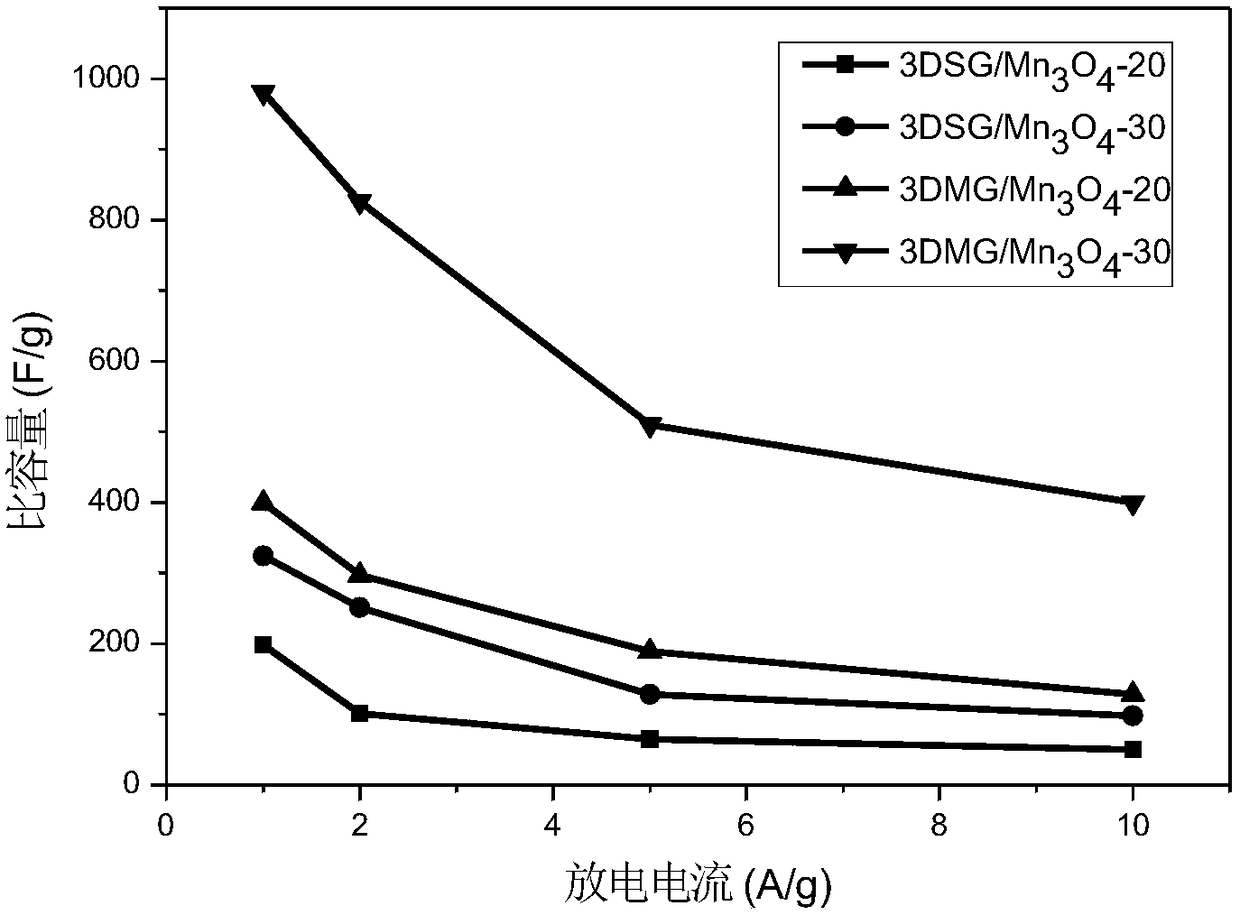

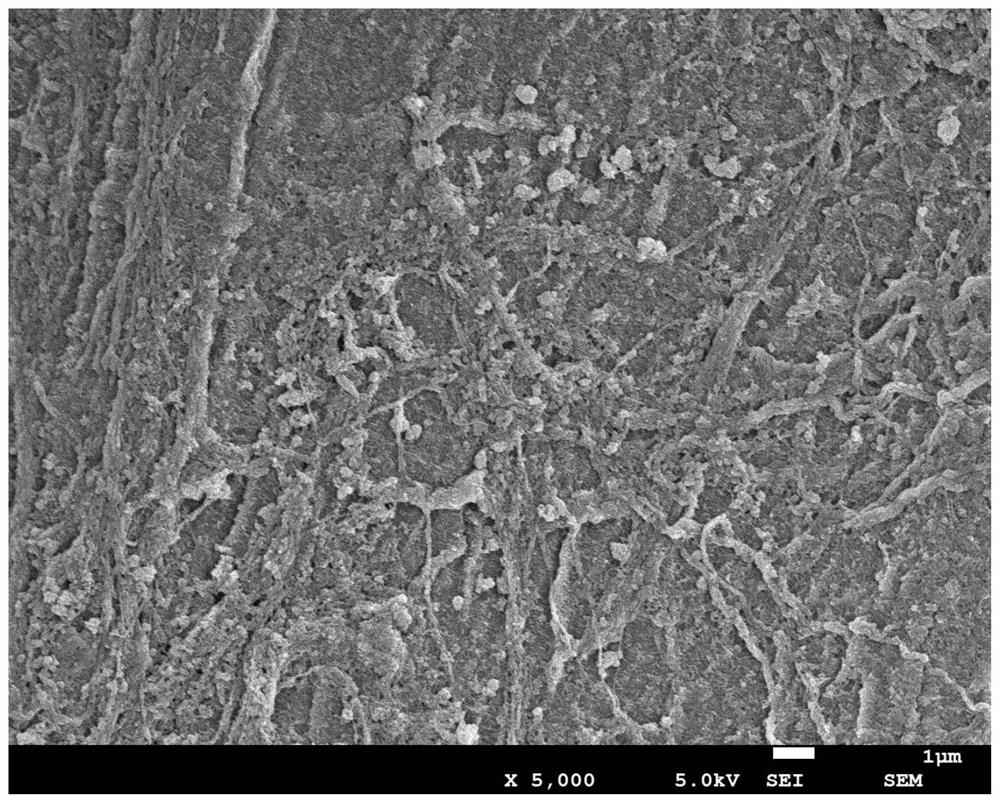

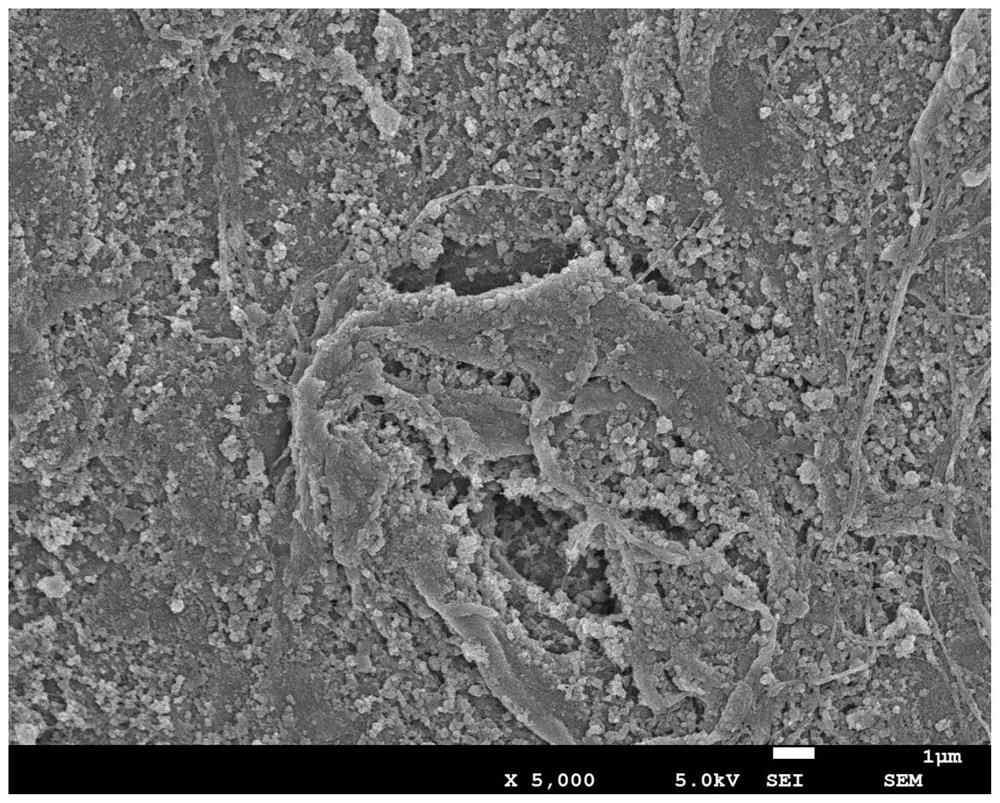

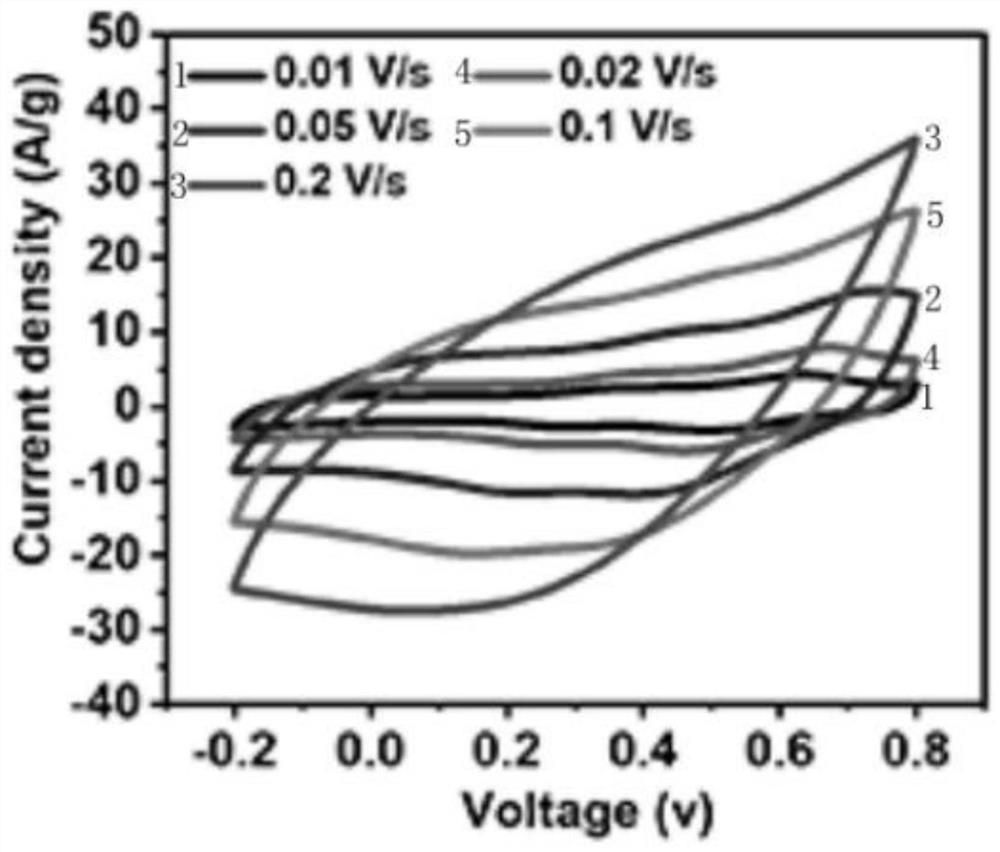

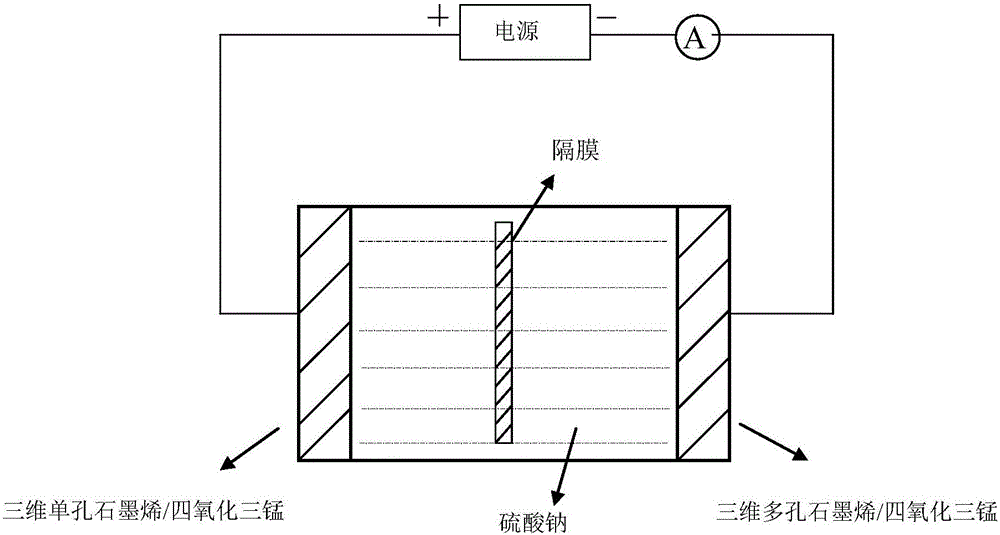

Asymmetric supercapacitor based on 3DSG/Mn3O4/3DMG and preparation method thereof

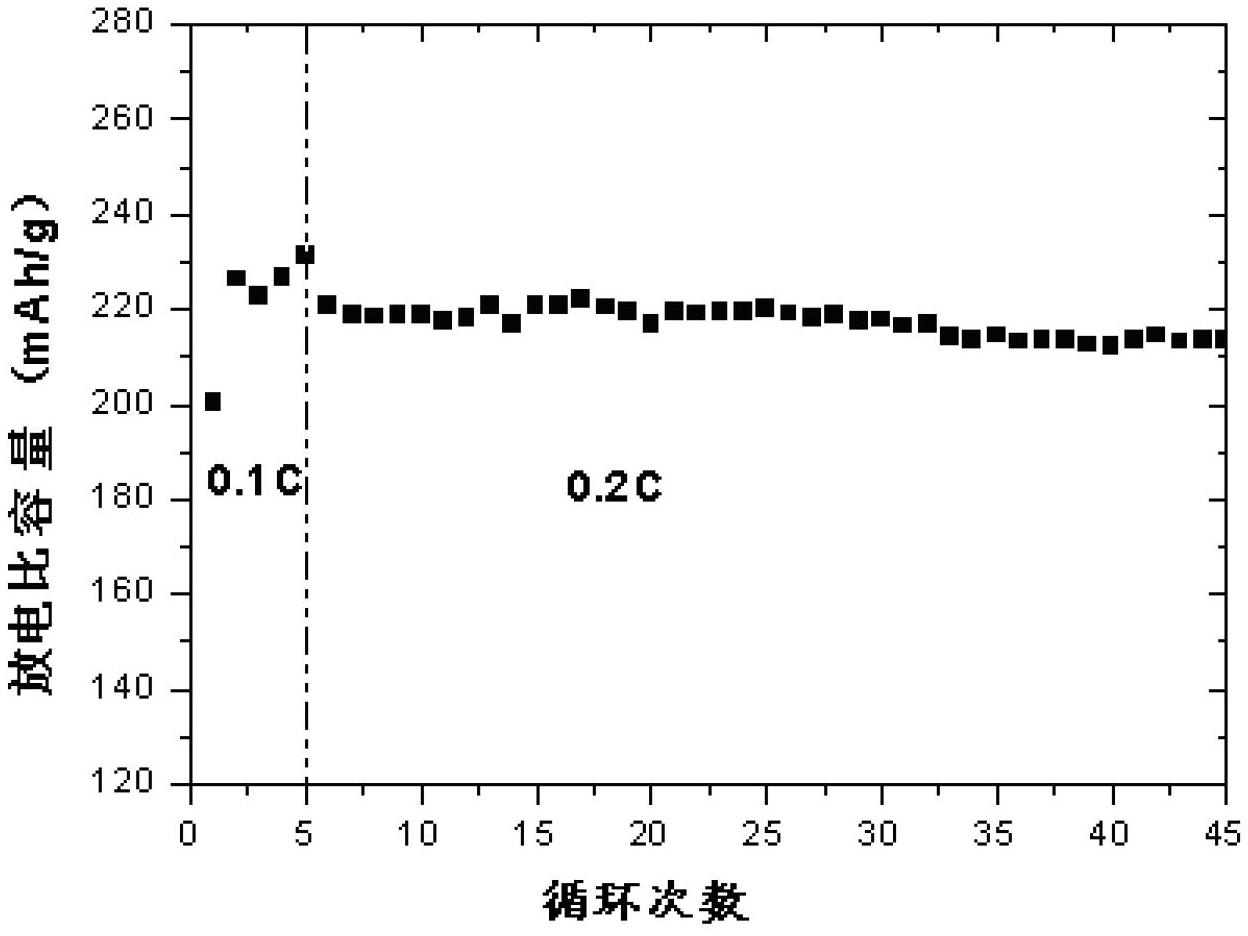

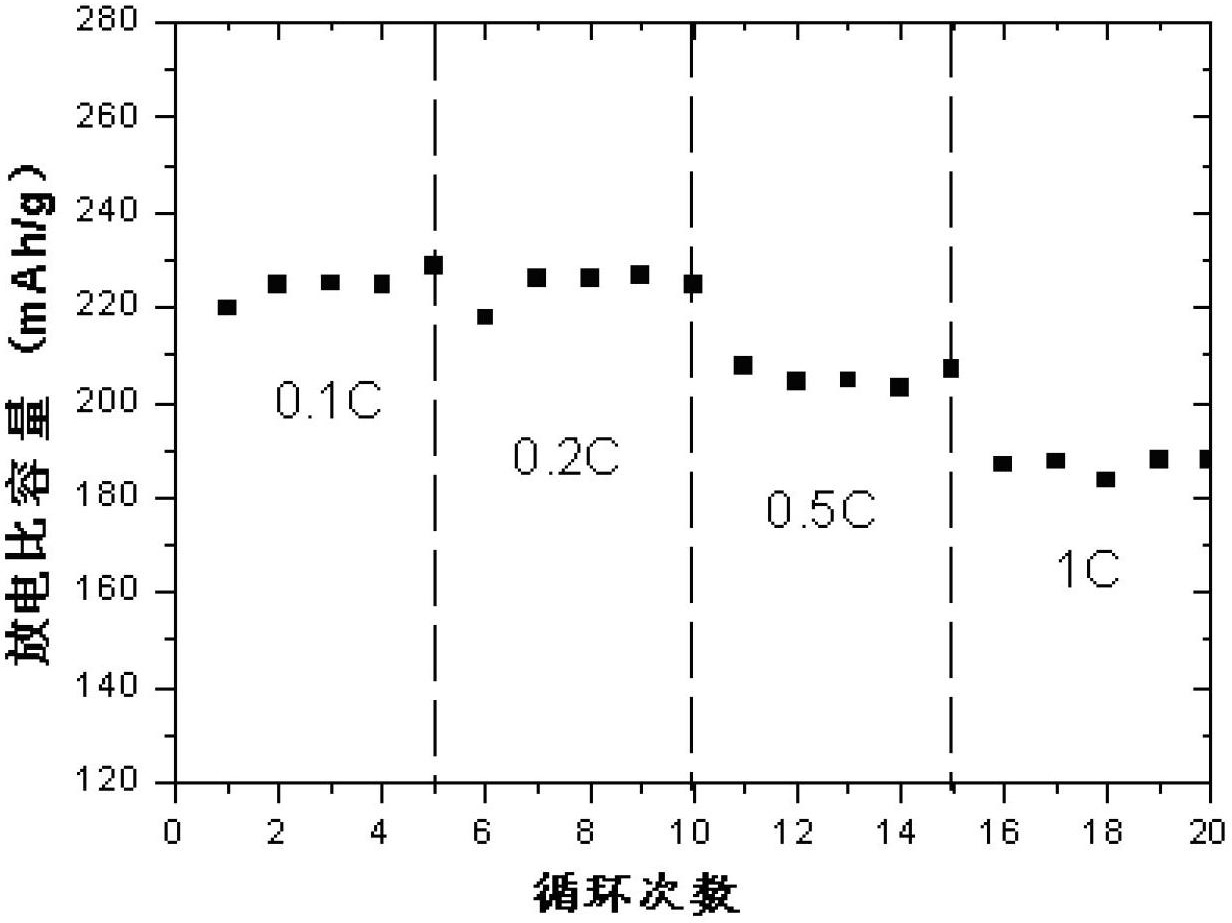

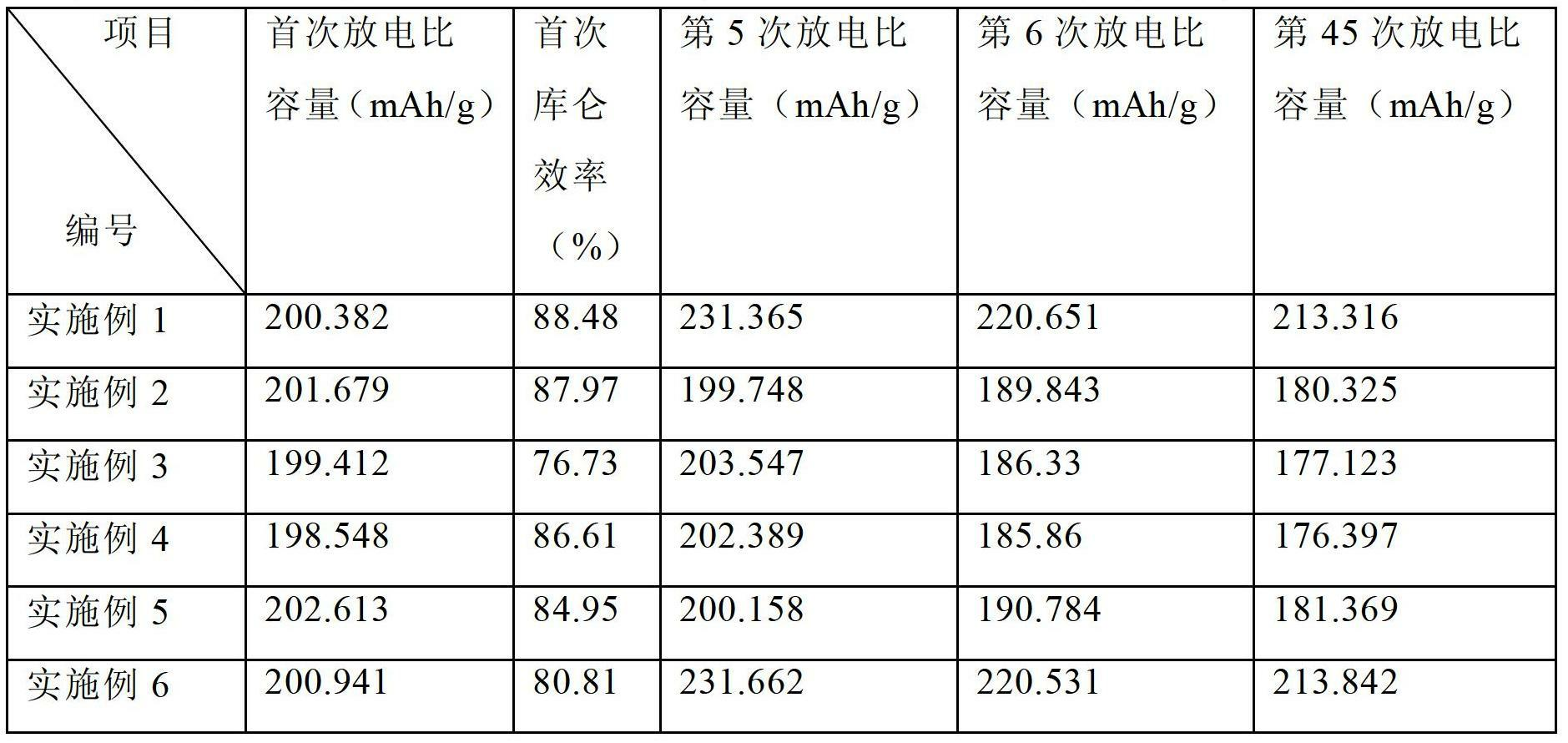

ActiveCN105845452ATo overcome the deficiency of the electrode specific surface area is not highLarge specific surface areaHybrid capacitor electrolytesHybrid capacitor electrodesSupercapacitorSodium sulfate

The invention discloses an asymmetric supercapacitor based on 3DSG / Mn3O4 / 3DMG and a preparation method thereof. The asymmetric supercapacitor based on 3DSG / Mn3O4 / 3DMG comprises an anode, a cathode, electrolyte solution and a diaphragm. The anode is made of a 3DSG / Mn3O4 composite material. The cathode is also made of the 3DSG / Mn3O4 composite material. The electrolyte solution is sodium sulfate solution. The preparation method of the invention comprises the steps of preparing the 3DSG / Mn3O4 composite material of the anode, preparing the 3DSG / Mn3O4 composite material of the cathode, preparing the sodium sulfate solution as the electrolyte solution, and assembling the capacitor. The asymmetric supercapacitor and the preparation method do not require binder or conductive agent. Furthermore the asymmetric supercapacitor and the preparation method have advantages of high metal oxide utilization rate, high conductivity and high storage capability. The asymmetric supercapacitor can be used for preparing an energy storage element.

Owner:泰州巨纳新能源有限公司

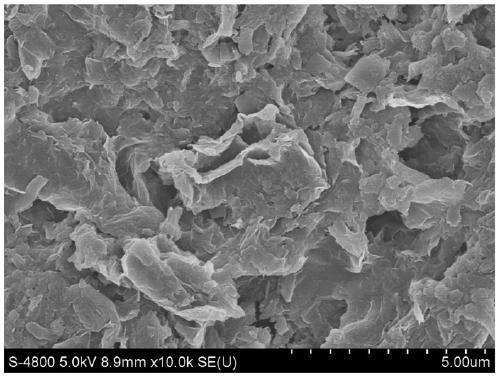

Three-dimensional porous carbon composite material for lithium-sulfur battery and preparation method of three-dimensional porous carbon composite material

ActiveCN114725347ALarge specific surface areaLow specific capacityCell electrodesPorous carbonLithium sulfur

The invention provides a three-dimensional porous carbon composite material for a lithium-sulfur battery and a preparation method of the three-dimensional porous carbon composite material. The preparation method provided by the invention comprises the following steps: 1) dissolving polyacrylamide in ultrapure water, and forming a gel substance under the action of magnetic stirring; 2) adding ferric nitrate and nickel nitrate into ultrapure water for dissolving, then dropwise adding a solution simultaneously containing ferric nitrate and nickel nitrate into the gelatinous substance obtained in the step 1), and then adding phytic acid and melamine as a phosphorus source and a nitrogen source into the mixture; (3) pouring out supernate from the mixture obtained in the step (2), drying in a drying oven, and heating a product obtained by drying in a tubular furnace at high temperature; and 4) immersing the sample obtained in the step 3) in a sulfuric acid solution to remove inactive substances, and finally centrifugally drying the sample to obtain the final product. The prepared material has a high-conductivity three-dimensional porous carbon skeleton, can adsorb soluble polysulfide, and can promote electron transfer so as to improve reaction kinetics.

Owner:NANJING UNIV OF POSTS & TELECOMM

Solid solution material and preparation method thereof as well as lithium ion battery containing material

ActiveCN102659184BLow specific capacityHigh specific capacityCell electrodesSecondary cellsPhysical chemistrySolid solution

The invention provides a solid solution material and a preparation method thereof as well as a lithium ion battery containing the material, belongs to the technical method of the lithium ion battery, and solves the problems of low first coulomb efficiency or low specific capacity and poor circulating performance of the existing 0.5LiNi0.5Mn1.5O4*0.5Li2MnO3*0.5LiNi0.5Mn0.5O2 material and the lithium ion battery prepared from the material. The preparation method of the solid solution material disclosed by the invention comprises a step of nickel-manganese precursor preparation based on a co-precipitation method, a step of precursor pre-treatment and a step of solid phase synthesizing. The solid solution material with a good performance can be obtained through selecting suitable technical parameters so that the material and the lithium ion battery prepared from the material have high first coulomb efficiency, high specific capacity and good circulating performance.. The solid solution material prepared by the invention is prepared by the preparation method. The lithium ion battery disclosed by the invention comprises the solid solution material.

Owner:CHERY AUTOMOBILE CO LTD

A kind of zinc-cobalt double metal oxide sandwich structure flexible film electrode and preparation method thereof

ActiveCN112185715BRaise the voltage windowImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureThin film electrodeCarbon nanotube

The invention provides a method for preparing a zinc-cobalt double metal oxide sandwich structure flexible film electrode, based on the vacuum filtration method, (1) dispersing cellulose nanofibrils and multi-walled carbon nanotubes in water, ultrasonic, magnetic Stir to obtain a uniform dispersion of cellulose nanofibrils-multi-walled carbon nanotubes; (2) disperse cellulose nanofibrils and zinc-cobalt double metal oxides in water, ultrasonically and magnetically stir to obtain uniform cellulose Nanofibril-zinc-cobalt double metal oxide dispersion; (3) cellulose nanofibril-multiwall carbon nanotube dispersion and cellulose nanofibril-zinc-cobalt double metal oxide dispersion are successively suction filtered Forming a film to obtain a flexible film electrode with a sandwich structure of coating layer-sandwich layer-coating layer-sandwich layer-coating layer. The invention aims to prepare a high-performance flexible and lightweight electrode material, which has broad application prospects in the fields of portable electronics and energy products.

Owner:GUANGXI UNIV

Potassium ion battery negative electrode active material, potassium ion battery negative electrode material, potassium ion battery negative electrode, potassium ion battery and application thereof

ActiveCN109659528BImprove cycle lifeHigh specific capacitySecondary cellsNegative electrodesElectrical batteryElectric capacity

The invention provides a potassium ion battery negative electrode active material, a potassium ion battery negative electrode material, a potassium ion battery negative electrode, a potassium ion battery and an application thereof, belonging to the technical field of potassium ion batteries. The potassium ion battery negative electrode active material provided by the invention comprises a ruthenium pentoxide composite material, wherein the ruthenium pentoxide composite material comprises a ruthenium pentoxide composite material containing a doping ions and / or a coating layer. The ruthenium pentoxide composite material has excellent potassium ion transport channels, can realize rapid insertion and de-intercalation of potassium ions, has stable crystal structure, adopts the reaction mechanism of intercalation and pseudocapacitance dual mechanism, prepares the potassium ion battery with the advantages of long cycle life, high specific capacity and low cost, can solve the problem of priceincrease caused by insufficient lithium resources, avoids the problems of expansion and pulverization of the alloy-type negative electrode of the potassium ion battery, slow dynamics of the intercalated carbon material and the like, and can be widely applied to electric tools, electronic equipment, electric vehicles or energy storage equipment.

Owner:SHENZHEN INST OF ADVANCED TECH

a fes 2 Synthesis method and battery of composite cathode material

ActiveCN107482185BHigh purityWell mixedCell electrodesNon-aqueous electrolyte cellsElectrolytic agentElectrical battery

The invention discloses a synthesis method of a FeS2 composite positive electrode material, and a battery. The method comprises the following steps: dispersing a ferrous salt of an organic acid, thiourea, PVP and a chelating agent in a solvent, carrying out a polymerization reaction to form sol, further generating gel, carrying out heat treatment and grinding to prepare FeS2 powder, adding metal powder with the mass percentage of 0.1-2%, and carrying out surface coating in order to obtain the FeS2 composite positive electrode material. The battery comprises the composite positive electrode material synthesized through the method. The synthesized composite positive electrode material has the characteristics of high purity, small particle size, fast ion diffusion rate and high specific capacity, and effectively controls the open circuit voltage of the produced battery to be lower than 1.83 V; and the metal powder is used to coat iron disulfide, so the electric conductivity of the positive electrode material is enhanced, the rate performances are improved, the erosion of an electrolyte to the material is alleviated, the life of the battery is prolonged, and the discharge performance of the battery at a heavy current is effectively improved.

Owner:东莞市天球实业有限公司 +1

A kind of preparation method of titanium oxide/tin oxide composite film for sodium ion battery negative electrode

ActiveCN109537021BLow specific capacityHigh specific capacityCell electrodesSurface reaction electrolytic coatingElectrolytic agentPlasma electrolytic oxidation

The invention provides a method of preparing a TiO2 / SnO2 cathode material of a sodium ion battery by using a plasma electrolytic oxidation technique. An electrolyte is prepared from 1-10 ml / l phosphoric acid (85wt.%), 1-10 g / L sodium silicate, 5-30 g / L sodium stannate and 5-30 ml / L glycerol separately. The method comprises the following steps: by taking foamed titanium as an anode and stainless steel as a cathode, immersing the anode and the cathode into a special electrolyte solution containing phosphoric acid, sodium silicate, sodium stannate, glycerol and deionized water; applying a bipolarpulse voltage between the two electrodes at constant temperature and constant pressure, wherein plasma discharge happens on the surface of the foamed titanium; turning off a power supply after discharge for a period of time to prepare the TiO2 / SnO2 composite membrane on the surface of the foamed titanium. The composite membrane can be used as a cathode material of the sodium ion battery. The TiO2 / SnO2 cathode material makes full use of a high capacity characteristic and high cyclic stability of TiO2. The method is simple in preparation process, low in production cost and suitable for industrial production.

Owner:TIANJIN NORMAL UNIVERSITY

Method for preparing titanium-silicon polymerized oxide composite lithium ion battery negative electrode material through thermal decomposition of organic titanium-silicon polymer

ActiveCN111916685ASmall volume changeOvercome the disadvantages of poor magnification performanceSecondary cellsNegative electrodesPtru catalystCarbon nanotube

The invention discloses a method for preparing a titanium-silicon polymer oxide composite lithium ion battery negative electrode material through thermal decomposition of an organic titanium-silicon polymer. The method comprises the following steps of (1) mixing carbon nanotubes (CNT), a solvent, organic dihydric alcohol, orthosilicate and orthotitanate, adding organic amine as a catalyst, and sufficiently stirring to obtain mixed slurry M; (2) putting the mixed slurry M into a reaction kettle, fully reacting at a certain temperature, carrying out solid-liquid separation, taking a solid, and drying the obtained solid to obtain a precursor S; and (3) calcining the precursor S under the protection of inert gas to obtain the TinSi (1-n) O2-CNT composite lithium ion battery negative electrodematerial. The TinSi (1-n) O2-CNT composite lithium ion battery negative electrode material prepared by the method has the characteristics of good rate capability, high cycling stability and high specific capacity.

Owner:ZHEJIANG FOLTA TECH CO LTD

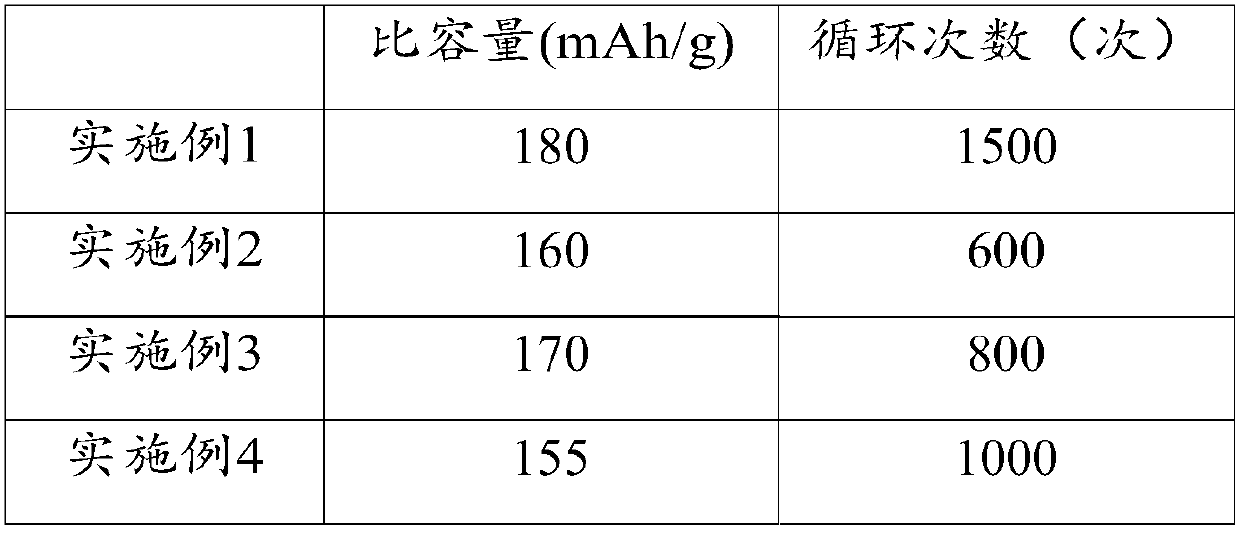

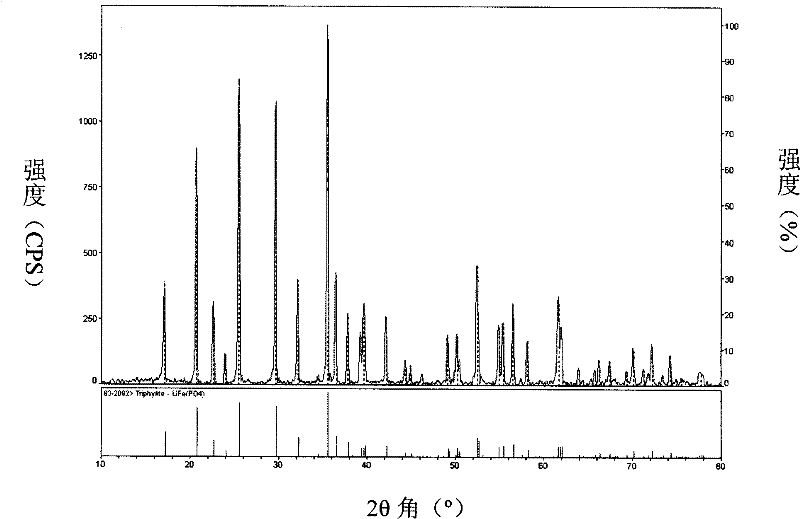

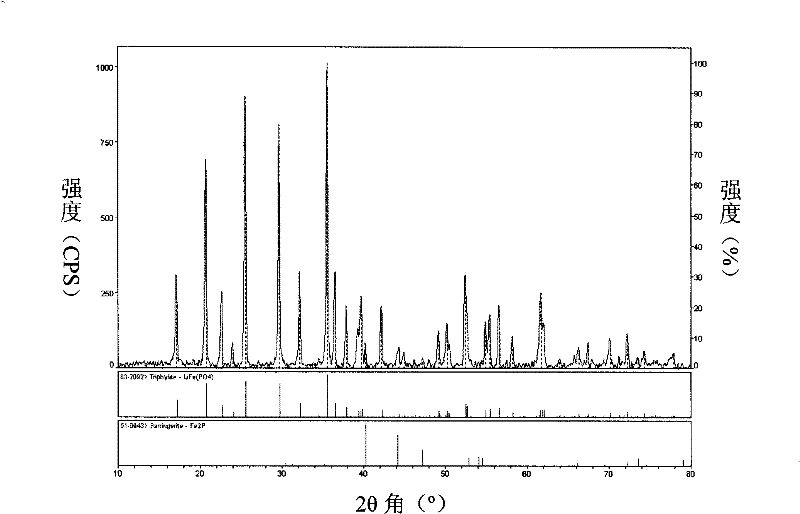

Method for preparing active substance lithium iron phosphate for lithium ion secondary battery anode

ActiveCN101407318BHigh specific capacityLow specific capacityCell electrodesPhosphorus compoundsLithium iron phosphatePhosphate

The invention discloses a preparation method of a lithium ferrous phosphate (LiFePO4) which is an anode active substance of a lithium-ion secondary battery. The method comprises the steps of: sintering a mixture containing a lithium compound, a ferro compound, a phosphorous compound and a carbon source additive in inert atmosphere, and then cooling the mixture to obtain sintering product, wherein, during sintering, the inert atmosphere is static and the pressure of the inert atmosphere is normal pressure. The LiFePO4 obtained by the preparation method does not contain Fe2P dephasign, and the batteries prepared by the LiFePO4 have high capacity, lower internal resistance and good cycle performance.

Owner:BYD CO LTD

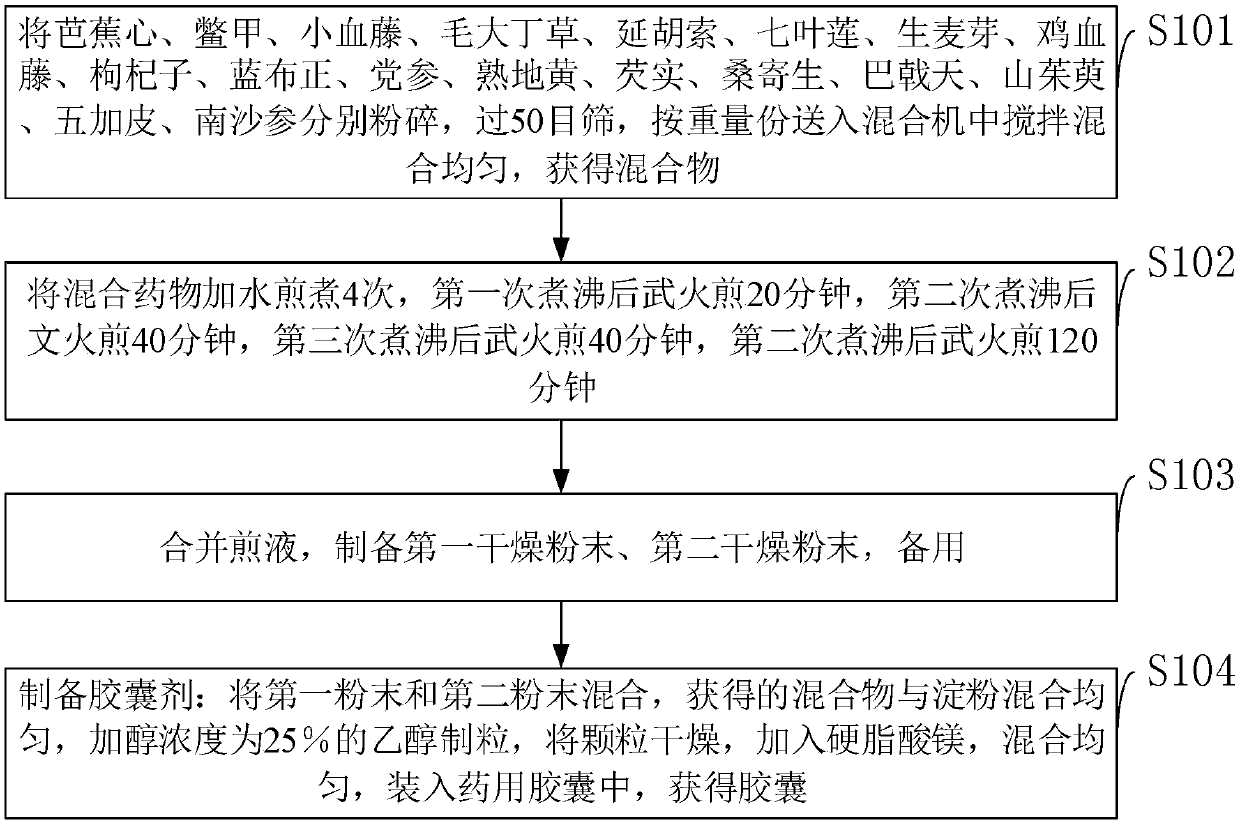

Medicine for reducing hormone resistance of patients with steroid-resistant nephrotic syndrome

PendingCN109528956AImprove product qualityPromote dissolutionUnknown materialsPharmaceutical non-active ingredientsNephrosisPrevention infection

The invention belongs to the technical field of medicine preparation, and discloses a medicine for reducing hormone resistance of patients with steroid-resistant nephrotic syndrome. The medicine preparation can be used for treating nephrotic syndrome, can reduce side effect of hormone, reduces rebound phenomenon after hormone is used, improves the sensitivity of nephrotic syndrome hormone, prevents infection, reduces recurrence, and improves the cure rate of nephrotic syndrome patients. Meanwhile, compared with common magnesium stearate, the magnesium stearate prepared by the method has the advantages of quite excellent fluidity, viscosity resistance and flow aiding property. The specific volume value of the magnesium stearate prepared by the invention is lower than 1.5g / ml, and the angleof repose is 30 degrees. The magnesium stearate is used in tablets together with common magnesium stearate in the same proportion so as to effectively improve the hardness of the tablets by about 30 percent, to fully improve the dissolution of the medicine, and to improve the quality of the prepared medicine for reducing the hormone resistance of patients with steroid-resistant nephrotic syndrome.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com