Nonaqueous electrolyte battery, electrode plate for nonaqueous electrolyte battery, and method for manufacturing electrode plate for nonaqueous electrolyte battery,

a manufacturing method and electrolyte technology, applied in the direction of secondary cells servicing/maintenance, cell components, sustainable manufacturing/processing, etc., can solve the problems of crimping part thickening, unstable impedance of the battery which had the tab plate 10 connected by this method, and method needs an extra work of removing the electrode mix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0128]

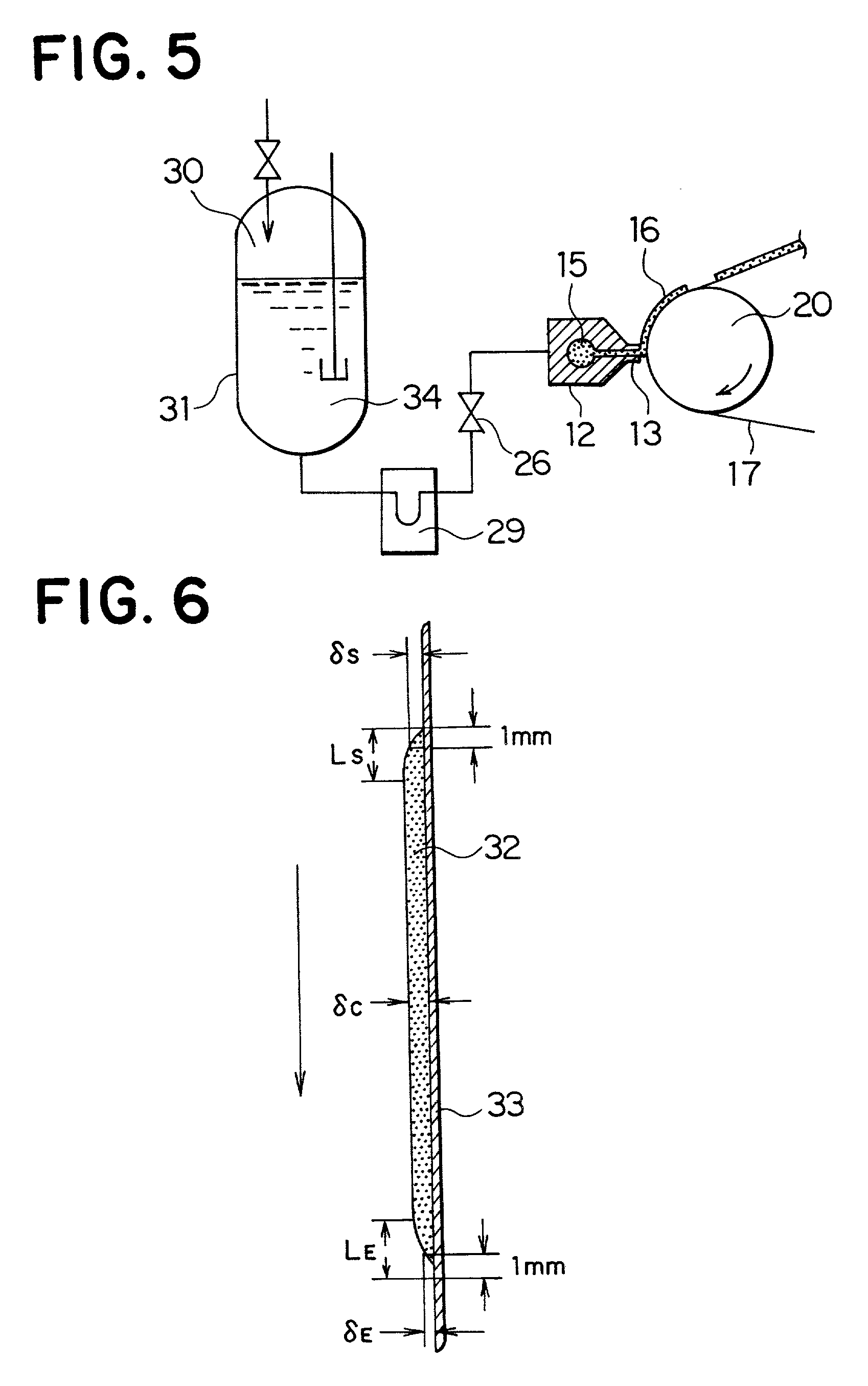

[0129] A cathode mix coating liquid having a solid content concentration of 60% by weight was prepared by mixing and dispersing 55.2 parts by weight of LiCoO.sub.2 as the cathode active material, 3.6 parts by weight of acetylene black as the conductive agent, 1.2 parts by weight of a fluororubber based binder as the binding agent, and 40 parts by weight of ethyl acetate as the solvent. This coating liquid had an apparent viscosity of 3000 mPa.multidot.S (a shear rate of 13 sec.sup.-1).

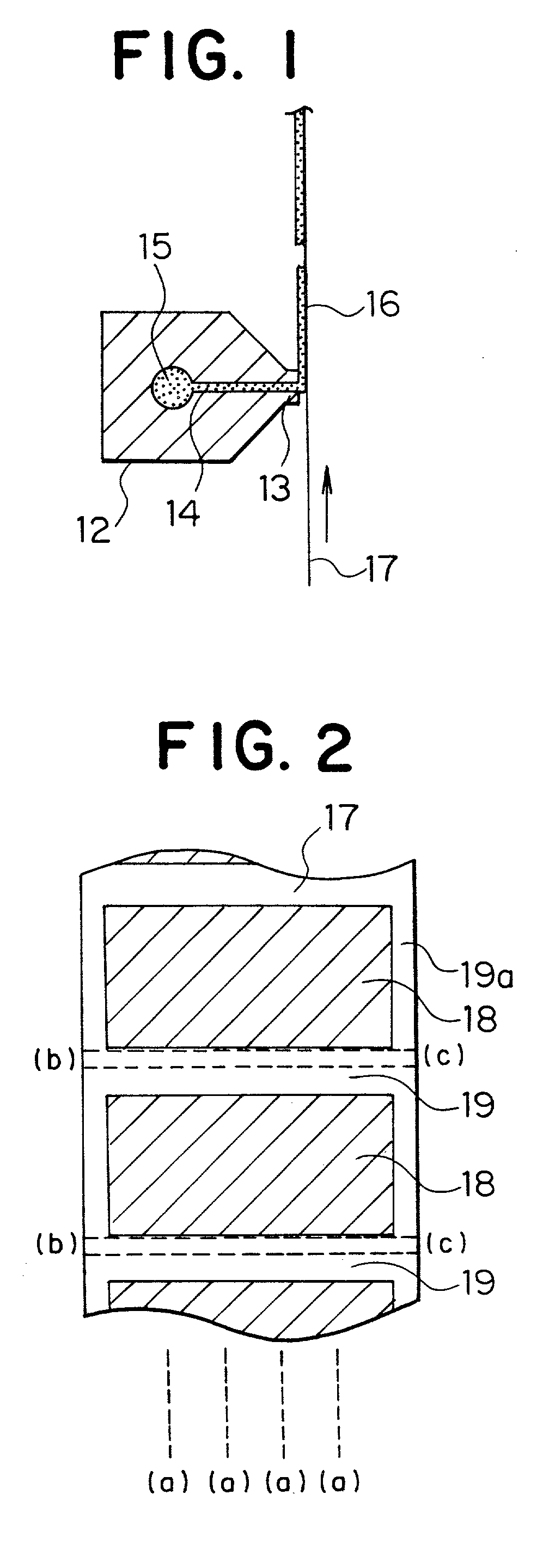

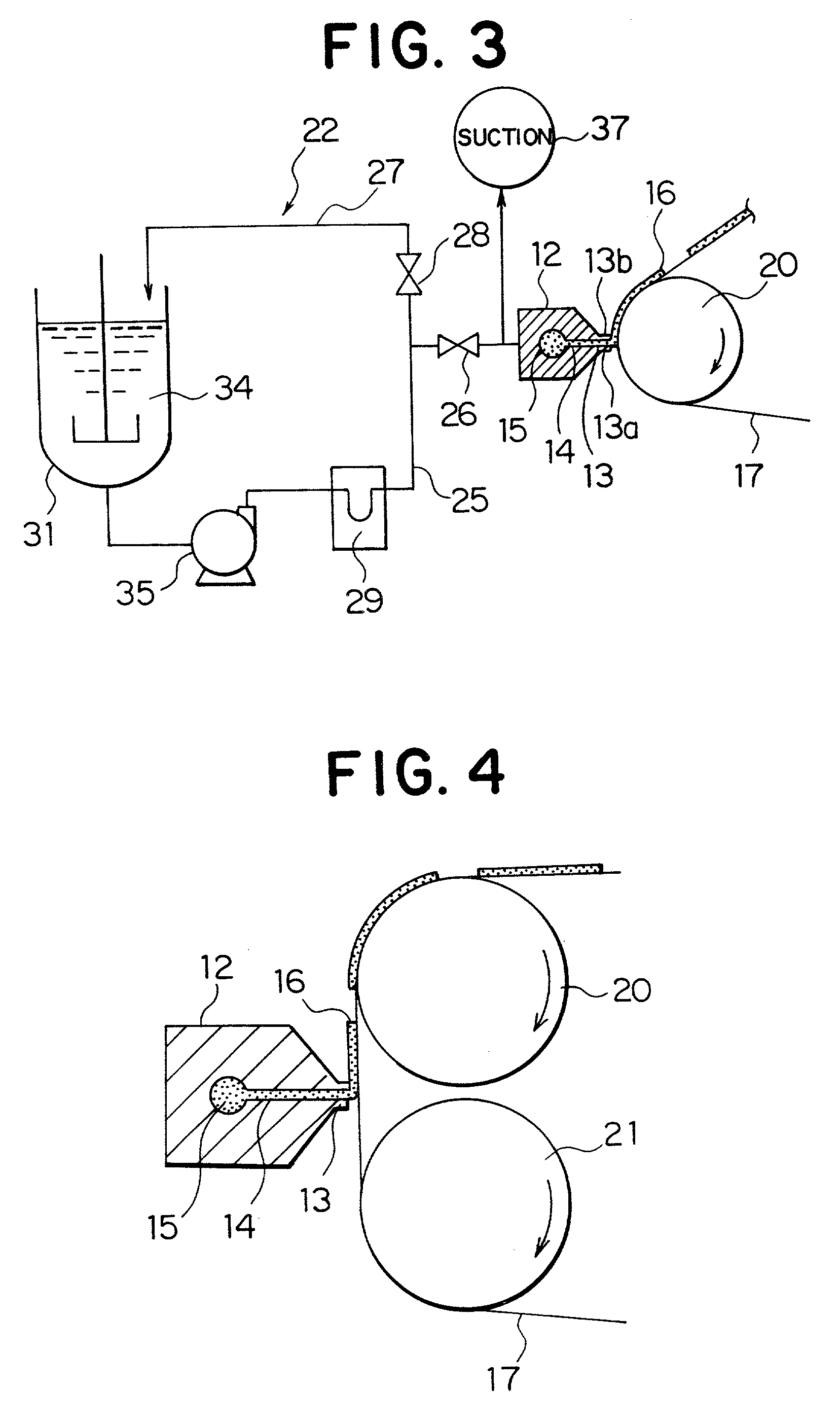

[0130] This slurry-like coating liquid was coated to both surfaces of an aluminum foil having a thickness of 15 .mu.m one surface at a time with uncoated areas formed at predetermined intervals in the longitudinal direction by means of the coating device shown in FIG. 3 according to the method 1) above, and the formed layers were dried in hot air at 120.degree. C. While the coating liquid was being coated, a space between the tips of the lips and the aluminum foil as the conductive base material ...

embodiment 2

[0131]

[0132] A cathode mix coating liquid having a solid content concentration of 65% by weight and an apparent viscosity of 25000 mPa.multidot.S (a shear rate of 13 sec.sup.-1) was prepared by kneading LiCoO.sub.2, acetylene black, a fluororubber-based binder and ethyl acetate in the same way as in Embodiment 1. This coating liquid was coated to both surfaces of an aluminum foil one surface at a time with uncoated areas formed at predetermined intervals in the longitudinal direction in the same way as in Embodiment 1.

embodiment 3

[0133]

[0134] A cathode mix coating liquid having a solid content concentration of 70% by weight and an apparent viscosity of 40000 mPa.multidot.S (a shear rate of 13 sec.sup.-1) was prepared by kneading LiCoO.sub.2, acetylene black, a fluororubber-based binder and ethyl acetate in the same way as in Embodiment 1. This coating liquid was coated to both surfaces of an aluminum foil one surface at a time with uncoated areas formed at predetermined intervals in the longitudinal direction in the same way as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com