A method for surface doping modified lithium cobalt oxide cathode material

A positive electrode material and surface doping technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of lithium ion diffusion coefficient and low electrical conductivity, unfavorable material rate performance of the coating layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

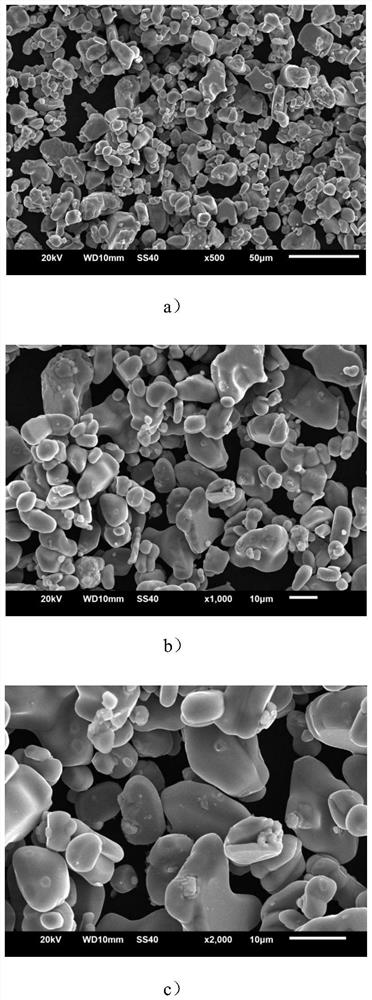

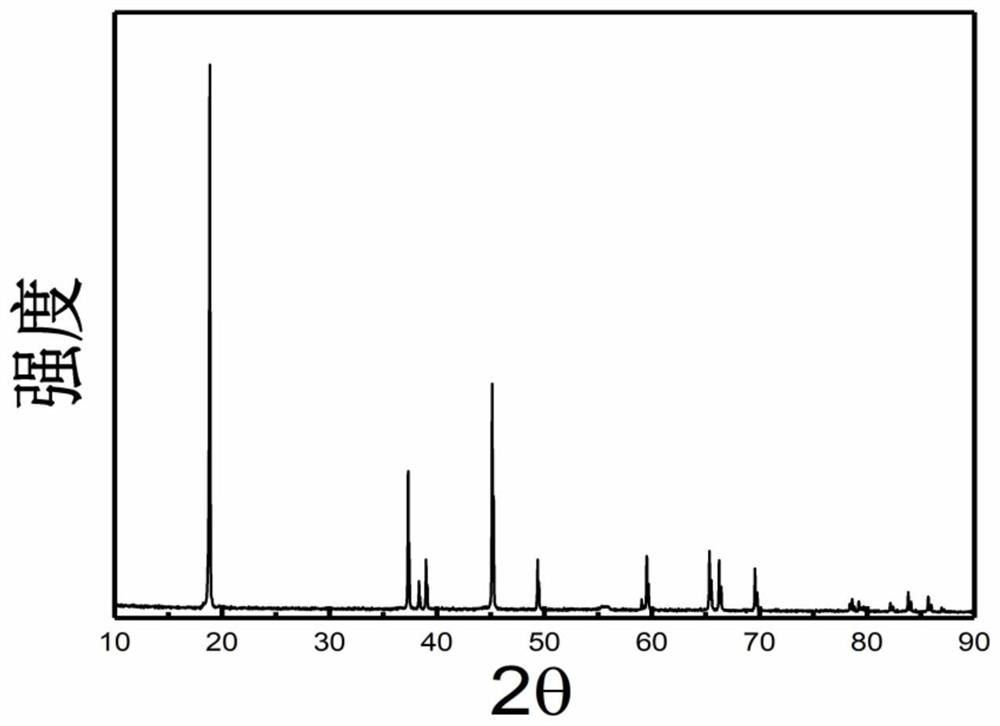

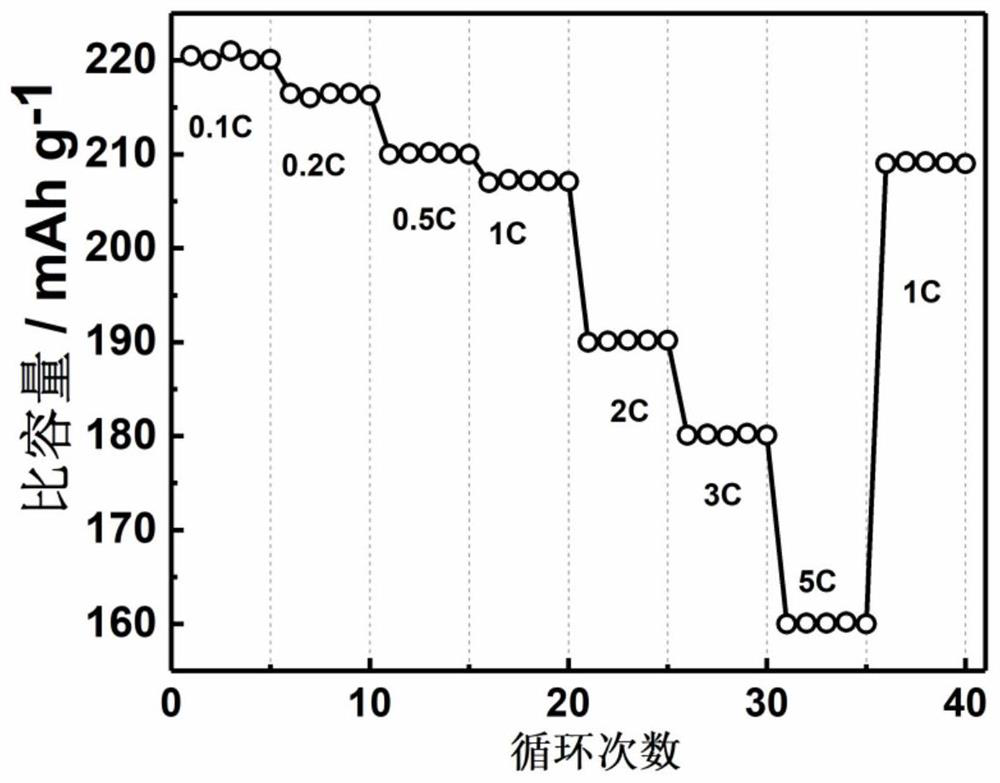

Embodiment 1

[0068] Take three clean and dry crucibles, put 0.002mol CaS and 0.007mol deionized water into the two crucibles respectively, and place them at the bottom of the hydrothermal reaction kettle.

[0069] Put 0.5mol lithium cobaltate in the crucible, place the crucible in the reaction kettle, in which, the lithium cobaltate should be evenly spread on the bottom of the crucible as thin as possible, and the crucible with lithium cobaltate should be placed higher than the other two A crucible 10cm. After carefully sealing the hydrothermal reaction kettle, place it in an oven for hydrothermal reaction. The condition of the hydrothermal reaction is constant temperature treatment at 90° C. for 6 hours.

[0070] After the hydrothermal reaction is over, take out the crucible in the hydrothermal reaction kettle after natural cooling, take out the reaction product in the crucible containing lithium cobaltate, wash the reaction product with absolute ethanol for many times and dry it to obtai...

Embodiment 2

[0072] Take three clean and dry crucibles, put 0.001mol CaS and 0.007mol deionized water into the two crucibles respectively, and place them at the bottom of the hydrothermal reaction kettle.

[0073] Put 0.5mol lithium cobaltate in the crucible, place the crucible in the reaction kettle, in which, the lithium cobaltate should be evenly spread on the bottom of the crucible as thin as possible, and the crucible with lithium cobaltate should be placed higher than the other two A crucible 10cm. After carefully sealing the hydrothermal reaction kettle, place it in an oven for hydrothermal reaction. The condition of the hydrothermal reaction is constant temperature treatment at 90° C. for 6 hours.

[0074] After the hydrothermal reaction is over, take out the crucible in the hydrothermal reaction kettle after natural cooling, take out the reaction product in the crucible containing lithium cobaltate, wash the reaction product with absolute ethanol for many times and dry it to obtai...

Embodiment 3

[0076] Take three clean and dry crucibles, put 0.002mol CaS and 0.007mol deionized water into the two crucibles respectively, and place them at the bottom of the hydrothermal reaction kettle.

[0077] Put 0.8mol lithium cobaltate in the crucible, place the crucible in the reaction kettle, in which, the lithium cobaltate should be evenly spread on the bottom of the crucible as thin as possible, and the crucible with lithium cobaltate should be placed at a higher height than the other two A crucible 10cm. After carefully sealing the hydrothermal reaction kettle, place it in an oven for hydrothermal reaction. The condition of the hydrothermal reaction is constant temperature treatment at 90° C. for 6 hours.

[0078] After the hydrothermal reaction is over, take out the crucible in the hydrothermal reaction kettle after natural cooling, take out the reaction product in the crucible containing lithium cobaltate, wash the reaction product with absolute ethanol for many times and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com