Lithium iron fluorophosphate composite material as well as preparation method and application thereof

A technology of lithium iron phosphate fluorophosphate and lithium iron phosphate, which is applied in the field of lithium iron phosphate fluorophosphate composite materials and its preparation, can solve problems such as uneven doping of fluorine elements, achieve simple process schemes, suppress irreversible phase transitions, The effect of the rate and cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this example, the positive electrode material of lithium iron phosphate fluorophosphate was prepared according to the following steps:

[0057] The specific molecular formula of the cathode material described in this embodiment is Li 1.06 Fe 0.97 PO 3.97 f 0.06 @C.

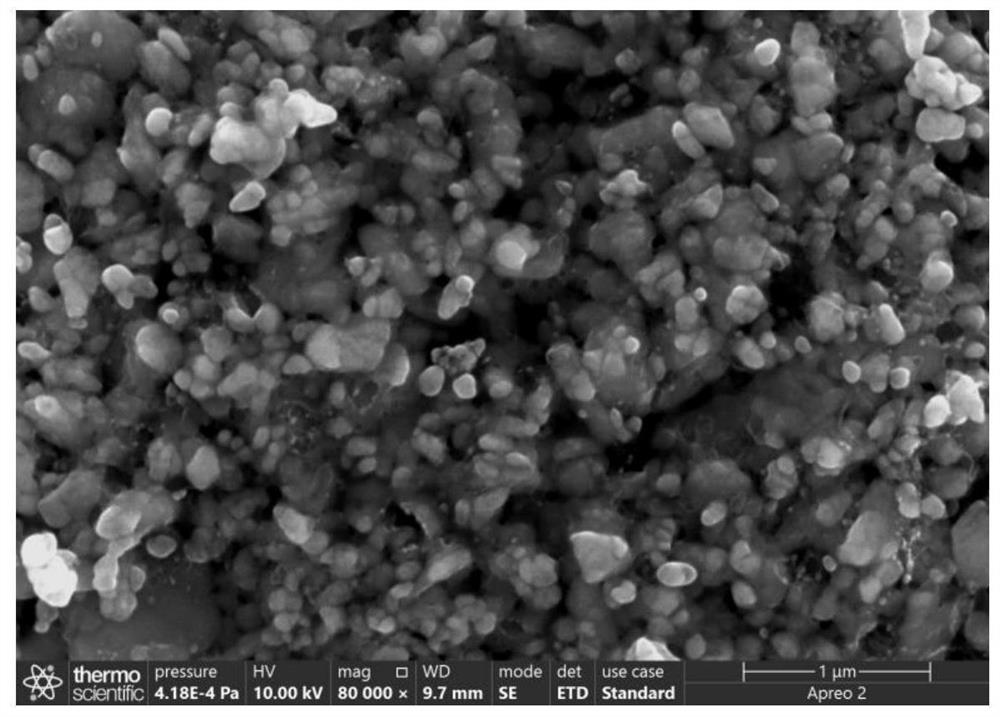

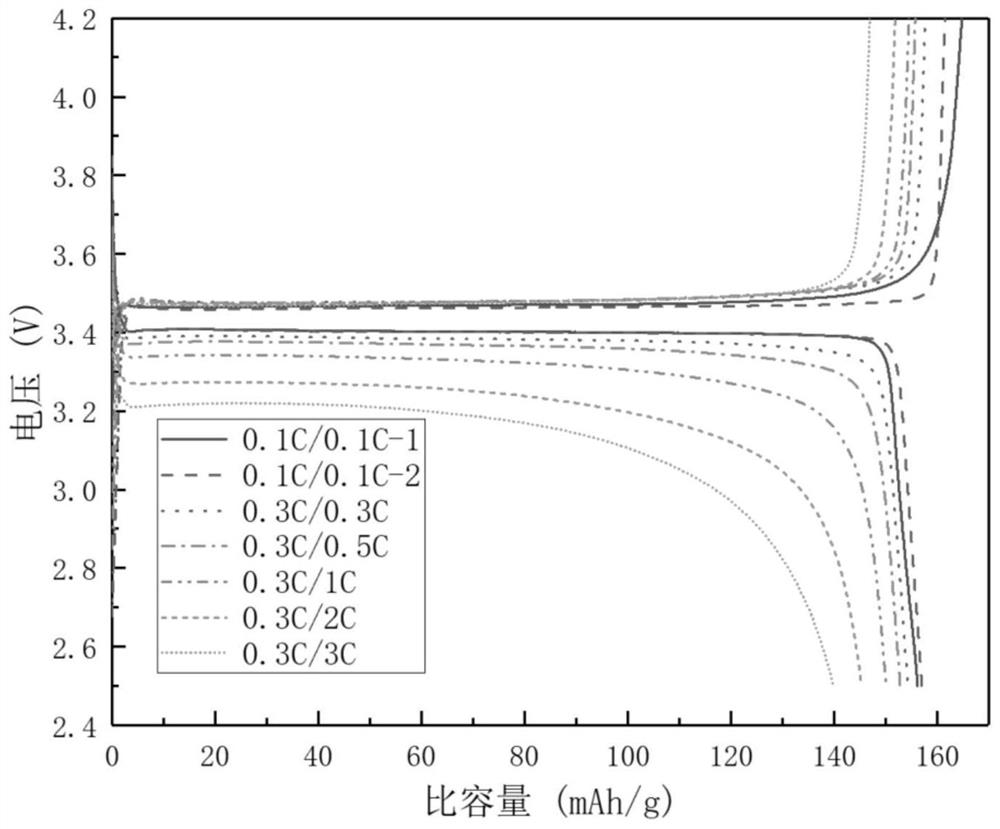

[0058]According to the molar ratio of lithium element: iron element: phosphate ion: fluorine element = 1.06:0.97:3.97:0.06, 8.83kg of iron phosphate, 2.18kg of lithium carbonate, and 0.13kg of LiF were weighed respectively, and 1.35kg of glucose was used for carbon coating. Use 0.27 kg of citric acid as a research aid, prepare a slurry solution with a solid content of 35%, and carry out water-based grinding in a 1L sand mill. Second fine grinding to 300nm. The particle size D50 of the spray-dried powder was 8 microns, and the water content was 1.5%. Then carry out graphite saggar filling treatment, and finally carry out high-temperature sintering at 700°C for 8 hours in a box-type atmosphere furnac...

Embodiment 2

[0062] In this example, the positive electrode material of lithium iron phosphate fluorophosphate was prepared according to the following steps:

[0063] The specific molecular formula of the cathode material described in this embodiment is LiFeP O3.9 f 0.2 @C.

[0064] Weigh respectively 59.1kg of iron phosphate, 35.7kg of ferrous oxalate, 23.0kg of lithium phosphate, FeF 2 0.26kg, 3.8kg of glucose was used for carbon coating, polyethylene glycol 1.59kg was selected as the research aid, a slurry solution with a solid content of 30% was prepared, and water system grinding was carried out in a 10L sand mill, wherein the water system grinding included coarse Grinding and secondary fine grinding, coarse grinding to 0.7μm, secondary fine grinding to 200nm. The particle size D50 of the spray-dried powder was 10 microns, and the water content was 1.5%. Then carry out graphite saggar filling treatment, and finally carry out high-temperature sintering at 750°C for 10 hours in a bo...

Embodiment 3

[0068] In this example, the positive electrode material of lithium iron phosphate fluorophosphate was prepared according to the following steps:

[0069] The specific molecular formula of the positive electrode material described in this embodiment is Li 1.4 Fe 0.8 PO 3.6 f 0.8 @C.

[0070] According to the molar ratio of lithium element: iron element: phosphate ion: fluorine element = 1.4:0.8:3.6:0.8, respectively weigh 1000kg of ferric phosphate, 95.5kg of ferrous oxalate, 22.0kg of lithium hydroxide, 76.8kg of phosphoric acid, and 208.4kg of lithium carbonate. kg, HF5kg, 139.8kg of glucose was used for carbon coating, 14.7kg of oxalic acid was selected as the research aid, a slurry solution with a solid content of 40% was prepared, and water-based grinding was carried out in a 10L sand mill. The water-based grinding included rough grinding and Secondary fine grinding, coarse grinding to 0.9μm, secondary fine grinding to 100nm. The particle size D50 of the spray-dried p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com