A kind of vanadium disulfide nanorod array electrocatalyst and preparation method thereof

A vanadium disulfide nanometer and nanorod array technology, applied in physical/chemical process catalysts, chemical instruments and methods, nanotechnology and other directions, can solve the problems of susceptibility, low earth reserves, high price, etc., and achieve low cost and low cost. The effect of synthesis temperature and morphology uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Cut the carbon cloth into a rectangle of 1×5 cm, reflux and activate it in concentrated nitric acid at 80-120°C for 1-3 hours, then wash it with ethanol and deionized water for 3 times, and dry it at 50°C for 8 hours to get the treatment carbon cloth;

[0019] (2) Weigh 0.1g NaVO respectively 3 , 0.2g TAA (CH 3 CSNH 2 ) and 0.5g C 6 h 12 N 4 , dissolved in 20ml deionized water, and magnetically stirred at room temperature for 40min to obtain a clear solution;

[0020] (3) Put the carbon cloth treated in (1) into the reaction lining, pour the clarified solution obtained in (2), seal it for hydrothermal reaction, set the reaction temperature to 160°C, and the reaction time to 18h;

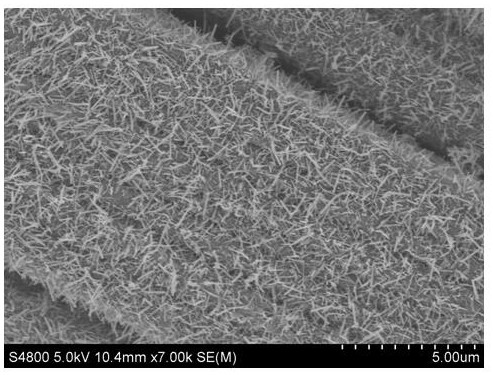

[0021] (4) After the reaction, the reaction kettle was naturally cooled to room temperature, the carbon cloth was taken out, and then washed with ethanol and deionized water for 3 times, and finally the carbon cloth was dried at 50°C for 8 hours to obtain uniform nanorod-shaped VS 2...

Embodiment 2

[0023] (1) Cut the carbon cloth into a rectangle of 1×5 cm, reflux and activate it in concentrated nitric acid at 80°C for 2 hours, then wash it with ethanol and deionized water for 4 times, and dry it at 50°C for 8 hours to obtain the treated carbon cloth;

[0024] (2) Weigh 0.3g NaVO respectively 3 , 0.9g TAA (CH 3 CSNH 2 ) and 0.8g C 6 h 12 N 4 , dissolved in 30ml deionized water, and magnetically stirred at room temperature for 40min to obtain a clear solution;

[0025] (3) Put the carbon cloth treated in (1) into the reaction lining, pour the clarified solution obtained in (2), seal it for hydrothermal reaction, set the reaction temperature to 200°C, and the reaction time to 22h;

[0026] (4) After the reaction, the reaction kettle was naturally cooled to room temperature, the carbon cloth was taken out, and then washed with ethanol and deionized water for 3 times, and finally the carbon cloth was dried at 50°C for 8 hours to obtain uniform nanorod-shaped VS 2 .

Embodiment 3

[0028] (1) Cut the carbon cloth into a rectangle of 1×5 cm, reflux and activate it in concentrated nitric acid at 80°C for 2 hours, then wash it with ethanol and deionized water for 5 times, and dry it at 60°C for 7 hours to obtain the treated carbon cloth;

[0029] (2) Weigh 0.4g NaVO respectively 3 , 1.2g TAA (CH 3 CSNH 2 ) and 1.2g C 6 h 12 N 4 , dissolved in 35ml deionized water, stirred magnetically at room temperature for 60min to obtain a clear solution;

[0030] (3) Put the carbon cloth treated in (1) into the reaction lining, pour the clarified solution obtained in (2), seal it for hydrothermal reaction, set the reaction temperature to 180°C, and the reaction time to 24h;

[0031] (4) After the reaction, the reactor was naturally cooled to room temperature, the carbon cloth was taken out, and then washed three times with ethanol and deionized water, and finally the carbon cloth was dried at 60°C for 7 hours to obtain uniform nanorod-shaped VS 2 .

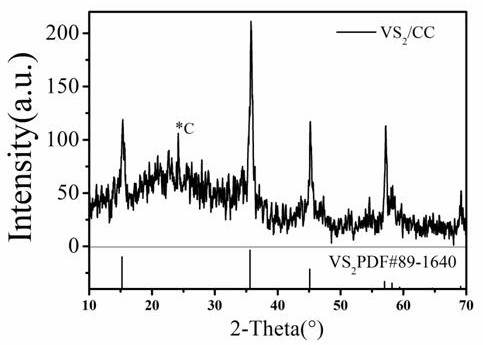

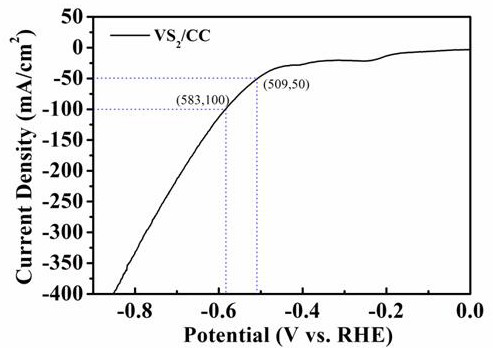

[0032] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com