Negative electrode material for secondary battery, preparation method of negative electrode material, negative electrode plate and secondary battery

A technology for secondary batteries and negative electrode materials, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve the problems of small interlayer spacing, inability to achieve alkali metal de-intercalation, etc., to promote transfer and improve kinetics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The second aspect of the present invention aims to provide a method for preparing the negative electrode material for secondary batteries, comprising the following steps:

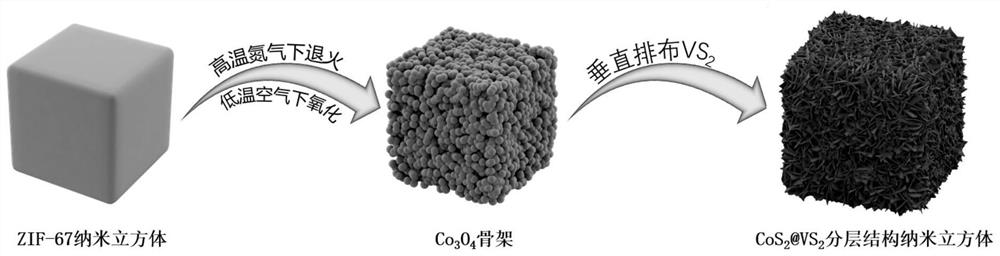

[0036] S1. Mix the aqueous solution of metal ion salt and surfactant to obtain solution A, and the aqueous solution of 2-methylimidazole as solution B. Pour solution A into solution B and stir, centrifuge and wash until colorless, and dry in vacuum to obtain nano A precursor of a cubic skeleton; then calcining the precursor of the nanocube skeleton at 300-650° C., and cooling to obtain a nanocube skeleton;

[0037] S2. Using a hydrothermal method to grow vanadium disulfide on the surface of the nanocube skeleton to obtain a negative electrode material for a secondary battery.

[0038] The present invention uses the zeolite imidazole metal-organic framework as a precursor to prepare a metal oxide and carbon-doped nano-cube skeleton with a stable structure, and vertically anchors the layered VS on the ...

Embodiment 1

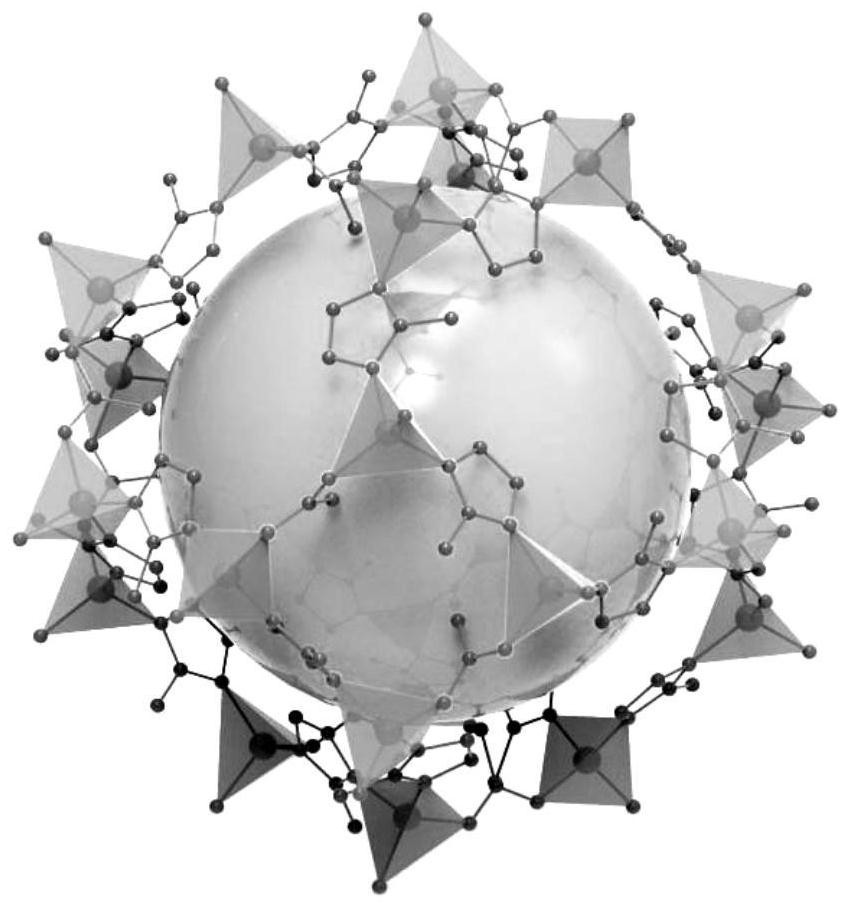

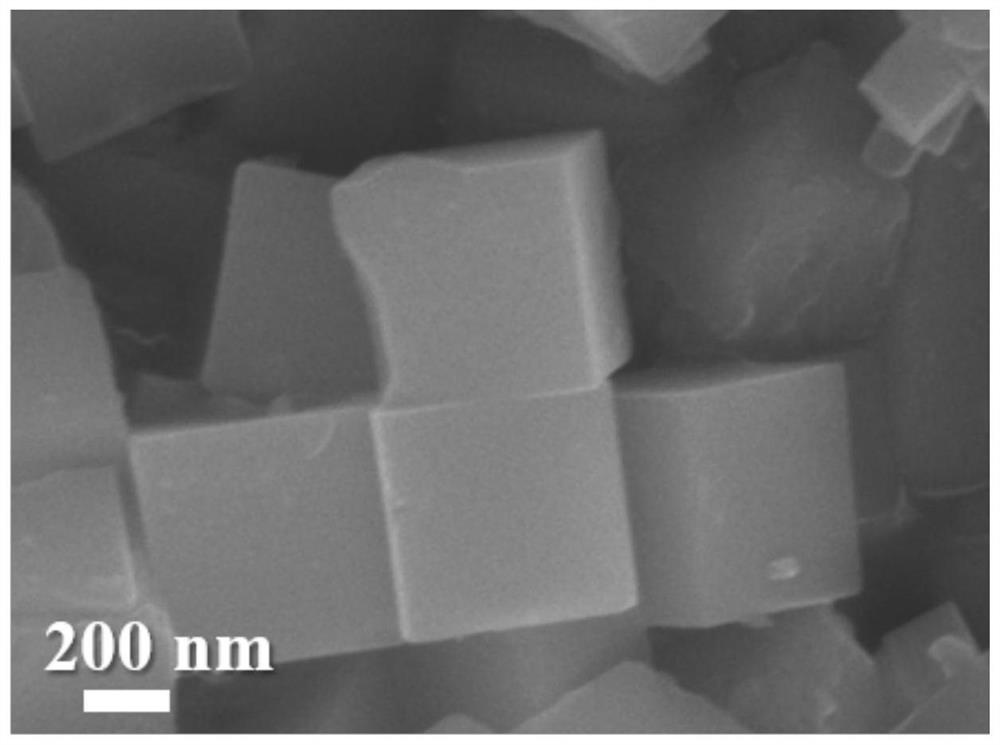

[0052] A negative electrode material for a secondary battery, comprising a nanocube framework and layered vanadium disulfide vertically anchored and grown on the surface of the nanocube framework; the precursor of the nanocube framework is a zeolite imidazole metal organic framework. Wherein, the zeolite imidazole metal organic framework is a zeolite imidazole framework structure (ZIF-67) with cobalt as the metal ion. Can be like Figure 1~2 shown.

[0053] The preparation method of this negative electrode material comprises the following steps:

[0054] S1, 0.58g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 20mL of pure water, add 10mg of cetyltrimethylammonium bromide, ultrasonically mix to obtain a clear and transparent solution A, completely dissolve 9.08g of 2-methylimidazole in 140mL of pure water as a solution B. Quickly pour solution A into solution B and stir for 20 minutes, then collect the product by centrifugation and wash repeatedly with ethan...

Embodiment 2

[0058] The difference from Embodiment 1 is step S2.

[0059] S2. Then place the ZIF-67 cube in a tube furnace, heat it to 600°C for 3h in the air at a heating rate of 2°C / min, and then cool it to room temperature to obtain Co 3 o 4 / C Nanocube.

[0060] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com