Application of bis-triphenylamine-imide polymer in preparation of positive electrode for lithium battery

A technology of bis-triphenylamine and bis-triphenylamine, which is used in the preparation of lithium battery positive electrodes, in the field of bis-triphenylamine-imide polymers, can solve problems such as low average discharge voltage, and achieve high discharge specific capacity and Average discharge voltage, good cycle stability, low solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] 3. Preparation of positive electrode.

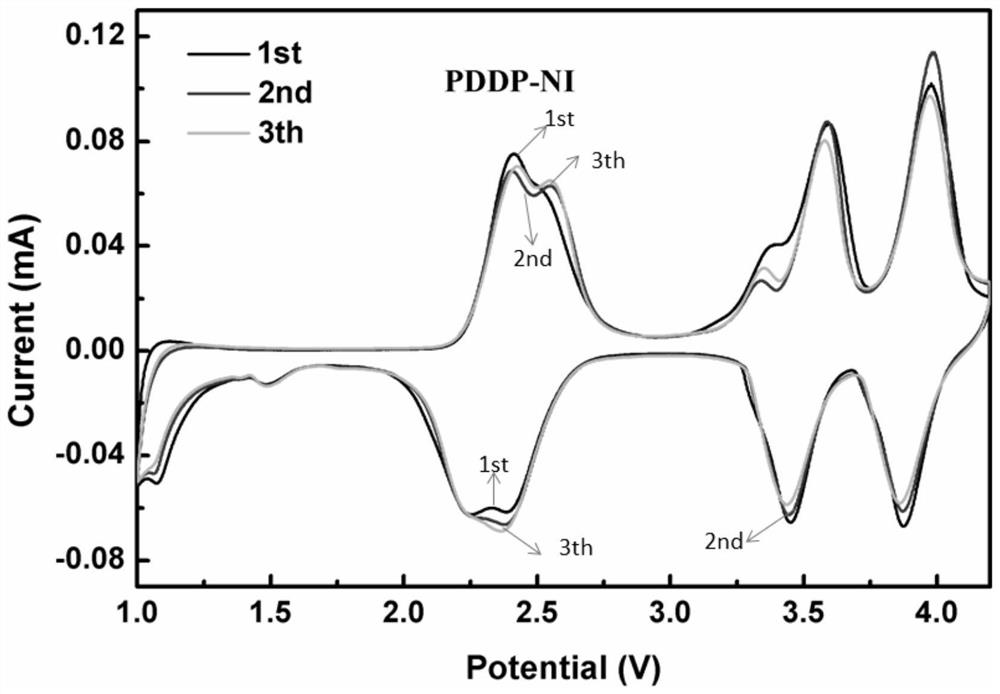

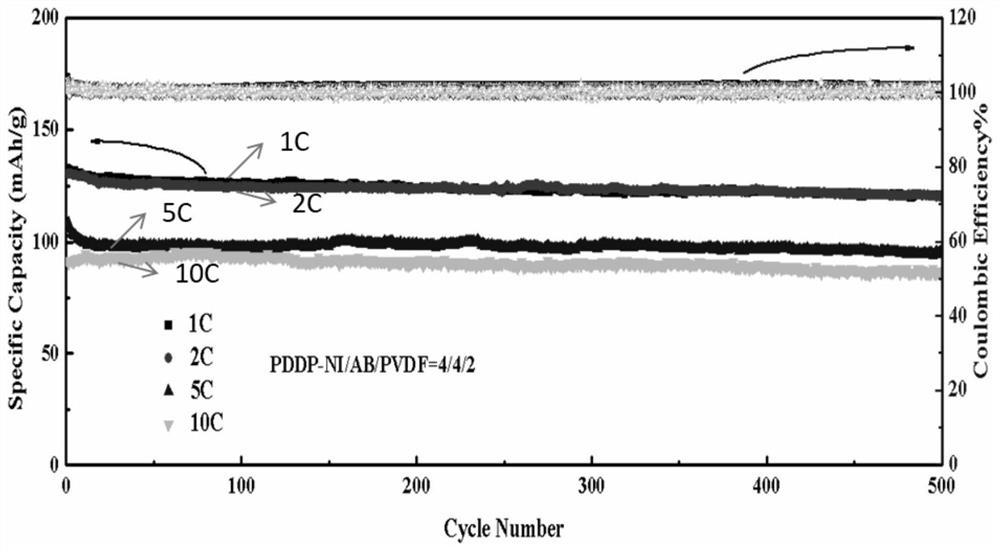

[0043]Add 20 drops of N-methylpyrrolidone solvent (NMP) (0.02 mg / drop) to 2 parts by mass of the binder PVDF, and stir for 1 h to form a slurry. Transfer 4 parts by mass of active material PDDP-NI and 4 parts by mass of conductive agent acetylene black into a ball mill jar, add the prepared slurry and ball mill for 1 hour, then add 5-8 drops of NMP and continue stirring for 1 hour (repeat 2 times). The slurry was obtained after ball milling for 4 hours, and the slurry was coated on an aluminum foil, and vacuum-dried at 80° C. for 24 hours to obtain a positive electrode.

Embodiment 2

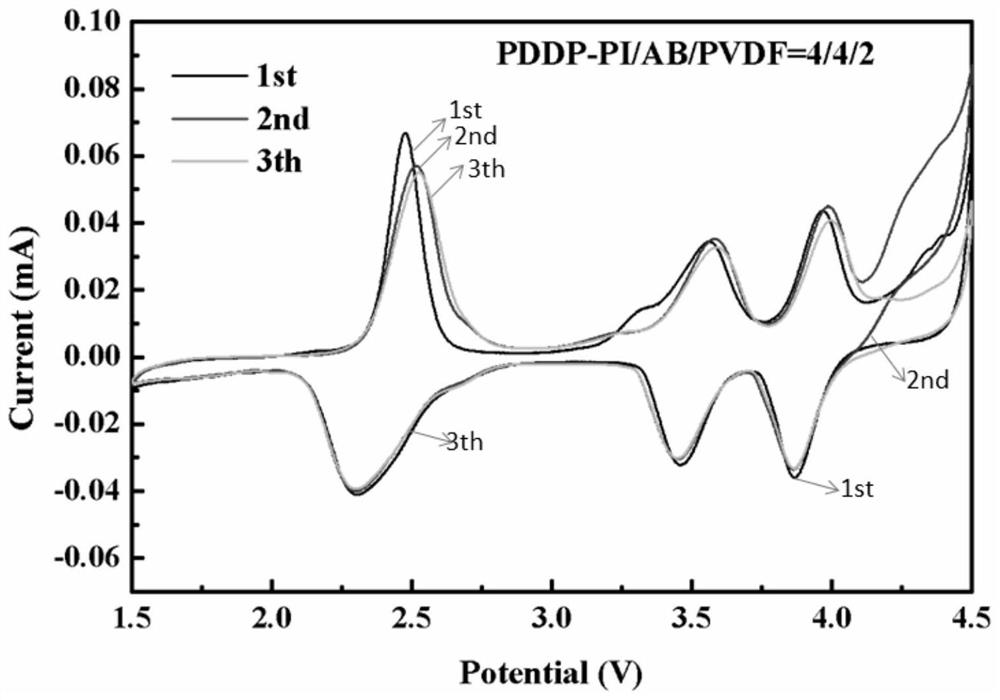

[0044] Embodiment 2 of the present invention is: the application of bis-triphenylamine-imide polymer (PDDP-PI) in the preparation of lithium battery positive electrode, comprising the following steps:

[0045] 1. Synthesis of PDDP-PI.

[0046]

[0047] Under nitrogen protection, add 15g of imidazole to a 50mL three-necked flask and dissolve at 130°C, then add the DDP-NH prepared in Example 1 above 2 (0.88g, 2mmol), add 3,4,9,10-perylene tetracarboxylic dianhydride (3,4,9,10-Perylene-tetracarboxylic dianhydride, PTCDA) (0.44g, 2mmol) after the dissolution is complete to continue the reaction for 16h , cooled to 90 degrees Celsius and added 30mL methanol to continue the reaction for 5h. After the reaction, the product was added to 300mL methanol and stirred and filtered, and extracted with dichloromethane for 3 days, washed twice with dimethyl carbonate, and washed twice with acetone. After vacuum drying at °C for 24 h, dark red powder PDDP-PI (0.66 g, 40.7%) was obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com