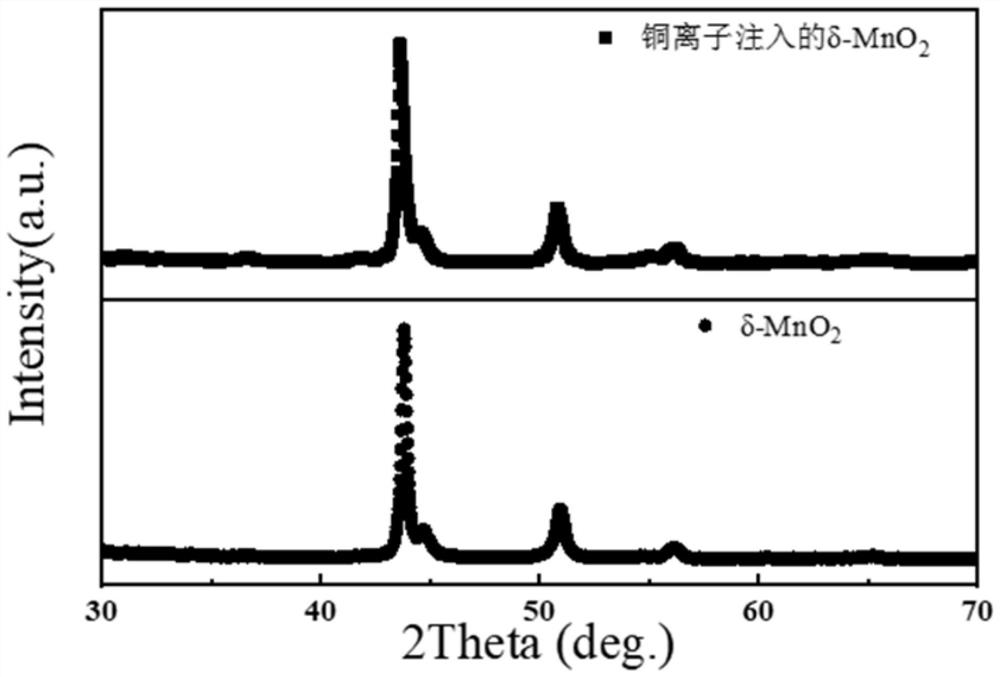

Modification method of copper ion implanted zinc battery positive electrode material delta-manganese dioxide

A manganese dioxide, cathode material technology, applied in battery electrodes, manganese oxide/hydroxide, circuits, etc., can solve the problems of flammability, toxicity of batteries, large consumption of lithium resources, etc. The effect of the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

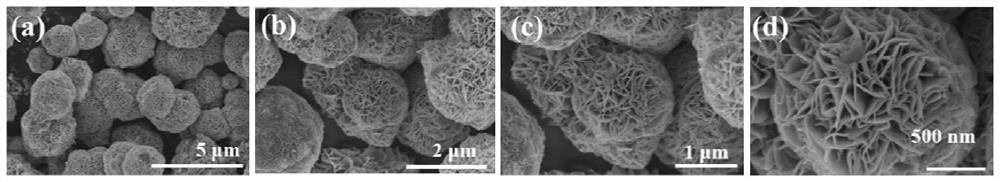

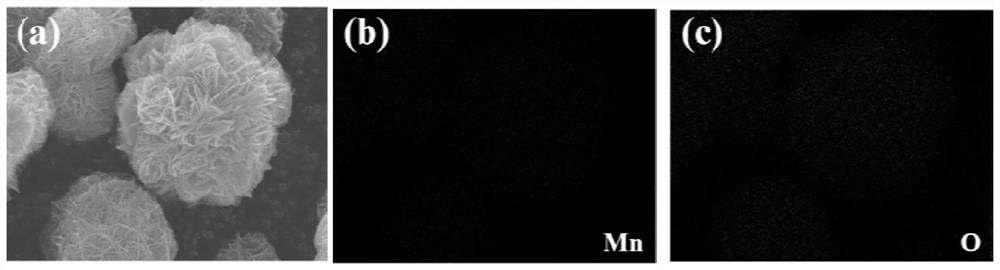

[0026] Embodiment 1: In this embodiment, a method for modifying copper ion-implanted zinc battery anode material δ-manganese dioxide is completed according to the following steps:

[0027] 1. Preparation of δ-manganese dioxide powder:

[0028] ①. First, dissolve potassium permanganate in deionized water, then magnetically stir, then drop in hydrochloric acid, and stir evenly to obtain a mixed solution;

[0029] ②. Transfer the mixed solution to an autoclave, then raise the temperature of the autoclave to 130°C to 150°C, and then conduct a hydrothermal reaction at 130°C to 150°C to obtain a precipitated substance;

[0030] ③. First, use deionized water as the cleaning agent to centrifugally clean the precipitated material for 3 to 5 times, then use absolute ethanol as the cleaning agent to perform centrifugal cleaning on the precipitated material for 3 to 5 times, and finally vacuum-dry and cool to room temperature naturally , to obtain δ-manganese dioxide powder;

[0031] 2....

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the volume ratio of the amount of the substance of potassium permanganate described in step one 1. and deionized water is 1.25mmol:34mL; The above magnetic stirring time is 10min-20min. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the concentration of hydrochloric acid described in step one 1. is 5mmol / L; The volume ratio of hydrochloric acid and deionized water described in step one 1. It is 0.416mL:34mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com