A vanadium disulfide nanosheet coated with vanadium hydroxide and its preparation method and application

A technology of vanadyl hydroxide package and vanadium disulfide, which is applied in impregnation manufacturing, electrode manufacturing, structural parts, etc., can solve the problems of insignificant electrochemical performance improvement, complex synthesis process, high cost, etc., and achieve improved cycle stability , high purity, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A VOOH coated VS 2 The preparation method of nano sheet, comprises the following steps:

[0041] Step 1: Weigh sodium metavanadate and thioacetamide and add them into 55-65ml deionized water at the same time, control the vanadium-sulfur molar ratio to 1:2.5-1:3.5, stir magnetically for 20-40min to obtain a semi-clear solution A, At this time, the concentration of sodium metavanadate is 0.1-0.15 mol / L.

[0042] Step 2: Pour solution A into the reaction liner and seal it, then install the liner in the outer kettle and fix it, then place it in a homogeneous reactor, and then set it at 155-165°C under the condition of 5-15r / min Under the reaction 23 ~ 25h. Among them, the reaction filling ratio should be controlled at 55-65%. The reaction must be carried out under rotating conditions, which is conducive to the full and uniform contact of the reactants, so that VOOH can be guaranteed at VS 2 Uniform growth on the surface.

[0043] Step 3: After the hydrothermal reaction...

Embodiment 1

[0046] Step 1: Weigh sodium metavanadate and thioacetamide and add them to 60ml deionized water at the same time, control the molar ratio of vanadium to sulfur to be 1:3.0, and stir magnetically for 30 minutes to obtain semi-clear solution A. At this time, the concentration of sodium metavanadate It is 0.137mol / L.

[0047] Step 2: Pour solution A into the reaction liner and seal it, then install the liner in the outer kettle and fix it, place it in a homogeneous reactor, and then react at 160°C for 24 hours under the condition of 10r / min. Among them, the reaction filling ratio should be controlled at 60%.

[0048] Step 3: After the hydrothermal reaction is completed, cool the reaction vessel to room temperature naturally, then take out the cooled product after the reaction, collect the product after 3 times of water washing and 3 times of alcohol washing alternately, and dry it at 60°C for 12 hours. You can get VOOH-coated VS 2 Nanosheets.

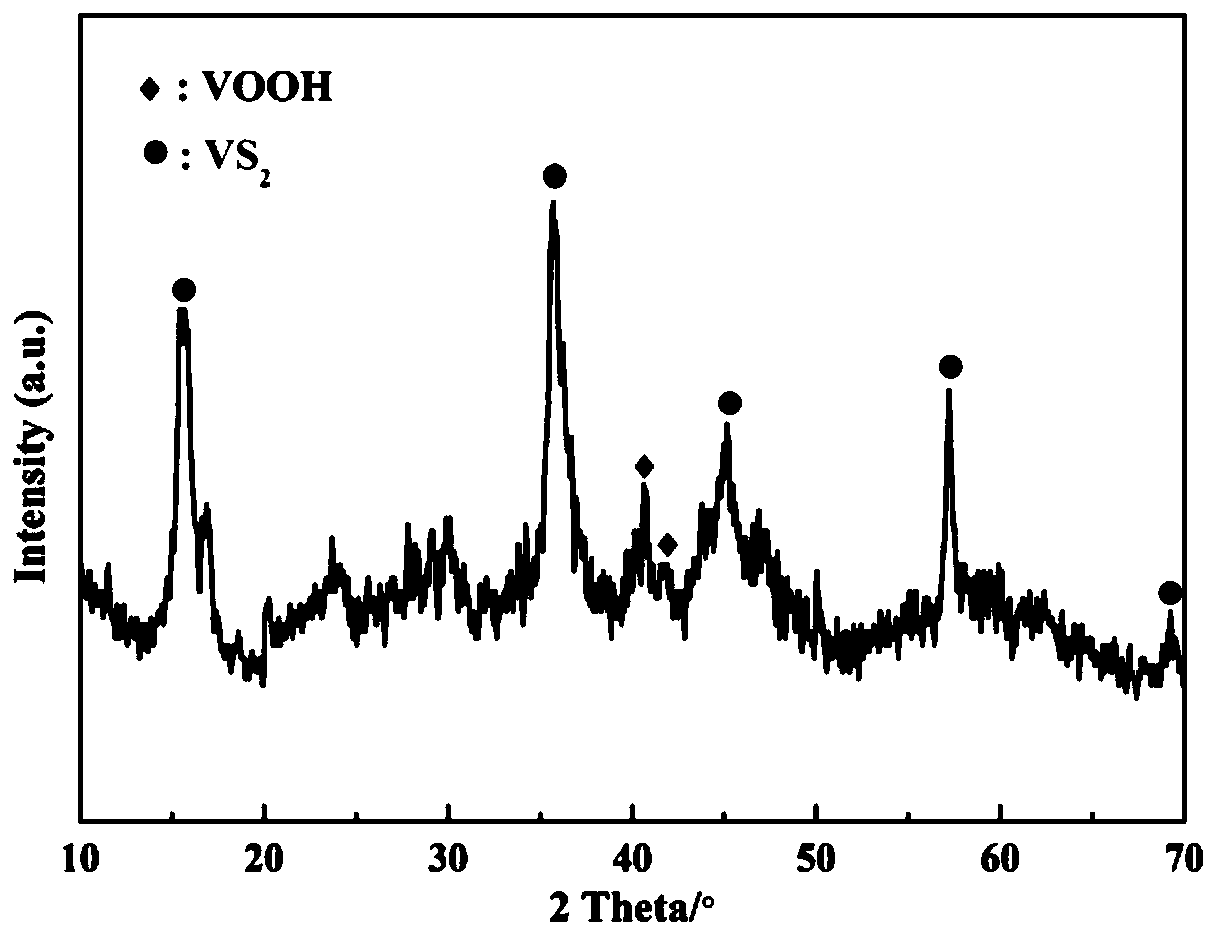

[0049] from figure 1 It can be ...

Embodiment 2

[0056] Step 1: Weigh sodium metavanadate and thioacetamide and add them to 55ml deionized water at the same time, control the molar ratio of vanadium to sulfur to be 1:2.5, and stir magnetically for 20 minutes to obtain semi-clear solution A. At this time, the concentration of sodium metavanadate It is 0.1mol / L.

[0057] Step 2: Pour solution A into the reaction liner and seal it, then install the liner in the outer kettle and fix it, place it in a homogeneous reactor, and then react at 155°C for 23 hours under the condition of 5r / min.

[0058] Step 3: After the hydrothermal reaction is completed, cool the reactor to room temperature naturally, then take out the cooled product after the reaction, wash it twice with water and wash it alternately with alcohol five times, then collect the product, and dry it at 55°C for 10 hours. You can get VOOH-coated VS 2 Nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com