Iron-copper-tin ternary selenide nano material for sodium-ion battery and preparation method of iron-copper-tin ternary selenide nano material

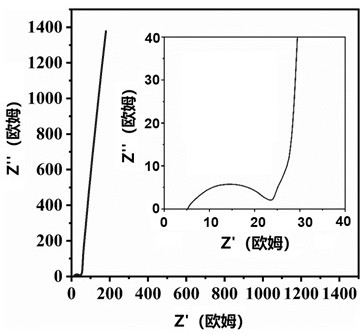

A sodium-ion battery and nano-material technology, applied in the field of multi-component selenide nano-materials and its preparation, and electrode materials for high-performance sodium-ion batteries, can solve the problems that graphite cannot meet the needs of sodium-ion batteries, etc., and achieve the benefits of charge transfer, Long cycle life and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

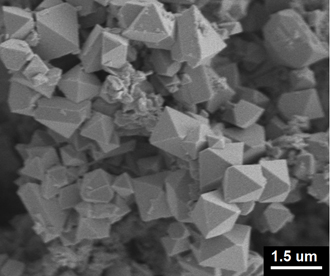

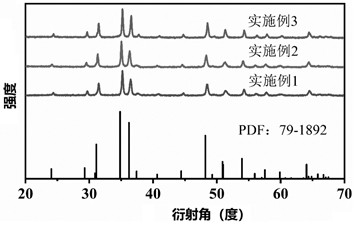

[0024] Weigh 1.60 mmol of iron dichloride, 0.20 mmol of copper dichloride, and 0.20 mmol of tin dichloride, dissolve them in 20 mL of deionized water, and after they are completely dissolved, add 1.8 g of citric acid, and continue to stir; then, add 3 mmol sodium selenite, 1 mmol selenium powder, and then add 30 mL of deionized water to form a mixed solution; after ultrasonic stirring for 2 to 3 hours, in vigorous stirring, add 10 mL of hydrazine hydrate dropwise to form a suspension; The turbid liquid was transferred to a 100 mL reaction kettle and reacted at 160 °C for 15 hours; after the reaction, the reaction product was obtained by centrifugation, repeatedly washed with deionized water and ethanol for 3 to 5 times, and dried at 70 °C for 12 hours. The desired product is obtained, which is an iron-copper-tin ternary selenide nanomaterial.

Embodiment 2

[0026] Weigh 1.58 mmol of ferric chloride, 0.19 mmol of copper dichloride, and 0.19 mmol of tin dichloride, and dissolve them in 19 mL of deionized water. After they are completely dissolved, add 2.0 g of citric acid and continue to stir; then, add 2.8 g of citric acid. mmol sodium selenite, 1.1 mmol selenium powder, and then add 28 mL of deionized water to form a mixed solution; after ultrasonic stirring for 2 to 3 hours, in vigorous stirring, add 9 mL of hydrazine hydrate dropwise to form a suspension; The suspension was transferred to a 100 mL reactor and reacted at 140 °C for 12 hours; after the reaction, the reaction product was obtained by centrifugation, washed with deionized water and ethanol repeatedly for 3 to 5 times, and dried at 70 °C for 12 hours , the desired product is obtained, which is an iron-copper-tin ternary selenide nanomaterial.

Embodiment 3

[0028]Weigh 1.62 mmol of iron dichloride, 0.21 mmol of copper dichloride, and 0.21 mmol of tin dichloride, and dissolve them in 21 mL of deionized water. After they are completely dissolved, add 2.1 g of citric acid and keep stirring; then, add 3.2 g of citric acid. mmol sodium selenite, 0.9 mmol selenium powder, and then add 32 mL of deionized water to form a mixed solution; after ultrasonic stirring for 2 to 3 hours, in vigorous stirring, add 11 mL of hydrazine hydrate dropwise to form a suspension; The suspension was transferred to a 100 mL reaction kettle and reacted at 180 °C for 18 hours; after the reaction, the reaction product was obtained by centrifugation, repeatedly washed with deionized water and ethanol for 3 to 5 times, and dried at 70 °C for 12 hours , the desired product is obtained, which is an iron-copper-tin ternary selenide nanomaterial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com