Lithium nickel manganese oxide material and preparation method thereof and lithium ion battery containing lithium nickel manganese oxide material

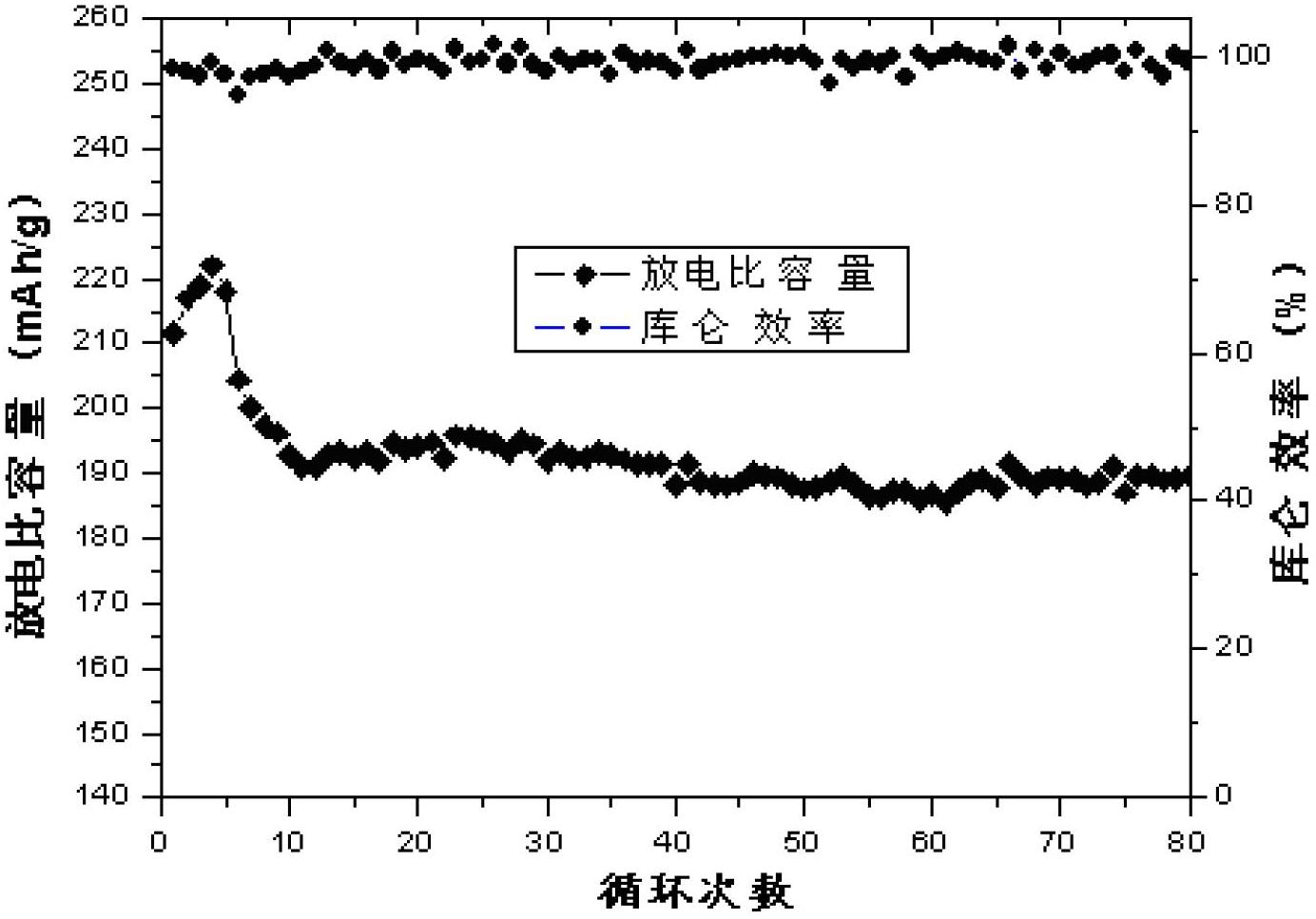

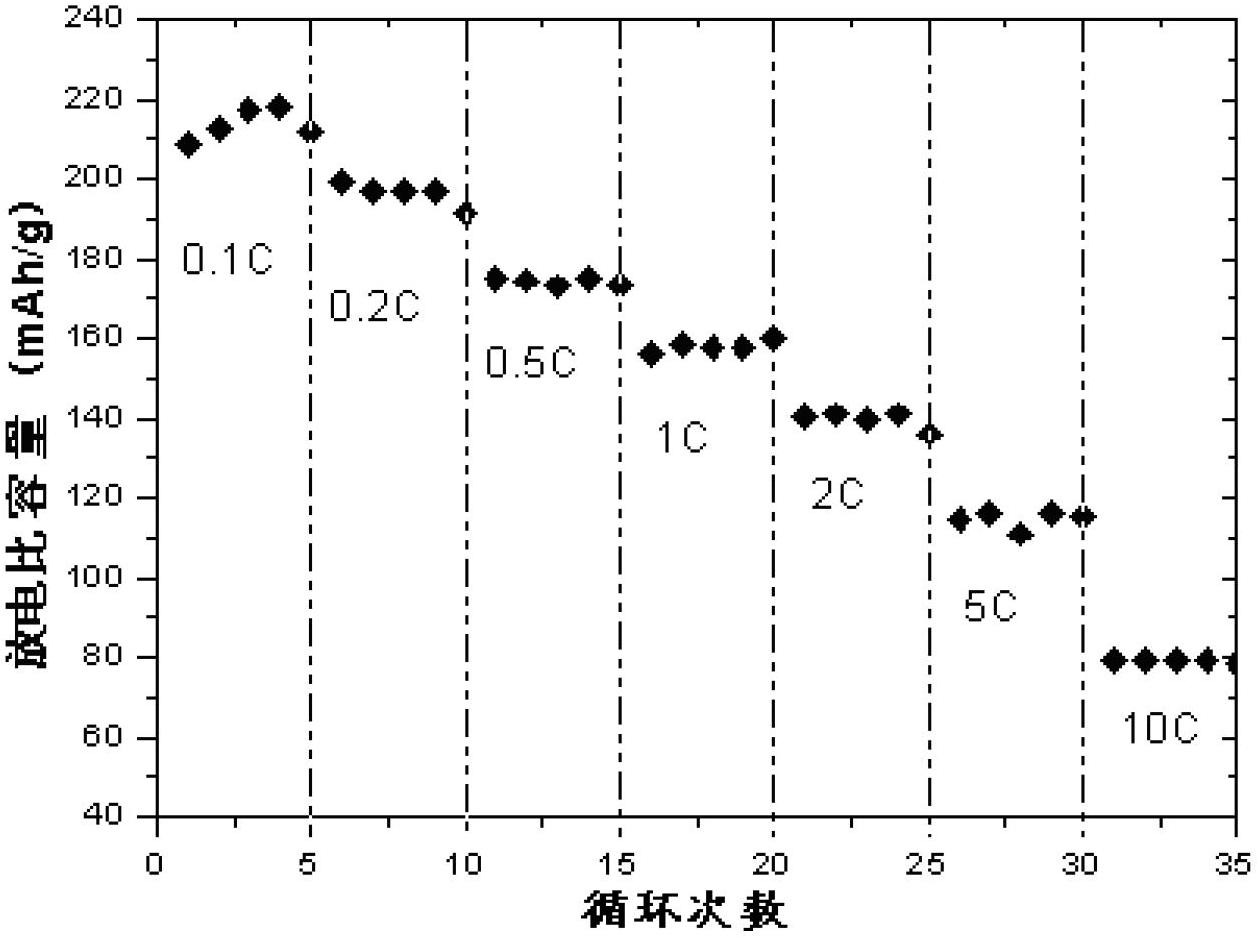

A lithium-nickel-manganese-oxygen and nickel-manganese technology, which is applied in the field of lithium-nickel-manganese-oxygen materials and their preparation, can solve the problems of low initial coulombic efficiency, low specific capacity, and poor cycle performance of lithium-ion batteries, and achieve excellent cycle performance and high performance ratio. The effect of high capacity and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

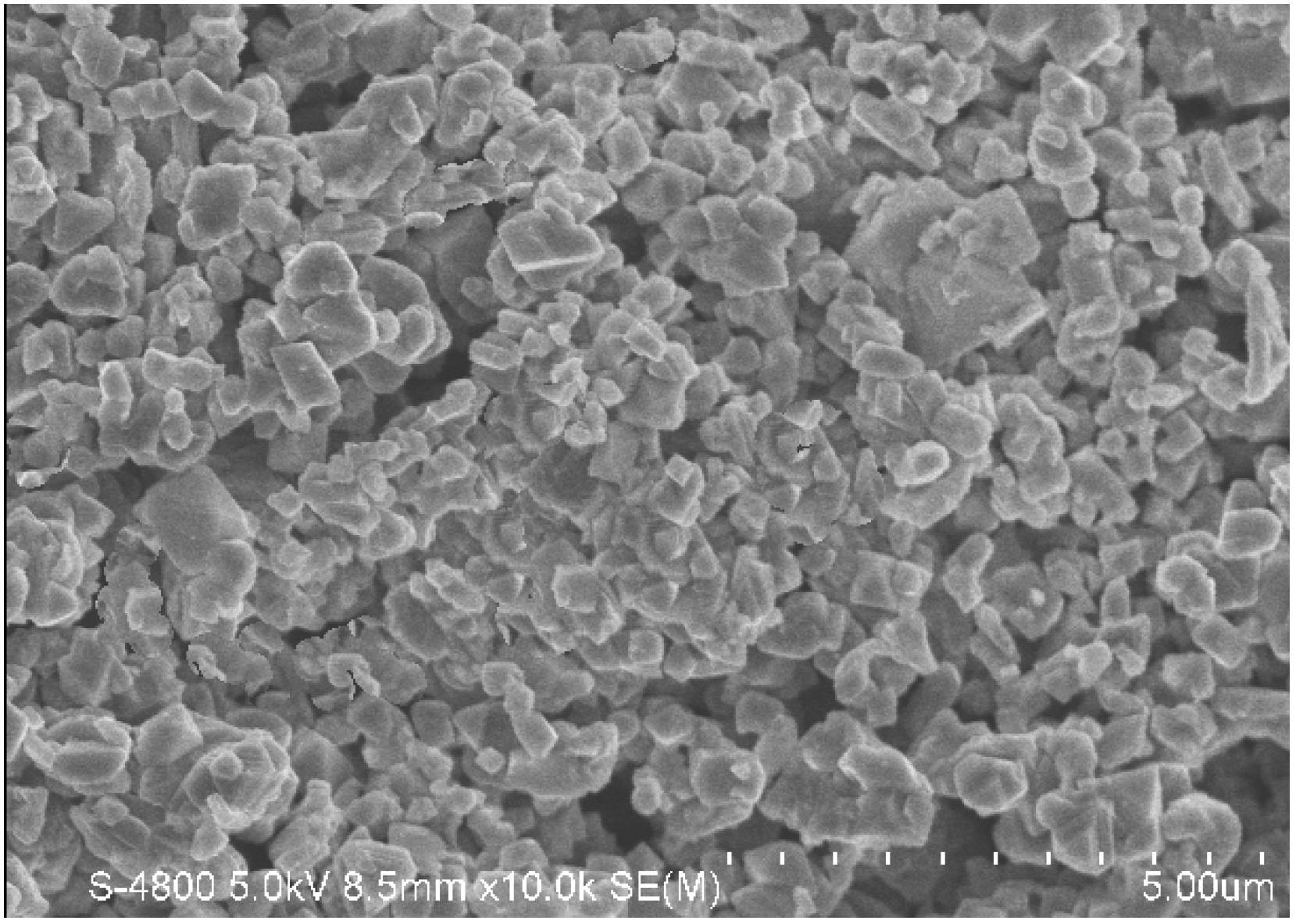

[0032] This embodiment provides a 0.62LiNi 0.5 mn 1.5 o 4 0.38 Li 2 MnO 3 0.38LiNi 0.5 mn 0.5 o 2 The method of preparation of the material, including:

[0033] Step 1. Preparation of precursor by co-precipitation

[0034] Prepare the aqueous solution of the mixture of nickel acetate and manganese nitrate according to the ratio of substance Ni:Mn=1:3, and add Na with a molar concentration of 0.5M to the mixed solution dropwise under stirring. 2 CO 3 solution to make Ni 2+ , Mn 2+ The precipitation was complete, and after standing for 2 hours, suction filtration, washing three times, and drying at 110° C. for 12 hours obtained the precursor nickel-manganese composite carbonate.

[0035] Step 2. Pretreatment of NiMn precursor

[0036] Lithium nitrate and Lithium Retard (both are 1: 1) and the precursor nickel-manganese composite carbonate are mixed to obtain a solid mixture by the amount ratio Li: Ni: Mn=3.463: 1: 3. The volatilization of Li during the treatment pro...

Embodiment 2

[0047] This embodiment provides a kind of 0.6LiNi 0.5 mn 1.5 o 4 0.4 Li 2 MnO 3 0.4LiNi 0.5 mn 0.5 o 2 Preparation method of material:

[0048] Step 1. Co-precipitation to prepare nickel-manganese precursor

[0049] According to the ratio of substance Ni:Mn=1:3, prepare nickel nitrate and nickel acetate (the ratio of substance of the two is 1:1), and the mixture aqueous solution of manganese sulfate is added dropwise to the mixed solution in a state of stirring. K at a concentration of 0.3M 2 CO 3 solution to make Ni 2+ , Mn 2+ The precipitation was complete, and after standing for 2 hours, suction filtration, washing three times, and drying at 110° C. for 12 hours obtained the precursor nickel-manganese composite carbonate.

[0050] Step 2. Pretreatment of NiMn precursor

[0051]Dry the nickel-manganese composite carbonate precursor obtained in step 1, sinter it in an air atmosphere, heat it up to 600°C at a heating rate of 10°C / min, keep it warm and sinter for 2...

Embodiment 3

[0059] This embodiment provides a kind of 0.61LiNi 0.5 mn 1.5 o 4 0.39 Li 2 MnO 3 0.39LiNi 0.5 mn 0.5 o 2 The method of preparation of the material, including:

[0060] Step 1. Co-precipitation to prepare nickel-manganese precursor

[0061] Prepare a mixture aqueous solution of nickel sulfate, manganese chloride and manganese sulfate (the ratio of the two substances is 1:1) according to the amount ratio of Ni:Mn=1:3, and add it dropwise to the mixed solution under stirring 2M NaHCO molarity 3 solution to make Ni 2+ , Mn 2+ The precipitation was complete, and after standing for 2 hours, suction filtration, washing three times, and drying at 110° C. for 12 hours obtained the precursor nickel-manganese composite carbonate.

[0062] Step 2. Pretreatment of NiMn precursor

[0063] Li:Ni:Mn=3.6312:1:3 according to the amount of substance ratio Lithium acetate and the precursor nickel-manganese composite carbonate are mixed to obtain a solid mixture; and the ratio of etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Primary particle size | aaaaa | aaaaa |

| Primary particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com