High-capacity silicon-carbon composited anode material, preparation method and application thereof

A technology of silicon-carbon composite materials and carbon materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problem of low initial irreversible specific capacity specific capacity cycle performance, material capacity and cycle performance deterioration, high price, etc. problems, to achieve the effects of low initial irreversible specific capacity, excellent cycle performance, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

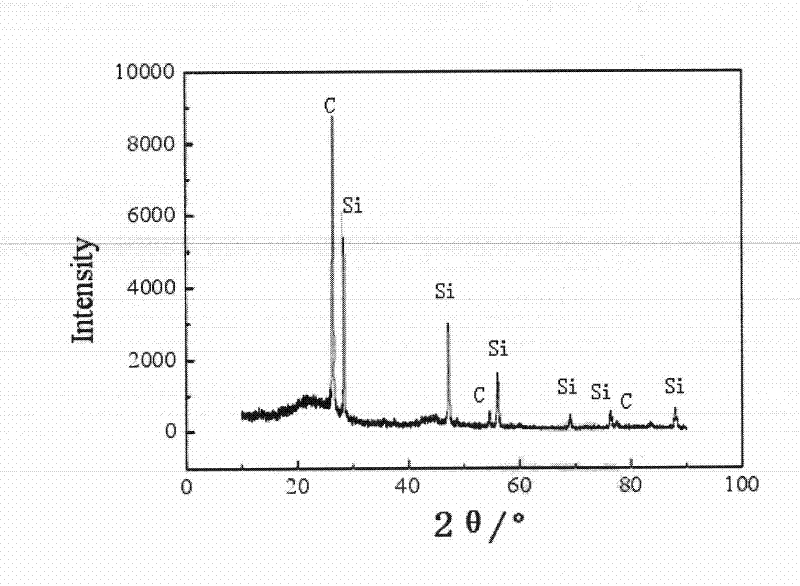

Image

Examples

Embodiment 1

[0059] Example 1 Preparation of silicon-carbon composite material of the present invention

[0060] (1) Preparation of silicon / carbon material composite particles

[0061] Weigh 0.50g of nanometer elemental silicon powder with a particle size of 30-80nm and 10.00g of D 50 Mesophase carbon microspheres of 20 μm, wherein, the fixed carbon content in the mesophase carbon microspheres is 99.8%; place the weighed nanometer elemental silicon powder and mesophase carbon microspheres in 60ml concentration of 33v / v% In the ethanol aqueous solution, after stirring for 30min, the ethanol aqueous solution (suspension) of the prepared nano-elemental silicon and mesophase carbon microspheres was placed in an ultrasonic oscillator, and ultrasonically dispersed for 2 hours to make the nano-silicon and mesophase carbon microspheres uniform After dispersion, filter and dry at 80° C. to obtain silicon / mesophase carbon microsphere composite particles (ie, silicon / carbon composite particles). ...

Embodiment 2

[0067] Example 2Preparation of silicon-carbon composite material of the present invention

[0068] (1) Preparation of silicon / carbon material composite particles

[0069] Weigh 0.50g of nanometer elemental silicon powder with a particle size of 30-80nm and 10.00g of D 50 Mesophase carbon microspheres of 20 μm, wherein, the fixed carbon content in the mesophase carbon microspheres is 99.8%; place the weighed nanometer elemental silicon powder and mesophase carbon microspheres in 60ml concentration of 33v / v% In the methanol aqueous solution, after stirring for 30 minutes, the methanol aqueous solution (suspension) of the prepared nano-element silicon and mesophase carbon microspheres was placed in an ultrasonic oscillator, and ultrasonically dispersed for 2 hours to make the nano-silicon and mesophase carbon microspheres uniform After dispersion, filter and dry at 80° C. to obtain silicon / mesophase carbon microsphere composite particles (ie, silicon / carbon material composite ...

Embodiment 3

[0076] Example 3 Preparation of silicon-carbon composite material of the present invention

[0077] (1) Preparation of silicon / carbon material composite particles

[0078] Weigh 0.50g of nanometer elemental silicon powder with a particle size of 30-80nm and 10.00g of D 50 Mesophase carbon microspheres of 20 μm, wherein, the fixed carbon content in the mesophase carbon microspheres is 99.8%; place the weighed nanometer elemental silicon powder and mesophase carbon microspheres in 60ml concentration of 33v / v% In the acetone aqueous solution, after stirring for 30min, the acetone aqueous solution (suspension) of the prepared nano-elemental silicon powder and mesophase carbon microspheres was placed in an ultrasonic oscillator, and ultrasonically dispersed for 2h to make the nano-silicon and mesophase carbon microspheres After uniform dispersion, filter and dry at 80° C. to obtain silicon / mesophase carbon microsphere composite particles (ie, silicon / carbon material composite p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com