Asymmetric supercapacitor based on 3DSG/Mn3O4/3DMG and preparation method thereof

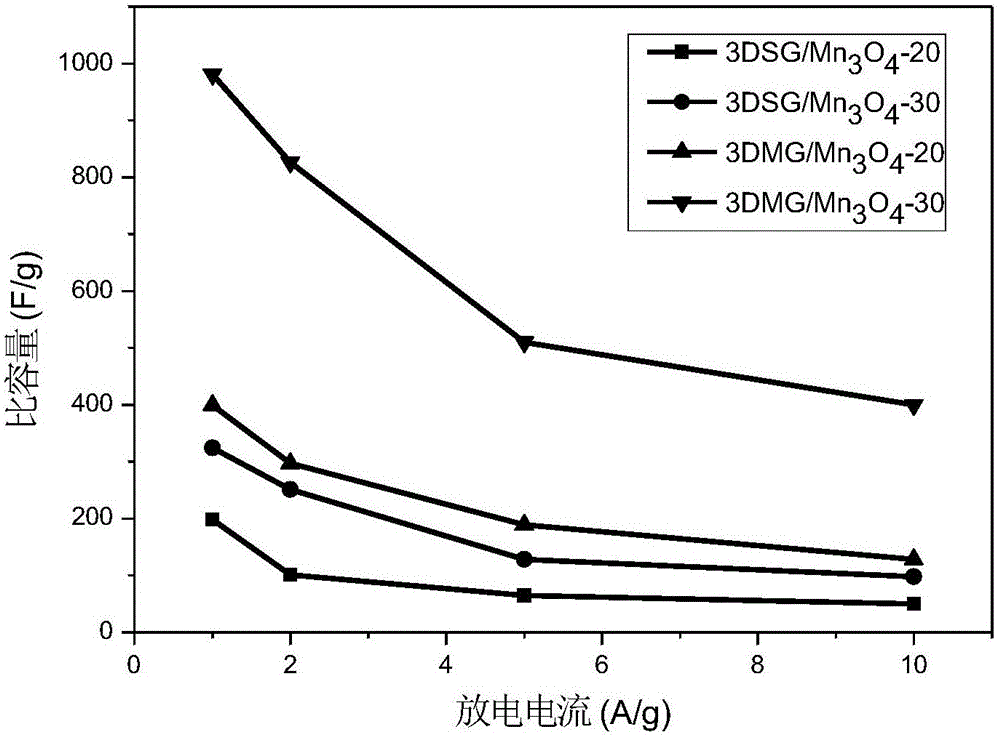

A supercapacitor, 3DMG technology, applied in the field of electronics, can solve the problems of inability to reflect the capacitance performance of capacitor materials, increase the equivalent series resistance of capacitors, reduce volume, mass specific capacity, etc., to achieve high storage capacity, low equivalent series resistance, The effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

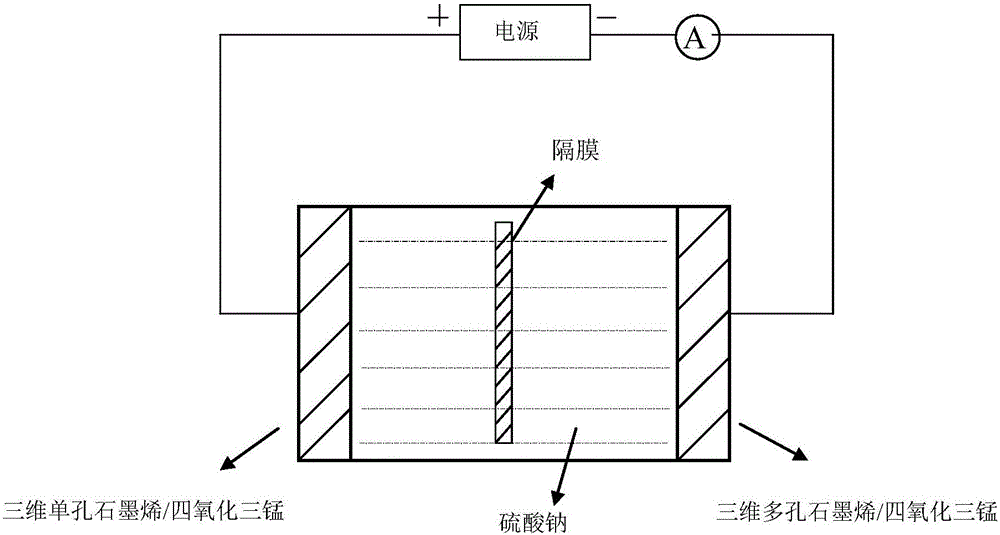

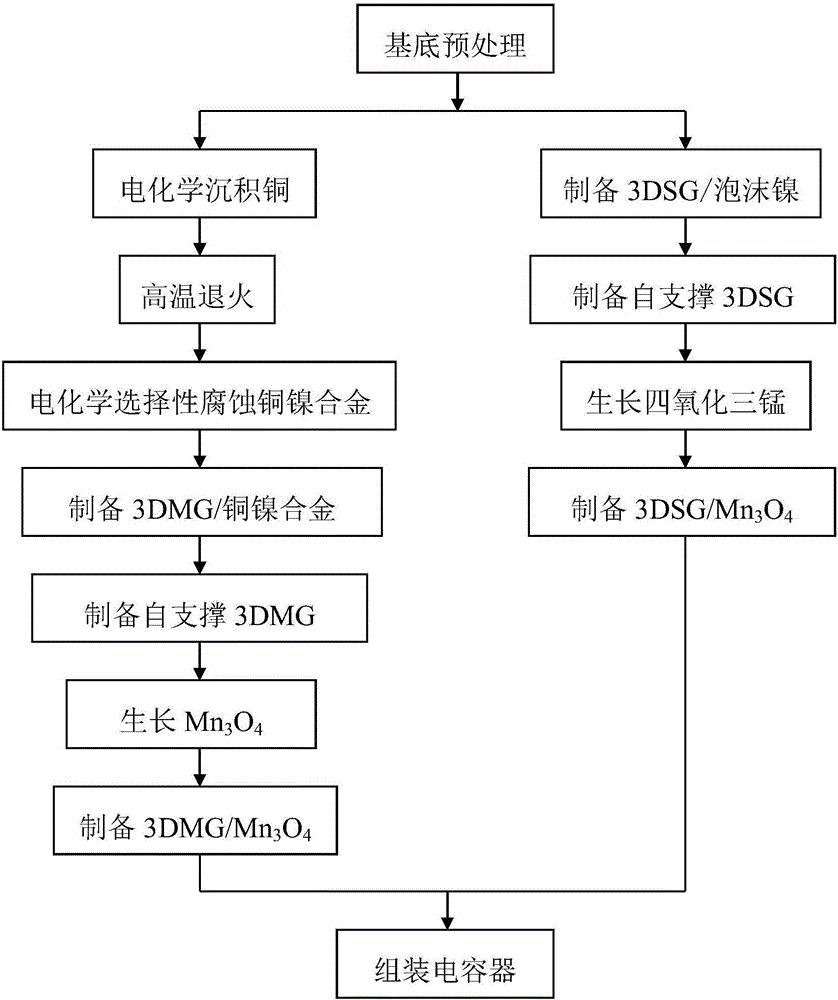

[0053] Embodiment 1: Based on 3DSG / Mn 3 o 4 / 3DMG Fabrication of Asymmetric Supercapacitors.

[0054] Step 1: Substrate pretreatment.

[0055] First, use a flattening machine to thin two pieces of nickel foam with a thickness of 1.6mm to obtain two nickel foam sheets with a thickness of 0.25mm, and then wash the two nickel foam sheets with ethanol, deionized water, and 5M HCl solution respectively. , and then use deionized water to clean the two foamed nickel sheets respectively, and use the two foamed nickel sheets as the positive electrode base foamed nickel sheet and the negative electrode base foamed nickel sheet respectively.

[0056] Step 2: preparing the negative electrode base skeleton.

[0057] The electrochemical three-electrode method is adopted, in which the working electrode is the negative electrode base foamed nickel sheet, the reference electrode is Ag / AgCl, and the auxiliary electrode is Pt, and the negative electrode base foamed nickel sheet is placed in 2...

Embodiment 2

[0068] Embodiment 2: Based on 3DSG / Mn 3 o4 / 3DMG Fabrication of Asymmetric Supercapacitors.

[0069] Step A: Substrate pretreatment.

[0070] First, use a flattening machine to thin two pieces of nickel foam with a thickness of 1.6mm to obtain two nickel foam sheets with a thickness of 0.25mm, and then wash the two nickel foam sheets with ethanol, deionized water, and 5M HCl solution respectively. , and then use deionized water to clean the two foamed nickel sheets respectively, and use the two foamed nickel sheets as the positive electrode base foamed nickel sheet and the negative electrode base foamed nickel sheet respectively.

[0071] Step B: preparing the negative electrode base skeleton.

[0072] The electrochemical three-electrode method is adopted, in which the working electrode is the negative electrode base foamed nickel sheet, the reference electrode is Ag / AgCl, and the auxiliary electrode is Pt, and the negative electrode base foamed nickel sheet is placed in 2M ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com