Patents

Literature

834results about "Impregnation manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

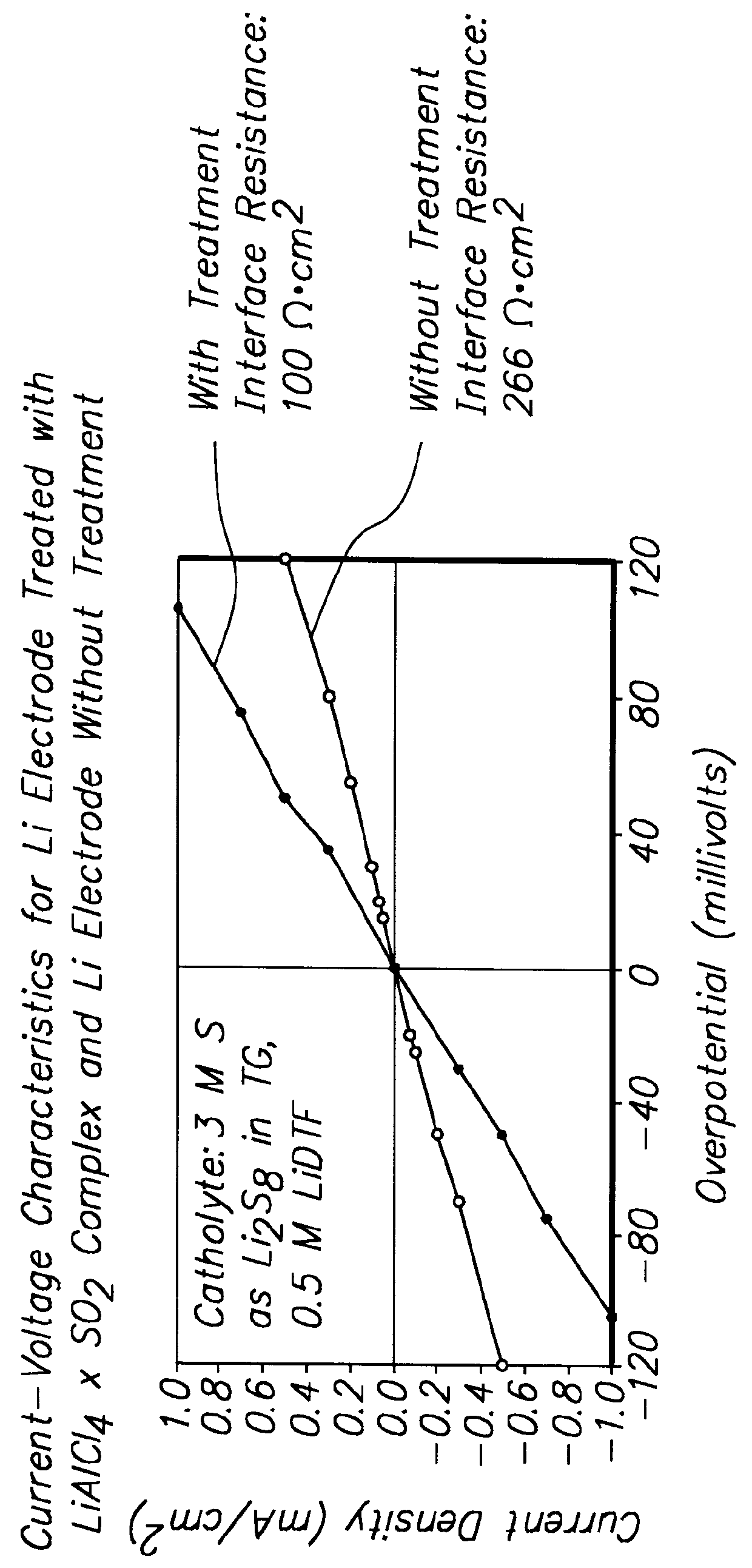

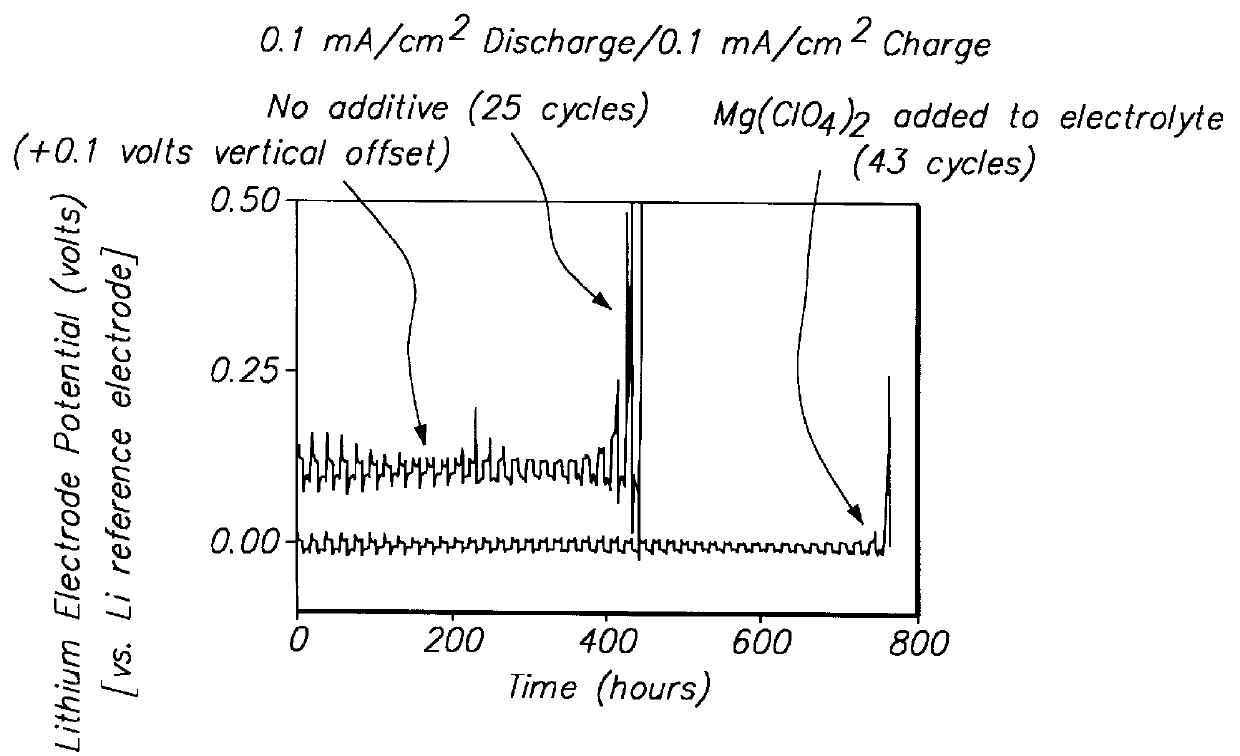

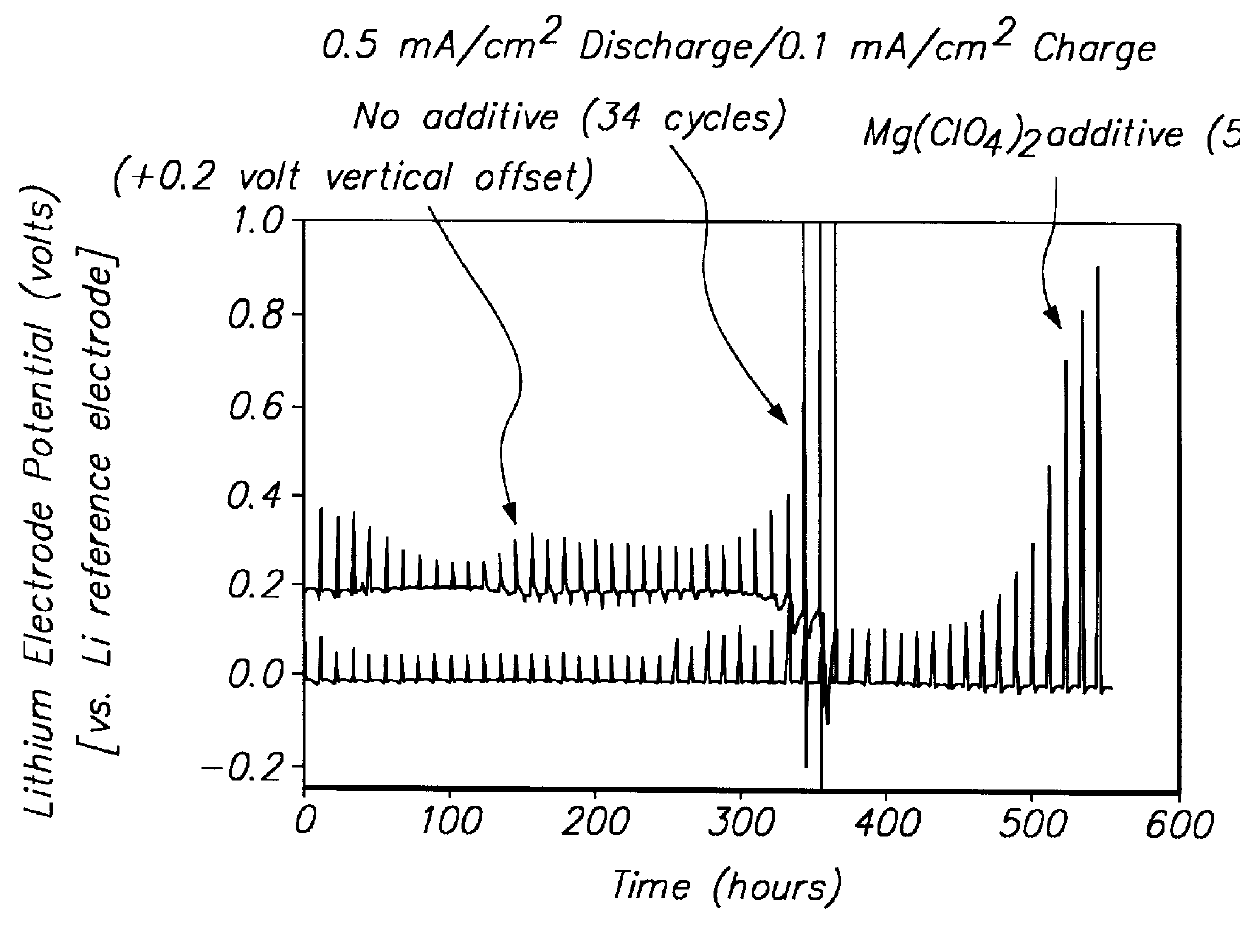

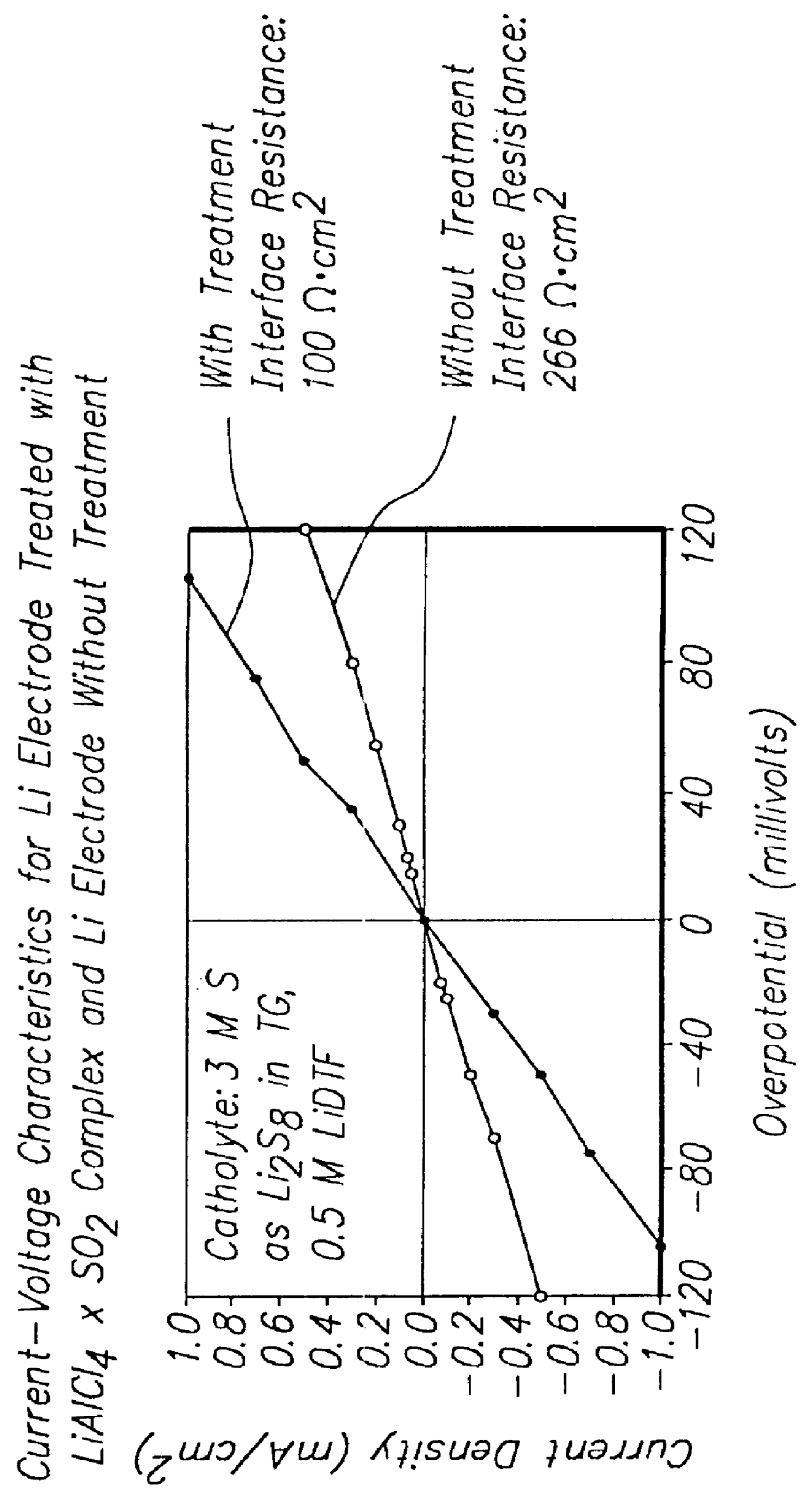

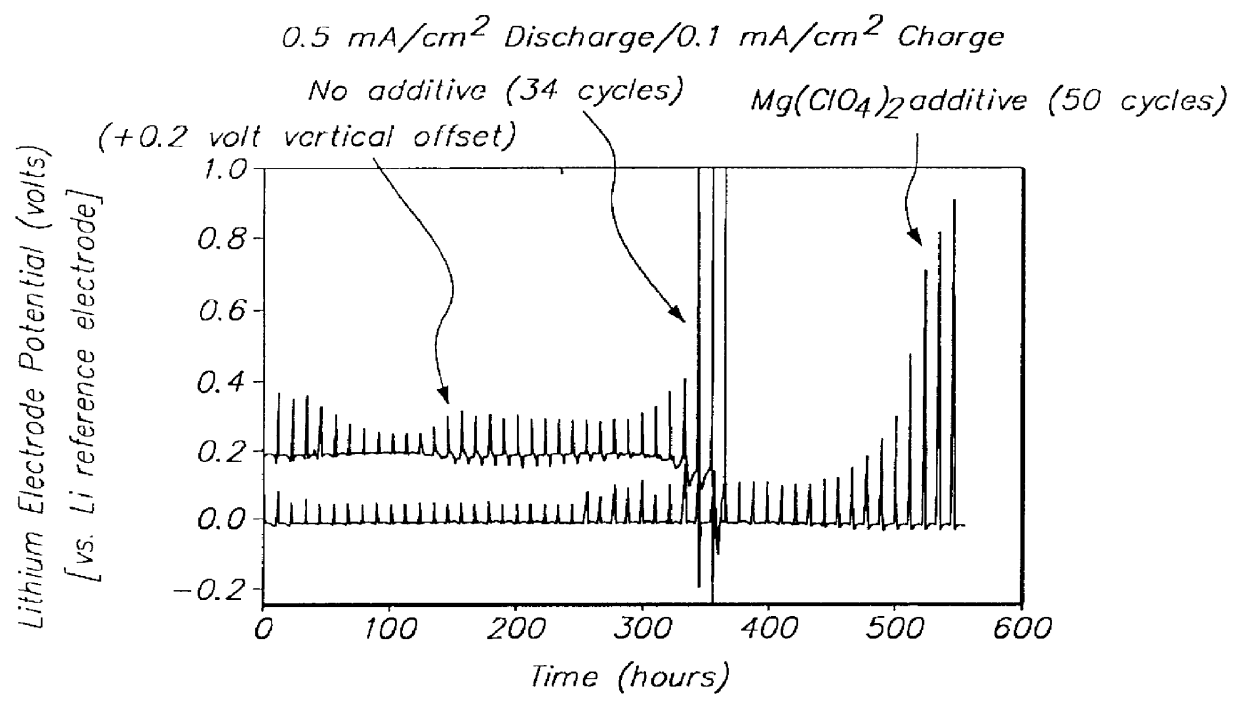

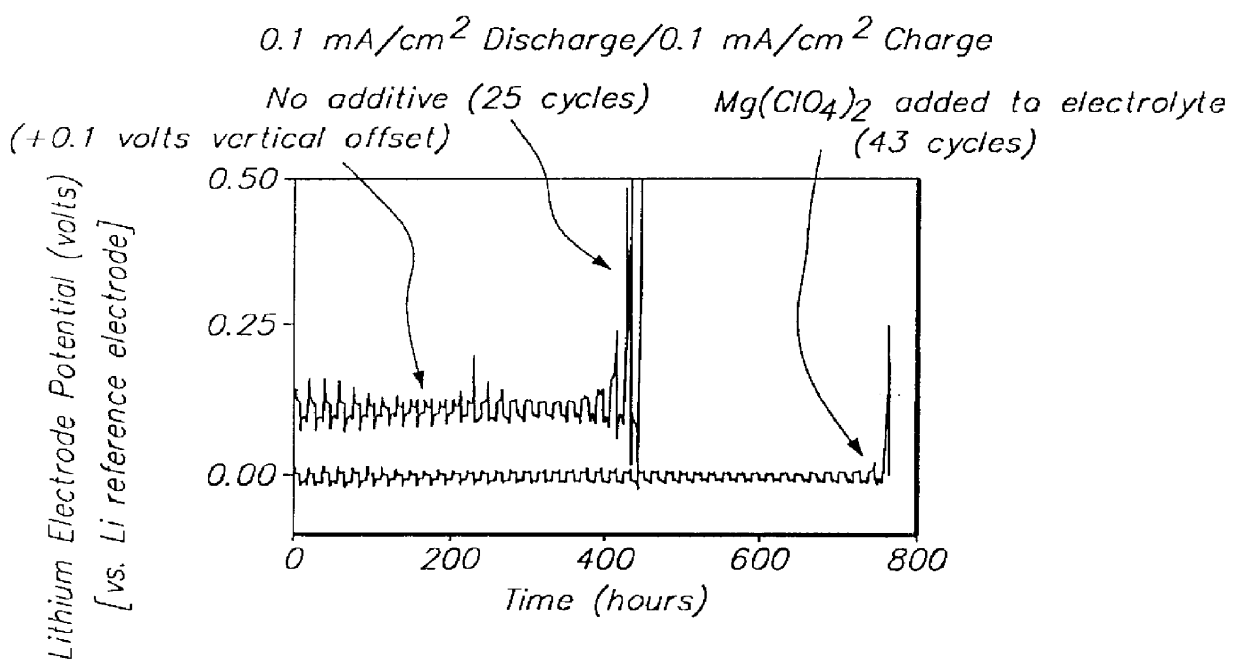

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6017651AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

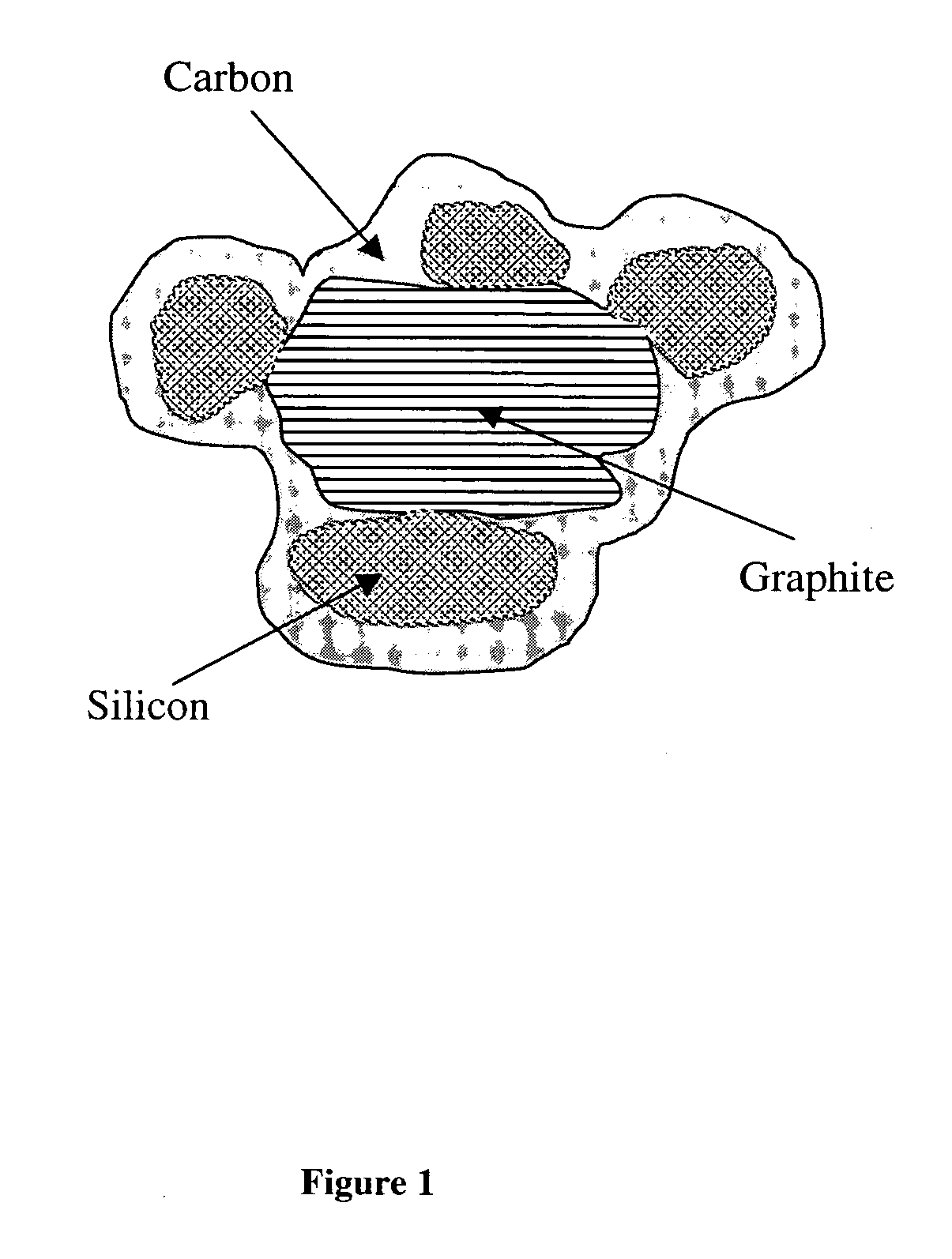

Carbon-coated silicon particle power as the anode material for lithium batteries and the method of making the same

InactiveUS20050136330A1Large capacityImprove efficiencyElectrode thermal treatmentElectrode carriers/collectorsCarbon compositesSilicon particle

A process for the production of coated silicon / carbon particles comprising: providing a carbon residue forming material; providing silicon particles; coating said silicon particles with said carbon residue forming material to form coated silicon particles; providing particles of a carbonaceous material; coating said particles of carbonaceous material with said carbon residue forming material to form coated carbonaceous particles; embedding said coated silicon particles onto said coated carbonaceous particles to form silicon / carbon composite particles; coating said silicon / carbon composite particles with said carbon residue forming material to form coated silicon / carbon composite particles; and stabilizing the coated composite particles by subjecting said coated composite particles to an oxidation reaction. The coated composite particles will have a substantially smooth coating. The particles may be coated with multiple layers of carbon residue forming material /

Owner:PYROTECK INC

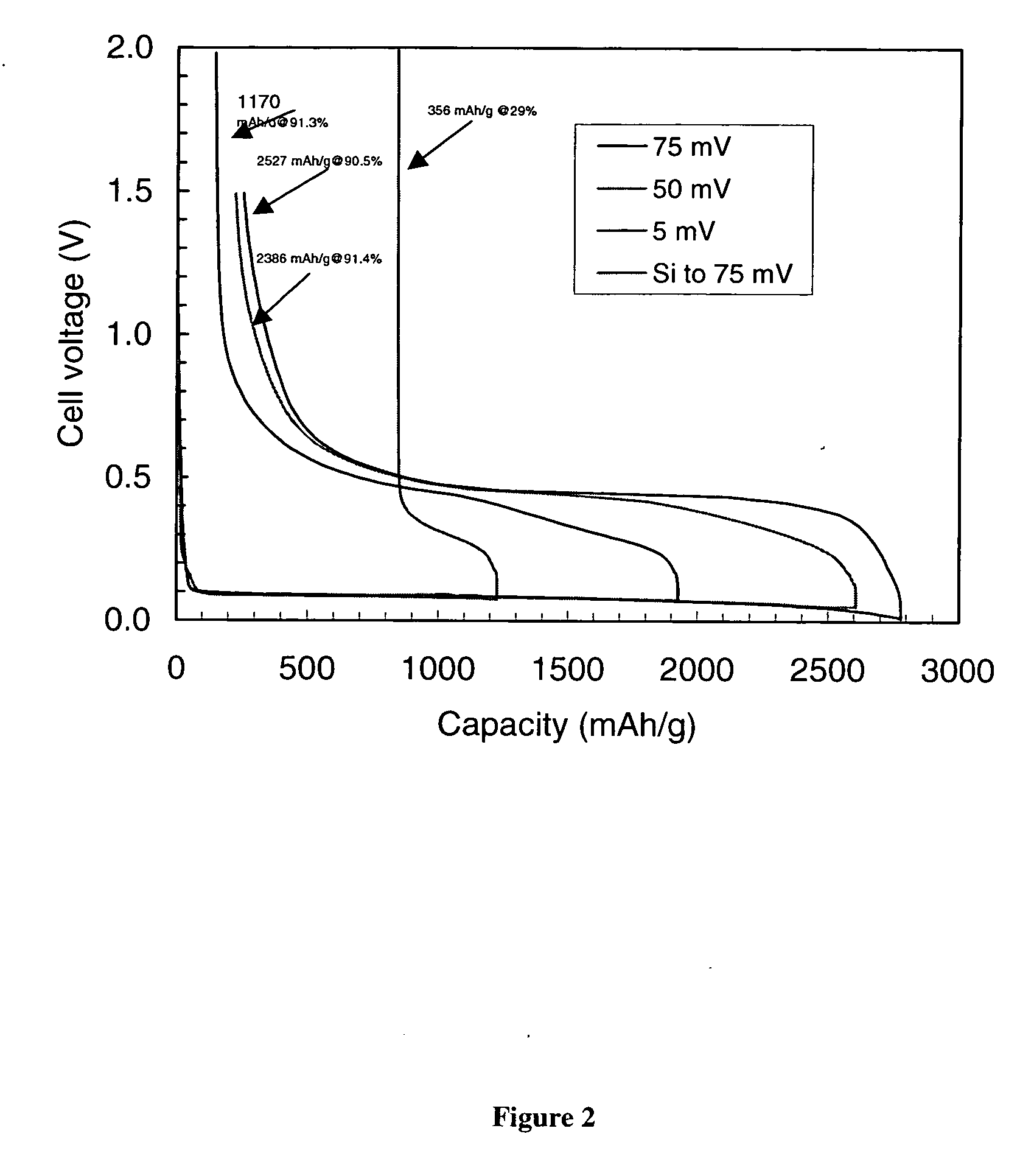

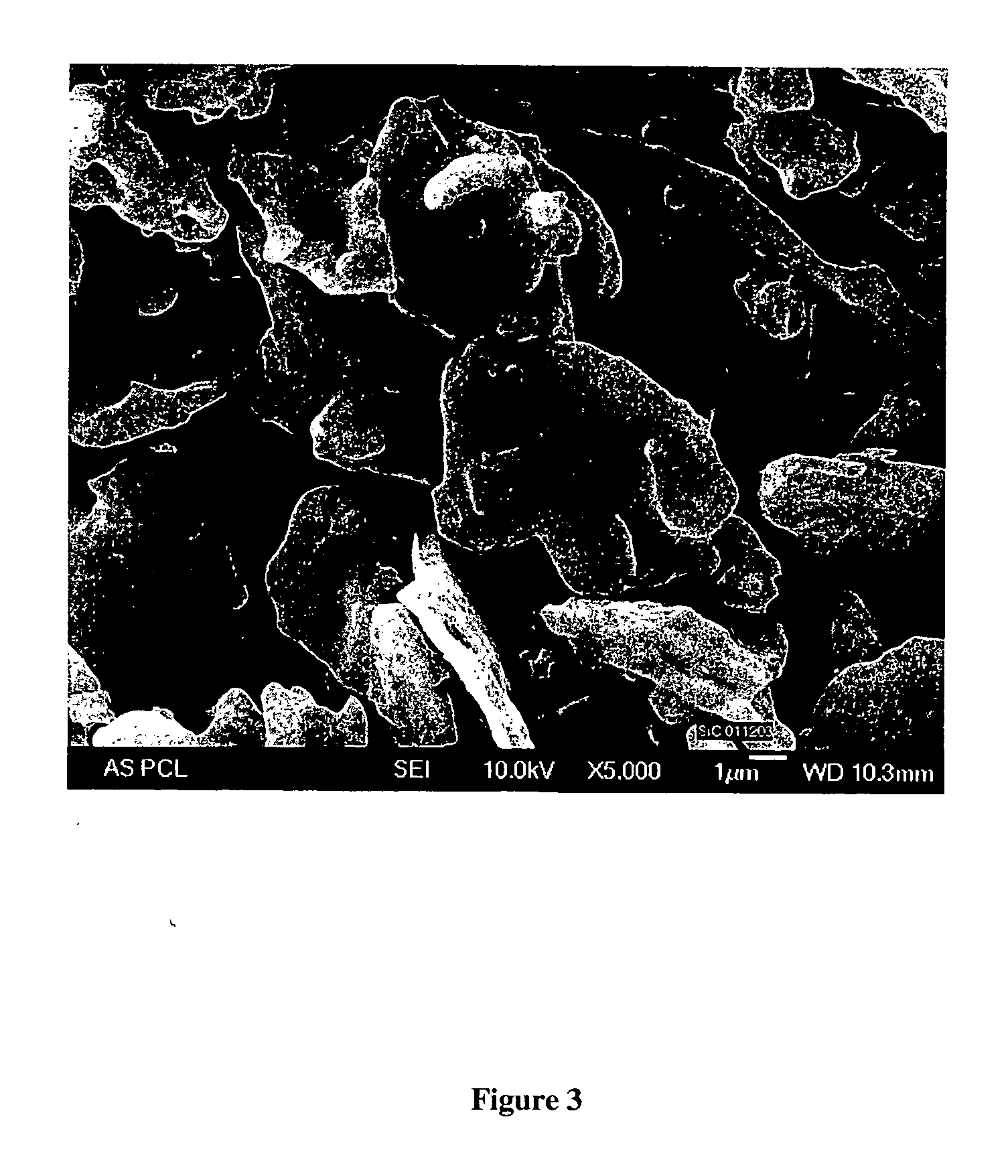

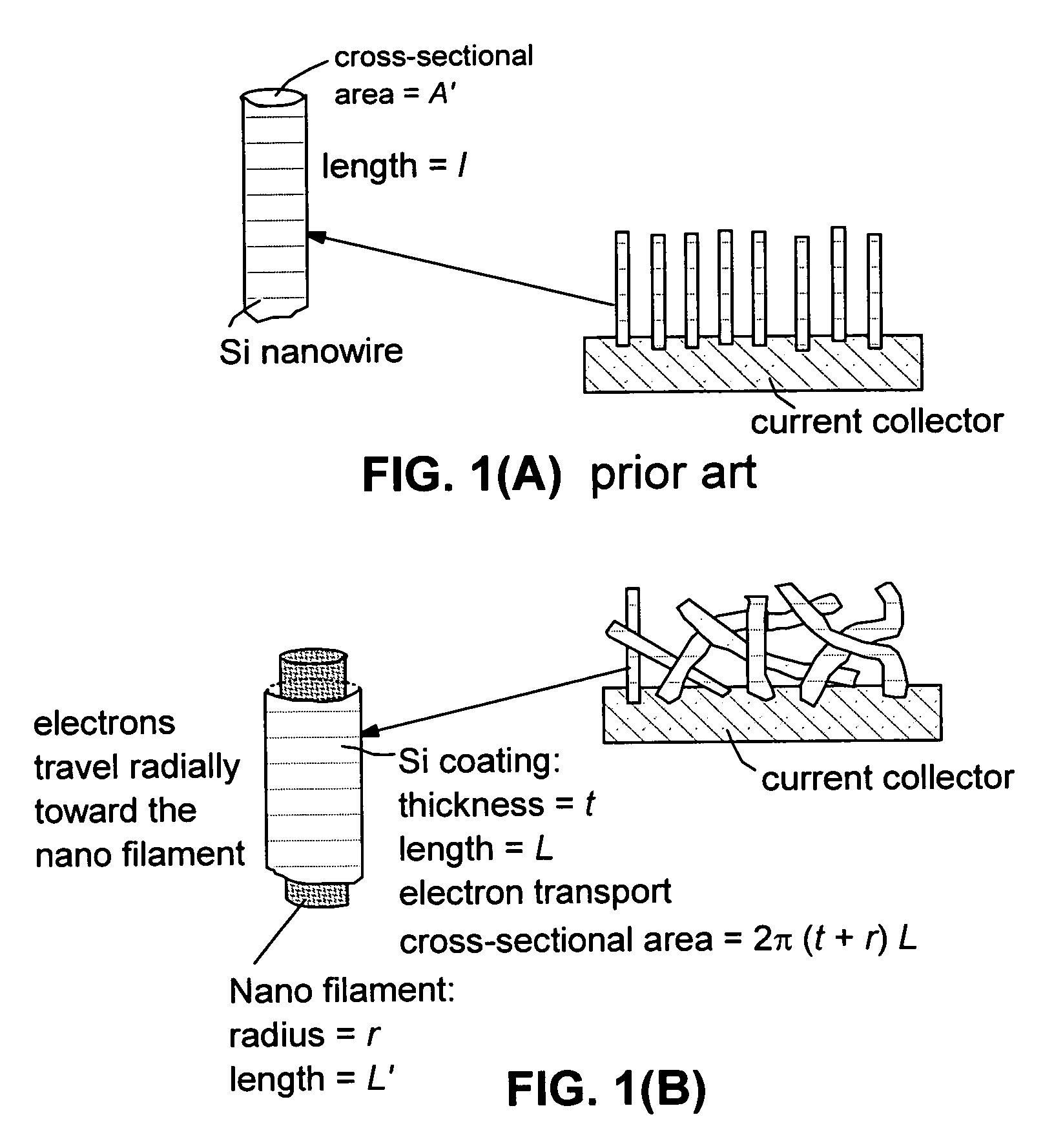

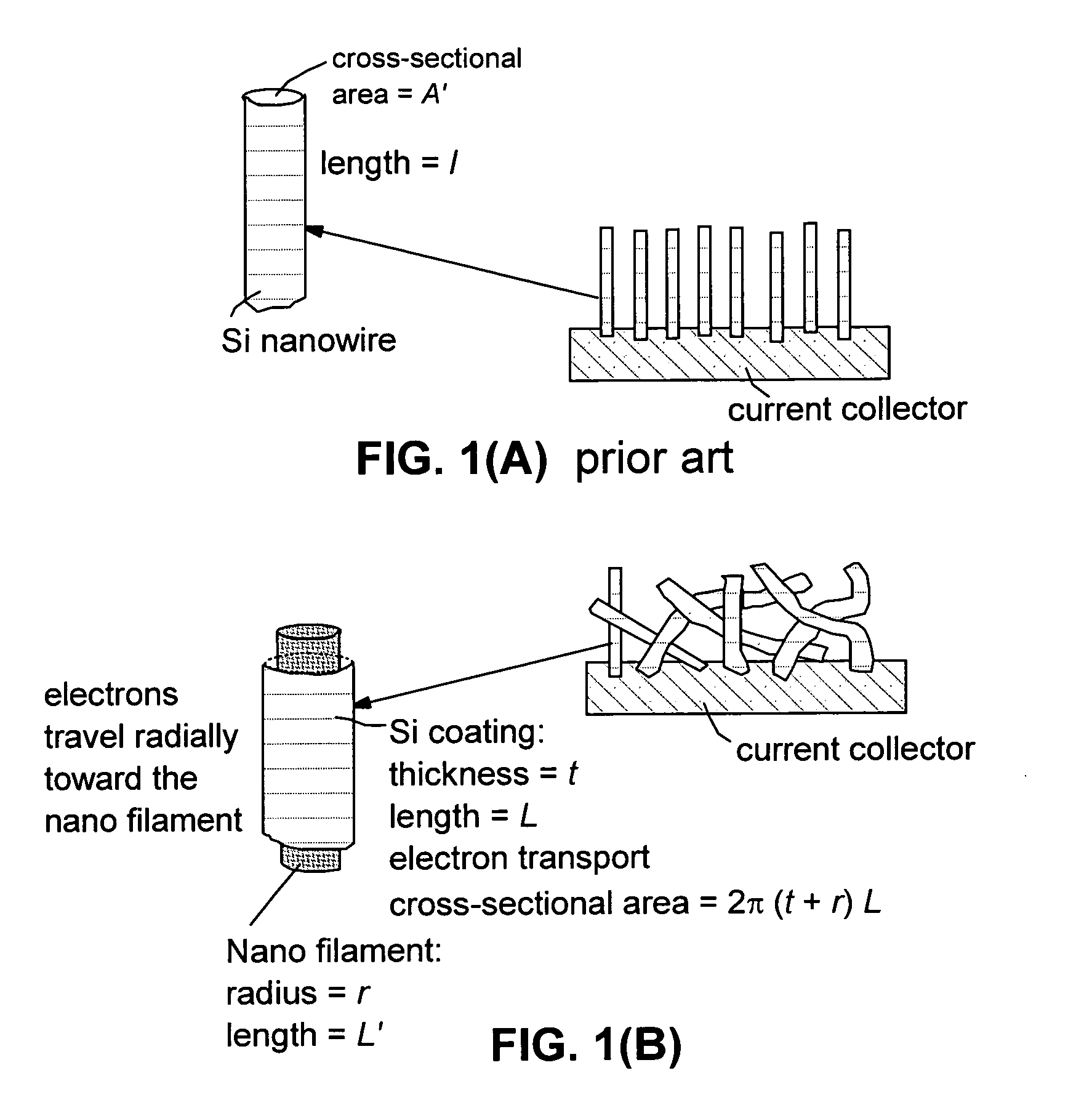

Hybrid nano-filament anode compositions for lithium ion batteries

ActiveUS20090169996A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesElectrode thermal treatmentLithium-ion batteryNanometre

This invention provides a hybrid nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network comprising substantially interconnected pores, wherein the filaments have an elongate dimension and a first transverse dimension with the first transverse dimension being less than 500 nm (preferably less than 100 nm) and an aspect ratio of the elongate dimension to the first transverse dimension greater than 10; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises an anode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 20 μm (preferably less than 1 μm). Also provided is a lithium ion battery comprising such an electrode as an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

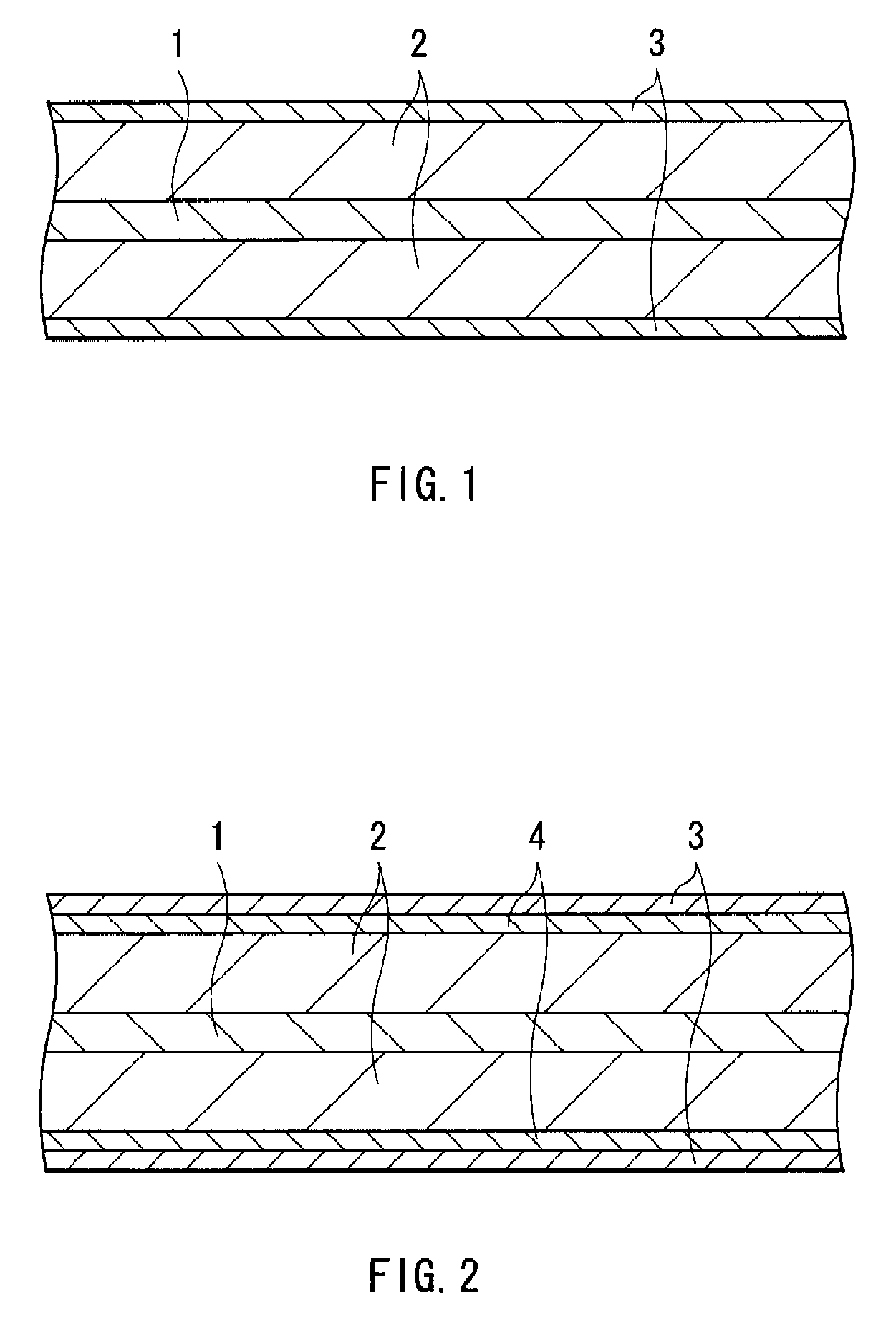

Method of manufacturing solid electrolyte battery

InactiveUS20050132562A1High trafficAvoid excessive power outputNon-aqueous electrolyte accumulatorsFinal product manufacturePolymer electrolytesBattery cell

A method of manufacturing a solid electrolyte battery includes a step of thermally pressing a composite layer including a positive electrode ink layer, an electrolyte ink layer and a negative electrode ink layer that are formed by coating a positive electrode ink, an electrolyte ink and a negative electrode ink. Further, the positive electrode ink, the electrolyte ink and the negative electrode ink contain a polymer electrolyte. By this method, it is possible to improve the flow of ions across respective interlayers of a positive electrode active material layer, a solid electrolyte layer and a negative electrode active material layer.

Owner:NISSAN MOTOR CO LTD

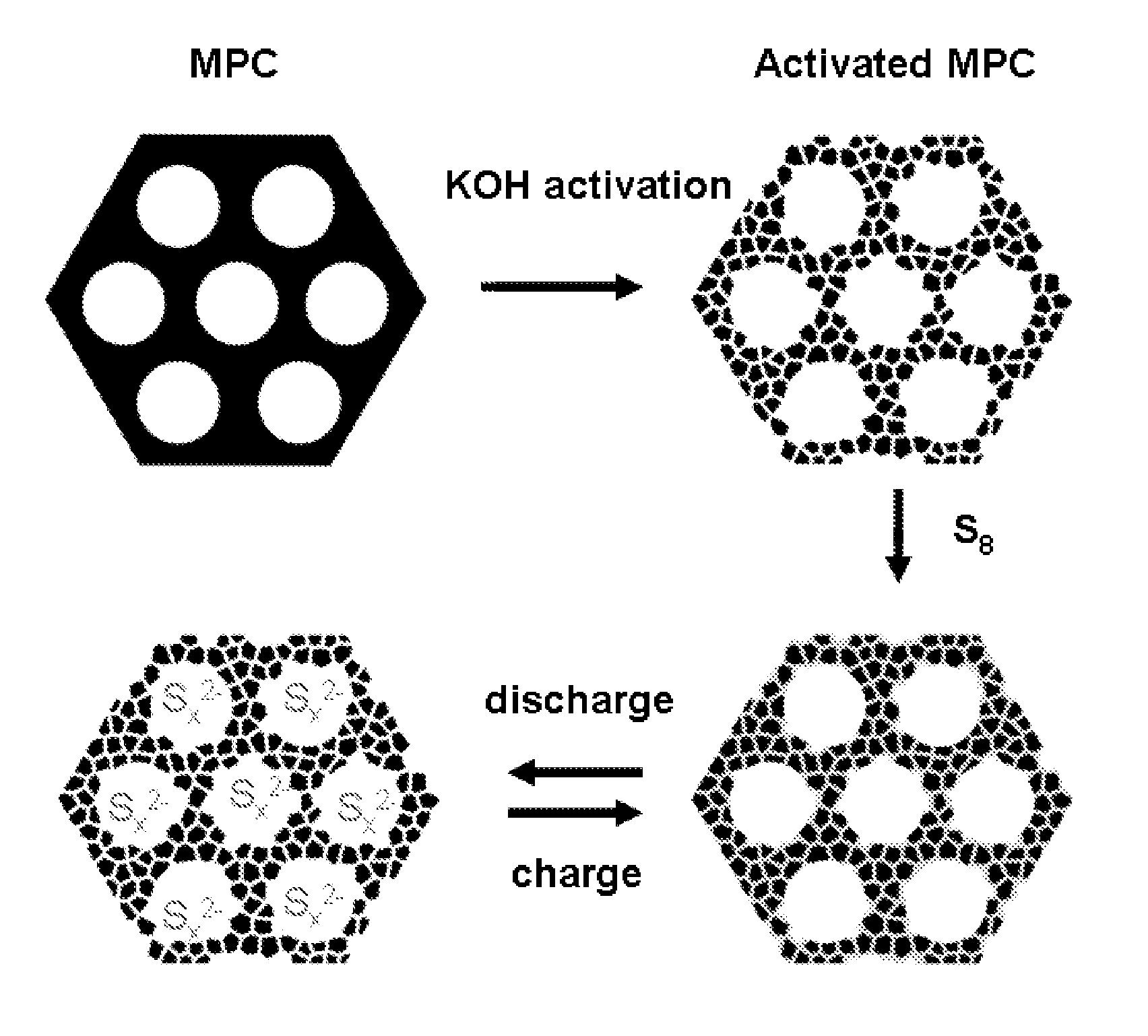

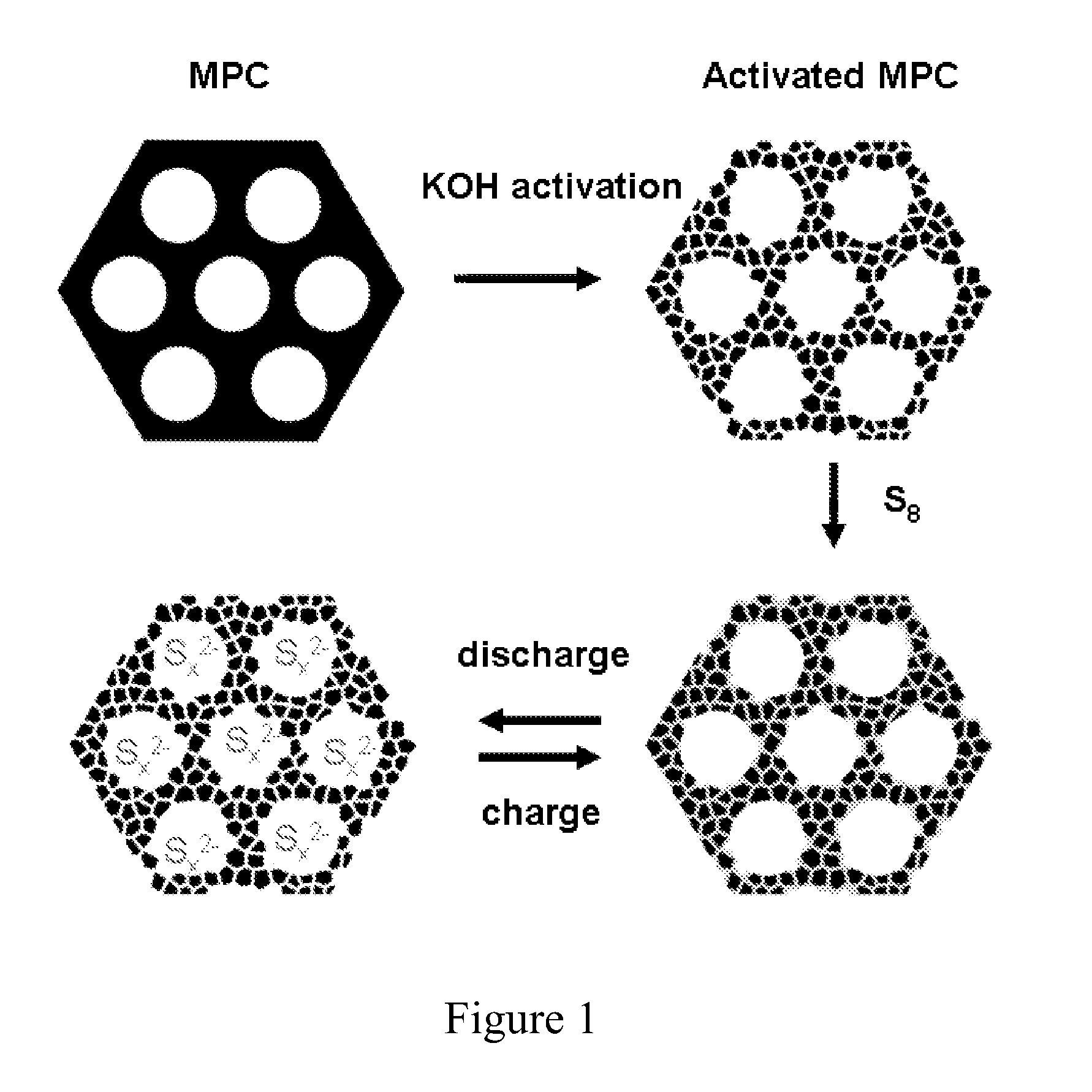

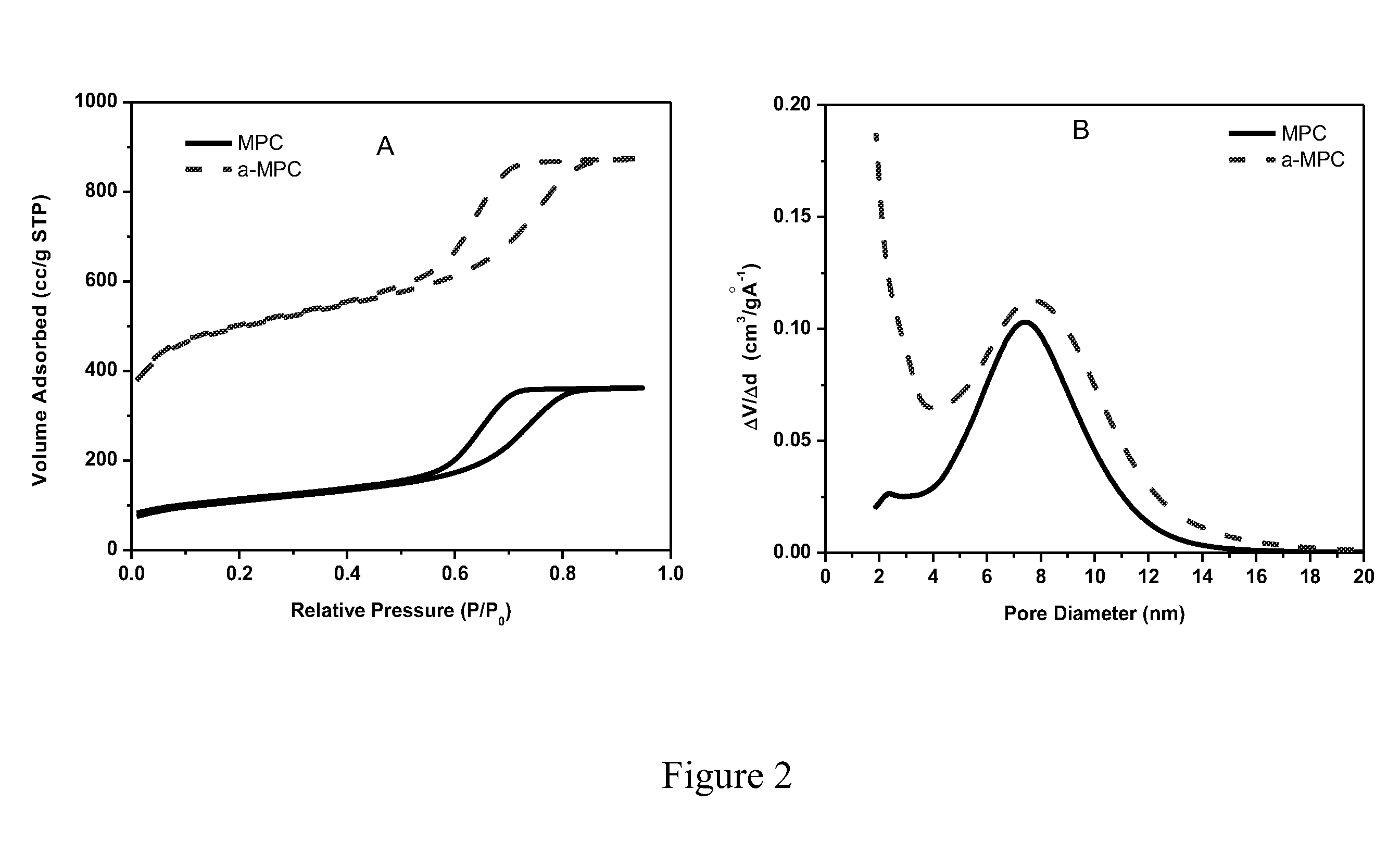

Sulfur-carbon nanocomposites and their application as cathode materials in lithium-sulfur batteries

ActiveUS20110052998A1Minimize formationEasy to transportAlkaline accumulatorsElectrode thermal treatmentCarbon compositesPorous carbon

The invention is directed in a first aspect to a sulfur-carbon composite material comprising: (i) a bimodal porous carbon component containing therein a first mode of pores which are mesopores, and a second mode of pores which are micropores; and (ii) elemental sulfur contained in at least a portion of said micropores. The invention is also directed to the aforesaid sulfur-carbon composite as a layer on a current collector material; a lithium ion battery containing the sulfur-carbon composite in a cathode therein; as well as a method for preparing the sulfur-composite material.

Owner:UT BATTELLE LLC

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

ActiveUS20090169725A1High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentChemical LinkageFiber

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6165644AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

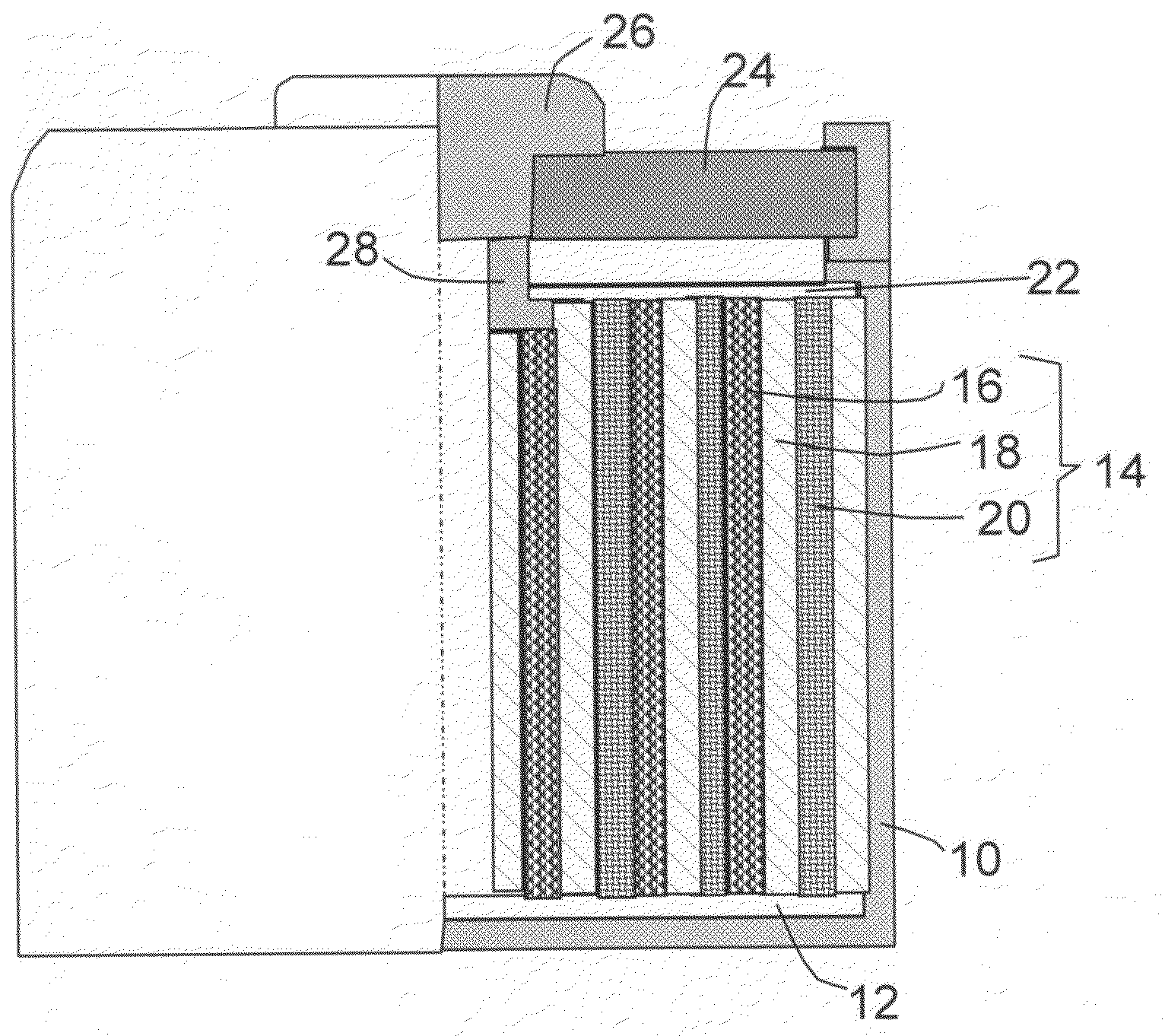

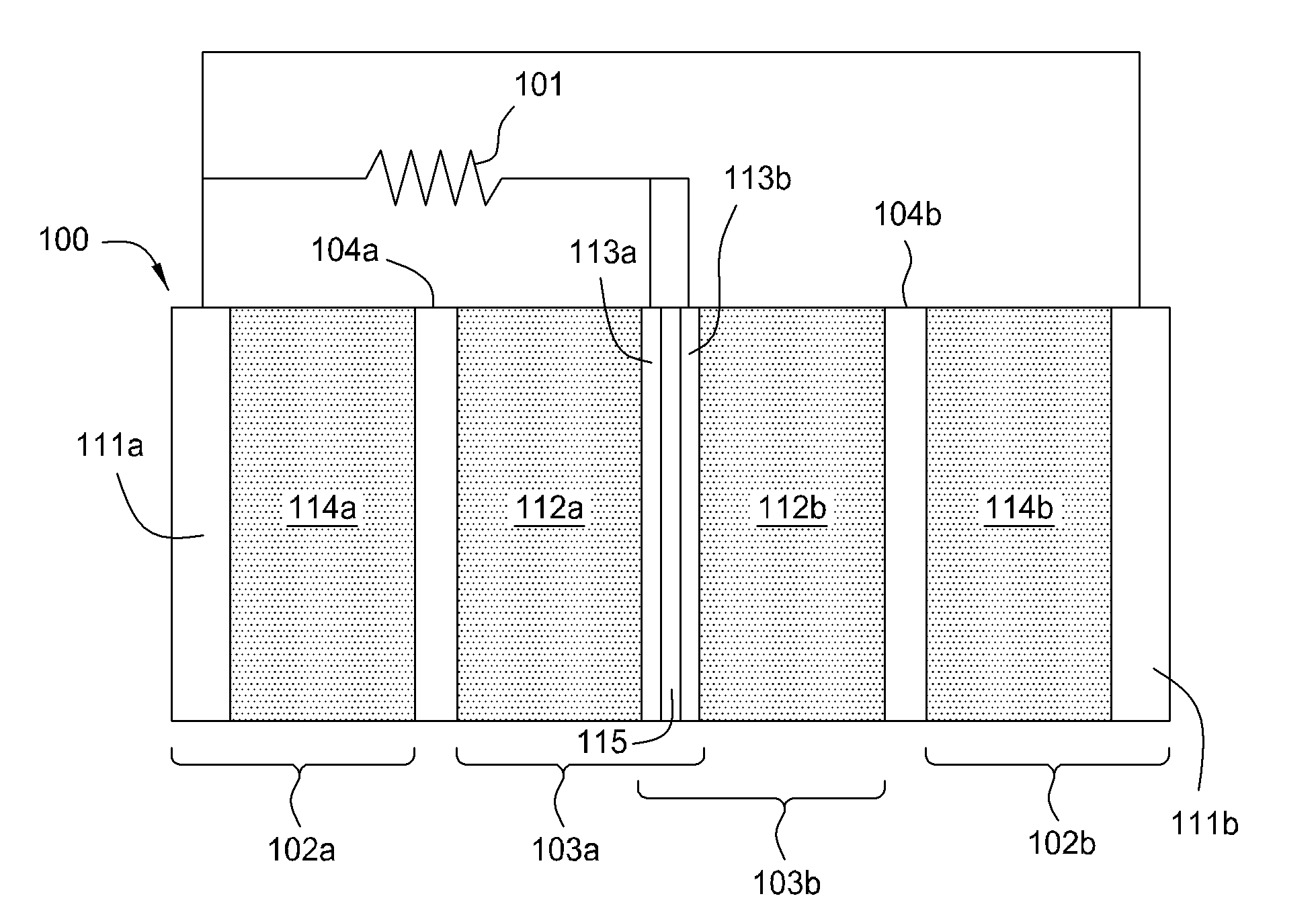

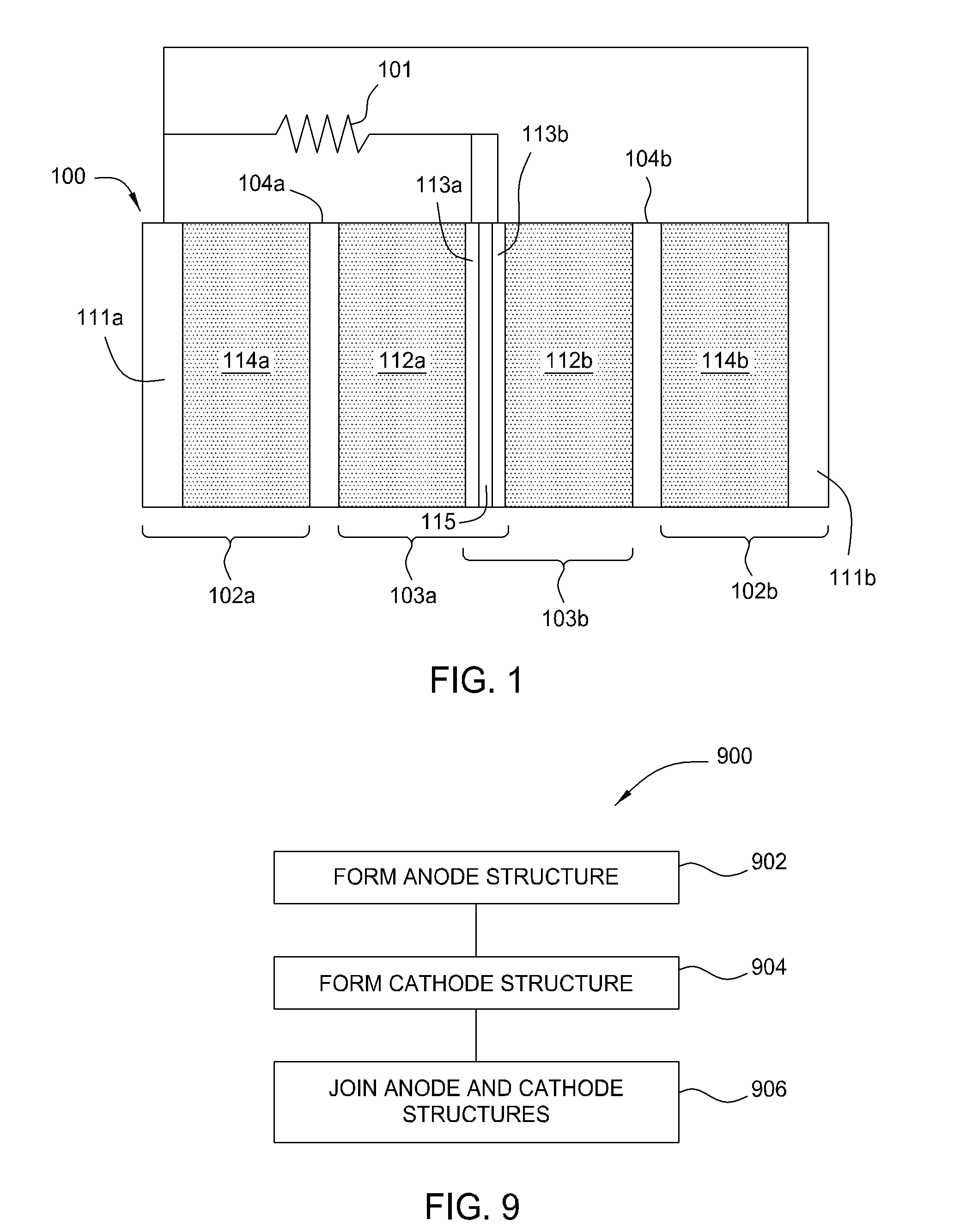

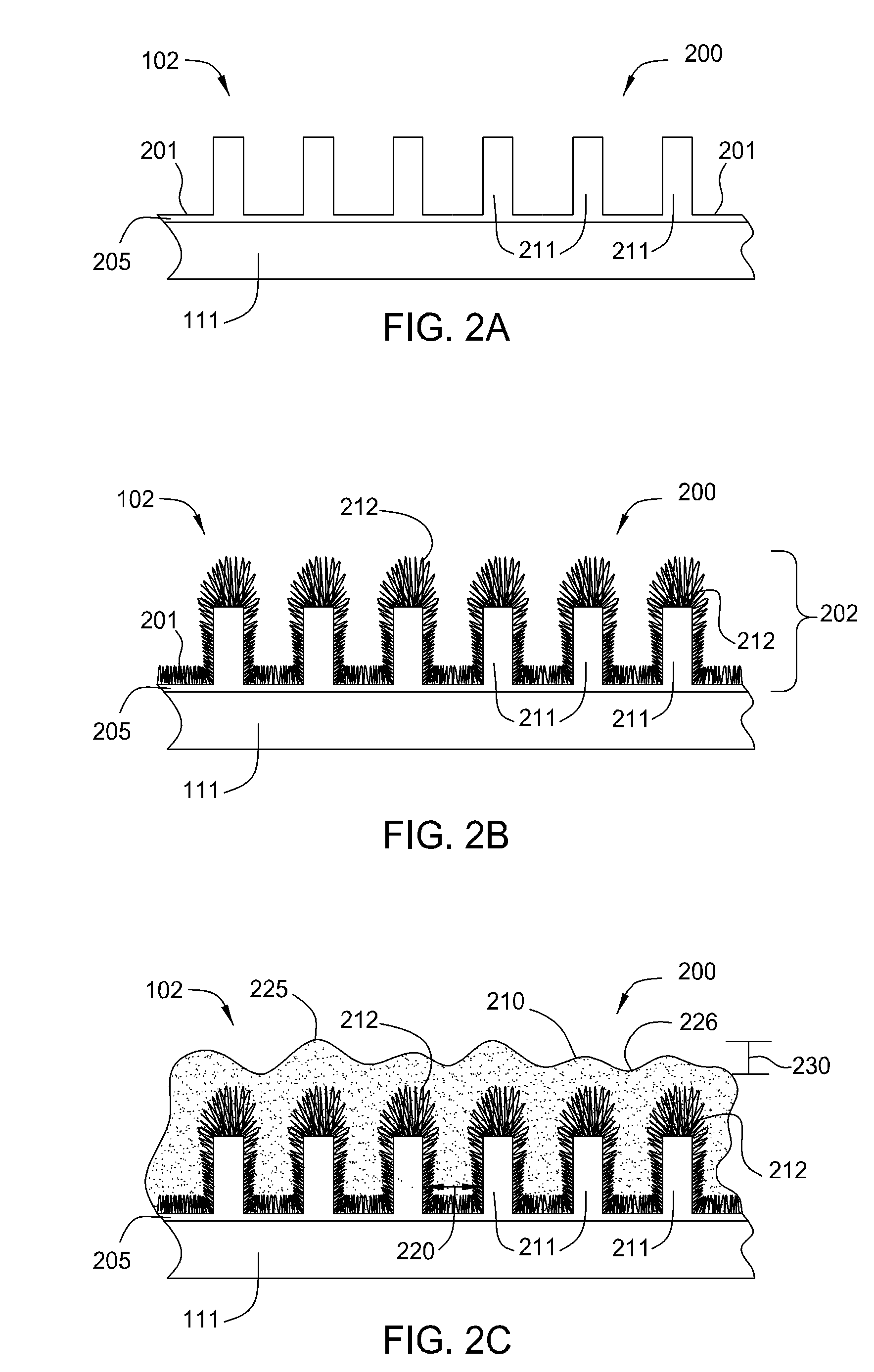

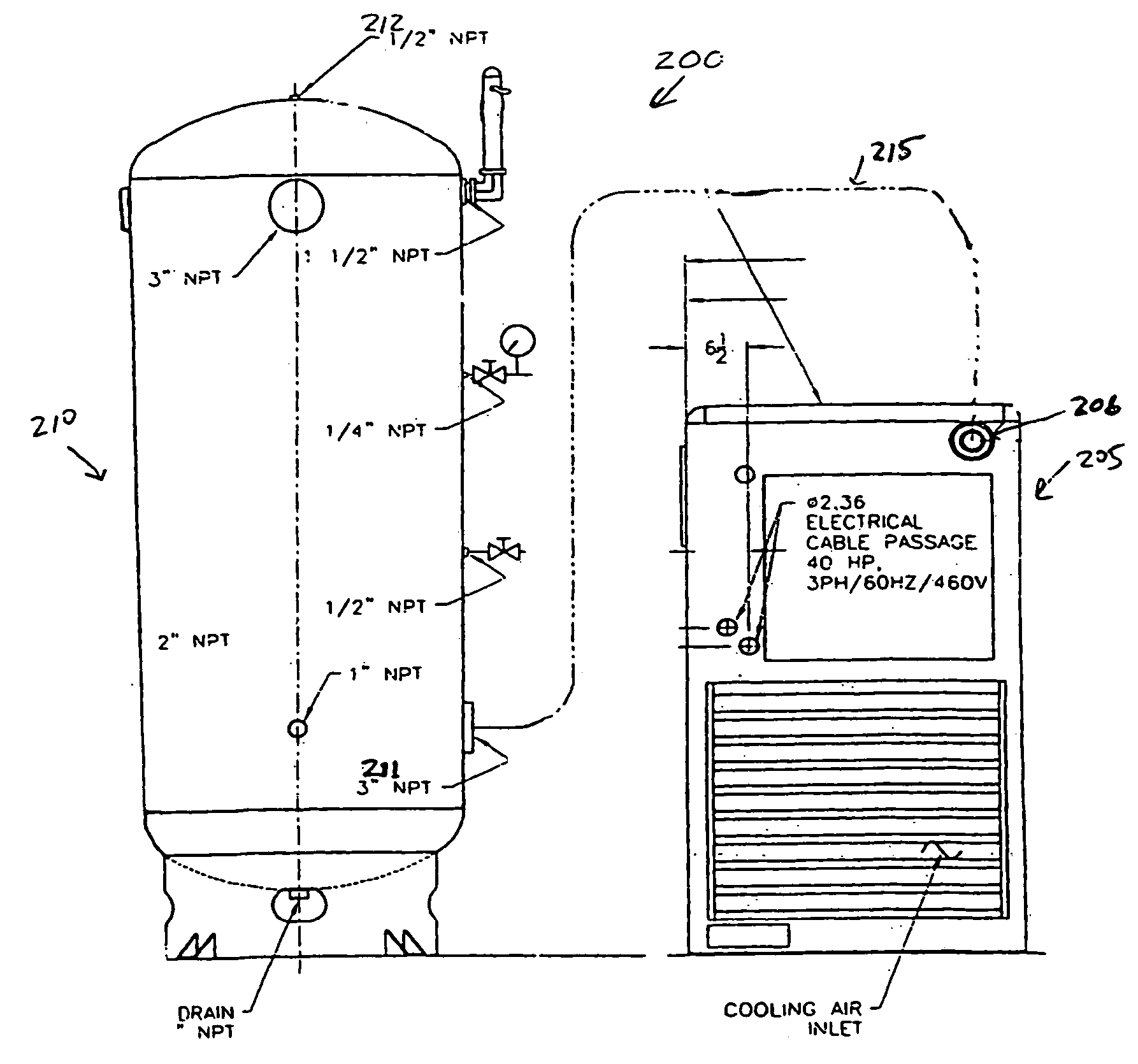

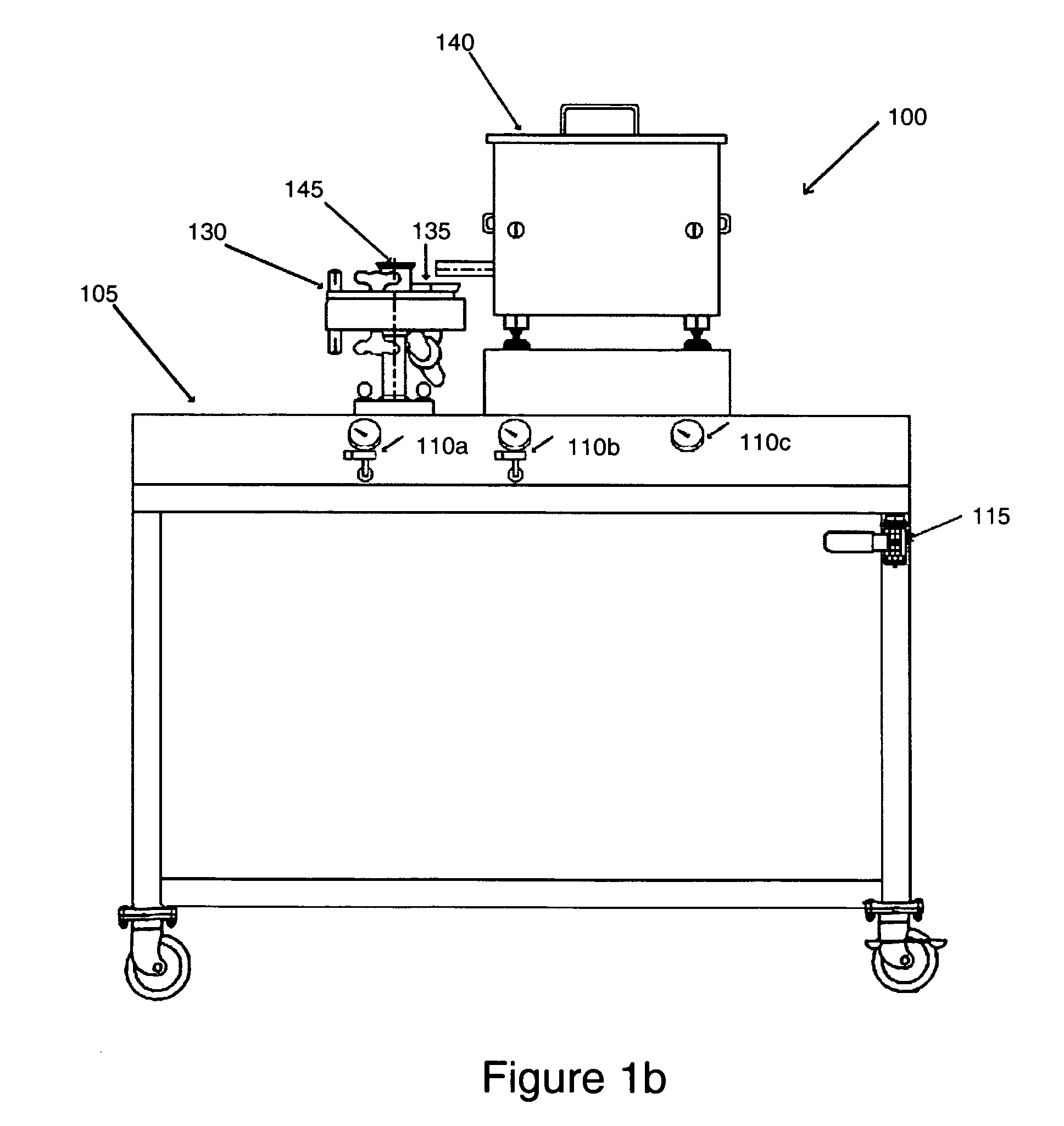

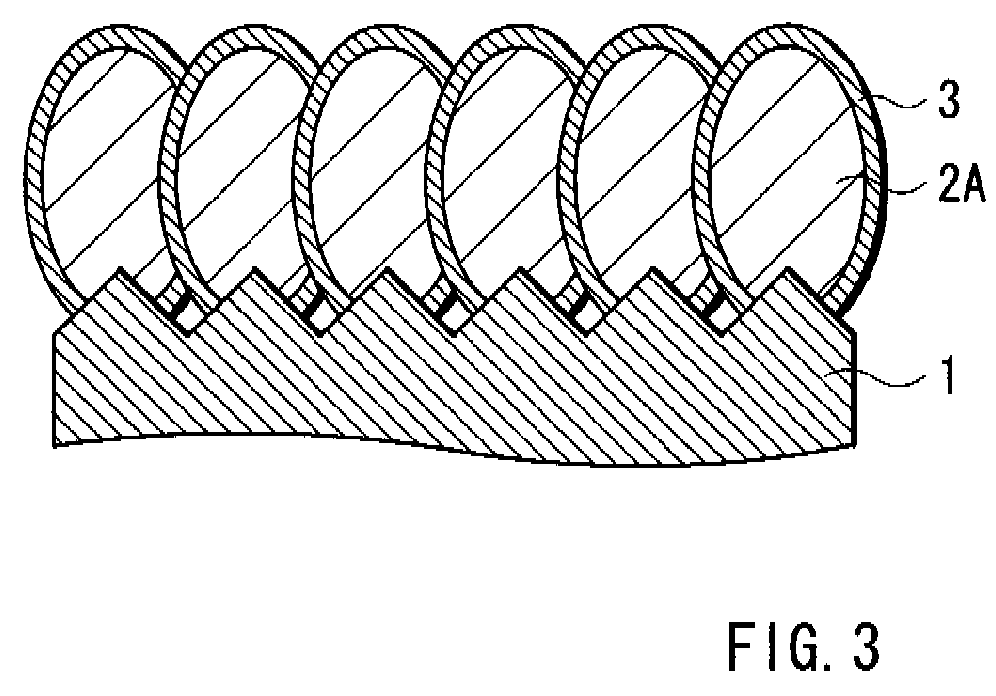

Compressed powder 3D battery electrode manufacturing

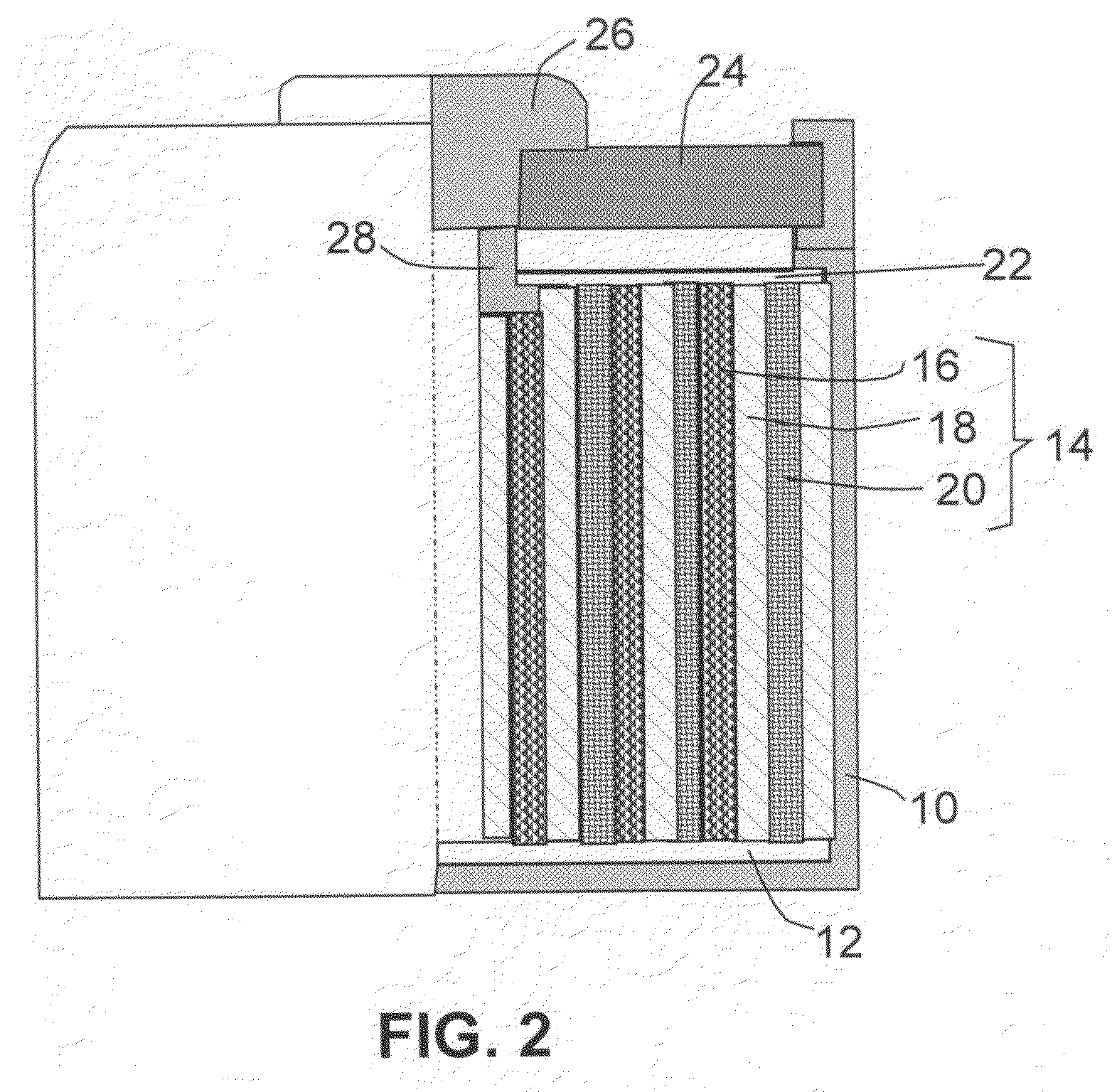

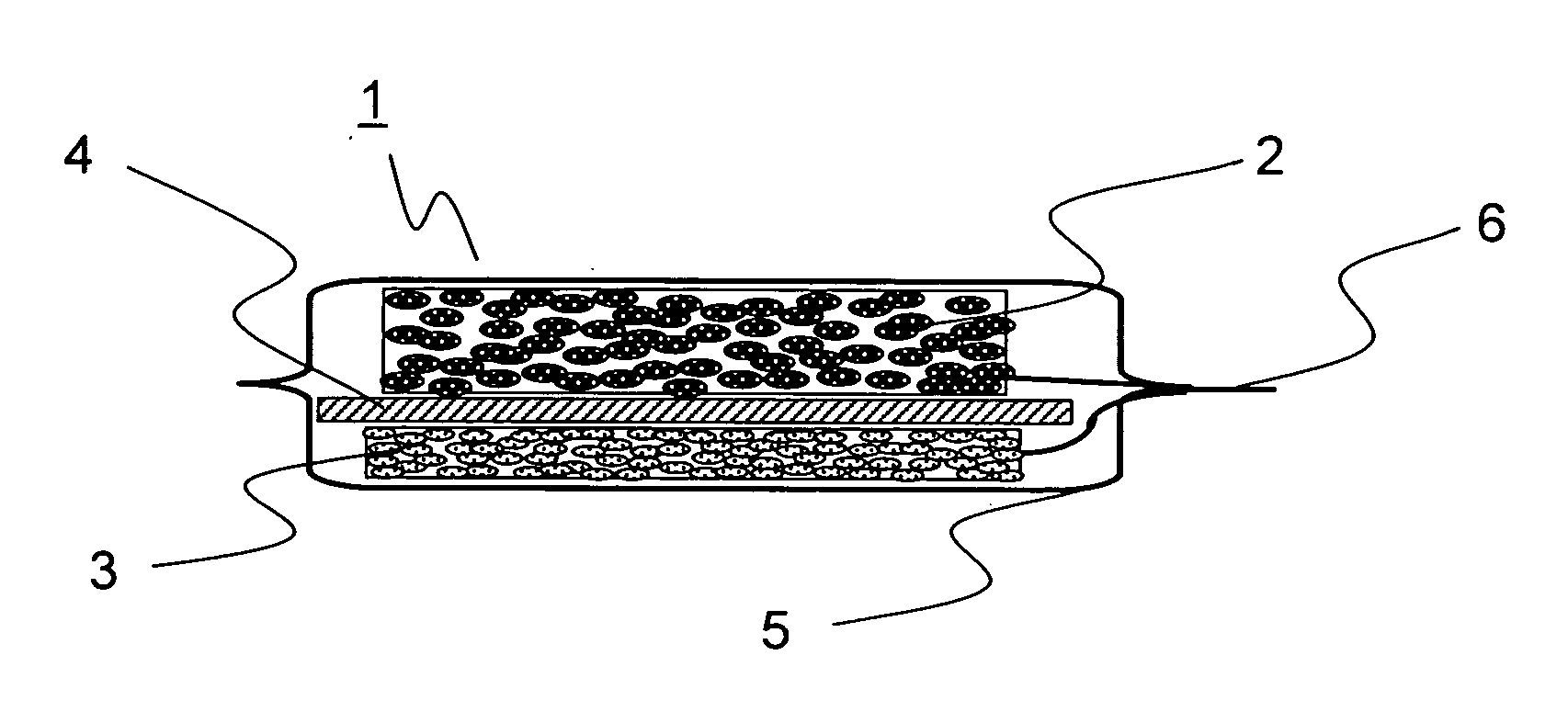

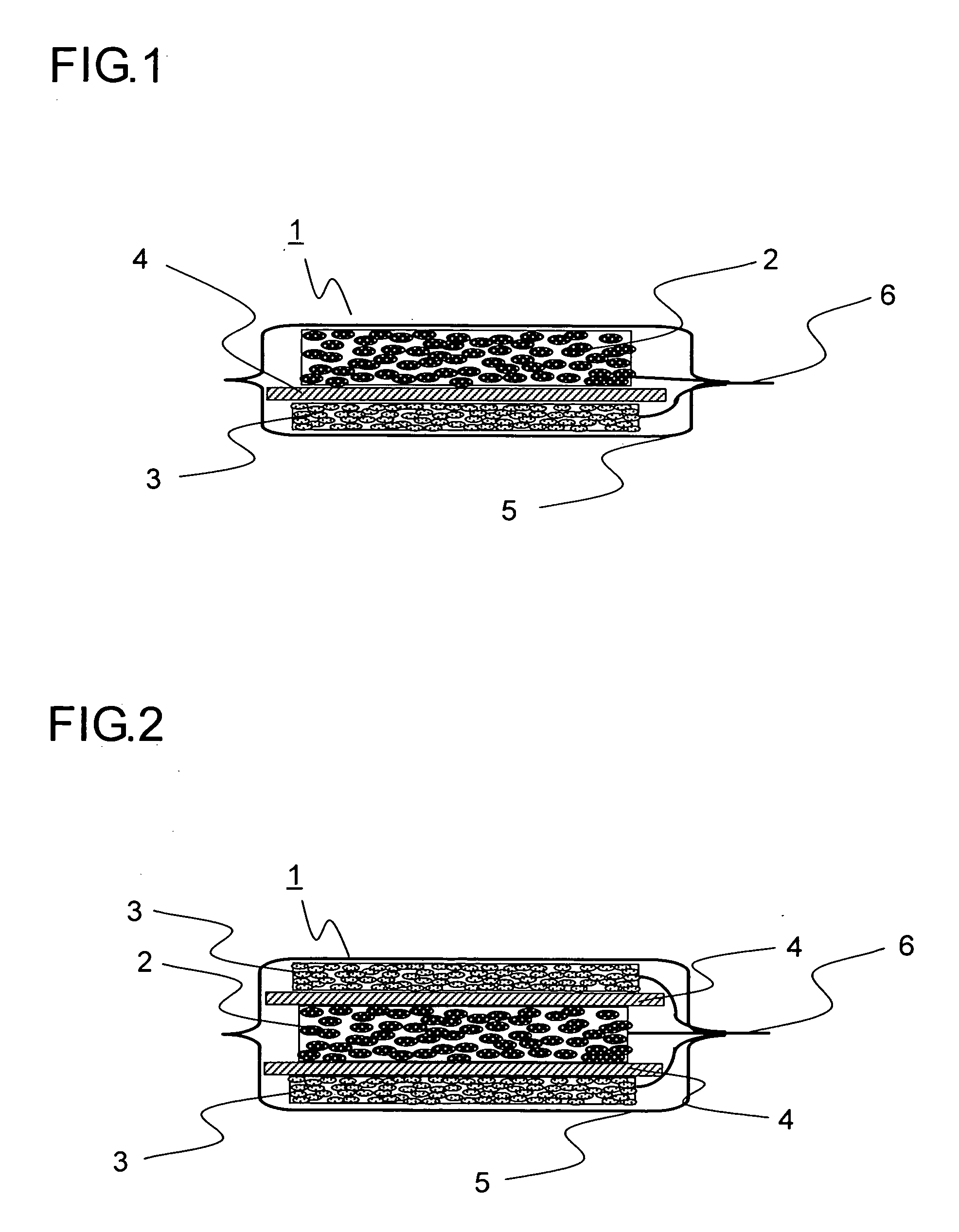

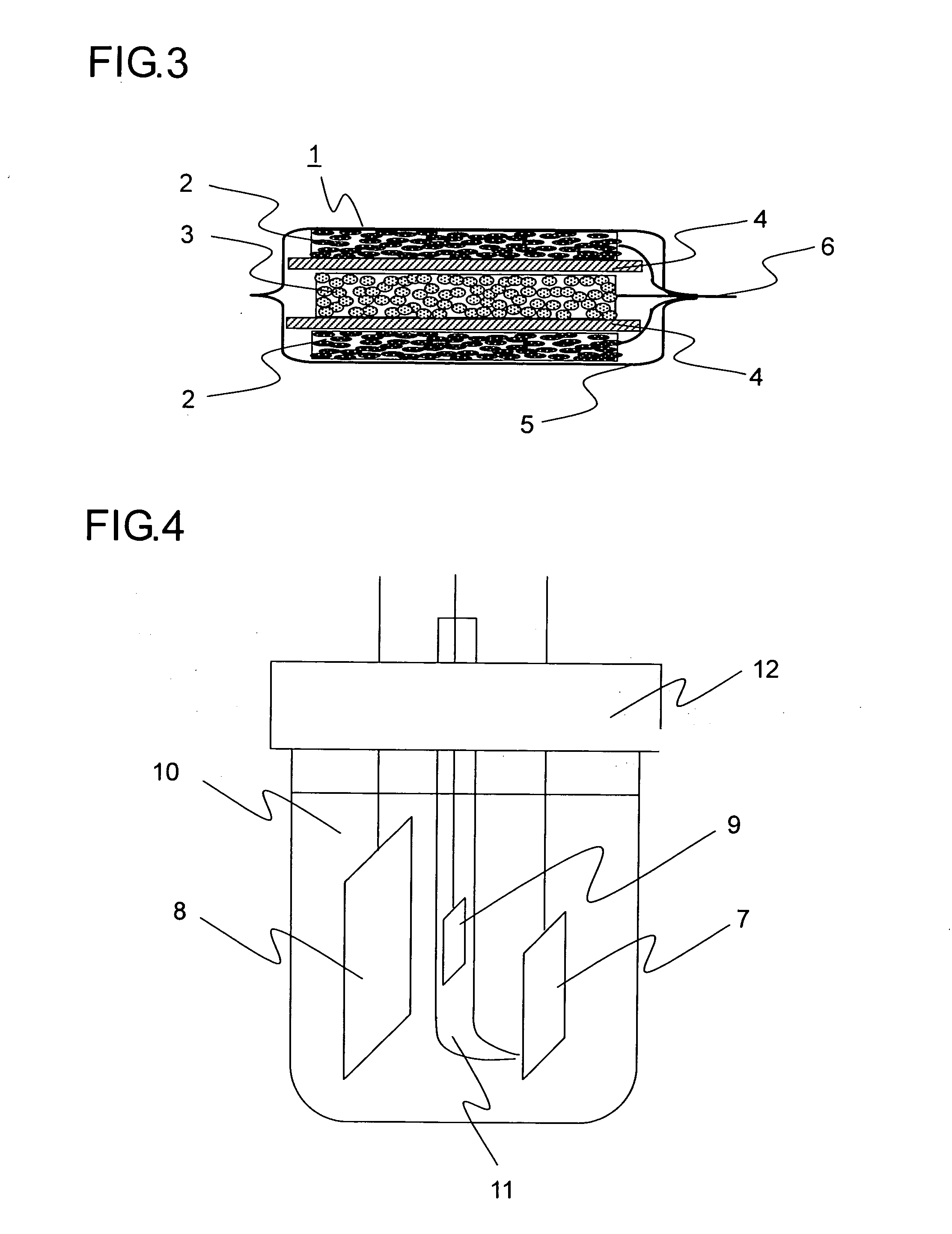

Embodiments of the invention contemplate forming an electrochemical device and device components, such as a battery cell or supercapacitor, using thin-film or layer deposition processes and other related methods for forming the same. In one embodiment, a battery bi-layer cell is provided. The battery bi-layer cell comprises an anode structure comprising a conductive collector substrate, a plurality of pockets formed on the conductive collector substrate by conductive microstructures comprising a plurality of columnar projections, and an anodically active powder deposited in and over the plurality of pockets, an insulative separator layer formed over the plurality of pockets, and a cathode structure joined over the insulative separator.

Owner:APPLIED MATERIALS INC

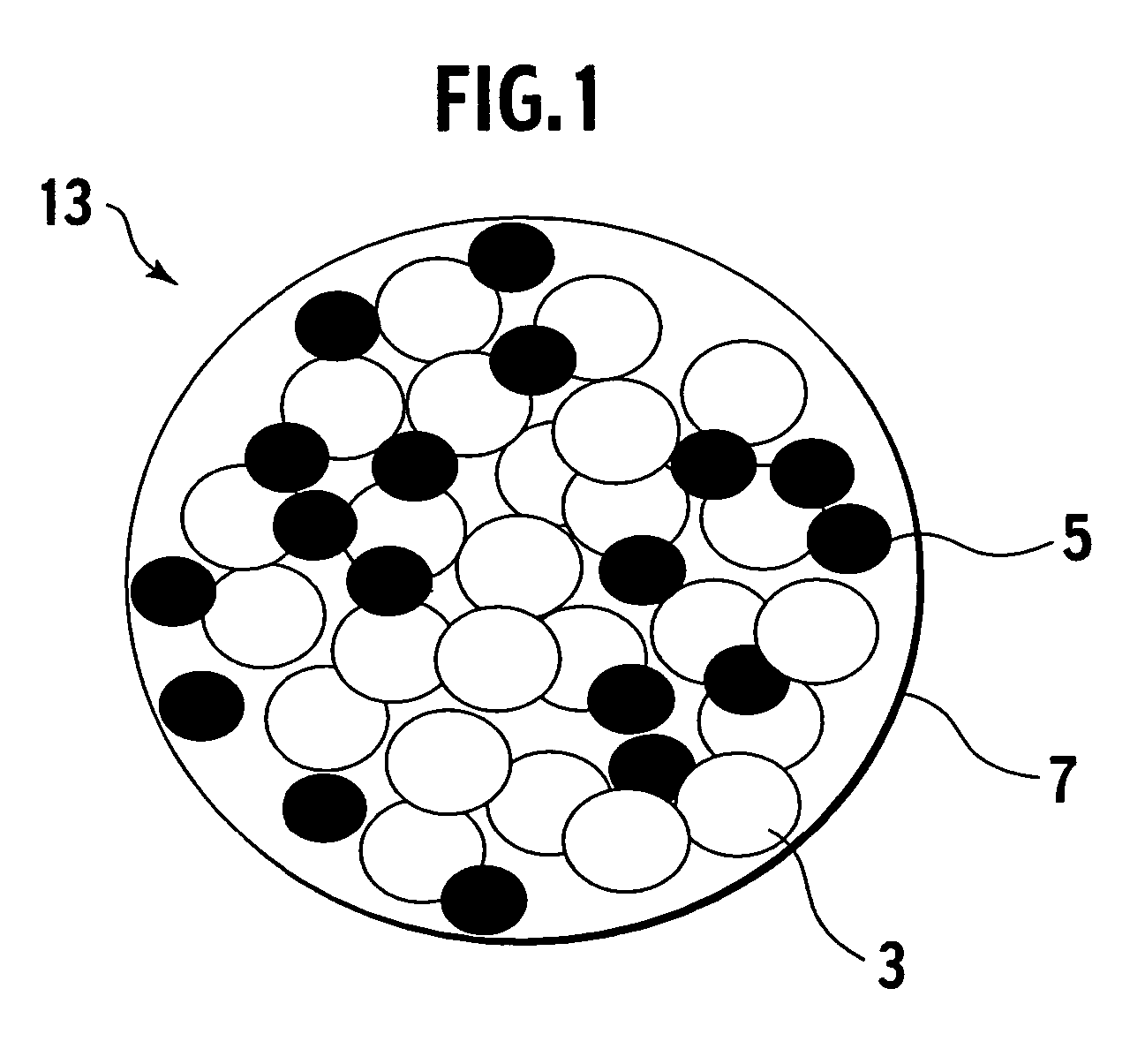

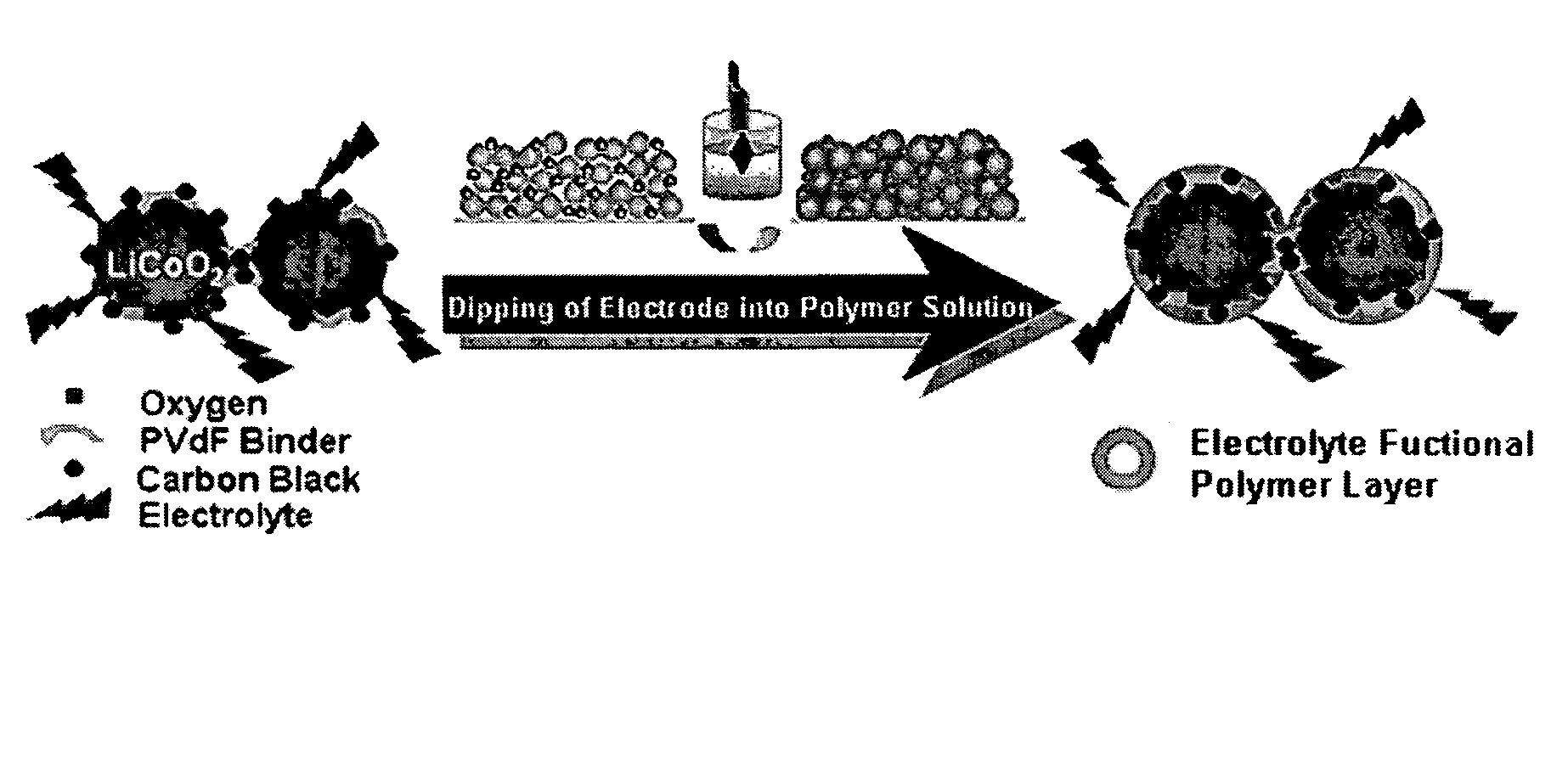

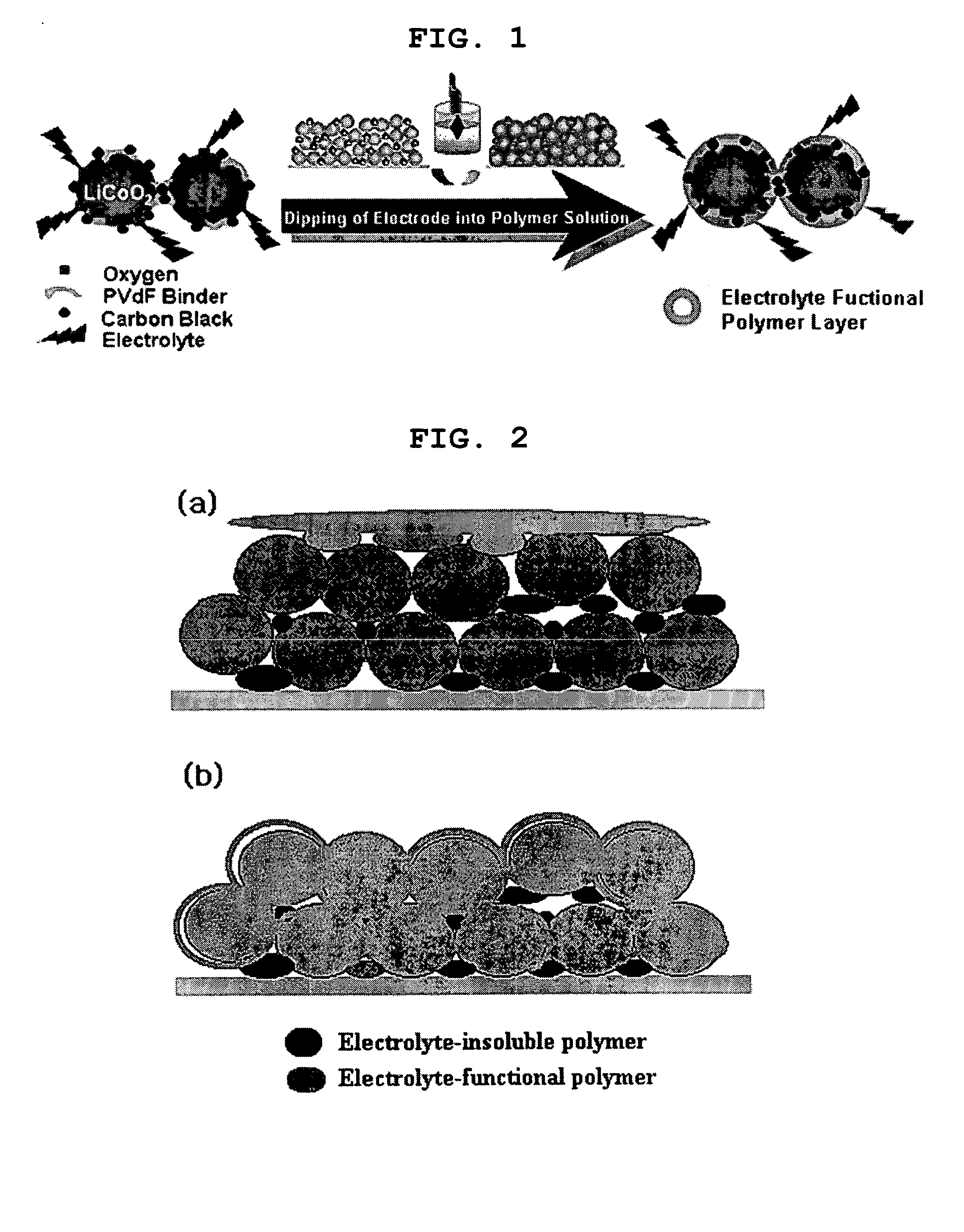

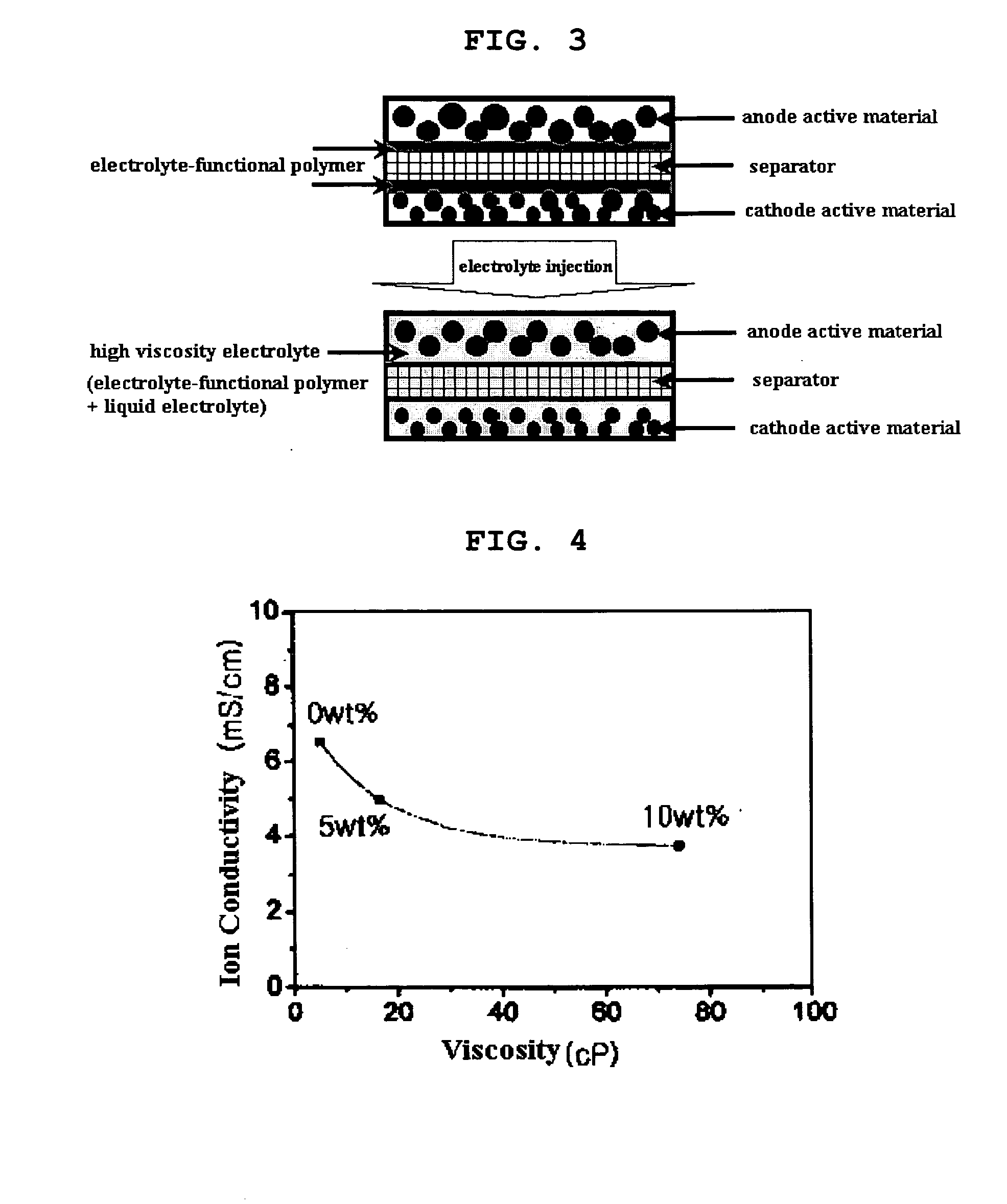

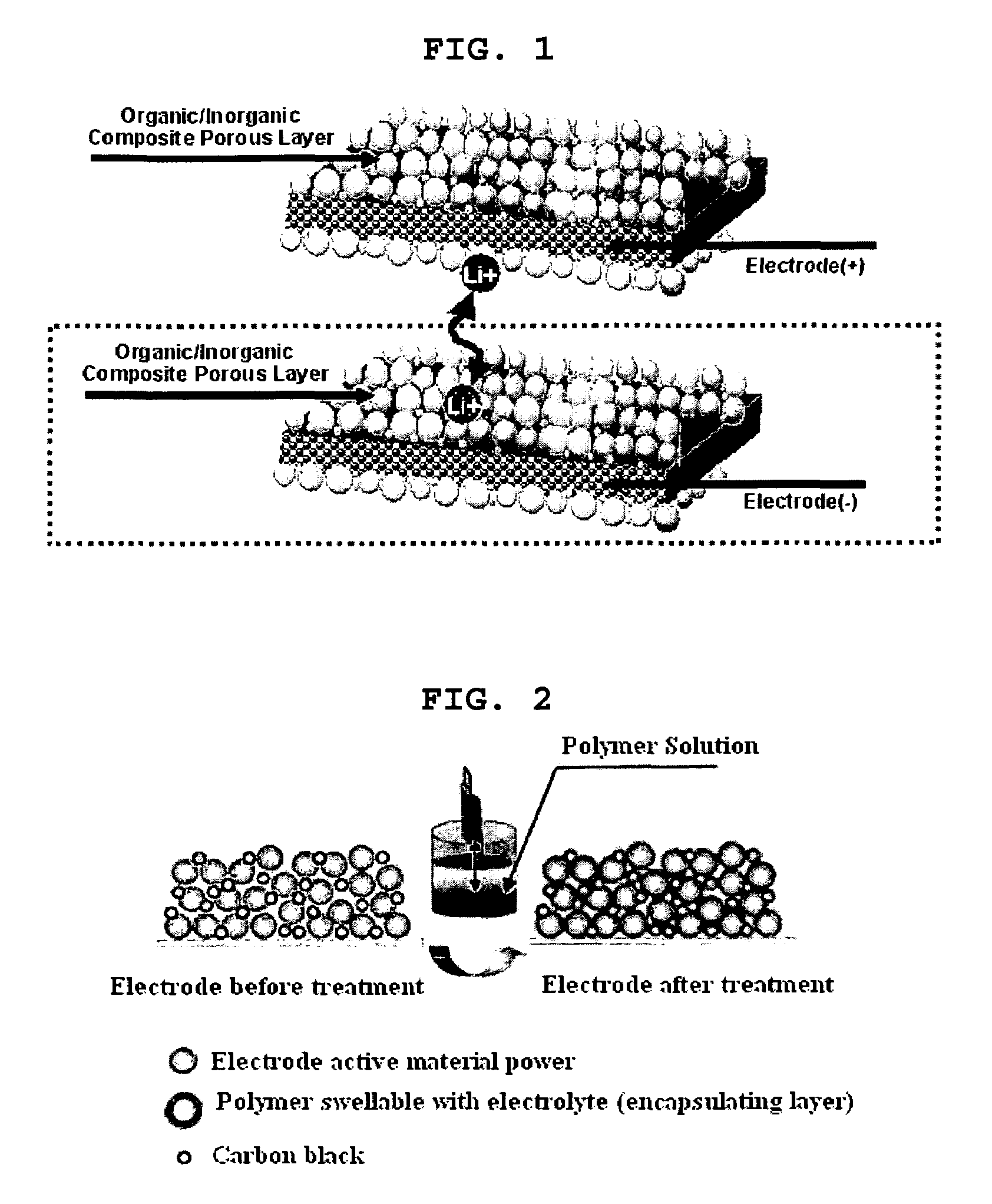

Functional polymer film-coated electrode and electrochemical device using the same

ActiveUS20050118508A1Lower performance requirementsImprove battery safetyGel electrodesElectrode carriers/collectorsSlurryPolymer thin films

The present invention provides an electrode in which an electrode active material particles as being interconnected are applied on current collector, wherein the interconnected surface of electrode active material particles is coated with a polymer, the polymer being present as an independent phase, while maintaining a pore structure formed among the interconnected electrode active material particles as well as an electrochemical device including the electrode. Also, the present invention provides a method for manufacturing an electrode coated with a polymer present on an interconnected surface of electrode active material as an independent phase, while maintaining a pore structure formed among the electrode active material particles, which comprises the steps of: (a) coating slurry for an electrode including an electrode active material on a current collector and drying it to form an electrode; and (b) dipping the electrode obtained from step (a) into a solution containing the polymer dissolved therein and a method for manufacturing an electrochemical device comprising the electrode obtained by the above method. The electrode coated with a polymer as an independent phase provides an electrochemical device with improved safety and prevents degradation of performance of an electrochemical device.

Owner:LG ENERGY SOLUTION LTD

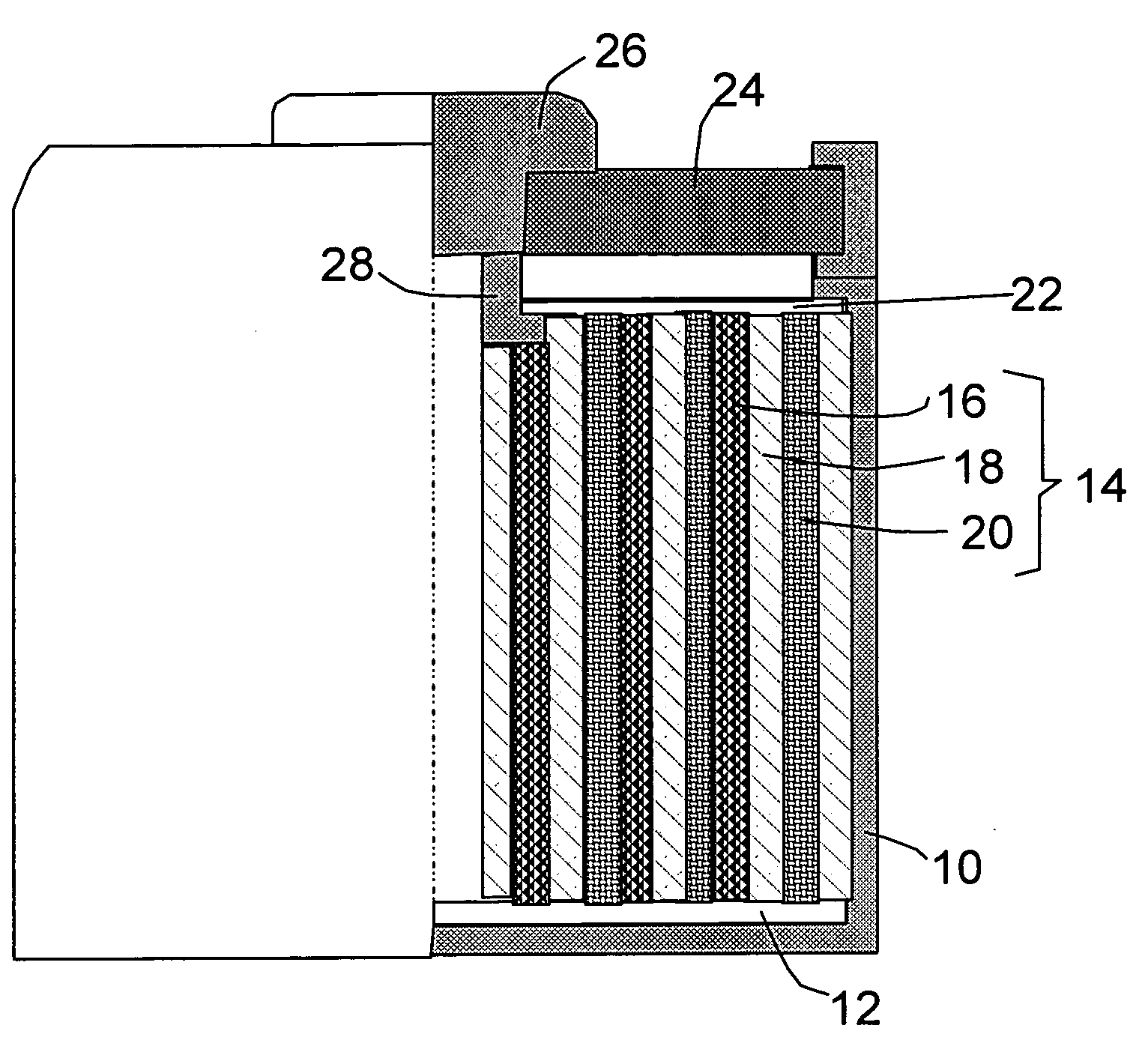

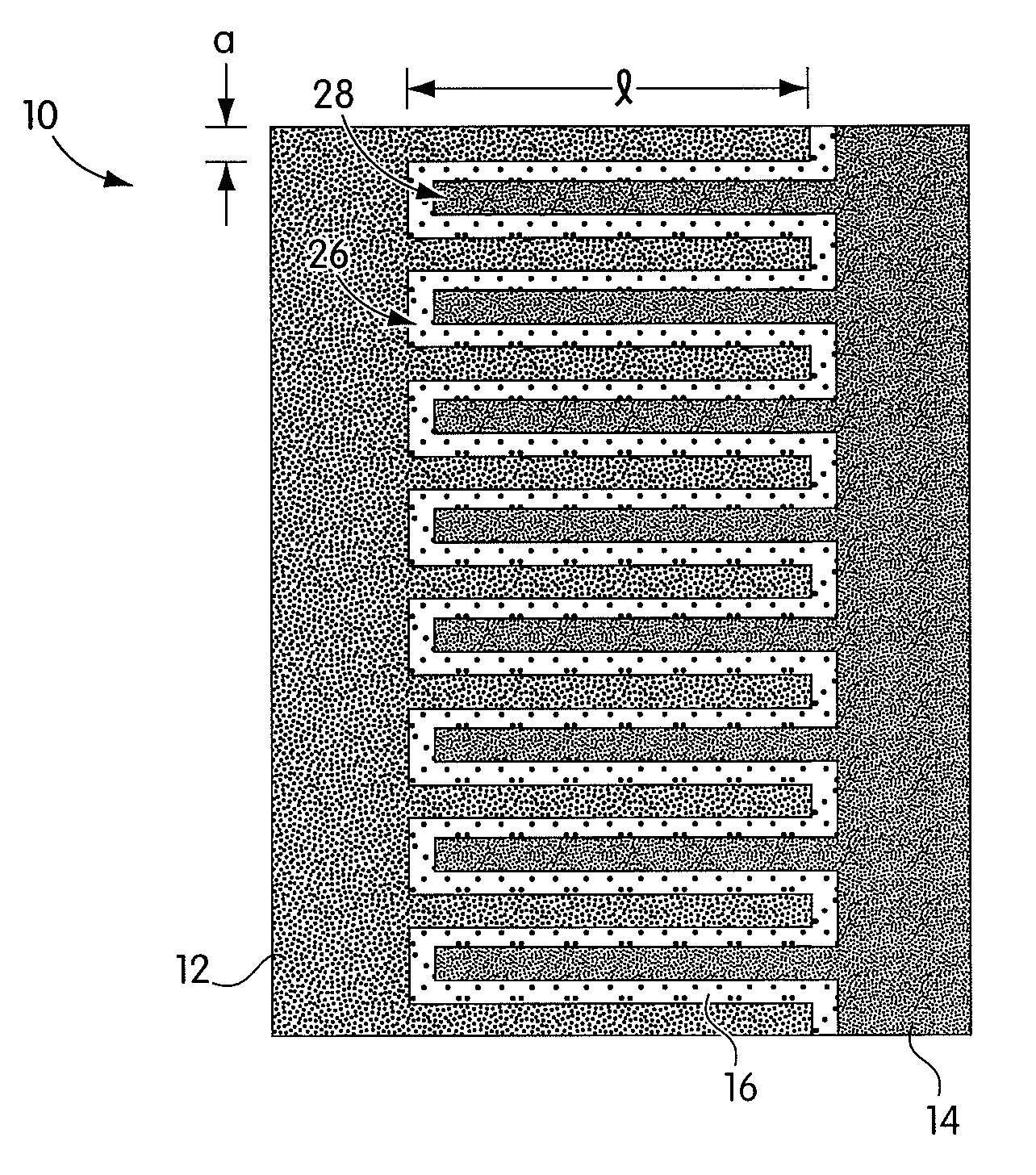

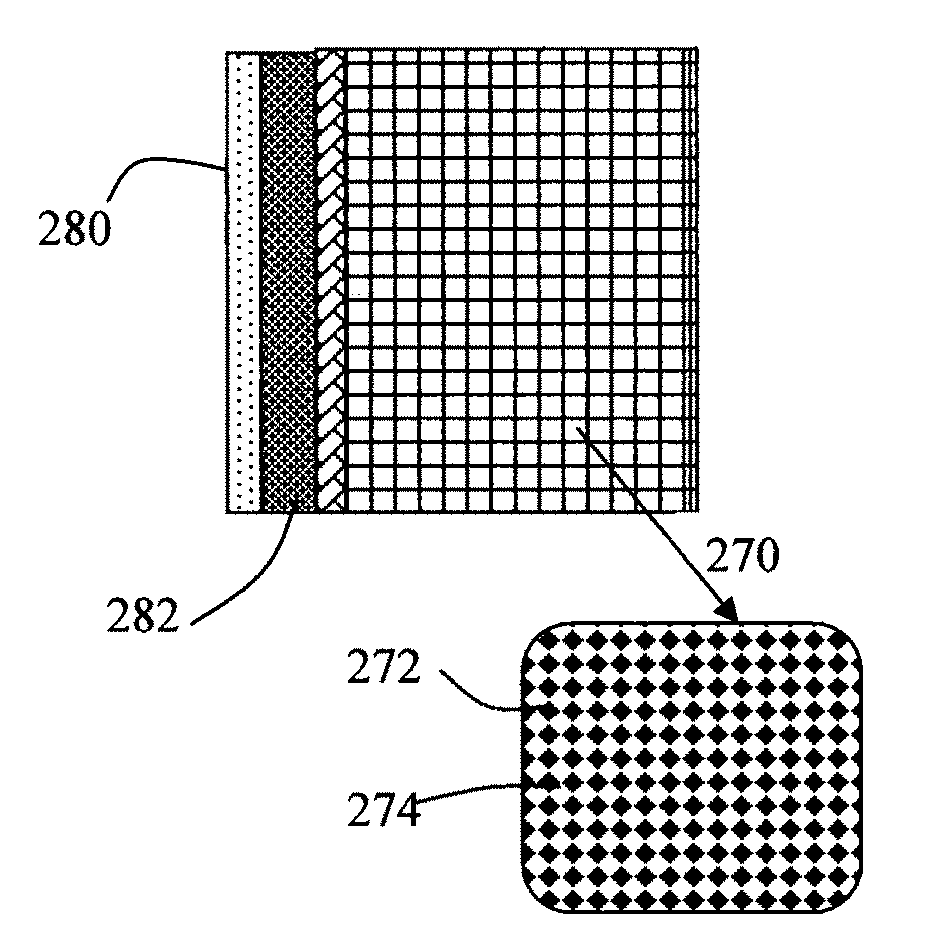

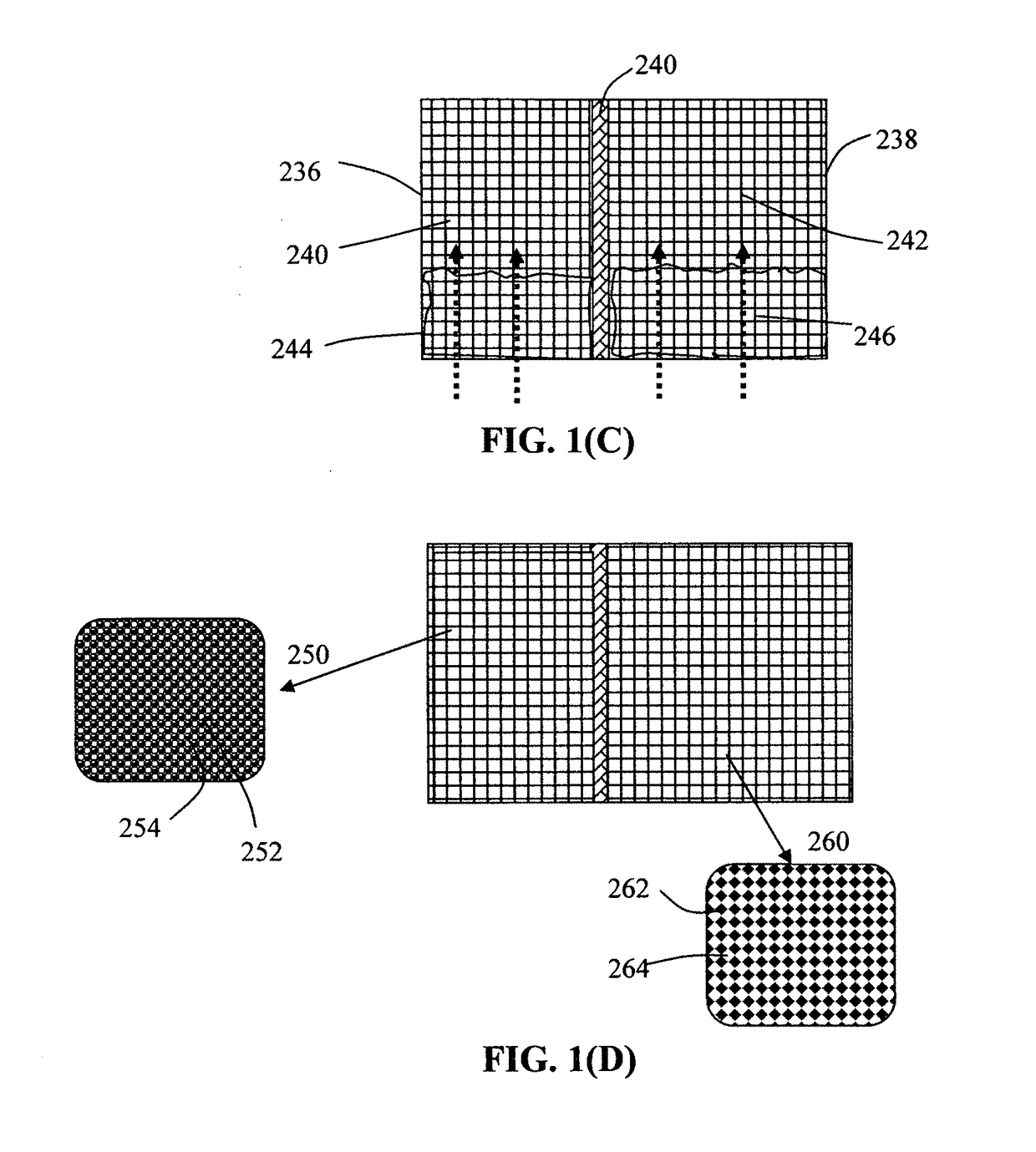

Reticulated and controlled porosity battery structures

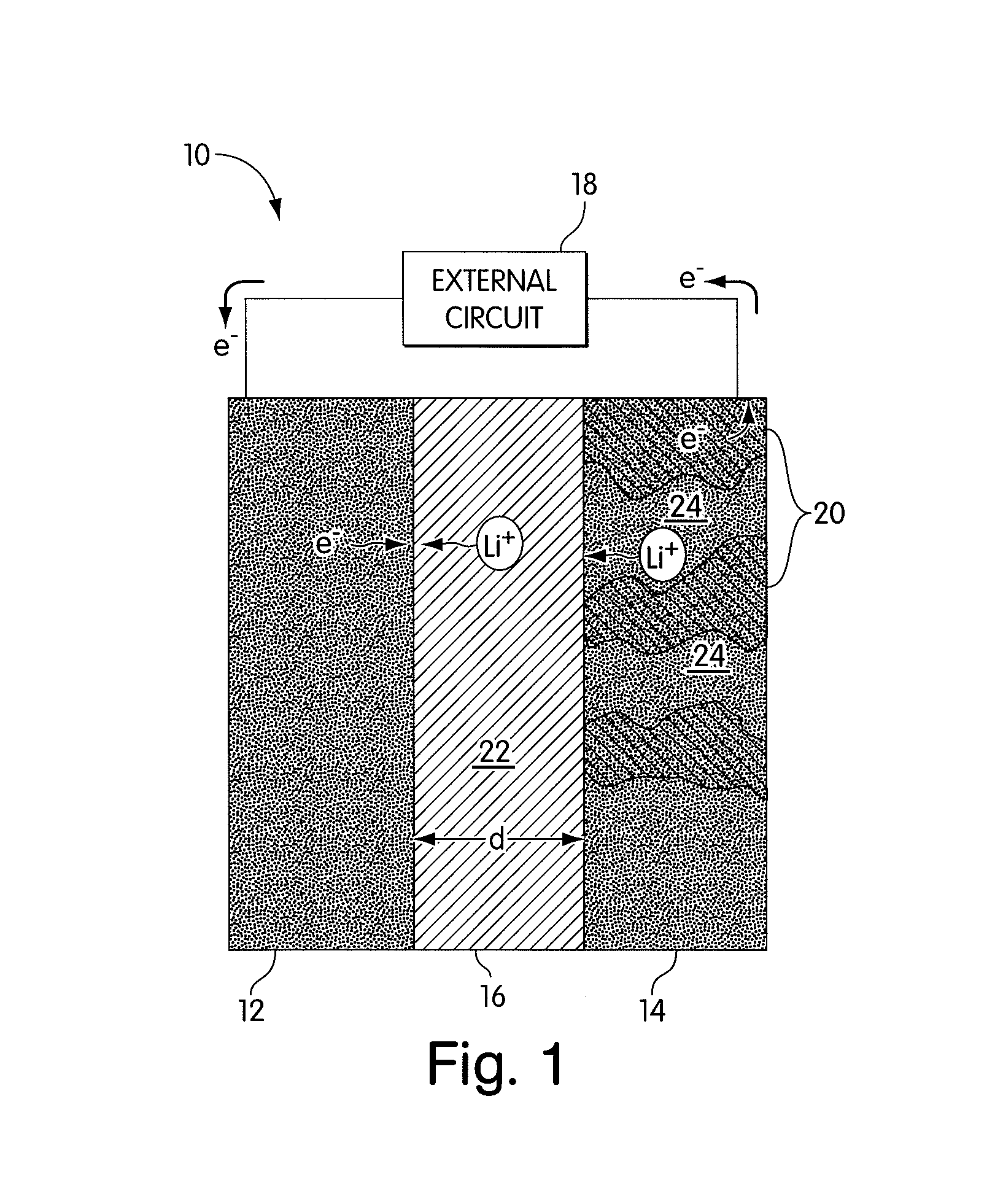

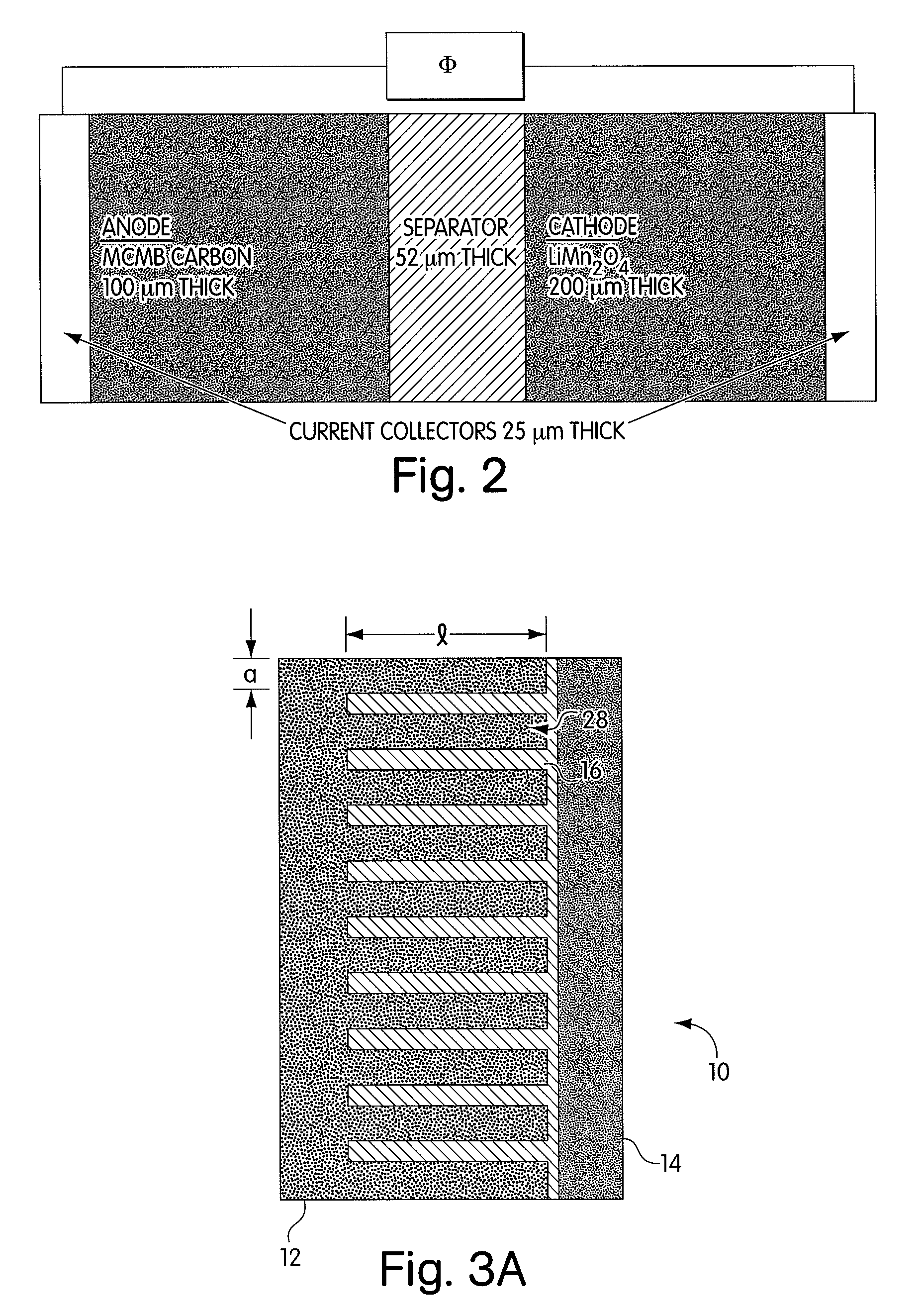

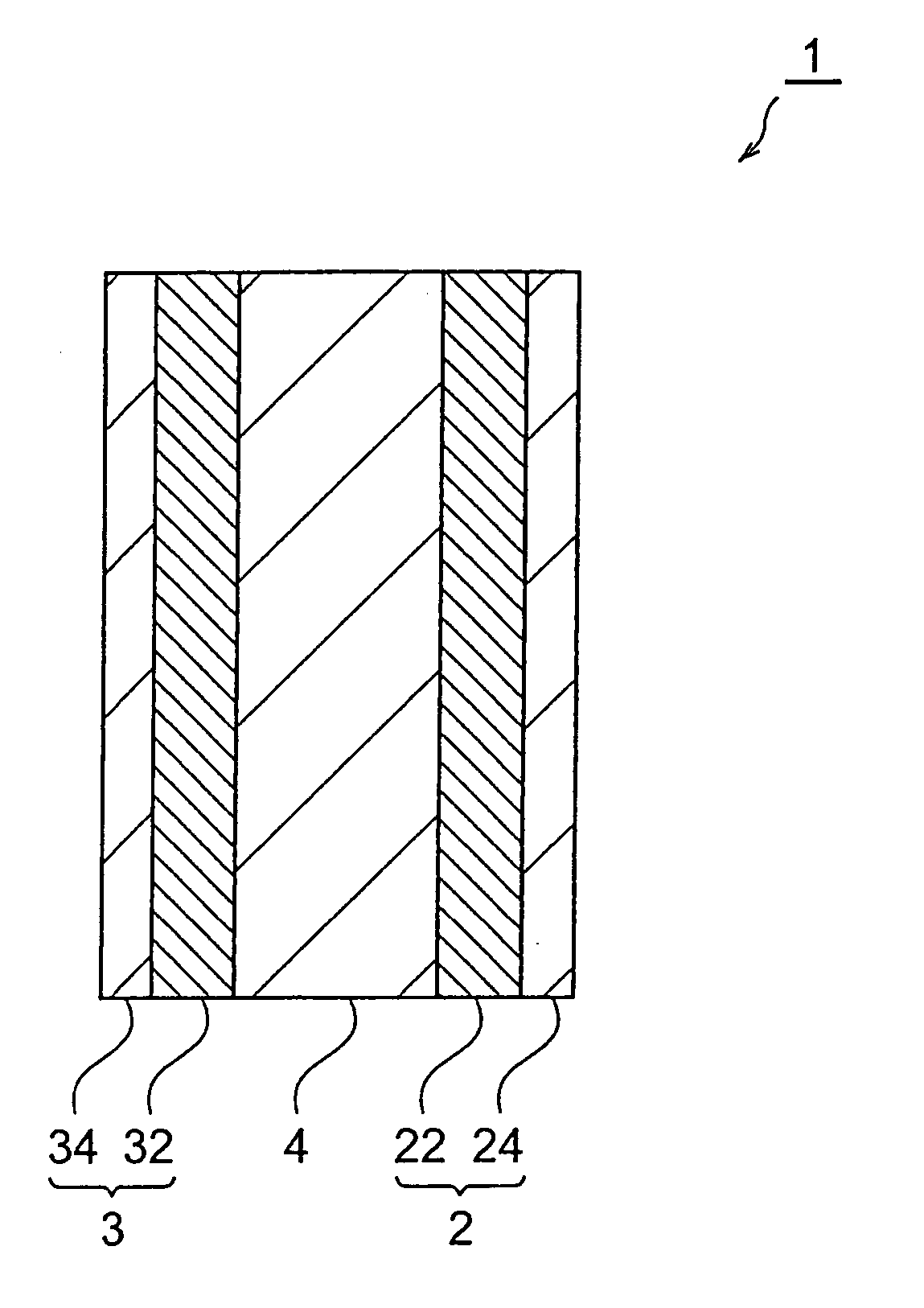

InactiveUS7553584B2Boost energyHigh porosityElectrode thermal treatmentElectrolytic capacitorsEngineeringTortuous retinal vessels

The effective ionic conductivity in a composite structure is believed to decrease rapidly with volume fraction. A system, such as a bipolar device or energy storage device, has structures or components in which the diffusion length or path that electrodes or ions must traverse is minimized and the interfacial area exposed to the ions or electrons is maximized. The device includes components that can be reticulated or has a reticulated interface so that an interface area can be increased. The increased interfacial perimeter increases the available sites for reaction of ionic species. Many different reticulation patterns can be used. The aspect ratio of the reticulated features can be varied. Such bipolar devices can be fabricated by a variety of methods or procedures. A bipolar device having structures of reticulated interface can be tailored for the purposes of controlling and optimizing charge and discharge kinetics. A bipolar device having graded porosity structures can have improved transport properties because the diffusion controlling reaction kinetics can be modified. Graded porosity electrodes can be linearly or nonlinearly graded. A bipolar device having perforated structures also provides improved transport properties by removing tortuosity and reducing diffusion distance.

Owner:MASSACHUSETTS INST OF TECH

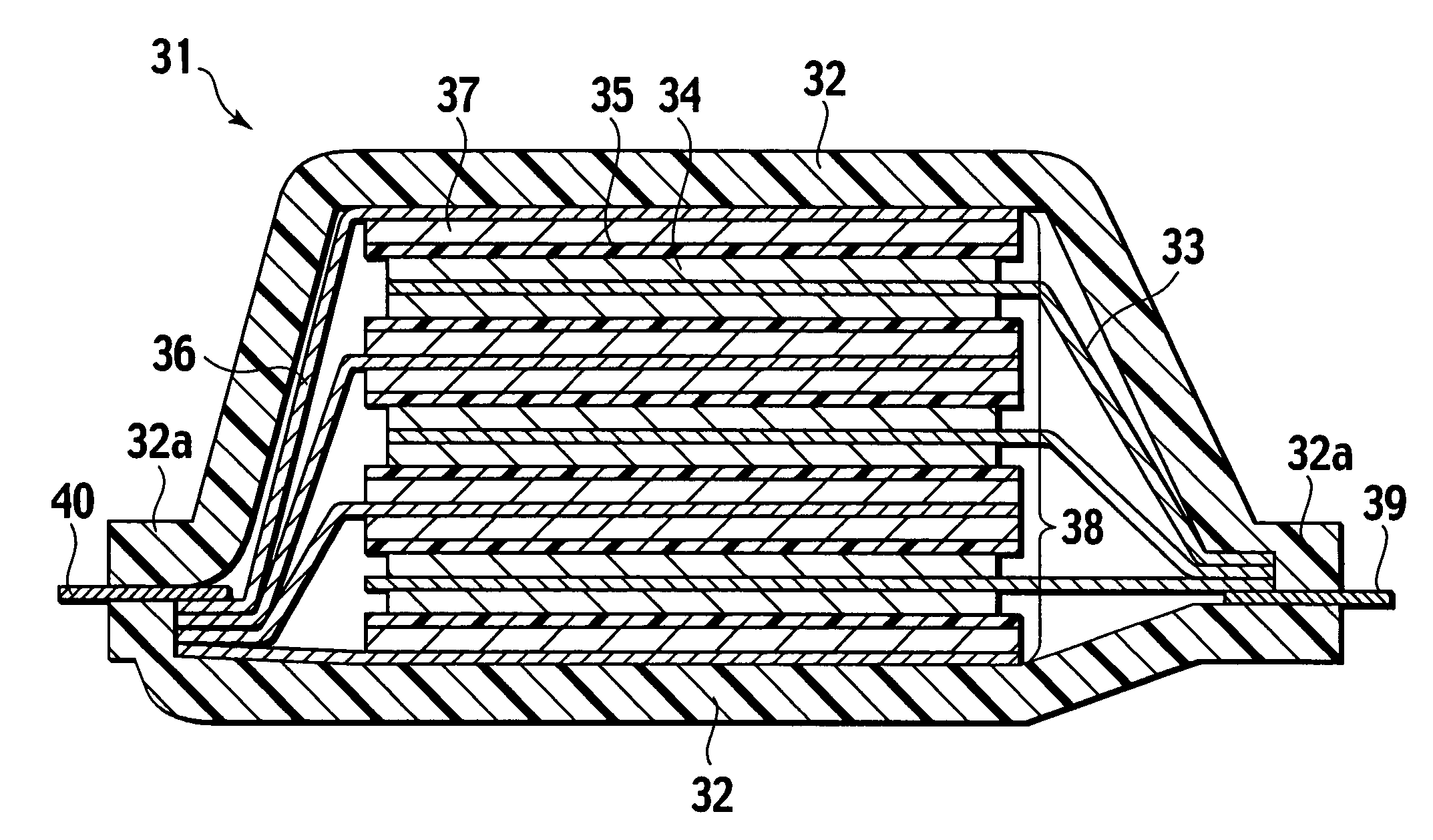

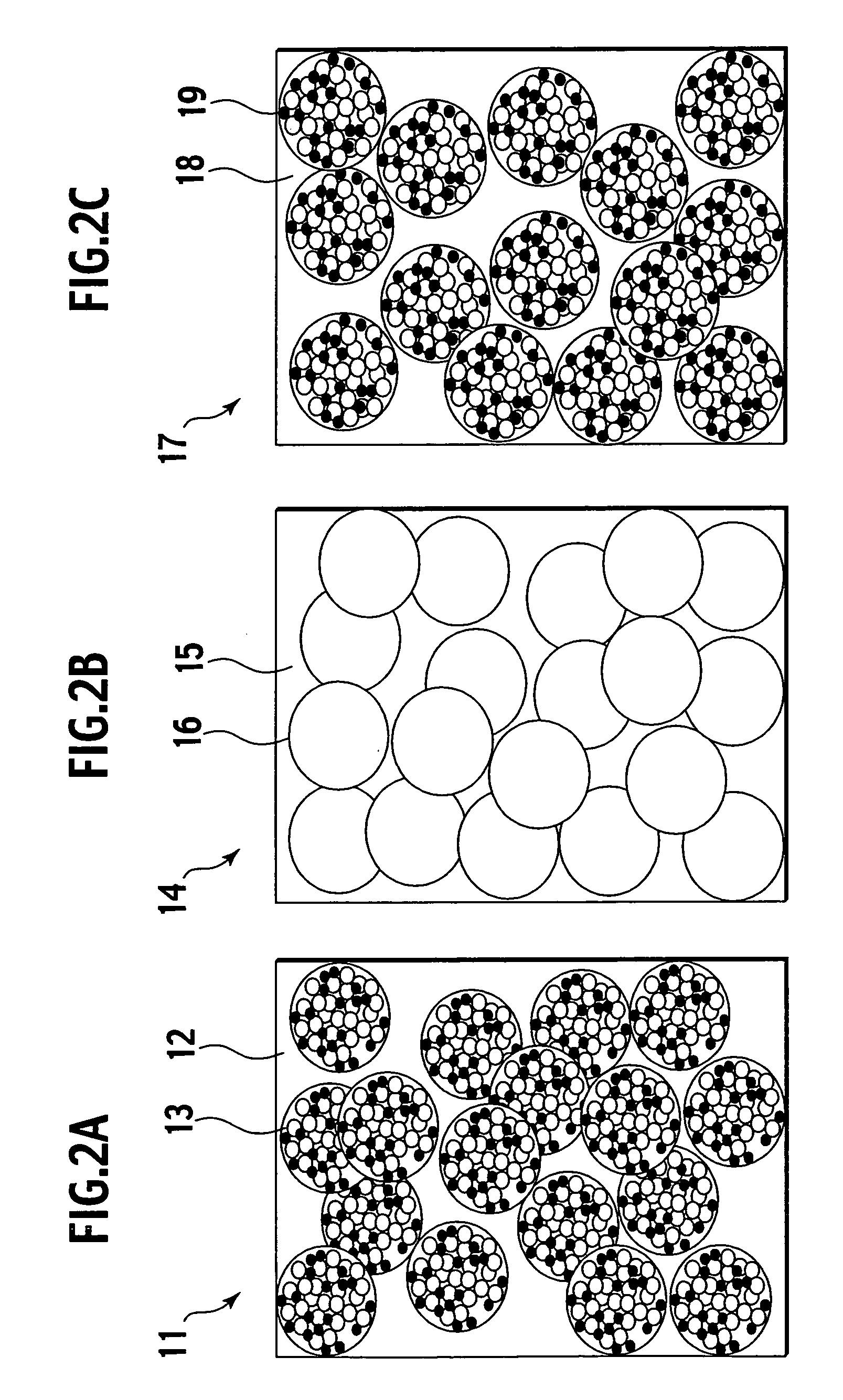

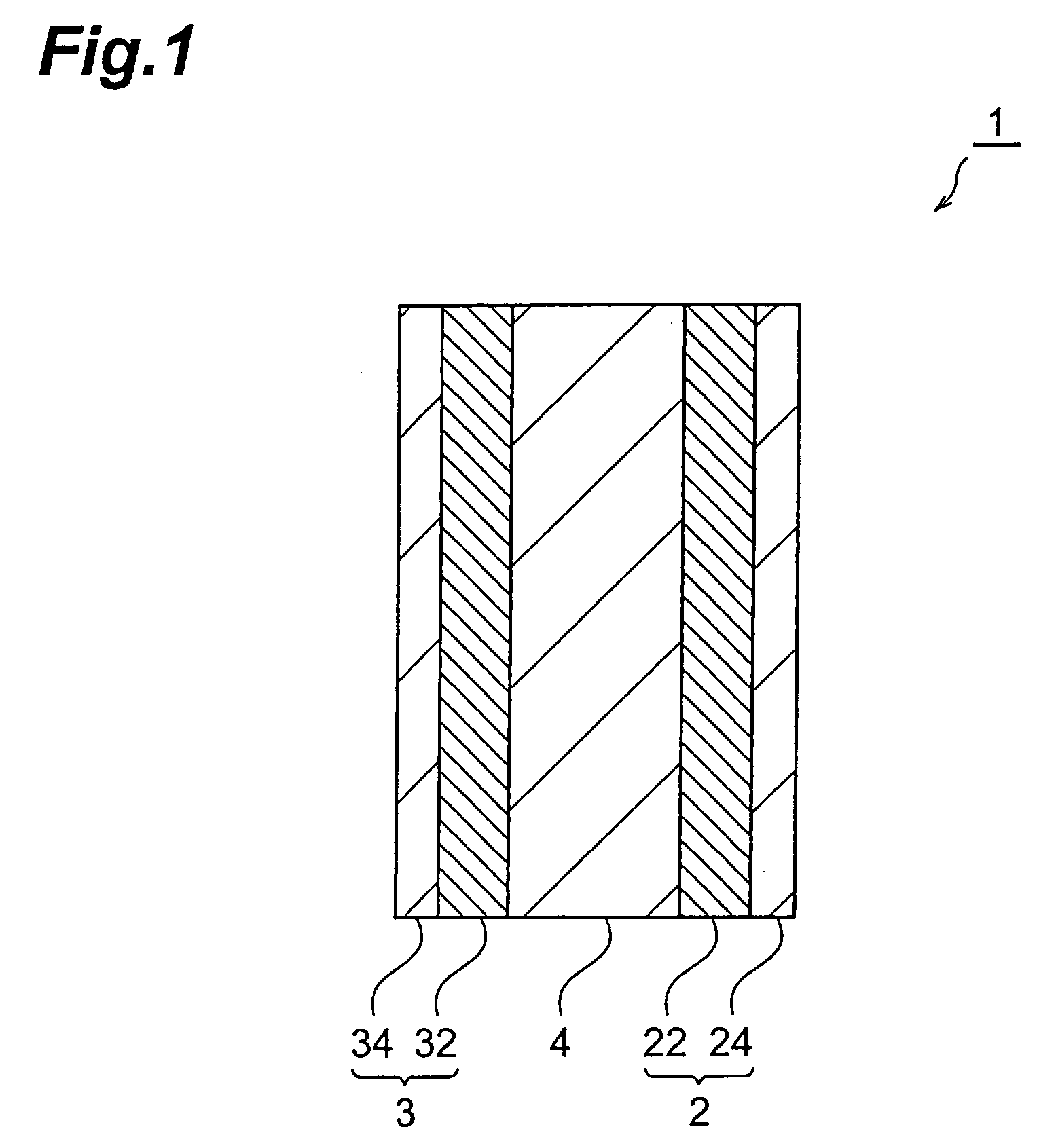

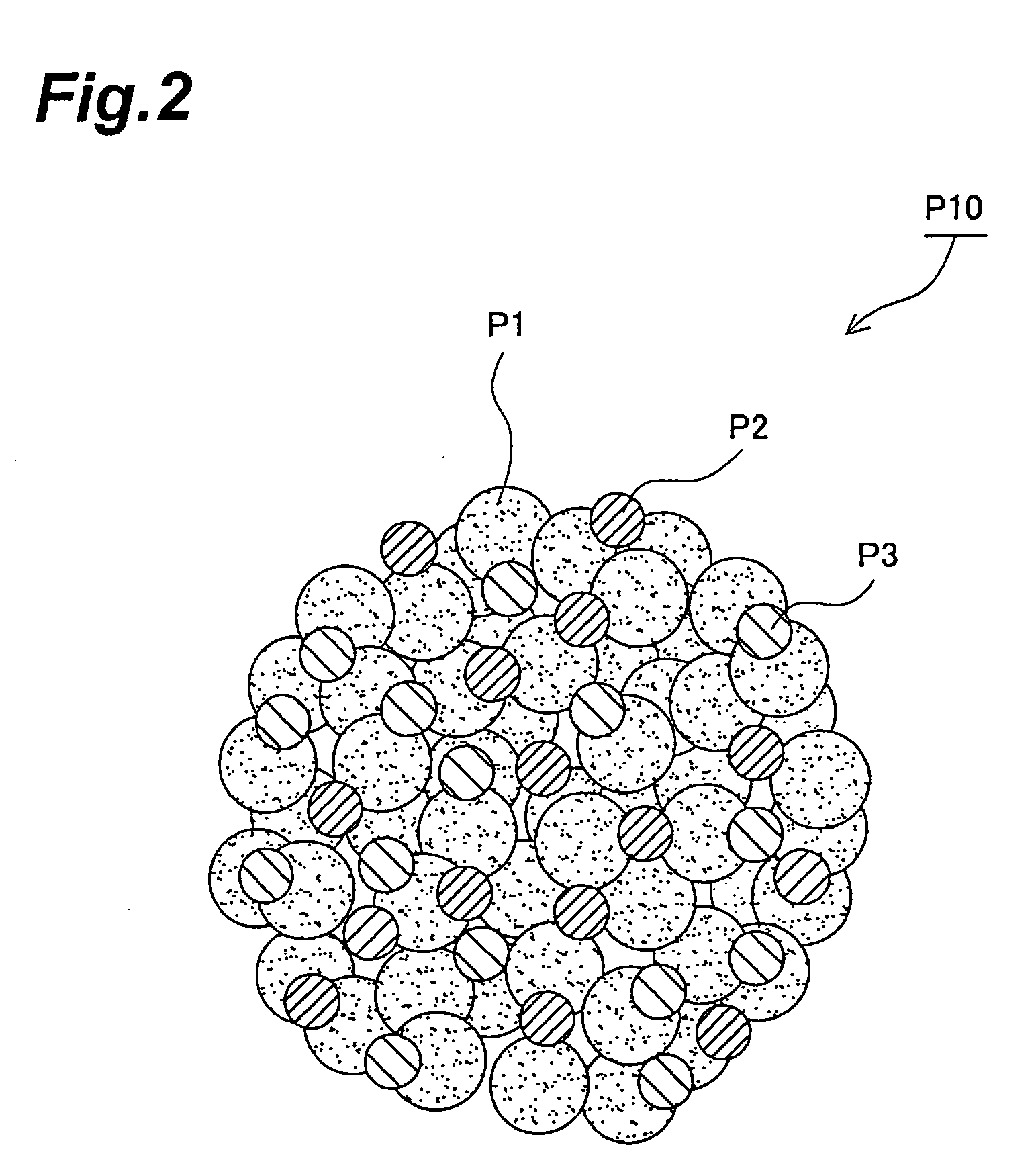

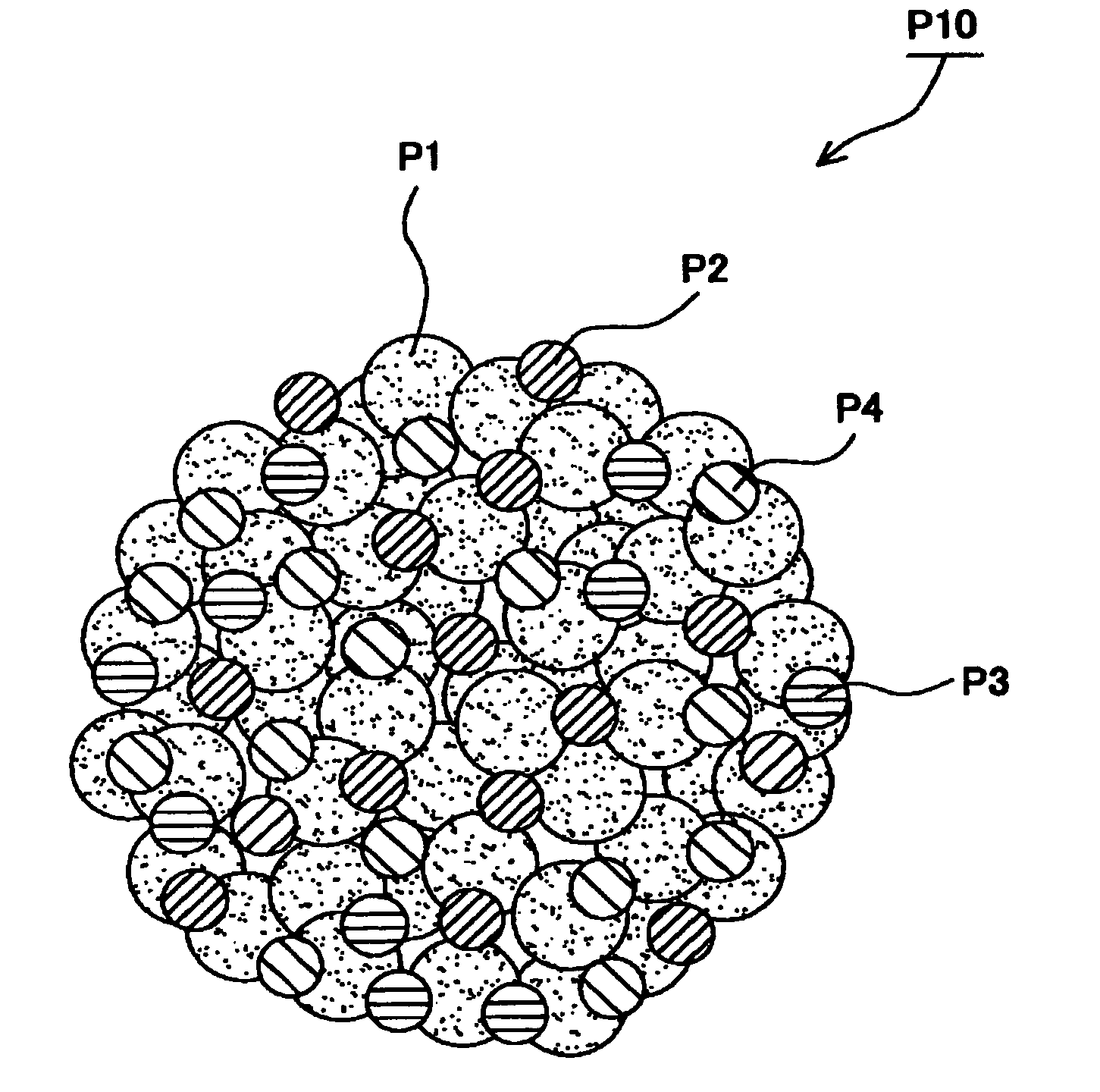

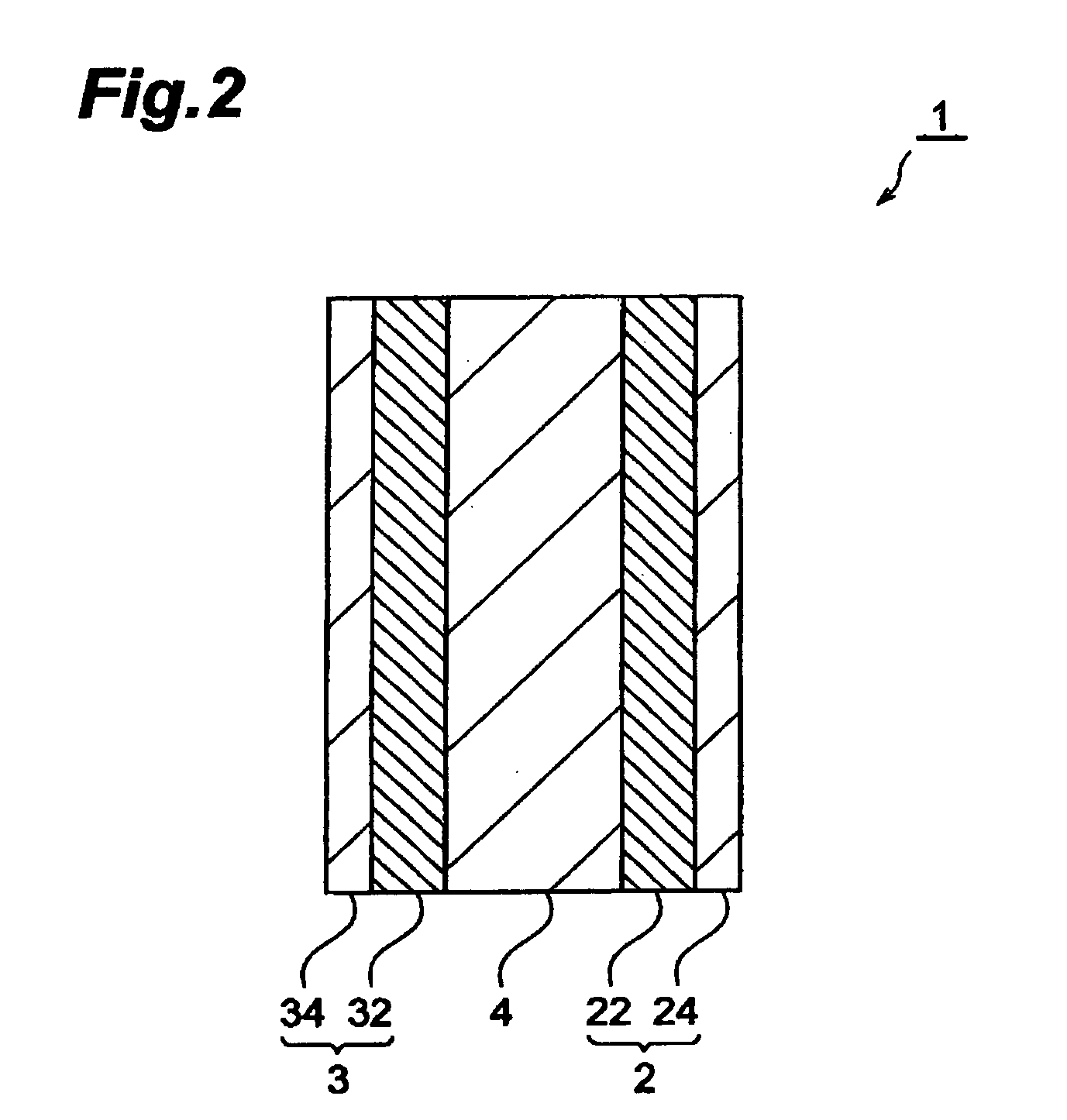

Electrode, electrochemical device, method for manufacturing electrode, and method for manufacturing electrochemical device

InactiveUS20050064289A1Distinguish clearlyReliably obtainedFixed capacitor electrodesActive material electrodesInternal resistanceElectrochemistry

The electrode of the present invention is provided with an active material-containing layer comprising as the structural material composite particles composed of an electrode active material, a conductive additive and a binder, and a current collector in electrical contact with the layer. The composite particles are formed by integrating the conductive additive and binder with the electrode active material particles. The active material-containing layer is formed by subjecting powder comprising at least the composite particles to pressurization treatment to form a sheet, and placing the sheet at the location of the current collector at which the active material-containing layer is to be formed. The electrode active material and conductive additive in the active material-containing layer are non-isolated and electrically linked. This construction allows an electrode with excellent electrical characteristics to be realized, which exhibits adequately reduced internal resistance and easily permits increased energy density to be achieved for electrochemical devices.

Owner:TDK CORPARATION

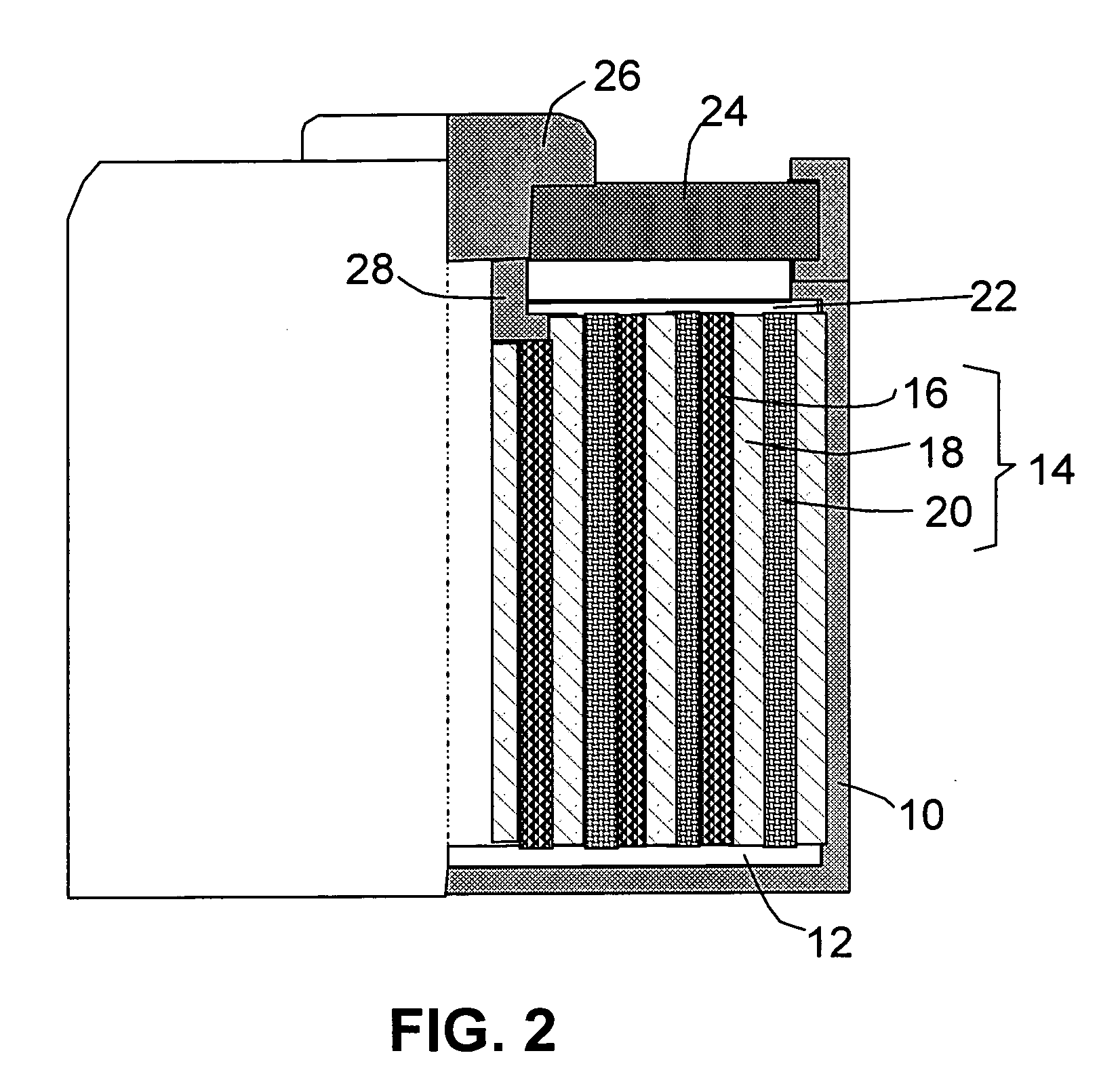

Lithium-sulfur batteries

InactiveUS7250233B2Improved cycle life characteristicsElectrochemical processing of electrodesFinal product manufactureElectrochemical responseLithium–sulfur battery

A lithium-sulfur battery having a positive electrode including a positive active material including an active sulfur, where the positive electrode comprises an electron-conductive path and an ion-conductive path, and includes active pores of the average size of up to 20 μm having both electron-conductive and ion-conductive properties, and are filled with the active sulfur during an electrochemical reaction of the battery.

Owner:SAMSUNG SDI CO LTD

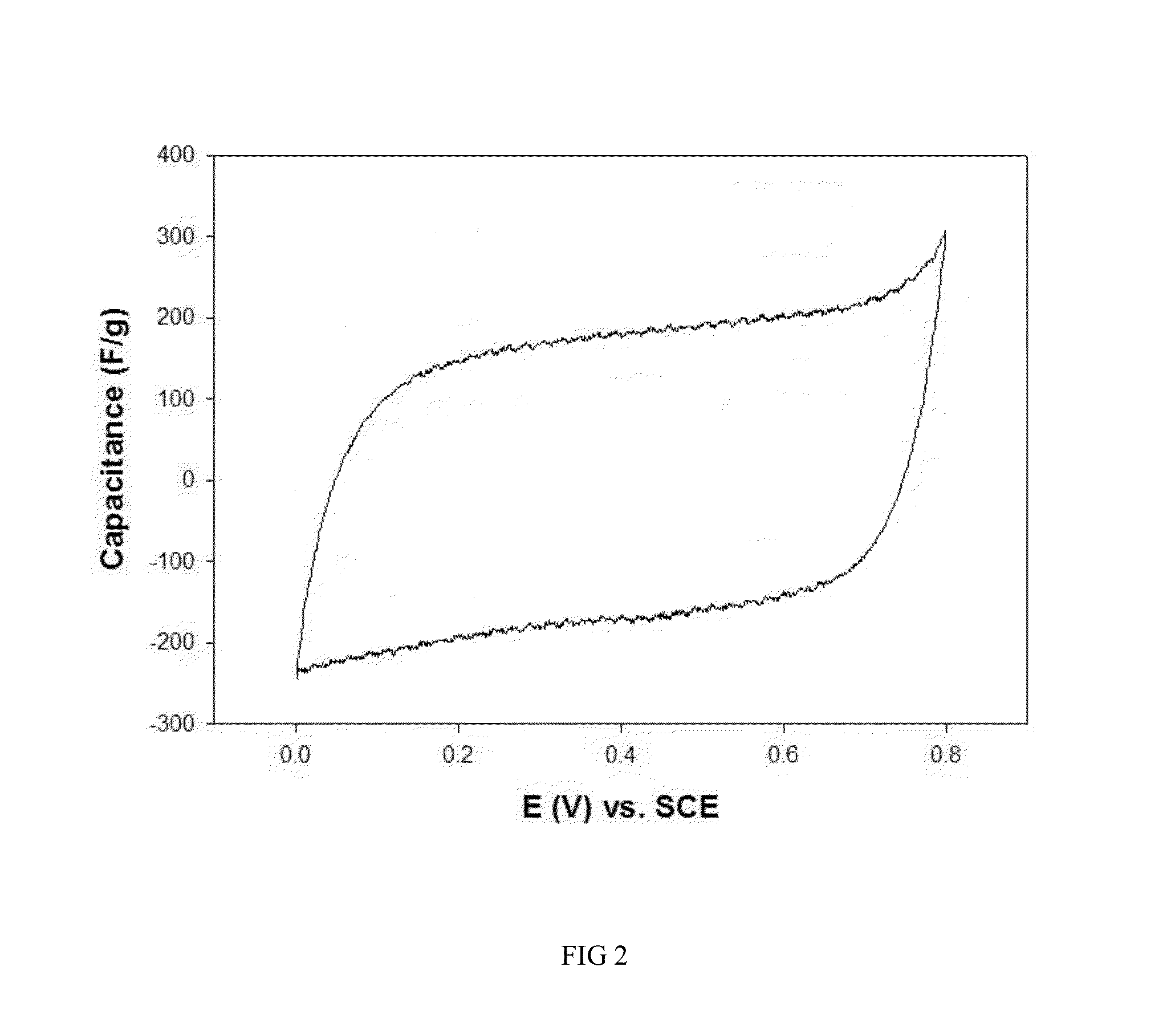

Functionalized Carbon Electrode, Related Material, Process for Production, and Use Thereof

InactiveUS20140113200A1Low costSimple processElectrolytic capacitorsHybrid capacitor electrodesFuel cellsPorous carbon

The present invention relates to a material for use as an electrode for electrochemical energy storage devices such as electrochemical capacitors (ECs) and secondary batteries, primary batteries, metal / air batteries, fuel cells, flow batteries and a method for producing the same. More specifically, this invention relates to an electrode material consisting of a functionalized porous carbon, a method for producing the same, and an energy storage device using said electrode materials.

Owner:SEYMOUR FRASER

Particle packaging systems and methods

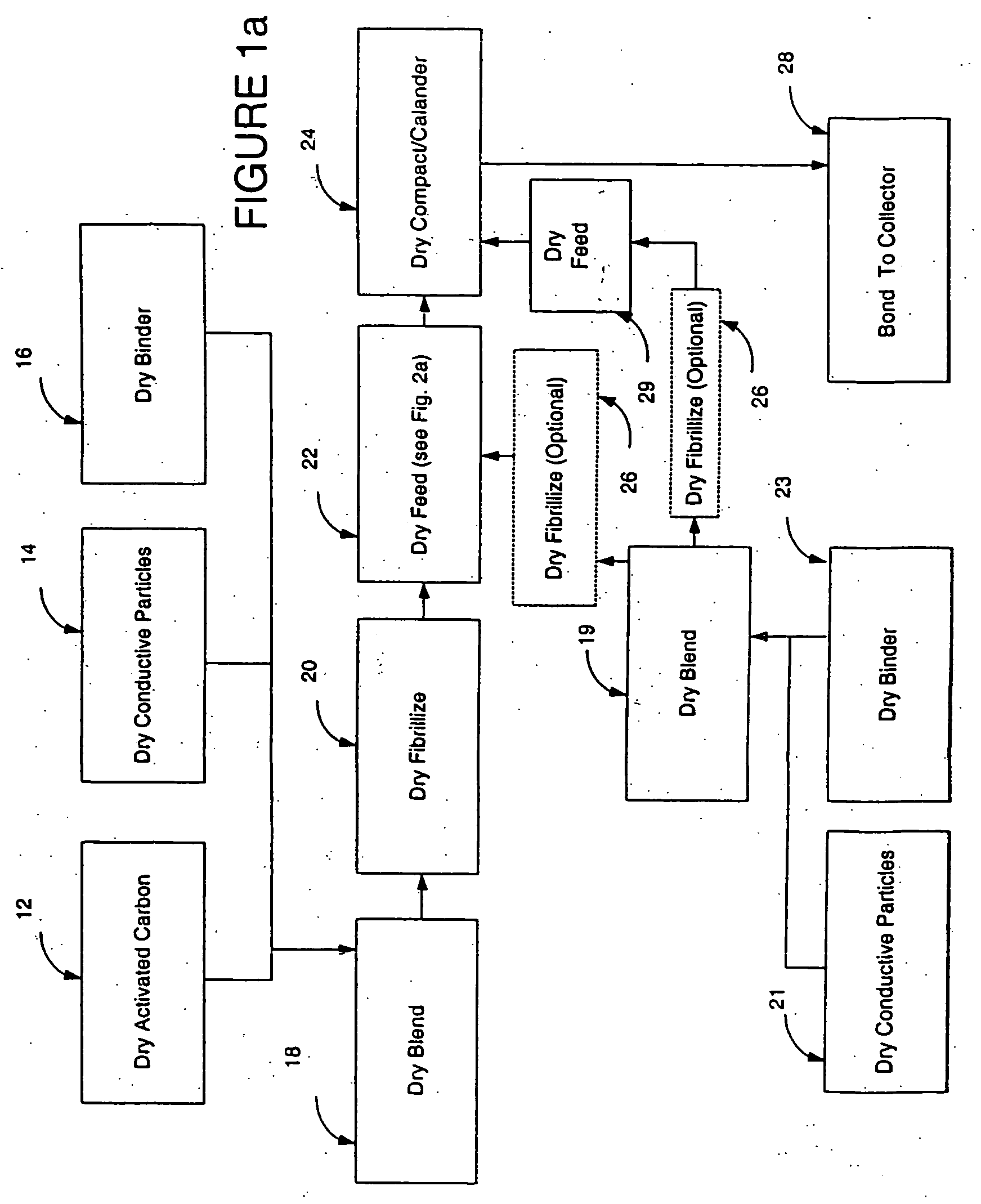

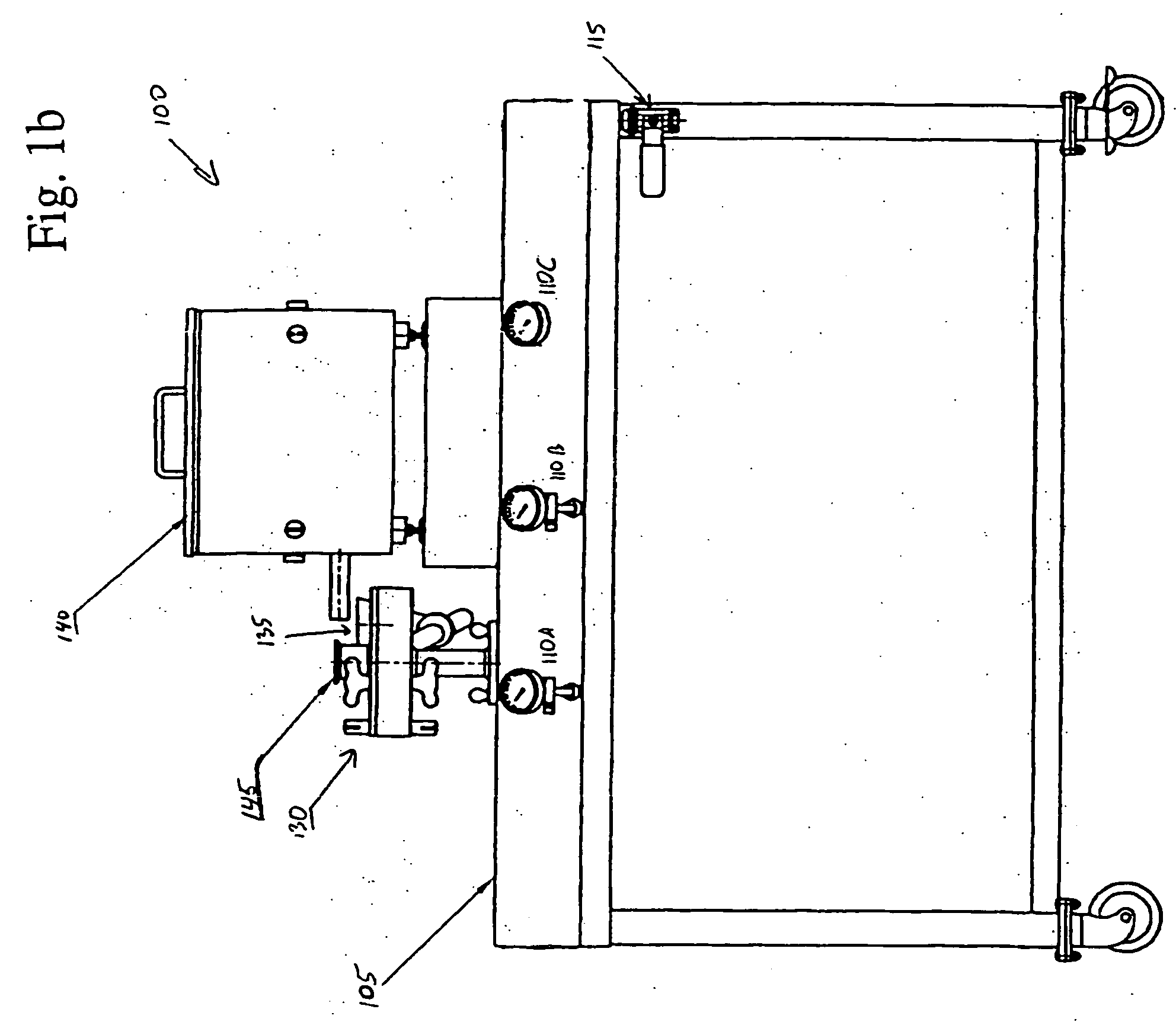

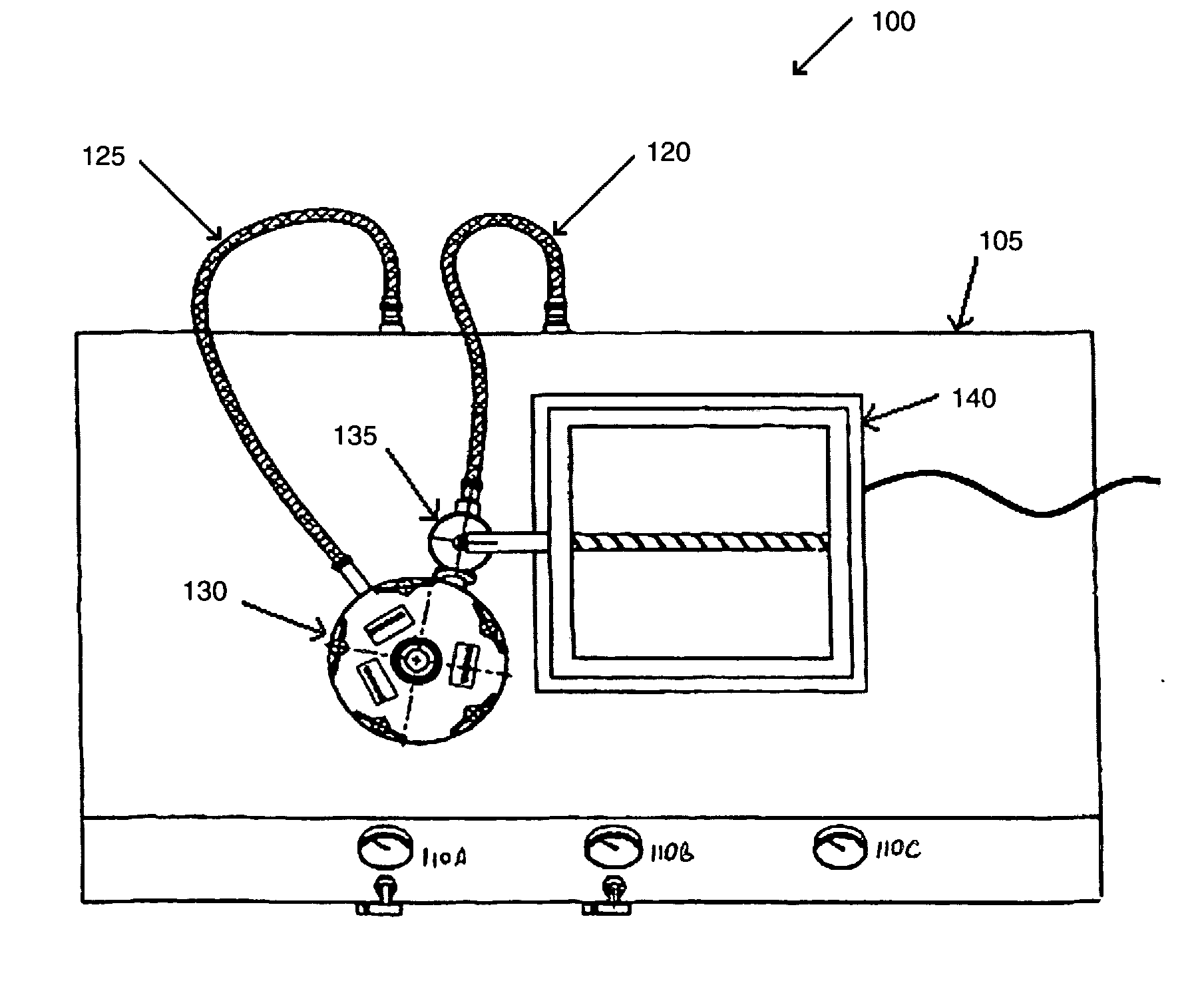

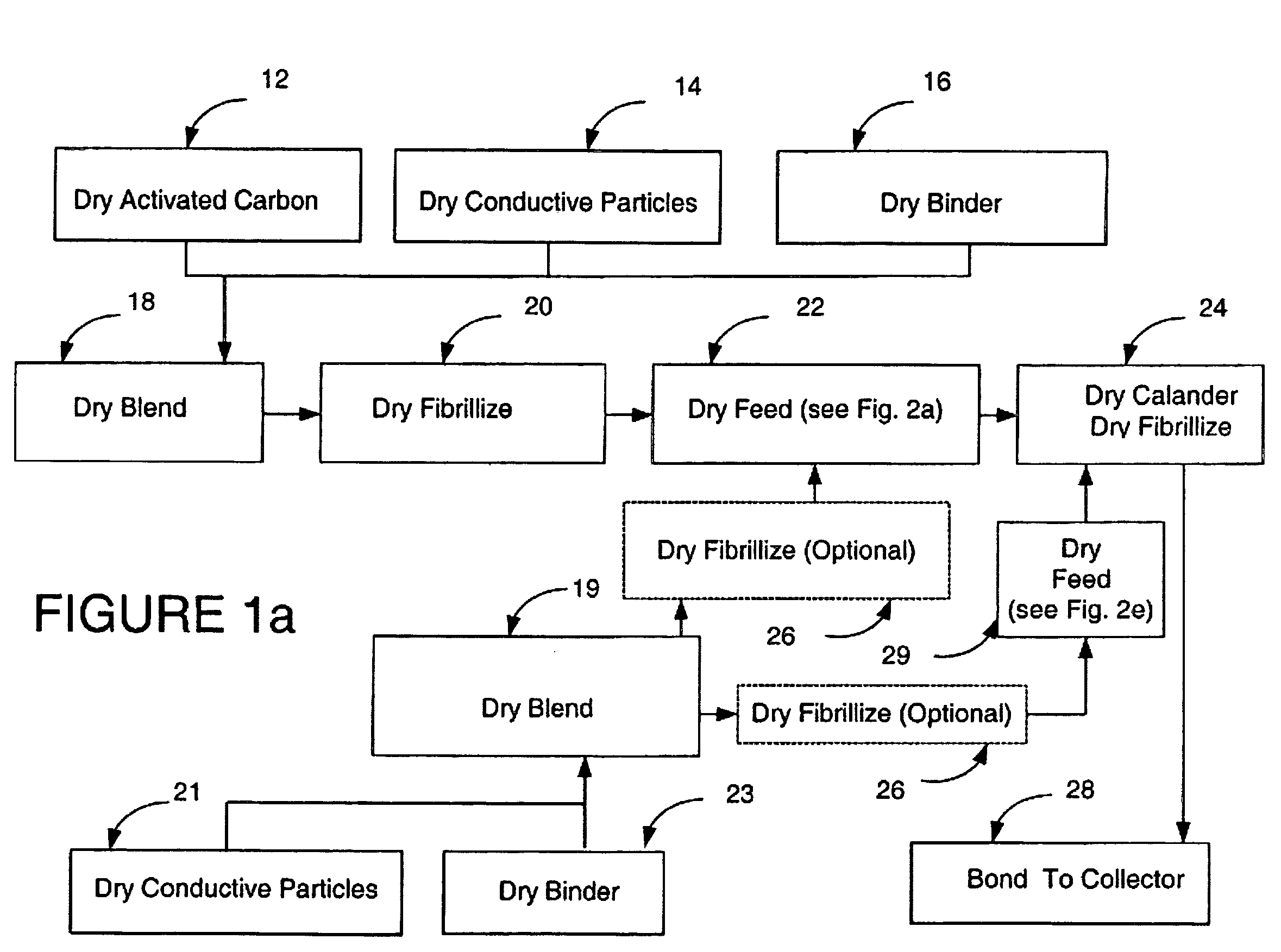

InactiveUS20050250011A1Reduce water consumptionHigh yieldElectrode rolling/calenderingHybrid capacitor electrodesFuel cellsMedical device

A dry process-based particle packaging method and system is disclosed where a matrix of dry fibrillized binder is formed so as to support one or more type of particle. Reliable and inexpensive products, including films, sheets, electrodes, batteries, capacitors, fuel cells, and / or medical devices can be thus manufactured.

Owner:TESLA INC

Dry-particle based adhesive and dry film and methods of making same

InactiveUS20070122698A1Reduce water consumptionHigh yieldElectrode rolling/calenderingFinal product manufactureAdhesiveEngineering

Dry process based energy storage device structures and methods for using a dry adhesive therein are disclosed.

Owner:TESLA INC

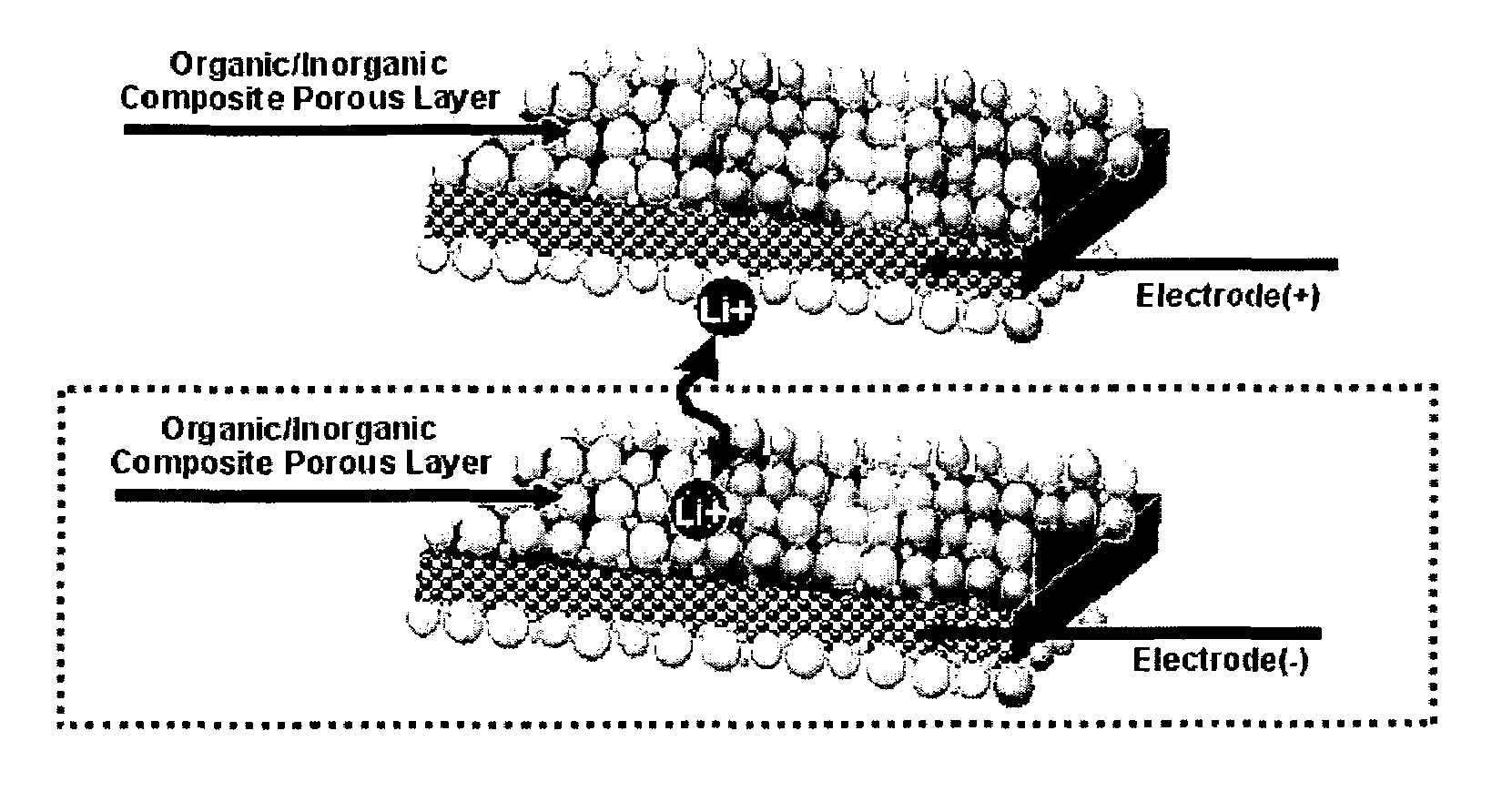

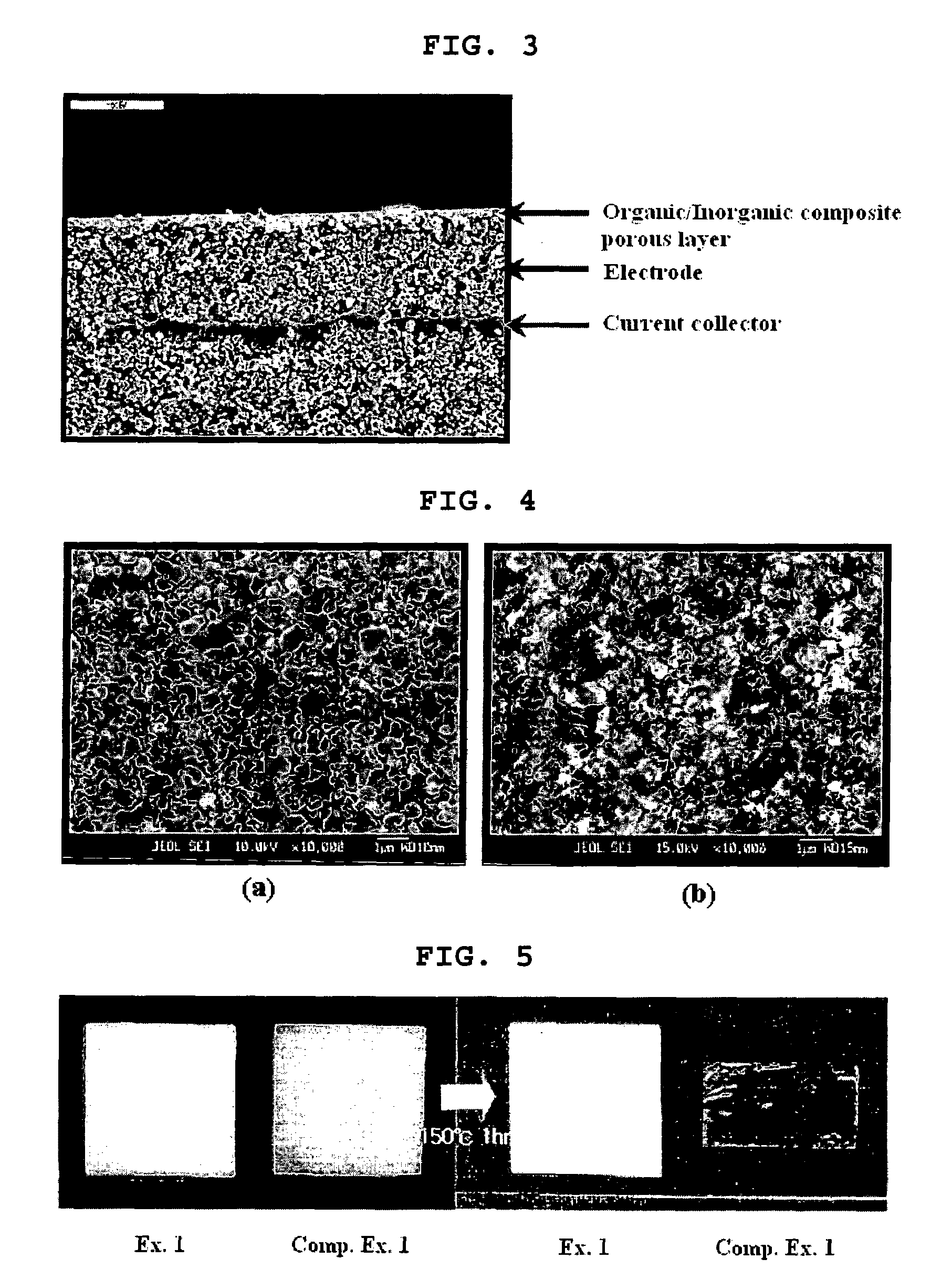

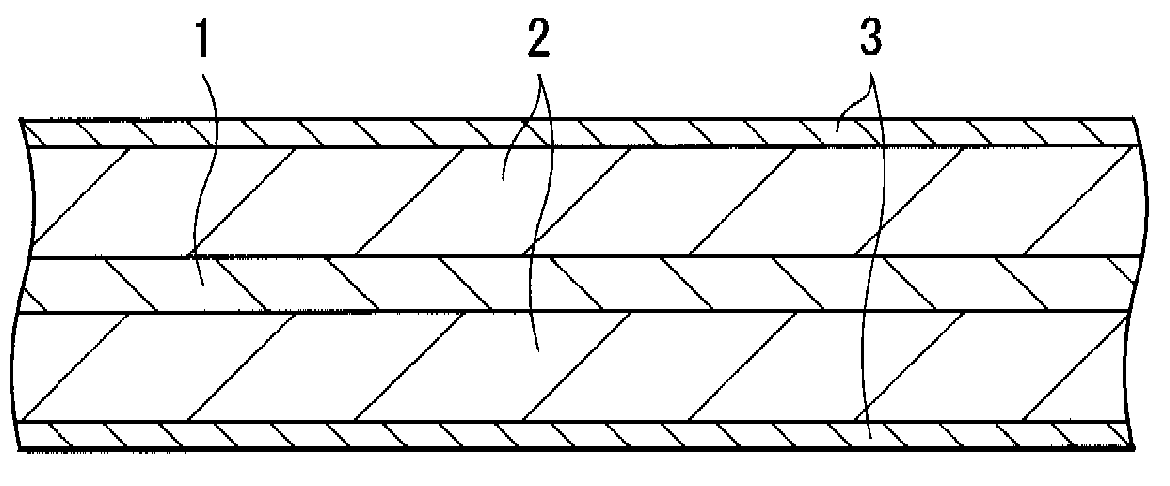

Organic/inorganic composite porous layer-coated electrode and electrochemical device comprising the same

ActiveUS7682740B2Improve performanceImprove securityElectrode rolling/calenderingNon-aqueous electrolyte accumulator electrodesPorous coatingInorganic particle

Disclosed is an electrode comprising a first organic / inorganic composite porous coating layer formed on its surface, wherein the first coating layer includes inorganic particles and a binder polymer for interconnecting and fixing the inorganic particles, and has micropores formed by interstitial volumes among the inorganic particles. An electrochemical device including the same electrode is also disclosed. Further, disclosed is a method for manufacturing an electrode having an organic / inorganic composite porous coating layer on the surface thereof, comprising the steps of: (a) coating a current collector with slurry containing an electrode active material and drying it to provide an electrode; and (b) coating the surface of electrode obtained from step (a) with a mixture of inorganic particles with a binder polymer. A lithium secondary battery including the electrode shows improved safety and minimized degradation in battery performance.

Owner:LG ENERGY SOLUTION LTD

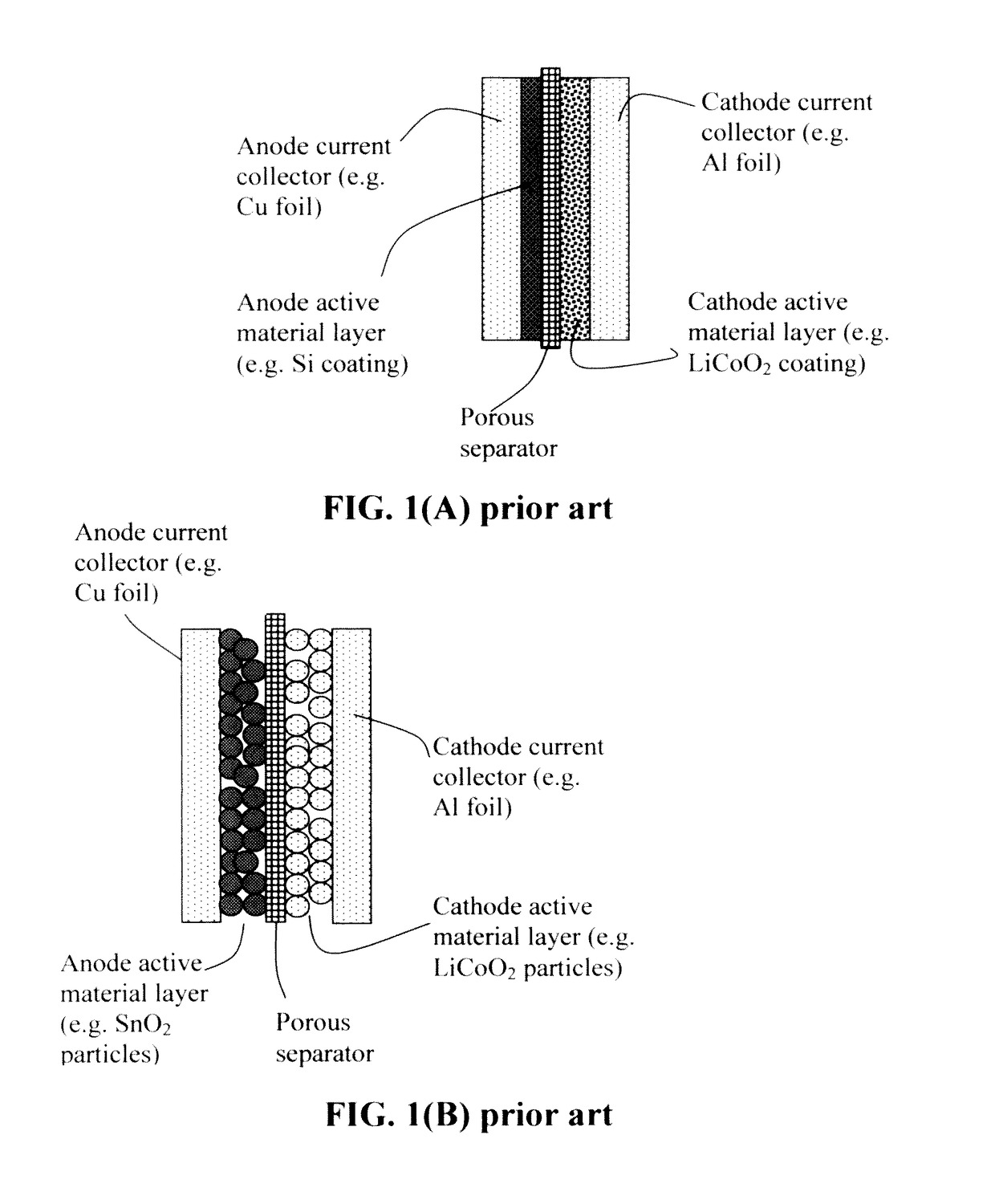

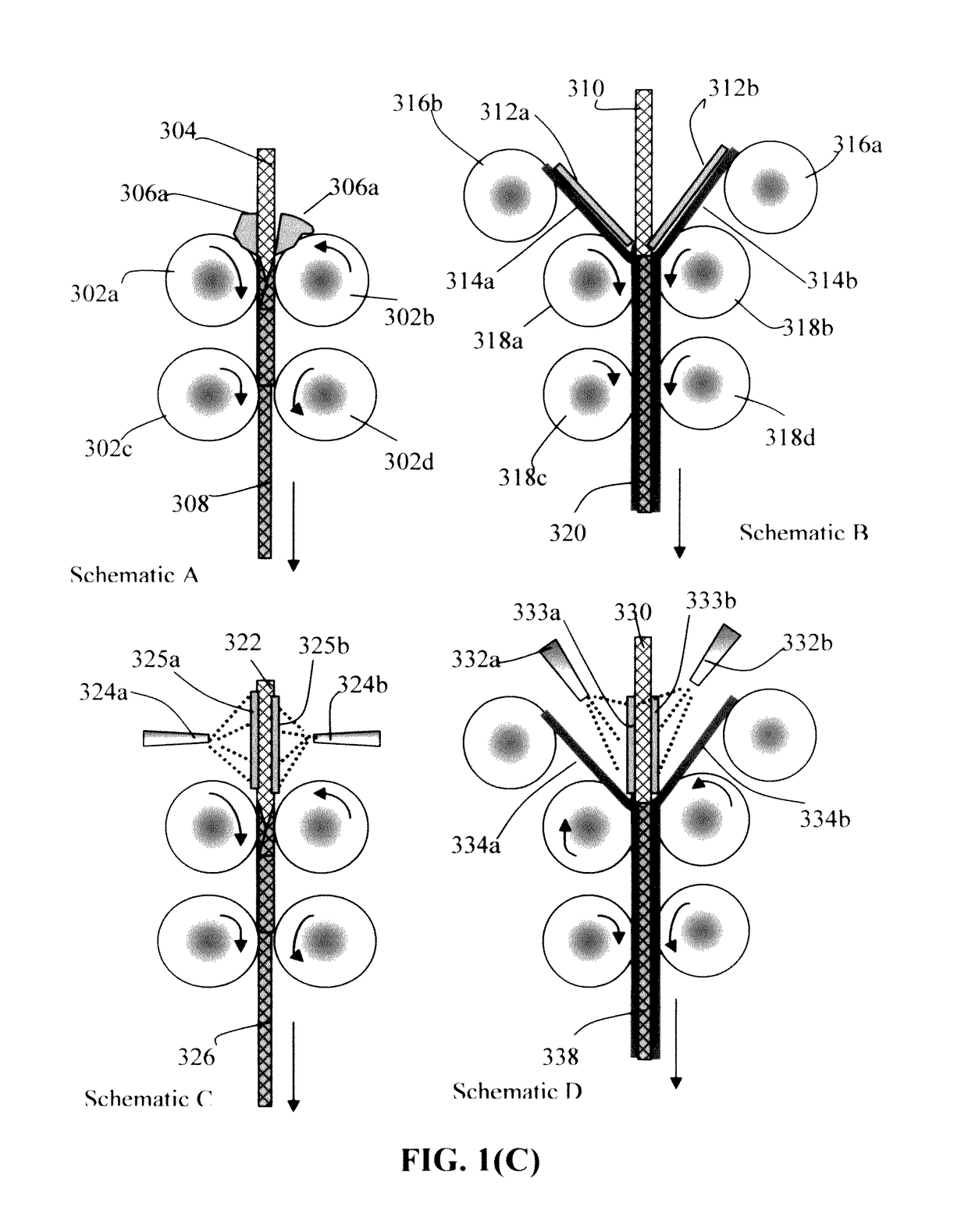

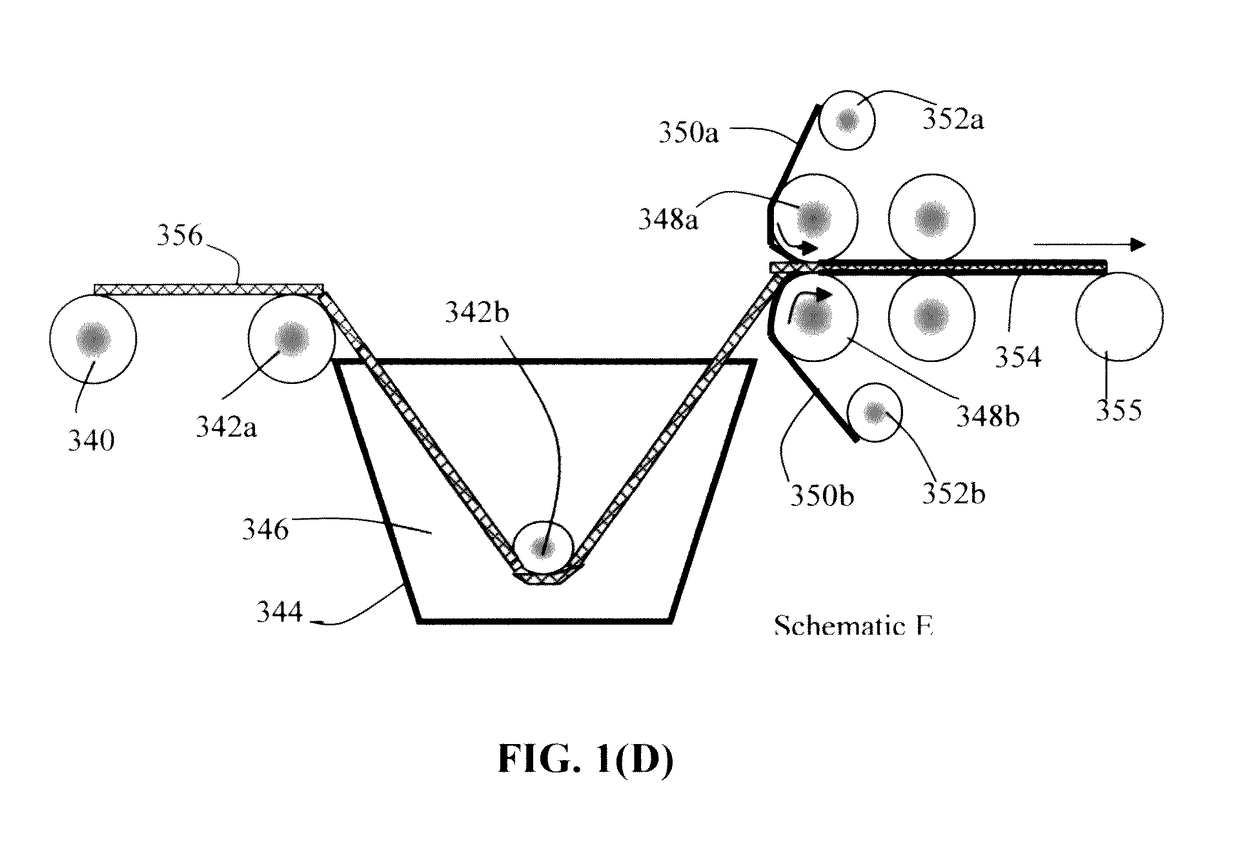

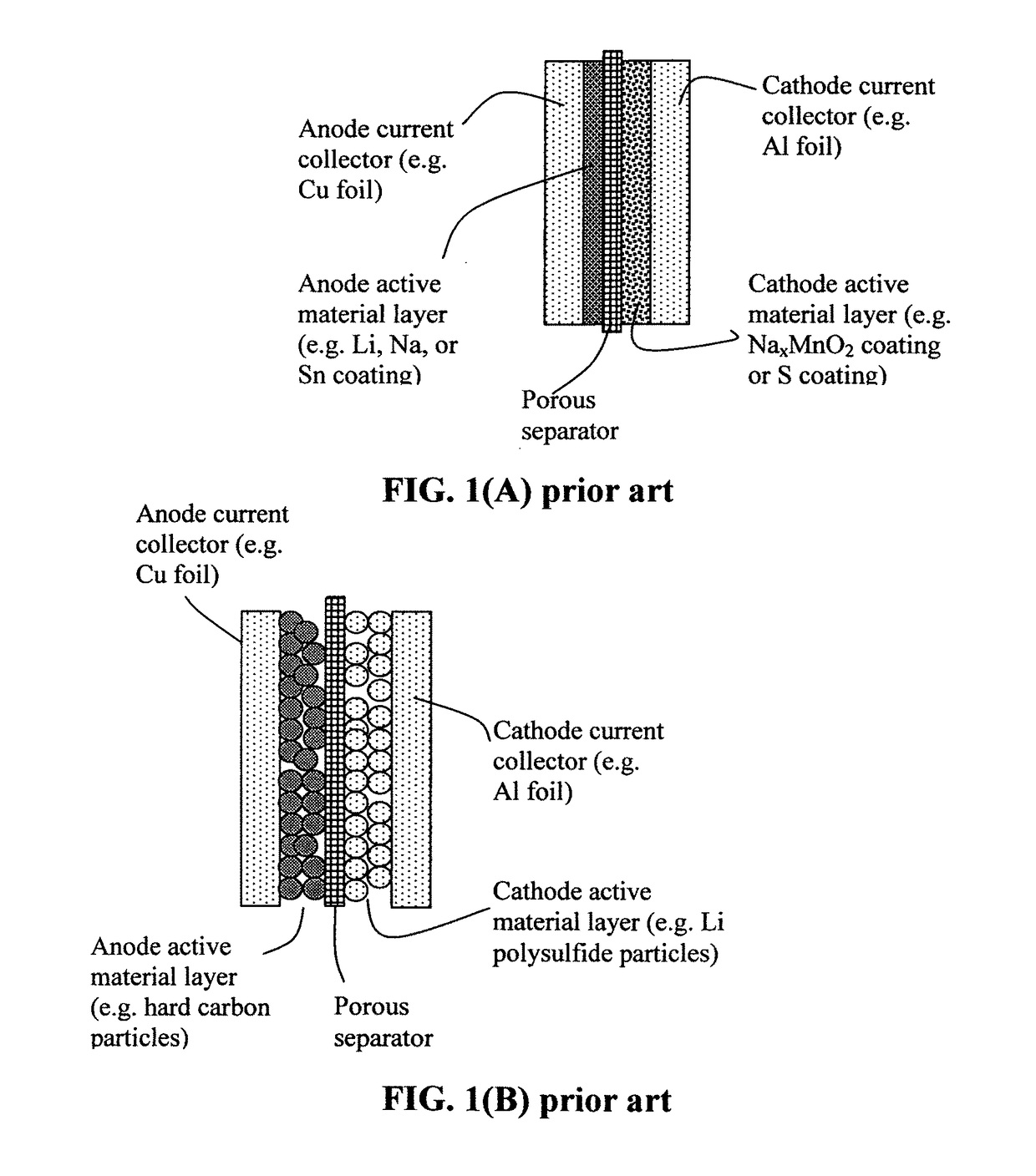

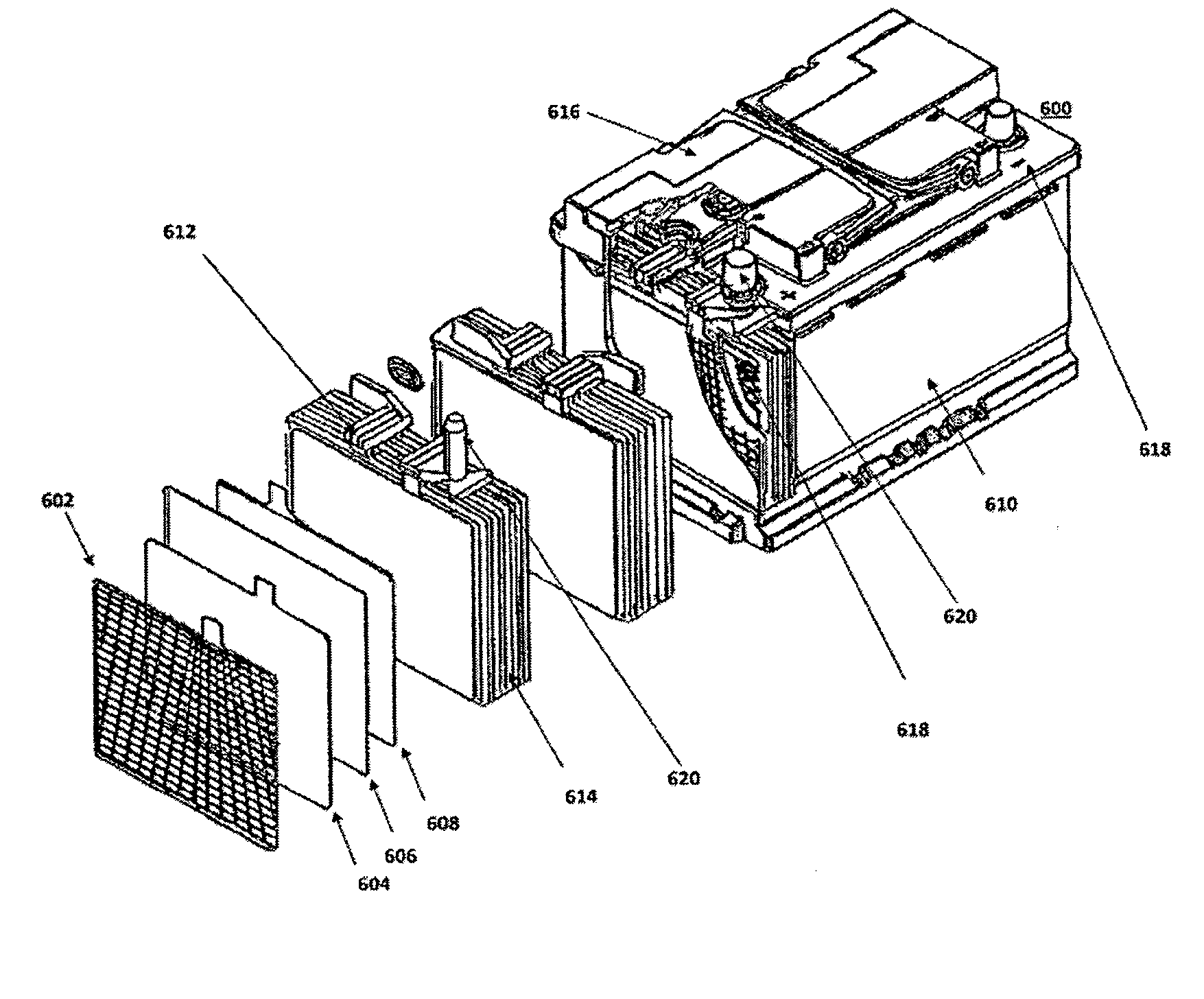

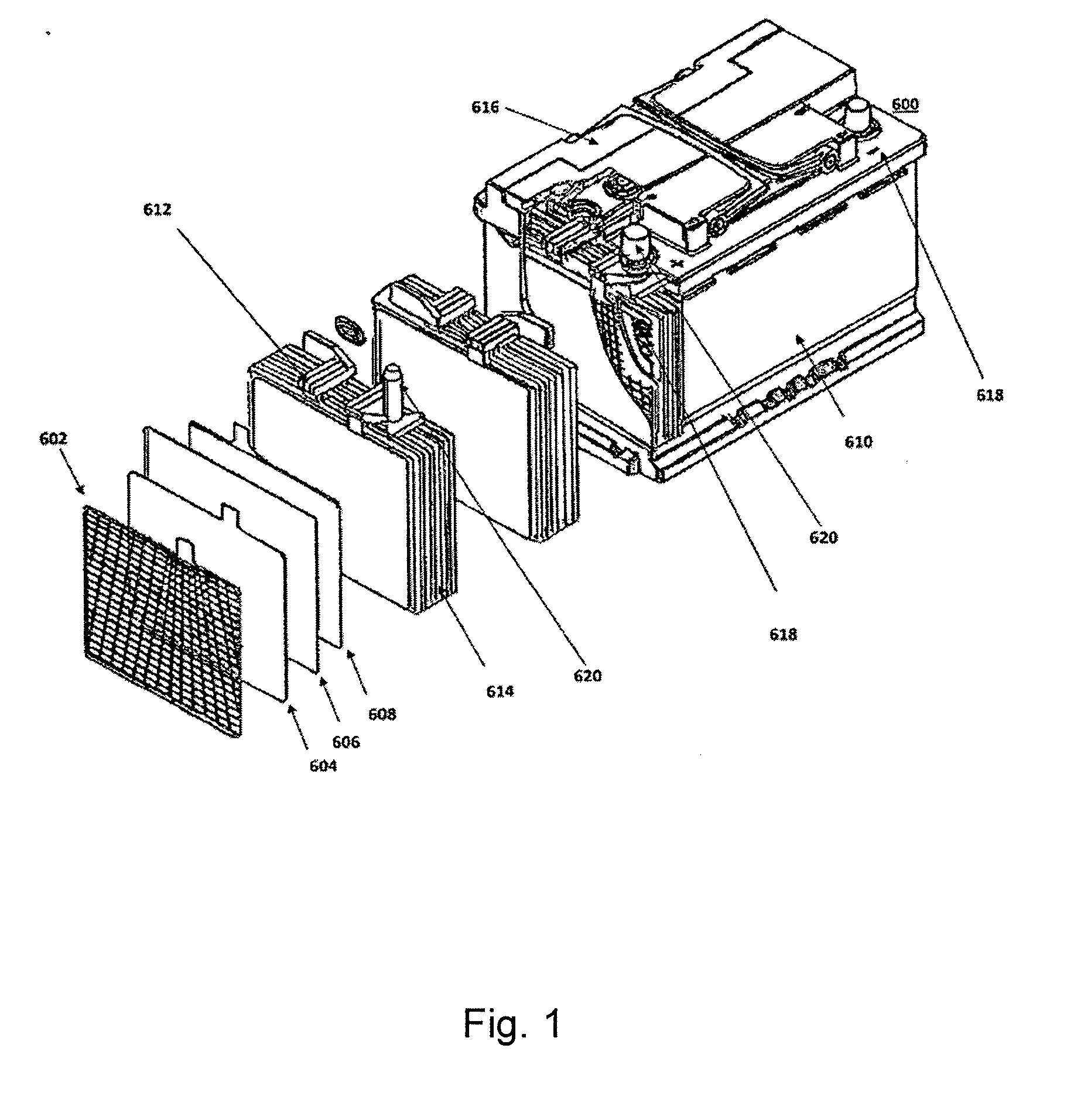

Continuous process for producing electrodes and alkali metal batteries having ultra-high energy densities

ActiveUS20170104204A1Increase energy densityImprove power densityFinal product manufactureElectrode carriers/collectorsTectorial membraneHigh energy

A process for producing an electrode for an alkali metal battery, comprising: (a) Continuously feeding an electrically conductive porous layer to an anode or cathode material impregnation zone, wherein the conductive porous layer has two opposed porous surfaces and contain interconnected conductive pathways and at least 70% by volume of pores; (b) Impregnating a wet anode or cathode active material mixture into the porous layer from at least one of the two porous surfaces to form an anode or cathode electrode, wherein the wet anode or cathode active material mixture contains an anode or cathode active material and an optional conductive additive mixed with a liquid electrolyte; and (c) Supplying at least a protective film to cover the at least one porous surface to form the electrode.

Owner:GLOBAL GRAPHENE GRP INC

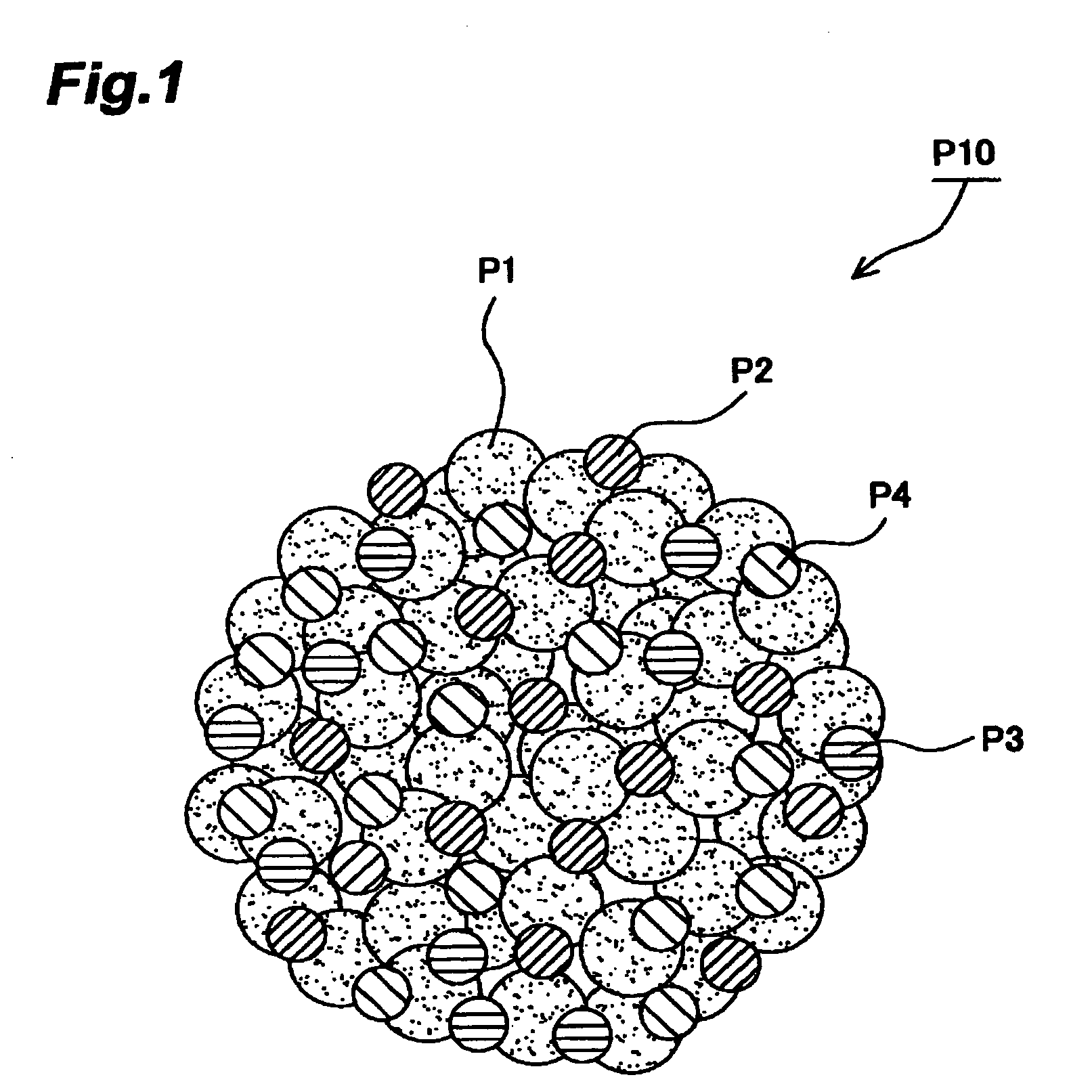

Composite particle for electrode and method of making the same, electrode and method of making the same, and electrochemical device and method of making the same

InactiveUS20050058907A1Lower internal resistanceGood equipment performanceCapacitor electrodesElectrode collector coatingElectronic conductivityOxidizing agent

The composite particle for an electrode in accordance with the present invention contains an electrode active material, a conductive auxiliary agent having an electronic conductivity, and an oxidizing / reducing agent. Therefore, this composite particle can construct an effective conductive network, and effectively provide so-called oxidizing / reducing capacity due to the oxidizing / reducing agent. Hence, when the composite particle for an electrode in accordance with the present invention is used as a constituent material of an electrode in an electrochemical device, the electrochemical device can realize a higher capacity.

Owner:TDK CORPARATION

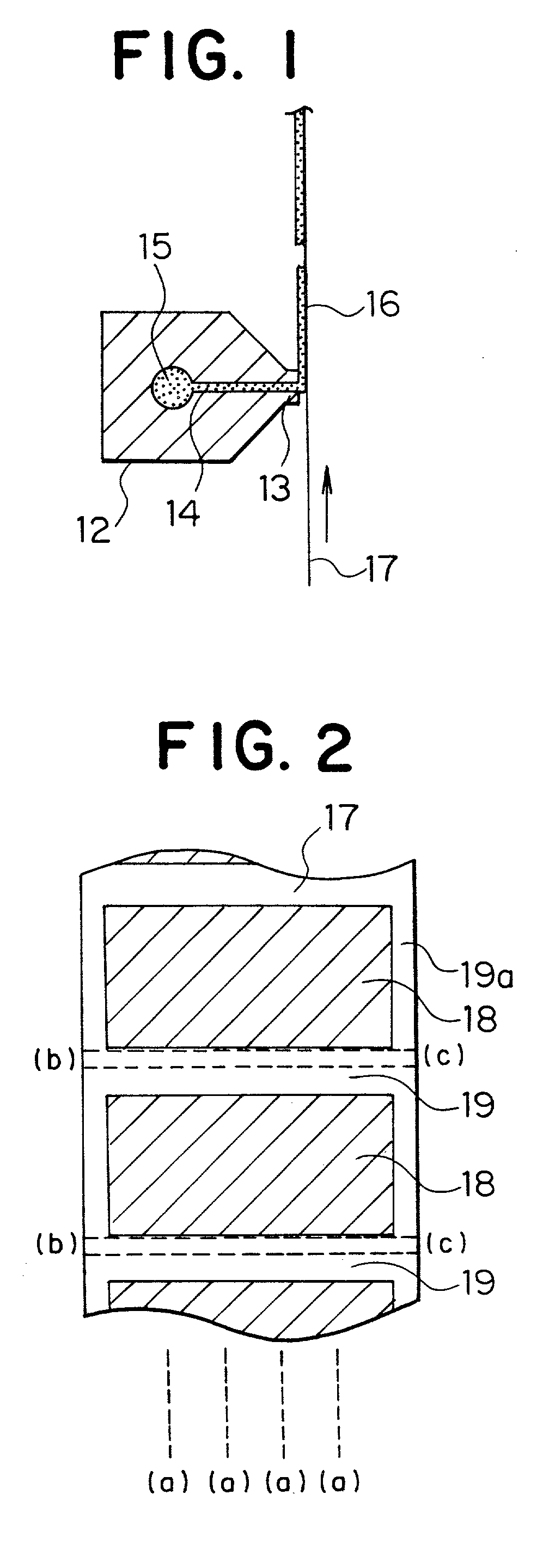

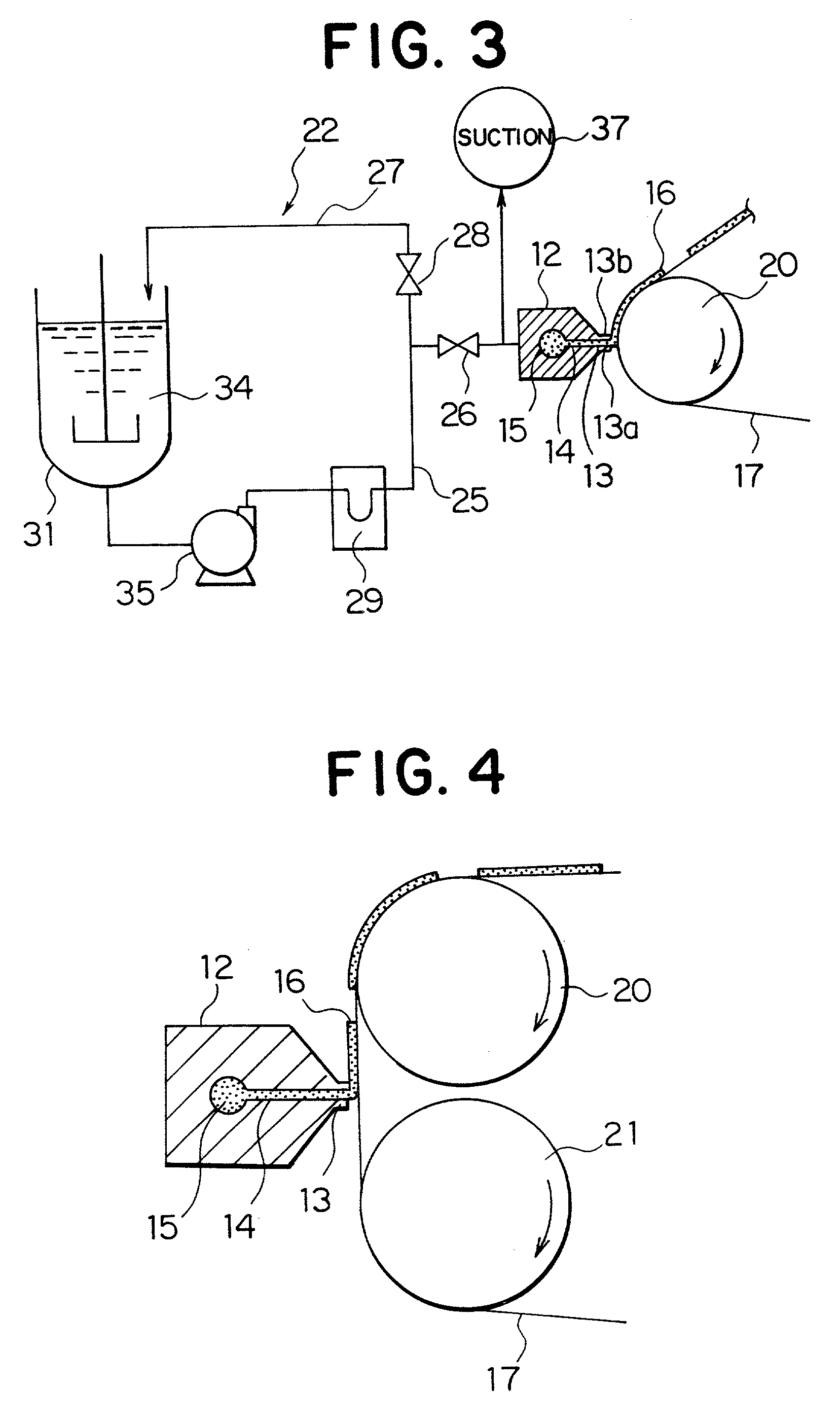

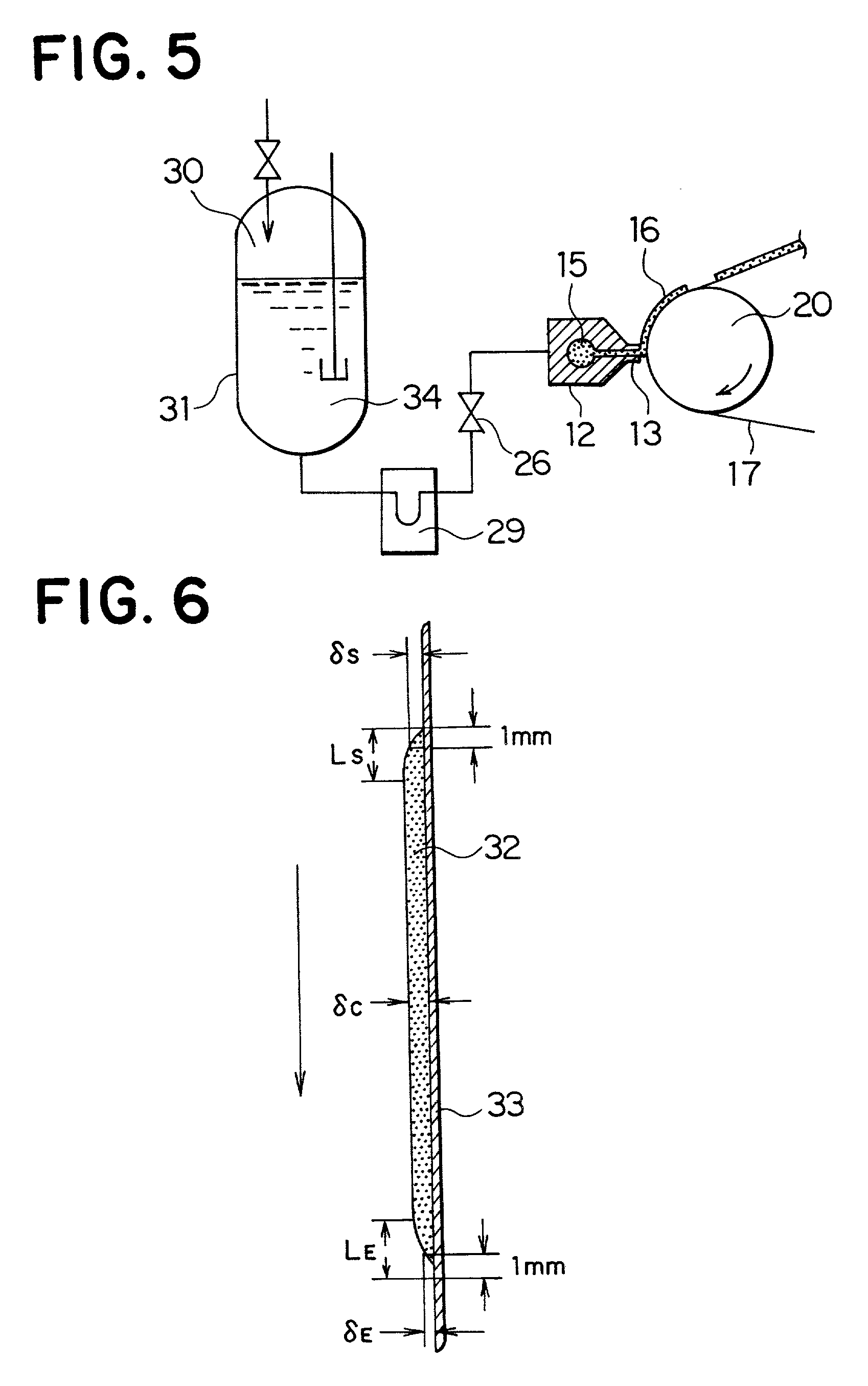

Nonaqueous electrolyte battery, electrode plate for nonaqueous electrolyte battery, and method for manufacturing electrode plate for nonaqueous electrolyte battery,

InactiveUS20010012588A1Electrode rolling/calenderingFinal product manufactureElectrolyteMaterials science

A method for manufacturing an electrode plate of a nonaqueous electrolyte battery comprises the steps of: running a sheet conductive base material in a first direction; and injecting an electrode material composition containing an electrolyte from a die nozzle onto a first surface of the running sheet conductive base material to form uncoated areas at predetermined intervals on the first surface along the first direction.

Owner:KK TOSHIBA

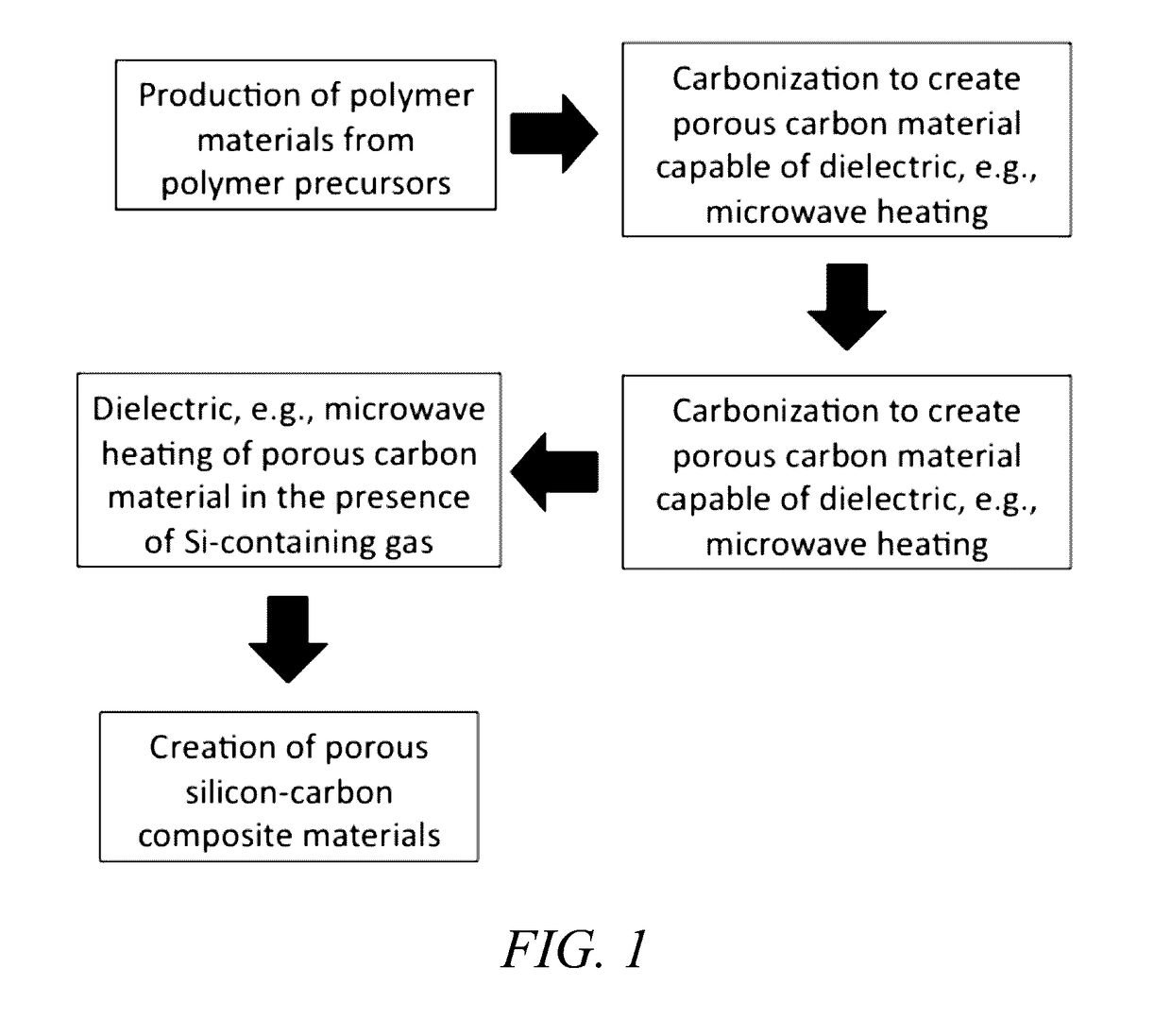

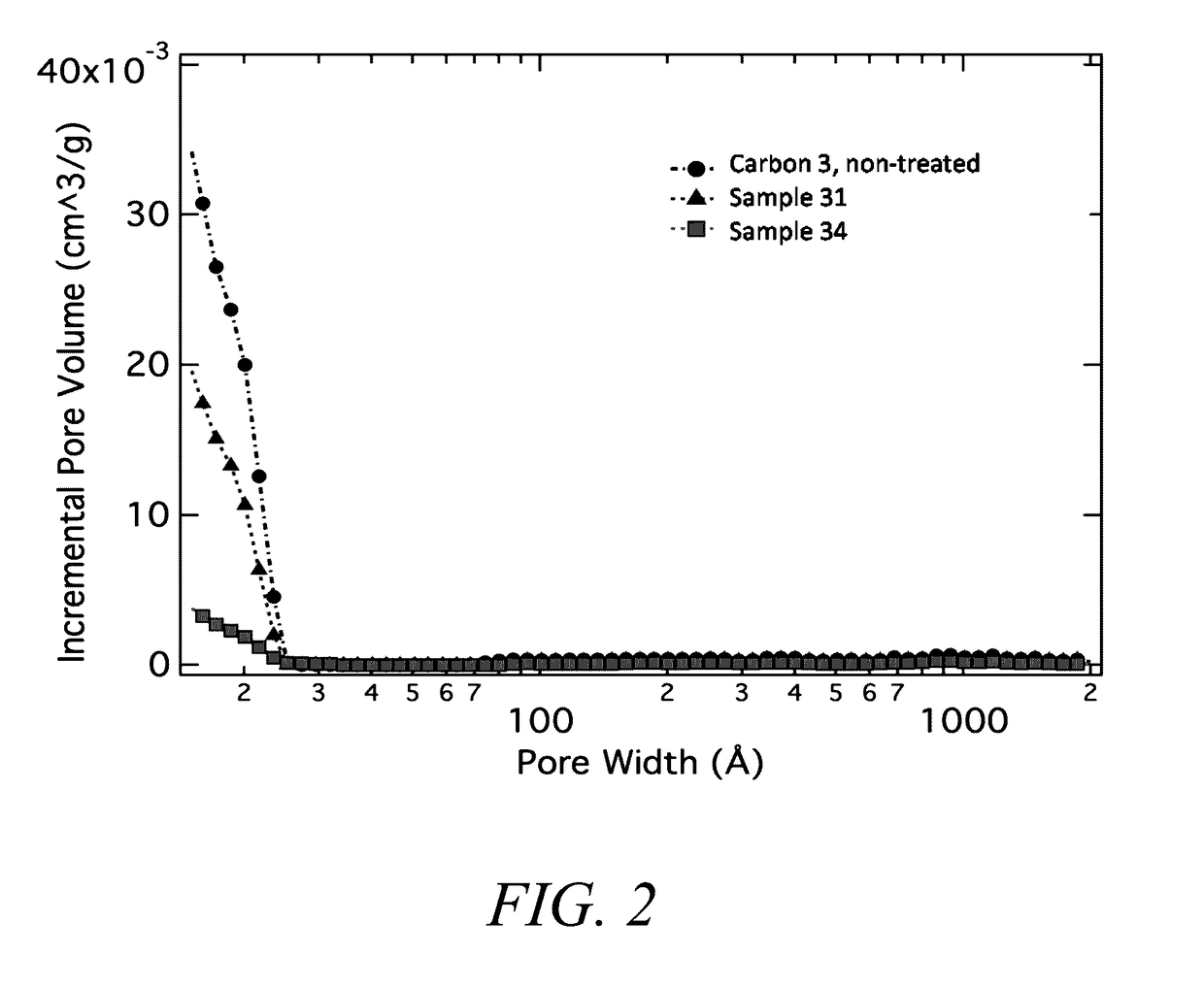

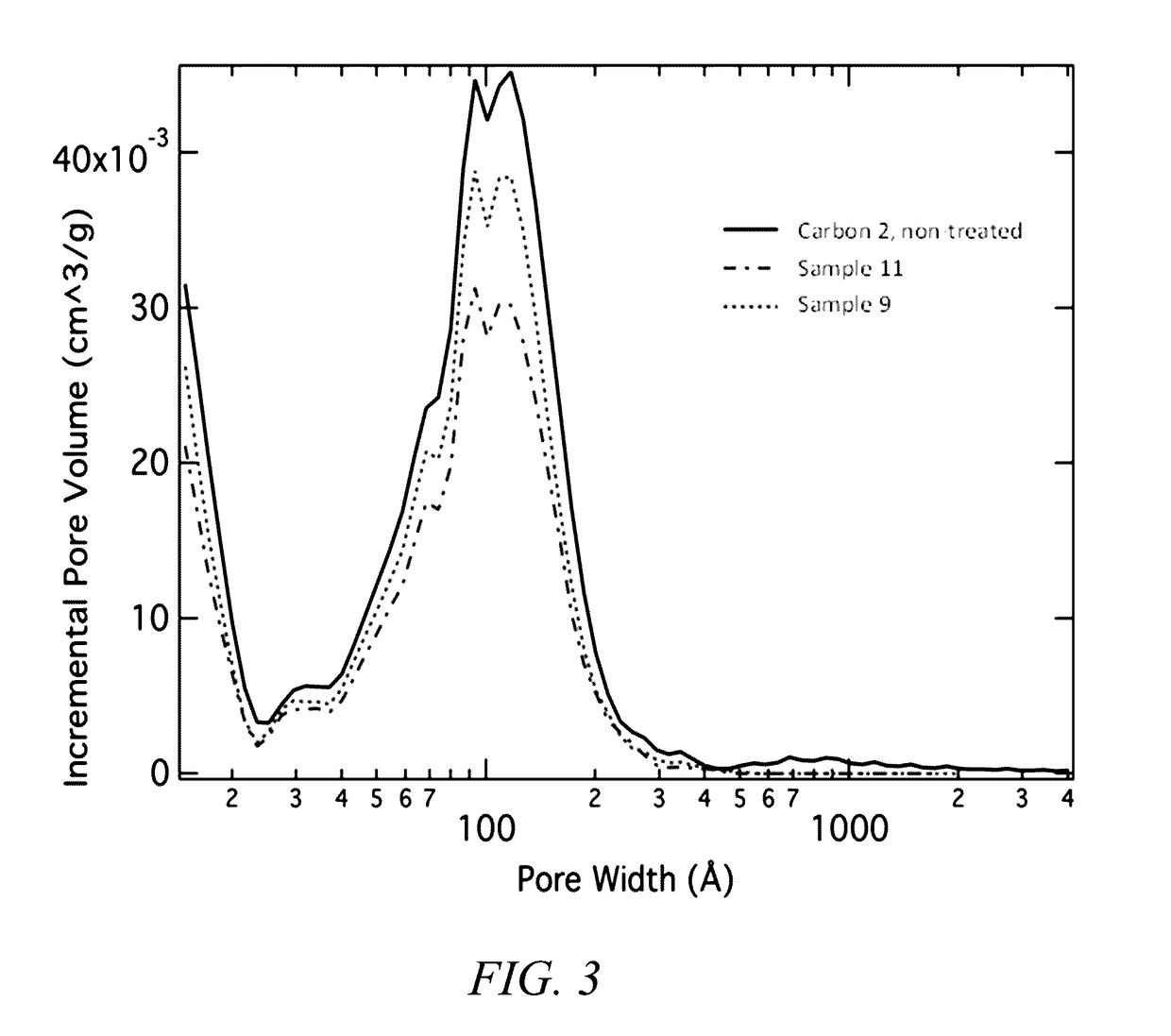

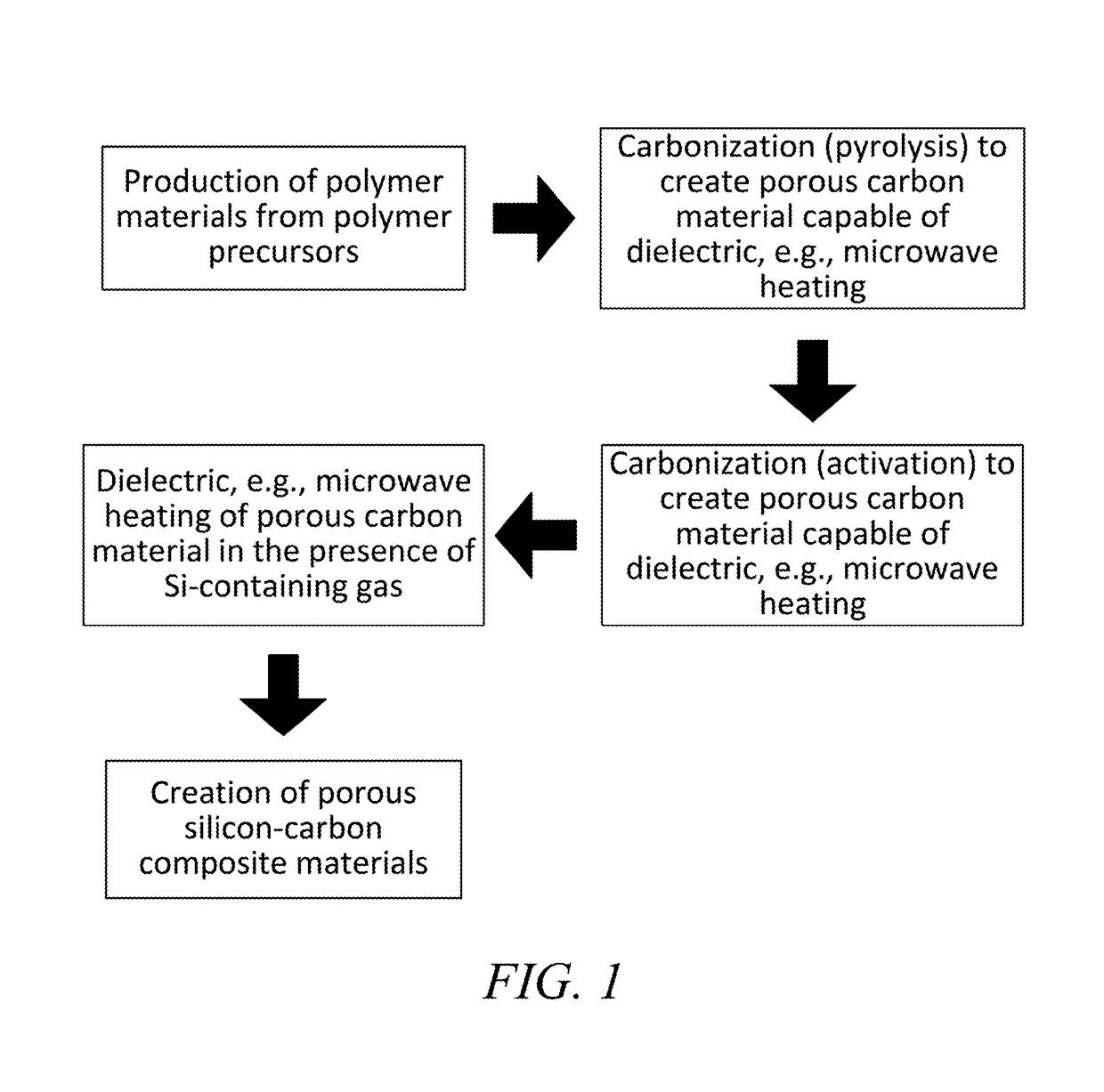

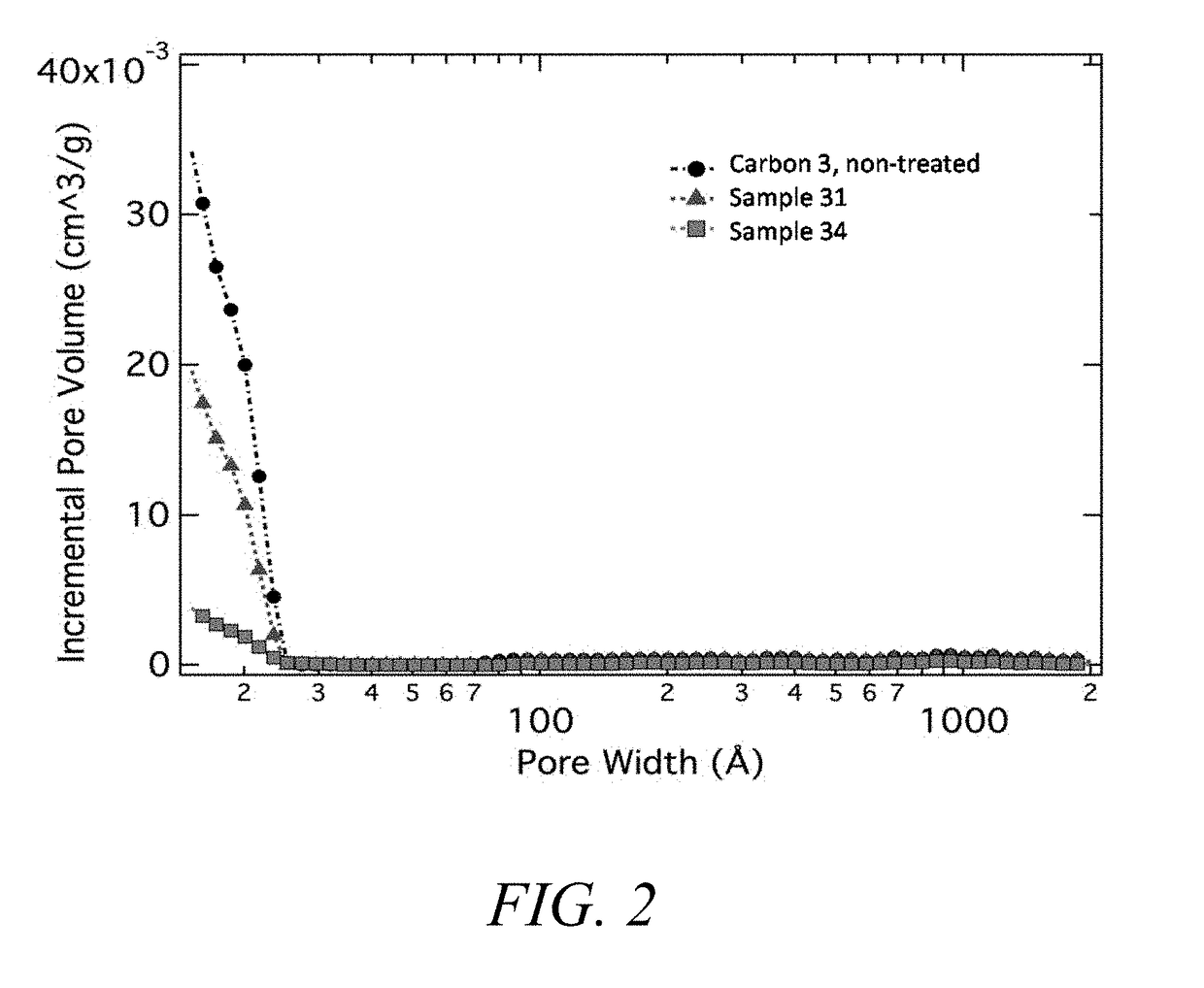

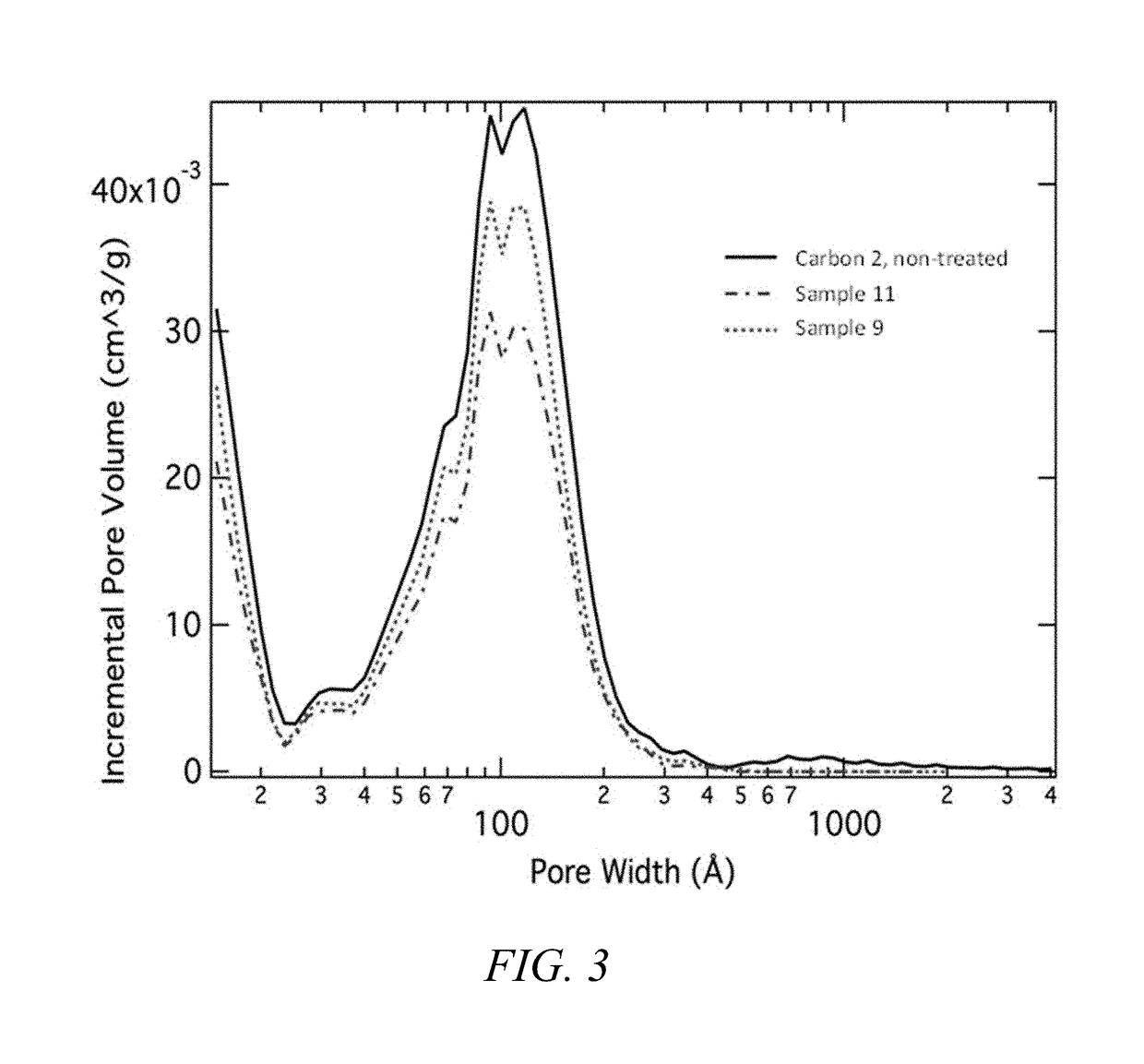

Novel materials with extremely durable intercalation of lithium and manufacturing methods thereof

Composites of silicon and various porous scaffold materials, such as carbon material comprising micro-, meso- and / or macropores, and methods for manufacturing the same are provided. The compositions find utility in various applications, including electrical energy storage electrodes and devices comprising the same.

Owner:GRP 14 TECH INC

Intercalation of silicon and/or tin into porous carbon substrates

The invention relates to a process for producing an electrically conductive, porous, silicon- and / or tin-containing carbon material which is suitable in particular for the production of an anode material, preferably for lithium ion batteries; in a first step of the process, preferably crystalline silicon nanoparticies and / or tin nanoparticies and / or silicon / tin nanoparticles are introduced into a matrix based on at least one organic polymer, being more particular dispersed therein, and subsequently, in a second step of the process, the resultant polymer matrix containing the silicon, tin and / or silicon / tin nanoparticies is carbonized to form carbon.

Owner:UNIV DUISBURG ESSEN

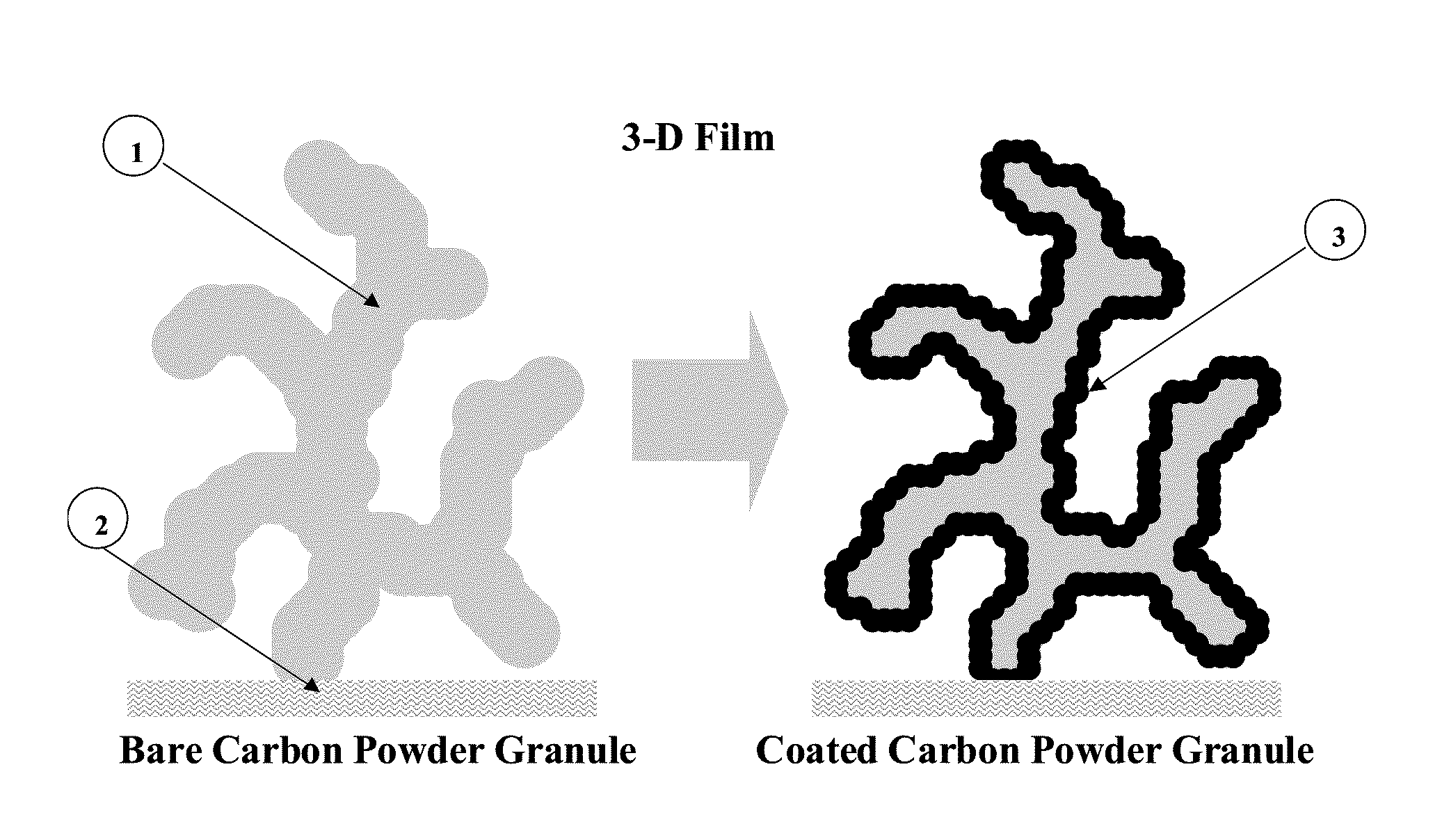

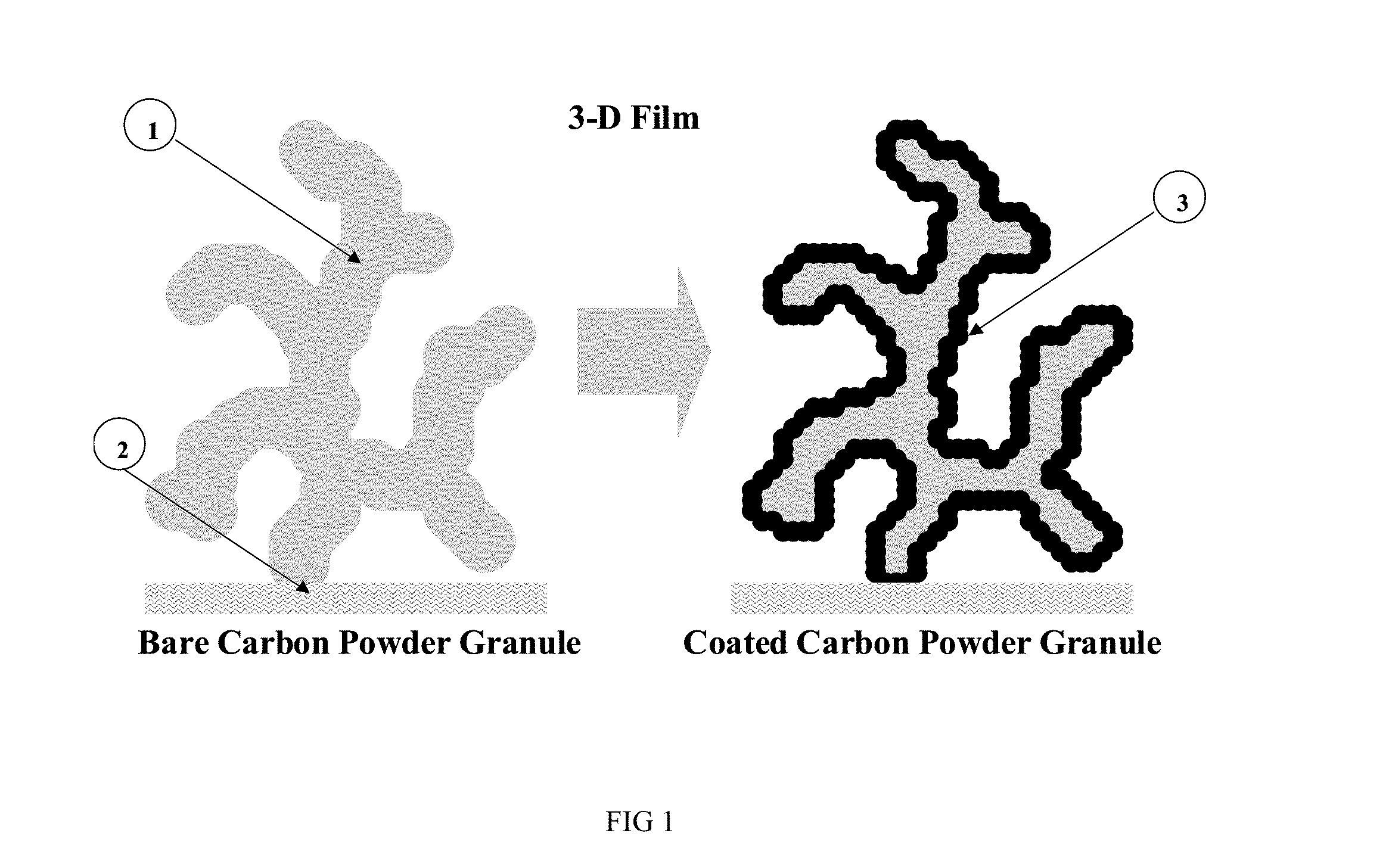

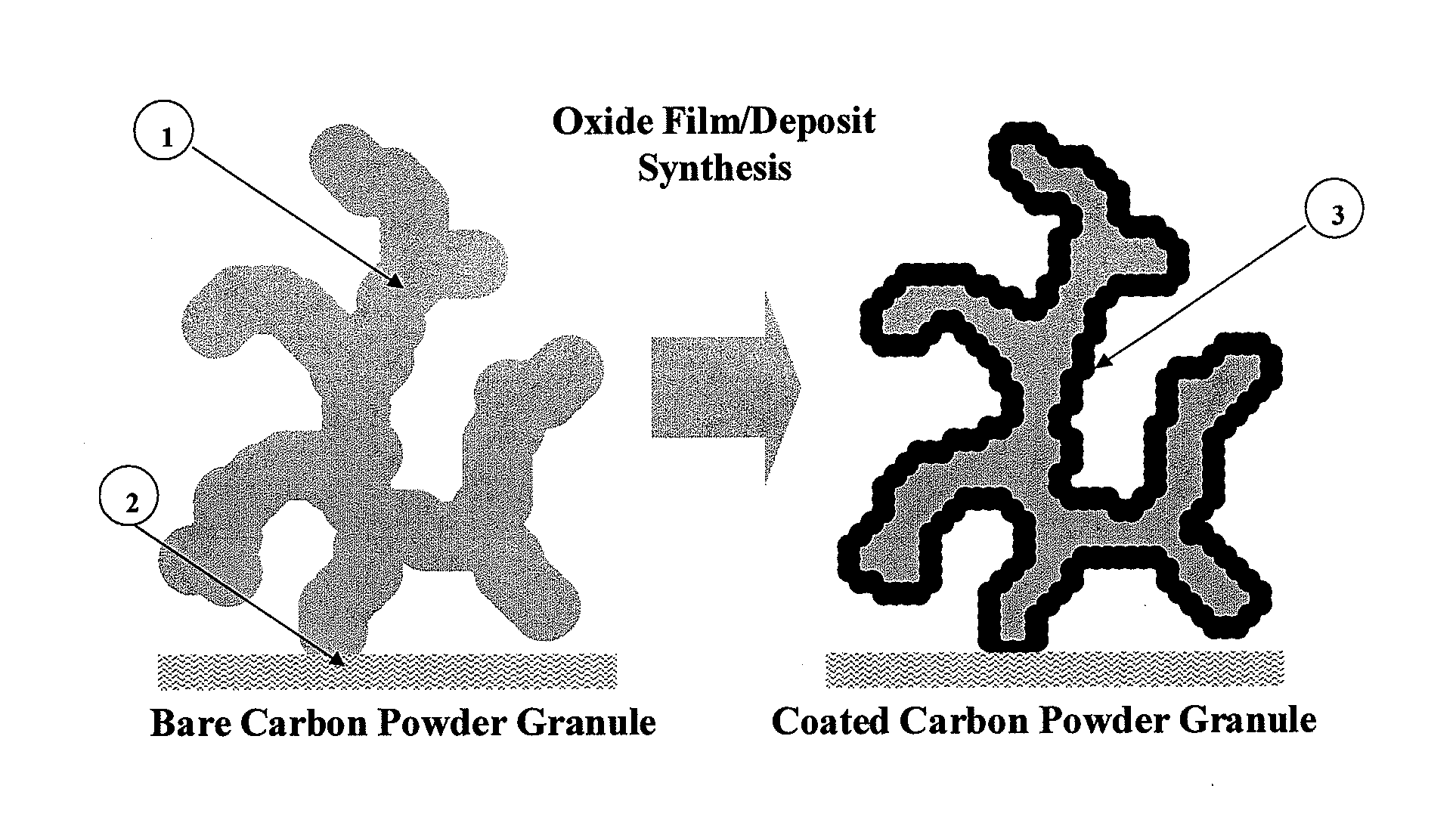

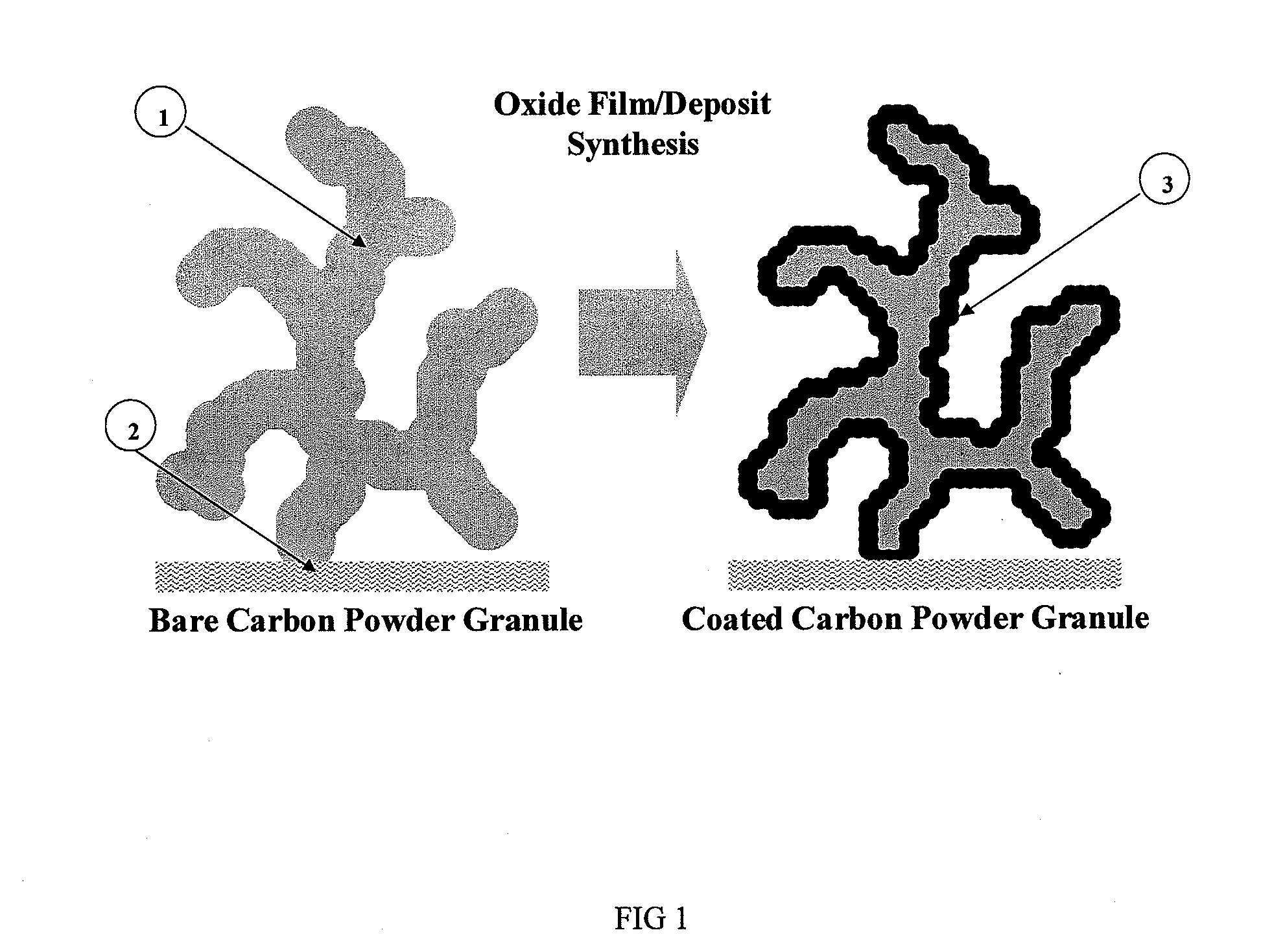

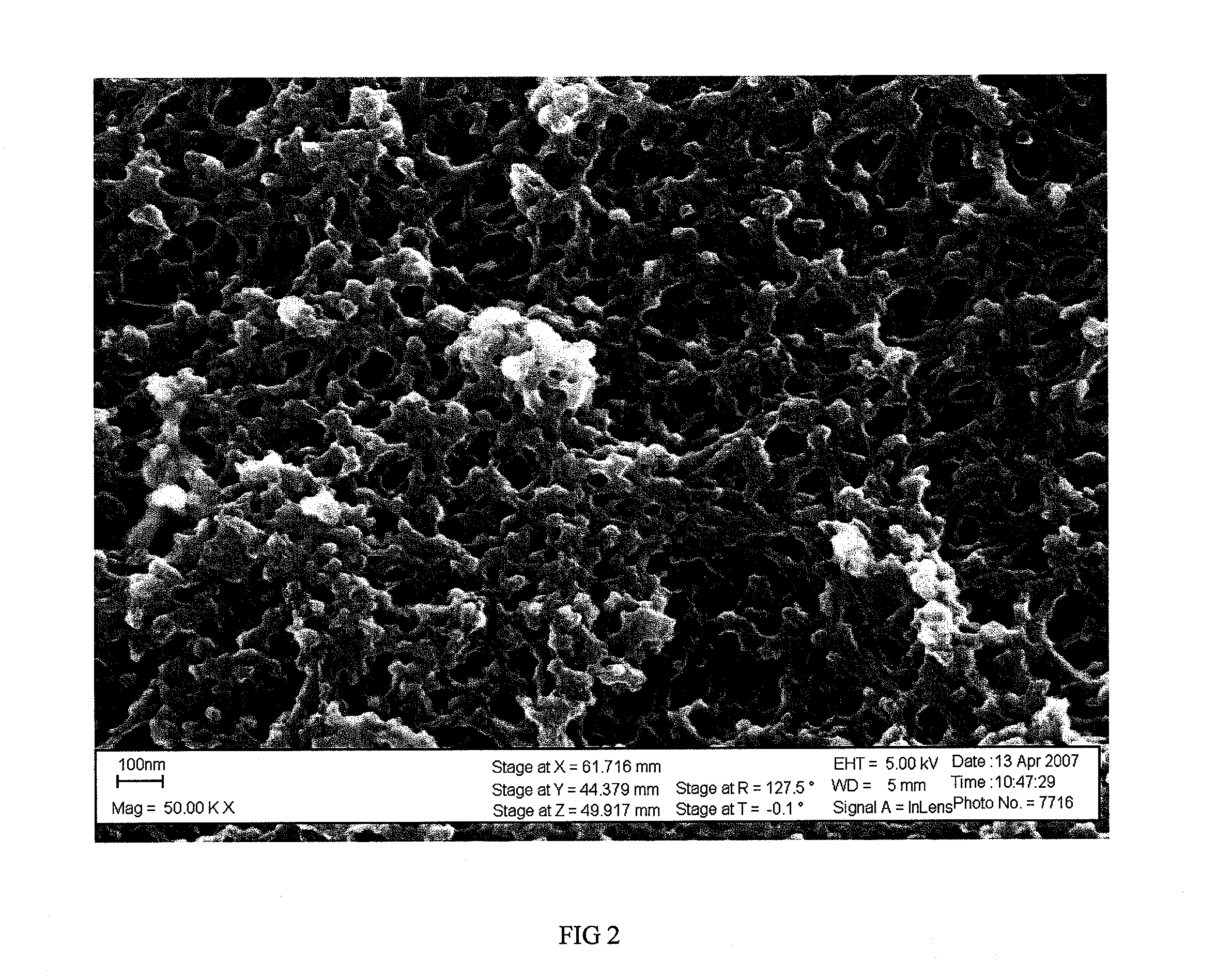

Nanoscale intercalation materials on carbon powder, process for production, and use thereof

InactiveUS20110281176A1Shorten charging timeIncreased usable storage capacityMaterial nanotechnologyElectric discharge heatingMethods of productionOxide coating

An electrode material is created by forming a thin coating or small deposits of metal oxide as an intercalation host on a carbon powder. The carbon powder performs a role in the synthesis of the oxide coating, in providing a three-dimensional, electronically conductive substrate supporting the metal oxide, and as an energy storage contribution material through ion adsorption or intercalation. The metal oxide includes one or more metal oxides. The electrode material, a process for producing said electrode material, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said electrode material is disclosed.

Owner:SEYMOUR FRASER W

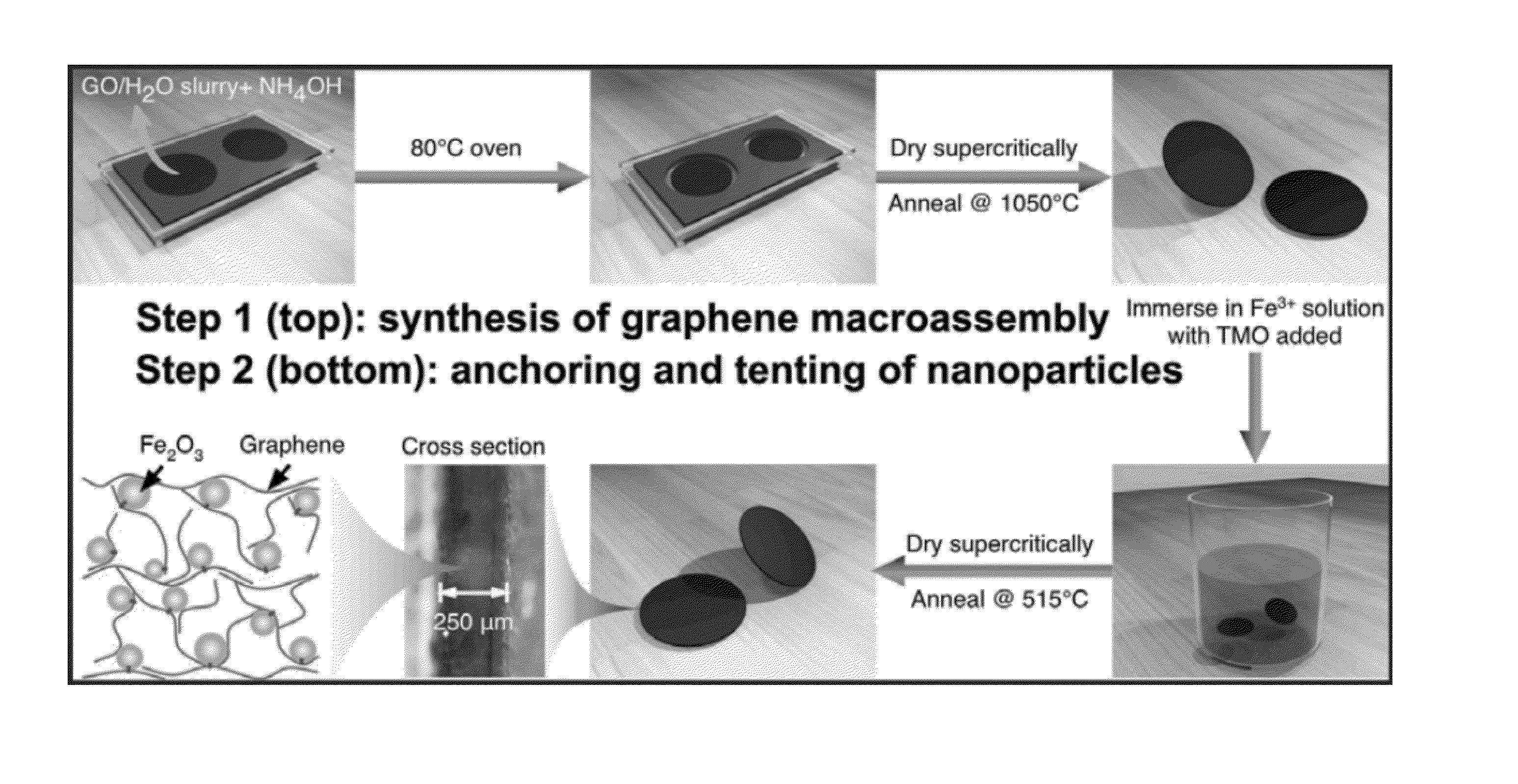

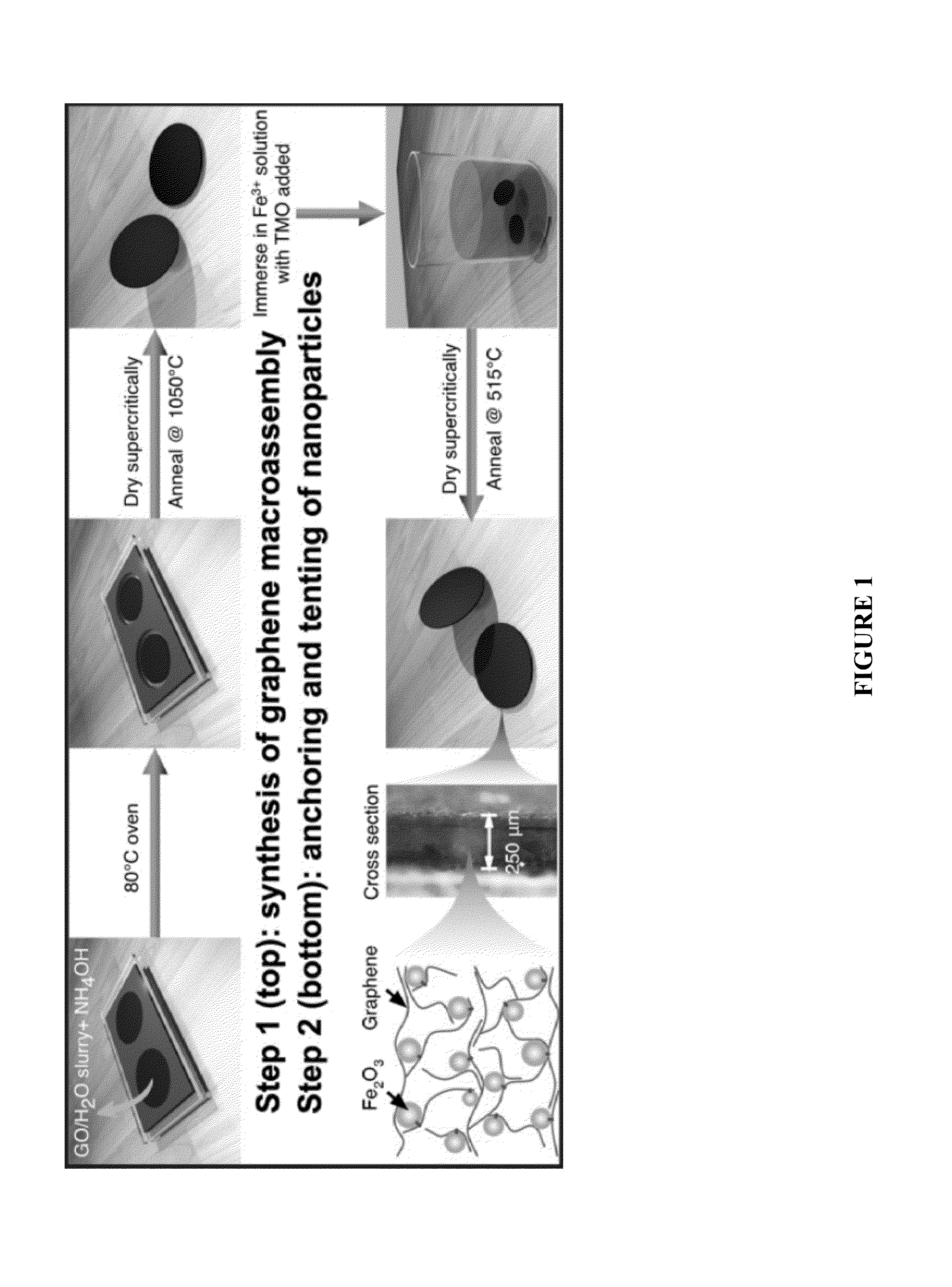

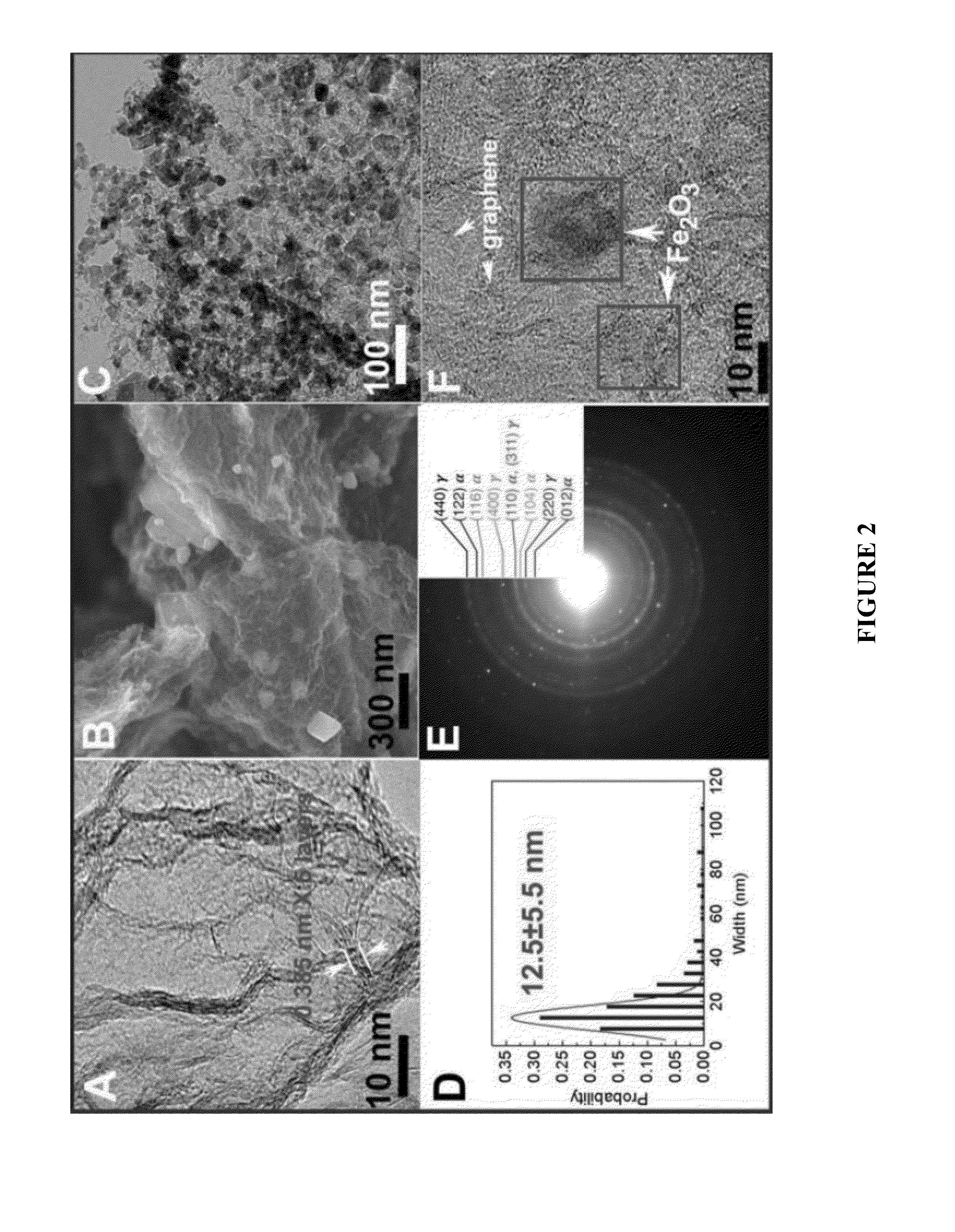

Graphene-supported metal oxide monolith

ActiveUS20140178759A1Large specific surface areaImprove conductivityMaterial nanotechnologyElectrode thermal treatmentIron oxideGraphene

A composition comprising at least one graphene-supported metal oxide monolith, said monolith comprising a three-dimensional structure of graphene sheets crosslinked by covalent carbon bonds, wherein the graphene sheets are coated by at least one metal oxide such as iron oxide or titanium oxide. Also provided is an electrode comprising the aforementioned graphene-supported metal oxide monolith, wherein the electrode can be substantially free of any carbon-black and substantially free of any binder.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

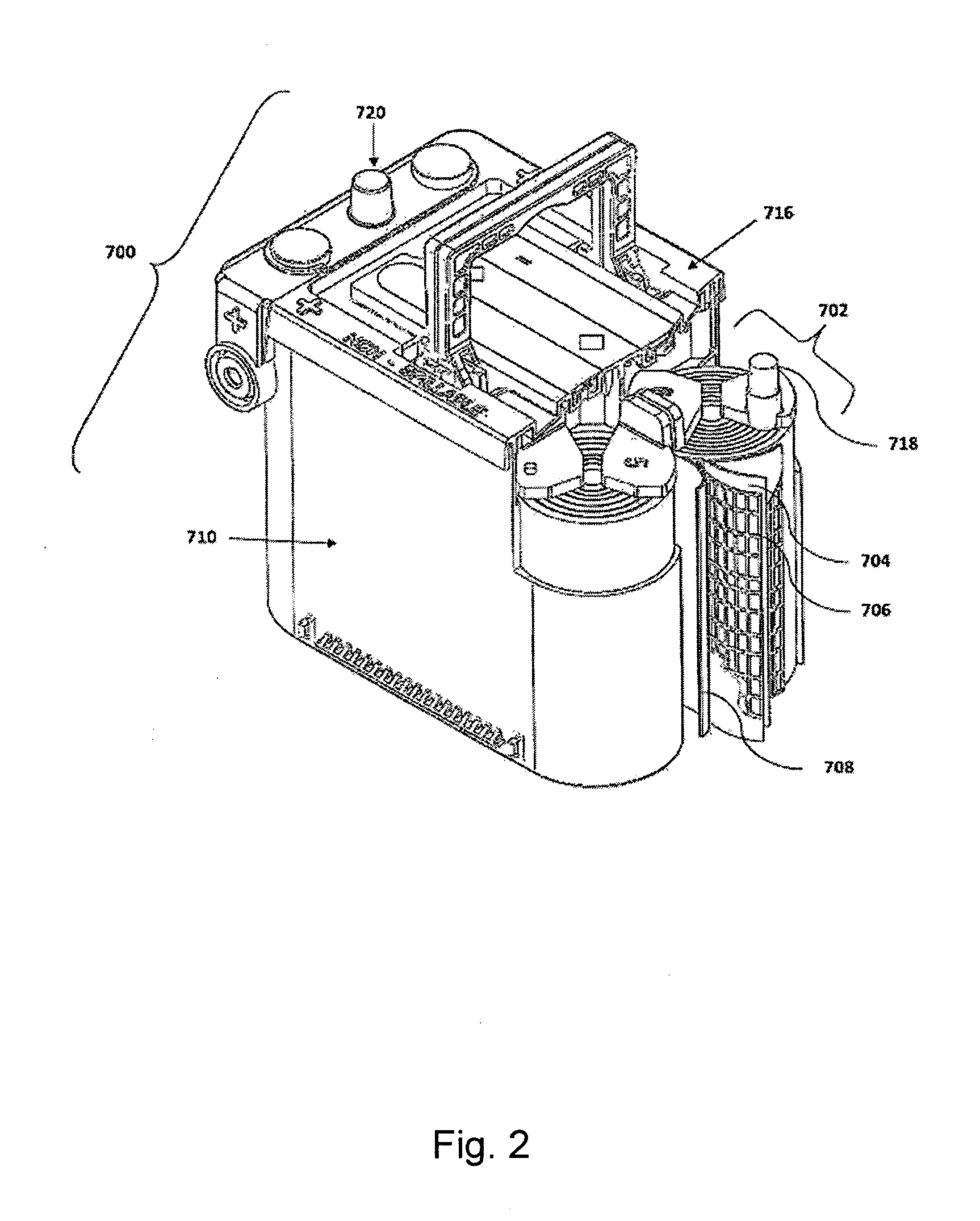

Alkali Metal-Sulfur Batteries Having High Volumetric and Gravimetric Energy Densities

ActiveUS20170207484A1Large capacityImprove the immunityFinal product manufactureElectrode carriers/collectorsCarbon compositesSlurry

Provided is an alkali metal-sulfur battery, comprising: (a) an anode; (b) a cathode having (i) a cathode active material slurry comprising a cathode active material dispersed in an electrolyte and (ii) a conductive porous structure acting as a 3D cathode current collector having at least 70% by volume of pores and wherein cathode active material slurry is disposed in pores of the conductive porous structure, wherein the cathode active material is selected from sulfur, lithium polysulfide, sodium polysulfide, sulfur-polymer composite, sulfur-carbon composite, sulfur-graphene composite, or a combination thereof; and (c) a separator disposed between the anode and the cathode; wherein the cathode thickness-to-cathode current collector thickness ratio is from 0.8 / 1 to 1 / 0.8, and / or the cathode active material constitutes an electrode active material loading greater than 15 mg / cm2, and the 3D porous cathode current collector has a thickness no less than 200 μm (preferably thicker than 500 μm).

Owner:GLOBAL GRAPHENE GRP INC

Energy storage devices comprising carbon-based additives and methods of making thereof

InactiveUS20120251876A1Improve charge acceptanceReduce conductivityElectrochemical processing of electrodesPretreated surfacesEngineeringEnergy storage

The present invention is directed to energy storage devices, such as lead-acid batteries, and methods of improving the performance thereof, through the incorporation of one or more carbon-based additives.

Owner:EXIDE TECHNOLOGIES LLC

Lithium-ion secondary battery and manufacturing method thereof

InactiveUS20070003837A1Reduce manufacturing costSimple procedureElectrode thermal treatmentFinal product manufactureLithiumFiber

In a lithium-ion secondary battery of the present invention, the electrical resistivity of the mixture of a positive electrode active material, an electrically conductive member, and a binder is 0.1 Ωcm or more but 1 Ωcm or less. The positive and negative electrodes each have an electrical capacity of 10 mAh or more but 50 mAh or less per volume of a rectangular parallelepiped that has a 1 cm2 square base on a face of the electrode of one polarity facing the electrode of the other polarity and that has a height equal to the thickness of the electrode of the one polarity at the square base. Used as the negative electrode thereof is a negative electrode formed by sintering graphite powder, non-graphitizing carbon, and fibrous powder retained in the pores of a porous metal structure in an inert gas atmosphere at a temperature of between 600 and 1000° C.

Owner:SHARP KK

Anode and method of manufacturing the same, and battery and method of manufacturing the same

ActiveUS20080311472A1Well formedGood chemical stabilityFinal product manufacturePrimary cellsMaterials scienceMetal salts

A battery capable of improving cycle characteristics is provided. An anode includes: an anode current collector; an anode active material arranged on the anode current collector; and a coating arranged on the anode active material layer, in which the coating includes at least one of a metal salt represented by Chemical Formula 1 and a metal salt of oxocarbonic acid.

Owner:MURATA MFG CO LTD

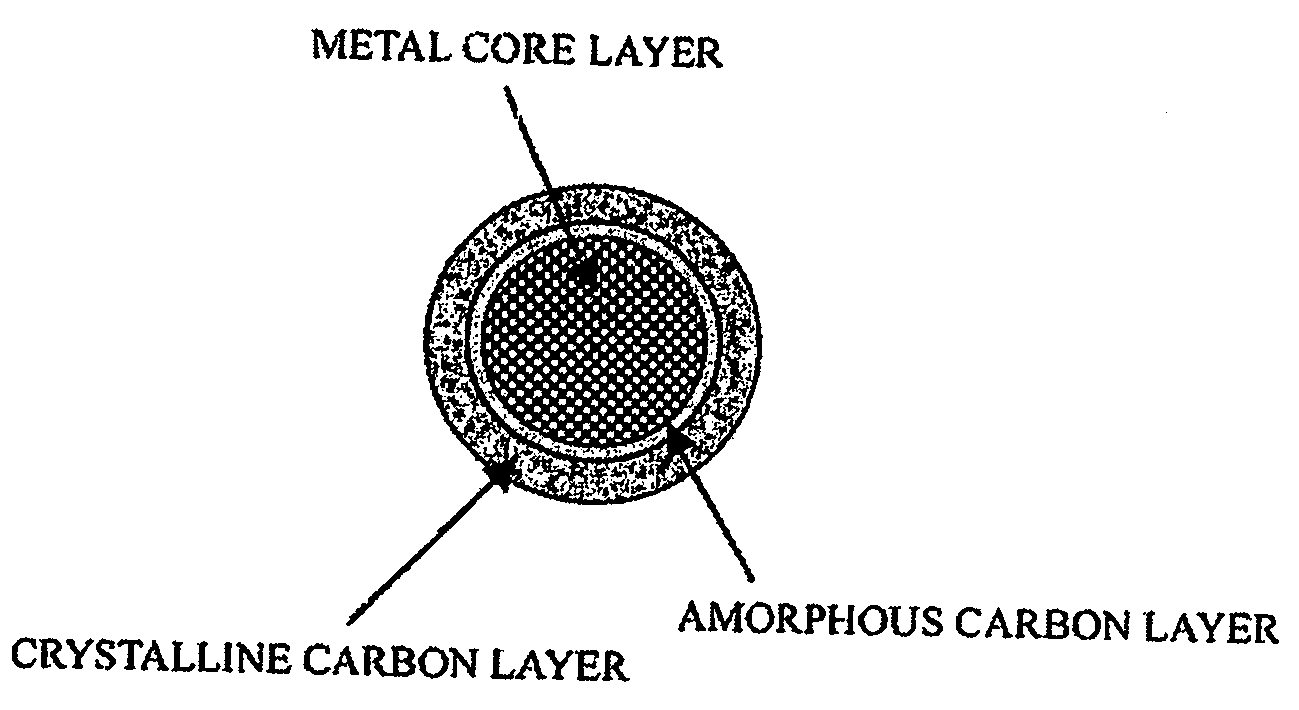

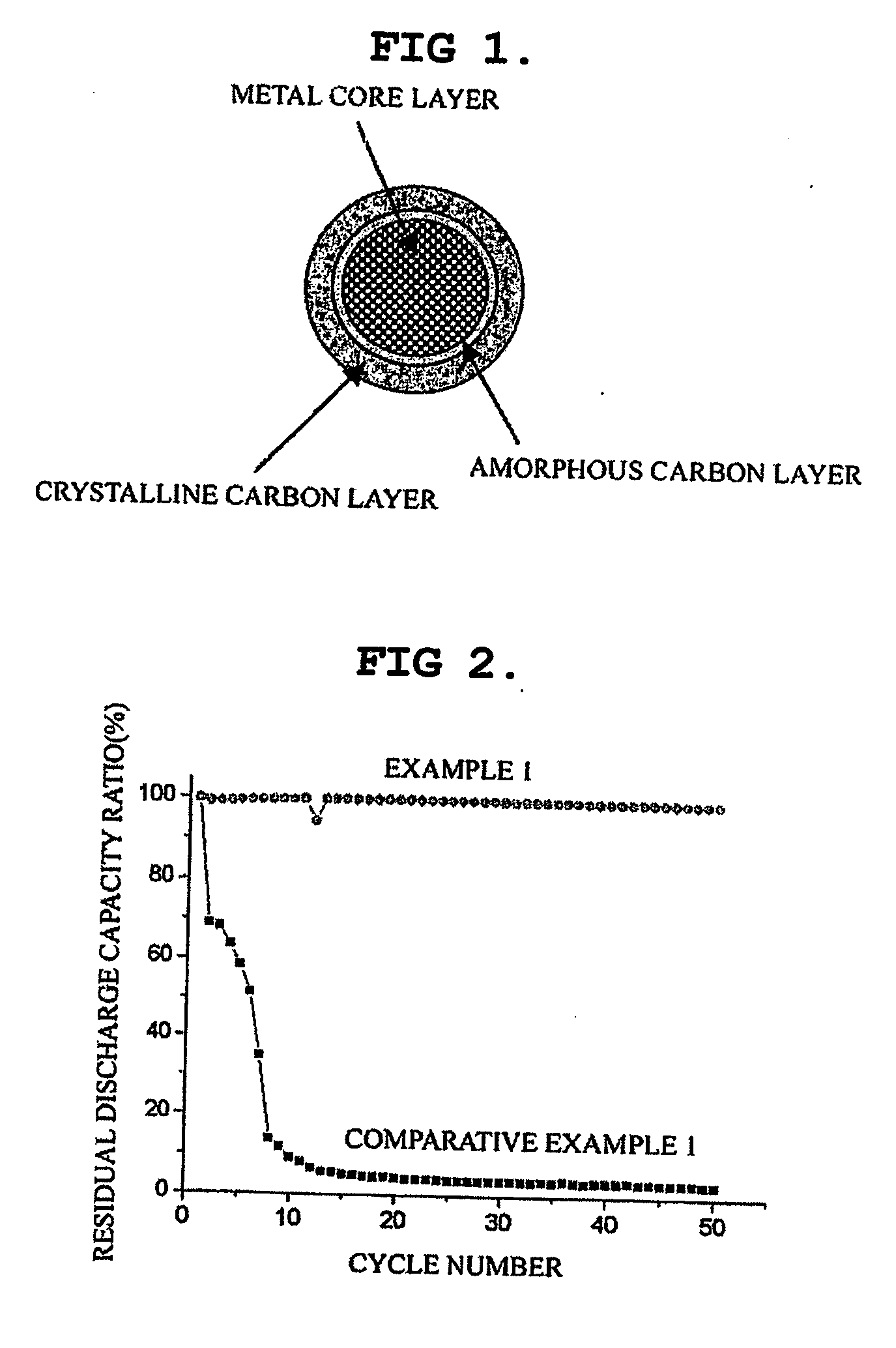

Anode material for lithium secondary cell with high capacity

ActiveUS20060234127A1High charge and discharge capacityImproved cycle life characteristicsNegative electrodesLi-accumulatorsCarbon layerLithium intercalation

Disclosed is an anode material comprising a metal core layer capable of repetitive lithium intercalation / deintercalation; an amorphous carbon layer coated on the surface of the metal core layer, and a crystalline carbon layer coated on the amorphous carbon layer. The anode material not only maintains a high charge / discharge capacity, which is an advantage of a metal-based anode material, but also inhibits changes in the volume of a metal core layer caused by repetitive lithium intercalation / deintercalation in virtue of an amorphous carbon layer and a crystalline carbon layer, thereby improving the cycle life characteristics of cells.

Owner:LG ENERGY SOLUTION LTD

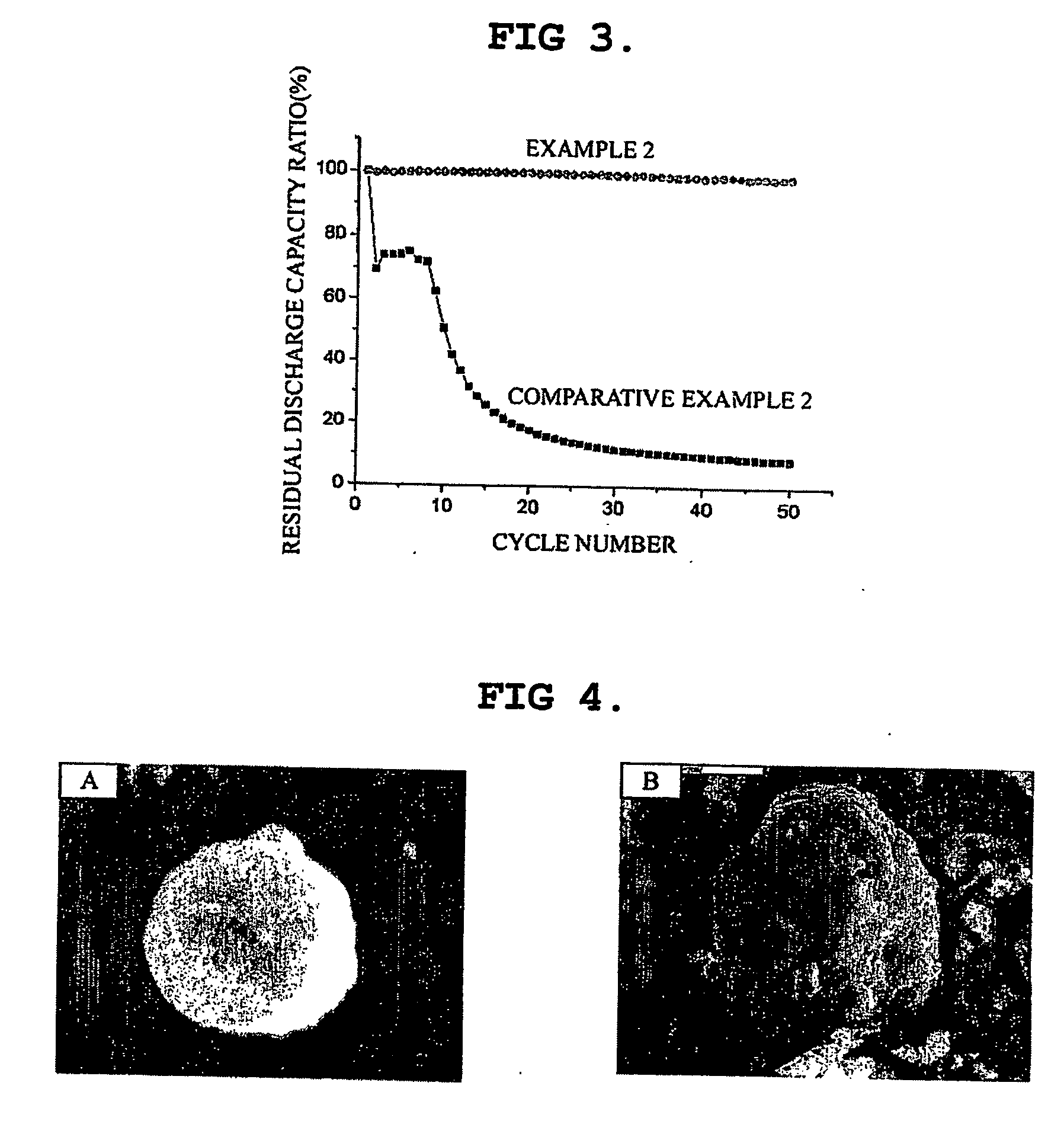

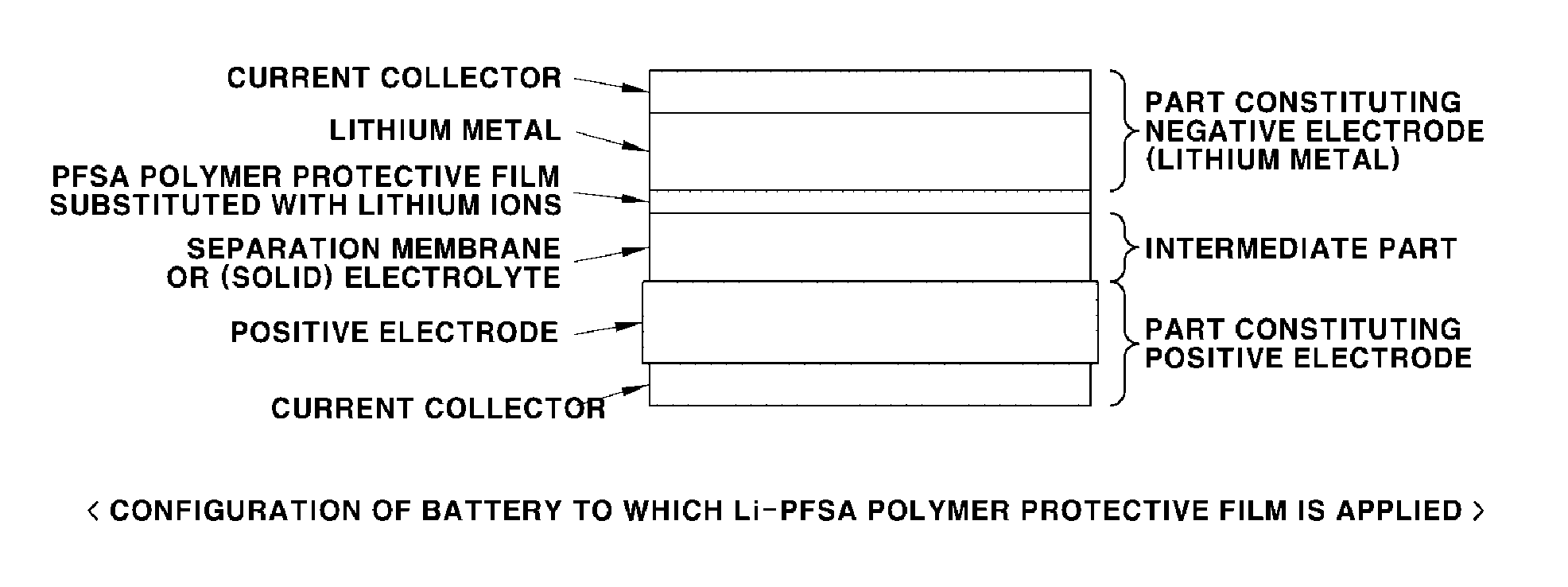

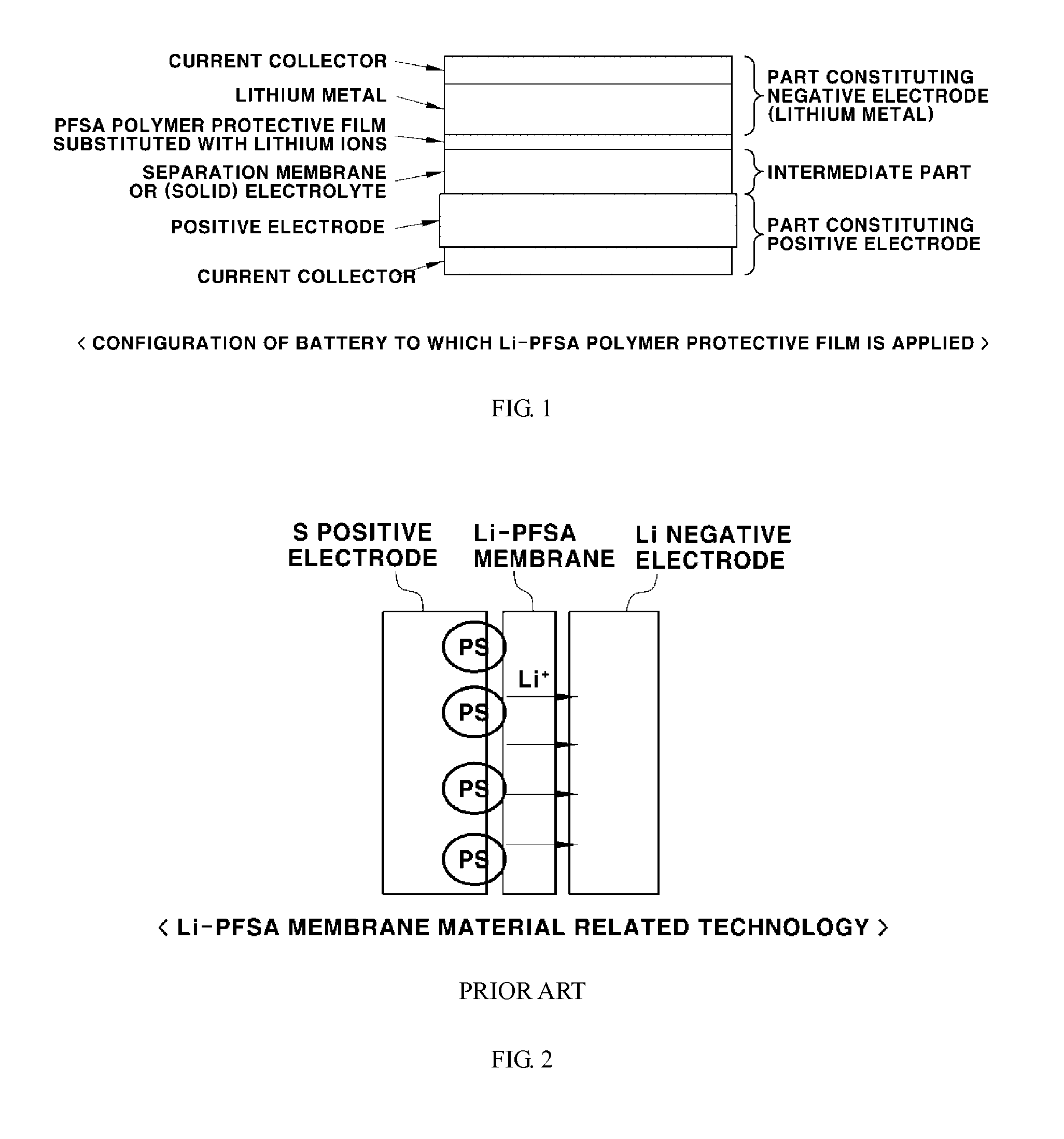

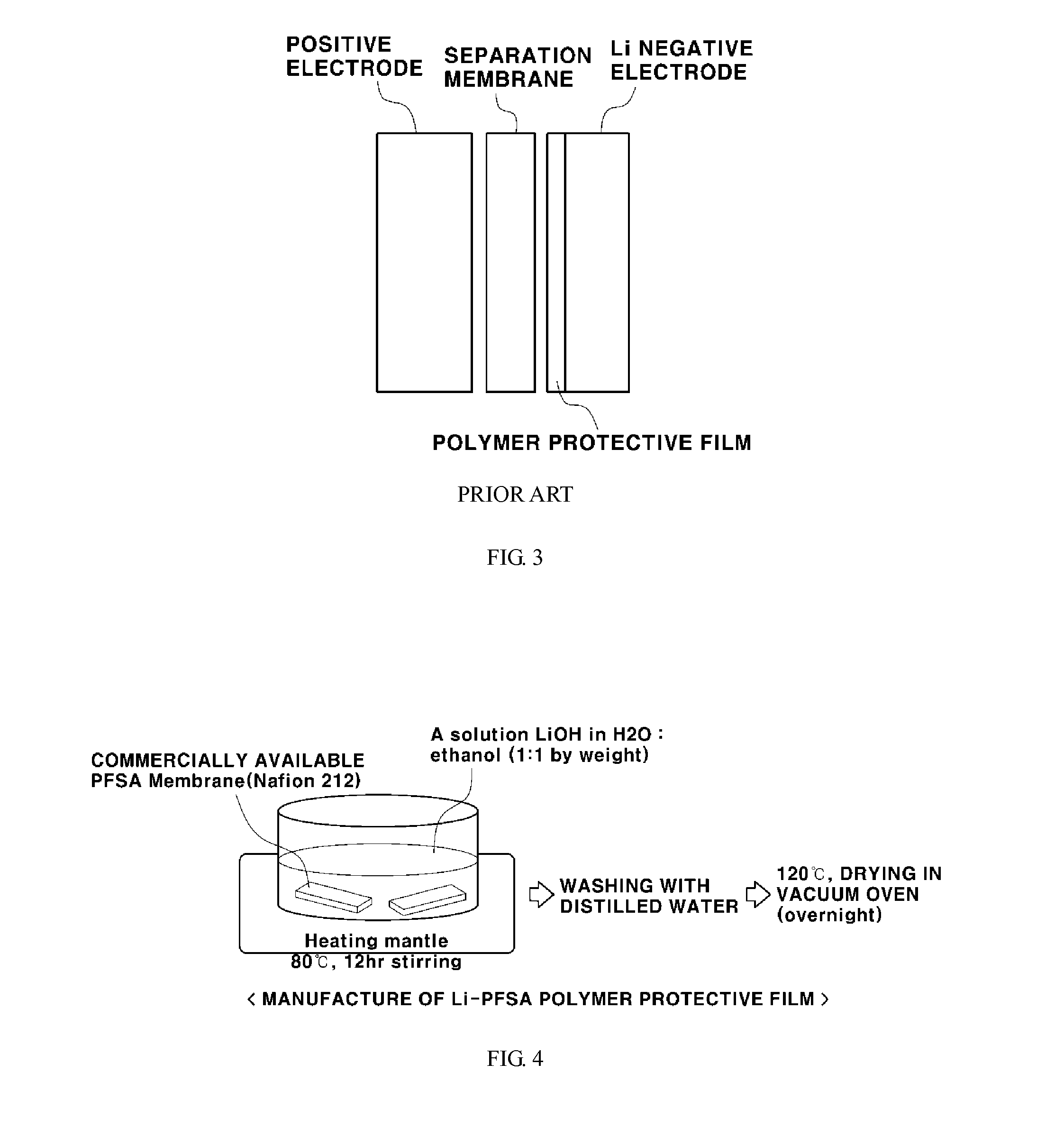

Separation membrane for lithium sulfur batteries

InactiveUS20150255782A1Improve lithium ion conductivityImprove stabilityFuel and secondary cellsElectrode thermal treatmentLithium–sulfur batteryLithium metal

Disclosed is a material which enhances stability for lithium in all the batteries, which use the lithium metal as an electrode material, by using and applying a lithium-substituted perfluoro sulfonic acid (PFSA) material in the form of a membrane or a powder to a lithium anode. Methods of manufacturing the material are also enclosed.

Owner:HYUNDAI MOTOR CO LTD

Materials with extremely durable intercalation of lithium and manufacturing methods thereof

Composites of silicon and various porous scaffold materials, such as carbon material comprising micro-, meso- and / or macropores, and methods for manufacturing the same are provided. The compositions find utility in various applications, including electrical energy storage electrodes and devices comprising the same.

Owner:GRP 14 TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com