P2-type sodium ion battery layered positive electrode material as well as preparation method and application thereof

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, electrode manufacturing, positive electrodes, etc., can solve the problems of low energy density and poor stability of positive electrode materials, and achieve improved electrochemical performance, good stability, and high energy density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

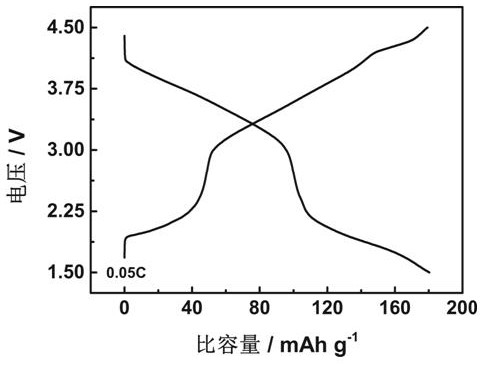

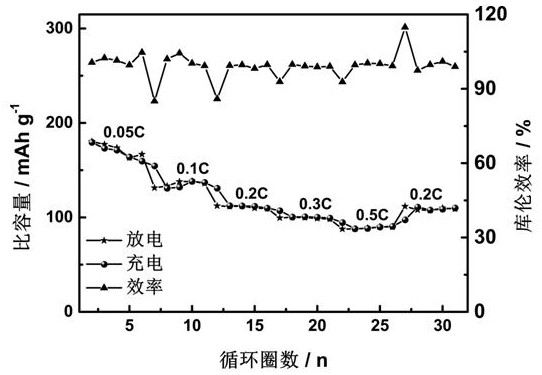

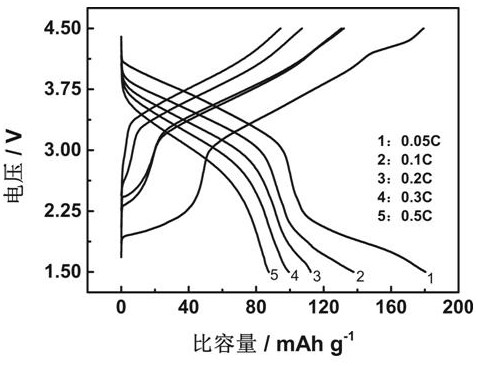

Embodiment 1

[0029] (1) Preparation of cathode material Na 0.67 Ni 0.33 mn 0.33 Ti 0.34 o 2 .

[0030] (1) According to Na 0.67 Ni 0.33 mn 0.33 Ti 0.34 o 2 The stoichiometric ratio of each element in the weighing Na 2 CO 3 , NiO, Mn 2 o 3 and TiO 2 In a mortar, grind for 45 min to mix well.

[0031](2) Press the mixture into ceramic tablets under 16 MPa using a tablet press.

[0032] (3) Calcinate the ceramic sheet obtained in step (2) in the air at 1000°C for 15 hours, the heating rate is 5°C / min, and cool to room temperature to obtain P2 type Na 0.67 Ni 0.33 mn 0.33 Ti 0.34 o 2 The cathode material was stored in an argon-filled glove box for future use.

[0033] (2) Assembling the Na-ion battery.

[0034] Assemble the sodium-ion battery with the positive electrode prepared in step (1) and the metallic sodium negative electrode, and the electrolyte contains NaClO 4 , the concentration is 1mol / L, the solvent is a mixed solvent of propylene carbonate (PC) and fluoroeth...

Embodiment 2

[0038] The rest are the same as in Example 1, except that the titanium doping amount of the positive electrode material prepared in step (1) is 10%, and 10% refers to the molar percentage of titanium element in the total transition metal elements, and the prepared positive electrode material is Na 0.67 Ni 0.33 mn 0.57 Ti 0.1 o 2 .

Embodiment 3

[0040] The rest are the same as in Example 1, except that the titanium doping amount of the positive electrode material prepared in step (1) is 20%, and 20% refers to the molar percentage of titanium element in the total transition metal elements, and the prepared positive electrode material is Na 0.67 Ni 0.33 mn 0.47 Ti 0.2 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com