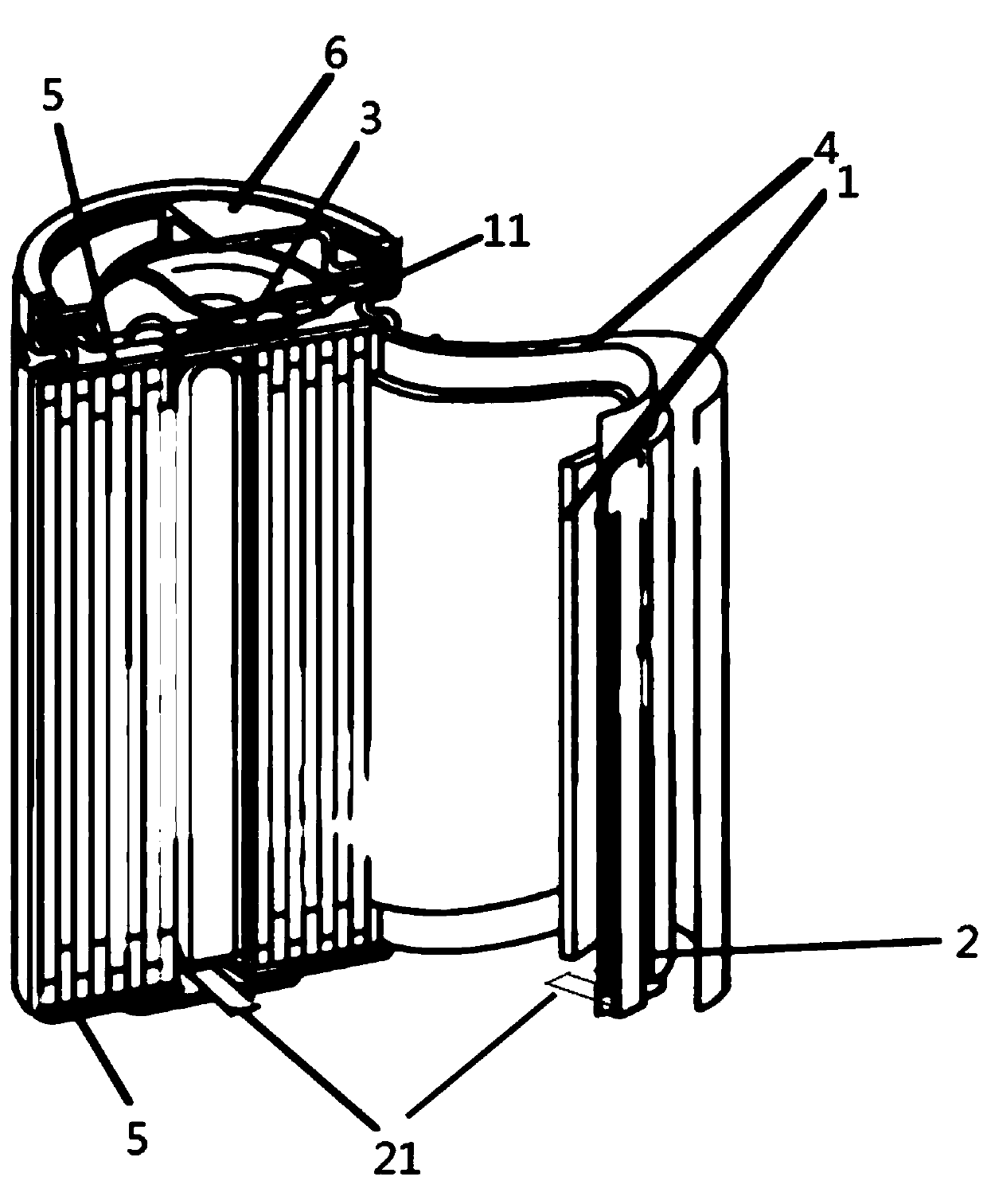

Negative pole piece, lithium ion battery and manufacturing method of lithium ion battery

A lithium-ion battery and negative pole piece technology, which is applied in battery electrodes, secondary batteries, and final product manufacturing, can solve problems that affect battery cycle life, slow ion migration speed, and low charge-discharge rate, and achieve high rate improvements The effect of discharge capacity, high content of active lithium ions, and high concentration of lithium salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for lithium ion battery negative electrode slurry, comprising the following steps:

[0035] 1) Fully mix and grind the carbon powder and metal copper powder at a weight ratio of 99.99:0.01, graphitize at a high temperature of 2900°C, and complete the doping after cooling; among them, the D50 of the metal copper powder is 10mm;

[0036] 2) Mix and pulverize the product doped in step 1) with phenolic resin in a weight ratio of 95:5, heat at 2700°C, complete carbon coating after cooling, and obtain artificial graphite;

[0037] 3) After the artificial graphite is pulverized, it is added to the ethanol solution of conductive carbon black and stirred evenly. After heating, evaporation, drying, pulverization and high temperature heat treatment at 1500°C, the negative electrode active material is obtained after cooling; wherein, artificial graphite powder and conductive carbon The weight ratio of black is 100:0.5.

[0038] 4) Mix the negative electrode ac...

Embodiment 2

[0054] 1) Fully mix and grind carbon powder and metal nickel powder at a weight ratio of 99.80:0.20, graphitize at a high temperature of 3000°C, and complete doping after cooling; among them, the D50 of metal copper powder is 10mm;

[0055] 2) Mix and pulverize the product doped in step 1) with the phenolic resin in a weight ratio of 93:7, heat at 2800° C., complete carbon coating after cooling, and obtain artificial graphite;

[0056] 3) After pulverizing the artificial graphite, add it to the ethanol solution of conductive carbon black and stir evenly. After heating, evaporating, drying, pulverizing and high temperature heat treatment at 1800°C, the negative electrode active material is obtained after cooling; among them, artificial graphite powder and conductive carbon The weight ratio of black is 100:0.2.

[0057] 4) Mix the negative electrode active material, binder, conductive agent and suspending agent obtained in step 3), wherein the negative electrode active material ...

Embodiment 3

[0073] 1) Fully mix and grind the carbon powder and metal silver powder at a weight ratio of 99.70:0.30, graphitize at a high temperature of 3100°C, and complete the doping after cooling; among them, the D50 of the metal copper powder is 10mm;

[0074] 2) Mix and pulverize the doped product in step 1) with phenolic resin in a weight ratio of 96:4, heat at 3000°C, complete carbon coating after cooling, and obtain artificial graphite;

[0075] 3) After the artificial graphite is pulverized, it is added to the ethanol solution of conductive carbon black and stirred evenly. After heating, evaporation, drying, crushing and high temperature heat treatment at 2000°C, the negative electrode active material is obtained after cooling; wherein, artificial graphite powder and conductive carbon The weight ratio of black is 100:3.

[0076] 4) Mix the negative electrode active material, binder, conductive agent and suspending agent obtained in step 3), wherein the negative electrode active m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com