Aqueous ion battery and application thereof

A technology of ion batteries and water systems, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low specific capacity, poor matching, and low cycle life of aqueous sodium ion batteries, and achieve low cycle life and low specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

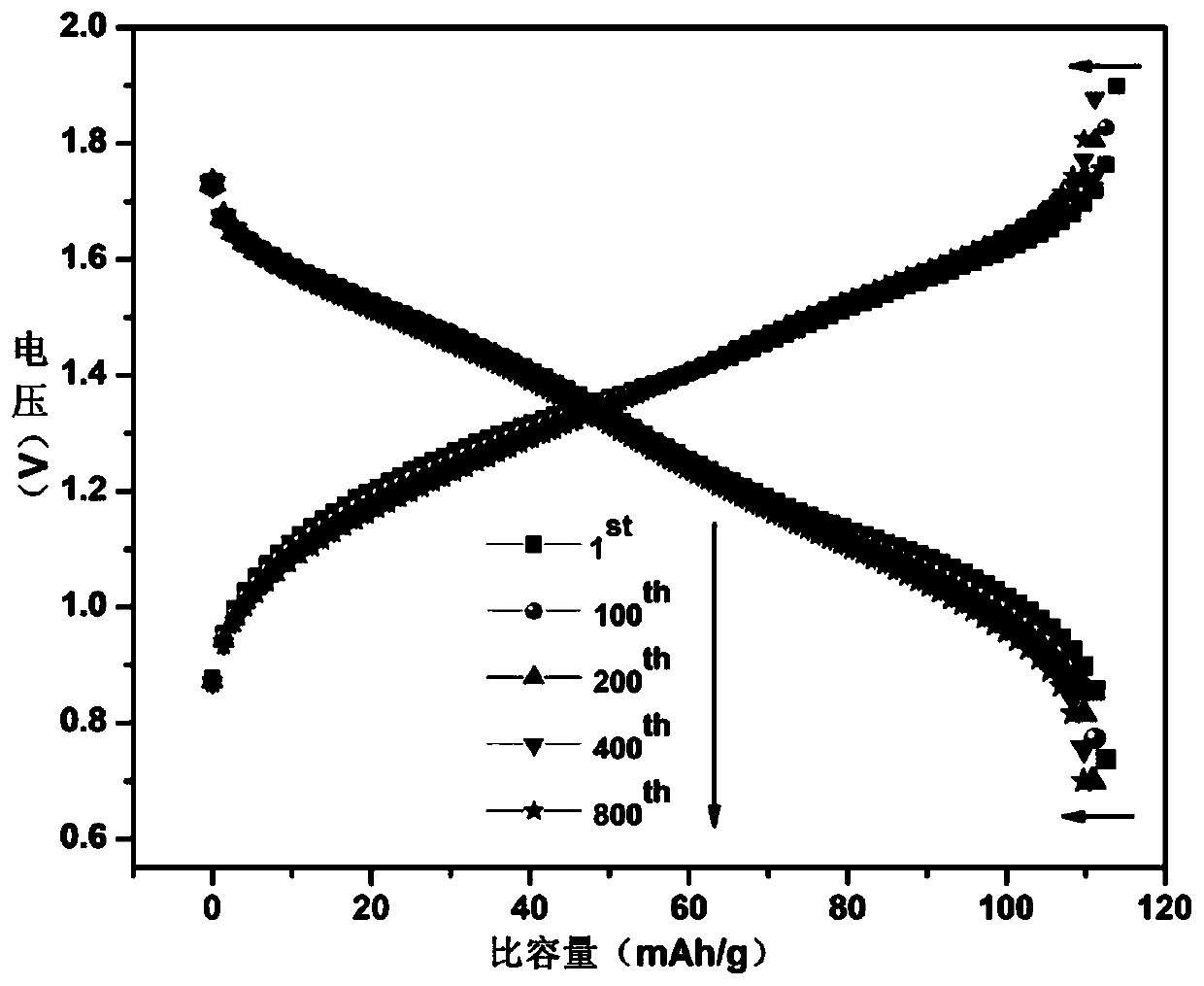

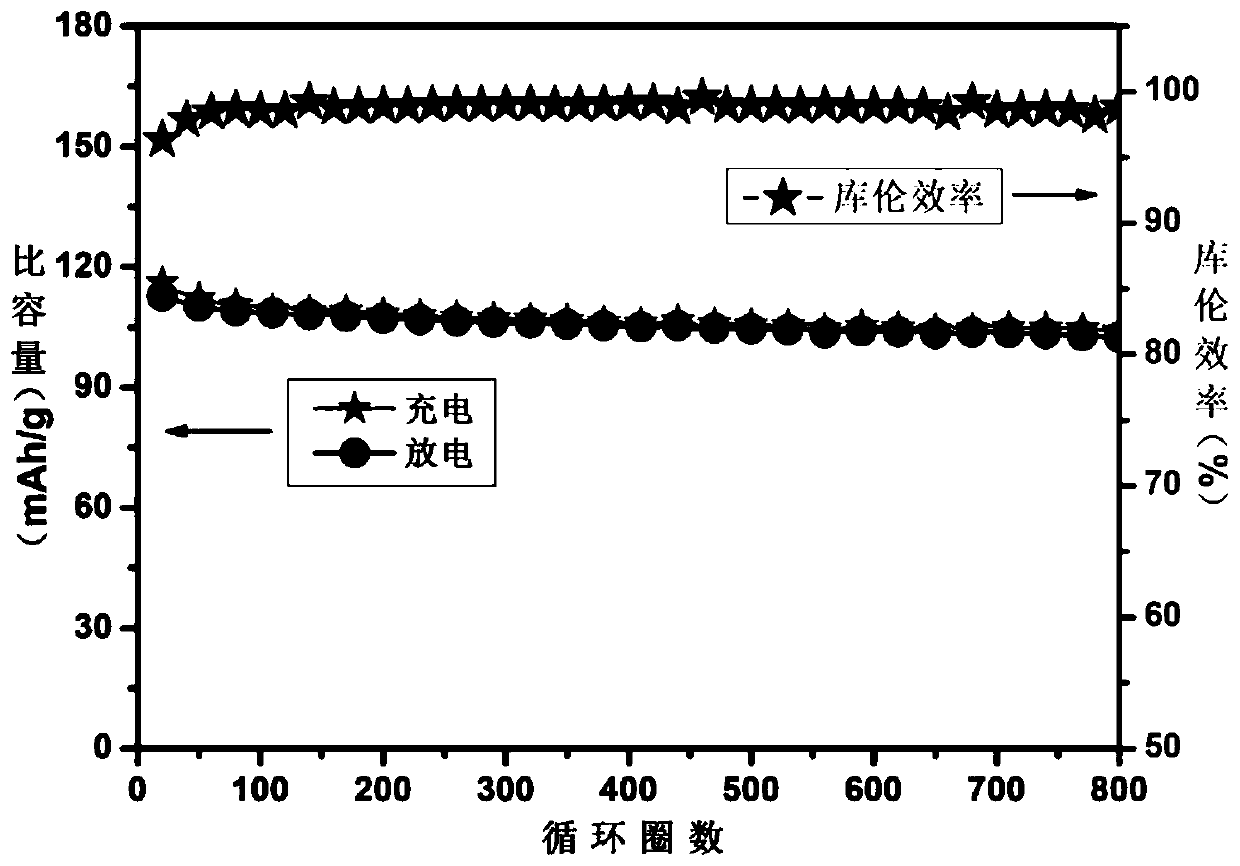

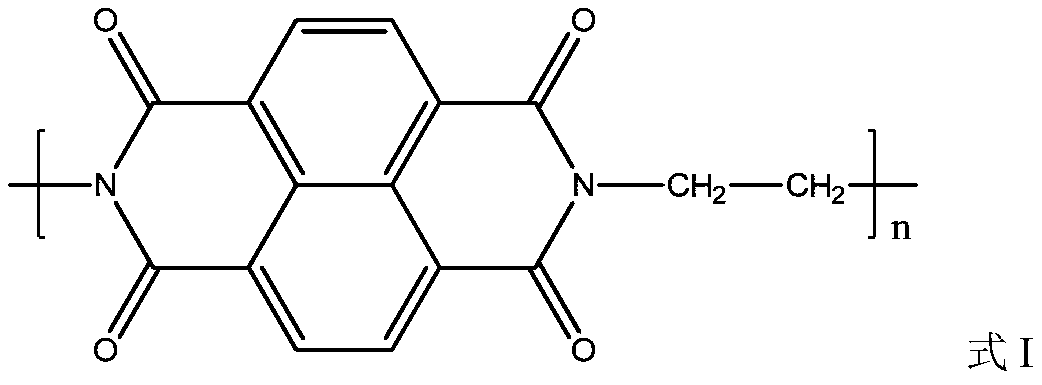

[0100] Example 1 Synthesis of negative electrode active material

[0101] Step A: Add 52.08g 1,4,5,8-naphthalenetetracarboxylic anhydride powder and 2.54mL monohydrate ethylenediamine solution to 400mL N-dimethylformamide (DMF) solution at a molar ratio of 1:1.01, keep Magnetic stirring. The reaction vessel is a glass flask. The flask was shielded with argon. The flask was transferred to a 50°C oil bath and gradually warmed to 150°C. The reaction was maintained at this temperature for 4 hours.

[0102] Step B: The resultant is collected, centrifuged, and the supernatant is removed. The lower centrifugation pellet was diluted with N-dimethylformamide and washed a second time. Then wash with ethanol and centrifuge. The final mass was dried in a vacuum oven to obtain a dry powder.

[0103] Step C: the above dry powder is sintered in a tube furnace, protected by an argon atmosphere. The sintering temperature was 350° C., and the sintering time was 3 hours, and a sample 1 w...

Embodiment 2

[0104] Example 2 Preparation of Electrodes

[0105] negative electrode

[0106] Active material: polyimide organic material sample 1 containing naphthalene ring

[0107] Conductive agent: Conductive carbon black (Super P carbon)

[0108] Binder: Polytetrafluoroethylene (PTFE) emulsion

[0109] Collector: stainless steel mesh

[0110] Preparation process: The active material, conductive carbon black and binder are mixed in an ethanol solution in a mass ratio of 6:3:1 to form a slurry, coated on a stainless steel mesh, and then vacuum dried. The electrode area is about 1.5cm 2 , the single surface density of the active material is 2 mg cm -2 .

Embodiment 3

[0111] Example 3 Preparation of Electrodes

[0112] positive electrode:

[0113] Active material: sodium manganate (NaMnO 2 , i.e. λ-MnO intercalated with sodium ions 2 )

[0114] Conductive agent: Conductive carbon black (Super P carbon)

[0115] Binder: Polytetrafluoroethylene (PTFE) emulsion

[0116] Collector: stainless steel mesh

[0117] Process: The active material, conductive carbon black and binder are mixed and stirred in ethanol according to the mass ratio of 8:1:1 to form a slurry, which is coated on the stainless steel mesh, and then vacuum dried. The electrode area is about 1.5cm 2 , the single surface density of the active material is 5 mg cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com